#chemical corrosion resistance

Explore tagged Tumblr posts

Text

ABS plastic: Why is it a popular choice in the construction industry?

In the ever-changing construction industry, the choice of materials is crucial. It not only determines the sturdiness, durability and aesthetics of the building, but also directly affects the construction efficiency and cost. In recent years, ABS plastic (acrylonitrile-butadiene-styrene copolymer) has shined in the construction industry with its unique properties and has become the preferred…

#ABS plastic#chemical corrosion resistance#colorability#construction industry#easy processing#Electrical Insulation#environmental protection#heat resistance#high strength#low temperature resistance#sustainability#toughness

0 notes

Text

Plasticair Environmental: Leading Ventilation Fan Solutions

Plasticair Environmental specializes in high-performance air filtration solutions, including Horizontal Packed Bed, Fume Hood, Chrome, Vertical Packed Bed, Venturi scrubbers, and Mist Eliminators. Trusted by Plasticair Inc.

#plasticair#plasticair enviromental#Fiberglass-Reinforced Plastics (FRP)#Corrosion Resistance#Fiber Reinforced Plastics#Reinforced Thermoset Plastic (RTP)#Reinforced Thermoset Resin (RTR)#Glass-Reinforced Plastic (GRP)#Hand Lay-up Fabrication#Resin Transfer Molding#Corrosion Barrier Coating#Plasticair FRP Fans#Cost-Effective Solution#Industrial Applications#Quality Control in FRP#Resin Brand Importance#Durability of FRP#Thermoplastics vs. Thermosets#Fan Specifications#Acid Scrubbers#Alkaline Scrubbers#Odor Scrubbers#Odour Scrubbers#Chlorine Scrubbers#H2S Scrubbers#SO2 Scrubbers#Wet Scrubbers#Chemical Scrubbers#Fume hood scrubbers#Venturi scrubber

2 notes

·

View notes

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

GRP Lining Solutions for Optimal Protection | RNSQatar

RNSQatar provides advanced GRP Lining solutions designed to offer superior corrosion resistance and waterproofing for a wide range of applications. Our durable, high-performance GRP coatings ensure long-lasting protection for infrastructure, industrial facilities, and construction projects. With expertise in fire and safety, we deliver reliable, customized solutions that meet the highest industry standards. Trust RNSQatar for innovative and effective GRP Lining systems that enhance the safety and longevity of your assets. Visit rnsqatar.com/grp-lining for more information.

#GRP Lining#Waterproofing#Corrosion Protection#Industrial Solutions#RNSQatar#Chemical Resistance#Durable Lining#Infrastructure Protection#Construction Services#Qatar#Fire and Safety#GRP Coating#Protective Solutions#Industrial Lining

0 notes

Text

Top Supplier of Flexible Pipe Connectors

In today’s industrial landscape, the demand for reliable and efficient flexible pipe connectors is higher than ever. At Udhhyog, we pride ourselves on being the top supplier of flexible pipe connectors in India, providing products that meet the highest standards of quality and performance.

What Are Flexible Pipe Connectors?

Flexible pipe connectors are crucial components designed to absorb vibrations, accommodate movement, and allow for easy installation in various piping systems. These connectors enhance the overall efficiency and longevity of your installations, making them ideal for both residential and industrial applications.

Why Choose Flexible Pipe Connectors?

Vibration Absorption: Flexible connectors help reduce vibrations and noise, leading to a quieter operation.

Easy Installation: Designed for straightforward installation, these connectors save time and labor costs.

Versatility: They can be used in a variety of applications, including HVAC systems, plumbing, and industrial piping.

Udhhyog’s Range of Flexible Pipe Connectors

At Udhhyog, we offer a diverse range of flexible pipe connectors tailored to various applications:

Rubber Flexible Connectors: Perfect for absorbing shock and providing excellent sealing capabilities.

Metal Flexible Connectors: Designed for high-pressure applications, offering durability and resistance to harsh environments.

PTFE Flexible Connectors: Ideal for chemical applications due to their excellent corrosion resistance.

Why Choose Udhhyog as Your Supplier?

Quality Assurance: Our connectors are manufactured using premium materials to ensure long-lasting performance.

Competitive Pricing: We offer the best prices without compromising on quality, making our products accessible for all industries.

Expert Support: Our knowledgeable team is available to assist you in selecting the right connectors for your specific needs.

Applications of Flexible Pipe Connectors

Our flexible pipe connectors are used in various industries, including:

HVAC Systems: To connect ducts while allowing for thermal expansion and contraction.

Plumbing: Providing reliable connections in water supply and drainage systems.

Industrial Applications: Used in manufacturing processes where flexibility and movement are essential.

Customer Feedback

“Udhhyog’s flexible pipe connectors have improved our system's efficiency significantly. Highly recommend their products!” — Innovative Engineering Ltd.

“We trust Udhhyog for all our piping needs. Their connectors are reliable and cost-effective.” — Streamline Plumbing Solutions

How to Order Flexible Pipe Connectors from Udhhyog

Explore Our Range: Check out our selection of flexible pipe connectors here.

Select the Right Product: Choose from our variety of sizes and materials to suit your requirements.

Simple Ordering Process: Enjoy a seamless online ordering experience with prompt delivery across India.

At Udhhyog, we are committed to providing you with the highest quality flexible pipe connectors to meet your needs. Trust us for reliable solutions that enhance the performance of your piping systems.

#Title & Heading:#Top Supplier of Flexible Pipe Connectors#Meta Search Description:#Udhhyog is the leading supplier of high-quality flexible pipe connectors. Enhance your piping systems with our reliable solutions.#In today’s industrial landscape#the demand for reliable and efficient flexible pipe connectors is higher than ever. At Udhhyog#we pride ourselves on being the top supplier of flexible pipe connectors in India#providing products that meet the highest standards of quality and performance.#What Are Flexible Pipe Connectors?#Flexible pipe connectors are crucial components designed to absorb vibrations#accommodate movement#and allow for easy installation in various piping systems. These connectors enhance the overall efficiency and longevity of your installati#making them ideal for both residential and industrial applications.#Why Choose Flexible Pipe Connectors?#Vibration Absorption: Flexible connectors help reduce vibrations and noise#leading to a quieter operation.#Easy Installation: Designed for straightforward installation#these connectors save time and labor costs.#Versatility: They can be used in a variety of applications#including HVAC systems#plumbing#and industrial piping.#Udhhyog’s Range of Flexible Pipe Connectors#At Udhhyog#we offer a diverse range of flexible pipe connectors tailored to various applications:#Rubber Flexible Connectors: Perfect for absorbing shock and providing excellent sealing capabilities.#Metal Flexible Connectors: Designed for high-pressure applications#offering durability and resistance to harsh environments.#PTFE Flexible Connectors: Ideal for chemical applications due to their excellent corrosion resistance.#Why Choose Udhhyog as Your Supplier?

1 note

·

View note

Text

Exploring ASTM B619 Welded Pipe: Applications and Advantages

ASTM B619 is a standard specification for welded nickel-chromium-molybdenum-copper alloy (UNS N06022) and nickel-chromium-molybdenum-tungsten alloy (UNS N10665) pipe. These alloys are designed for use in corrosive environments, particularly those containing reducing and oxidizing chemicals. ASTM B619 welded pipes are critical in industries such as chemical processing, petrochemicals, pharmaceuticals, and power generation. This blog explores the properties, applications, and benefits of ASTM B619 welded pipes, emphasizing their importance in modern industrial applications.

What is ASTM B619 Welded Pipe?

ASTM B619 specifies seamless and welded pipes made from nickel-chromium-molybdenum-copper (Alloy C276, UNS N06022) and nickel-chromium-molybdenum-tungsten (Alloy B-2, UNS N10665) alloys. These materials are highly resistant to corrosion in a wide range of aggressive environments, including acids, chlorides, and seawater. Welded pipes under ASTM B619 are manufactured using fusion welding processes, ensuring uniformity, strength, and integrity throughout the pipe length.

Key Properties of ASTM B619 Welded Pipe

ASTM B619 welded pipes exhibit several critical properties that make them suitable for corrosive environments:

Corrosion Resistance: Nickel-based alloys like C276 and B-2 offer exceptional resistance to a wide range of corrosive chemicals, including acids (sulfuric, hydrochloric), chlorides, and seawater.

High Temperature Performance: These alloys maintain their mechanical strength and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications.

Mechanical Strength: ASTM B619 welded pipes provide excellent mechanical properties, including high tensile strength and toughness, ensuring reliability in demanding conditions.

Weldability: The alloys are easily weldable using conventional welding techniques, allowing for easy fabrication and repair of piping systems.

Low Maintenance: Due to their corrosion resistance, ASTM B619 welded pipes require minimal maintenance, reducing downtime and operational costs.

Longevity: These pipes have a long service life in aggressive environments, offering reliable performance over extended periods.

Applications of ASTM B619 Welded Pipe

ASTM B619 welded pipes find extensive use in industries requiring resistance to corrosive environments:

Chemical Processing: They are used in chemical plants for transporting acids, alkalis, and other corrosive chemicals.

Petrochemical Industry: ASTM B619 pipes are employed in oil refineries, gas processing plants, and offshore platforms where exposure to corrosive fluids is common.

Pharmaceutical Industry: These pipes are used in pharmaceutical manufacturing processes that involve corrosive solvents and chemicals.

Power Generation: ASTM B619 pipes are utilized in power plants for handling corrosive cooling water, steam, and chemicals in boiler systems.

Waste Treatment: They are used in wastewater treatment facilities for conveying corrosive liquids and gases.

Pulp and Paper Industry: ASTM B619 pipes find application in pulp and paper mills for handling corrosive chemicals used in bleaching and processing.

Benefits of Using ASTM B619 Welded Pipe

ASTM B619 welded pipes offer numerous advantages, making them a preferred choice in corrosive environments:

Corrosion Resistance: Superior resistance to a wide range of corrosive chemicals ensures longevity and reliability.

High Performance: These pipes maintain their mechanical properties at high temperatures, ensuring consistent performance in demanding conditions.

Safety: Reliable corrosion resistance reduces the risk of leaks and failures, enhancing operational safety.

Cost-Effectiveness: Despite their initial cost, ASTM B619 welded pipes offer long-term savings due to reduced maintenance and extended service life.

Versatility: Available in various sizes and configurations, they can be tailored to meet specific application requirements.

Environmental Sustainability: Nickel-based alloys are fully recyclable, promoting environmental sustainability and compliance with green initiatives.

Conclusion

ASTM B619 welded pipes made from alloys such as C276 and B-2 play a crucial role in industries where corrosion resistance and reliability are paramount. Their exceptional properties make them ideal for handling corrosive chemicals in chemical processing, petrochemicals, pharmaceuticals, and power generation. Understanding the benefits and applications of ASTM B619 welded pipes underscores their critical importance in ensuring efficient, safe, and sustainable operations in modern industrial environments.

#ASTM B619 Welded Pipe#Nickel-Chromium-Molybdenum Alloys#Corrosion Resistance#Chemical Processing#Petrochemical Industry#Power Generation#Mechanical Strength#High Temperature Performance

0 notes

Text

Durable and Corrosion-Resistant Stainless Steel 304 Pipe Fittings for Reliable and Efficient Fluid Handling in Diverse Industrial Applications

Our Stainless Steel 304 Pipe Fittings provide reliable and corrosion-resistant connections for various piping systems. Suitable for applications such as food processing, chemical processing, and water treatment, these fittings ensure a precise fit and long-lasting service. Available in multiple sizes and configurations, they meet the demands of projects requiring efficient fluid handling solutions.

#Stainless Steel 304#Pipe Fittings#Corrosion Resistance#Piping Systems#Food Processing#Chemical Processing#Water Treatment#Precise Fit#Long-Lasting Service#Fluid Handling Solutions

0 notes

Text

In the realm of modern manufacturing and electronics, the importance of surface finishing techniques, particularly electroplating, cannot be overstated. This intricate process not only enhances the appearance of metal products but also significantly boosts their durability, resistance to corrosion, and electrical conductivity. This article dives into the fascinating world of electroplating, explaining its fundamental principles and diverse applications.

#electroplating#metal finishing#surface finishing techniques#corrosion resistance#electrical conductivity#manufacturing#electronics#chemical process#metal coating#A-Gas Electronic Materials

0 notes

Text

Seamless Protection: Exploring the Polyurea Coatings Market

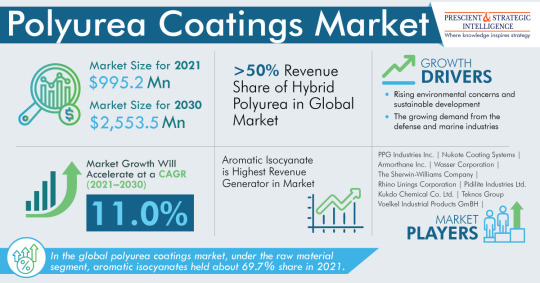

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry. This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry. Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry. The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly. The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings. It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Text

Innovative Application and Prospects of PVDF in the Coatings Industry

At the beginning of the third decade of the 21st century, the global coatings industry is undergoing unprecedented changes and innovations. Among them, PVDF (polyvinylidene fluoride) fluorocarbon coatings have become the focus of industry attention with their excellent performance and broad application prospects. As a high-performance fluoropolymer material, PVDF has shown extraordinary value in…

#automotive applications#chemical applications#chemical resistance#construction applications#corrosion resistance#electrical applications#environmental protection characteristics#PVDF fluorocarbon coatings#weather resistance

0 notes

Text

Global Nickel Alloys Market Is Estimated To Witness High Growth Owing To Increasing Demand for Corrosion-resistant Materials

The global Nickel Alloys market is estimated to be valued at US$14.24 billion in 2022 and is expected to exhibit a CAGR of 5.1% over the forecast period 2023-2028, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Nickel alloys are highly corrosion-resistant materials that are widely used in various industries such as aerospace, automotive, electronics, energy, and chemical processing. These alloys offer excellent mechanical properties and high temperature strength, making them suitable for a wide range of applications. The need for high-performance materials in these industries is driving the demand for nickel alloys.

B) Market Key Trends:

One key trend in the Nickel Alloys market is the growing demand for nickel-based superalloys in the aerospace industry. These superalloys are used in the manufacturing of components for gas turbines, jet engines, and rocket engines. The aerospace industry is experiencing significant growth due to increasing air travel and defense expenditure, which is boosting the demand for nickel alloys. For example, Allegheny Technologies Incorporated, one of the key players in the nickel alloys market, offers a wide range of nickel-based alloys specifically designed for aerospace applications. These alloys provide high strength, corrosion resistance, and excellent mechanical properties, meeting the stringent requirements of the aerospace industry.

C) PEST Analysis:

Political: The political stability of a country can impact the production and trade of nickel alloys. Government regulations and policies can affect the availability of raw materials and the export-import scenario.

Economic: Economic factors such as GDP growth, industrialization, and infrastructure development influence the demand for nickel alloys. Rising disposable income and urbanization are also driving the market.

Social: Increasing population, urbanization, and changing lifestyles contribute to the demand for products associated with the nickel alloys market. The growing middle-class population is more inclined towards high-performance materials for various applications.

Technological: Advancements in manufacturing technologies, such as additive manufacturing and advanced processing techniques, are driving innovation in the nickel alloys market. These technologies enable the production of complex components with improved performance.

D) Key Takeaways:

The global nickel alloys market is expected to witness high growth, exhibiting a CAGR of 5.1% over the forecast period. This growth is primarily attributed to the increasing demand for high-performance materials in industries such as aerospace, automotive, and chemical processing. For example, the aerospace industry is driving the demand for nickel-based superalloys due to the need for lightweight and heat-resistant materials. In terms of regional analysis, North America is expected to be the fastest-growing and dominating region in the nickel alloys market. This growth can be attributed to the presence of major aerospace manufacturers and increasing investments in defense and aerospace industries. Europe and Asia Pacific are also significant regions due to their expanding automotive and chemical processing sectors. Key players operating in the global nickel alloys market include Allegheny Technologies Incorporated, Ametek Inc., Aperam S.A., Carpenter Technology Corporation, Haynes International Inc., Kennametal Inc., Precision Castparts Corporation, Rolled Alloys Inc., Sandvik Materials Technology, ThyssenKrupp AG, VDM Metals GmbH, and Voestalpine AG. These companies focus on product development, collaborations, and mergers & acquisitions to strengthen their market position. In conclusion, the global nickel alloys market is expected to witness significant growth driven by the increasing demand for high-performance materials in various industries. The aerospace industry's need for lightweight and corrosion-resistant materials is a key trend shaping the market. Government policies, economic factors, social trends, and technological advancements also influence the market dynamics. North America is expected to be the fastest-growing region, and key players are focusing on innovation and strategic partnerships to stay competitive in the market.

#Coherent Market Insights#Chemicals and Materials Industry#Specialty and Fine Chemicals#Nickel Alloys Market#Metal Alloys#corrosion resistance

0 notes

Text

Mild Steel Chlorine Gas Cylinder Manufacturers

Looking for the Best Mild Steel Chlorine Gas Cylinder Manufacturers. Chemtrade International is a leading distributor of Mild Steel Chlorine Gas Cylinder, providing high-quality products and exceptional service to customers across industries.

#Chlorine Cylinder#Mild Steel Cylinder#Chlorine Gas#Gas Cylinder Safety#Cylinder Handling#Industrial Safety#Chemical Industry#Gas Storage#Pressure Vessel#Gas Handling#Hazardous Material#Safety First#Gas Storage Safety#Cylinder Maintenance#Corrosion Resistance#Industrial Gas Cylinder#Gas Cylinder Storage#Gas Cylinder Transportation#Safe Cylinder Handling

1 note

·

View note

Note

Hi! :D, i have 2 questions for karma, 1. Karma is tradicional vampire or is he like the Twilight vampires?. 2 He is willing to let me give him some kisses on his face and leave marks on him?. ;) PD(Sorry if i sound a bit rude, i am learning english and Google a helped me a litte haha)

Ooh! This was a question I've been waiting for!

Also your English is understandable relax bestie <3333

But first - let's get your smooching session out of the way ;)

Now, to answer your first question - Karma falls under the Twilight vampires; however he is not entirely a full vampire. In fact, his family and him fall under half-vampires.

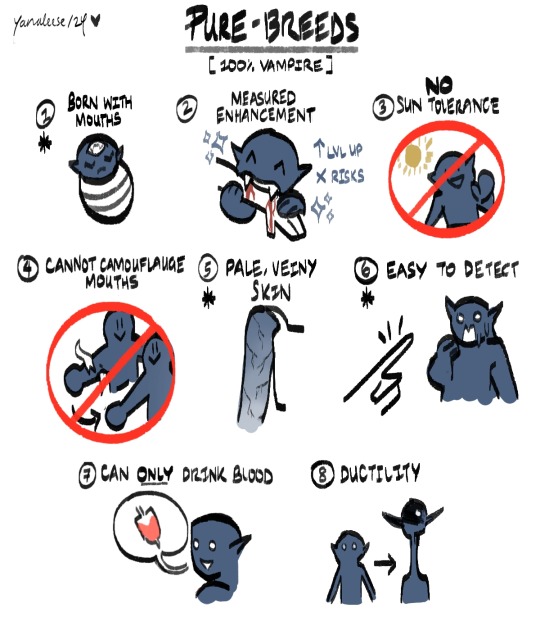

Here is a basic (but LONG) comparison between half-breeds and pure-breeds!

Note that this is still in the works, so some information may be changed to fully tie in Karma's story and lineage!

(1) Yup! You read that right - pure-bloods are born with extra mouths, or none at all. They can be randomly placed anywhere on the body e.g. their backs, their hands, etc. However over time, pure-bloods have been able to move their mouths towards different areas thanks to genetics!

(2) Measured Enhancement is a state that allows pure-bloods to renew their strength and abilities. The blood acts like a charger to your phone battery, similar to how we need food and water to survive. It poses little to no risks due to a chemical called vialene, which helps them to resist losing control of themselves.

(3) No Sun Tolerance - Just like traditional vampires, they cannot go in sunlight, as it can lead to their bodies to burn, decay or even explode. Although these effects are dependent on the pure-blood's age, genetics and their decomposition process.

(4) Due to most mouths being permanent from birth, they cannot camouflage their mouths nor make it disappear. As a result, it causes pure-bloods to be susceptible to their environment, leading to these extra mouths being infected. It also does not help the fact that these pure-bloods are decomposing bodies, since decomposed areas can leave the mouths no longer usable. Thus, many vampires wear long-sleeved clothing to hide these mouths - and over time - learn how to gain blood without being detected!

(5) 99% of the time pure-bloods have pale, veiny skin since they lack blood; but that doesn't mean they don't have any. In fact, the chemical that makes up their blood is called Pyrotoxinum (fire + poison). Pyrotoxinum is a black, poisonous chemical that is highly reactive with sunlight and human blood. It's composition is similar to blood, and it tastes like oil and grease. It is corrosive to skin after being exposed in sunlight, can be colorless in sunlight, and is odorless. Lastly, Pyrotoxinum is also poisonous when being ingested, making it a useful tool for humans and vampires to kill people in their sleep, and cause explosions to occur. So be extremely careful when coming across pure-bloods!

(6) With so many mouths, extremely pale skin, and no sun tolerance - pure-bloods are super easy to detect. Hence, many pure-bloods do not openly integrate themselves within human society. This means they use their environment particularly well, making them incredible predators.

(7) Unfortunately, pure-bloods can only drink blood. Eating meats, grains, and dairy is out of the question, since all human food comes from the sun. Besides, pure-bloods are not a fan of organ failure and dying an explosive death lol

(8) Ductility - Pure-bloods are able to stretch their body parts whenever their please, and return to their normal size. This ability works well for middle-aged vampires, since in their younger years - their body goes through puberty and other hormonal changes. Although, it appears in teens, it is recommended by older vampires to not dabble in this ability until they're older. They can receive training for it though!

Bonus: Short comparison between PURE-bloods and TRADITIONAL vampires

(B - Both , P - Purebloods , T - Traditional , TBD - To Be Decided)

Undead? - B

Fangs? - B

No reflection? - T

Superhuman Strength, Speed, Senses and Healing? - B

Hypnotic Eyes? - B

Shapeshifting? - B

Aversion to Holy Symbols? - T

Stake Thru the Heart? - B

Fire? - B

Invitation Needed to Enter? - TBD

Running Water? - If you mean washing your hands and rubbing your face, then T. But if it's exposed to sunlight e.g. rivers, pools? Then B.

(1) Hemomancy is the ability to control your blood in the form of weaponry, shielding, etc. This is because the human blood in their body serves as fuel for their vampiric blood. The vampire blood acts a conductor, allowing them to channel the life energy within themselves! It is by far the easiest, and notable ability that most half-vampires have.

(2) Frenzied Enhancement is an uncontrolled, bloodthirsty state that occurs immediately when drinking blood or seconds after drinking. Although it's risky, it helps half-breeds activate their strength and abilities (huge difference!!!). In simpler terms, drinking blood acts like a key to a closed treasure chest. Drinking blood is purely optional, and simply an additional tool for half-breeds to survive. However, due to vialene being reduced, half-bloods are unable to lower their adrenaline - causing a lack of self-control.

(3) Sun Tolerance - Compared to pure-bloods, most half-bloods are able to go in the sunlight without problems. Their human halves need sunlight, so having sun tolerance is a major plus!

(4) Stemming from genetics and adaptation, half-bloods have the ability to camouflage their mouths. They are able to move these mouths around, assimilate it into their skin, and in rare cases remove it from their skin completely! This process is similar to blood clotting, which is why their body is compatible with such major changes. This ability is by far one of the most envied by pure-bloods!

(5) Another trait that half-bloods can have are patchy, mosaic skin. This skin condition can come in the form of stitches, spots and spirals. Most of the vampiric race believes that this patchy skin substitutes extra body parts, e.g. the mouth. However, the reasoning behind it remains a mystery to most, since this condition has become rarer in the current generation of half-breeds (which Karma falls into).

(6) Since half-bloods are practically human, they are hard to detect appearance-wise. This doesn't stop modern methods from finding them through vialene tests, sensory overload, starvation, etc. Hence, many half-bloods try to build their endurance and stamina to remain undetected. Sometimes half-bloods even try to live off without vialene, which normally goes to shit if you're not careful. But it is possible - there's even a myth about it!

(7) Another ability that pure-bloods envy are half-bloods being able to eat human food and drink blood! Usually, many half-bloods have a strong preference of one over the other. Either way, half-bloods can live on a blood-only diet or a human-based diet. But it is strongly recommended by older generations to ingest both, since it can cause hormonal and emotional imbalances. So it's best to be on the safe side!

(8) Fixed shape - Fortunately, half-bloods are unable to twist and stretch their body parts. This is thanks to their human side kicking in, and hemoglobin being pumped around the body. Pyrotoxinum in most cases, is quite dormant. It is only activated when half-bloods use hemomancy, in fight/flight/freeze mode and possibly more!

Bonus: Short comparison between HALF-bloods and TWILIGHT vampires

(B - Both , H - Halfbloods , T - Twilight , TBD - To Be Decided)

Do they have sparkling skin in sunlight? - T

Superhuman Beauty - B, but it is not as potent as the Twilight vampires in my honest opinion.

Superhuman Strength, Speed, Senses, and Stamina? - B

Invulnerable? - T

Diamond-Hard Skin? - T. But I'd argue that falls under pure-bloods lol

Thirst for Blood? - T

Superficial Sleep? - T

No Religious Restrictions? - B

Enhanced Emotions? - TBD

Vulnerable to Fire? - T

Decapitation? - B

Bloodlust? - DEF B

Covens? - T. I wouldn't describe their family-like groups as covens, but as cliques? I don't have a full on name for it as yet...

Mate Bonds? - T

Transformation? - TBD, but I think transformation would be more suited to pure-bloods.

<>

If you're curious about anything stated here, feel free to blast my inbox (lol)!

Once again thank you for the amazing ask @mylovelyhorror ! I hope you all continue sending your asks - thirsty, unthirsty, romantic, or just pure fluff! MWAH 💋💋💋 trust me guys i'm not dead i swear

#karma#karma ask#karma lore#lc#qc#aleese comments#yandere#male yandere#yandere blog#yandere oc#yancore#yandere x reader#yandere x you#yan#yanblr#yan blog#yanderes#yandere tendencies#yande.re#yandere male#yandere boyfriend#yandere x darling#yandere boy#yandere community#yandere thoughts#yandere bf#tw yandere#soft yandere#yandere darling#yandere x male darling

62 notes

·

View notes

Note

So in my fantasy setting, magic not only doesn't work on iron, but applying it immediately nullifies any spell upon contact. This means that iron, in a setting with a lot of beings made of magic, is the one universal weakness that can easily kill them. Naturally, considering the fact that we're talking about a world overrun with them that are not afraid to eat people, this means societies tend to form around veins of iron ore (that's the right word, vein, right?) and are naturally going to be much more inclined to crafting iron weapons to deal with the magical beings wanting to eat people.

However, it was in thinking through that only pure iron weapons are what give iron its power that I run into issues. Considering that means steel is effectively blocked off when it comes to weapon making and magical enchantments don't work on iron here (though they do work on other kinds of metal), how exactly might that impact the tech tree on weapons in my setting? As well as anything else I might not have thought of when writing this? Thank you!

I poked at a similar thought process awhile back, and there's some problems I never fully worked around.

The problem with, “iron, but not steel,” is that, when you really get down to it, steel is just purer iron.

Let me put this another way, you're wandering around in a fantasy world that is geologically similar to our own, with similar metallurgy to 12thcentury Europe. An iron weapon you find will be mostly iron with some trace amounts of other metals such as nickle, copper, and whatever else didn't get filtered out.

In contrast, if you get your hands on a steel weapon, that's going to be almost exclusively iron, with a little carbon, maybe some phosphorus or sulfur. (There's a fairly long list of elements you can find in trace quantities, but this is also true of normal iron weapons.) The important thing to understand is, iron weapons are made from iron, steel weapons are made from better iron.

Even as far back as the first millennium, some smiths were intentionally purifying their iron to produce higher quality weapons (including the first super alloys, such as Damascus steel.) But, it was still iron.

Really, the one kind of iron you're likely to find in that world that isn'talmost exclusively iron would be meteoric iron. This is, as the name implies, iron that came from a meteor strike. In these cases, you're actually looking at a significant amount of nickle (usually 5-10%), along with a bit of cobalt and traces of a mix of other elements.This stuff was used in weapon making, but was extraordinarily rare. As a weapon, meteoric iron isn't incredibly useful, it's still inferior to steel weapons, but it will resist corrosion, and can make for a very showy weapon. This, in turn, can result in a weapon that appears to be somewhat magical, and may be while, “starmetal,” “starsteel,” or meteoric iron is a semi-popular material for magical weapons.

So, if the issue is iron itself, then there's no chemical reason steel shouldn't also function. Of course, that does nothing to eliminate potential mystical or supernatural explanations, but if this is a magical vulnerability, you're not going to find an answer in chemistry.

This leads to two possibilities. I'm going to use orichalcum as an arbitrary example, if you're unfamiliar, this was a metal Plato claimed was mined on the isle of Atlantis, and was the foundation for their economy, but you'll frequently find this brought up in fantasy without any connection to that original context.

So, either your world is one where human on human violence is conducted with something other than (and superior to) iron and steel, for example: Orichalcum, and that creates a situation where using steel weapons could actually put fighters at a disadvantage against properly equipped troops.

Alternatively, it's possible that, while iron and steel are marginally effective against monsters, there are other, much rarer, possibly irreplaceable, materials that are far more effective. In this example, it's possible that there are no sources of raw orichalcum remaining in the world, and the artifacts that have been mined and forged are all that is left. To make matters worse, it's possible that no living smiths have the knowledge to forge (or reforge) these weapons, meaning that any damage to these items is irreparable.

For an amusing twist on this, if titanium was the metal needed to harm monsters, that would create serious issues. The problem is, you cannot mine titanium. It's impossible (at least on Earth.) This is because titanium does not naturally occur as a metal, and only as an oxide (a white powder), and it wasn't until 1910 that the first metallic titanium was produced in a lab. It would be over 20 years before a process was discovered to produce it on an industrial grade. If your setting is built off of a distant apocalypse, it's possible there would be weapons produced from this material, but there would be absolutely no way to get more, while still having a veneer of chemical plausibility. (Alternately, it's possible some alchemist in the past developed a method to produce titanium in your setting... and they may or may not still be around, with the weapons being extremely difficult to produce, or signs of a lost technology.)

Actually, a fun side note, chemistry comes from the same root as alchemy, and it's a case where a pseudo-mystical field transitioned into a hard science over time.

Now, don't consider this part an indictment, but, a couple years back, I remember watching someone's, how-to: world-building on YouTube, and they blasted the concept of the, “trade city,” as semi-nonsensical. The issue is that basically any city will get its start based on trade, and really, cities live and die based on their economies. So, when you say, “this city started as a trade city,” yeah, that's how you get a city. It's the rare cities that are founded for some other reasons (like a massive fortress that gradually accumulated a civilian population of people fleeing from beyond its walls, and adventurers or crusaders using it as a last stop before moving on into the wastes, with the city, and its trade economy growing due to factors unrelated to its usefulness as a trade port.)

Now, if you're wondering how this is relevant to your question, this is about the distribution of iron. There's some discrepancies between the largest iron deposits in the real world and the distribution of people, but access to iron was a critical consideration in the development of Western Europe. Or, put another way, if you have iron mines in the hills, but farmland and a river in the lowlands, you'll probably build your city in the lowlands, on the banks of the river, and then export whatever iron and food you don't need in exchange for other goods that you do find useful. It doesn't, really, matter much if there are ravenous hellbeasts wandering the foothills, if you can dispatch them with iron weapons. All that really means is you'll have slightly less iron to export. This creates a situation where settlements may range pretty far the iron mines, if there are other economic resources worth extracting. Trade would more heavily favor access to iron than in real world history, but it's not a completely alien scenario. In some ways, this isn't that different from a continent in a permanent state of total war, the only difference is that the monsters don't need their own iron supply lines. Settlements would need to be guarded, mines, farms, and other resources would also need protection. Trade lines would need guards. The overall level of fortification may be higher than in real history (though, this isn't a certainty), but a lot of the same considerations wouldn't be affected.

Now, on a grand scale, persistent hunting by supernatural monsters would amount to a greater economic drain than witnessed in real world history. This would slow some technological, and economic growth. I'd say that cities would, likely, be more fortified, but when looking at medieval cities, I'm not sure that would be the case. I'm also not certain this would meaningfully shift the balance of power (assuming an alternate history), simply because those monsters would hit everyone roughly equally. (Though, if the monsters do play favorites, that could heavily skew the balance of power.) While access to iron would be critical, access to other trade goods such as salt, clay, grains, and other things would still be useful. The best iron mine in the world won't keep your troops fed on its own.

I doubt you'd see a situation where iron became the dominant currency metal, and too valuable to waste on coinage. You would probably still see gold and silver as the dominant metal coinage, and that would also result in some geographical skewing, as there would be some settlements built around mining gold or silver, and then selling those materials to others in exchange for iron. It's also worth remembering that for a large part of the middle ages, most coin based transactions took place at the upper echelons of society. The barter economy would still be going strong in most fantasy settings. When talking about roleplaying game settings, that does get a bit warped, as players tend to swing around extraordinary amounts of wealth.

The biggest changes I'd expect would be slightly more terra nullius. If the plains between two mountains have no mineral wealth, and the mines on either side are already well supplied, there wouldn't be much reason to settle there. You might also see a move away from river travel. Historically, this was an extremely efficient way to move large amounts of resources, but if there are monsters in the water that pose a real threat to brown water shipping, that could cause some significant changes. Settlements might be more isolated from one another initially, until technological development got to the point where overland shipping (by cart) became more viable. It might also reduce the scope of trade overall, meaning situations like the gold mining settlement above, wouldn't be able to import enough food and iron to be viable. This might also inflate the value of other, secondary, goods. For example, access to limestone deposits large enough to effectively quarry, might become a defining factor on where fortified settlements can be built. If there isn't enough limestone on site, there simply might not be a way to effectively transport more. Even if it was only 20 miles from the settlement.

At the end, how much would it change the world? I don't know. There's a lot of factors which could heavily skew how the world shakes out. It could be almost non-existent, or it could be an entirely alien world. It depends on how much pressure your monsters apply to the world.

-Starke

This blog is supported through Patreon. Patrons get access to new posts three days early, and direct access to us through Discord. If you’re already a Patron, thank you. If you’d like to support us, please consider becoming a Patron.

306 notes

·

View notes

Text

Laser technique uncovers how titanium's electron behavior influences its physical properties

A research team at Yokohama National University has developed a way to study how the orientation and behavior of electrons in titanium influence its physical characteristics. Their findings, published in Communications Physics on December 18, 2024, could pave the way for the development of more advanced and efficient titanium alloys. Titanium is a very valuable metal because of its remarkable resistance to chemical corrosion, lightweight nature, and high strength-to-weight ratio. Its biocompatibility makes it ideal for medical applications, such as implants, prosthetics, and artificial bones, while its strength and durability are useful in aerospace and precision manufacturing. To get an idea of how titanium's atoms and electrons generate these properties, the researchers used a process called high harmonic generation.

Read more.

#Materials Science#Science#Lasers#Titanium#Electrons#Materials characterization#Computational materials Science#Yokohama National University

22 notes

·

View notes

Text

Zirconium is a soft metal, but very resistant to certain forms of chemical corrosion. Zirconium dioxide is usually used for crucibles, furnaces, and dental ceramics, but when it's in cubic crystal form it's used as a substitute for diamonds in jewelry.

21 notes

·

View notes