#aluminum-die-casting-manufacturers

Explore tagged Tumblr posts

Text

#aluminum-die-casting-companies#die-casting-companies#aluminum-die-casting-manufacturers#custom-die-maker

0 notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

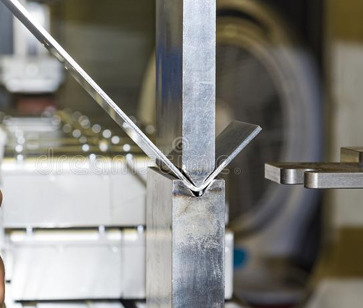

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

#automotive component manufacturers#auto parts Manufacturers In India#EV parts Manufacturing#EV Aluminium Components#Indian auto components manufacturer#auto component manufacturer#Aluminum Die-Casting parts manufacturing company#EV parts manufacturing

1 note

·

View note

Text

Custom Aluminum High Pressure Die Casting Parts Manufacturer for Every Industry

G.M. Hi-Tech is a leading Custom Aluminum High Pressure Die Casting Parts Manufacturer for Every Industry, delivering precision-engineered solutions tailored to your unique needs. With advanced technology and unmatched expertise, we provide high-quality, durable components for automotive, aerospace, and industrial applications. Trust G.M. Hi-Tech for innovative designs, efficient production, and exceptional customer service across industries.

0 notes

Text

#aluminum casting prototype manufacturer#Aluminum Die casting prototype manufacturer:#Aluminum casting assembly services

0 notes

Text

Aluminum Die Casting: An In-Depth Overview

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This process is widely used for producing metal parts with precision, smooth finishes, and complex shapes. Among the different materials used in die casting, aluminum stands out due to its superior qualities like lightweight, corrosion resistance, and excellent thermal conductivity. This blog provides an in-depth exploration of aluminum die casting, highlighting its significance, process, advantages, applications, and recent advancements.

The Importance of Aluminum in Die Casting

Aluminum has emerged as one of the most preferred materials in die casting because of its distinctive properties. Its low density, combined with high strength, makes it ideal for producing lightweight components without compromising on durability. Aluminum is also resistant to corrosion, making it suitable for components exposed to harsh environmental conditions. Its excellent thermal and electrical conductivity further expands its application in industries like automotive, aerospace, and electronics. Additionally, aluminum is highly recyclable, making it an eco-friendly option for manufacturers committed to sustainability.

The Aluminum Die Casting Process

Aluminum die casting typically involves the following key steps:

1. Preparation of the Mold

A steel mold, or die, is designed and fabricated to the desired shape of the component. The die is made of two halves – the fixed half, called the "cover die," and the movable half, known as the "ejector die." These dies are precisely engineered to ensure accurate shapes and dimensions.

2. Melting Aluminum

Aluminum is melted in a furnace at a temperature between 660°C and 750°C, depending on the alloy used. The molten aluminum is maintained at this temperature to keep it in a liquid state for casting.

3. Injection of Molten Aluminum

The molten aluminum is injected into the die cavity at high pressure using a hydraulic press. The pressure ensures that the molten aluminum fills every nook and cranny of the die, forming a solid and detailed shape once cooled.

4. Cooling and Solidification

After the molten aluminum is injected, it begins to cool and solidify rapidly within the die. This cooling process ensures that the part retains the shape of the mold, with excellent dimensional accuracy.

5. Ejection of the Component

Once the aluminum solidifies, the ejector die is opened, and the component is pushed out of the die using ejector pins. The component may undergo further cooling outside the mold.

6. Finishing and Post-Processing

After ejection, the component may require trimming, deburring, and surface finishing. In some cases, heat treatments, machining, or coating are applied to improve the part's performance or aesthetics.

Advantages of Aluminum Die Casting

Aluminum die casting offers a multitude of advantages, making it a highly sought-after manufacturing process across industries.

1. Lightweight and High Strength

Aluminum's low density makes it an ideal material for components that require reduced weight without compromising on strength. This is especially beneficial in the automotive and aerospace industries, where reducing weight is critical to improving fuel efficiency and overall performance.

2. Corrosion Resistance

One of aluminum's standout properties is its natural corrosion resistance. This characteristic makes die-cast aluminum components suitable for applications that are exposed to moisture, chemicals, and extreme environmental conditions.

3. Excellent Thermal Conductivity

Aluminum's high thermal conductivity makes it an excellent material for components used in applications where heat dissipation is critical. It is commonly used for manufacturing heat sinks, engine parts, and electronic enclosures.

4. High Dimensional Accuracy and Surface Finish

The high-pressure injection process in aluminum die casting ensures that the final component has excellent dimensional accuracy, reducing the need for extensive post-processing. The smooth surface finish of die-cast aluminum also minimizes the need for additional treatments.

5. Complex Shapes with Thin Walls

Aluminum die casting allows for the production of complex geometries that would be challenging or impossible with other manufacturing processes. The ability to produce intricate shapes with thin walls reduces material usage and weight, contributing to cost savings.

6. Recyclability

Aluminum is highly recyclable without losing its properties, making aluminum die casting a sustainable manufacturing option. Scraps and defective parts can be melted down and reused, contributing to waste reduction and resource efficiency.

Applications of Aluminum Die Casting

Aluminum die casting has a wide range of applications across various industries, thanks to the versatility of the material and the precision of the die casting process.

1. Automotive Industry

The automotive sector is one of the largest consumers of aluminum die-cast components. Parts such as engine blocks, transmission cases, oil pans, and structural components are commonly made using this process. Aluminum's lightweight nature helps reduce vehicle weight, contributing to improved fuel efficiency and lower emissions.

2. Aerospace Industry

Aluminum's high strength-to-weight ratio and corrosion resistance make it an ideal material for aerospace applications. Components like aircraft frames, landing gear, and turbine blades are often manufactured using aluminum die casting, ensuring durability and performance in extreme conditions.

3. Electronics Industry

Aluminum die casting is extensively used in the electronics industry for producing housings, heat sinks, and connectors. Its excellent thermal conductivity ensures efficient heat dissipation, which is crucial for preventing electronic components from overheating.

4. Consumer Goods

Die-cast aluminum is commonly used in manufacturing consumer products like kitchen appliances, lighting fixtures, and furniture hardware. The process allows for the production of durable, lightweight, and aesthetically pleasing components at a lower cost.

5. Telecommunications

In the telecommunications industry, aluminum die casting is used to produce enclosures and frames for routers, antennas, and other communication devices. The material's corrosion resistance and heat dissipation properties make it well-suited for outdoor and high-temperature environments.

Advancements in Aluminum Die Casting

Recent advancements in technology have further improved the efficiency and precision of aluminum die casting. Some of these developments include:

1. Computer-Aided Design (CAD) and Simulation

Modern die casting relies heavily on computer-aided design (CAD) and simulation software to optimize the design of dies, predict material flow, and identify potential defects. These tools help reduce production errors, improve cycle times, and enhance overall product quality.

2. High-Pressure Die Casting (HPDC)

High-pressure die casting (HPDC) has become a popular method for producing large quantities of aluminum components with exceptional precision. HPDC uses high-speed injection of molten aluminum into the die, resulting in reduced cycle times and lower production costs.

3. Vacuum-Assisted Die Casting

Vacuum-assisted die-casting technology helps eliminate air pockets and porosity in the final component. By removing trapped air from the mold, this method improves the strength and surface finish of the part, making it suitable for critical applications.

4. Advanced Alloys

The development of new aluminum alloys with enhanced mechanical properties has expanded the application range of aluminum die casting. Alloys with improved heat resistance, corrosion resistance, and strength are now used in industries that demand higher performance.

Conclusion

Aluminum die casting is a versatile and efficient manufacturing process that offers numerous advantages, including lightweight components, high strength, corrosion resistance, and complex shapes. Its wide range of applications, from automotive to aerospace, electronics, and consumer goods, highlights its importance in modern industry. As technology advances and new alloys emerge, aluminum die casting is set to continue playing a crucial role in the production of high-quality metal components. Whether for reducing vehicle weight, improving heat dissipation, or creating intricate designs, aluminum die casting remains an essential process in today's manufacturing landscape.

0 notes

Text

The Role of Die Casting in Modern Manufacturing

In today's world of precision engineering, Die casting manufacturers play a vital role in producing high-quality parts used across various industries. Aluminum die casting is a widely preferred method because of its durability, lightweight properties, and cost-effectiveness. From automotive components to electronics and lighting, die casting helps manufacturers meet the growing demand for precision-made parts.

0 notes

Text

Die Casting - An Insight into the Intricate Metal Forming Process

Die casting is a metal forming process where molten metal is injected at high pressure into steel molds or dies. Due to the high pressures involved, it results in products with very tight tolerances and precise dimensional specifications. This helps produce intricate components with complex internal passages in high volumes, at competitive costs compared to other manufacturing processes. History and Applications It is a relatively old manufacturing technology that was first developed in the late 18th century for producing metal buttons and thimbles. Over the years, advancements in metal alloys and casting equipment led to expanding applications of it, especially for zinc and aluminum. Today, commonly die cast metals include aluminum, zinc, magnesium, copper and tin-based alloys. Major industries using die cast components include automotive, industrial equipment, electronics, hardware, and household appliances. Common applications are engine parts, transmission components, housings, casings, and covers for electronics, tools, and consumer goods. It accounts for over 60% of all aluminum cast parts produced globally. Different Methods There are two main casting methods in use today - hot chamber and cold chamber Die Casting . Hot chamber machines maintain molten metal at a high temperature inside a holding furnace. Cold chamber machines solidify molten metal in a shot sleeve before injecting it into the die under pressure. Within these, there are further variants depending on the type of filling method - gravity, low/high pressure, and squeeze casting. Hot chamber casting is preferred for zinc and tin-based alloys, while aluminum alloys are commonly cold chamber die cast. Each method has merits suited for certain alloy compositions and part sizes/thicknesses. Process Steps The key steps involved in casting are: 1. Preparation of die and mold cavity 2. Melting and alloying of metal 3. Metal conditioning and transfer 4. Shot delivery into the die cavity 5. solidification under applied pressure and cooling 6. Die opening and part ejection 7. Finishing of cast parts The die or mold containing the cavity of desired part shape is first prepared using tool steels. Molten metal at 700-800°C is transferred and conditioned in the shot sleeve of the Die Casting machine. On trigger, a shot of melt is injected rapidly into the die cavity under very high pressures of 600-1500 kg/sq cm before solidifying. Accurate temperature control is vital to obtain quality castings. Design Considerations for Die Cast Parts Designing die cast parts requires careful planning to ensure production feasibility, dimensional accuracy, and assembly/performance needs. Key factors considered are part size/weight limitations, wall thickness variations and thick/thin sections, draft angles, gates and risers placement, machining/finishing requirements post casting, functional lives under service loads/temperatures, and surface finish needs. Finite element analysis involving thermo-mechanical simulations is often used at the design stage to validate castability. Functional designs help achieve dimensional consistency and elimination of defects in high volume production. Get more insights on Die Casting

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Die Casting#Metal Casting#Precision Manufacturing#Aluminum Casting#Zinc Casting#Casting Process#Industrial Casting#Mold Casting

0 notes

Text

Looking for a reliable partner in the automotive industry? Look no further than our Aluminum Die Casting Auto Parts Manufacturer. Our expertise in aluminum die casting ensures top-quality auto parts tailored to your needs. As a leading Aluminum Die Casting Auto Parts Manufacturer, we prioritize precision, durability, and performance. Our state-of-the-art facilities and skilled workforce make us the best choice for all your automotive components.

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Precision Redefined: Exploring the Expertise of China's Mold Makers

In the realm of manufacturing, precision is the cornerstone of excellence. Nowhere is this more evident than in China's mold making industry, where skilled craftsmen and advanced technologies converge to redefine the standards of precision. In this article, we delve into the expertise of China's mold makers, exploring their intricate craftsmanship, innovative approaches, and unwavering commitment to precision.

The Art of Mold Making

Mold making is both a science and an art, requiring meticulous attention to detail and unparalleled craftsmanship. China's mold makers are masters of this craft, possessing the skills and expertise to transform raw materials into precision-engineered molds with exceptional accuracy and quality.

Using advanced CAD/CAM software and state-of-the-art machining equipment, mold makers meticulously design and fabricate molds with intricate features and complex geometries. Every contour, every angle, and every dimension is carefully crafted to meet the exact specifications and requirements of each customer.

Advanced Technologies for Precision

Central to the expertise of China's mold makers is their ability to leverage advanced technologies to achieve precision redefined. Computer simulation software allows mold makers to simulate the casting process and optimize mold designs for maximum efficiency and accuracy.

High-speed CNC machining centers enable mold makers to fabricate molds with tight tolerances and fine surface finishes, ensuring that every component meets the highest standards of precision. Additionally, additive manufacturing techniques, such as 3D printing, offer new possibilities for creating molds with intricate details and complex geometries.

Customization and Adaptability

One of the hallmarks of China's mold makers is their ability to customize molds to meet the unique requirements of each customer. Whether it's a small-scale prototype or a high-volume production run, mold makers can tailor molds to suit the specific needs and applications of their clients.

By collaborating closely with customers and understanding their unique challenges and objectives, mold makers can develop customized solutions that deliver exceptional results. From design modifications to material selection, every aspect of the mold can be customized to optimize performance and efficiency.

Rigorous Quality Control Measures

Precision is not just a goal for China's mold makers—it's a commitment. Rigorous quality control measures are implemented at every stage of the mold making process to ensure that every component meets the strictest standards of excellence.

Advanced inspection techniques, such as coordinate measuring machines (CMMs) and laser scanning systems, are used to verify dimensional accuracy and surface finish. Non-destructive testing methods, such as X-ray and ultrasound, are employed to detect any defects or imperfections that may affect the integrity of the mold.

Continuous Improvement and Innovation

Continuous improvement is a driving force in China's mold making industry, with mold makers constantly seeking new ways to enhance precision, efficiency, and quality. Through ongoing training and development programs, mold makers stay abreast of the latest advancements in technology and techniques, allowing them to remain at the forefront of the industry. See here Aluminum die Casting manufacturer

Innovation is also key to the expertise of China's mold makers, who are constantly exploring new materials, processes, and technologies to push the boundaries of what is possible. By embracing innovation and adaptability, mold makers are able to meet the evolving needs of customers and stay ahead of the competition.

Global Impact and Reach

China's mold makers have a global impact and reach, serving customers in industries ranging from automotive and aerospace to electronics and consumer goods. With a vast network of suppliers, distributors, and partners around the world, mold makers have the resources and capabilities to deliver precision-engineered molds to customers wherever they may be.

By maintaining high standards of excellence and reliability, China's mold makers have earned a reputation for quality and precision that extends far beyond their borders. Whether it's a small-scale prototype or a large-scale production run, customers trust China's mold makers to deliver molds of uncompromising quality and precision.

Conclusion: Precision Perfected

In conclusion, China's mold makers are experts in precision redefined, pushing the boundaries of what is possible and setting new standards of excellence in the industry. With their intricate craftsmanship, innovative approaches, and unwavering commitment to quality, mold makers continue to redefine the standards of precision and shape the future of manufacturing on a global scale.

0 notes

Text

#aluminum-die-casting-manufacturers#custom-die-casting#deep-draw-stamping#deep-draw-stamping-companies#extrusion-die-design#zinc-die-casting-companies#zinc-die-casting-manufacturers

0 notes

Text

EV Aluminum Components Making EVs More Comfortable and Safer

Lightweight

Aluminum is lightweight and strong. It’s an ideal metal for EV components reducing the weight of the vehicle and extending the battery life. The EV aluminum components have enabled EV manufacturers to introduce lighter versions of two-wheelers and four-wheelers.

Enhanced safety

The high strength-to-weight ratio of aluminum improves the safety parameters to a great extent. The component manufacturers like Rockman as well as the auto makers ensure that EVs meet stringent safety standards.

Design flexibility

EV aluminum components can be customized to any extent. High malleability and trusted die-casting processes allow for complex designs of various components improving vehicle efficiency and augmenting aerodynamics. Rockman supplies customizable components to the automotive manufacturers and OEMs.

Durability

High strength-to-weight ratio and corrosion resistivity make every EV unit durable. The use of aluminum die-cast components also reduces the maintenance costs remarkably.

For more information on EV aluminum components visit: https://rockman.com

#EV aluminum components#aluminium die casting#die casting process#Rockman supplies#auto parts manufacturers in india

0 notes

Text

Low Volume Manufacturing Expertise in CNC Machined Aluminum

Discover the epitome of low volume manufacturing excellence with our CNC machining expertise in aluminum. From concept refinement to prototype delivery, our dedicated team ensures the highest quality and accuracy in every custom machined aluminum part.

#sheet metal manufacturing#low volume manufacturing#cnc milling services#aluminum die casting#sheet metal stamping#cnc machining services#cnc machined parts#cnc aluminum#aluminum prototype manufacturing#low volume cnc machining

0 notes

Text

Top Aluminum High Pressure Die Casting Parts Manufacturer for Quality and Precision

Discover G.M. Hi-Tech, the top Aluminum High Pressure Die Casting Parts Manufacturer known for unmatched quality and precision. With advanced technology and expertise, we deliver durable, high-performance parts tailored to your needs. Trusted by industries worldwide, G.M. Hi-Tech combines innovation and reliability to ensure excellence in every product. Choose us for superior solutions and exceptional service.

0 notes

Text

Top Casting Manufacturers in Howrah, West Bengal | Call 9163221666

✔️ Strictly follow quality control regime ✔️ Products at competitive prices ✔️ Consider the latest market demands ✔️ Maintain prompt and scheduled delivery ✔️ Encourage suggestions and feedback from customers

#Casting Manufacturer in West Bengal#aluminium die casting factory kolkata west bengal#casting manufacturer in west bengal#casting manufacturer#injection moulding companies#investment casting companies#zinc die casting#stainless steel casting companies#die casting companies near me#aluminum die casting manufacturer

0 notes