#die cast manufacturer

Explore tagged Tumblr posts

Text

#die cast manufacturer#casting company in india#die casting company in india#casting manufacturers#die casting manufacturer

0 notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

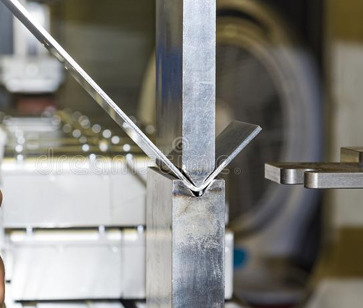

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

Advance Technologies is a trusted name in the industry, and their range of components is highly demanded by clients due to their optimum quality and dimensional accuracy. They specialize in:

Mould Making Services

High-Pressure Die Casting Services (Aluminium Components)

Custom Mould Making Services

Machining of Aluminium Components

Tool Room - Dies and Moulds

Tool Design

What sets them apart is their commitment to delivering high-quality products at effective prices within the assured timeframe. Established in 2010, they have built a strong reputation for reliability and excellence.

1 note

·

View note

Text

Core Pins: Essential for Precision Molding & Die Casting

What is a Core Pin?

A core pin is a precision-machined metal component used in die casting, plastic injection molding, and metal fabrication to form internal holes, cavities, or intricate features in molded parts. These pins play a crucial role in ensuring accuracy and consistency in manufacturing.

Types of Core Pins

🔹 Standard Core Pins – Used for basic hole formation. 🔹 Shoulder Core Pins – Provide precise positioning inside molds. 🔹 Tapered Core Pins – Allow easy removal and reduce wear. 🔹 Ejector Core Pins – Assist in ejecting the molded part. 🔹 Custom Core Pins – Designed for unique manufacturing needs.

Materials Used

Core pins must withstand extreme heat, pressure, and wear, making tool steel (H13, D2, S7), carbide, and stainless steel the most commonly used materials. Special coatings like TiN (Titanium Nitride) enhance durability and reduce friction.

Applications of Core Pins

✅ Die Casting – Creates cavities in metal parts (automotive, aerospace). ✅ Plastic Injection Molding – Forms internal features in plastic products. ✅ Medical & Aerospace – Used in precision manufacturing of critical components.

Why Core Pins Matter

✔ High precision & accuracy ✔ Improved production efficiency ✔ Durability for long-term use

Choosing the right core pin ensures smoother manufacturing, fewer defects, and cost-effective production.

Looking for high-quality core pins? Explore Raga Group’s Core Pins for durable, precision-engineered solutions!

0 notes

Text

Discover top-notch metal rule die makers close to you. Experience superb craftsmanship, precision, and quick turnaround on all your die making desires. Providing extraordinary industry know-how for green, lengthy-lasting solutions. Trust in our expert provider to your production success.

0 notes

Text

Electronic Manufacturing Services and PCBA Solutions by Topwell Moulding

In today's fast-paced world of technology, the demand for innovative and reliable electronic manufacturing services (EMS) is at an all-time high. From developing intricate printed circuit board assemblies (PCBA) to offering comprehensive manufacturing solutions, Topwell Moulding has established itself as a trusted partner for businesses seeking excellence in electronics production.

What Are Electronic Manufacturing Services (EMS)?

EMS encompasses a wide range of services, from designing and assembling electronic components to producing fully functional products. These services ensure precision, efficiency, and quality in every stage of the manufacturing process. Topwell Moulding specializes in delivering these comprehensive solutions, making it easier for companies to focus on innovation while leaving the complexities of production to experts.

PCBA: The Heart of Modern Electronics

A Printed Circuit Board Assembly (PCBA) integrates electronic components onto a PCB to create functional circuits used in devices like smartphones, medical equipment, and industrial machinery. PCBA requires precision engineering and advanced manufacturing capabilities to ensure flawless performance.

Topwell Moulding employs state-of-the-art technology to handle:

Component Sourcing: Reliable sourcing of high-quality components.

Surface Mount Technology (SMT): Precise placement of components for compact and efficient designs.

Through-Hole Assembly: Robust solutions for products requiring durable and high-current components.

Quality Control: Rigorous testing to ensure all assemblies meet industry standards.

Why Choose Topwell Moulding for EMS and PCBA?

1. Advanced Infrastructure: Topwell Moulding is equipped with cutting-edge machinery and tools that enable efficient and accurate production. From prototyping to mass production, the company ensures every project receives meticulous attention.

2. Customization and Scalability: Whether you need small-batch prototypes or large-scale production runs, Topwell Moulding tailors its services to meet your exact specifications, ensuring flexibility and scalability.

3. Commitment to Quality: Quality assurance is at the core of every process. The company adheres to international standards such as ISO certifications to ensure reliability and durability in all products.

4. Cost-Effective Solutions: Topwell Moulding focuses on optimizing production processes, which translates to competitive pricing without compromising quality.

Industries Served

Topwell Moulding caters to a diverse range of industries, including:

Consumer Electronics: Smartphones, wearables, and home appliances.

Healthcare: Medical devices and diagnostic equipment.

Automotive: Electronics for safety, infotainment, and navigation systems.

Industrial Automation: Components for robotics and automated systems.

Partner with Topwell Moulding

By choosing Topwell Moulding, you gain a partner dedicated to transforming your ideas into market-ready products. With expertise in electronic manufacturing services and PCBAs, the company stands ready to help your business thrive in a competitive market.

Explore more about their services at Topwell Moulding and take the first step toward innovation today!

0 notes

Text

Trusted Die Casting Manufacturer for Precision Solutions

Partner with Bian Die Cast, a leading die casting manufacturer specializing in high-precision parts. From prototyping to full-scale production, we provide tailored solutions that meet your industry needs.

0 notes

Text

#Gravity Die Casting parts manufacturing Company in India#Gravity Die Casting Manufacturing facility#Gravity Die Casting Company india#Custom GDC Solution#Automotive GDC Components#Industrial GDC Suppliers#Expert GDC Solution#precision GDC Parts Manufacturers#High Quality GDC Parts Manufacturers

0 notes

Text

Custom Aluminum High Pressure Die Casting Parts Manufacturer for Every Industry

G.M. Hi-Tech is a leading Custom Aluminum High Pressure Die Casting Parts Manufacturer for Every Industry, delivering precision-engineered solutions tailored to your unique needs. With advanced technology and unmatched expertise, we provide high-quality, durable components for automotive, aerospace, and industrial applications. Trust G.M. Hi-Tech for innovative designs, efficient production, and exceptional customer service across industries.

0 notes

Text

Injection mold "two-color mold" front mold slider with slider structure sharing

First color material: PA Second color village quality: ASA The two materials have good adhesion PA characteristics: Brrel temperature: 250-310℃ Shrinkage rate 0.6~1.4% Mold temperature 40~90℃ Heat distortion temperature: 65℃ High mechanical strength, good toughness, high tensile and compressive strength Disadvantages: easy to absorb water and poor dimensional stability. ASA…

View On WordPress

#die casting#die casting defects#die casting process#die-casting additives#Die-casting mold#die-casting parts#die-casting process parameters#mold design#mold design and manufacturing#mold manufacturing

0 notes

Text

Iron Casting Company in India: Aqeel Industries

India has long been recognized as a global leader in manufacturing, and within this robust industrial ecosystem, Aqeel Industries stands out as a trusted name in iron casting. Renowned for its high-quality products and state-of-the-art technology, Aqeel Industries has become synonymous with reliability, precision, and innovation.

Superior Craftsmanship and Technology

Aqeel Industries takes pride in blending traditional expertise with modern advancements in casting technology. The company specializes in a wide range of iron casting solutions, including gray iron, ductile iron, and alloy iron castings, catering to diverse industries such as automotive, agriculture, construction, and machinery manufacturing. By employing advanced molding techniques and quality control systems, Aqeel Industries ensures that every casting meets stringent international standards.

Commitment to Quality and Sustainability

What sets Aqeel Industries apart is its unwavering commitment to quality. The company maintains rigorous testing protocols at every stage of production, from raw material selection to the final inspection. This meticulous approach guarantees durability, dimensional accuracy, and optimal performance in its cast products.

Sustainability is also a key focus for Aqeel Industries. The company adopts eco-friendly practices, such as recycling foundry sand and reducing carbon emissions, to contribute to a greener future while delivering exceptional value to its clients.

Customer-Centric Approach

At Aqeel Industries, customer satisfaction is paramount. The company collaborates closely with clients to understand their unique requirements and delivers tailored solutions that exceed expectations. This dedication to customer service has helped Aqeel Industries build long-lasting relationships and a stellar reputation in both domestic and international markets.

Conclusion

For businesses seeking top-notch Iron Casting Company in India, Aqeel Industries is a name to trust. With its expertise, innovation, and customer-first philosophy, the company continues to shape the future of the iron casting industry.

#Iron Casting Company in India#Cast Iron Casting Manufacturers in India#Die Casting Manufacturers in India#Iron Casting Manufacturers

0 notes

Text

Aluminium Die Casting Manufacturers: Taural India’s Impact and Expertise

Aluminium die casting has become a crucial part of the modern manufacturing industry, especially in sectors that require durable, lightweight, and cost-effective components. One company that stands out in this space is Taural India, an industry leader with expertise in producing high-quality aluminium die-cast parts for various applications. Operating with a focus on precision, efficiency, and sustainability, Taural India has earned a strong reputation among aluminium die casting manufacturers worldwide. This blog explores the essential role of Taural India in the aluminium die casting industry, the processes they employ, and the industries they serve.

1. An Overview of Aluminium Die Casting

Aluminium die casting is a manufacturing process where molten aluminum is injected into steel molds, or “dies,” under high pressure. The process allows for complex, highly detailed designs with excellent accuracy and consistency. Aluminium die casting is favored across industries for its unique properties:

Lightweight Strength: Aluminium has a high strength-to-weight ratio, which is invaluable in industries such as automotive and aerospace.

Corrosion Resistance: Aluminium’s natural resistance to corrosion enhances the durability of parts in various applications.

Cost Efficiency: Once a die is created, the casting process is repeatable, making it cost-effective for large production runs.

Recyclability: Aluminium is 100% recyclable, making it an environmentally friendly choice.

2. Taural India: A Leader in Aluminium Die Casting

Taural India has grown into one of the most respected aluminium die casting manufacturers in India. With a commitment to quality, innovation, and sustainability, Taural India delivers die-cast components that meet the high standards required by diverse industries. They leverage state-of-the-art technology and a team of skilled engineers to manufacture precision parts for their clients across the globe.

Quality Assurance at Taural India

Quality is at the core of Taural India’s mission. Every step of their production process, from material sourcing to final inspection, adheres to stringent quality standards. Taural India invests in advanced technology, such as high-pressure die-casting machines, CNC machining, and automated inspection tools. This ensures that every product meets both the customer’s specifications and global industry standards.

Their commitment to quality also extends to maintaining high standards in testing and certification, enabling Taural India to meet the stringent requirements of industries such as automotive, aerospace, and electronics.

Precision Engineering and Advanced Technologies

To achieve high precision and accommodate complex designs, Taural India employs advanced engineering techniques. Using computer-aided design (CAD) and computer-aided manufacturing (CAM), they can achieve intricate part geometries with minimal tolerances. Additionally, Taural India’s use of sophisticated simulation software helps in predicting and mitigating potential issues in the casting process, ensuring a higher yield of defect-free components. This use of technology also allows for flexibility in producing both large and small parts with consistent accuracy and durability.

Sustainability Initiatives and Environmental Responsibility

In line with global shifts toward sustainable practices, Taural India prioritizes environmental responsibility. Aluminium, being highly recyclable, aligns with this commitment as it can be reused without compromising quality. Taural India minimizes waste by recycling aluminium scrap and optimizing energy consumption across their operations. By focusing on sustainable manufacturing practices, Taural India not only contributes to a greener environment but also attracts clients who value eco-conscious suppliers.

3. Industries Served by Taural India

The versatility of aluminium die casting has enabled Taural India to supply high-quality components to a wide array of industries, meeting specific requirements for each.

a) Automotive Industry

The automotive industry is a primary consumer of aluminium die-cast parts due to the lightweight and durable properties of aluminium. Taural India provides critical components such as engine parts, transmission casings, and structural parts that reduce vehicle weight, improve fuel efficiency, and enhance performance. With vehicles moving toward electrification, Taural India’s parts are essential in creating lightweight structures that accommodate the added weight of electric power systems.

b) Aerospace Industry

In aerospace, precision and weight reduction are crucial. Aluminium’s lightweight properties are perfect for components like fuselage frames, support brackets, and engine housings. Taural India’s expertise in high-quality die casting enables them to meet the stringent safety and performance standards required by the aerospace sector, delivering reliable and precise components that withstand extreme conditions.

c) Electronics and Telecommunications

Electronics manufacturers benefit from aluminium die-cast parts due to aluminium’s excellent thermal conductivity and shielding capabilities. Taural India produces housings and enclosures that protect sensitive electronic components from electromagnetic interference (EMI) and heat. These parts are commonly used in applications like telecommunication devices, LED lighting systems, and computer hardware, providing durability, heat dissipation, and protection from environmental hazards.

d) Industrial and Heavy Machinery

Taural India’s aluminium die-cast parts are essential for various industrial machinery applications. They produce parts like pump housings, motor covers, and hydraulic components that require strength, durability, and resistance to corrosion. The precision casting techniques ensure that these components meet the high demands of heavy machinery, allowing for efficient and reliable performance under rigorous conditions.

4. Taural India’s Competitive Advantage

Taural India’s competitive edge lies in its unwavering commitment to innovation, quality, and customer satisfaction. Their key advantages include:

State-of-the-Art Facilities: Equipped with the latest die casting technology, Taural India can handle high-volume production runs with consistent quality.

Dedicated Research and Development (R&D): Taural India invests significantly in R&D to continuously improve their processes and materials. This enables them to stay ahead of industry trends and provide solutions for emerging market demands, such as lightweight electric vehicle parts.

Customization and Flexibility: Taural India is known for its ability to cater to specific customer needs, offering custom casting solutions and collaborating closely with clients to meet unique specifications.

5. The Future of Aluminium Die Casting with Taural India

As industries evolve, so do the demands for aluminium die-cast components. Taural India is prepared to meet these evolving needs by continuing to innovate, enhance sustainability, and expand their capabilities.

a) Emphasis on Electric Vehicles (EVs)

With the global push for electric vehicles, the demand for lightweight, energy-efficient parts has surged. Taural India is at the forefront of this movement, producing parts that not only reduce vehicle weight but also enhance battery life and energy efficiency. By partnering with automotive companies focused on EV development, Taural India is positioned to be a key supplier of aluminium die-cast parts for the electric mobility industry.

b) Increased Automation and Smart Manufacturing

Taural India is leveraging automation and digital technology to streamline operations, reduce lead times, and enhance product quality. The incorporation of automation in their production lines and the use of real-time monitoring systems allow them to minimize defects and improve efficiency. This smart manufacturing approach ensures that Taural India remains competitive and responsive to market changes.

c) Commitment to Green Manufacturing

In addition to recycling, Taural India is exploring ways to reduce its carbon footprint further. This includes investing in cleaner energy sources, optimizing energy use in their facilities, and exploring new eco-friendly alloys. Taural India’s commitment to green manufacturing aligns with the sustainability goals of many of its clients, further strengthening its market position.

Conclusion

Taural India has established itself as a leader among aluminium die casting manufacturers, offering quality, innovation, and sustainability to its clients. Their dedication to producing precise, durable, and eco-friendly aluminium die-cast parts has made them a preferred partner across multiple industries. With a future-focused approach that embraces sustainability, automation, and customization, Taural India is set to play a pivotal role in shaping the aluminium die casting landscape. For industries that require high-performance, lightweight components, Taural India remains a trusted name, delivering reliable solutions that meet the demands of a fast-changing world.

0 notes

Text

0 notes

Text

Leading China Die Casting Manufacturer – Bian Die Cast

Discover top-notch die casting solutions with Bian Die Cast, a trusted China die casting manufacturer specializing in precision engineering. From high-quality materials to advanced production techniques, we cater to diverse industries worldwide.

0 notes

Text

#High Pressure Die Casting Suppliers#HPDC Manufacturing Services#Custom HPDC Solution#precision HPDC Part#HPDC Parts Suppliers#HPDC Automotive Components Suppliers#High Pressure Die Casting parts Manufacturers in India#HPDC parts Manufacturers

0 notes

Text

Top Aluminum High Pressure Die Casting Parts Manufacturer for Quality and Precision

Discover G.M. Hi-Tech, the top Aluminum High Pressure Die Casting Parts Manufacturer known for unmatched quality and precision. With advanced technology and expertise, we deliver durable, high-performance parts tailored to your needs. Trusted by industries worldwide, G.M. Hi-Tech combines innovation and reliability to ensure excellence in every product. Choose us for superior solutions and exceptional service.

0 notes