#ardiuno

Explore tagged Tumblr posts

Text

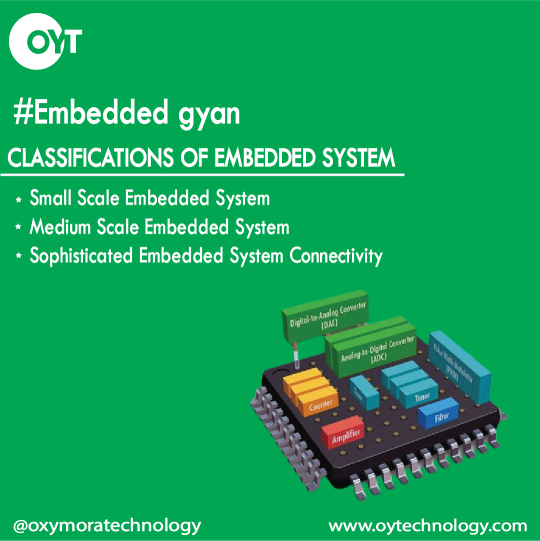

Embedded system is classified in 3 categories as given above in poster for an easy study of vast system.

#embedded_gyan#embedded_gyaan#embeddedgyan#embeddedgyaan#hardware#software#libraryfiles#ardiuno#uploadcode#ardiunonano#ardiunouno#embeddedknowledge#embeddedsystem#embeddedtech#AVR#embeededsoftware#embeeddedtechnology#embeddedsystems#embeddedreporter#embeddedworld#embeddedsoftware#embedded_system#ufcembedded#embeddedc#embeddedprogramming#embedded_systems#embeddedflowers#embeddedcomputing#embeddedtechnology

1 note

·

View note

Video

tumblr

3D model of Skittle Sorter

0 notes

Photo

Pet şişeden araba yapma 🚗 . . #Oyunlarlafen #stem #stemislab #anaokulukodlamaeğitimi #robotik #ardiuno #lehim #lcd #matematica #robotica #kodlama #robotikodlama #robotics #robotic #adana #mersin https://www.instagram.com/p/B2HGSXzA1o7/?igshid=1fycee7qr273q

#oyunlarlafen#stem#stemislab#anaokulukodlamaeğitimi#robotik#ardiuno#lehim#lcd#matematica#robotica#kodlama#robotikodlama#robotics#robotic#adana#mersin

0 notes

Photo

Laver et sytem som gør planten vander sig selv når den vand % er lav

0 notes

Video

instagram

Want your #child to #learn about #robotics #signup now for a #free trial class today @iplaytek #legorobotics #minecraft #girlsintech #brooklynkids #queenskids #mommy #manhattan #glendale #middlevillage #astoria #funtolearn #nyc #tinkering #stemcamp #education #womenowned #womenentrepreneur #tnutts48 #knutts48 #ardiuno #art #music #creative #dream (at iPlayTek)

#learn#child#education#astoria#middlevillage#ardiuno#funtolearn#mommy#nyc#manhattan#queenskids#creative#robotics#signup#womenowned#glendale#womenentrepreneur#art#knutts48#music#legorobotics#brooklynkids#free#tnutts48#girlsintech#minecraft#stemcamp#dream#tinkering

1 note

·

View note

Text

@flowers-of-io

1. Rok 3035

2. Świadek jest w posiadaniu piramidy z ciemnością o zasięgu 40 000 km.

3. 'Uczniu Calusie, cel ostatnie miasto'

4. czerwonyguzik.gif

5. Umierający z niedożywienia sługa źle podłączył klona ardiuno.

6. Rakieta leci w drugą stronę.

7. Cel: farma ems.

8. Ostatnie Miasto dalej nie dało tarczy.

9. Rakieta w zasięgu radarów.

10. Trzeba ostrzec mieszkańców.

11. syrena.wav

12. 'GRAZYNA WYŁONCZ FAMILJADE JAKIEŚ ŚWIENTO JEST STÓJ NA BACZNOŚĆ MINUTA CISZY'

13. mielone.jpg

14. Straty oszacowano na 32 migotu

#destiny 2#destiny the game#polski#przeznaczenie posting sekcja twojego starego niebieskiego (miesiąc ''bardziej tego mówcę żółtego zrób")

8 notes

·

View notes

Note

Ardiuno bilgim yok ama breadboard dersi almıştım devre şemanı bulursan ne yapacağımızı anlarız :D

gruba yazdım herkes internetten şema buldum anlamaya çalışıyorum dedi kafayı yicem

bunu attılar ama bildiklerimi de unuttum

3 notes

·

View notes

Text

IR remote control for the home - part 3

IR remote control for the home – part 3

In the previous two posts, we set up an ESP32 development board with an IR receiver to read codes sent by a remote control. Now it’s time to add MQTT capability.

I chose the PubSubClient library – available in the Arduino IDE library manager – because it claims compatibility with the ESP32. When I looked closer, it turns out that the degree of support for the ESP32 is, shall we say, disputed. But…

View On WordPress

0 notes

Text

Petits robots à fabriquer, 13 projets D.I.Y.

Petits robots à fabriquer, 13 projets D.I.Y.

J’ai reçu des éditions EYROLLES le livre « Petits robots à fabriquer » dans la collection « serial makers ».

résumé du livre : Vous avez toujours rêvé de pouvoir fabriquer un robot qui puisse se déplacer et répondre à vos ordres ? Ce livre très accessible exaucera votre souhait et bien plus encore, grâce à ces 13 projets de robots à monter à l’aide de composants électroniques courants et d’objets…

View On WordPress

0 notes

Text

Tech pirates

we are workig on a project to reduce electricity wastage and we will produce electricity by dynamos on speed brakers and in gym equipments to produce electricity. we have used a smart system on street lights as we have used ultra sonic sensors on roads. when ultra sonic sensors will sense a object on road then it will switch on the street lights otherwise the street lights would be switch off. even we have used home automation in which we have used an ardiuno component called nord mc which will connect to our smart phones with help of a app called blynk. then it will help us to on or off the electric appliances from any pointbof world.

1 note

·

View note

Text

We provided you the way how to connect hardware and software together in Embedded system. Do you want to know which platforms are used to interface?

#embedded_gyan#embedded_gyaan#embeddedgyan#embeddedgyaan#hardware#software#libraryfiles#ardiuno#uploadcode#ardiunonano#ardiunouno#embeddedknowledge#embeddedsystem#embeddedtech#AVR#embeededsoftware#embeeddedtechnology#embeddedsystems#embeddedreporter#embeddedworld#embeddedsoftware#embedded_system#ufcembedded#embeddedc#embeddedprogramming#embedded_systems#embeddedflowers#embeddedcomputing#embeddedtechnology

0 notes

Video

tumblr

Things are becoming smart nowadays and autonomous also. IoT devices don't need human intervention. The cameras on the road are automatic they don't need human things, sensors, and microcontrollers so it creates maximum jobs in good MNCs. To know about IoT Training in Delhi. Visit: https://shapemyskills.in/courses/iot-ardiuno-training/ or contact us @ +91-9873922226.

0 notes

Text

Iterations of the First Project 9

We discussed how our prototypes for the circuit cards were coming along. Angelica had made some more over the weekend. The horizontal one had some contact issues, but could still work. The vertical one was made with some stronger copper tape and worked better, it can work both horizontally and vertically. Over time the vertical one slowly gained contact issues as well.

Charles play tested the prototypes Angelica made, and found out that the different prototypes could be mixed together and still work.

We want to work with reasonably hard/thick plastic. What I had originally used as the prototype for my “expression cards”. Jordan and Tiger worked on soldering the RGB LEDs that we were looking at using. While Angelica and I were making more cards out of scrap plastic in the Mechatronics Lab.

Once we were finished, Angelica worked on some more prototypes. She found that the RGB LEDs can still run on the little batteries we’re using, and be easily connected, but they won’t have the easily flowing, dynamic colour range they would with an ardiuno. Jordan realised how impractical it would be to use the cool RGB LEDs. Soldering each one individually would take far to long, and be extremely difficult.

2 notes

·

View notes

Video

instagram

Learning robotics @iplaytek come join the fun today call 718-785-9323 #fun #fox5ny #ardiuno #kerbalspaceprogram #gamedesign #minecraft #lego #legorobotics #nyckids #queenskids #brooklynkids #flushing #kids #kidscode #bigkids #coding #women #mommy #mommypoppins #womenentrepreneur #womenownedbusiness #striveforgreatness #goforit #tnutts48 #knutts48 #krashae #abcny7 #cbs #3dprinting #birthdayparty #birthday #education #ibm #billgates #warrenbuffet #oprah #joeybats19 (at iPlayTek)

#bigkids#ibm#fox5ny#ardiuno#minecraft#striveforgreatness#kids#billgates#legorobotics#oprah#queenskids#women#mommy#fun#lego#kerbalspaceprogram#womenentrepreneur#gamedesign#birthday#joeybats19#abcny7#womenownedbusiness#3dprinting#flushing#cbs#education#coding#tnutts48#brooklynkids#nyckids

1 note

·

View note

Text

Why I couldn't learn a normal language like phyton or html, bitch what the fuck is Ardiuno

#solarin talks#Like wtffffffff#I mean I can work with an Arduino but that doen't help me at anything

0 notes

Text

Experiment #2 : The Icarus Servo

Experiment conducted 2021/03/02

In this experiment I actually tried a series of things. First I tried controlling the brightness of an LED with a potentiometer. When that didn't work, I replaced the LED with a servo motor instead. At the end, I replaced the potentiometer with a photoresistor to the servo. I attached it to the arm of the servo and attempted to create a program that would make the servo move the resistor towards the brightest light reading it could find. I like to call it the Icarus Servo!

Part 1: Potentiometer Controlled LED

How the Potentiometer Works

The potentiometer has three pins - two terminal pins and one wiper pin. The terminal pins connect to the live and ground wires. Internally, these terminals are connected to each other along a track. A wiper connects to the middle of the track, where its position along the track rotates with the potentiometer's dial. This essentially makes the two sides of the track variable resistors, and the whole track a potential divider circuit - whose signal can be read from the wiper pin. (Fun fact: Because of how the potentiometer works, it doesn't technically matter which way around you connect the terminals!) If you're curious about potentiometers, Jeff Feddersen has a clear and concise explanation on their website.

For this experiment, we can read the signal from the wiper pin into the Arduino, and then use code to output a voltage to the LED. More voltage means more light!

Components Used

This experiment uses the Arduino UNO R3 Project Starter Kit.

1 x UNO R3 Controller Board (the Arduino)

1 x Breadboard

Breadboard jumper wires

1 x Potentiometer

1 x LED

1 x 220Ω resistor

The Wiring

The Code

void setup() { pinMode(7, OUTPUT); // LED ouput Serial.begin(9600); } void loop() { int val = analogRead(A0); // Potentiometer input int out = map(val, 0, 1023, 0, 255); // Converts the input range of the potentiometer (0-1023) to the output range of the analog pin (0-255) analogWrite(7, out); // Write to the LED output Serial.println(out); delay(10); }

You can see all the code for this experiment on GitHub.

The code here takes the signal from the potentiometer via pin A0, and outputs the signal to the LED on pin 7. The potentiometer input is a 10-bit value (in the range 0-1023), but the output pin is only an 8-bit output (in the range 0-255). For this reason, we use the map function to convert the value from the input range into the output range, so that we can use the input to control the LED.

There you have it! But not really...

I set it up in TinkerCAD and it worked a treat! Then I set it up my physical kit, and it didn't work.

The LED only switched between full brightness and completely off, with not even the smallest zone of "inbetween". After double checking the wiring, plotting potentiometer readings in the IDE's serial plotter, and switching out the LED for every colour in the kit, I discovered that the LEDs provided in this kit don't fade!

So let's connect it to a servo instead. Much more fun!

Side note: It took me a moment to realise you need to assemble the potentiometer yourself. The two parts you need are in the small box with eight smaller compartments, specifically they're in the top compartment second from the right.

Part 2: Setting Up the Servo

How the Servo Works

A servo motor is a particular kind of motor that, though only able to rotate in a 180°, uses a potential divider circuit to know it's position at all times. Using the Arduino we can send a target state to motor, and then it will compare the target state of the potential divider to it's actual state to determine how to drive the underlying DC motor. GreatScott! on YouTube has a great video that does more in-depth on how servos work, and even how you can modify them to have more degrees of rotation.

Components Used

This experiment uses the Arduino UNO R3 Project Starter Kit.

1 x UNO R3 Controller Board (the Arduino)

1 x Breadboard

Breadboard jumper wires

1 x Potentiometer

1 x Servo Motor (SG90)

The Wiring

I removed the LED and wired up the servo instead. The brown wire connects to ground, the red to live, and the orange to our control signal from the Arduino. I used pin 9.

The Code

I first ran example code that comes with the Ardiuno IDE to test the servo was working. You can load the example by going to File > Examples > Servo > Sweep. My wiring worked! I then wrote a program to use input from the potentiometer instead.

#include Servo servo; void setup() { servo.attach(9); // Servo output Serial.begin(9600); } void loop() { int val = analogRead(A0); // Potentiometer input int out = map(val, 0, 1023, 0, 180); servo.write(out); // Write to the servo output Serial.println(val); delay(15); }

You can see all the code for this experiment on GitHub.

Like in our LED example, I use the map method to translate the value from the input range to the output range, but this time the output range is 0-180, the rotations in degrees our servo can handle. The Ardiuno kindly abstracts away converting that value into the electrical signal the servo actually wants.

There you have it! Sort of...

youtube

Can't see the video? Watch it on YouTube!

Judging by the plot of the potentiometer signal, it seems that as the potentiometer and other components wobble about, it sends a somewhat volatile signal, hence the weird movement from the servo. Blu-tacking the potentiometer to the breadboard helped to minimise that. It worked well enough for my purposes, and I was curious to try what I've now dubbed the Icarus servo!

Part 3: The Icarus Servo

Components Used

This experiment uses the Arduino UNO R3 Project Starter Kit.

1 x UNO R3 Controller Board (the Arduino)

1 x Breadboard

Breadboard jumper wires

1 x Photoresistor

1 x 5KΩ resistor

1 x Servo Motor (SG90)

The Wiring

I replaced the potentiometer with a photoresistor, in the same setup I used in my first experiment. To begin with, I just set it up on the breadboard, as to test that it was working. I wired the output of the potential divider to pin A0 so I could reuse the code I was currently using.

The photoresistor was not giving a huge range of values, certainly not the full 0-1023 range theoretically possible. Replacing the 10KΩ resistor I was originally using with a 5KΩ resistor helped increased the range. After that however, I just used the serial plotter to see what range of inputs the sensor was giving me, and updated my map function call to work in this range instead.

int out = map(val, 10, 360, 0, 180);

To make my Icarus servo, I wanted to attach the photoresistor to one of the servo motor arm attachments. To ensure that the photoresistor wouldn't swing into the side of the servo, I used code to set the servo to 0 degrees, then attached the servo arm such that it would swing around the "outisde" of the servo i.e. keep clear of the blue box. I then slotted the photoresistor into the servo arm and connected it to the breadboard using plug-to-socket jumper wires.

The Code

I wanted my servo to move the arm areas of light. My simple approach to this was to create a hill climbing algorithm. The program stores a current position in variable, and then continually rotates slightly to either side of this position to see if either of them produce a higher light reading than the current position. If they do, the current position is updated to the new one.

#include Servo myservo; int pos = 0; void setup() { myservo.attach(9); // Servo output Serial.begin(9600); } void loop() { int highestLightLevel = 0; int newpos = pos; for (int i = -1; i <= 1; i++) { // Iterates i through the values -1, 0, 1 - corresponding to "left", "centre", and "right" // Calcuate next position to take a light reading from int testpos = pos + i * 5; if (testpos < 0) testpos = 0; if (testpos > 180) testpos = 180; // Move to that position myservo.write(testpos); delay(200); // The the servo time to reach it's target before taking a light reading // Take a light reading int light = analogRead(A0); // Photoresistor input // If that reading is the highest so far, save it and the tested position to refer to later if (light > highestLightLevel) { highestLightLevel = light; newpos = testpos; } } // Update the "current" position of the servo to the one that produced the highest light reading pos = newpos; Serial.println(highestLightLevel); }

You can see all the code for this experiment on GitHub.

There you have it! For real this time!

youtube

Can't see the video? Watch it on YouTube!

While recording the video I had my phone torch on, which I used to encourage the servo to move in particular directions. Sometimes the jumper wires would push against it, but otherwise it worked reasonably well! Working on this experiment in particular, I was surprised to see just how prevalent potential divider circuits are in electronics.

On reflection, I think part of why the movement of the servo is so janky is that each time the code pulls a signal from the photoresistor, it only takes one reading, meaning ambient variations in reading can cause the servo to move in different directions essentially at random. Taking an average reading over a few milliseconds would help prevent against this. It was definitely good insight onto how to best use the photoresistor.

The code could be also further improved by, instead of hard coding the input range from the photoresistor, dynamically setting it during runtime depending on what signals the motor receives.

0 notes