#aluminium sheet

Explore tagged Tumblr posts

Text

Aluminium Sheet Prices, News, Trend, Graph, Chart, Forecast and Historical

The aluminium sheet market plays a pivotal role in the global industrial landscape, with its pricing dynamics influenced by a myriad of factors ranging from raw material costs to geopolitical events. Aluminium sheets are essential in various sectors such as construction, automotive, aerospace, and packaging, making them a cornerstone of modern infrastructure and manufacturing. The market for aluminium sheets is vast and diverse, catering to both high-end applications requiring advanced specifications and more general uses. Price trends in this sector are highly sensitive to the fluctuating costs of bauxite and alumina, the primary raw materials for aluminium production. The extraction and refining processes for these materials are energy-intensive, which links the aluminium sheet prices closely to global energy prices. Any significant change in the cost of electricity or fuel has a direct impact on production costs, subsequently affecting market prices.

Global demand and supply dynamics are another critical determinant of aluminium sheet prices. The rapid industrialization and urbanization in emerging economies like China and India have fueled a surge in demand for aluminium products, including sheets. China, being a dominant player in both production and consumption of aluminium, significantly influences global price trends. A shift in Chinese policies, such as the imposition of export restrictions or environmental regulations, can cause ripple effects across the global market. Similarly, trade relations and tariffs between major economies impact international pricing. For instance, import duties imposed by the United States or European Union on aluminium products from certain countries can alter the supply chain dynamics, influencing regional and global prices.

Get Real time Prices for Aluminium Sheet: https://www.chemanalyst.com/Pricing-data/aluminium-sheet-1493

Another factor affecting aluminium sheet prices is the level of technological advancement in the production processes. Modern manufacturing techniques and the adoption of innovative technologies can reduce production costs and enhance the quality of aluminium sheets. Recycling also plays a crucial role in the market, as recycled aluminium is significantly less expensive to produce compared to primary aluminium. With increasing emphasis on sustainability, the proportion of recycled aluminium in the market is growing, which has a stabilizing effect on prices. Furthermore, the integration of renewable energy sources into production facilities can mitigate the volatility caused by fluctuating energy prices, contributing to a more predictable cost structure.

Economic cycles and market speculation also exert considerable influence over aluminium sheet prices. During periods of economic expansion, demand for aluminium sheets tends to rise due to increased construction activities and manufacturing output, leading to upward pressure on prices. Conversely, during economic downturns, reduced demand can lead to price declines. Speculation in commodity markets can amplify these trends, with traders’ expectations about future supply and demand scenarios driving price movements. Market sentiment, shaped by factors such as geopolitical tensions, natural disasters, or pandemics, can also lead to short-term volatility in prices.

Environmental regulations and policies have become increasingly significant in shaping the aluminium sheet market. Governments worldwide are tightening emissions standards and encouraging the use of eco-friendly materials. Aluminium, being lightweight and recyclable, is often favored over other metals, driving demand. However, stricter regulations on mining and refining activities can increase production costs, impacting prices. Carbon pricing mechanisms and cap-and-trade systems further add to the cost considerations for aluminium producers, particularly in regions with stringent environmental policies.

Seasonal variations and regional disparities also play a role in determining aluminium sheet prices. Construction activities, which are a major driver of demand, often follow seasonal patterns, with higher activity levels in certain months leading to price increases. Regional differences in energy costs, labor expenses, and logistical challenges contribute to price variations across different markets. For instance, aluminium sheets produced in regions with lower energy costs or abundant raw material reserves may be priced more competitively compared to those in areas with higher production expenses.

The role of currency exchange rates cannot be overlooked in the aluminium sheet market. Since aluminium is traded globally, fluctuations in the value of major currencies such as the US dollar can impact prices. A stronger dollar, for example, makes aluminium more expensive for buyers using other currencies, potentially dampening demand and exerting downward pressure on prices. On the other hand, a weaker dollar can boost demand by making aluminium more affordable internationally, pushing prices upward.

In recent years, the focus on sustainability and green initiatives has further reshaped the aluminium sheet market. Consumers and industries are increasingly prioritizing products with a lower environmental footprint. This trend has encouraged producers to invest in sustainable practices, such as using low-carbon energy sources and enhancing recycling capabilities. While these initiatives contribute to long-term cost efficiency, the initial investment and transition costs can temporarily impact prices. Companies that can successfully balance these factors are better positioned to remain competitive in the evolving market landscape.

In conclusion, aluminium sheet prices are determined by a complex interplay of factors, including raw material costs, energy prices, global demand and supply dynamics, technological advancements, economic conditions, and regulatory policies. The market’s sensitivity to external influences such as geopolitical events and environmental trends underscores the importance of strategic planning for industry stakeholders. As the world continues to prioritize sustainability and technological innovation, the aluminium sheet market is poised for further evolution, with its pricing trends reflecting broader economic and environmental shifts. Understanding these dynamics is crucial for businesses and investors seeking to navigate this critical segment of the metals industry effectively.

Get Real time Prices for Aluminium Sheet: https://www.chemanalyst.com/Pricing-data/aluminium-sheet-1493

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Sheet#Aluminium Sheet Price#Aluminium Sheet Price Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

5 Common Applications of Aluminium Sheet

It does not matter the industry; these products have become a cornerstone of success. But are they really that useful? Does the versatile word that they are often associated with do them justice? Well, to find out, let's look at the five common applications of this material.

Read more: https://refmonindustries.livepositively.com/5-common-applications-of-aluminium-sheet/

#refmonindustries#refractorybricks#insulation#acid proof bricks#refmon#hot insulation material#aluminium sheet#aluminum

0 notes

Text

A day at the Aluminum factory

0 notes

Text

#aluminium supplier#aluminium sheets manufacturer#aluminium sheets#aluminium metal#aluminium sheet#aluminium sheets stockist#aluminium sheets supplier

0 notes

Text

aluminium mesh sheet manufacturer since 2006, offer all types of customized aluminium sheet

0 notes

Text

Aluminium Sheet Design -E3 ACP

E3 ACP is the first company in South India to construct an ACP sheet manufacturing plant. Aluminium Composite Panels are adaptable and distinctive, and are available in a variety of colors and finishes from E3. Wooden, stone, glitter, gloss, pebbles, and other materials are available. This substance can be bent, folded, and formed into shapes that would be impossible with any other material. ACP sheets are developed following comprehensive quality testing since E3 ACP is never complacent about quality.

ACP sheets have transformed the worlds of architecture and design by providing the ideal balance of strength, versatility, and aesthetic appeal. Their influence on contemporary architecture is evident, as they continue to alter facades, interiors, and signage. As architects and designers seek innovative solutions, E3 ACP sheets provide endless possibilities to create structures that inspire and stand the test of time. With sustainability and safety considerations in mind, the future of ACP sheets looks promising as they continue to shape the skyline of our cities.

For Any Query email us : [email protected]

0 notes

Text

Warehouse Office in Ageo, Japan - Arii Irie Architects

#Arii Irie Architects#architecture#design#building#modern architecture#interiors#minimal#modern#contemporary#contemporary architecture#design blog#cool architecture#cool design#industrial#chic#light#transparent#polycarbonate sheets#metal cladding#steel#aluminium#urban#city#warehouse#office#office design#timber frame#beautiful architecture#japan#japanese architecture

66 notes

·

View notes

Text

The Importance of Aluminium Ingots in Various Industries

Aluminium is a lightweight and versatile metal that is widely used in many different industries, including construction, automotive, aerospace, and packaging. Aluminium ingots are an essential part of the manufacturing process for producing high-quality aluminium products. In this blog, we will discuss the importance of aluminium ingots and their use in various industries.

What are Aluminium Ingots?

Aluminium ingots are rectangular or trapezoidal blocks of pure aluminium metal that are used to produce various aluminium products. They are produced by smelting raw aluminium ore and then pouring the molten metal into a mould. Once the metal has cooled and solidified, it is removed from the mould and processed further to create a wide range of aluminium products.

Uses of Aluminium Ingots

Construction Industry: Aluminium is widely used in the construction industry due to its lightweight and corrosion-resistant properties. Aluminium ingots are used to produce various building materials such as window frames, roofing sheets, and structural components.

Automotive Industry: Aluminium is also extensively used in the automotive industry due to its lightweight, high strength, and durability. Aluminium ingots are used to produce car parts such as engine blocks, wheels, and chassis.

Aerospace Industry: Aluminium is a critical material in the aerospace industry due to its lightweight and high strength-to-weight ratio. Aluminium ingots are used to produce aircraft parts such as wings, fuselages, and landing gear.

Packaging Industry: Aluminium is widely used in the packaging industry due to its excellent barrier properties and ability to preserve the freshness and quality of food and beverages. Aluminium ingots are used to produce various types of packaging such as cans, foils, and containers.

Advantages of Using Aluminium Ingots

Lightweight: Aluminium is one-third the weight of steel, which makes it an ideal material for applications where weight reduction is crucial.

Corrosion Resistance: Aluminium is highly resistant to corrosion, which makes it ideal for outdoor applications and harsh environments.

High Strength-to-Weight Ratio: Aluminium has a high strength-to-weight ratio, which makes it suitable for applications where high strength and low weight are required.

Aluminium ingots are a critical component in the manufacturing process for producing high-quality aluminium products. They are widely used in various industries such as construction, automotive, aerospace, and packaging. Aluminium offers numerous advantages over other materials, such as its lightweight, corrosion resistance, and high strength-to-weight ratio, making it an ideal material for a wide range of applications.

57 notes

·

View notes

Text

Aluminium Sheet Prices | Pricing | Trend | News | Database | Chart | Forecast

Aluminium sheet prices have experienced considerable fluctuations over the years, driven by various factors including global supply and demand dynamics, production costs, and economic conditions. As a versatile and widely used material, aluminium sheets are integral in numerous industries, from aerospace and automotive to construction and packaging. The price of aluminium sheets is influenced by the cost of raw aluminium, which in turn is affected by mining activities, energy costs, and geopolitical events. Additionally, aluminium is traded on global commodity markets, and shifts in these markets can lead to significant price changes. One of the primary determinants of aluminium sheet prices is the cost of bauxite, the ore from which aluminium is extracted. Mining and refining bauxite into alumina, and then electrolyzing alumina to produce aluminium, involves substantial energy consumption, which can impact pricing. When energy costs rise, it often leads to increased aluminium production costs, thereby pushing up the prices of aluminium sheets. Similarly, fluctuations in the value of the US dollar can affect aluminium sheet prices as it is a globally traded commodity. A stronger dollar generally makes aluminium more expensive for buyers using other currencies, potentially reducing demand and impacting prices.

Get Real Time Prices for Aluminium sheet: https://www.chemanalyst.com/Pricing-data/aluminium-sheet-1493

Demand for aluminium sheets is another crucial factor influencing their price. In the construction industry, aluminium sheets are valued for their durability and lightweight properties, making them ideal for applications in roofing, facades, and interior designs. As construction activities vary with economic cycles, so does the demand for aluminium sheets. The automotive and aerospace industries also drive significant demand, with aluminium sheets used extensively in vehicle body panels, aircraft components, and packaging materials. Changes in these sectors can lead to fluctuations in aluminium sheet prices based on their production schedules and technological advancements. Supply chain disruptions and trade policies also play a significant role in determining aluminium sheet prices. Political instability, natural disasters, or trade restrictions can affect the availability of raw materials and the distribution of finished products. For instance, tariffs or trade barriers imposed by major aluminium-producing countries can lead to increased costs for importing aluminium sheets, affecting prices in the domestic market. Conversely, trade agreements that facilitate smoother access to raw materials and finished products can help stabilize prices. Technological advancements and innovations in aluminium production and processing can also impact prices. New methods that improve efficiency or reduce energy consumption can lower production costs and potentially reduce aluminium sheet prices. However, the initial investment in such technologies can be substantial, and these costs may be passed on to consumers until the technologies become more widespread and cost-effective. Additionally, the quality and thickness of aluminium sheets influence their pricing. Higher-quality sheets, which may offer enhanced strength, corrosion resistance, or specific surface finishes, generally command higher prices. Similarly, thicker sheets or those with special treatments can be more expensive due to the additional processing required. The specific requirements of a project or application often determine the type and grade of aluminium sheets needed, impacting overall costs. Market trends and consumer preferences can also affect aluminium sheet prices. As industries evolve and new applications for aluminium emerge, demand patterns can shift, influencing prices. For example, the growing focus on sustainability and lightweight materials has led to increased use of aluminium in various sectors, potentially driving up demand and prices. Conversely, economic downturns or reduced industrial activity can lead to decreased demand, exerting downward pressure on prices. In summary, aluminium sheet prices are shaped by a complex interplay of factors including raw material costs, energy prices, global market dynamics, and industry demand. Fluctuations in the cost of bauxite, changes in energy expenses, and shifts in the global economy all contribute to the variability in aluminium sheet prices. Furthermore, supply chain disruptions, trade policies, and technological advancements play pivotal roles in determining pricing trends. Understanding these factors can help businesses and consumers anticipate price changes and make informed decisions regarding aluminium sheet procurement.

Get Real Time Prices for Aluminium sheet: https://www.chemanalyst.com/Pricing-data/aluminium-sheet-1493

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Sheet#Aluminium Sheet Price#Aluminium Sheet Price Monitor#Aluminium Sheet Pricing#Aluminium Sheet News#Aluminium Sheet Database

0 notes

Text

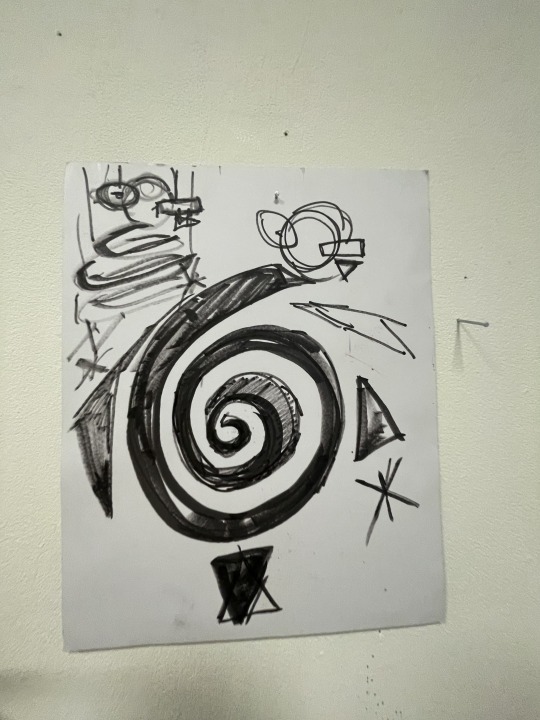

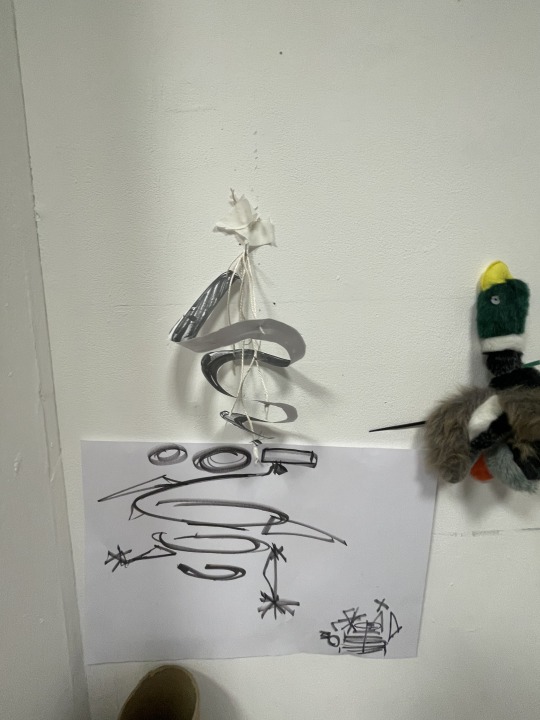

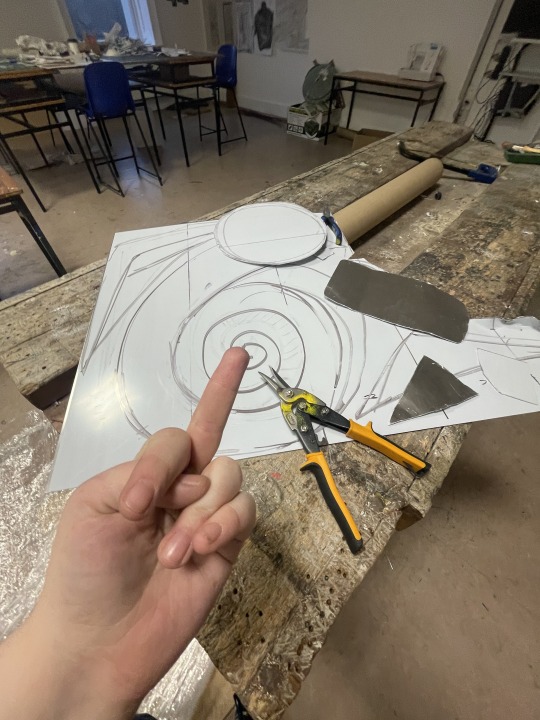

Hanging Objects, Attempt 1: Sheet Metal "Chandeliers"

My first attempt at making a hanging sculpture was a collection of shapes made cut out of Aluminium Sheet, on the suggestion of my tutor Mike Fox.

[insert original scrap exploration]

I drew out some shapes for for what I was hoping to make- a sort of chandelier, when viewed from below would for a sort of pigeon-y shape. I photo copied this and cut it out in a paper prototype.

I originally thought this was a promising material- I like the lard scale possible with it, i like the sheen of the metal, the ease it held its shape.

It was only once I started that Idiscovered something terrible, a fundamental flaw with this plan

I Hate Sheet Aluminium.

I have never met a material that I've disliked. Not gotten, sure, but disliked? Not really. But I hate Sheet Aluminium and I think it must be mutual considering how much difficulty and strife it's caused me. Its unwieldily, sharp, and difficult to cut- the shears get in their own way and the strain cramps you arms into an unusable state

With more working and effort I might be able to pull something from this, but for the time being I've pivoted to exploring my shapes in other mediums, namely Hessian.

Good Riddance, I say.

#college project#lsad#k00323703#limerick#first year#movement#sheet metal#all my homies hate sheet metal/aluminium

4 notes

·

View notes

Text

youtube

5 Advantages of Buying Aluminium Sheet from Trusted Manufacturers - Refmon Industries

Hello Everyone, In this video, we will give you complete information about aluminum sheets and what benefits you will get if you buy aluminum sheets from trusted manufacturers...

Watch now: https://youtu.be/jKSCtSdJdXU

Visit our website: https://www.refmon.in/detail/aluminium-sheet-coil-manufacturers

#insulation products#aluminium sheet#glasswool insulation#hot insulation material#refractorymaterials#rockwool insulation#Youtube

0 notes

Text

I forgot how much I hate working with aluminium.

#I tried to figure out something large scale right away for like half an hour#Then I decided you know what#Let's just make a smol bbys first aluminium producer#Just so I can get the sheets and casings needed to upgrade my power production#Getting turbofuel going is going to be an experience#Satisfactory#Lini plays satisfactory

4 notes

·

View notes

Text

Exploring the Artistry of Front Elevation Design with Eurobond ACP: A Comprehensive Guide

In the realm of contemporary architecture, the front elevation of a building plays a pivotal role in defining its visual appeal and aesthetic character. Among the myriad materials available for front elevation design, Aluminum Composite Panel (ACP) stands out as a versatile and innovative choice. Eurobond, a leading name in the ACP industry, has been at the forefront of providing cutting-edge…

View On WordPress

#ACP panels#ACP sheet#ACP sheet front elevation design#Aluminium composite panels#building front elevation design#Eurobond ACP#Eurobondacp#front elevation#front elevation design

2 notes

·

View notes

Text

alcadex professional aluminium cladding sheet manufacturer, With a professional team more than 17 years of solid experience in the field of aluminium cladding sheet and aluminum composite materials (ACM)

1 note

·

View note

Text

Aluminium Roofing Sheet Manufacturers

Gupta Iron & Steel Co. is one of India's top Aluminium Roofing Sheet Manufacturers. We offer a wide array of products in different colors, coatings, and profiles to match a range of applications. Aluminium roofing sheets are a popular option for roofing and cladding in many regions of the world. We are renowned for their dependability, lightness, corrosion resistance, and ease of installation. Aluminum roofing sheets are suitable for a wide range of applications since they are available in a great number of hues, textures, and profiles.

Address: X-9 Loha Mandi, Naraina, New Delhi

Phone: +91 9999740008

Email: [email protected]

Visit our website: https://www.guptaironsteel.com/aluminium-roofing-sheet.html

#Galvanized Iron Shee#Colour Coated Sheet#Decking Sheet#Color Curved Roofing Sheet#Air Ventilator#MS Pipes#Metal Roofing Sheet#Aluminium Roofing Sheet#Mild Steel Round Pipe

3 notes

·

View notes