#biscuit machine manufacturer

Explore tagged Tumblr posts

Text

Looking for Great Chocolate Moulding Machines at BBL Foods?

Looking for Great Chocolate Moulding Machines at BBL Foods?

Who wants to have this amazing opportunity now? Children want to at least make a great gift for sweets and chocolate. If the customer can, they can ask something or eat a big chocolate bar. We have added some new non-stop mixes to complement our store's snacks. Some fashions are fully integrated into milk chocolate, baking chocolate, cocoa powder, cross tray, ruby chocolate, milk chocolate, white chocolate, chocolate, milk chocolate. Of course, you can offer additional flavors and options.

Difficult situations, chocolate production, large selection, near-scene improvements, marketing and marketing issues should be checked for humans.

What is appropriate below?

You will need a device to produce chocolate and other options to make chocolate. It's clear that BBL Foods is the chocolate-powered device. Regardless of the shape of the chocolate rod, the device can provide light and funky blocks, chips and parts.

These tasty machines have exclusive edges that can be made up of a variety of elements with openings. When these houses get cold and hard, you really see beautiful chocolate. Use a Chocolate Moulding Machines. Typically, the actual results of a device differ from the typical variety of signs.

Enabling additional large protection spans usually results in exclusive results. You can speak faster and with less effort, which opens up new possibilities and leads to improved profits. An exceptional element is that BBL Foods, the leading producer of Chocolate Moulding Machines, is now a small participant in the market. You are ready to see many business opportunities. The device consists of stacks, vibration systems, conveyor systems, mild cooling devices, scales, operating systems, scary heads, provider plates and cooling rails to cool the process. The device is also available on the provider plate.

The production chain includes many stations. With the mold support, the shape is loaded into the manufacturing loader and heated to a safe temperature with the help of the mold master. Mixing and cleaning is completed with additional wheel units. Fill the pine filling with chocolate, separate the grain, cool the Prince's function, and quickly empty the shape when it has to be handled in the same way. The BBL Foods Cocosette Shape is the perfect piece for chocolate production.

For more details visit our website: Chocolate Moulding Machines, Pasta line supplier

BBL FOODS Private Limited

Contact: 98480 50607

Address: Santosh Nagar 'X' Road,Hyderabad - 500 059,Telangana State, India.

Facebook: https://www.facebook.com/bblfoodsofficial/

Instagram: https://www.instagram.com/bblfoodsofficial/

#biscuit machine manufacturer#5 roll refiner machinery#food manufacturing consultants#chocolate machines manufacturer#chocolate moulding machines#pasta line supplier#potato chips line supplier#cookies plant#bblfoods

0 notes

Text

Scaling Your Biscuit Production: Why a Biscuit Making Machine Is a Game Changer

In the competitive world of baked goods, consistency, efficiency, and speed are key to running a successful business. If you're looking to take your biscuit production to the next level, investing in a biscuit making machine could be the game changer you need. Whether you’re a small-scale bakery or looking to expand your food production, here’s why upgrading to automated equipment can transform your biscuit business.

0 notes

Text

The Expert Guide To Biscuit Making Machine For Small Businesses In 2024

Starting or expanding a small biscuit-making business in 2024 requires the right equipment to ensure quality, efficiency, and profitability. This guide covers essential equipment and tips for small businesses entering the biscuit industry. Here, you can see a list of the best biscuit making machine from the biscuit making machine manufacturers at affordable prices.

#Biscuit making machine suppliers#Biscuit making machine manufacturers#Biscuit machine#Biscuit making macchine#biscuit#machine#industrial#industrial machine#snacks machine#food machine#food processing#food#foodies

0 notes

Text

Packaging Machine Manufacturer in Guwahati

As a leading Packaging Machine Manufacturer in Guwahati, we specialize in designing and producing high-quality packaging machinery tailored to the specific requirements of our customers. With years of experience and expertise in the industry, we understand the importance of reliable and efficient packaging solutions in today's competitive market.

One of our flagship products is the Pouch Packing Machine in Guwahati. Engineered with precision and built to the highest standards, our Pouch Packing Machines are designed to efficiently package a wide range of products into pouches of various sizes and materials.

One of our flagship products is the Milk Packaging Machine in Guwahati. Engineered with precision and built to the highest standards, our Milk Packaging Machines are designed specifically for the dairy industry.

One of our specialized products is the Ice Candy Packaging Machine in Guwahati. Engineered with precision and built to the highest standards, our Ice Candy Packaging Machines are designed specifically for businesses in the frozen treat industry.

One of our specialized products is the Cap Sealing Machine in Guwahati. Engineered with precision and built to the highest standards, our Cap Sealing Machines are designed to securely seal caps onto containers of various sizes and materials.

In addition to manufacturing state-of-the-art packaging machines, we also serve as a trusted Packaging Material Supplier in Guwahati. We recognize the critical importance of top-quality packaging materials in ensuring the safety, preservation, and presentation of products.

One of our flagship products is the Shrink Wrapping Machine in Guwahati. Engineered with precision and built to the highest standards, our Shrink Wrapping Machines are designed to efficiently wrap products in shrink film, providing a tight and protective seal that enhances the presentation and protection of your packaged goods.

One of our specialized products is the Vacuum Packing Machine in Guwahati. Engineered with precision and built to the highest standards, our Vacuum Packing Machines are designed to remove air from packaging, creating a tight seal that extends the shelf life and preserves the freshness of your products.

Among our specialized products are biscuit and soap wrapping machines in Guwahati. Engineered with precision and built to the highest standards, our biscuit and soap wrapping machines are designed to efficiently wrap these products, ensuring their protection and presentation.

Among our specialized products is the Liquid Filling Machine in Guwahati. Engineered with precision and built to the highest standards, our Liquid Filling Machines are designed to accurately fill liquid products into containers of various shapes and sizes.

#packaging machine manufacturer#packaging material supplier#shrink wrapping machine in guwahati#vacuum packing machine#pouch packing machine#milk packaging machine#ice candy packaging machine#liquid feeling machine#biscuit and soap wrapping machines#cap sealing machine

0 notes

Link

Large Format Automatic Thermoforming Machines: High-Speed Production | RIDAT

Ridat's ATF series of Large Format Thermoforming machines can produce a range of thermoformed components at high speeds such as chocolate box inserts, biscuit trays, roofing panels, etc.

#thermoforming machine#large format thermoforming machine#automatic thermoforming machine#high-speed thermoforming machine#Ridat thermoforming machine#thermoforming equipment#thermoformed components#chocolate box inserts#biscuit trays#underfloor heating panels#roofing panels#automotive door protection covers#packaging machinery#food packaging#candy packaging#bakery packaging#food trays#food blisters#automotive manufacturing#automotive parts

0 notes

Text

Flow Wrap and Form Fill Seal Machines Manufacturing in Ahmedabad

New – Tech Industries is a leading manufacturer of flow wrap and form fill seal (FFS) machines in Ahmedabad, providing top-quality solutions for various packaging applications. Our flow wrap machines are designed for high-speed packaging of products like biscuits, chocolates, soaps, and medical items, ensuring secure and attractive wrapping. Meanwhile, our form fill seal (FFS) machines are ideal for efficiently packaging powders, granules, and liquids in pouches with precise filling and sealing mechanisms. We use state-of-the-art technology to deliver machines that offer speed, reliability, and consistency, making them the preferred choice for businesses looking for efficient packaging solutions.

2 notes

·

View notes

Text

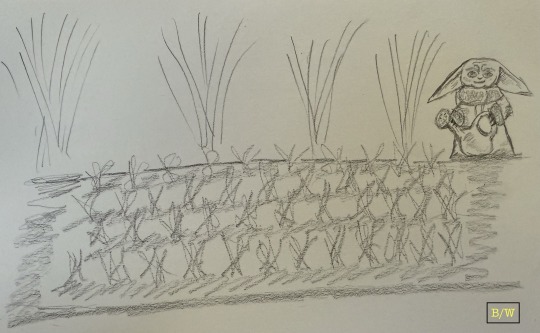

Grogu holding a watering can, standing next to a small garden freshly planted with bean creepers. Rushes are in the background. Pencil sketch on off white paper by me.

Wow. It had been such a tiring day. Grogu had needed a nap and his dad had said ‘Fine, take a nap. You did a lot of good today, kid. You earned it.’ That was nice, but now that he was awake again, Grogu wanted to take another nap, because the last nap had been exhausting.

He hadn’t realized that when you worked so hard, delivering biscuits all around Nevarro City and it’s un-incorporated surrounding farms, villages, and ranches, that you could get so tired that taking a nap just reminded your body of how much work you’d done. He’d tossed and turned and did everything possible to get comfortable. He’d rearranged his stuff animals more than once. He’d flipped his pillow over to the ‘cool’ side about a thousand times. He’d even kicked all of his covers off and then dragged them all back over him because he had gotten too cold after being too hot. He liked the too hot more than the too cold.

Of course it had all been worth while. He’d delivered all the biscuits and the people who got them seemed very pleased. Initially he planned on going right back home and starting another batch, but his dad had reminded him that they had actually run out of veggies to use to make the biscuits. That had been eye opening. He’d never thought it was possible to run out veggies. His dad always seemed to have some waiting for him, no matter where they were or what they had been doing.

Grogu asked his dad where he got the veggies from to begin with.

“I pick ‘em up at the farmer’s market. We pretty much cleaned them out of stock yesterday. We’ll have to wait until they have time to pick more. Maybe tomorrow or the next day.”

What? Veggies needed to be picked? Grogu had assumed that they were just a bad program from a food synth machine that the farmer’s hid behind their stalls. At least on the couple of Imperial ships he’d been on that seemed to be the way food of any sort was obtained. Now he had to find out the truth about veggies and see if he had the parts laying around in their shed that would be required to sort them out.

A quick search of available data sets revealed a horrifying truth. Veggies had to be grown. From the ground. In the dirt with worms, and water and a lot of dung. A lot of dung. And not just any dung. Nope. It had to come from certain critters. And be processed. Then rehydrated. Then spread in the appropriate thickness. It was a whole, huge, detailed, time consuming process.

Now the only reason Grogu found all that horrifying was because he knew how much the Mandalorian hated dirt. It got everywhere in the cabin and had to addressed on a daily and sometimes thrice daily basis. Grogu had been prohibited from participating in a whole host of activities that caused more than the typical amount of dirt to be introduced into the cabin. Mud puddle jumping? Nope. Dirt pie manufacturing? Nope. Construction activities focused on moving dirt from point alpha to point beta? Nope. Using dirt as a means of camouflage? Nope.

The only sort of dirt Grogu was allowed to interact with was the dirt that inevitably got on his coverall and the sole aspect of interaction was to strip off the coverall when demanded and give it to his dad for cleaning. That would have been fine, if it weren't for the fact that his beskar shirt often became coated with the stuff as well and he’d been sent to the porch to clean it while his coverall was being cleaned by his dad.

Grogu had suggested, more than once, that he just go about in his first layer and the beskar and they could save the coverall for important occasions, when you absolutely, positively had to wear something fancy. His dad had shook his head from side to side and commented that it was ‘not the Way’ and pointed out to Grogu that he had missed a spot while cleaning the back of the shirt. Dank Farrik.

Now, if he wanted to make more veggie biscuits his choices were limited. He could wait the time it took for the farmer’s market to have fresh veggies, or he could try to plant veggies and do something to keep himself clean. Maybe he could ride R5 around the garden he envisioned? The mech was good at keeping itself clean and as long as Grogu wasn’t hip deep in the rows of the garden he wouldn’t get that dirty, right?

Of course he looked at himself in R5’s shiny surface and realized how dirty he had gotten just traveling around Nevarro with his dad to hand out the goods they had made. He hadn’t been hip deep in anything other than the smiles and thank you’s of the folks he’d given the treats to that morning. He sighed. Deeply. Noisily. Annoyed and sad.

“Buddy, you know what we could do? I’ll go talk to Karga and we’ll set up a community garden. That way anyone who wants to grow veggies and make the biscuits can do it. We’ll work with the farmers on what to grow and help them establish a trading program with Mandalore. That way the food doesn’t go to waste when the community garden produces too much. We don’t want to hurt another set of people while we help the first set, right? The Mandalorians will take as much as they can get given what a mess Mandalore still is. We can even share your recipe for biscuits with them.”

Grogu looked up at his dad and smiled. It was a good idea. Even though it would take time, it wouldn’t depend on him or his dad doing all the work, which was good, because right now he really needed to take a nap.

5 notes

·

View notes

Text

SINOBAKE Group Limited is a leading biscuit and cookie making machinery manufacturer based in China. The company designs, develops, and manufactures a wide range of high-quality baking equipment, including biscuit and cookie production lines, chips line,cake line,automatic raw material feeding and dosing system,ovens and mixing machines. Mold size width: 800/1000/1200/1500/1800mm. According to different types of biscuits, the output of production is not the same. Capacity can achieve 100~5000kgs/h,

We has a strong reputation for producing reliable and efficient machinery that is easy to use and maintain. The company has a team of experienced engineers and technicians who are dedicated to researching and developing innovative new equipment and technologies to meet the evolving needs of the baking industry.

We has a global customer base, and its equipment is used by many well-known food brands and manufacturers around the world. The company has a strong commitment to customer satisfaction, providing comprehensive support services, including installation, training, and after-sales support.

Overall, SINOBAKE Group Limited is a trusted and respected player in the biscuit and cookie making machinery industry, and its equipment is renowned for its quality, reliability, and performance.

2 notes

·

View notes

Text

Unwrap - Premium Hazelnut Ganache Chocolate

Gift Hampers| Chocolate Gift Hampers| Cookies Gift Hampers| Personal and Corporate Gifts| Wedding Gift Hampers| Festival Gift Hampers| Dry Fruits| Wafer Rolls| Snacks Gift Hampers| Customized Gifts| Premium Herbal Teas

Joy comes in many flavors, and at Unwrap Happiness, we’ve mastered them all! From velvety chocolates and fragrant teas to the crunchiest nuts, we craft treats that celebrate India’s rich heritage with a fun, modern twist. Whether you’re marking a milestone, sharing a sweet moment, or simply indulging, our beautifully packaged hampers are designed to spread happiness—one bite at a time!

1. Manufacturing Process:

Step 1: Preparing the Hazelnut Ganache

Roast Hazelnuts (if not pre-processed):

Roast hazelnuts at 160°C (320°F) for 10-12 minutes to enhance flavor.

Blend into a fine hazelnut paste.

Melt Dark Chocolate:

Use a double boiler or tempering machine to melt couverture chocolate at 45-50°C (113-122°F).

Heat Cream and Sugar:

Warm heavy cream and glucose/invert sugar until just below boiling.

Emulsify:

Gradually mix the hot cream into the melted chocolate.

Add hazelnut paste and butter for a silky texture.

Stir gently until fully incorporated.

Cool and Set:

Let the ganache cool to room temperature (ideally 18-20°C) before piping.

Step 2: Preparing the French Biscuit (Feuilletine) Layer

Make Biscuit Dough:

Cream butter and sugar.

Add eggs, then fold in flour, baking powder, and salt.

Bake the Biscuit:

Spread thinly on a baking sheet.

Bake at 180°C (356°F) for 10-12 minutes until golden brown.

Let it cool completely.

Crush into Small Crisps:

Break into small feuilletine-style flakes for added crunch.

Step 3: Assembly & Chocolate Coating

Layer the Biscuit and Ganache:

Spread the hazelnut ganache over the crispy biscuit layer.

Allow to set for 4-6 hours at 16-18°C.

Cut into Bite-Sized Pieces:

Once firm, cut into small squares or bars.

Coat with Chocolate:

Temper dark/milk chocolate (31-32°C for dark, 29-30°C for milk).

Dip or enrobe the ganache-filled biscuit pieces in the tempered chocolate.

Decorate & Final Touches:

Sprinkle with chopped caramelized hazelnuts, gold dust, or cocoa nibs.

Let set at room temperature.

2. Ingredients:

Ganache Filling:

Hazelnut Paste (50%) – Made from finely ground roasted hazelnuts.

Dark Chocolate (40%) – Minimum 55-70% cocoa, for richness.

Heavy Cream (35-40%) – For a smooth, velvety texture.

Butter (5-10%) – Enhances mouthfeel and flavor.

Invert Sugar/Glucose Syrup (2-5%) – Prevents crystallization, improves shelf life.

Vanilla Bean Extract – Adds aromatic complexity.

Sea Salt (pinch) – Balances flavors.

Chocolate Coating:

Dark or Milk Chocolate (Couverture, 55%-70% cocoa content).

Cocoa Butter – For a glossy finish and smooth texture.

French Biscuit Layer (Feuilletine or Crispy Base):

Butter – For richness.

Flour – For structure.

Sugar – Adds sweetness and caramelization.

Eggs – Provides structure.

Baking Powder – Helps with lightness.

Salt – Enhances flavor.

Optional: Caramelized Biscuit Crumbs – Adds extra depth.

3. Flavor Profile & Variations:

Main Flavor Notes:

✔ Nutty & Creamy – From roasted hazelnut paste. ✔ Rich & Velvety – From high-quality dark chocolate. ✔ Crunchy & Buttery – From the French biscuit layer. ✔ Balanced Sweetness – Dark chocolate and biscuit provide a contrast.

Flavor Variations:

Salted Caramel Version: Add caramel filling between ganache and biscuit.

Orange Zest Infusion: Enhance with candied orange zest for a citrusy note.

Espresso-Infused Ganache: Mix in espresso powder for a coffee kick.

Milk Chocolate & Hazelnut Praline: Use milk chocolate instead of dark, add more praline.

For More Details: https://www.unwraphappiness.in

#cookies gift hampers#chocolate gift hampers#festival gift hampers#dryfruits#wedding gift hampers#customized gifts#wafers sticks#herbal tea#snacks gift hampers#order gift hampers online

0 notes

Text

How Chocolate Coating Machines Ensure Consistent, High-Quality Coating

Chocolate-covered treats are a universal favorite—whether it’s biscuits, nuts, or candies, a perfectly coated chocolate layer enhances both taste and appearance. But how do manufacturers achieve such uniformity across thousands of pieces? The secret lies in precision-engineered chocolate coating machines designed to deliver flawless, even coverage every time.

In this article, we’ll explore how chocolate enrobing machines work, key factors that affect coating consistency, and best practices for optimizing production quality.

What Is a Chocolate Coating Machine?

A chocolate coating machine, also known as a chocolate enrober, is essential for large-scale confectionery production. These machines help manufacturers achieve a uniform chocolate layer, ensuring every batch meets strict quality standards.

Beyond aesthetics, consistency in chocolate coating is crucial for: ✔ Texture and Mouthfeel – A smooth, even coating enhances the eating experience. ✔ Shelf Life – Properly coated products are less prone to cracking, melting, or absorbing moisture. ✔ Taste Preservation – Uneven coatings can impact flavor distribution, leading to an inconsistent product experience.

Chocolate coating machines control variables such as temperature, chocolate viscosity, and cooling speed to maintain quality. Let’s take a closer look at how they work.

How Do Chocolate Coating Machines Work?

A chocolate enrobing machine operates through a series of precise steps to achieve a consistent, high-quality finish:

1. Tempering the Chocolate

Tempering is the first and most crucial stage in achieving a shiny, smooth, and stable chocolate coating. The machine carefully heats and cools the chocolate to stabilize cocoa butter crystals, preventing bloom (a whitish coating that forms due to improper crystallization).

2. Coating the Product

Once tempered, the liquid chocolate flows into the coating section. Products—such as biscuits, nuts, or confections—move along a conveyor belt, passing under a controlled chocolate waterfall or through a dipping process.

🔹 Pumps and nozzles regulate chocolate flow to ensure even distribution. 🔹 Blowers or vibrating screens remove excess chocolate for a uniform finish.

3. Cooling the Chocolate Coating

After coating, products travel through a cooling tunnel that rapidly sets the chocolate. Controlled cooling prevents cracking, melting, or dull finishes—resulting in a glossy, perfectly hardened chocolate shell.

Key Factors That Affect Chocolate Coating Uniformity

Even with advanced chocolate coating machines, several variables must be managed to ensure a smooth and flawless chocolate layer:

✅ Temperature Control

Chocolate is highly temperature-sensitive. If it’s too hot, it becomes thin and fails to adhere properly; if too cold, it thickens and coats unevenly. Precise temperature control ensures proper chocolate flow and adhesion.

✅ Conveyor Speed & Alignment

If products move too fast, the chocolate layer may be too thin or incomplete. If too slow, the coating may be too thick, leading to excess waste. Proper product alignment on the conveyor ensures all sides receive equal chocolate coverage.

✅ Chocolate Viscosity

The chocolate’s consistency plays a vital role. Too thick, and it won’t flow smoothly; too thin, and it may not coat properly. Maintaining the right chocolate formulation is key to achieving an even, professional finish.

Best Practices for Achieving Consistent Chocolate Coating

Using state-of-the-art chocolate coating machines is just one part of the equation. Here’s how top manufacturers maintain superior quality:

🔹 Regular Machine Maintenance – Frequent cleaning and calibration prevent residue buildup that can disrupt the coating process. 🔹 High-Quality Chocolate Ingredients – Premium chocolate flows better and ensures a smooth, glossy finish. 🔹 Trained Machine Operators – Experienced operators can quickly adjust machine settings to maintain consistency. 🔹 Real-Time Monitoring Systems – Modern enrobing machines feature automated sensors that detect inconsistencies and adjust accordingly.

By following these best practices, manufacturers can maximize efficiency and ensure flawless chocolate coatings in every batch.

Invest in High-Performance Chocolate Coating Machines

For businesses looking to streamline production and enhance product quality, investing in a reliable chocolate enrobing machine is essential. At Latini Hohberger Dhimantec, we specialize in cutting-edge chocolate coating equipment designed for precision, efficiency, and consistency.

📞 Contact us today to find the right chocolate coating solution for your business!

Source URL: Blogspot.com

0 notes

Text

Can you see the Biscuit Machine manufacturer?

Can you see the Biscuit Machine manufacturer?

The perfect breakfast for a single is the gentle, authentic, delicious bread from BBL Foods. Age does not rely on important roles. Everywhere in the sector, delicious breads have a robust reference to people in every respect. Bread has an overwhelming practicality, and it will adorn its charm by experiencing additional schools on the university stage. Have you ever thought about the most important elements of jogging at a bakery?

Biscuit Machine manufacturer especially use butter and sugar to improve their bread. In any case, the backscene offers a variety of factors, including baking standards and consistency. Whether you believe it or not, this is all the other worlds. They want to be organized to invest in a variety of important obligations, such as back pans, glue, and overwhelmed objects. Various Biscuit Machine manufacturer around the sector produce biscuit machines.

As the producer, select a cell unit of a typical length. Capacity Role Make-Advocates the use of makeup. This celebration has a smooth way to target other systems to create guides and use complex improvements. Some of the well-known producers of Biscuit Machine manufacturer have to appear more in family-owned businesses, as they have built a totally huge conservation base. Some of these machines have a huge protective base.

Really, what about bread and cookies? In summary, miles are truly a tough process when you consider everything from the preliminary costs, the right length and extraordinary, the conversion of nearby residents, the conversion of far residents, the fate and simplicity of parts, the machinery and presence. Mix different layers to get amazing bread too. Because so many excess components are important, bread attracts and controls the market. So visionaries come here to expand mixers, shells and alternatives, telling experts and many chefs from all industries.

Biscuit Machine manufacturer want to reach every region, especially in the areas that support your company. We support companies with manufacturers with a wide range of products. Whether you choose a method plate for baking gentle or difficult breads, there are safe and inexpensive mixers for players. It is also smooth to operate the product stock that is started for clean transactions. The Rotary version can be used to support cookie system producers' decision-making processes.

Use a rotary foam system to divide your role into the most important parts and perspectives. In metal backing chambers, the bread is heated by an import burner and transferred to a defined location for the grill. To my surprise, the role of an unknown vehicle transporter has been transformed into a callback vehicle. The snack system from Wire Reduce was absolutely modernised to become a crown, with multiple squirts and shims in the shape to shorten customer access.

For more details visit our website: Biscuit Machine manufacturer

BBL Foods Private Limited

Contact: 98480 50607

Address: Santosh Nagar 'X' Road,Hyderabad - 500 059,Telangana State, India.

Facebook: https://www.facebook.com/bblfoodsofficial/

Instagram: https://www.instagram.com/bblfoodsofficial/

#biscuit machine manufacturer#5 roll refiner machinery#food manufacturing consultants#chocolate machines manufacturer#chocolate moulding machines#pasta line supplier#potato chips line supplier#cookies plant#bblfoods

0 notes

Text

Machines for Producing Biscuits of Superior Quality for Efficient Production Steps

Being efficient and consistent is crucial in the commercial food production industry for staying ahead of the competition. With the correct equipment, you can optimize your manufacturing processes and yet produce biscuits of the highest quality. You can guarantee consistently high-quality and efficient production by investing in the Biscuit making machinery , regardless of whether you're operating a small bakery or a large-scale biscuit manufacturing plant.

#Biscuit Making Machinery#Biscuit Making Machinery Manufacturers#Biscuit making Machinery Suppliers#Biscuit Machine Suppliers#Biscuit Machine Manufacturers

0 notes

Text

Tanishka Packaging Machines, based in Rajasthan, is a trusted name in the packaging industry, specializing in advanced biscuit and soap wrapping machines in Rajasthan and band sealing machines in Rajasthan. These high-performance machines are designed to meet the specific needs of industries requiring precise and efficient packaging solutions. Whether you're in the biscuit manufacturing sector or producing soaps, Tanishka’s biscuit and soap wrapping machines ensure secure, high-quality packaging that enhances product presentation and protection. Additionally, their band sealing machines are engineered for durability and speed, making them an ideal choice for sealing products quickly and effectively. Known for their innovation and reliability, Tanishka Packaging Machines has earned a reputation for providing top-tier packaging equipment across Rajasthan, delivering unmatched quality to businesses in need of superior packaging solutions.

0 notes

Text

Packaging Material Supplier in Guwahati

Welcome to Maharani Machine And Textiles - A House Of Packaging Machines in Guwahati

we are also your trusted Packaging Material Supplier in Guwahati. We understand that reliable packaging materials are essential for ensuring the safety, preservation, and presentation of your products. That's why we offer a comprehensive range of high-quality packaging materials to complement our machinery and meet all your packaging needs.

So whether you're in need of a Pouch Packing Machine in Guwahati, packaging materials, or both, trust Maharani Machine And Textiles to be your one-stop solution for all your packaging needs in Guwahati.

In addition to being a leading Packaging Machine Manufacturer in Guwahati, we also excel as a trusted Packaging Material Supplier.

In addition to being your trusted supplier of packaging materials, we also specialize in Milk Packaging Machines in Guwahati. Our Milk Packaging Machines are specifically designed to cater to the unique needs of dairy businesses in the region.

we specialize in Ice Candy Packaging Machines in Guwahati. Our Ice Candy Packaging Machines are specifically designed to cater to the unique needs of businesses in the frozen treat industry.

Moreover, we specialize in Cap Sealing Machines in Guwahati. Our Cap Sealing Machines are specifically designed to ensure the secure sealing of caps onto containers, preserving the integrity of your products and protecting them from tampering and contamination.

Furthermore, we specialize in Shrink Wrapping Machines in Guwahati. Our Shrink Wrapping Machines are specifically designed to securely wrap products in shrink film, providing a tight and protective seal that enhances the presentation and protection of your packaged goods.

we specialize in Vacuum Packing Machines in Guwahati. Our Vacuum Packing Machines are specifically designed to remove air from packaging, creating a tight seal that extends the shelf life and preserves the freshness of your products.

we specialize in Biscuit and Soap Wrapping Machines in Guwahati. Our Biscuit and Soap Wrapping Machines are specifically designed to efficiently and hygienically wrap biscuits and soaps, ensuring that your products are securely packaged and presented in an attractive manner.

Moreover, we specialize in Liquid Filling Machines in Guwahati. Our Liquid Filling Machines are specifically designed to efficiently fill liquid products into containers of various shapes and sizes with precision and accuracy, ensuring consistent results and minimizing wastage.

At Maharani Machine And Textiles, customer satisfaction is our top priority

#packaging material supplier#packaging machine manufacturer#shrink wrapping machine in guwahati#biscuit and soap wrapping machines#ice candy packaging machine#cap sealing machine#liquid feeling machine#vacuum packing machine#milk packaging machine#pouch packing machine

0 notes

Text

Revolutionizing Biscuit Production with Biscuit Making Machines – Timesautomation

In the modern food processing industry, the demand for high-quality, consistent biscuits has led to the rise of automated machinery. The biscuit making machine plays a crucial role in streamlining production and ensuring uniform quality. Timesautomation offers top-of-the-line biscuit making machines that help bakeries and food manufacturers improve their production efficiency.

A biscuit making machine from Timesautomation ensures precision in every step of the biscuit production process. Whether it's mixing, shaping, or baking, these machines are designed to handle every task with high efficiency. Timesautomation has built a reputation for providing reliable biscuit making machines that minimize waste and maximize output.

One of the main advantages of using a biscuit making machine is the ability to scale production. With automation, companies can increase their production volumes while maintaining consistency and reducing labor costs. Timesautomation’s biscuit making machines are engineered to meet the needs of businesses looking to produce large quantities of biscuits without compromising on quality.

Not only do biscuit making machines help in mass production, but they also ensure the biscuits are baked to perfection. Timesautomation integrates advanced technology into their biscuit making machines that control baking times, temperatures, and humidity, ensuring each batch is baked evenly.

For businesses in the biscuit manufacturing industry, choosing the right biscuit making machine is vital. Timesautomation offers machines that can be customized to fit your specific needs, ensuring you get a high-performing system that will help your business thrive.

If you are looking to take your biscuit production to the next level, Timesautomation provides cutting-edge biscuit making machines that ensure the highest quality and efficiency in every batch.

0 notes

Text

Bakemate C-Vita Candy

Chocolate Manufactures|Bakemate|C-Vita Candy|Largest Chocolate Manufactures|Candies|Lollipops|Biscuit Manufactures|Chocolates|Orange Candy|Global Chocolate Manufactures|

Experience a burst of citrus bliss with Bakemate C Vita Orange Candy! Infused with the vibrant essence of fresh oranges, each piece delivers a perfect balance of sweet and tangy flavors that refresh your senses with every bite.

More than just a treat, Bakemate C Vita is a delightful indulgence for any moment. Whether you're craving a quick energy boost, a flavorful snack to share, or simply a refreshing taste of orange goodness, these candies are your perfect companion for a zesty and satisfying experience!

1. Manufacturing Process

The production of orange candy involves several key steps to ensure quality, taste, and consistency.

Step 1: Ingredient Mixing

Sugar, glucose syrup, and water are heated in a controlled environment to form a syrup.

Citric acid or other acidulants are added to balance the sweetness with tanginess.

Step 2: Boiling & Concentration

The syrup is heated to high temperatures (typically around 145-150°C) to reach the desired consistency.

At this stage, color, flavor, and vitamin C (if fortified) are added.

Step 3: Cooling & Shaping

The molten candy mixture is poured onto cooling trays or passed through cooling rollers.

The semi-cooled mixture is shaped using molds or cutting machines to create uniform candy pieces.

Step 4: Wrapping & Packaging

Once the candies are set, they go through a coating process (if needed) for shine and longevity.

They are then wrapped in individual packaging or packed in bulk for distribution.

2. Ingredients

The key ingredients in orange candy include:

Sugar – Provides sweetness and structure.

Glucose Syrup – Prevents crystallization and adds a smooth texture.

Citric Acid – Enhances the tangy flavor and balances the sweetness.

Natural & Artificial Orange Flavors – Gives the candy its distinct citrus taste.

Vitamin C (Optional) – Added for a health boost in fortified variants.

Food Coloring (E160b, E110, etc.) – Provides the vibrant orange hue.

Gelling Agents (Optional, e.g., Pectin, Gelatin) – Used in chewy or gummy versions.

3. Flavors & Variations

While classic orange flavor is the most common, manufacturers offer a variety of citrus-inspired flavors:

Classic Sweet Orange – A perfect balance of sweetness and tanginess.

Blood Orange – A deeper, richer citrus taste with a hint of berry.

Tangerine – A sweeter and slightly less acidic variant.

Mandarin – A mild and naturally sweet flavor.

Sour Orange – Extra tangy for those who love a zingy kick.

Orange-Mint Fusion – A refreshing twist with a cool aftertaste.

Orange-Ginger – A spicy and citrusy combination for a unique experience.

Orange-Honey – A smooth and naturally sweet alternative.

For More Details:https://bakemate.in

#bakemate#chocolate manufacturers#delicious chocolate#biscuit manufacturers#chocolate#candy#biscuits#fmcg

1 note

·

View note