#anodizing

Explore tagged Tumblr posts

Note

*clown honking from inside of Irene’s stomach*

“Don’t pay any mind to that. I’m not sure how they got there.”

“Irene .. did you eat my clowns ??? .. .. why ?”

2 notes

·

View notes

Text

Adopt: Ani Diza $65

Available!

Check out our pinned for rules and inquiries! $5 from every sale goes towards Crips for ESims.

#adoptable#adopts#anthro#spider#huerachnid#huerachnid available#huevember#purple#anodizing#damascus steel#$65

3 notes

·

View notes

Text

Enhance your parts with CreateProto’s top-tier surface finishing services! From bead blasting and anodizing to powder coating and polishing, we offer a wide range of options tailored to meet your specific needs. Improve both the appearance and durability of your metal and plastic components with our expert techniques. Fast turnaround times, exceptional customer service, and customizable solutions ensure your satisfaction. Get an instant quote today!

Visit : https://createproto.com/services/surface-finishing/

#SurfaceFinishing#Anodizing#PowderCoating#MetalFinishing#PlasticFinishing#RapidPrototyping#QualityMatters#Customization#CreateProto

0 notes

Text

Industrial Process Tanks: A Key to Efficient Operations

In industries like galvanizing, electroplating, and anodizing, precision and efficiency are critical. That’s where Industrial Process Tanks come into play, supporting everything from pre-treatment to the final steps of coating and plating. 🌟

👉 Pre-Treatment Plant Tanks: Vital for preparing surfaces, ensuring maximum adhesion for coatings and paints. 👉 7 Tank Process Tanks: Specialized multi-stage tanks designed to handle complex processes, enhancing productivity and precision. 👉 Galvanizing Plant Tanks: Crucial for applying a protective zinc layer to metals, ensuring longevity and rust resistance. 👉 Electroplating Tanks: These tanks are engineered for precision metal coating through electrochemical processes, improving corrosion resistance and enhancing aesthetic qualities. 👉 Anodizing Tanks: Essential for creating a durable, corrosion-resistant oxide layer on metals like aluminum.

These process tanks are the backbone of many industrial processes, ensuring the highest quality standards while boosting operational efficiency. 💡

Contact us for best quotation on M: +91 9106892627 For more info visit: https://bit.ly/3XC8Dn8

#IndustrialSolutions#ProcessTanks#ManufacturingExcellence#Galvanizing#Electroplating#Anodizing#PreTreatment#EfficiencyMatters#EngineeringInnovation#SurfaceTreatment#MetalProcessing#CoatingTechnology#Plating#ChemicalEngineering#IndustrialAutomation#ManufacturingTech#TankSystems#CorrosionResistance#ProductionEfficiency#IndustrialEngineering#TechInnovation#SustainableManufacturing#SurfaceFinishing#MetalCoatings#IndustrialDesign#PlatingSolutions#AnodizingTechnology

1 note

·

View note

Text

Effects of Anodized Aluminum in CNC machining

Surface treatment is an important part of the CNC aluminum machining process, with a variety of methods and different results. Sometimes only one method can meet the requirements, and sometimes a variety of methods can be used to meet the requirements of the product. Among them, anodizing is the most widely used method.

There are 7 major effects of CNC aluminum machining for anodizing as follows:

1.Enhance the corrosion resistance of aluminum parts. Anodizing treatment on the surface of CNC parts to form a layer of oxidation film, this film is chemically stable and makes the surface of CNC parts harder, more wear-resistant, while reducing the erosion of various chemical reactions on the CNC parts to improve their corrosion resistance. Anodizing can change the colour of the surface of CNC parts, provide a variety of colour options, improve the decorative effect of CNC parts, keep the surface clean, beautiful, and not easy to be affected by the outside world.

2.Improve the adsorption capacity of aluminum parts to materials. Aluminum products are chemically or electrochemically polished and then anodized to form a highly transparent oxidation film on the surface. In addition, the oxidation film is porous and has good adsorption capacity, which can effectively adsorb a variety of organic or inorganic dyes, as well as paints and organic films. This aluminum product can come in a variety of vibrant colours, which not only adds to the beauty of the appearance, but also provides excellent corrosion protection. The surface of some industrial aluminum profiles needs to be sprayed with paint, and the surface voids of the anodized aluminum profiles have strong adsorption, which makes the spray paint more even and beautiful.

3.Improve the wear resistance of aluminum parts. The anodized film is not only corrosion resistant, but also very dense. The presence of this oxidation film greatly enhances the wear resistance of aluminum products and effectively adapts them to frictional working conditions. The porous oxidation film on the surface has the ability to adsorb lubricants, making the surface of industrial aluminium profiles more wear-resistant, such as automobile engine cylinders, pistons and other parts of the use.

4.Improve thermostability The thermal conductivity of the anodizing oxidation film is much lower than that of the aluminum profile substrate. The aluminum oxidation film can withstand high temperatures up to 1500 degrees Celsius, while the aluminum profile substrate can only withstand high temperatures of up to 660 degrees Celsius. Aluminum's electrical conductivity is very good, but aluminum profiles need to be insulated in some situations. Anodizing oxidation films, on the other hand, are chemically structured as metal oxides rather than metals and are highly electrically insulating. Some aluminum materials require electrical insulation, such as capacitive dielectric layers. This can be achieved by anodizing.

5.Realize the electrical insulation of aluminum parts. The non-conductive oxidation layer formed during the anodizing process to improve the electrical insulation of the part, make it suitable for use in electronic components and equipment. Anodized surfaces provide an excellent basis for the application of paints, primers and other coatings, ensuring strong adhesion and long-lasting results. Anodizing is an environmentally friendly process as the chemicals used can be recycled and the resulting oxide layer is non-toxic and harmless.

6.As a substrate for aluminium plating Aluminum products must be coated on the substrate before plating. There are various methods of applying a primer to the surface of aluminum products, including zinc plating, zinc dipping, chemical nickel plating and, of course, anodizing. Due to the porous nature of the anodized film, the plating process can be facilitated.

7.Protect against electromagnetic interference For special CNC parts such as electronic parts, certain electromagnetic waves may be generated during operation. After anodizing, the sealed oxide film formed on the surface can effectively prevent electromagnetic interference and ensure that the equipment is not affected by any external factors.

Aluminium is a very common metal in industry and life. In aluminium alloy processing, anodizing is a very important surface treatment method, which can enhance corrosion resistance, improve adsorption capacity, wear resistance, thermal insulation and electrical insulation, and can be used as an aluminium-plated substrate to improve the performance and quality of aluminium products. At GD Prototyping, machining aluminum parts is one of our strengths in terms of CNC machining services, affordable prices, beautiful surfaces, quality and performance.

The protective oxidation layer formed during the anodizing process improves the wear, corrosion and UV damage resistance of the part, resulting in a more durable component, and anodized parts present a uniform, attractive finish that can be further coloured using dyes for a wide range of colours and appearances.

https://gdprototyping.en.alibaba.com/

#prototyping#prototype#prototype machining#cnc machining#precision machining#machining parts#cnc aluminum machining#aluminum machining#anodizedaluminum#anodizing#rapid prototyping

1 note

·

View note

Text

9/27/2024 - homebuilt anodizing. Looks amazing.

0 notes

Text

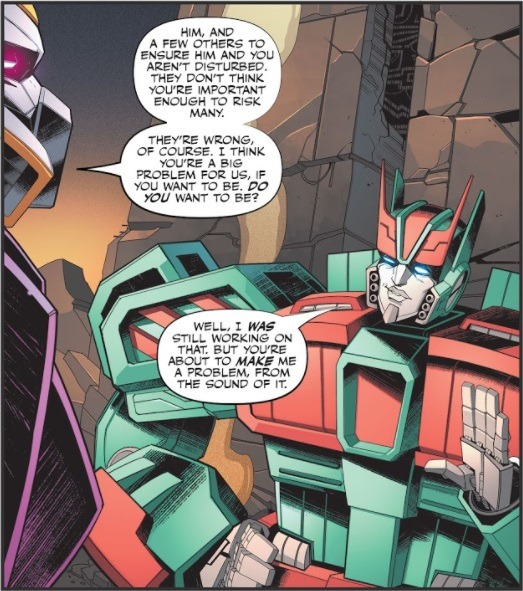

Transformers "More Than Meets The Eye" comic has recently torpedoed me down the feelsy space car robots hellhole, an therefore i present a sketchy collection of Lost Light crew as homo sapiens. I had SO MUCH fun coming up with the designs! Now off to actually learn how to draw robots i guess

#mtmte#tf mtmte#transformers idw#maccadams#maccadam#am i gonna tag them all? hold my energon pals#rodimus prime#megatron#drift#ratchet#ultra magnus#minimus ambus#first aid#cyclonus#whirl#tailgate#anode#lug#velocity#nautica#perceptor#brainstorm#rung#swerve#cygate#dratchet#how do we tag anolug?#luganode#comic page redraw#BIGGEST RODIMUS STAN HERE

6K notes

·

View notes

Text

Understanding Anodizing: Type II vs. Type III

Anodizing is a surface treatment process that imparts a range of benefits to metal, most commonly aluminum. This electrochemical process not only enhances the aesthetic appeal of the metal but also provides several functional advantages.

Two prominent types of anodizing, known as Type II and Type III anodizing, offer distinct properties and applications.

Type II Anodizing: The Essentials

Type II anodizing, often referred to as conventional or sulfuric anodizing, is a widely employed method for aluminum finishing. This process involves immersing the aluminum in a sulfuric acid bath and applying an electrical current. The result is the growth of an oxide layer on the metal surface. Key characteristics of Type II anodizing include:

Thickness of Oxide Layer:

The oxide layer formed in Type II anodizing is relatively thin, typically ranging from 0.0001 to 0.001 inches.

Color Options:

Type II anodizing offers a variety of color options, making it suitable for decorative applications. Dyes can be introduced during the process to achieve different colors.

0 notes

Text

The Role of Anodizing in Electronics: Protecting and Beautifying Components

Can you define the word "anodizing" for me? If not, get ready to have your mind blown! The corrosion-resistant properties of anodized metals are just one of the many advantages of this intriguing finishing procedure. Anodizing is a service that should be considered if you are in the Vancouver area and need metal finishing.

Learn more about anodizing and why it's crucial for providing top-notch corrosion resistance in this in-depth article. The numerous anodizing technologies that are used to make metal parts last longer and look better will also be examined in detail. So, settle back with a cup of coffee (or tea) as we explore the fascinating world of anodizing in lovely Vancouver.

Anodizing Parts to Prevent Corrosion and Its Advantages

Corrosion is an annoying problem when working with metal parts. It degrades the parts' structural integrity and functionality in addition to their visual appeal. Anodizing is the hero that comes to the rescue in these situations. Anodizing is a procedure used to protect metal surfaces against corrosion by coating them in a thin layer of oxide first.

Anodizing's ability to increase the corrosion resistance of metals like aluminum and titanium is one of its primary advantages. Anodizing produces an oxide coating that is highly resistant to corrosion and corrosion-causing elements such moisture, humidity, salinity, and chemicals. With the right anodized coatings, metal components can withstand harsh environments and corrosive substances for considerably longer.

Furthermore, unlike paint or plating, which can crack or wear off over time, anodized coatings are an essential part of the material and will not disappear. They won't easily peel or flake off because of this. Furthermore, these coatings are extremely long-lasting, making them ideal for uses where reliability over time is paramount.

Anodization not only greatly reduces the likelihood of corrosion, but it also increases the hardness and scratch resistance of the material. As a result of these improvements, anodised parts are more durable and more pleasing than their untreated counterparts. Metal products in Vancouver (or anywhere) would benefit greatly from anodizing as a finishing procedure because it provides excellent corrosion protection and also makes the parts significantly more durable.

Methods and Procedures for Anodizing

Adding an oxide layer to the surface of a metal is known as anodizing, and it's used as a finishing process. Vancouver is home to a wide range of sectors, and one that relies heavily on this process is metal finishing. So how does anodizing function, exactly?

Immersing the metal part in an electrolyte bath and applying an electric current induces a controlled oxidation reaction, which is the first step in the anodizing process. This results in oxygen ions bonding with the metal, which forms an oxide layer. Variables like voltage and time can be used to change the thickness of this layer.

Anodizing Comes in a Variety of Flavors

Different anodizing methods achieve different results and have their own set of advantages. The corrosion resistance and aesthetic alternatives provided by sulfuric acid (Type II) anodizing, for example, make it a popular choice for general-purpose applications.

Hardcoat (Type III) anodizing, on the other hand, is appropriate for components that will be exposed to significant stress or friction because of its better wear resistance and hardness qualities. It results in a more substantial oxide layer but requires higher processing voltages.

By learning about these processes, Vancouver companies may select the best anodized finish for their goods or components, maximizing their functionality and durability.

The Anodizing Process: An Overview

Anodizing is a process used to improve the aesthetics of metal components, most commonly aluminum, by coating them with an oxide layer. This treatment improves the material's look and makes it more corrosion-resistant and long-lasting.

To begin anodizing, the metal is submerged in an electrolytic solution while a direct current is applied. Aluminum oxide is formed when oxygen ions combine with aluminum atoms at the surface. This oxide layer can be adjusted in thickness to serve a variety of reasons, from aesthetic enhancement to enhanced corrosion resistance.

After forming, this barrier can be dyed or sealed to give it a new look or improve its protective abilities. These additional procedures guarantee that the anodic finish will turn out exactly as planned.

To truly appreciate the benefits of anodizing, one must have a firm grasp of how the process works. Anodizing is a trustworthy method that may be tailored to a wide range of purposes, including but not limited to increasing corrosion resistance, enhancing visual appeal, and increasing durability.

Anodizing Comes in a Variety of Flavors

Anyone looking for metal finishing in Vancouver should have a firm grasp of the Anodizing Process. But did you know that anodizing comes in a variety of forms? Because each kind offers its own set of benefits and uses, you can pick the one that works best for you.

Sulfuric acid anodizing is a typical process for protecting metals from corrosion. This method forms a thick, porous oxide coating on the metal's surface using sulfuric acid as the electrolyte. It is highly resistant to corrosion and can be dyed to a wide range of colors, making it perfect for use in ornamentation.

Type III anodizing, often known as hard coat anodizing, is another common process. This method forms an oxide layer that is thicker by employing lower temperatures and greater voltages. The resultant coating is ideal for parts that experience friction or abrasion because of its high resistance to wear.

In place of sulfuric acid, chromic acid can be used as an electrolyte in chromic acid anodizing. For precision products where dimensional correctness is of the utmost importance, this type of anodizing is ideal because it produces a thin but dense oxide coating that provides superior corrosion protection.

By learning about the many anodizing techniques in Vancouver, you'll be more equipped to select the one that meets your needs. Whether you're looking to improve corrosion resistance, wear protection, or dimensional precision, a particular type of anodization is available to meet your needs.

Different Metal Finishing Techniques, Including Anodizing

There are a number of options for giving metals a polished appearance, each with their own advantages and disadvantages. But anodizing stands out because of how long it lasts and how well it resists corrosion.

When it comes to preventing corrosion, anodizing is typically superior to other metal finishing procedures like plating or painting. The increased durability of anodized parts makes them a good choice for use in demanding conditions or in sectors where corrosion is a problem.

In addition, the homogeneous coating provided by anodizing penetrates deeply into the surface of the metal to produce a bond that can withstand wear and tear over time. This is especially useful for parts that see heavy use or are frequently exposed to harsh environments.

There is a wide range of color possibilities available when anodizing. Traditional coatings, such as paint or powder, can chip or fade over time, whereas anodized coatings retain their color and quality for far longer.

Anodizing is also environmentally safe, unlike other metal finishing methods that frequently use hazardous chemicals or heavy metals. This method employs safe materials and generates little in the way of waste.

Anodizing provides improved corrosion resistance and durability along with environmental friendliness compared to other metal finishing procedures, which may provide some amount of protection and aesthetic appeal. If you're trying to improve your product's aesthetics or give it a longer lifespan in harsh environments, anodizing is the metal finishing solution for you.

Look no further than Anotek Anodizing Inc if you're in the Vancouver area and need high-quality metal finishing services like Vancouver Electropolishing and dependable anodic coatings. With a focus on complete client satisfaction, we are experts at delivering professional-grade final products. Don't take chances with the quality of your metal finishing; use a professional who knows the value of anodizing.

0 notes

Text

Super excited to finally post this, here's my piece for the @medicalgradezine! All of our wonderful women medics across multiple continues come together to study a very gory tech setup. Inspired by “The Anatomy Lesson of Dr. Nicolaes Tulp” I hope everyone likes it!

#transformers#maccadam#tf fanart#tf anode#tf red alert#tf velocity#tf nickel#tf airachnid#tf moonheart#tf minerva#tf lifeline#tf animated#idw transformers#artists on tumblr#hystdraws#medical grade zine

796 notes

·

View notes

Text

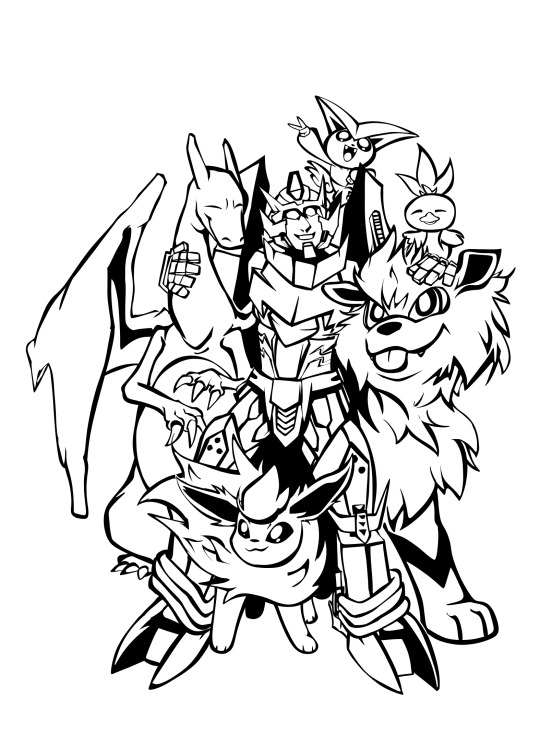

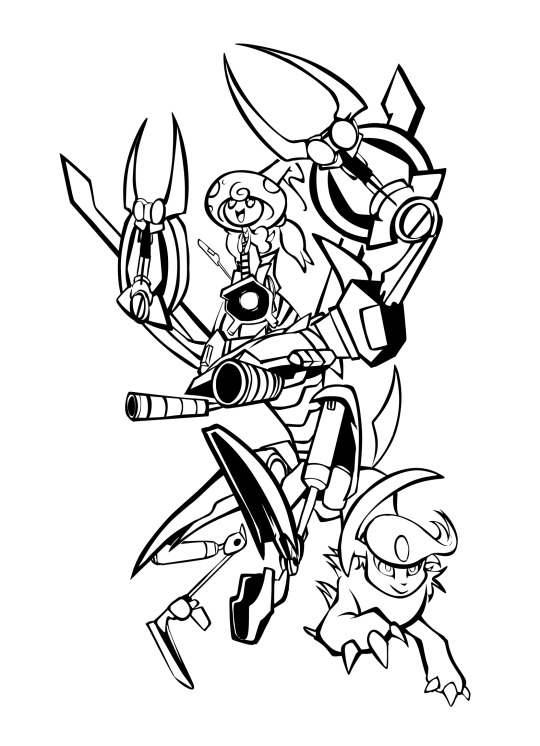

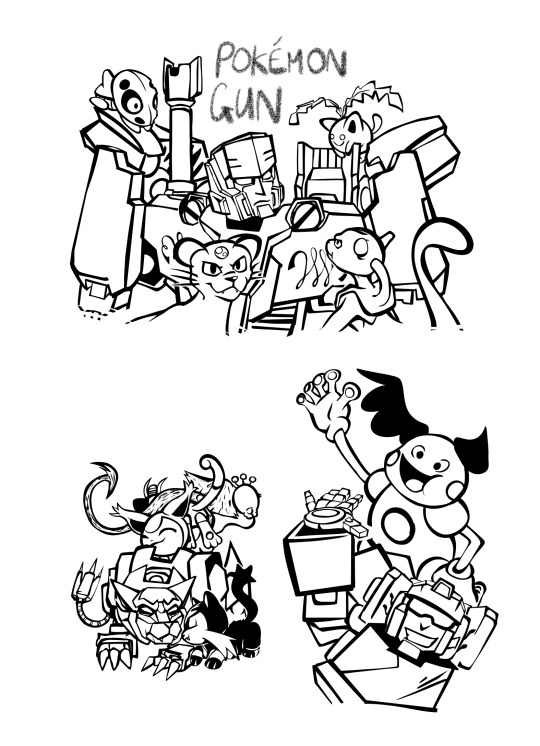

I realized I never posted ALL the colouring book illustrations, and since I no longer have any stock, I figured I'd share.

A collection of little Pokémon teams for Lost Lighters, drawn in 2021! There's a bunch of details I forgot about, but I still consider Ultra Magnus + 10% Forme Zygarde to be the biggest brained choice lol

#mtmte#fanart#whirl#rodimus prime#thunderclash#ultra magnus#getaway#tailgate#cyclonus#skids#idw rung#anode and lug#chromedome#rewind#brainstorm#perceptor#drift#ratchet#megatron#ravage#riptide#nautica#velocity#nightbeat#trailcutter#swerve#pokemon crossover#idw continuity#lost light#my art

2K notes

·

View notes

Text

"I miss his eyes"

#tfa#transformers animated#transformers#tf anode#starscream#skyfire#tfa skyfire#tfa starscream#skystar#tfa skystar#tfa skyfire and starscream my beloved

243 notes

·

View notes

Text

Looking for top-notch CNC aluminum machining services? Get an instant quote for precision machining and manufacturing of aluminum alloy enclosures, frames, and complex parts. We offer surface treatments like anodizing in various colors, polishing, matte oxidation, and more. Benefit from our tight tolerances, lower prices compared to US and European markets, and fast turnaround times for on-time delivery. Quality and precision are guaranteed with every project! Learn more : https://createproto.com/services/cnc-aluminium-machining-parts-service/

#CNCmachining#aluminummachining#precisionmanufacturing#anodizing#surfacetreatments#fastturnaround#ontimedelivery#affordablemachining#qualityandprecision#aluminumenclosures

0 notes

Text

ty @cumjunxendura for letting me steal this joke! 💖👍

370 notes

·

View notes

Text

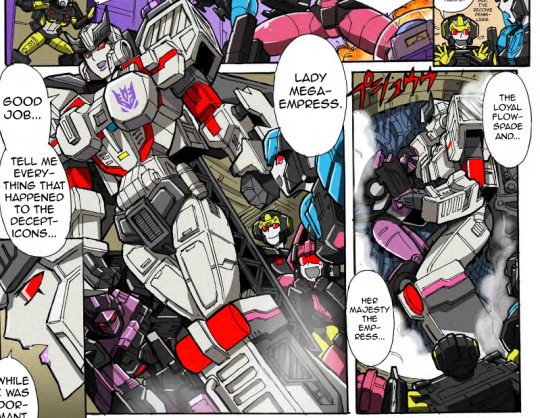

Transformers yuri

#transformers#arcee#aileron#greenlight#lug#anode#road rage#nautica#slipstream#shadow striker#flamewar#lancer#velocity#firestar#airazor#elena wallace#termagax#pyra magna#blackarachnia#chromia#windblade#moonracer#megaempress#flowspade#jumpstream#dustup#strongarm#nightra#strika

604 notes

·

View notes

Text

9/27/2024 - one unusual receipe

0 notes