#chemical refinery

Explore tagged Tumblr posts

Text

The global Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to a new report by MarketsandMarkets™.

#pressure vessels market#pressure vessel tank#pressure vessel#pressure vessels#pressure vessel market#energy#power#electricity#power generation#utilities#oil and gas#oil and gas industry#vessels#vessel#nuclear power plant#power plant#power plants#steam boilers#oil refinery#chemical refinery#refining#petroleum refining#refineries

0 notes

Text

Vidal [...] emphasizes the close relationship that existed between the Louisiana settlement [at New Orleans] and the Caribbean island [Haiti, the colony of Saint-Domingue] during the former’s French colonial period (1718-69). It has become a bit of a popular adage to describe New Orleans as the northernmost port of the Caribbean, but Vidal’s Caribbean New Orleans: Empire, Race, and the Making of a Slave Society demonstrates the substance behind these claims. [...] New Orleans is the missing link, a late-forming city that largely inherited its founding ideas, practices, peoples, plants, and laws from its longer-established imperial neighbors [France, Spain, Britain, and what would become the United States]. It thus offers the ideal case study in which to consider how colonies around the Americas developed in conversation with one another [...].

Vidal convincingly argues that New Orleans was a “slave society,” or a settlement in which racialized slavery informed every part of everyday life from its inception, whose physical construction was done alongside the “construction of racial categories” (p. 1).

This is an important shift within Louisiana historiography, which has long stood by [...] [the] argument that early New Orleans offered the semi-unique example of a “slave society” devolving into a “society with slaves.” Abandoned by the French following the spectacular failure of the Compagnie des Indes, the standard story goes, New Orleans became an isolated backwater until the 1770s, struggling to survive and permitting, out of sheer need, less disciplined contact between residents of European, Indigenous, and African birth and descent. [But] Vidal, in contrast, shows that, while Louisiana struggled to create a full-fledged plantation economy during the French era, this did not prevent its capital from organizing itself along the highly stratified lines of the Caribbean islands.

---

Furthermore, she argues, because New Orleans did not see many new residents after 1731, free or enslaved, and because it was a smaller settlement, white inhabitants were able to build upon these ideas in a relatively stable environment - focusing much of their energies on surveilling, containing, and disciplining the enslaved and free persons of color (p. 26). [...]

Vidal especially points to the 1729 Natchez attack and ensuing Natchez Wars [against Indigenous peoples] as pivotal moments in the militarization of white New Orleanians [...].

Subsequently, a scrupulous supervision of racial boundaries became the norm for the rest of the French era and fostered “a sense of community among white urbanites” (p. 141). Chapter 3 takes readers to the streets, levees, and other public spaces of New Orleans, where whites sought to sculpt the privileges of “whiteness” against both residents of African birth and descent as well as one another. Elite men and their wives scuffled over the best seating at church in an effort to recreate France’s ancien régime culture; socially lower [...] nonslaveholders, meanwhile, carefully guarded their weaker claims at mastery through street violence [...]. Beginning with a careful reading of census categories, Vidal traces how distinctions between European settlers [...] were increasingly replaced with those centered exclusively on race by 1763. [...] [Vidal then] follows the ways in which the demographically diverse workforce of the early colony made up of white indentured servants, convicts, and soldiers in addition to enslaved Africans - gave way to associations of difficult and degrading labor limitedly with the enslaved. [...]

---

French Louisiana inherited racial categories from the Caribbean but adjusted them to fit local needs, experiencing “not so much a loosening, but a more complex transformation” of its racial regime, largely through violence (p. 371).

Vidal documents how the Superior Council utilized targeted prosecutions and punishments to increasingly “imprint terror and instill obedience” on the enslaved (p. 390). [...] [The book] thus details a society in which racial hierarchies were asserted and supported through both top-down and bottom-up policies and practices, as “no social institution or relationship was left untouched by race” (p. 504).

To this end, Vidal speaks to important conversations by historians of enslaved women in the British Caribbean, including Jennifer Morgan and Marissa Fuentes. These authors have used a similarly wide range of sources [...] [and] archives to underscore the invasive nature of colonial racism. [...] [I]n part [...] Vidal’s [chapters work] to decouple lower Louisiana history from the fur traders of New France [Ontario, Quebec, and the watershed of the Mississippi River] and to reattach it to the planters of Saint-Domingue [in Haiti and the Caribbean]. [...] Combing through administrative papers, censuses, laws, parish registers, correspondence, and judicial records from both sides of the Atlantic, readers will get a sense that there is little Cécile Vidal has not seen or considered. [...] Her book [...] hopefully will convince an even wider audience [...] [to engage with] comparative, cis-Atlantic, and transatlantic studies of imperialism, race, and slavery.

---

All text above by: Kristin C. Lee. "Review of Vidal, Cécile, Caribbean New Orleans: Empire, Race, and the Making of a Slave Society". H-Atlantic, H-Net Reviews. January 2022. URL at: h-net dot org/reviews/showrev.php?id=56913 [Bold emphasis and some paragraph breaks/contractions added by me. Presented here for commentary, teaching, criticism purposes.]

#tho american louisiana 1805ish to 1865 was obviously brutal slave society and an epicenter of US slavery vidals book makes case that#earlier french new orleans also fundamentally slave society in own distinct ways despite citys reputation as relatively cosmopolitan#and today louisiana now home to cancer alley pollution y fossil fuel pipelines y industrial chemical refineries y prisons built on plantati#300 years of violent racial hierarchy in louisiana wearing different masks#her footnotes are extensive y detailed enough to be a whole other book quite the synthesis#tidalectics#abolition#archipelagic thinking#geographic imaginaries#caribbean#black methodologies#indigenous#indigenous pedagogies#debt and debt colonies#agents of empire

18 notes

·

View notes

Text

dissapointed auferstanden aus ruinen club mix is mid

2 notes

·

View notes

Text

Human Factors Engineering (HFE): Making Oil and Gas Facilities Safer and More Efficient

Human Factors Engineering (HFE) is the application of scientific principles to the design of products, systems, and environments to optimize human performance and safety. HFE is particularly important in the oil and gas industry, where workers face a variety of hazards and where even a small mistake can have catastrophic consequences.

There are many ways that HFE can be used to improve the design of oil and gas facilities. For example, HFE can be used to:

Design controls that are easy to see and reach, and that are clearly labeled.

Design layouts that minimize the risk of accidents and injuries.

Provide workers with the information and training they need to perform their jobs safely and efficiently.

Create a positive work environment that supports worker well-being.

Here are a few specific examples of how HFE has been used to improve the design of oil and gas facilities:

Color-coding pipes and valves to make it easier for workers to identify them.

Using non-slip surfaces to reduce the risk of falls.

Designing control panels that are easy to use and that minimize the risk of errors.

Providing workers with clear and concise instructions on how to perform their jobs safely.

Creating break rooms and other spaces where workers can relax and socialize.

By incorporating HFE principles into the design of oil and gas facilities, companies can improve safety, efficiency, and worker well-being.

Here is a more detailed example of how HFE was used to improve the design of an oil and gas facility:

In one case, an oil and gas company was experiencing a high rate of accidents involving workers tripping and falling on slippery surfaces. The company hired an HFE consultant to help them identify and address the problem.

The HFE consultant conducted a site visit and interviewed workers to learn more about the problem. The consultant found that the slippery surfaces were caused by a combination of factors, including oil and grease spills, rainwater, and condensation.

The consultant recommended a number of solutions to the company, including:

Installing non-slip surfaces in areas where workers are likely to walk.

Improving drainage in areas where rainwater and condensation accumulate.

Providing workers with training on how to avoid slips and falls.

The company implemented the consultant's recommendations, and the rate of accidents involving slips and falls decreased significantly.

This is just one example of how HFE can be used to improve the safety of oil and gas facilities. HFE can also be used to improve efficiency and worker well-being. For example, HFE can be used to design workstations that are ergonomically correct and that minimize fatigue. HFE can also be used to develop training programs that are effective and engaging.

Here are some additional benefits of using HFE in the oil and gas industry:

Reduced costs: HFE can help to reduce the costs associated with accidents and injuries.

Improved productivity: HFE can help to improve productivity by reducing errors and improving efficiency.

Increased employee satisfaction: HFE can help to create a safer and more comfortable work environment, which can lead to increased employee satisfaction.

Overall, HFE is a valuable tool that can be used to improve safety, efficiency, and worker well-being in the oil and gas industry.

Conclusion

HFE is a valuable tool that can be used to improve safety, efficiency, and worker well-being in the oil and gas industry. By incorporating HFE principles into the design of oil and gas facilities, companies can create a safer and more productive work environment for their employees.

#human factor engineering#oilandgas#chemical industry#crude oil#health and safety#industrial safety animation#petrol#refinery#riskassessment#riskmanagement#engineering

6 notes

·

View notes

Text

and tell that to MY great great uncle, who once stopped an oil refinery fire in texas by saying "wait a minute, the flames are the wrong color for this to be an oil fire; it's a kerosene fire. We just need to shut off the gas valve." and then without further discussion he walked into the burning building, shut off the main gas valve and saved the plant from exploding and killing them all.

It only takes three generations for you to be basically forgotten

#in my family the moral of this story is#'always know your chemical fires'#and yes there are a lot of engineers on my dad's side#why do you ask#fire#oil refinery#family history

294K notes

·

View notes

Text

Gold Refining Process: The Ultimate Guide

Discover the step-by-step gold refining process, from raw ore to pure gold, with tips, tools, and techniques for ultimate precision.

for more info visit: https://kjhil.com/gold-refining-process-the-ultimate-guide/

0 notes

Text

#pharmacy#hospital#medicine#medication#research scientist#research chemicals#refinedelegance#refinery#weight loss#i want to lose weight#diets#weight management#fat loss#ozempic#health#healthcare#medical care#doctors#surgery

0 notes

Text

Will we need oil in 2060?_Crimson Publishers

Abstract:

Since long time ago, in the early 1840 at the end of the Industrial revolution, we found than oil was a very useful energy vector. Now, we use items for our life that were produce with some energy transformation. In the near future, perhaps 2020, the energy transformation will not change a lot. Data from International Energy Agency (iea.org) show great energy dependence from coal, natural gas and oil.

Registered anomaly temperature since 1880 to 2010 show a tendency: there is a climate change. Of course the human activities are the cause for this phenomenon. Even if we replace all process with another fuel into combustion, the CO2 will be part of the stoichiometry reaction and this will never diminish while combustion will be.

In fact, all renewable energy process use devices than came from process with oil reaction, then in the present day, global energy needs oil for humanity activities. But, in the future? In 2060: we will need oil? Yes. We will need about a 99EJ (99x10^18J) in 2060 from Energy Technology Perspectives 2017 report edited by International Energy Agency. This is a 54.39% of the transformed oil in 2014. This value implies that we need to work in most efficiency transformation of the fuel. Not only of oil fuel, must all transformations be improved.

At 2060 we need 35% of renewable energy in our world energy transformation and 38% of efficiency energy transformation in all levels: refineries, oil products, electricity and power or co-generation plants. If we do not do an effort to develop now the new efficient process in petrochemical science we will not provide the energy that we will need in the future. All (renewable and conventional) energy process needs to be analyzed, evaluated and integrated for the new world. Oil fuels do exist and this help us to create the new balanced energy future energy system.

Read More About this Article: https://crimsonpublishers.com/pps/fulltext/PPS.000507.php

Read More Articles: https://crimsonpublishers.com/pps/index.php

#crimson publishers#progress in petrochemical science#petroleum#chemical engineering#peer review journals#refineries#renewable energy

0 notes

Text

/PRNewswire/ -- Air Quality Control Systems Market in terms of revenue was estimated to be worth $107.4 billion in 2024 and is poised to reach $150.7 billion by 2029, growing at a CAGR of 7.0% from 2024 to 2029 according to a new report by MarketsandMarkets™.

#Air Quality Control Systems#Air Quality Control Systems Market#Air Quality Control#air pollution#energy#power generation#enviromental#environment#sustainable development#sustainable#sustainability#sustainable future#Pollution Monitoring#industrial#industrialization#manufacturing#automotive#construction#chemical industry#chemicals#oil#refinery#oil refinery

0 notes

Text

/PRNewswire/ -- Pressure Vessels Market is projected to reach USD 62.7 billion in 2028 from USD 50.3 billion in 2023 at a CAGR of 4.5% according to...

#pressure vessels#pressure vessels market#pressure vessel#oil and gas#oil#oil rig#oil refinery#chemical refinery#refining#petroleum refining#refineries#chemical sector#chemical plant#chemical industry#chemical#chemicals#power generation#power plant#power plants#nuclear power plant#thermal power plants#thermal power plant#energy#petrochemicals#petrochemical#petroleum

0 notes

Text

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

Piping systems are the lifelines of industrial plants, carrying fluids and gases to various components and ensuring the smooth operation of critical processes. However, the design and analysis of piping systems require meticulous attention to detail to prevent catastrophic failures that can lead to safety hazards and costly downtime. In Canada and the USA, engineers and professionals turn to tools like AutoPIPE for piping stress analysis, and Little P.Eng. Engineering has emerged as a trusted name in providing expert services for this critical task.

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

The Significance of Piping Stress Analysis

Piping systems in industrial plants, refineries, power plants, and chemical facilities are subjected to a wide range of stresses during their operational lifespan. These stresses can result from various sources, including temperature fluctuations, pressure changes, seismic activity, and the weight of the piping itself. Piping stress analysis is the process of evaluating and predicting how these stresses affect the integrity and safety of the piping system.

Here are some key reasons why piping stress analysis is of paramount importance:

Safety: Ensuring the safety of personnel and assets is the primary concern in any industrial setting. Piping failures can lead to leaks, ruptures, and even explosions, posing a significant risk to human lives and the environment.

Compliance: Regulatory bodies in Canada and the USA have strict standards and codes governing the design and operation of piping systems. Compliance with these standards is mandatory to avoid legal issues and penalties.

Reliability: Reliable piping systems are essential for continuous production and minimal downtime. Stress analysis helps identify potential weaknesses and areas of concern, allowing for proactive maintenance and improvements.

Cost Savings: Early detection of piping issues through stress analysis can prevent costly repairs, replacements, and unplanned shutdowns.

AutoPIPE: A Powerful Piping Stress Analysis Tool

AutoPIPE is a state-of-the-art software solution designed for the analysis and design of piping systems. Developed by Bentley Systems, it offers a comprehensive set of tools and features for performing piping stress analysis with precision and efficiency. AutoPIPE is widely used in the engineering and construction industry across Canada and the USA due to its versatility and reliability.

Key capabilities of AutoPIPE include:

Stress Analysis: AutoPIPE can calculate stresses, displacements, and forces within piping systems under various load conditions, including thermal expansion, pressure, and external loads. It considers complex interactions between different components and materials.

Code Compliance: The software is equipped with a vast library of international piping codes and standards, ensuring that the analysis results align with industry regulations in Canada and the USA. Engineers can easily select the appropriate code for their projects.

Advanced Modeling: AutoPIPE allows for the creation of detailed 3D models of piping systems, including components such as elbows, tees, and flanges. This level of detail is crucial for accurate analysis.

Material Database: Users can access a comprehensive material database, which includes a wide range of materials commonly used in piping systems. This simplifies the process of specifying material properties.

Post-Processing and Reporting: AutoPIPE generates detailed reports and graphical representations of analysis results, making it easier for engineers to communicate findings and make informed decisions.

Little P.Eng. Engineering: Your Trusted Partner

While AutoPIPE is a powerful tool for piping stress analysis, it requires expertise and experience to harness its full potential effectively. This is where Little P.Eng. Engineering steps in as a trusted partner for clients across Canada and the USA. With a team of highly skilled and certified engineers, Little P.Eng. Engineering offers a range of services that complement and enhance the capabilities of AutoPIPE.

Let's explore the key aspects that make Little P.Eng. Engineering a reliable choice for piping stress analysis:

Expertise: The engineers at Little P.Eng. Engineering have years of experience in the field of piping stress analysis. They possess in-depth knowledge of industry codes and standards, ensuring that all analyses are compliant and accurate.

Customized Solutions: Every project is unique, and Little P.Eng. Engineering tailors its services to meet the specific needs of clients. Whether it's a complex refinery system or a simple water distribution network, the team can handle it all.

Seamless Integration: Little P.Eng. Engineering seamlessly integrates AutoPIPE into its workflow, ensuring that clients receive the full benefits of this powerful software. The combination of software and expert analysis enhances the quality and reliability of results.

Cost-Effective Solutions: By detecting and addressing potential issues early in the design phase, Little P.Eng. Engineering helps clients avoid costly rework and repairs during construction or operation. This proactive approach results in significant cost savings.

Timely Delivery: In the fast-paced world of engineering and construction, timing is critical. Little P.Eng. Engineering is known for its commitment to meeting deadlines and delivering results on schedule, helping clients stay on track with their projects.

Case Studies: Little P.Eng. Engineering in Action

To better understand the real-world impact of Little P.Eng. Engineering's services using AutoPIPE, let's examine a couple of case studies from projects conducted in both Canada and the USA:

Case Study 1: Canadian Refinery Expansion

A major refinery in Canada was planning a significant expansion project to increase its production capacity. Little P.Eng. Engineering was contracted to perform a comprehensive piping stress analysis using AutoPIPE. The project involved intricate piping networks, including high-temperature lines, complex fittings, and multiple load scenarios.

The engineers at Little P.Eng. Engineering utilized AutoPIPE's advanced modeling capabilities to create a detailed 3D representation of the refinery's piping system. They then conducted a thorough stress analysis, considering factors such as thermal expansion, pressure variations, and seismic loads.

The analysis identified critical areas where piping stresses exceeded acceptable limits, allowing for proactive design modifications. By addressing these issues early in the project, costly delays and potential safety risks were avoided. The refinery expansion project was completed on schedule, and the client praised Little P.Eng. Engineering for its expertise and contribution to the project's success.

Case Study 2: USA Power Plant Retrofit

In the USA, a power plant undergoing a retrofit faced the challenge of integrating new piping systems into the existing infrastructure. The client turned to Little P.Eng. Engineering for its expertise in piping stress analysis using AutoPIPE.

Little P.Eng. Engineering's team began by conducting a site assessment and a thorough review of the plant's existing piping systems. They then used AutoPIPE to model the proposed modifications and analyze the stress implications. The analysis revealed potential conflicts with existing structures and equipment that could lead to operational issues and safety concerns.

Working closely with the client, Little P.Eng. Engineering provided recommendations for design changes and rerouting of piping to mitigate stress-related problems. The collaborative approach ensured that the retrofit project progressed smoothly, with minimal disruptions to plant operations.

Conclusion

Piping stress analysis is a critical component of ensuring the safety, reliability, and compliance of industrial piping systems in Canada and the USA. AutoPIPE, a powerful software solution, plays a pivotal role in this process by providing advanced analytical capabilities. However, to maximize the benefits of AutoPIPE, the expertise of professionals like Little P.Eng. Engineering is indispensable.

Little P.Eng. Engineering's commitment to excellence, combined with their extensive experience and seamless integration of AutoPIPE, makes them the go-to partner for clients seeking top-notch piping stress analysis services. Through case studies, we have seen how their expertise has contributed to the success of projects in both Canada and the USA, saving clients time and money while ensuring the integrity of their piping systems.

As industries in Canada and the USA continue to evolve and expand, the demand for reliable piping stress analysis services remains high. Little P.Eng. Engineering stands ready to meet this demand, providing innovative solutions that contribute to the growth and success of various industries across North America. With a dedication to safety, compliance, and cost-effective solutions, they are a driving force behind the reliability and efficiency of piping systems in the region.

Pipe Stress Analysis Program AutoPIPE: Unlocking Its Capabilities

Piping systems are the arteries of industrial plants and facilities, ensuring the smooth flow of fluids and gases critical to various processes. The integrity and reliability of these systems are paramount, as any failure can lead to catastrophic consequences, including safety hazards and costly downtime. To safeguard these systems, engineers and professionals across the globe rely on advanced pipe stress analysis programs like AutoPIPE. In this comprehensive article, we will delve deep into the capabilities of AutoPIPE, covering static and dynamic analysis, a range of international codes and standards, and additional features that make it an indispensable tool in the world of piping engineering.

Introduction to AutoPIPE

AutoPIPE, developed by Bentley Systems, is a state-of-the-art software solution designed for the analysis and design of piping systems. Its versatility, accuracy, and compliance with industry standards have made it a trusted choice among engineers and organizations worldwide. AutoPIPE empowers engineers to assess the behavior of piping systems under various conditions, ensuring they meet safety standards, code requirements, and operational needs.

Static Analysis with AutoPIPE

Linear Analysis

Linear analysis is the foundation of pipe stress analysis, and AutoPIPE excels in this fundamental aspect. It performs linear static analysis to calculate stresses, strains, and deflections in piping systems under a variety of loads, including gravity, temperature, pressure, static earthquake, wind, and snow. Let's delve into each of these static loadings:

Gravity: AutoPIPE accounts for the weight of the piping system and its components, ensuring that stress due to gravity is properly considered.

Temperature: Temperature changes can cause significant stress in piping systems due to thermal expansion or contraction. AutoPIPE accurately predicts these effects.

Pressure: Pressure variations within the system, such as startup and shutdown, are analyzed to assess their impact on pipe stress.

Static Earthquake: In regions prone to seismic activity, the software performs seismic analysis according to the relevant seismic code, assessing the system's response to ground motion.

Wind and Snow: AutoPIPE evaluates the stresses induced by wind loads and the weight of accumulated snow, crucial in structures exposed to harsh environmental conditions.

Non-Linear Analysis

While linear analysis covers a wide range of scenarios, there are instances where non-linear behavior must be considered. AutoPIPE supports non-linear analysis, enabling engineers to assess situations such as plastic deformation, large deflections, and material non-linearities. This capability is particularly valuable in extreme loading conditions or when dealing with materials with nonlinear stress-strain behavior.

Dynamic Analysis with AutoPIPE

In addition to static analysis, AutoPIPE offers advanced capabilities for dynamic analysis, crucial for assessing the behavior of piping systems under time-varying loads. Here are some of the dynamic analysis features provided by AutoPIPE:

Modal Analysis

Modal analysis helps identify the natural frequencies and mode shapes of the piping system. This information is crucial for understanding the system's dynamic behavior and resonance frequencies.

Response Spectra Analysis

For seismic events and seismic anchor movement, AutoPIPE can perform response spectra analysis. This method assesses the system's response to ground motion, allowing engineers to design piping systems that can withstand seismic forces.

Time History Analysis

In scenarios involving fast-acting loads like slugs, fast-acting valves, or hammers, AutoPIPE conducts time history analysis. This analysis method considers the time-dependent nature of the loads to predict the system's response accurately.

Harmonic Analysis

Vibrations caused by oscillating loads can lead to fatigue and structural issues. AutoPIPE can conduct harmonic analysis to evaluate the effects of these vibrations on the piping system, helping engineers make necessary design modifications.

International Codes and Standards

AutoPIPE supports a wide range of international piping codes and standards, ensuring that analyses are conducted in compliance with industry regulations. Here is a list of some of the prominent codes and standards that AutoPIPE accommodates:

ASME B31.1: Power Piping

ASME B31.3: Process Piping

ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8: Gas Transmission and Distribution Piping Systems

ASME B31.12: Hydrogen Piping and Pipelines

EN 13480: European Standard for Metallic Industrial Piping

CSA-Z662: Canadian Standard for Oil and Gas Pipeline Systems

ISO14692: International Standard for Petroleum and Natural Gas Industries - Glass Reinforced Plastics (GRP) Piping

DNV F101: Design of Offshore Steel Structures, General (LRFD Method)

European Piping Codes: Including Sweden SPC, Norway TBKS 6, Russian SNIP, France SNCT & RCC-M, and United Kingdom BS 806

Additional Code Features

AutoPIPE offers a range of additional features to enhance compliance with codes and standards. Some of these features include:

ASME B31J Flexibilities

This feature allows engineers to assess the flexibility factors of piping components, ensuring that they meet the requirements of ASME B31J, a code used for evaluating the flexibility and stress intensification factors of pipe fittings.

Code Case N755 for HDPE

AutoPIPE incorporates Code Case N755, enabling engineers to perform stress analysis on High-Density Polyethylene (HDPE) piping systems as per ASME B31.3 and B31.1.

Basic Static Loading and Analysis

AutoPIPE handles a variety of basic static loading scenarios:

Gravity

It considers the weight of the piping and its components.

Temperature

AutoPIPE accurately predicts the effects of thermal expansion or contraction due to temperature changes.

Pressure

Pressure variations within the system are analyzed to assess their impact on pipe stress.

Static Earthquake

For regions prone to seismic activity, the software conducts seismic analysis according to the relevant seismic code.

Wind

AutoPIPE evaluates the stresses induced by wind loads, ensuring compliance with design requirements.

Snow

It accounts for the weight of accumulated snow, particularly important for structures in snowy regions.

Dynamic Loads

AutoPIPE's capabilities extend to dynamic loads, enabling engineers to assess complex scenarios:

Modal Analysis

This feature helps identify natural frequencies and mode shapes, providing critical insights into dynamic behavior.

Response Spectra for Seismic Events and Seismic Anchor Movement

AutoPIPE performs response spectra analysis, assessing the system's response to ground motion during seismic events.

Time History Analysis for Fast Acting Loads

Fast-acting loads, such as slugs and fast-acting valves, are accurately analyzed using time history analysis.

Harmonic Analysis of Vibrations

Vibrations caused by oscillating loads are evaluated through harmonic analysis to prevent fatigue and structural issues.

Buried Piping

For buried piping systems, AutoPIPE offers specialized features:

Soil Stiffness Calculator

Engineers can calculate soil stiffness to assess the interaction between buried pipes and the surrounding soil.

Soil Overburden Loads

The software considers the weight of soil overburden when analyzing buried piping.

Seismic Wave

AutoPIPE accounts for seismic waves that can affect buried piping systems.

Building Settlement

Settlement of nearby structures can impact buried piping, and AutoPIPE incorporates this consideration.

Upheaval Buckling

To prevent upheaval buckling in buried piping, AutoPIPE provides the necessary tools for analysis and design.

Offshore

AutoPIPE addresses the unique challenges of offshore piping systems:

Buoyancy

The software evaluates buoyancy forces, a critical factor in offshore piping design.

Wave Loading

AutoPIPE accounts for wave-induced loads on offshore structures.

Nuclear

In nuclear applications, AutoPIPE ensures compliance with stringent requirements:

ASME III Class 1, 2, and 3

It supports ASME III codes for nuclear piping, including Class 1 (NB), Class 2 (NC), and Class 3 (ND).

ASME Fatigue Analysis

AutoPIPE provides tools for ASME fatigue analysis, crucial for nuclear piping integrity.

QA Program and Compliance

The software's QA program has been in place since 1989 and complies with class 1, 2, 3, plus ASME NQA-1, NB, NC, ND codes, and ISO 9001.

Flange Design and Analysis

AutoPIPE supports flange design and analysis, ensuring that flanged connections meet the required standards and safety margins. It covers:

ANSI

ASME VIII Div 1 and 2

ASME III Appendix XI

Additional Loadings

AutoPIPE accommodates various additional loadings to provide a comprehensive analysis:

Hydrotest

It assesses stresses during hydrostatic testing, which is crucial to verify the integrity of the piping system.

Force Spectrum

The software can handle force spectra analysis, particularly relevant in systems subjected to varying loads.

Thermal Bowing

AutoPIPE predicts thermal bowing, helping engineers address potential issues due to temperature differentials.

Thermal Transient Analysis

In cases where temperature changes occur over time, thermal transient analysis is conducted to ensure accurate stress predictions.

Additional Features

AutoPIPE includes several additional features that streamline the pipe stress analysis process:

Spring Hanger Analysis

Engineers can analyze spring hanger supports, crucial for managing pipe movement and vibration.

Automatic Support Optimizer

AutoPIPE offers an automatic support optimizer to help engineers identify optimal support locations, minimizing stress and ensuring system integrity.

Creation of Digital, Customizable Stress Isometrics

The software allows for the creation of digital stress isometrics, aiding in communication and documentation of analysis results.

Interoperability

AutoPIPE seamlessly integrates with other engineering software and platforms:

Structural with STAAD and SACS

It can interface with structural analysis software like STAAD and SACS for comprehensive structural-piping interaction analysis.

Import from 3D CAD

AutoPIPE supports importing from various 3D CAD platforms, including OpenPlant, AutoPLANT, PlantSpace, SP3D, Plant 3D, PDS, PDMS, and Revit, simplifying the modeling process.

Nozzle Loads to AutoPIPE Vessel

For vessels connected to piping systems, AutoPIPE can calculate and transfer nozzle loads to AutoPIPE Vessel for vessel analysis.

Importing Time History FRC File

Time history data can be imported into AutoPIPE from external sources to perform dynamic analysis accurately.

Conclusion

AutoPIPE is a comprehensive and versatile pipe stress analysis program that caters to the diverse needs of engineers and organizations across the globe. With its robust static and dynamic analysis capabilities, support for a multitude of international codes and standards, and additional features that streamline the analysis process, AutoPIPE has established itself as an indispensable tool in the field of piping engineering. As industries continue to evolve and face new challenges, AutoPIPE remains at the forefront, empowering engineers to design, analyze, and optimize piping systems with confidence, ensuring the safety, reliability, and efficiency of critical infrastructure.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Canada

USA

Little P.Eng. Engineering

Compliance

Safety

3D modeling

Piping stress analysis

Thermal expansion

Regulatory standards

AutoPIPE

Retrofit

Material properties

Infrastructure

Industrial piping

Reliability

Cost savings

Refinery

Power plant

Chemical facilities

Seismic analysis

Engineering codes

Expertise

Proactive maintenance

Site assessment

Design modifications

Analytical capabilities

Project success

Compliance with industry regulations

Risk mitigation

Timely delivery

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Canada#USA#Little P.Eng. Engineering#Compliance#Safety#3D modeling#Piping stress analysis#Thermal expansion#Regulatory standards#AutoPIPE#Retrofit#Material properties#Infrastructure#Industrial piping#Reliability#Cost savings#Refinery#Power plant#Chemical facilities#Seismic analysis#Engineering codes#Expertise#Proactive maintenance#Site assessment#Design modifications#Analytical capabilities#Project success#Compliance with industry regulations#Risk mitigation#Timely delivery

0 notes

Text

#review of the last week in photos#was sick with a fever for a whole week & was a miserable wet rag the whole time#the oil refinery/chemical production that's 3km away from us had a malfunction and has been burning Something the last 36h#but apparently there's no danger to humans or animals despite the ghastly color of the smoke#the flame is loud as fuck too can't sleep with this low roaring sound it's driving me crazy#then the two cats of my grandparents. one's 13 the other's 2 and they do not get along#and last my sweety baby kitty that can do no wrong and also provide an excellent massage against period cramps#also it's been like -5 for a week and my car had to get jumpstarted :(#meins

0 notes

Text

#mechanical seals#mechanical seal supplier#mechanical seal manufacturer#single coil#multi spring#cartridge seals#bellow seals#reverse balanced#teflon bellow#repair and service#reconditioning#oil gas industry#petrochemical#refinery#chemical industry#food and beverages

1 note

·

View note

Text

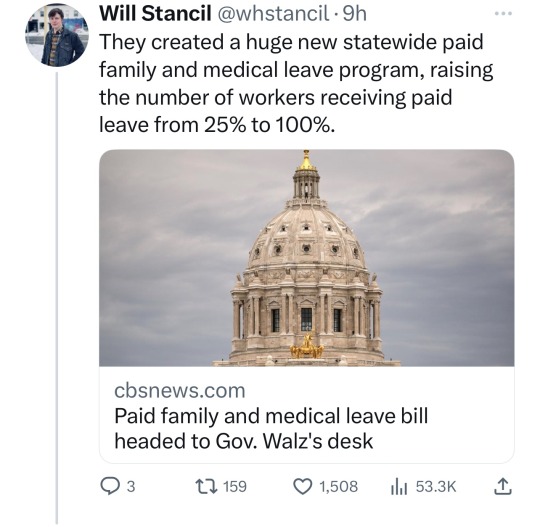

🗣️THIS IS WHAT INCLUSIVE, COMPASSIONATE DEMOCRACY LOOKS LIKE

Minnesota Dems enacted a raft of laws to make the state a trans refuge, and ensure people receiving trans care here can't be reached by far-right governments in places like Florida and Texas. (link)

Minnesota Dems ensured that everyone, including undocumented immigrants, can get drivers' licenses. (link)

They made public college free for the majority of Minnesota families. (link)

Minnesota Dems dropped a billion dollars into a bevy of affordable housing programs, including by creating a new state housing voucher program. (link)

Minnesota Dems massively increased funding for the state's perpetually-underfunded public defenders, which lets more public defenders be hired and existing public defenders get a salary increase. (link)

Dems raised Minnesota education spending by 10%, or about 2.3 billion. (link)

Minnesota Dems created an energy standard for 100% carbon-free electricity by 2040. (link)

Minnesota already has some of the strongest election infrastructure (and highest voter participation) in the country, but the legislature just made it stronger, with automatic registration, preregistration for minors, and easier access to absentee ballots. (link)

Minnesota Dems expanded the publicly subsidized health insurance program to undocumented immigrants. This one's interesting because it's the sort of things Dems often balk at. The governor opposed it! The legislature rolled over him and passed it anyway. (link)

Minnesota Dems expanded background checks and enacted red-flag laws, passing gun safety measures that the GOP has thwarted for years. (link)

Minnesota Dems gave the state AG the power to block the huge healthcare mergers that have slowly gobbled up the state's medical system. (link)

Minnesota Dems restored voting rights to convicted felons as soon as they leave prison. (link)

Minnesota Dems made prison phone calls free. (link)

Minnesota Dems passed new wage protection rules for the construction industry, against industry resistance. (link)

Minnesota Dems created a new sales tax to fund bus and train lines, an enormous victory for the sustainability and quality of public transit. Transit be more pleasant to ride, more frequent, and have better shelters, along more lines. (link)

They passed strict new regulations on PFAS ("forever chemicals"). (link)

Minnesota Dems passed the largest bonding bill in state history! Funding improvements to parks, colleges, water infrastructure, bridges, etc. etc. etc. (link)

They're going to build a passenger train from the Twin Cities to Duluth. (link)

I can't even find a news story about it but there's tens of millions in funding for new BRT lines, too. (link)

A wonky-but-important change: Minnesota Dems indexed the state gas tax to inflation, effectively increasing the gas tax. (link)

They actually indexed a bunch of stuff to inflation, including the state's education funding formula, which helps ensure that school spending doesn't decline over time. (link)

Minnesota Dems made hourly school workers (e.g., bus drivers and paraprofessionals) eligible for unemployment during summer break, when they're not working or getting paid. (link)

Minnesota Dems passed a bunch of labor protections for teachers, including requiring school districts to negotiate class sizes as part of union contracts. (Yet another @SydneyJordanMN special here. (link)

Minnesota Dems created a state board to govern labor standards at nursing homes. (link)

Minnesota Dems created a Prescription Drug Affordability Board, which would set price caps for high-cost pharmaceuticals. (link)

Minnesota Dems created new worker protections for Amazon warehouse workers and refinery workers. (link)

Minnesota Dems passed a digital fair repair law, which requires electronics manufacturers to make tools and parts available so that consumers can repair their electronics rather than purchase new items. (link)

Minnesota Dems made Juneteenth a state holiday. (link)

Minnesota Dems banned conversion therapy. (link)

They spent nearly a billion dollars on a variety of environmental programs, from heat pumps to reforestation. (link)

Minnesota Dems expanded protections for pregnant and nursing workers - already in place for larger employers - to almost everyone in the state. (link)

Minnesota Dems created a new child tax credit that will cut child poverty by about a quarter. (link)

Minnesota Democrats dropped a quick $50 million into homelessness prevention programs. (link)

And because the small stuff didn't get lost in the big stuff, they passed a law to prevent catalytic converter thefts. (link)

Minnesota Dems increased child care assistance. (link)

Minnesota Dems banned "captive audience meetings," where employers force employees to watch anti-union presentations. (link)

No news story yet, but Minnesota Dems forced signal priority changes to Twin Cities transit. Right now the trains have to wait at intersections for cars, which, I can say from experience, is terrible. Soon that will change.

Minnesota Dems provided the largest increase to nursing home funding in state history. (link)

They also bumped up salaries for home health workers, to help address the shortage of in-home nurses. (link)

Minnesota Dems legalized drug paraphernalia, which allows social service providers to conduct needle exchanges and address substance abuse with reduced fear of incurring legal action. (link)

Minnesota Dems banned white supremacists and extremists from police forces, capped probation at 5 years for most crimes, improved clemency, and mostly banned no-knock warrants. (link)

Minnesota Dems also laid the groundwork for a public health insurance option. (link)

I’m happy for the people of Minnesota, but as a Floridian living under Ron DeSantis & hateful Republicans, I’m also very envious tbh. We know that democracy can work, and this is a shining example of what government could be like in the hands of legislators who actually care about helping people in need, and not pursuing the GOP’s “culture wars” and suppressing the votes of BIPOC, and inflicting maximum harm on those who aren’t cis/het, white, wealthy, Christian males. BRAVO MINNESOTA. This is how you do it! And the Minnesota Dems did it with a one seat majority, so no excuses. Forget about the next election and focus on doing as much good as you can, while you still can. 👏🏿👏🏿👏🏿👏🏿👏🏿👏🏿👏🏿

👉🏿 https://threadreaderapp.com/thread/1660846689450688514.html

#politics#minnesota#social justice#culture wars#this is what democracy looks like#republicans are evil

25K notes

·

View notes

Text

How Precious Metals Refineries Recover Value from Scrap Materials

Discover how precious metals refineries extract valuable elements from scrap materials, turning waste into profit through advanced recovery techniques.

for more info visit: https://chemicalprocesssystems.blogspot.com/2024/11/how-precious-metals-refineries-recover.html

0 notes

Text

Refinery Chemical / Oil and Gas Chemicals

The oilfield chemical industry is a sector that focuses on the development, production of chemicals, stimulation chemicals, and distribution of chemicals used in various processes within the oil and gas industry. These chemicals play a crucial role in enhancing the efficiency, safety, and productivity of oil and gas exploration, drilling, production, and refining operations. This petrochemical industry significantly influences the trajectory of the global economy. Its growth is propelled by the consistent rise in oil drilling activities, which directly correlates with the demand for chemicals used in oilfield operations.

Drilling Fluids mainly have garnered significant attention in recent years due to their pivotal role in hydrocarbon recovery. These chemicals can be broadly categorized into three main segments: Upstream, Midstream, and Downstream. The Upstream sector encompasses activities involving the exploration and extraction of oil and gas resources. The Midstream sector involves tasks related to the establishment and operation of pipelines and storage facilities, ensuring the secure and efficient transportation of oil and gas from production sites to refineries or end consumers. The Downstream segment oversees the refining, processing, and distribution of oil and gas products.

Advantages of using these chemicals

Enhancement of production efficiency at drilling sites and refinery processes

Shielding of metallic surfaces from corrosive agents released during crude oil extraction, boosting their durability and lifespan

Achieving near-complete extraction of crude from storage tanks, mitigating sludge buildup at the tank bottom

Utilizing these specialized chemicals proves economically advantageous in contrast to extensive mechanical interventions

Time-saving benefits and assured financial gains for owners and stakeholders.

Range of Chemicals of Chemtex

Upstream Chemicals

Completion & Drilling Fluid Additives: Deflocculants, Defoamers, pH Controllers, Scale Inhibitors, PHPA LT and PHPA HT, Surfactants

Cementing Additives: Accelerators, Dispersants, Extenders, Retarders etc.

Simulation Fluid Additives: Bactericides, Breakers, Mutual Solvents, Polymeric Viscosifier

E&P Chemicals: Biocides, De-oilers, Demulsifiers or Emulsion breakers, Scale Inhibitors, Corrosion Inhibitors, Surfactants, Polyelectrolytes, Wax Inhibitors

Water Injection Chemicals: Calcium Carbonate Scale Inhibitor, Biocides, Corrosion Inhibitors, Defoamers, Flocculation Aid.

Midstream Chemicals

Crude Tank Treatments: De-watering Agent, Sludge Breaker, Solid Setting Agents, Tank Cleaning Additives, petrochemical additives, crude oil treatment Dehydration, Hydrotesting Inhibitor, Degassing Chemical

Pipeline Chemicals: Crude Pipeline Corrosion Inhibitor, Hydrotesting Corrosion Inhibitor, Pipeline Cleaning Chemicals

Downstream Chemicals

Pipelines: Viscosity Reducers, Biocides, Drag Reducers, Flow Improvers, Scale Inhibitors, Corrosion Inhibitors, etc. De Salter: Demulsifier, Metal Remover Aid, Antiscalants etc.

Crude Pre-Heat: Antifoulant, Corrosion Inhibitors

Primary Units: Antifoam, Neutralizing Amine etc.

Secondary Units: DHDT, FCCU, DCU, Visbreaker

Auxiliary Units: Merox Unit, ATU, Sour Water Stripper

Finished Fuel Additives: Octane Boosters, PPD, Lubricity improver etc.

Petrochemical additives: Dispersant, Antistatic agent, Dehazer additives, lubricity improver

Besides this, Chemtex Speciality Limited, an eminent chemical manufacturing company also manufacture chemicals such as

Utility Chemicals - Process Cooling & Heating Chemicals (Boiler, Cooling Tower, Chiller), Desalination Plant Chemicals, Wastewater Treatment Chemicals

Performance and maintenance Chemicals – Organic Acids, Quats & Aldehydes, Imidazoline, Silicones, Polyacrylates & Polyacrylamides, General Treatment Additives

Specialty chemicals play a critical role in areas such as drilling optimization, enhanced oil recovery, metal protection, and fluid stabilization, among other aspects. These specialized oil refinery chemicals find application in various oil and gas extraction operations, enhancing their overall efficiency and productivity. For more information visit https://www.chemtexltd.com/products-and-solutions/energy-chemicals/downstream-chemicals/

#oil field chemical#oil refinery#upstream#downstream#midstream#speciality chemicals#refinery chemicals#Chemtex Speciality limited

0 notes