#aluminum alloy die casting

Explore tagged Tumblr posts

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Customized OEM Aluminum Die Casting Parts: Precision and Performance

In the realm of manufacturing, OEM Aluminum Die Casting Parts are recognized for their exceptional precision and performance. These parts are crafted through a process that involves injecting molten aluminum into a mold, creating a high-quality product that is both durable and lightweight. Our company specializes in producing OEM Aluminum Die Casting Parts that meet the specific requirements of our clients, ensuring that each component is tailored to their unique specifications.

OEM Aluminum Die Casting Parts are known for their strength and corrosion resistance, making them ideal for a wide range of applications across various industries. From automotive to aerospace, these parts are essential in the construction of complex machinery and systems. Our commitment to excellence ensures that every OEM Aluminum Die Casting Part we produce adheres to the highest standards of quality and reliability.

One of the key advantages of OEM Aluminum Die Casting Parts is their design flexibility. With the ability to create intricate shapes and designs, these parts can be customized to fit the exact needs of any project. This level of customization is unmatched by other manufacturing processes, making OEM Aluminum Die Casting Parts a popular choice for companies seeking to create unique, high-performance products.

Another benefit of OEM Aluminum Die Casting Parts is their cost-effectiveness. The die casting process allows for the production of parts in large quantities at a lower cost per unit compared to other methods. This efficiency is particularly important for businesses looking to maintain competitive pricing while still offering high-quality products.

Our company prides itself on the ability to deliver OEM Aluminum Die Casting Parts that are not only precision-engineered but also environmentally friendly. By using recycled aluminum and implementing sustainable practices, we contribute to a greener manufacturing process that reduces waste and conserves resources.

In conclusion, OEM Aluminum Die Casting Parts offer a combination of strength, durability, and customization that is unmatched in the industry. Whether you need components for a high-performance vehicle or a complex piece of machinery, our OEM Aluminum Die Casting Parts are designed to exceed your expectations. Contact us today to discuss how our OEM Aluminum Die Casting Parts can be the perfect solution for your next project.

#magnesium alloy castings#aluminum die casting auto parts#OEM Aluminum Die Casting Parts#Aluminum Die Casting Parts

0 notes

Text

Mold design experience (serial one)

1. Height of slider guide rail must be at least 1/3 of slider height to ensure stability of slider and smooth sliding.2. Pay attention to opening lubrication grooves in locations with sliding friction. In order to prevent lubricating oil from flowing out, it is not advisable to make grooves “open” but should be “closed”. Generally, they can be milled out directly on a milling machine with a…

View On WordPress

#casting solidification process#die-cast differential castings#die-casting defects#die-casting forming process#Die-casting mold#die-casting process#high-pressure die-cast aluminum alloy differentials#high-pressure die-casting process

0 notes

Text

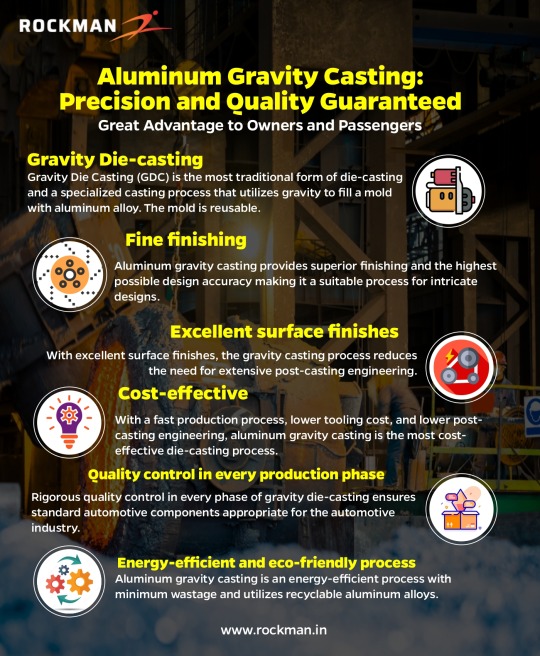

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Text

Innovation in Zinc Die Casting Alloys: Driving Progress and Performance

Utilise zinc die casting alloys to stay on the cutting edge of innovation. This dynamic industry is always changing, bringing better performance, better surface finishes, and shorter lead times. Learn about the most recent innovations and growing trends in zinc die-casting alloys and how they are improving product efficiency and quality in a variety of sectors.

#Zinc Die Casting Alloys#aluminum die casting#pressure die castings#precision cnc machining#permanent mold casting#low pressure die casting

0 notes

Text

Aluminum Alloy Die Casting Services

Aluminum Alloy Die Casting Services offer precision manufacturing solutions for creating intricate and durable aluminum components. By utilizing the die casting process, they produce high-quality parts with excellent dimensional accuracy, strength, and corrosion resistance, meeting diverse industrial requirements. For more visit us!

0 notes

Text

0 notes

Text

Are you looking for H13 (DIN 2344) Steel for your new projects?

H13 steel | DIN 2344 | 1.2344 steel | H13 Die Steel | AISI H13

H13 Steel the perfect tool steel for hot work and cold work! Look no further Virat Special Steels is one the best H13 steel suppliers in India.

H13 tool steel stockholders and suppliers, delivering to the whole of the India. VIRAT SPECIAL STEELS PVT. LIMITED , INDIA specialize in highly refined steel grades like H13 are offering the custom products to the secondary and ancillary units of the economy.

The demand of it has increased because of such custom catering that makes possible economical making of components and castings in demanded dimensions. The desirable attributes of hardness could be also customized through regulated annealing and tempering of the base products!

The H13 grade steel from Virat Special Steels is not just a metal; it’s a testament to the company’s commitment to quality and excellence. This high-quality aluminum extrusion die steel is engineered to excel in various application areas, making it a versatile choice for manufacturers.

H13 tool steel is the most popular steel grade for various Industries. The main features of high alloyed Cr-Mo-V Hot Work tool steel is high wear resistance to thermal shock and to heat cracking, good mechanical characteristics & toughness in hot conditions.

To know about more specific details of h13 steel ( 2344 steel ), please visit the website https://www.h13steel.in/

Contact us today to buy the best quality of h13 Steel https://www.viratsteels.com/h13.html

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#h13steel#h13steelbarexporter#h13steelmanufacturer#h13diesteel#h13toolsteels#din 2344#aisih13

2 notes

·

View notes

Text

What are all the types of aluminium fabrication?

Aluminum fabrication design encompasses a myriad of techniques and processes that transform raw aluminum into various finished products. Each method offers unique advantages, catering to diverse applications across industries ranging from aerospace to construction and automotive to electronics.

Extrusion stands as one of the most common aluminum fabrication techniques, involving the shaping of aluminum alloys by forcing them through a die. This process enables the creation of complex profiles with consistent cross-sectional shapes, ideal for applications requiring lightweight yet durable components such as window frames, structural beams, and heat sinks.

Sheet metal fabrication utilizes flat sheets of aluminum, which are cut, bent, and formed into desired shapes and sizes. From precision components for electronics to automotive body panels and aircraft fuselages, sheet metal fabrication offers versatility and efficiency in producing lightweight, corrosion-resistant parts with high structural integrity.

Casting processes, including sand casting, die casting, and investment casting, are employed to create intricate aluminum components with precise geometries. Sand casting is suitable for producing large, complex parts such as engine blocks and transmission housings, while die casting offers fast production of small to medium-sized components with tight tolerances. Investment casting, also known as lost-wax casting, enables the creation of finely detailed parts for aerospace, medical, and jewelry applications.

Welding plays a crucial role in aluminum fabrication, allowing for the joining of aluminum components through various techniques such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding. TIG welding ensures precise control over the welding process, making it suitable for thin materials and intricate designs, while MIG welding offers higher deposition rates for thicker sections. Resistance welding methods like spot welding and seam welding are commonly used in automotive assembly and sheet metal fabrication.

The diverse types of aluminum fabrication techniques provide manufacturers and designers with a wealth of options to meet specific performance, cost, and design requirements. Whether it's extrusion, sheet metal fabrication, casting, or welding, each method contributes to the production of high-quality aluminum components for a wide range of applications. With expertise and quality materials from Alugrow Trading, manufacturers can leverage the full potential of aluminum fabrication to bring their designs to life.

Alugrow Trading

2 notes

·

View notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

WHAT IS MAGNESIUM USED FOR IN MANUFACTURING?

Magnesium is a lightweight, durable, and highly versatile metal that has a wide range of applications in various manufacturing industries. This metal is the eighth most abundant element in the Earth's crust and has excellent corrosion resistance, making it an ideal choice for many industrial applications. In this blog, we will explore some of the most common uses of magnesium in manufacturing.

Magnesium metal used for Die Casting:

Magnesium is widely used in die casting applications due to its low density, high strength, and excellent dimensional stability. Magnesium die casting is used to manufacture parts for the automotive, aerospace, and electronics industries, among others. Some of the parts that can be die-cast from magnesium include engine blocks, transmission cases, steering wheels, and laptop and mobile phone frames.

Some of the benefits of die-casting magnesium include:

1. Lightweight: Magnesium is one of the lightest metals available, with a density that is two-thirds that of aluminum and one-quarter that of steel. This makes it an excellent choice for applications where weight is a critical factor, such as in the automotive and aerospace industries.

2. High Strength-to-Weight Ratio:

Magnesium alloys have a high strength-to-weight ratio, making them stronger and more durable than many other materials. This is particularly important in applications where the part must withstand high stress and loads.

3. Good Corrosion Resistance:

Magnesium metal alloys have excellent corrosion resistance, which makes them ideal for use in harsh environments. They are particularly resistant to saltwater and other corrosive substances, making them useful in marine applications.

The combination of low weight, high strength, good corrosion resistance, good thermal conductivity, and excellent machinability makes magnesium an ideal choice for die casting applications.

Magnesium metal used for Welding

Magnesium is also used in welding applications due to its low melting point and excellent heat conductivity. Magnesium welding is used to manufacture components such as aircraft and aerospace parts, bicycle frames, and automotive parts.

Magnesium is a reactive metal that is prone to oxidation, which can create problems when welding. Here are some of the key factors to consider when welding magnesium:

1. Cleanliness: Magnesium must be cleaned thoroughly before welding to remove any oils, grease, or other contaminants that can interfere with the welding process.

2. Shielding Gas: Welding magnesium requires the use of a shielding gas, such as argon or helium, to protect the molten metal from the surrounding air and prevent oxidation.

3. Welding Technique: Magnesium is best welded using the gas tungsten arc welding (GTAW) process, also known as TIG welding. This process allows for precise control of the heat input and minimizes the risk of oxidation.

4. Preheat: Magnesium material should be preheated before welding to reduce the risk of cracking and ensure a strong weld.

5. Filler Metal: Magnesium filler metal should be used when welding magnesium to ensure a strong, durable weld. The filler metal should match the composition of the base metal as closely as possible.

Welding magnesium requires careful preparation and execution to ensure a strong, durable weld. It is important to follow best practices and work with a skilled welder who has experience working with magnesium.

Magnesium metal used for Welding

Magnesium metal used for Extrusion

Magnesium extrusion is used to manufacture a wide range of components for various industries, including automotive, aerospace, and construction. Extruded magnesium components include window frames, door frames, heat sinks, and decorative elements.

Magnesium and magnesium alloys are easy to machine and extrude, which makes them an excellent choice for complex shapes and designs. And magnesium has good thermal conductivity, which means that it can quickly dissipate heat. This makes it useful in applications where heat dissipation is important, such as in electronic devices and automotive parts.

Overall, the combination of low weight, high strength, good corrosion resistance, excellent machinability, and good thermal conductivity makes magnesium an ideal choice for extrusion applications. It is important to note, however, that magnesium is a reactive metal and must be handled carefully to prevent oxidation during the extrusion process. Special precautions must be taken to ensure that the metal is properly protected from the surrounding atmosphere during extrusion.

Magnesium metal used for Extrusion

Magnesium metal used for Sheet Metal Fabrication:

Magnesium sheet metal is used in the manufacture of various components for the aerospace and automotive industries. Magnesium sheet metal is lightweight, strong, and easy to work with, making it an ideal material for producing complex shapes and designs.

Magnesium metal for sale at Yirui Metal can be used for sheet metal fabrication, but there are some important considerations that need to be taken into account. Sheet metal fabrication involves forming, cutting, and joining thin sheets of metal to create a desired shape or structure. Here are some of the key factors to consider when using magnesium for sheet metal fabrication:

1. Cutting and Forming:

Magnesium metal can be cut and formed using many of the same tools and techniques used for other metals. However, it is important to use tools that are designed for use with magnesium to prevent damage to the metal and to ensure a clean, accurate cut.

2. Welding and Joining:

Magnesium material can be welded using a variety of techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. However, it is important to take special precautions to prevent oxidation during the welding process, as magnesium is highly reactive.

3. Surface Treatment:

Magnesium materialcan be treated with a variety of surface coatings, such as anodizing or plating, to improve its corrosion resistance or to enhance its appearance.

Magnesium material can be a good choice for sheet metal fabrication when its unique properties are needed. However, it is important to work with a skilled fabricator who has experience working with magnesium and who understands the special precautions that must be taken to prevent oxidation during the fabrication process.

Magnesium metal used for Machining

Magnesium metal is also used in machining applications to produce a wide range of components for various industries, including automotive, aerospace, and electronics. Magnesium can be machined to produce complex shapes and designs, making it an ideal material for producing intricate components such as gears, bearings, and connectors.

Magnesium metal is often used for machining because it is a lightweight and easy-to-machine metal with good mechanical properties. Machining involves using cutting tools to remove material from a workpiece to create a desired shape or finish. Here are some of the key factors to consider when machining magnesium:

1. Cutting Tools:

Magnesium material is a soft metal, so it requires cutting tools that are designed for use with soft metals. Carbide tools are a popular choice for machining magnesium, as they are durable and can be used at high speeds.

2. Lubrication:

Magnesium material can be prone to galling, which is a form of surface damage that can occur during machining. To prevent galling, it is important to use a suitable lubricant during the machining process.

3. Safety:

Magnesium material is a flammable metal and can ignite when exposed to heat or sparks. It is important to take proper safety precautions when machining magnesium, such as using fire-resistant barriers and ensuring proper ventilation.

4. Surface Finish:

Magnesium material can be machined to a high degree of accuracy and can achieve a smooth surface finish. However, care must be taken to avoid creating burrs or other defects during the machining process.

Magnesium is a good choice for machining when its unique properties are needed. However, it is important to work with a skilled machinist who has experience working with magnesium and who understands the safety considerations that must be taken when machining this metal.

Magnesium metal used for Powder Metallurgy

Magnesium is also used in powder metallurgy applications to manufacture a wide range of components for various industries, including aerospace and automotive. Magnesium powder metallurgy is used to produce components such as engine parts, gears, and bearings.

Magnesium metal can be used for powder metallurgy, a manufacturing process that involves forming metal powders into a desired shape or structure using heat and pressure. Here are some of the key factors to consider when using magnesium for powder metallurgy:

1. Powder Production:

Magnesium powders can be produced using a variety of techniques, including atomization, chemical reduction, and mechanical milling. The choice of production technique depends on the desired powder characteristics, such as particle size, shape, and purity.

2. Forming:

Magnesium alloy powder can be formed into a desired shape or structure using various techniques, such as hot pressing, cold pressing, or injection molding. Care must be taken to ensure that the powder is properly consolidated and that the final part has the desired properties.

3. Sintering:

After forming, the magnesium part is typically sintered at high temperatures to create a fully dense, solid structure. During the sintering process, the powder particles are bonded together to create a solid mass.

4. Surface Treatment:

Magnesium parts produced using powder metallurgy can be treated with a variety of surface coatings, such as anodizing or plating, to improve their corrosion resistance or to enhance their appearance.

Magnesium is a good choice for powder metallurgy when its unique properties are needed. However, it is important to work with a skilled metallurgist who has experience working with magnesium and who understands the special considerations that must be taken when working with this metal powder.

In conclusion, magnesium is a highly versatile metal that finds a wide range of applications in various manufacturing industries. Its low density, high strength, and excellent corrosion resistance make it an ideal choice for die casting, welding, extrusion, sheet metal fabrication, machining, and powder metallurgy applications. As technology continues to advance, the use of magnesium is likely to expand further, making it an increasingly valuable material in the years to come.

PREV: Is Magnesium Considered a Heavy Metal?

NEXT: Is Magnesium a Soft Metal?

3 notes

·

View notes

Text

The design of aluminum die casting parts begins with the consideration of wall thickness. It is a critical factor that affects not only the part's strength but also its cooling rate and overall quality. Generally, uniform wall thickness is preferred to ensure consistent material properties throughout the part. However, when varying thicknesses are necessary, gradual transitions should be incorporated to prevent stress concentrations and potential defects.

Ribs, or reinforcements, are essential in aluminum die casting parts to provide additional strength where needed without adding excessive material. They should be designed to follow the natural flow of the casting process, allowing for even distribution of the molten aluminum and reducing the risk of voids or inclusions. The size and spacing of ribs are determined by the part's function and the material's mechanical properties.

An efficient cooling system is vital for aluminum die casting parts to ensure quick and even cooling, which is crucial for achieving the desired mechanical properties. The design of the cooling system must take into account the part's geometry, material flow, and the heat transfer characteristics of aluminum. Cooling channels can be integrated into the die itself or designed as part of the casting to facilitate heat dissipation.

0 notes

Text

Design points and precautions of three-plate mold style of plastic mold "two-color mold"

Primary Color Material: ABS Secondary Color Material: TPS Appearance of TPS elastomer is transparent or natural color particles, and hand feel is super soft or flexible. Hardness of material usually ranges from 30 to 90A. Hardness of TPS material for special applications can reach 0A, or 120A. TPS elastomer has rubber-like elasticity and wear resistance, and has a unique soft touch. TPS…

View On WordPress

#cold chamber die casting#die casting#die-cast aluminum alloy#die-casting process#die-casting production#hot chamber die casting#Zinc alloy die casting

0 notes

Text

Sustainable Manufacturing: The Rise of Recycled Aluminum in Die Casting

The aluminum die casting market is experiencing significant growth, driven by advancements in technology, increasing demand for lightweight materials, and the expansion of various industries such as automotive, aerospace, and consumer electronics. As per Intent Market Research, the Aluminum Die Casting Market was valued at USD 30.5 billion in 2023 and is projected to surpass USD 65.2 billion by 2030, growing at a CAGR of 11.5% during 2024 - 2030. This article explores the dynamics of the aluminum die casting market, its applications, challenges, and future prospects.

Understanding Aluminum Die Casting

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold under high pressure. This method allows for the production of complex shapes with excellent surface finish and dimensional accuracy. The process is widely used in various industries due to its efficiency and ability to produce lightweight yet strong components.

Access Full Report @ https://intentmarketresearch.com/latest-reports/aluminum-die-casting-market-4852.html

Key Advantages of Aluminum Die Casting

High Strength-to-Weight Ratio: Aluminum components produced through die casting are lighter than those made from steel or iron, making them ideal for applications where weight reduction is critical.

Complex Geometries: The die casting process can create intricate designs that would be challenging or impossible to achieve with other manufacturing methods.

Cost-Effectiveness: High-volume production capabilities lead to lower per-unit costs, making aluminum die casting a cost-effective solution for many applications.

Market Drivers

Growing Demand in Automotive Industry

The automotive industry is one of the largest consumers of aluminum die-cast products. With the increasing emphasis on fuel efficiency and performance, manufacturers are replacing heavier materials with lightweight aluminum components. This shift not only enhances vehicle performance but also helps in meeting stringent emissions regulations.

Expansion of Aerospace Sector

The aerospace industry is also contributing to the growth of the aluminum die casting market. The need for lightweight materials that can withstand high stress and temperature variations has led to increased adoption of aluminum components in aircraft manufacturing.

Rising Consumer Electronics Market

Aluminum die casting is gaining traction in the consumer electronics sector as well. The demand for lightweight, durable casings for devices such as smartphones, laptops, and tablets is driving manufacturers to utilize aluminum die casting for producing high-quality enclosures.

Challenges Facing the Market

Despite its growth potential, the aluminum die casting market faces several challenges:

High Initial Costs: Setting up die casting operations requires significant capital investment in machinery and tooling.

Environmental Regulations: The industry must navigate stringent environmental regulations concerning emissions and waste management.

Competition from Alternative Materials: While aluminum offers many advantages, competition from other materials like plastics and composites can pose a threat to market growth.

Download Sample Report @ https://intentmarketresearch.com/request-sample/aluminum-die-casting-market-4852.html

Future Outlook

The future of the aluminum die casting market looks promising, with several trends expected to shape its trajectory:

Technological Advancements

Innovations in die casting technology, including improvements in automation and robotics, are likely to enhance production efficiency and reduce costs. Additionally, advancements in alloy formulations will enable manufacturers to produce even stronger and lighter components.

Sustainability Initiatives

As industries increasingly focus on sustainability, the recycling of aluminum will become more prominent within the die casting sector. Recycled aluminum has a lower environmental impact compared to primary aluminum production, making it an attractive option for manufacturers aiming to reduce their carbon footprint.

Regional Growth Dynamics

The global aluminum die casting market is expected to witness significant growth across various regions:

North America: Dominating the market due to advanced manufacturing capabilities and a strong automotive sector.

Asia-Pacific: Expected to be the fastest-growing region as countries like China and India ramp up their manufacturing capabilities and investments in infrastructure.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

Exploring the Versatility and Benefits of Aluminum Die Casting Alloys

Aluminum die casting alloys are widely used in the manufacturing industry due to their exceptional mechanical properties and superior quality. These alloys are highly versatile and can be used in a variety of applications, ranging from automotive components to electronic devices. They possess excellent strength, durability, and resistance to corrosion, making them ideal for use in harsh environments. Additionally, aluminum die casting alloys are cost-effective, lightweight, and easy to machine, making them a popular choice for many industries. At Siamlex, we specialize in producing high-quality aluminum die casting alloys that meet the unique needs of our customers.

0 notes

Text

The Role of Aluminum Casting Suppliers in Aerospace and Automotive Industries

Aluminum casting plays a vital role in the manufacturing of components for the aerospace and automotive industries. Its lightweight, durable, and versatile properties make aluminum the material of choice for critical applications. High-performance parts are made possible by the expertise of aluminum casting suppliers. These suppliers ensure precision, quality, and innovation throughout the process.

This blog explores the significance of aluminum casting suppliers in the aerospace and automotive sectors. It details how these suppliers contribute to efficiency, safety, and technological advancement.

Why Aluminum is the Material of Choice

Aluminum’s popularity in the aerospace and automotive industries stems from its exceptional properties:

Lightweight: Aluminum significantly reduces the weight of vehicles and aircraft. It improves fuel efficiency and performance.

High Strength-to-Weight Ratio: Despite being lightweight, aluminum offers remarkable strength. Also, this makes it suitable for structural and load-bearing components.

Corrosion Resistance: Its natural resistance to rust and corrosion enhances durability, even in harsh environments.

Thermal and Electrical Conductivity: Aluminum is highly conductive. Therefore, this makes it ideal for heat management in engines and electrical systems.

Recyclability: Aluminum’s recyclability aligns with sustainability goals, an increasingly important factor in modern manufacturing.

The Role of Aluminum Casting Suppliers

Aluminum casting suppliers are more than just manufacturers. They are strategic partners in the development of advanced components for aerospace and automotive applications. Their role involves several critical functions:

1. Delivering High-Quality Components

Suppliers use advanced casting methods. These methods include die casting, sand casting, and investment casting. They produce parts with exceptional precision and durability. They ensure the components meet strict industry standards, such as those set by ISO or AS9100 for aerospace manufacturing.

2. Innovating with Advanced Technology

Modern aluminum casting suppliers use cutting-edge technologies. These technologies include 3D modeling, CNC machining, and computer-aided design (CAD). These tools enable the production of lightweight, high-performance parts. These parts meet the unique demands of both industries.

3. Customization and Flexibility

Every aerospace and automotive project comes with its own set of challenges. Suppliers provide customized solutions. They tailor components to specific requirements, whether it's an engine block for a high-performance car or a structural component for an aircraft.

4. Enhancing Efficiency

Suppliers help manufacturers reduce costs and streamline operations. They do this by optimizing production processes and material usage. Their expertise in mold design, tooling, and alloy selection minimizes waste and maximizes output.

5. Supporting Sustainability Goals

Suppliers play a key role in promoting environmental responsibility. Many incorporate recycled aluminum into their processes. They also adopt energy-efficient manufacturing techniques to help industries reduce their carbon footprint.

Applications in the Aerospace Industry

The aerospace industry requires materials that can withstand extreme conditions. These materials must also maintain lightweight properties. Aluminum casting suppliers meet these demands by producing components like:

Aircraft Fittings: Lightweight fittings that reduce overall aircraft weight without compromising safety.

Engine Components: Heat-resistant parts capable of enduring high temperatures in jet engines.

Structural Components: Durable yet lightweight castings used in fuselages and wings.

Precision-engineered aluminum parts help aerospace manufacturers achieve better fuel efficiency. They also help reduce emissions and enhance performance.

Applications in the Automotive Industry

The automotive sector relies on aluminum casting for lightweight vehicles. These vehicles meet stringent fuel efficiency and emission standards. Key applications include:

Engine Blocks and Cylinder Heads: High-strength components that improve engine efficiency while reducing weight.

Transmission Housings: Durable yet lightweight housings that enhance vehicle performance.

Chassis Components: Strong, corrosion-resistant parts used in suspension systems and other structural areas.

By partnering with reliable aluminum casting suppliers, automakers can produce vehicles that are safer, more efficient, and environmentally friendly.

Benefits of Partnering with a Reliable Aluminum Casting Supplier

Choosing the right aluminum casting supplier can make all the difference in achieving manufacturing excellence. Here’s why:

Consistent Quality Reliable suppliers prioritize quality control at every stage, from material sourcing to final inspection. It ensures every part meets the required specifications.

Timely Delivery With streamlined production processes and efficient logistics, top suppliers deliver components on time. Also, it supports seamless manufacturing schedules.

Cost-Effectiveness Suppliers with advanced technology and efficient operations offer competitive pricing without compromising quality.

Collaborative Approach Trusted suppliers offer expert advice on design, material selection, and production techniques. They work closely with clients to optimize results.

Final Thoughts

Aluminum casting suppliers are crucial partners for the aerospace and automotive industries. They drive innovation and excellence in manufacturing. They deliver lightweight, durable, and high-performance components. These components enable industries to meet their goals of efficiency, safety, and sustainability.

Whether it’s producing an intricate jet engine part or a high-performance car chassis, the role of an aluminum casting supplier is central to the success of modern engineering. With their expertise and commitment to quality, these suppliers continue to shape the future of aerospace and automotive technology.

0 notes