#Stainless Steel 304

Explore tagged Tumblr posts

Text

Durable and Corrosion-Resistant Stainless Steel 304 Pipe Fittings for Reliable and Efficient Fluid Handling in Diverse Industrial Applications

Our Stainless Steel 304 Pipe Fittings provide reliable and corrosion-resistant connections for various piping systems. Suitable for applications such as food processing, chemical processing, and water treatment, these fittings ensure a precise fit and long-lasting service. Available in multiple sizes and configurations, they meet the demands of projects requiring efficient fluid handling solutions.

#Stainless Steel 304#Pipe Fittings#Corrosion Resistance#Piping Systems#Food Processing#Chemical Processing#Water Treatment#Precise Fit#Long-Lasting Service#Fluid Handling Solutions

0 notes

Text

0 notes

Text

One of the key properties of stainless steel 304 grade is its corrosion resistance. It is highly resistant to corrosion from most oxidizing acids, organic acids, and chloride solutions, making it suitable for a wide range of applications in various industries, including food and beverage, medical, and chemical processing.

1 note

·

View note

Text

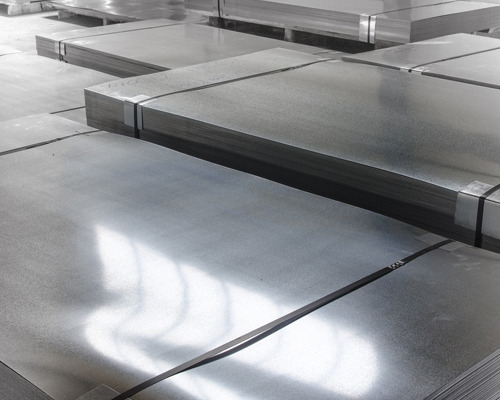

Benefits of Stainless Steel 304/304L Coils

Stainless Steel 304/304L Coils are widely utilized in various industries due to their exceptional properties. At Shree Venktesh Wires and Steels Pvt Ltd, we are the leading SS 304/304L Coil suppliers in India, as well as being stockists and exporters of Stainless Steel 304/304L Coils in India, Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany.

In this blog post, we will explore the benefits of Stainless Steel 304/304L Coils and how they can be useful in different industries.

Stainless Steel 304 Coils

Stainless Steel 304 Coils are a type of stainless steel product that is composed of 18% chromium and 8% nickel. These S30400 coils are highly resistant to corrosion, making them ideal for use in harsh environments such as the chemical and food industries. They are also known for their excellent mechanical properties, making them easy to form and weld. Stainless Steel 304 Coils are widely used in various industries due to their versatility, reliability, and sustainability.

Stainless Steel 304L Coils

Stainless Steel 304L Coils are a type of stainless steel product that is similar to SS 304 Coils but with lower carbon content. The lower carbon content in SS 30403 Coils helps to reduce the formation of harmful carbides during welding, making them suitable for welding applications. These SS 30403 Coils also exhibit excellent corrosion resistance, high-temperature strength, and good formability. They are widely used in various industries, including chemical processing, food processing, and medical equipment manufacturing, due to their excellent properties and versatility.

Properties of Stainless Steel 304/304L Coils:

Corrosion resistance is superior to other steels in various Steel

Excellent low-temperature performances

Good welding characteristics

Post-weld annealing is not normally required

Heat resistant performances

Hot workability such as punching or bending

The material used in this stainless steel does not harden during the heat treatment (non-magnetic, uses temperatures -196°C and 800°C)

Applications of Stainless Steel 304/304L Coils:

Due to their exceptional properties, Stainless Steel 304/304L Coils find a wide range of applications in different industries.

Energy and Heavy Industries Such as Oil and Gas, Electrical steel (Silicon Steel)

Solar Board.

Power Plant.

Heat Exchangers, Boilers

Chemical Storage Vessels

Automotive and Transportation

Architectural and Construction

Marine Building

Medical Equipment

Food Machine Manufacturing, Food, and Catering, and many more.

Advantages of Stainless Steel 304/304L Coils:

The durability, high strength-to-weight ratio, aesthetic appearance, ease of fabrication, and recyclability of SS 304/304L Coils make them an ideal choice for various applications. We will discuss these advantages in detail and explain how they can benefit different industries.

Cost-effectiveness of Stainless Steel 304/304L Coils:

They may be more expensive than other materials, but their long-term cost savings make them a cost-effective choice. We will compare the cost of SS S30400/S30403 Coils with other materials and explain why they can be a more economical option in the long run.

Maintenance of Stainless Steel 304/304L Coils:

To ensure the longevity of these coils, proper maintenance is required.

Safety and Health Benefits of Stainless Steel 304/304L Coils:

They offer several safety and health benefits, making them an ideal choice for various applications.

Sustainability of Stainless Steel 304/304L Coils:

They are environmentally friendly and sustainable. We will explore how they contribute to sustainability and compare them with other materials. Additionally, we will discuss the environmental benefits of SS 304/304L Coils.

Limitations of Stainless Steel 304 Coils:

Moreover, they also have some limitations that need to be considered before using them in certain applications.

Chemical Composition of Stainless Steel 304 / S30400 & DIN 1.4301 Coils

C - 0.08 max

Mn - 2.00 max

Si - 1.00 max

P - 0.045 max

S - 0.03 max

Cr - 18.0 - 20.0

Ni - 8.0 - 10.5

Fe - Balance

Chemical Composition of Stainless Steel 304L / S30403 Coils

C - 0.03 max

Mn - 2.00 max

Si - 1.00 max

P - 0.045 max

S - 0.03 max

Cr -18.0 - 20.0

Ni - 8.0 - 10.5

Fe - Balance

Conclusion:

Stainless Steel 304 & 304L Coils offer a wide range of benefits and find numerous applications in various industries. At SV Stainless Steel, we are committed to providing high-quality Stainless Steel 304 & 304L Coils to our clients. We hope this blog post has helped you understand the benefits of SS304 & 304L Coils and how they can be useful in different industries.

If you have any questions or would like to learn more about our products, please do not hesitate to contact us.

0 notes

Text

SS 304 Flange: Features, Applications, and Price List

The SS 304 flange is a key component in the world of industrial piping, offering outstanding durability, corrosion resistance, and strength. Whether you're managing a large-scale industrial project or a smaller application, SS 304 flanges play a vital role in ensuring secure and leak-proof connections. In this article, we will explore the features, applications, and pricing of SS 304 flanges, along with the latest SS 304 flange price list. At Udhhyog, we provide high-quality SS 304 flanges at competitive prices to meet all your project needs.

What is SS 304 Flange?

SS 304 flange refers to a flange made from Stainless Steel 304, an austenitic steel known for its excellent corrosion resistance, strength, and versatility. Grade 304 stainless steel is composed of 18% chromium and 8% nickel, making it highly resistant to rust and other forms of corrosion in both mild and harsh environments.

Flanges are used to connect pipes, valves, pumps, and other equipment in piping systems, ensuring a secure seal and facilitating easy assembly, disassembly, and maintenance. The SS 304 flange is one of the most commonly used types of stainless steel flanges in industries like oil and gas, chemical processing, food production, and water treatment.

Key Features of SS 304 Flanges

Corrosion Resistance The high chromium and nickel content in SS 304 flanges makes them resistant to corrosion from chemicals, moisture, and gases, making them ideal for both indoor and outdoor applications.

Heat Resistance SS 304 flanges can withstand high temperatures, making them suitable for steam lines, hot water systems, and other high-temperature applications.

Strength and Durability SS 304 flanges offer excellent mechanical strength, ensuring reliable performance even under high pressure. They are durable, long-lasting, and require minimal maintenance.

Ease of Fabrication These flanges are easy to weld and machine, allowing for customization based on specific project requirements. Whether you need special dimensions or configurations, SS 304 flanges are highly adaptable.

Versatility From chemical plants to marine environments, SS 304 flanges are used in a wide range of industries due to their resilience and ability to perform in extreme conditions.

Applications of SS 304 Flanges

SS 304 flanges are used in various industrial sectors, including:

Chemical Processing: With their ability to withstand corrosive chemicals and extreme temperatures, SS 304 flanges are frequently used in chemical plants and processing facilities.

Food and Beverage Industry: The sanitary properties of SS 304 make it a popular choice for food processing and packaging systems.

Oil and Gas Industry: The durability and resistance to corrosion make SS 304 flanges ideal for pipelines in the oil and gas sector.

Water Treatment: In water treatment plants, where corrosion and exposure to water are constant, SS 304 flanges provide reliable, long-lasting performance.

Pharmaceutical Industry: These flanges are suitable for pharmaceutical applications due to their hygienic properties and resistance to contamination.

Factors Influencing SS 304 Flange Prices

When considering the price of SS 304 flanges, several factors can affect the cost. Here's what you should consider:

Material Costs Fluctuations in the price of stainless steel raw materials, especially nickel and chromium, can impact the price of SS 304 flanges.

Size and Type of Flange Larger flanges or those with specialized designs (such as weld neck, slip-on, or blind flanges) are typically priced higher due to the additional material and labor required for production.

Surface Treatment and Finishing Flanges with additional surface treatments, such as polishing or galvanization, may have a higher price, especially if intended for use in corrosive environments.

Manufacturing Precision SS 304 flanges that undergo precision manufacturing processes, such as forging or CNC machining, are generally priced higher, but they offer superior performance and quality.

Quantity Bulk purchases usually offer better pricing. At Udhhyog, we provide attractive discounts for bulk orders, making our flanges more affordable for large-scale projects.

Market Demand Market conditions and demand for stainless steel products can also affect the price of SS 304 flanges.

SS 304 Flange Price List

Here’s a general price overview for common sizes of SS 304 flanges:

1 inch SS 304 flange: ₹300 to ₹650 per piece

2 inch SS 304 flange: ₹400 to ₹850 per piece

3 inch SS 304 flange: ₹600 to ₹1,400 per piece

4 inch SS 304 flange: ₹900 to ₹2,100 per piece

6 inch SS 304 flange: ₹1,600 to ₹3,500 per piece

Please note that these prices are subject to change based on market trends, material costs, and supplier terms. For an accurate and up-to-date SS 304 flange price list, we encourage you to contact Udhhyog directly.

Why Choose Udhhyog for SS 304 Flanges?

At Udhhyog, we are committed to providing high-quality SS 304 flanges at the most competitive prices. Here’s why businesses trust us:

Superior Quality: Our flanges are manufactured using premium-grade SS 304 stainless steel, ensuring maximum durability and performance.

Affordable Prices: We offer some of the most competitive prices in the market, along with bulk purchase discounts.

Customization: We can customize the dimensions and finishes of flanges to meet your project’s specific requirements.

Strict Quality Control: All our flanges undergo rigorous quality checks to ensure they meet industry standards for performance and safety.

Timely Delivery: Our streamlined supply chain ensures that orders are delivered on time, helping you stay on schedule.

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

5 Factors to Consider When Choosing a 304 Stainless Steel Tube Supplier

2 notes

·

View notes

Text

0 notes

Text

Latest Stainless Steel 304 Price Per Kg | Steel Tube Co.

Stainless Steel 304 is one of the most commonly used stainless steel grades due to its excellent corrosion resistance, durability, and versatility. The SS 304 price per kg varies based on market demand, raw material costs, and supplier rates. At Steel Tube Co., we offer competitive and updated SS 304 price per kg for sheets, plates, pipes, and rods. Whether you need bulk or retail quantities, we provide high-quality stainless steel at the best rates.

Visit our website SteelTube.co.in today for the latest SS 304 price per kg in India and get customized quotes. Fast delivery and best deals available!

0 notes

Text

Trusted Stainless Steel 304L Sheet Supplier for High Performance | Bhagya Laxmi Industrial

Bhagya Laxmi Industrial is a depended on call for extremely good stainless steel products in Saudi Arabia. We focus on supplying durable and corrosion-resistant Stainless Steel 304L Sheet for numerous industries, ensuring reliability and energy. Our sheets are ideal for production, chemical processing, and marine packages.

As a leading Stainless Steel 304 Sheet Manufacturer, we awareness on precision and pleasant. Our superior production technique ensures that every sheet meets enterprise requirements, supplying tremendous sturdiness and overall performance. We offer sheets in different sizes and finishes to in shape your needs.

Being a reputed Stainless Steel 304L Sheet Supplier we guarantee well timed shipping and aggressive pricing. Our sheets are made with advanced uncooked substances, ensuring lengthy-lasting performance in difficult environments. Contact us today for the satisfactory chrome steel answers.

0 notes

Text

Information

The Instant Pot Duo 7-in-1 Mini is a versatile and compact kitchen appliance designed to replace multiple cooking devices, making meal preparation quicker and more convenient. This 3-quart version is perfect for small households, individuals, or those who need a secondary cooker for side dishes, travel, or RVs. Features

✅ 7 Cooking Functions in One Device

Pressure Cooker: Cooks food up to 70% faster than traditional methods.

Slow Cooker: Perfect for tenderizing meats and making stews.

Rice Cooker: Cooks white, brown, or multigrain rice effortlessly.

Steamer: Steams vegetables, seafood, and more.

Sauté Mode: Allows you to brown meats or sauté vegetables before pressure cooking.

Yogurt Maker: Ferments milk into creamy homemade yogurt.

Warmer: Keeps food warm until ready to serve. ✅ Compact 3-Quart Size

Ideal for 1-3 people or for making smaller portions.

Fits well in small kitchens, dorm rooms, RVs, and campers. ✅ Stainless Steel Inner Pot

Made from food-grade 304 stainless steel with a tri-ply bottom for even heating.

No chemical coatings – safe and durable.

Dishwasher-safe for easy cleaning.

✅ Smart Programs for Easy Cooking

13 one-touch smart programs for cooking soups, rice, beans, poultry, and more.

Customizable settings allow adjustments for different recipes. ✅ Safety Features

10+ built-in safety mechanisms, including overheat protection, a safety lock, and an anti-blockage vent for worry-free cooking.

✅ Energy Efficient & Fast Cooking

Reduces cooking time by up to 70%, saving energy and preserving nutrients. ✅ Free Instant Pot App

Access over 1,900 recipes via the Instant Pot app, available for iOS and Android.

What's Included

Instant Pot Duo Mini 3-Quart Cooker

Stainless Steel Inner Pot

Steam Rack with Handles

Sealing Ring

Condensation Collector

Recipe Booklet & User Manual Ideal Uses

Meal prepping for individuals or couples

Making side dishes or desserts

Cooking in small spaces like dorms or RVs

Experimenting with different cooking techniques in a single appliance

Product Specifications:

Capacity: 3 Quarts

Material: Stainless Steel (inner pot)

Power: 700W

Dimensions: Approx. 11.4 x 10 x 11.2 inches

Weight: 8.65 lbs

The Instant Pot Duo 7-in-1 Mini is a fantastic addition to any kitchen, combining convenience, safety, and versatility in a compact size. Whether you’re a beginner or an experienced cook, this multi-functional appliance makes cooking faster and easier!

#Information#The Instant Pot Duo 7-in-1 Mini is a versatile and compact kitchen appliance designed to replace multiple cooking devices#making meal preparation quicker and more convenient. This 3-quart version is perfect for small households#individuals#or those who need a secondary cooker for side dishes#travel#or RVs.#Features#✅ 7 Cooking Functions in One Device#Pressure Cooker: Cooks food up to 70% faster than traditional methods.#Slow Cooker: Perfect for tenderizing meats and making stews.#Rice Cooker: Cooks white#brown#or multigrain rice effortlessly.#Steamer: Steams vegetables#seafood#and more.#Sauté Mode: Allows you to brown meats or sauté vegetables before pressure cooking.#Yogurt Maker: Ferments milk into creamy homemade yogurt.#Warmer: Keeps food warm until ready to serve.#✅ Compact 3-Quart Size#Ideal for 1-3 people or for making smaller portions.#Fits well in small kitchens#dorm rooms#RVs#and campers.#✅ Stainless Steel Inner Pot#Made from food-grade 304 stainless steel with a tri-ply bottom for even heating.#No chemical coatings – safe and durable.#Dishwasher-safe for easy cleaning.

0 notes

Text

Rajpushp Metal – Precision, Strength, and Reliability in Every Product

At Rajpushp Metal, we are committed to delivering top-quality stainless steel solutions for industries worldwide. Our expertise in manufacturing premium-grade stainless steel 304 flanges and other industrial components makes us a trusted name in the market.

Why Choose Rajpushp Metal?

🔹 Uncompromising Quality – Every product meets stringent industry standards. 🔹 Tailored Solutions – We provide custom sizes and specifications to fit your needs. 🔹 Global Reach – Supplying industries across oil & gas, petrochemicals, food processing, and more. 🔹 Customer-Centric Approach – Dedicated to timely delivery and exceptional service.

With Rajpushp Metal, you get more than just a product—you get a promise of durability and efficiency.

📩 Get in Touch: https://rajpushpmetal.com/ 📞 Call Us: +91-98706 86118

#stainless steel 304 flanges#ss 430 stainless steel#stainless steel manufacturers in mumbai#ss pipe fittings manufacturer in india

0 notes

Text

Jay Steel Corporation- Stainless Steel 304 Round Bar Exports to Kuwait

Jay Steel Corporation is a trusted name in the global export of remarkable stainless steel products, which includes stainless steel 304 round bar exports to Kuwait. With certifications along with ISO 17025, ISO 2020-2021, and the Pressure Equipment Directive (EU), we preserve the best requirements in production. We offer various stainless steel products that meet every countrywide and international quality norm, like ASTM, BS, IS, DIN, ASME, ANSI, MSS, and greater. Whether you're in Kuwait or everywhere else, we are your dependable accomplice for superior stainless steel round bars.

Why Choose Jay Steel Corporation for Stainless Steel 304 Round Bar Exports to Kuwait?

We are devoted to turning in products that meet your precise desires. Our SS 304 round bars are perfect for numerous business applications, thanks to their sturdiness, power, and corrosion resistance. Here's why we're the renowned supplier of Stainless Steel 304 Round Bar Exports to Kuwait:

1. Top-Quality SS 304 Round Bars

Our SS 304 Round Bars are manufactured from top-quality substances, making sure of power and long-lasting performance. Stainless Steel 304 is understood for its superb resistance to corrosion, making it appropriate for pretty a few programs, from creation to production and beyond. Our corporation guarantees that every round bar meets stringent, exquisite standards and is made to cope with annoying environments.

2. Certifications and Compliance

We are ISO 17025, ISO 2020-2021, and Pressure Equipment Directive (EU) licensed, making sure that our Stainless Steel 304 Round Bars are synthetic to the very exceptional worldwide necessities. We moreover hold certifications from the Federation of Indian Export Organizations (FIEO), showcasing our commitment to exceptional customer delight. These certifications ensure that the stainless steel products we export to Kuwait are reliable and of outstanding quality.

3. Custom Solutions for Kuwait

We apprehend that special industries and customers have particular requirements. We offer customized SS 304 Round Bars custom-made to the specific dimensions and finishes desired in your initiatives. Whether you require a small quantity or huge bulk orders, we are able to accommodate your needs and deliver exactly what you’re seeking.

Why is Stainless Steel 304 Popular in Kuwait?

Kuwait’s challenging weather and commercial landscape call for materials that could face immoderate environmental conditions. Stainless Steel 304 is a brilliant choice because of its extraordinary corrosion resistance, mainly in environments with high moisture or saline exposure. This makes it a favoured material for industries such as creation, infrastructure, and oil and gasoline in Kuwait.

Stainless Steel 304 Round Bars are long-lasting and dependable, presenting the power required for structural applications, piping, and more. Their versatility in harsh conditions is one of the reasons why businesses in Kuwait accept as true with this material for their obligations.

4. Reliable and Timely Exports to Kuwait

We are aware of how important being on time is to the business. We guarantee the timely and optimal condition of our stainless steel 304 round bars. No matter where you live in Kuwait, your order will arrive without any delays thanks to our seasoned export system and trustworthy shipping partners.

Benefits of SS 304 Round Bars

1. Corrosion Resistance

The advanced corrosion resistance of SS 304 makes it first-class to be used in harsh environments, inclusive of those placed in Kuwait. This function permits it to resist moisture, chemical compounds, and severe temperatures without deterioration.

2. Durability and Strength

Stainless Steel 304 Round Bars provide splendid power, ensuring that they can cope with heavy-duty applications. Whether utilized in advent or equipment, these bars are built to last.

3. Versatility in Applications

These round bars are utilized in a wide range of industries, from structural programs to production tactics. Their adaptability and strength cause them to be essential for several duties.

4. Aesthetic Appeal

In addition to their sensible benefits, SS 304 Round Bars additionally provide an aesthetically attractive polished stop that is often desired in architectural and layout applications.

Why Buy Stainless Steel 304 Round Bars from Our Corporation?

Choosing us for your Stainless Steel 304 Round Bar Exports offers numerous benefits:

ISO Certified: Our certifications guarantee top-notch manufacturing and reliable merchandise.

Custom Solutions: We provide tailored products to suit your task specs.

Timely Deliveries: Our streamlined export method ensures punctual deliveries to Kuwait.

Wide Range of Products: We provide pretty a few stainless steel products, catering to one-of-a-kind industries.

Conclusion: Your Trusted Partner for Stainless Steel 304 Round Bar Exports to Kuwait

As a leading provider of Stainless Steel 304 Round Bar Exports to Kuwait, we guarantee you get the best, most notable product that meets global standards. With a commitment to the best, timely delivery, and client satisfaction, we are the preferred issuer for industries in Kuwait and around the sector.

Contact Jay Steel Corporation nowadays for a free session and permit us to help you supply excellent stainless steel products for your business needs.

0 notes

Text

304 Stainless Steel Fasteners | S30400 bolt

When it comes to fastening solutions for industrial, marine, and architectural applications, 304 stainless steel fasteners stand out as a top choice. These fasteners, often recognized by their UNS designation S30400, are a versatile and reliable option that combines strength, corrosion resistance, and aesthetic appeal.

What is 304 Stainless Steel?

304 stainless steel, commonly known as 18/8 stainless steel, is an alloy primarily composed of 18% chromium and 8% nickel, with a balance of iron and trace elements. Its properties make it a widely used material in various industries, especially for fasteners.

Key properties include:

Corrosion Resistance: Excellent resistance to rust and oxidation, even in harsh environments.

Strength: High tensile and yield strength for demanding applications.

Non-Magnetic: Typically non-magnetic in annealed conditions.

Ease of Fabrication: Good weldability and machinability.

Types of 304 Stainless Steel Fasteners

Bolts: Available in various sizes, including hex bolts, carriage bolts, and U-bolts.

Nuts: Hex nuts, lock nuts, and flange nuts complement bolts for secure fastening.

Screws: Options include self-tapping screws, machine screws, and wood screws.

Washers: Flat and spring washers provide additional stability and load distribution.

Threaded Rods: For structural and machinery applications requiring extended fastening.

Applications of S30400 Bolts

Due to their excellent properties, S30400 bolts find use in industries such as:

Construction: Structural frameworks, bridges, and roofing systems.

Marine: Boats, docks, and other equipment exposed to salty water.

Automotive: Components requiring long-term durability.

Food Processing: Equipment and machinery that require hygiene and corrosion resistance.

Chemical Processing: Fasteners in mildly corrosive environments.

Advantages of Choosing 304 Stainless Steel Fasteners

Corrosion Resistance: Perfect for outdoor or high-humidity environments.

Versatility: Suitable for diverse industrial and commercial applications.

Aesthetic Appeal: Smooth and shiny surface finish enhances the appearance of projects.

Cost-Effective: Offers a long service life, reducing maintenance and replacement costs.

Recyclability: A sustainable option that aligns with environmental goals.

Care and Maintenance

While 304 stainless steel fasteners are highly resistant to corrosion, certain factors can influence their longevity. Follow these tips for optimal performance:

Avoid exposure to chlorides or clean with a mild solution to prevent pitting.

Use a protective coating for environments with high salinity.

Regularly inspect and clean to remove dirt or chemical residues.

Why Choose 304 Stainless Steel Fasteners for Your Next Project?

Whether you're working on a small DIY project or a large-scale industrial installation, 304 stainless steel fasteners offer a dependable solution that balances durability, strength, and aesthetics. Their superior performance in challenging environments makes them a go-to choice for engineers, architects, and builders worldwide.

1 note

·

View note