#chip manufacturers

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/semiconductors--logic--74-series--a-hc-t/74hc594d-118-nexperia-1604081

74 A/HC/T Series Applications, programmable logic gate, digital gates

74HC Series 6 V 8-Bit Shift Register with Output Register - SOIC-16

#Logic#74 Series#A/HC/T#74HC594D#118#Nexperia#chip manufacturers#FCT#A/LVT#logic gate circuit#logic gate#chips#Logic Circuit#digital gates#gate logic#electronic logic gate ICs#programmable logic gate

1 note

·

View note

Text

AMSDigital is renowned as the best digital marketing agency in Bangalore, India for chip manufacturers. Our expertise and dedicated approach make us the ideal partner for businesses seeking to enhance their digital presence and achieve substantial growth.

#best digital marketing agency in Bangalore#India for chip manufacturers#Chip Manufacturers#Semiconductor Company

0 notes

Text

https://www.futureelectronics.com/p/semiconductors--analog--amplifiers--low-noise-amplifier/ba4560f-e2-rohm-3414471

Low noise amplifier, Ultra low noise op amp, Microwave low noise amplifiers,

Dual Channel 30 V 6 mV Surface Mount Low Noise Amplifier - SOP-8

#ROHM#BA4560F-E2#Amplifiers#Low Noise Amplifiers#Low noise instrumentation#chip manufacturers#power operational amplifier#power amplifier#Op amp circuits#What is a low noise amplifier#Ultra low noise op amp#Microwave low noise amplifiers

1 note

·

View note

Text

A Deep Dive into Top 10 Chip Manufacturers in India

Overview of the Semiconductor Industry in India India, a country of 1.3 billion inhabitants and a burgeoning technological powerhouse, has observed a significant surge in its semiconductor industry over recent years. This trend is a testament to the nation’s increasing role in global electronic production, propelled by rapid digitization, policy support from the government, and a vast pool of…

View On WordPress

0 notes

Text

I just love having washing machines tied to electronic payment systems! There are just so many cheerful ways that they can prevent you from doing your laundry that just never come-up with coin-op systems! Digitization is great!

46 notes

·

View notes

Text

I haven't been around as much lately, but that's mostly because I got a new job! My stepdad has a small business that's finally starting to take off, and he hired me on! I don't think I ever expected to go into small-scale manufacturing, but I like working with my hands and my art background is actually proving really useful, it keeps me active and there's enough variety of tasks that it's not boring... Anyway, I think it's going to work out really well and I'm excited! 😊

#And today I got to clip plastic nubbins off of freshly manufactured parts! Which is one of my favorite things to do. 😂#Because I'm the kind of person who chips wax drippings off the side of candles for fun in my free time#Hahaha

31 notes

·

View notes

Text

if trump actually does put tariffs on fuckin everything that could be very good for america in the long run tbf

#stream#like ok yea incentivize bringing manufacturing back to the us which forces businesses to raise wages for employees in the us or hire#illegally to pay less in taxes but if they’re an importer they don’t give a fuckkkkkkk 😭😭😭😭#it’s just going to be an. even bigger amazon monopoly until the us actually decides to break it which they fucking won’t because they’re#fucking stupid & would’ve & COULDVE DONE YEARS AGO#LIKE THE UK WHICH THEY FUCKING WONT EITHER#literally how is amazon more reliable than ur own mail service. than ur OTHER SHIPPING PROVIDERS#like amazon WILL get to me but if i order ANYTHINGGGGG ROYAL MAIL DPD FEDEX UPS NO#NEVER#NOT ONE PARCEL WILL COME#AT ALL !!!!!!!!! I HATE THIS COUNTRYYYYYYYYYYYYYYY !!!!!!!!!!!!!!!!!!#britain SINK !!!!!!!!!!!#like why didn’t the steel tariffs work in whenever he put them in: we didn’t & don’t have the steel production anymore since we outsourced#it all. but for everything else ????? THTS INFANT INDUSTRY BAYBEEEEEEE#let’s make our own computer chips how about#why is apple still manufacturing in china#(we know why) watch samsung start manufacturing in the us ALSKALSKLAKSLKSLAKSLAKAL#HUAWEI STARTS MANUFACTURING IN THE US 😭😭😭😭😭😭😭

4 notes

·

View notes

Video

youtube

The U.S. "Chip Act" 84 billion US dollars in subsidies, projects were suspended or delayed after the money was taken. #ChipAct #Chip #Manufacturing #Factory #Semiconductor #integratedcircuit #icgoodfind #Electronics www.icgoodfind.com

2 notes

·

View notes

Text

eating turbos rn and I found just a giant hard ball of the powder flavoring. god it was so fucking good like it was the most delicious thing I think I've ever eaten . woe

#yknow how brands will like. capitalize off their manufacturing mistakes and like. sell those as their own things#like extra toaster cheese its and stuff... do this#blabs#also y'know when takis r like . doubled up? like two chips got rolled into one... that too#desperately need those those r thr best takis in the bag and im actually so surprised they havent done that yet#theres like every possibly taki product u could think of but not that... sad

2 notes

·

View notes

Text

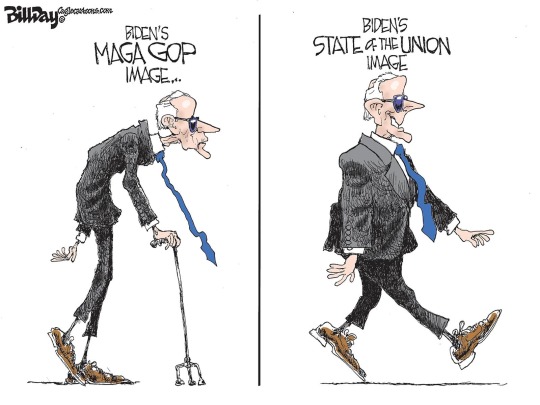

Bill Day

* * * *

Wow! You can’t make this up!

March 21, 2024

ROBERT B. HUBBELL

It’s hard to believe that the dysfunction in the Republican Party could get worse, but Wednesday saw new heights (or depths?) of chaos in the GOP. You are undoubtedly interested in hearing how the GOP impeachment hearing directed at Joe Biden produced damning evidence—against Donald Trump! But first, let’s look away from the GOP car crash to view the important work that President Biden is doing on behalf of the American people. (You’re welcome!)

As Trump and the GOP were entering panic mode at warp speed, President Biden was delivering on his promises to the American people. The Biden administration began the day by announcing a rule that would accelerate the production of hybrid and all-electric cars. See NYTimes, Biden Administration Announces Rule Aimed at Expanding Electric Vehicles. (This article is accessible to all.)

Per the NYTimes,

The Biden administration on Wednesday issued one of the most significant climate regulations in the nation’s history, a rule designed to ensure that the majority of new passenger cars and light trucks sold in the United States are all-electric or hybrids by 2032. Nearly three years in the making, the new tailpipe pollution limits from the Environmental Protection Agency would transform the American automobile market.

Accelerating the transition to hybrid and electric cars will deliver enormous economic and health benefits to the American people. Again, per the Times, the new regulation will

avoid more than seven billion tons of carbon dioxide emissions over the next 30 years . . . That’s the equivalent of removing a year’s worth of all the greenhouse gases generated by the United States . . . . The regulation would provide nearly $100 billion in annual net benefits to society [including] $13 billion of annual public health benefits thanks to improved air quality. The standards would also save the average American driver about $6,000 in reduced fuel and maintenance over the life of a vehicle, the E.P.A. estimated.

As the new “tailpipe emissions” standard was being announced, President Biden announced a massive investment in an Intel chip fabricating facility in Arizona. See Politico, Biden boosts Intel with massive CHIPS payout in swing state Arizona.

Per Politico, Biden said

“We will enable advanced semiconductor manufacturing to make a comeback here in America after 40 years. It’s going to transform the semiconductor industry and create entirely new ecosystems.” Biden said Intel would also invest “over $100 billion” across the country, in facilities in Arizona, Oregon, Ohio and New Mexico. Those investments should put the U.S. on track to produce roughly 20 percent of the world’s leading-edge chips by 2030, Biden said. He added that Intel’s new projects are expected to create 30,000 jobs nationwide in construction and manufacturing.

Beyond creating tens of thousands of jobs in the high-tech sector, the CHIPS and Science Act protects US national security. Recall that during the COVID pandemic, supply chain issues disrupted the flow of semiconductors into the US, hampering the manufacture and sale of hundreds of consumer products that rely on microprocessors. Manufacturing the chips in the US serves as a hedge against that future risk.

For most presidents, the Intel announcement and new tailpipe admissions standard would be the year's crowning achievements. For Joe Biden, those announcements were known as “Wednesday.” Biden gets stuff done. Tell a friend.

[Robert B. Hubbell Newsletter]

#Robert B. Hubbell#Robert B. Hubbell Newsletter#CHIPS#semiconductor manufacturing#jobs#CHIPS and Science act#Biden Administration#getting things done

3 notes

·

View notes

Link

The Israeli government and Intel have confirmed plans to build a $25 billion chipmaking complex in the country’s south, which Prime Minister Benjamin Netanyahu has called the largest investment in Israeli history

2 notes

·

View notes

Text

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

New Post has been published on https://thedigitalinsider.com/scientists-3d-print-self-heating-microfluidic-devices-technology-org/

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

The one-step fabrication process rapidly produces miniature chemical reactors that could be used to detect diseases or analyze substances.

MIT researchers have used 3D printing to produce self-heating microfluidic devices, demonstrating a technique which could someday be used to rapidly create cheap, yet accurate, tools to detect a host of diseases.

MIT researchers developed a fabrication process to produce self-heating microfluidic devices in one step using a multi-material 3D printer. Pictured is an example of one of the devices. Illustration by the researchers / MIT

Microfluidics, miniaturized machines that manipulate fluids and facilitate chemical reactions, can be used to detect disease in tiny samples of blood or fluids. At-home test kits for Covid-19, for example, incorporate a simple type of microfluidic.

But many microfluidic applications require chemical reactions that must be performed at specific temperatures.

These more complex microfluidic devices, which are typically manufactured in a clean room, are outfitted with heating elements made from gold or platinum using a complicated and expensive fabrication process that is difficult to scale up.

Instead, the MIT team used multimaterial 3D printing to create self-heating microfluidic devices with built-in heating elements, through a single, inexpensive manufacturing process. They generated devices that can heat fluid to a specific temperature as it flows through microscopic channels inside the tiny machine.

The self-heating microfluidic devices, such as the one shown, can be made rapidly and cheaply in large numbers, and could someday help clinicians in remote parts of the world detect diseases without the need for expensive lab equipment. Credits: Courtesy of the researchers / MIT

Their technique is customizable, so an engineer could create a microfluidic that heats fluid to a certain temperature or given heating profile within a specific area of the device. The low-cost fabrication process requires about $2 of materials to generate a ready-to-use microfluidic.

The process could be especially useful in creating self-heating microfluidics for remote regions of developing countries where clinicians may not have access to the expensive lab equipment required for many diagnostic procedures.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the fabrication technique.

He is joined on the paper by lead author Jorge Cañada Pérez-Sala, an electrical engineering and computer science graduate student. The research will be presented at the PowerMEMS Conference this month.

An insulator becomes conductive

This new fabrication process utilizes a technique called multimaterial extrusion 3D printing, in which several materials can be squirted through the printer’s many nozzles to build a device layer by layer. The process is monolithic, which means the entire device can be produced in one step on the 3D printer, without the need for any post-assembly.

To create self-heating microfluidics, the researchers used two materials — a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing, and a modified version of PLA.

The modified PLA has mixed copper nanoparticles into the polymer, which converts this insulating material into an electrical conductor, Velásquez-García explains. When electrical current is fed into a resistor composed of this copper-doped PLA, energy is dissipated as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties. This is something we don’t fully understand yet, but it happens and it is repeatable,” he says.

Using a multimaterial 3D printer, the researchers fabricate a heating resistor from the copper-doped PLA and then print the microfluidic device, with microscopic channels through which fluid can flow, directly on top in one printing step. Because the components are made from the same base material, they have similar printing temperatures and are compatible.

Heat dissipated from the resistor will warm fluid flowing through the channels in the microfluidic.

In addition to the resistor and microfluidic, they use the printer to add a thin, continuous layer of PLA that is sandwiched between them. It is especially challenging to manufacture this layer because it must be thin enough so heat can transfer from the resistor to the microfluidic, but not so thin that fluid could leak into the resistor.

The resulting machine is about the size of a U.S. quarter and can be produced in a matter of minutes. Channels about 500 micrometers wide and 400 micrometers tall are threaded through the microfluidic to carry fluid and facilitate chemical reactions.

Importantly, the PLA material is translucent, so fluid in the device remains visible. Many processes rely on visualization or the use of light to infer what is happening during chemical reactions, Velásquez-García explains.

Customizable chemical reactors

The researchers used this one-step manufacturing process to generate a prototype that could heat fluid by 4 degrees Celsius as it flowed between the input and the output. This customizable technique could enable them to make devices which would heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” he says.

However, one limitation comes from the fact that PLA can only be heated to about 50 degrees Celsius before it starts to degrade. Many chemical reactions, such as those used for polymerase chain reaction (PCR) tests, require temperatures of 90 degrees or higher. And to precisely control the temperature of the device, researchers would need to integrate a third material that enables temperature sensing.

In addition to tackling these limitations in future work, Velásquez-García wants to print magnets directly into the microfluidic device. These magnets could enable chemical reactions that require particles to be sorted or aligned.

At the same time, he and his colleagues are exploring the use of other materials that could reach higher temperatures. They are also studying PLA to better understand why it becomes conductive when certain impurities are added to the polymer.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” he adds.

“In Japanese culture, it’s often said that beauty lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic systems embody simplicity and beauty, offering a wide array of potential derivations and applications that we foresee in the future,” says Norihisa Miki, a professor of mechanical engineering at Keio University in Tokyo, who was not involved with this work.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” adds Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#additive manufacturing#amazing#applications#biodegradable#biomarkers#Biotechnology news#blood#chemical#chemical reactions#Chemistry & materials science news#chips#computer#Computer Science#conference#continuous#covid#Developing countries#Developments#devices#Disease#Diseases#energy#Engineer#engineering#equipment#Fabrication#Featured life sciences news#Featured technology news

2 notes

·

View notes

Text

Daily Semiconductor Industry Information By Lansheng Technology

1. At the VLSI Symposium 2023, which will be held next month, Intel will demonstrate the PowerVia technology verification chip.

2. On May 5th, Samsung Electronics is expected to surpass its main competitor TSMC in the field of chip foundry within 5 years.

3. According to media reports, Meta recruited a team from the British artificial intelligence chip company Graphcore. The team previously worked in Oslo, Norway, and was developing AI networking technology at Graphcore until late last year.

4. On May 5, 2023, semiconductor product companies Alpha and Omega Semiconductor once fell by 11.64% in intraday trading, and once touched $20.64. The stock price hit a new low since November 18, 2020.

5. Following in the footsteps of #Samsung, SK Hynix and Micron, the US chip giant Qualcomm’s latest quarterly revenue fell -16.9% year-on-year to US$9.275 billion, and its net profit fell sharply -41.9%. The three major business segments of mobile phones, automobiles and IoT All have declined to varying degrees, and its forecast data for the third fiscal quarter is also lower than market expectations.

Lansheng Technology Limited (https://www.lanshengic.com/) is a global distributor of electronic components that has been established for more than 10 years, headquartered in Shenzhen China, who mainly focuses on electronic spot stocks

6 notes

·

View notes

Text

The Crucial Role of Chips: Unveiling the Technological Advancements in China's 2023 College Entrance Examination

Introduction:

The 2023 College Entrance Examination in China witnessed an extraordinary leap in technological advancements, particularly in the field of chips. These tiny electronic components have become the backbone of modern society, revolutionizing various industries and empowering the development of cutting-edge technologies. In this blog post, we will explore the significance of chips in the context of the 2023 Chinese College Entrance Examination and the broader implications for China's technological landscape.

1. The Era of Smart Devices:

In recent years, China has witnessed a remarkable surge in the popularity of smart devices. Smartphones, tablets, and wearable gadgets have become an integral part of our daily lives. This trend heavily relies on the advancements in chip technology, specifically in terms of processing power, energy efficiency, and connectivity. The 2023 College Entrance Examination embraced this technological wave, as students were allowed to utilize electronic devices during certain sections of the exam, utilizing the power of chips to enhance their test-taking experience.

2. Empowering Artificial Intelligence:

Artificial Intelligence (AI) has emerged as a transformative force across various sectors, including education. In the 2023 College Entrance Examination, AI-powered systems were employed to analyze and evaluate students' answers, ensuring fair and accurate grading. The success of such systems largely depends on the performance of chips embedded within these AI frameworks. Advanced chips equipped with neural processing units (NPUs) can efficiently process massive amounts of data, accelerating AI algorithms and enabling real-time analysis.

3. The Rise of Edge Computing:

The proliferation of Internet of Things (IoT) devices has given rise to the concept of edge computing, where data processing occurs closer to the source rather than relying solely on centralized cloud servers. Chips play a pivotal role in enabling efficient edge computing, ensuring low latency and enhancing data security. In the context of the 2023 College Entrance Examination, edge computing facilitated seamless data transfer and real-time interaction between students' devices and the examination system, thereby enhancing efficiency and reliability.

4. Next-Generation Chip

To maintain China's position as a global technological leader, significant investments have been made in developing next-generation chip technologies. The 2023 College Entrance Examination served as a testing ground for these advancements, showcasing chips with enhanced performance, power efficiency, and miniaturization. Technologies such as 7-nanometer and 5-nanometer process nodes, stacked chip architectures, and novel materials like gallium nitride (GaN) contributed to the creation of highly advanced chips that powered the examination systems.

5. Addressing Challenges and Future Prospects:

Despite the remarkable progress in chip technology, challenges remain. The shortage of key raw materials, increasing energy consumption, and geopolitical considerations are among the obstacles that need to be addressed. However, China's commitment to research and development, collaboration with global partners, and strategic investments in semiconductor manufacturing capacity indicate a promising future for chip technology. The 2023 College Entrance Examination exemplified China's determination to leverage chips as a driving force behind its technological advancements.

Conclusion:

The 2023 Chinese College Entrance Examination highlighted the vital role of chips in enabling technological progress across various sectors. From empowering smart devices and AI systems to facilitating edge computing, chips have revolutionized the way we interact with technology. China's dedication to chip research, development, and manufacturing is shaping a future where chips will continue to be at the forefront of technological innovation. As we move forward, it is crucial to address challenges and seize opportunities, ensuring a prosperous era for chip technology in China and beyond.

#gaokao#electroniccomponents#icchip#semiconductor#semiconductor industry#semiconductor chips#semiconductor manufacturing

2 notes

·

View notes

Text

Hey! You forgot a very important step! You have to POISON the crystal chips, usually with arsenic!

If you don't poison them, they won't do their very fast flippy motions like when you turned the light switch on and off really fast to the beat of a song so you and your friends could pretend you were at a rave. Without the flippy motions fucking NOTHING happens, they will just sit there.

Don't even get me started on wireless by the way, I will spend my entire lunch break talking about communication protocols and the ISM frequency band and Jesus, I gotta stop myself.

(Also, here is my recommendation of James Burke's Connections series that is mandatory for me to make any time someone mentions the loom to computer connection. That and many other fascinating technological threads are explored in it, it is both engaging and very educational!

https://archive.org/details/james-burke-connections_s01e01 )

Computers are very simple you see we take the hearts of dead stars and we flatten them into crystal chips and then we etch tiny pathways using concentrated light into the dead star crystal chips and if we etch the pathways just so we can trick the crystals into doing our thinking for us hope this clears things up.

105K notes

·

View notes

Text

Various Biscuit Machine manufacturer round the sector produce cookie machines. As a producer, pick a general length cell unit. We advocate the usage of a capacity roll making device. This celebration has a smooth manner to definitely goal every other system celebration the usage of guide creation and complicated improvements.

#biscuit machine manufacturer#5 roll refiner machinery#food manufacturing consultants#chocolate machines manufacturer#chocolate moulding machines#pasta line supplier#potato chips line supplier

0 notes