#zinc-die-casting-manufacturers

Explore tagged Tumblr posts

Text

#aluminum-die-casting-manufacturers#custom-die-casting#deep-draw-stamping#deep-draw-stamping-companies#extrusion-die-design#zinc-die-casting-companies#zinc-die-casting-manufacturers

0 notes

Text

Die Casting - An Insight into the Intricate Metal Forming Process

Die casting is a metal forming process where molten metal is injected at high pressure into steel molds or dies. Due to the high pressures involved, it results in products with very tight tolerances and precise dimensional specifications. This helps produce intricate components with complex internal passages in high volumes, at competitive costs compared to other manufacturing processes. History and Applications It is a relatively old manufacturing technology that was first developed in the late 18th century for producing metal buttons and thimbles. Over the years, advancements in metal alloys and casting equipment led to expanding applications of it, especially for zinc and aluminum. Today, commonly die cast metals include aluminum, zinc, magnesium, copper and tin-based alloys. Major industries using die cast components include automotive, industrial equipment, electronics, hardware, and household appliances. Common applications are engine parts, transmission components, housings, casings, and covers for electronics, tools, and consumer goods. It accounts for over 60% of all aluminum cast parts produced globally. Different Methods There are two main casting methods in use today - hot chamber and cold chamber Die Casting . Hot chamber machines maintain molten metal at a high temperature inside a holding furnace. Cold chamber machines solidify molten metal in a shot sleeve before injecting it into the die under pressure. Within these, there are further variants depending on the type of filling method - gravity, low/high pressure, and squeeze casting. Hot chamber casting is preferred for zinc and tin-based alloys, while aluminum alloys are commonly cold chamber die cast. Each method has merits suited for certain alloy compositions and part sizes/thicknesses. Process Steps The key steps involved in casting are: 1. Preparation of die and mold cavity 2. Melting and alloying of metal 3. Metal conditioning and transfer 4. Shot delivery into the die cavity 5. solidification under applied pressure and cooling 6. Die opening and part ejection 7. Finishing of cast parts The die or mold containing the cavity of desired part shape is first prepared using tool steels. Molten metal at 700-800°C is transferred and conditioned in the shot sleeve of the Die Casting machine. On trigger, a shot of melt is injected rapidly into the die cavity under very high pressures of 600-1500 kg/sq cm before solidifying. Accurate temperature control is vital to obtain quality castings. Design Considerations for Die Cast Parts Designing die cast parts requires careful planning to ensure production feasibility, dimensional accuracy, and assembly/performance needs. Key factors considered are part size/weight limitations, wall thickness variations and thick/thin sections, draft angles, gates and risers placement, machining/finishing requirements post casting, functional lives under service loads/temperatures, and surface finish needs. Finite element analysis involving thermo-mechanical simulations is often used at the design stage to validate castability. Functional designs help achieve dimensional consistency and elimination of defects in high volume production. Get more insights on Die Casting

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Die Casting#Metal Casting#Precision Manufacturing#Aluminum Casting#Zinc Casting#Casting Process#Industrial Casting#Mold Casting

0 notes

Text

Achieving Net Shape with Zinc Die Casting

When to Choose Zinc Die Casting

In die cast manufacturing, choosing the right material is an important first step in the design process. When considering the varied materials for your next design, zinc emerges as an option for a multitude of reasons. A key factor to consider is zinc's ability to achieve net shape in die casting.

What Does Net Shape Mean?

The concept of “net shape” is an important consideration in part design. A typical goal in one’s part design is to include many features and geometry into a part and reduce the number of parts.

Often fewer parts will result in a more effective design and lower cost solution since there is less to manufacture and join. Ultimately, it is a better design and solution for all as there are fewer parts to buy, inventory, and assembly.

The design of a zinc castings can align well with “net shape” objectives as this manufacturing process allows for feature designs that have various depths and is 3-dimensional vs a design of a stamping that is flat and limited.

Achieving Net Shape with Fluidity

One of zinc's standout characteristics is its remarkable fluidity when melted, it is similar to water. This property allows for the creation of parts that are complex and intricate and thus eliminating the need for extensive secondary operations or machining. Zinc's versatility extends to its ability to accommodate tight corners and thin wall conditions. This makes zinc die casting an excellent choice for design flexibility. This feature empowers designers to bring intricate concepts to life.

Easier Fastening and Joining of Parts

Zinc casting can also incorporate fastening/joining features into the part and thus minimize or eliminate the need for welding or the use of additional screws, etc.

For example, zinc die castings are well-aligned with industries requiring parts like fittings for fluid transportation. Zinc alloy parts can have threads cast-in and thus minimizes the need for secondary machining, saving both time and resources. Additionally, zinc part can have features designed in to act as a fastening rivet. The material can be formed to provide a “staked” join and thus eliminate the need for a fastener all together.

Strength Beyond Comparison

Zinc stands strong among moldable materials, surpassing the strength of alternatives like plastic or aluminum. When you are striving to meet precise design specifications, zinc delivers the resilience required. The decision to switch to zinc hinges on the specific needs of your products or parts. If strength, especially for tensile or fatigue, is a critical requirement, zinc is a common choice for improved performance.

Cost-Efficiency for Complex Assemblies

In situations where cost savings are crucial, consider the shift from steel stamping and welding to zinc die casting. As part usage increases, the cost justification for zinc die-cast parts becomes increasingly evident. Integrating essential details directly into the part streamlines the process.

Zinc processes faster than other materials, enabling you to produce parts more quickly. Therefore, impacting the bottom line of a design compared to other materials.

Investigate the Potential

For manufacturers seeking cost reduction, improved quality, or decreased reliance on secondary operations, it is worthwhile to explore zinc.

Dave Magner, Director of Sales, and Marketing at Deco Products was interviewed on the video podcast, Small Business Talks. Dave provided insights into the zinc die casting process. He emphasizes the advantages of Zinc, such as its strength, fluidity, and net shape capabilities. Listen here: https://www.podbean.com/ew/pb-3a3fz-154e6d7

High-volume parts are particularly suitable for zinc casting, given its exceptional tooling lifespan compared to aluminum.

Size Matters

While zinc can accommodate parts up to 24 inches in length, it is especially ideal for those weighing under a pound. For smaller parts, around four inches or less, zinc is well suited.

Deco's Expertise in the Design Process

For manufacturers without designers experienced in zinc die casting, Deco Products can help. Our team of experts can guide you through the design process. Ensuring your products meet the highest standards of quality and efficiency.

In conclusion

When considering zinc for die casting, focus on its fluidity, design flexibility, strength, and alignment with your industry needs. Explore how zinc can optimize your manufacturing process, reduce costs, and enhance product quality.

With Deco Products by your side, you can confidently navigate zinc die casting and gain the full potential for your projects.

Zinc Die Casting Services

As a leading manufacturer of zinc die cast products made in the USA. Deco Products understands the importance of the zinc die casting process in the manufacturing industry. With our social responsibility and commitment to sustainable manufacturing.

We have the capacity to partner with you on your next zinc die cast project. Our team of highly skilled professionals provides the highest quality products and value-added services to our clients.

Visit our capabilities and services page to learn more.

0 notes

Text

Top Casting Manufacturers in Howrah, West Bengal | Call 9163221666

✔️ Strictly follow quality control regime ✔️ Products at competitive prices ✔️ Consider the latest market demands ✔️ Maintain prompt and scheduled delivery ✔️ Encourage suggestions and feedback from customers

#Casting Manufacturer in West Bengal#aluminium die casting factory kolkata west bengal#casting manufacturer in west bengal#casting manufacturer#injection moulding companies#investment casting companies#zinc die casting#stainless steel casting companies#die casting companies near me#aluminum die casting manufacturer

0 notes

Text

Shaping the Future of Manufacturing: The Evolution of Aluminum and Zinc Die Casting Techniques

Seize the opportunity to collaborate with an industry-leading die casting manufacturer and unlock the full potential of aluminum and zinc die casting techniques in transforming your manufacturing processes and capabilities. With Biandiecast as your trusted partner, you can embark on a journey towards manufacturing excellence and operational efficiency, redefining the standards of precision casting and engineering innovation within your industrial

1 note

·

View note

Text

Magnesium Die Casting Alloys: Lightness Meets Unwavering Strength

Take a look at how magnesium die-casting alloys combine strength and lightweight. Because of their exceptional tensile strength and low density, these alloys are extremely valuable and expand the boundaries of engineering. Magnesium alloys are used in fields including electronics, aerospace, and automotive fields because of their extraordinary capacity to be formed into complex shapes. Accept the strength of lightweight durability as magnesium die-casting alloys offer the way to unrivaled innovation.

#Magnesium Die Casting Alloys#Low pressure die casting#Railroad castings manufacturers#Zinc die casting#zinc die casting alloys

0 notes

Text

issuu

Godani Export - Investment Casting & Die Casting Manufacturer

The PPT presentation showcases Godani Export as a leading manufacturer and exporter of high-quality casting and hardware products based in India. The presentation highlights the company's expertise in Zinc High Pressure Die Casting, Precision Casting, Door Hardware, Glass Hardware, and Faucet Handles.

#Duplex Steel Casting Manufacturers#Glass Hardware Manufacturers In India#Door Hardware Manufacturer#Precision Casting Manufacturer#Faucet Handle Manufacturers In India#Zinc High Pressure Die Casting Manufacturers

0 notes

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more : https://www.viratsteels.com/hot-work-steel.html https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

#aluminum-die-casting-manufacturers#deep-draw-stamping-companies#extrusion-die-design#custom-die-casting#zinc-die-casting-manufacturers#zinc-die-casting-companies#deep-draw-stamping

0 notes

Text

From Scrap to Metal

Aluminium is one of the most sought-after metals and is used in high volumes across multiple industries, including defence, transport, construction, food & beverages, and electronics. But extraction of pure aluminium from the bauxite ore is quite expensive and hence shoots up the manufacturing cost of the end products. Additionally, cheap imports of aluminium products from the foreign markets put pressure on India's domestic rolled products industry. With India’s annual aluminium consumption projected to double by 2023 to 7.2 million tons, there is a dire need for an alternative to this.

Solution: Secondary Aluminium!

The large-scale demand and usage of aluminium, generates massive amounts of scrap. This scrap serves as the source for the secondary aluminium! It comprises around 30% of India's total aluminium consumption of 3.3 million tons annually. Recycling aluminium is environmentally friendly, as the process consumes 95% less energy than generating primary aluminium. And since the atomic structure of aluminium remains unaltered upon melting, it enables the usage of the molten metal for various applications. It has been observed that the demand for secondary aluminium has grown faster than primary aluminium due to better cost economics, especially in the price-sensitive automotive castings sector.

Our customer who is India's largest producer of aluminium and zinc die-casting alloys, has been tapping the potential of India's aluminium recycling industry. From setting up its first plant in Tatarpur, near New Delhi, our customer’s expanse has grown to 12 plants across the country. These plants have a combined annual capacity of approximately 310,700 MT, making it the Rank One nationally in aluminium and zinc die-casting alloy production!

The plants have collection, segregation, processing, recycling, and treatment facilities for all types of secondary metal raw materials. The group also has joint ventures with renowned Japanese companies such as Toyota Tsusho Corporation and Nikkei MC Aluminium. Its most recent joint venture is for a plant in Gujarat, where the recycling of end-of-life vehicles (ELVs) is conducted through dismantling, shredding, and sorting.

Generating value for customers is the focus of the business, and there is constant attention to improving quality, controlling costs, and streamlining delivery. To ensure compliance with industry norms, the group has acquired ISO 14001, TS16949, 45001, and OHSAS 18001 certifications, along with other research and development certifications.

Our customer has a technology-focused approach in all its processes, making business activities more cost-effective and environmental-friendly.

Following are the steps involved in converting scrap metal into molten metal:

Manufacturing

Various steps are deployed to improve metal recovery rates while saving fuel costs. High-pressure hot air is used to vaporize ink from the surface, regenerative burners heat the metal, de-coaters remove the scales to reduce dross, and furnace circulation maintains temperature.

Segregation

Segregation is a critical step that ensures no impurities or contaminants enter the furnace. The process is mechanized using floatation systems, induction-based sorting systems, colour sorters, rotary sieves, eddy current separators, gravimetric separators, and shredders. Combining these pieces of equipment helps maintain the quality of the recycled aluminium.

Delivery

The molten metal obtained at the end of the process meets industry standards and is ready for delivery. However, specially designed ladles and trucks are used for transportation, as it is necessary to maintain the temperature of the molten metal during transit. Anti-pollution control mechanisms and baghouses are also used to reduce harmful emissions.

The Stumbling Block

Despite the smart energy-saving techniques, our customer’s non-ferrous recycling plants needed high-quality air processors to ensure that each shred of aluminium was free from contaminants and decorations before being added to the furnace. This was critical because the foreign particles could disrupt the quality of the aluminium recycled and would also increase fuel costs.

So, the challenge was to deploy an air system that could provide the highest quality of hot air as it would directly impact the product quality and cost.

Compressed air solution by ELGi

Our customer decided to install EG 22, EG 30, EG 37, EG 55, and EG 110 models of ELGi Screw Compressors across all their plants.

Each compressor was enabled with DCS and SCADA remote monitoring to ease operations. Additionally, every compressor met the highest air purity standards as per ISO regulations, maintaining a constant flow of hot air while ensuring the raw material was contaminant-free. In short, ELGi's EG Series Screw Air Compressors ensured that the metal recycling plants processed more shreds of aluminium at a much faster pace and that too with least downtime.

Additionally, ELGi provided installation & maintenance services for all compressors. We also provided preventive maintenance along with it. However, given the robustness of the EG series, no breakdowns were reported at any plant thus resulting in minimal downtime.

The ELGi Advantage:

Decontamination of raw material: High-quality air helped the brand conform to industry standards and deliver the accurate aluminium composition to its customers.

Cost control: Decontaminating raw materials reduced fuel consumption and energy costs. Further energy consumption was also realized by installing or retrofitting the air compressor with a Variable Frequency Drive (VFD). Our customer has leveraged this benefit to reduce costs and generate more value for its customers.

Minimal downtime: With no maintenance requirement since installation, ELGi's engineers swiftly performed routine servicing of the compressors, thus allowing our customer to focus on their business and timely delivery.

As an environmentally conscious organization, our customer focused on more innovative and sustainable solutions that met its business needs. And the EG series fulfilled that need by reducing energy loss and operating with minimal sound; hence, controlling the environmental impact.

Since then, they have relied on ELGi air compressors for years, accrediting its operational efficiency to ELGi’s high-performance, energy-efficient, environment-friendly air compressors that help to reduce energy costs.

Customer feedback:

"ELGi's innovative, high-quality products are helping us embark on our journey to become more energy efficient. Their products are so reliable that they bring peace of mind for all the stakeholders", says the management at our customer’s organisation.

Conclusion:

Recycling metal scrap to extract secondary aluminium is not only a significant business activity with enormous headroom for growth; but is also a fundamentally important industry in a world battling climate change.

ELGi’s screw air compressors play an enormous part in making this process profitable and sustainable.

#Oil lubricated screw Compressors#oil free piston Compressors#Oil lubricated piston Compressors#diesel portable Compressors#air compressor thailand

0 notes

Text

Automotive Parts Zinc Die Casting Market Report: Insights, Drivers, and Trends

Automotive Parts Zinc Die Casting Market Report: Insights, Drivers, and Trends

The global Automotive Parts Zinc Die Casting Market is experiencing robust growth. Valued at USD 4.15 billion in 2023, it is projected to expand to USD 5.53 billion by 2032, achieving a CAGR of 3.25% during the forecast period (2024–2032). This article highlights key drivers, developments, segmentation, and top players shaping the industry.

Download Free Sample Report: https://straitsresearch.com/report/automotive-parts-zinc-die-casting-market/request-sample

Market Size and Growth Drivers

Rising Demand for Lightweight Automotive Components

The growing need for fuel-efficient vehicles drives the demand for lightweight components, such as zinc die-cast parts. These components are preferred for their strength, corrosion resistance, and cost-effectiveness.

Technological Advancements in Manufacturing

The industry benefits from innovations in die-casting processes, such as pressure die casting and vacuum die casting. These methods enhance production efficiency and component quality, meeting stringent automotive standards.

Expanding Electric Vehicle Market

The surge in electric vehicle (EV) production boosts the demand for zinc die-cast parts, particularly for battery housings, body assemblies, and transmission systems.

Key Developments in the Automotive Parts Zinc Die Casting Market

Sustainability Initiatives: Companies are adopting eco-friendly manufacturing techniques, reducing emissions and energy consumption during the die-casting process.

Product Innovations: Advanced zinc alloys and coatings enhance durability, expanding the applications of die-cast parts in harsh environments.

Strategic Collaborations: Partnerships between automakers and die-casting firms drive innovation and improve supply chain efficiency.

Top Key Players in the Market

Prominent players driving the market include:

Dynacast

Ningbo Die Casting Man Technology Co., Ltd.

Ryobi Die Casting Inc.

Ashok Minda Group

Shanghai Cosmopolitan Automobile Accessory Co., Ltd.

CWM Automation

Bruschi SpA

Deco Products Company

Magic Precision Inc.

PHB Inc.

J&M Precision Die Casting, Inc.

These companies focus on innovation, strategic partnerships, and regional expansion to maintain competitive advantages.

Buy Full Report: https://straitsresearch.com/buy-now/automotive-parts-zinc-die-casting-market

Segmentation Analysis of the Market

By Production Process Type

Pressure Die Casting

Dominates the market due to high efficiency and superior surface finish.

Vacuum Die Casting

Preferred for complex components with minimal porosity.

Other Production Processes

Includes gravity and semi-solid die casting.

By Applications

Body Assemblies

Zinc die-cast parts improve structural integrity and reduce vehicle weight.

Engine Parts

Components like cylinder heads and crankcases benefit from zinc's durability.

Transmission Parts

Ensures smooth and reliable vehicle operation.

Other Applications

Includes battery housings and interior components.

Market Segmentation: https://straitsresearch.com/report/automotive-parts-zinc-die-casting-market/segmentation

Regional Market Insights

North America: High adoption of advanced automotive technologies fuels growth.

Europe: A strong EV market drives demand for zinc die-cast components.

Asia-Pacific: Rapid industrialization and growing automotive production make it the fastest-growing region.

Rest of the World: Increasing investments in automotive manufacturing enhance market potential.

Future Outlook

The Automotive Parts Zinc Die Casting Market is poised for continued growth, supported by technological advancements and rising demand for sustainable manufacturing solutions. Companies investing in R&D and automation will likely secure significant market shares.

0 notes

Photo

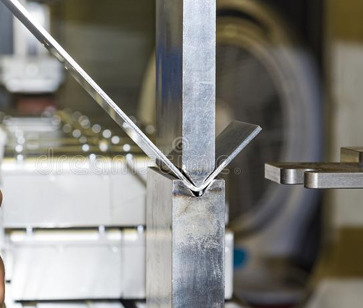

Chicago Die Cast 5 in. Dia. Zinc Single V Grooved Pulley

Sold as 2 UNITS at $13.63 per unit. (1 unit = each.) "A" section belt width. Zinc die cast. For fractional horse power electric motors. Bulk. 5" D x 5/8" Bore. Manufacturer number: 500A6. SKU #: 22825. Country of origin: (TBA). Distributed by Chicago Die Casting.

0 notes

Text

DST Tech: Revolutionizing Zinc Die-Casting for Sanitary Manufacturers

In a world where excellence and efficiency define the manufacturing landscape, DST Tech Private Limited stands tall as the leading manufacturer of zinc die-cast products in India. Unlike the majority of Chinese companies and all Indian companies, DST Tech proudly houses all operations under one roof, a unique aspect that sets us apart from the rest. From tool design and manufacturing to casting, machining, electroplating, and packaging, DST Tech’s seamless approach ensures “Peace of Mind” for our esteemed customers in terms of quality and timely delivery commitments.

Key Differentiators that Set DST Tech Apart

1. Tooling & Development Excellence: DST Tech’s dedication to precision and innovation has earned us several prestigious awards, including the International Zinc Association (IZA) award in 2023 for “best tool design” and the China Die Casting award in 2018 for excellence in tool design. Our tool designers, using cutting-edge software like Siemens NX19.0 and Hitachi Adstefen, are specialists in “Feed System design” for Zinc Die Casting, ensuring flawless material flow for impeccable high surface integrity, crucial for chrome plating.

2. Zinc Die Casting Shop of Distinction: DST Tech’s zinc die casting shop is renowned for its quality systems certified by TUV, Germany – the world’s highest-ranked certification body. This dedication to excellence has earned us accolades like the North American Die Casting (NADCA) award in 2018 for “Best zinc die casting” and the China Die Casting award in 2018 for “Excellence in Casting.” With a production capacity of 150 tons of Zinc Alloy per month and sourcing the best alloy manufacturers worldwide, DST Tech guarantees no question of alloy contamination.

3. Polishing & Electroplating Expertise: The polishing and electroplating facilities at DST Tech are designed with inputs from international experts. Our quality systems, certified by TUV, Germany, are a testament to Our commitment to excellence. Our largest and most modern electroplating shop for Zinc in India can process up to 1 million castings per month, and Our in-house laboratory ensures precise control and monitoring of the electroplating process.

Driving Sanitary Excellence Worldwide

DST Tech has emerged as the only Zinc die-cast company in India already supplying to the largest MNCs in sanitary & kitchenware worldwide. In addition, we are in discussions with top sanitary MNC brands for “Start of Production” partnerships. With professionally qualified personnel and directors with a background in Automotive and distinction in professional studies (B.Tech & MBA), DST Tech is poised to celebrate its 25th year in operation, reaching the zenith of quality for Zinc die-cast products.

Partnering for Growth and Sustainability

Sanitary manufacturers seeking credible and professional sources for Zinc die-casting in India need not look further. DST Tech offers a partnership that empowers growth worldwide with impunity. As we gear up to embrace international operational automation standards, DST Tech relies on support and collaboration to hedge against Chinese dominance and continue delivering excellence.

For More Information Pls Visit On :

#zinc die castings#casting manufacturer#die cast manufacturer#aluminium casting manufacturers#aluminium die casting manufacturers in india#die casting company in india#casting manufacturers#Precision Die Casting

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

0 notes

Text

Quality Zinc High Pressure Die Casting Manufacturers - GODANI EXPORTS

Look no further than Godani Exports Pvt. Ltd. if you're searching for outstanding Zinc High Pressure Die Casting Manufacturers. We are your go-to source for all of your Zinc High Pressure Die Casting requirements thanks to our years of experience and dedication to excellence. Our expert team is committed to providing high-quality products that precisely match your requirements. To learn more about our services for zinc high pressure die casting, get in touch with us right away!

Visit: https://www.godaniexport.com/zinc-high-pressure-die-casting.html

#Zinc High Pressure Die Casting Manufacturers#Zinc High Pressure Die Casting Manufacturers In India#GODANI EXPORTS#Quality Zinc High Pressure Die Casting#Zinc Die Casting Services

0 notes