#aerospace composites industry

Explore tagged Tumblr posts

Text

The Aerospace Composites Market is expected to reach USD 22.74 billion in 2023 and grow at a CAGR of 9.51% to reach USD 35.81 billion by 2028. Toray Industries Inc., SGL Carbon SE, Hexcel Corporation, Solvay SA, DuPont are the major companies.

#aerospace composites market report#aerospace composites market share#aerospace composites industry#aerospace composites market size#aerospace composites market growth#aerospace composites market analysis#aerospace composites market forecast

0 notes

Text

Interview: This is how Lohia Aerospace Systems plugs the composites gap in the Indian defence industry

By N. C. Bipindra In the wake of India’s Operation Sindoor against terror camps inside Pakistan and Pakistan-occupied Kashmir in May 2025, what stood out was the indigenous military systems that defended civilians and military infrastructures against Pakistani missiles, drones, and artillery fire. The effectiveness of Indian military equipment mainly depends on the key input of raw materials…

#A&D Industry#A&D Industry News#Adani#Aerospace#Aerospace and Defence#Aerospace and Defence News#Aerospace and Defense#Aerospace News#Air Force News#Anurag Lohia#Anvi Lohia#Army News#Composites#Defence#Defence Capital#Defence Capital Conversation#Defence Ministry#Defence News#Defence.Capital#DefenceCapital#Defense#Defense Ministry#Defense News#DGFT#Directorate General of Foreign Trade#GST#HAL#Hindustan Aeronautics Limited#Human Resources#IAF

0 notes

Text

Aerospace Adhesives & Sealants Market - Forecast(2024 - 2030)

Aerospace adhesives and sealants market size is forecast to reach $1.2 billion by 2025, after growing at a CAGR of 5.6% during 2020-2025, owing to the increasing demand of adhesives and sealants from the aerospace industries. Physical properties of adhesives and sealants, for example, high protection from warmth and substance responses add to its broad use in the aviation industry. Increasing passenger growth worldwide is likely to fuel the demand for adhesives and sealants products.

#aerospace#adhesives#sealents#aerospace and defense industry#aerospace technology#aerospace composites market#aviationgrowth#aviation#aviation industry

0 notes

Text

The global aerospace and unmanned composite market represents a pivotal segment within the broader aerospace and defense industry, characterized by its utilization of advanced composite materials to revolutionize the design, performance, and functionality of aircraft, spacecraft, and unmanned systems.

#Aerospace and Unmanned Composite Report#Aerospace and Unmanned Composite Industry#Aerospace#BISResearch

0 notes

Text

Mastering the Art of Bonding with Composite Adhesive Techniques

Understanding the composition of composite adhesive is essential for mastering bonding techniques. Typically composed of resins, fillers, and additives, composite adhesive is engineered to create a strong and durable bond between different materials. The precise formulation of these components determines the adhesive's properties, such as curing time, strength, and resistance to environmental factors.

Surface preparation plays a crucial role in ensuring the effectiveness of Composite Adhesive bonding. Before applying the adhesive, surfaces must be clean, dry, and free of any contaminants that could compromise the bond. Proper surface preparation ensures maximum adhesion strength and promotes long-term durability.

Selecting the right application method is vital for achieving optimal bonding results with composite adhesive. Depending on the materials being bonded and the specific requirements of the application, various techniques can be employed, including brush application, spray application, and automated dispensing systems. Each method offers unique advantages and considerations, allowing for precise control over adhesive application and distribution.

Proper curing is essential for maximizing the strength and durability of composite adhesive bonds. Curing refers to the process by which the adhesive undergoes chemical reactions to harden and create a strong bond between the bonded surfaces. Factors such as temperature, humidity, and curing time must be carefully controlled to ensure consistent and reliable bonding results.

Get More Insights On This Topic: Composite Adhesive

#Composite Adhesive#Bonding Agents#Structural Adhesives#Composite Materials#Adhesive Bonding#Industrial Adhesives#Aerospace Adhesives#High Performance Adhesives#Composite Repair Materials

0 notes

Text

Advantages of Carbon Fiber in the Aerospace Industry

carbon fiber has revolutionized the aerospace industry by offering a myriad of advantages ranging from enhanced structural strength and corrosion resistance to improved fuel efficiency and streamlined fabrication processes.

Source by- https://theamberpost.com/post/advantages-of-carbon-fiber-in-the-aerospace-industry

0 notes

Text

Bonding Excellence: Navigating Trends in the Epoxy Adhesive Market

Adhesives are essential products that are often overlooked. They’re noticed, until they fail. If your supports aren’t correctly fused, it could bring about disjointed parts, damaged equipment, and worn-out piping systems.

So, this blog has the ins and outs of epoxy adhesives, which can help you secure the pipe supports with confidence.

What Is an Epoxy Adhesive?

From time-to-time epoxy adhesives are confused with bonding products like glue. However, they’re far more complex than most adhesives. These are often called structural adhesives These terms make their role clearer: They’re high-performance adhesives meant for applications calling for powerful bonding, such as aircraft, automobiles, aerospace technology, or heavy process piping systems.

Uses of Epoxy Adhesives Coming to process piping systems, the epoxy adhesives have a vital role to play. These systems frequently require to join unlike materials together, like composite pipe shoes and metal piping. Besides, adhesives need to hold structures together in heavy vibrations, high pressure, and corrosive environments.

An area where epoxy adhesives have advantage is when you’re including pipe supports like wear pads, pipe shoes, and Flat Plates. That’s since this mixture enables to install without welding.

Benefits of Epoxy Adhesives? • By safeguarding pipes or adding wear pads to the system, raw piping can be insulated. Suddenly, you’ve protected pipes from metal-on-metal contact deprived of the high cost of specialized labor. Also, by eliminating welding, you’ll be evading susceptible spots requiring special heat treatments. • These pipe supports can increase the life of the systems, need to be held together. These adhesives work pretty well since they are sturdy and can stand extreme environments. • An epoxy can also work as a sealant filling open gaps. This guards pipes and supports from corrosion.

Different Kinds of Epoxy Adhesives There are numerous epoxy adhesives, but they can be split into two one-component and two-component

One-Component Adhesives These more often than not come as a single paste. Though, the name can deceive a few. Though they come as only a single physical substance, they still require external elements to start the curing process. That means they require moisture, heat treatment, or special lighting for bonding.

Two-Component Adhesives These require you to blend two elements. When applied properly, the outcome is a powerful bond. Though, since two-part adhesives need mixing, there’s the likelihood for a human error.

What’s the Solution? If you desire to get the paybacks of a two-component adhesive without mixing the right ratio or getting it on the skin, use a static applicator. This loads onto a standard epoxy cartridge and brings a two-part epoxy in a flawless mixing ratio, saving the mess and guesswork that from time to time come with physically mixing two-component epoxies.

Due to the increasing demand for these adhesives in numerous industries, the total value of the epoxy adhesives will reach $13,484 million by 2030.

#epoxy adhesive#adhesive technology#market trends#industrial applications#construction industry#global market outlook#bonding solutions#market dynamics#epoxy resin#research and development#composite materials#market growth factors#aerospace applications

0 notes

Text

Crafting the perfect bite of meat: Engineers develop metamaterials that mimic muscle and fat architecture

In a new publication in Nature Communications, Israeli and Palestinian engineers from The Hebrew University of Jerusalem pioneered the use of metamaterials to create whole cuts of meat. The work leverages cutting-edge materials science to overcome the long-standing challenges of replicating the texture and structure of traditional meat while offering a scalable and cost-effective production method that surpasses 3D printing technology. Metamaterials are composite materials whose properties arise from their structure rather than their composition. By adopting principles typically used in the aerospace industry, the team, led by Dr. Mohammad Ghosheh and Prof. Yaakov Nahmias from Hebrew University, developed meat analogs that mimic the intricate architecture of muscle and fat. These analogs are produced using injection molding, a high-capacity manufacturing process borrowed from the polymer industry, marking the first time this technology has been applied to alternative meat production.

Read more.

#Materials Science#Science#Metamaterials#Food#Meat#Composites#Biomaterials#Injection molding#Hebrew University of Jerusalem

30 notes

·

View notes

Text

⭕KINDERGARTEN HIT, PREEMPTIVE RUMORS - Real time from Israel

ISRAEL REALTIME - Connecting to Israel in Realtime

( VIDEO - Kindergarten HIT by a Hezbollah rocket in Acre. )

❗️For the 2nd time in a week, Hezbollah HIT a kindergarten, this time in Acre. Fortunately the little children were not killed. But, as in the last case, the explosion was in the playground where the children were a minute before. We await the condemnations and indictment for war crimes.

🔸CEASEFIRE NEWS.. US envoy Amos Hochstein will arrive in Israel tonight to discuss a Lebanon ceasefire deal. However, those close to the speaker of the Lebanese Parliament told Sky News in Arabic: There are agreements on almost 80% of the issues.

.. Hezbollah Secretary General Naim Kassem on the cease-fire proposal: We have forwarded our comments, stopping the war now depends on the Israeli response.

.. Senior officials in Israel: The two main controversies, pertaining to Israeli freedom of action in Lebanon in the event of a violation, and the composition of the supervisory committee in Lebanon.

▪️OPPOSITION MK EISENKOT.. submitted a bill to finance academic tuition for combatants and supporters of combat, failed in the plenary following opposition from the coalition. Earlier, the coalition asked to postpone the vote in order to examine whether the proposal is possible in terms of budget - but he refused.

Likud: The law "Dimensions for studies" established 100% funding for a bachelor's degree for combat soldiers, passed on Dec. 2023. Why is the opposition creating a false image?

▪️UN SEC COUNCIL.. attempted to pass a resolution demanding an immediate ceasefire in Gaza without immediately returning the hostages - but with Israel releasing Palestinian terror prisoners. US veto’d.

▪️I.C.J. .. Prof. Malcolm Shaw, head of Israel's defense team at the International Court of Justice in The Hague, at the Security and Democracy Conference of the Israel Democracy Institute: "At the international level, Israel's position is weak. Israel is not Russia. Russia can afford to break the law and get away with it."

▪️MILITARY INDUSTRY.. The aerospace industry reports a backlog of orders of about 25 billion dollars - an all-time record. Among other things, the company presented an increase of about 74% in the net profit in the first 9 months of 2024, this in relation to the corresponding period last year.

❗️IRAQ - reports of Israeli preparations for a pre-emptive strike in Iraqi territory against the Shia militias supported by Iran. Transportation of heavy Iranian missiles to these militias in recent weeks.

♦️LEBANON - Wave of airstrikes through the day.

♦️SAMARIA - JENIN - forces carrying out works to expose terror infrastructures and destroy them, and eliminate terrorists. IED’s encountered.

♦️SYRIA - significant airstrikes in Palmyra, central Syria. Enemy report: a meeting was held that included officers from the regime with members of the Iranian militias.

⭕ROCKET HIT - Kiryat Shmona - apartment building seriously damaged. No injuries.

#Israel#October 7#HamasMassacre#Israel/HamasWar#IDF#Gaza#Palestinians#Realtime Israel#Hezbollah#Lebanon#🎗️

32 notes

·

View notes

Text

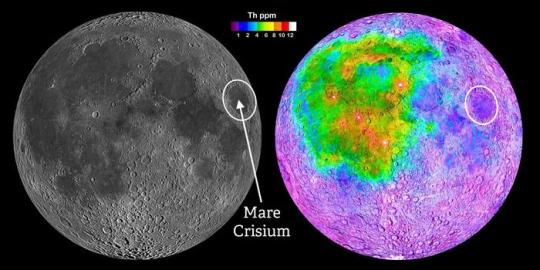

SwRI is sending its first instrument to the lunar surface to survey the Moon’s interior

LMS instrument aboard the Blue Ghost Lander heading to Mare Crisium in early 2025

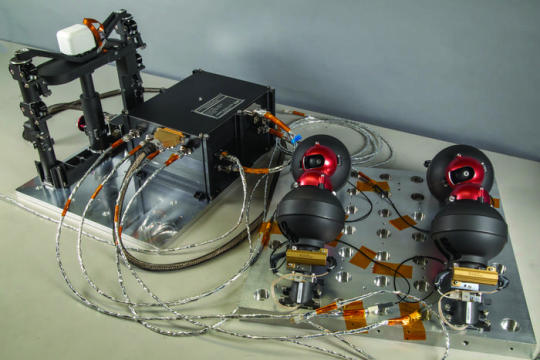

Through NASA’s Commercial Lunar Payload Services (CLPS) initiative, Southwest Research Institute developed the Lunar Magnetotelluric Sounder (LMS) to characterize the structure and composition of the Moon’s mantle by measuring electric and magnetic fields. The LMS instrument — manifested on the Blue Ghost lunar lander developed by Firefly Aerospace and targeted to launch on January 15, 2025 — will be the first SwRI instrument to touch the lunar surface. “For more than 50 years, scientists have used magnetotellurics on Earth for a wide variety of purposes, including to find oil, water, geothermal and mineral resources as well as to understand geologic processes such as the growth of continents,” said SwRI’s Dr. Robert Grimm, principal investigator of LMS. “The LMS instrument will be the first extraterrestrial application of magnetotellurics. NASA’s Artemis program is developing a series of increasingly complex missions to ultimately build a sustained human presence at the Moon for decades to come. To support these goals, LMS is part of a 14-day lunar lander mission to help understand the Moon’s subsurface in a previously unexplored location. Mare Crisium is an ancient, 350-mile-diameter impact basin that subsequently filled with lava, creating a dark spot visible to the naked eye on the Moon. Early astronomers who dubbed dark spots on the moon “maria,” Latin for seas, mistook them for actual seas. Mare Crisium stands apart from the large, connected areas of dark lava to the west where most of the Apollo missions landed. These vast, linked lava plains are now thought to be compositionally and structurally anomalous with respect to the rest of the Moon. From this separate vantage point, LMS may provide the first geophysical measurements representative of most of the Moon. Magnetotellurics uses natural variations in surface electric and magnetic fields to calculate how easily electricity flows in subsurface materials, which can reveal their composition and structure. LMS will allow scientists to probe the interior of the Moon to depths up to 700 miles or two-thirds of the lunar radius. The measurements will shed light on the material differentiation and thermal history of our Moon, a cornerstone to understanding the evolution of solid worlds. The LMS instrument ejects cables with electrodes at 90-degree angles to each other and distances up to 60 feet. The instrument measures voltages across opposite pairs of electrodes, much like the probes of a conventional voltmeter. The magnetometer is deployed via an extendable mast to reduce interference from the lander. The method reveals a vertical profile of the electrical conductivity, providing insight into the temperature and composition of the penetrated materials in the lunar interior. “The five individual subsystems of LMS, together with connecting cables, weigh about 14 pounds and consume about 11 watts of power,” Grimm said. “While stowed, each electrode is surrounded by a ‘yarn ball’ of cable, so the assembly is roughly spherical and the size of a softball.” The LMS payload was funded for delivery to the lunar surface through NASA’s CLPS initiative. SwRI designed the instrument, built the electronics box and leads the science investigation. Goddard Space Flight Center provided the LMS magnetometer to measure the magnetic fields, and Heliospace Corp. provided the magnetometer mast and four electrodes used to measure the electrical fields. Under the CLPS model, NASA is investing in commercial delivery services to the Moon to enable industry growth and support long-term lunar exploration. As a primary customer for CLPS deliveries, NASA aims to be one of many customers on future flights. NASA’s Marshall Space Flight Center in Huntsville, Alabama, manages the development of seven of the 10 CLPS payloads carried on Firefly’s Blue Ghost lunar lander.

TOP IMAGE: From within the Mare Crisium impact basin, the SwRI-led Lunar Magnetotelluric Sounder (LMS) may provide the first geophysical measurements representative of the bulk of the Moon. Most of the Apollo missions landed in the region of linked maria to the west (left image), whose crust was later shown to be compositionally distinct (right image) as exemplified by the concentration of the element thorium. Mare Crisium provides a smooth landing site on the near side of the Moon outside of this anomalous region. Credit NASA

LOWER IMAGE: LMSwRI led the development of the LMS instrument for the Mare Crisium lander mission, which includes (from left) a magnetometer, a central electronics box and four spring-launched electrodes. Credit Southwest Research Institute

7 notes

·

View notes

Text

Green and Eco-Friendly Blasting Media: Current Development, Trends, and Future Challenges

——An In-Depth Industry Analysis for Manufacturing Managers and Environmental Engineers

Introduction: The Revolution of Blasting Technology in the Era of Environmental Transformation

As global environmental regulations tighten (e.g., EU REACH, U.S. EPA standards) and the ESG (Environmental, Social, Governance) concept gains traction, the manufacturing industry is increasingly demanding sustainable surface treatment technologies. Traditional blasting media, such as silica sand and steel grit, are under scrutiny due to dust pollution, high energy consumption, and health risks. In contrast, green and eco-friendly blasting media are emerging as a core breakthrough for industry transformation. This article combines the latest market data and technological trends to analyze the current development and future challenges in this field, providing strategic insights for decision-makers.

I. Market Status: Policy-Driven Growth and Technological Advancements

1. Market Size and Growth Potential

According to Grand View Research, the global blasting media market reached $5.2 billion in 2023, with the share of eco-friendly media rising from 12% in 2018 to 28% in 2023, achieving a compound annual growth rate (CAGR) of 9.7%. By 2030, the market share of green media is expected to exceed 45%, with the Asia-Pacific region (especially China and India) becoming a growth engine due to manufacturing upgrade demands.

2. Mainstream Eco-Friendly Media Types

Plant-Based Materials (walnut shells, corn cobs): Biodegradable, low dust emission (70% less than silica sand), suitable for precision parts.

Synthetic Ceramic Particles (alumina, silicon carbide): High hardness, reusable 5-8 times, reducing long-term costs.

Ice/Dry Ice: Zero-residue technology, with over 40% penetration in the aerospace sector.

Recycled Glass Beads: Made from waste glass, reducing carbon emissions by 65% compared to traditional processes.

3. Policy and Industry Standards Driving Adoption

The EU Circular Economy Action Plan aims to increase industrial waste recycling to 70% by 2030.

China’s 14th Five-Year Plan tightens blasting dust emission limits to 10mg/m³ (previously 20mg/m³).

Automotive giants (e.g., Toyota, Volkswagen) have incorporated "green blasting certification" into supply chain standards.

II. Technological Advantages and Business Value: Why Choose Green Media?

1. Environmental Benefits

Dust Control: Plant-based media reduce dust concentration to <2mg/m³ (compared to 15-20mg/m³ for silica sand), lowering the risk of silicosis.

Carbon Reduction: Each ton of recycled glass beads reduces CO₂ emissions by 1.2 tons compared to new steel grit.

Waste Management: 95% of synthetic ceramic media can be recycled, reducing landfill costs.

2. Economic Breakthroughs

Lower Lifecycle Costs: In the automotive industry, switching to ice media reduced annual maintenance costs by 18% per production line (source: Frost & Sullivan).

Improved Efficiency: High-precision ceramic particles increase blasting speed by 30% and reduce rework rates.

III. Future Challenges: Technological Bottlenecks and Industry Collaboration

1. Technical Pain Points

Material Limitations: Plant-based media have low hardness (Mohs 2-3), making them unsuitable for hard substrates like high-strength steel.

Cost Barriers: Green media prices remain 20-50% higher than traditional materials, hindering adoption by SMEs.

Lack of Recycling Systems: Only 35% of global companies have media recycling equipment, relying on third-party processing.

2. Industry Collaboration Challenges

Lack of Standardization: Differing definitions of "eco-friendly media" across countries create barriers to cross-border procurement.

Insufficient R&D Investment: SMEs lack funding for new material testing (single certification costs exceed $50,000).

IV. Solutions: Innovation and Ecosystem Building

1. Technological Breakthrough Paths

Composite Material Development: For example, "bio-resin + ceramic" hybrid media balancing hardness and biodegradability.

Smart Blasting Equipment: AI algorithms optimize media usage, reducing waste.

Cryogenic Plasma Technology: A zero-media alternative to physical blasting (currently in the lab stage).

2. Industry Ecosystem Recommendations

Policy Subsidies: Governments should offer tax credits for green media procurement (e.g., U.S. IRA Act).

Industry Alliances: Establish cross-company recycling networks to share regeneration facilities.

Customer Education: Use Life Cycle Assessment (LCA) reports to quantify long-term benefits and boost decision-maker confidence.

V. Conclusion: Green Blasting—A Must for Sustainable Manufacturing

Eco-friendly blasting media are not just a compliance requirement but a strategic choice for cost reduction, efficiency improvement, and brand value enhancement. To overcome the dual challenges of technological evolution and market education, innovation, policy coordination, and industry collaboration are essential to transition this field from an "optional solution" to an "industry standard."

Keywords: Green blasting media, eco-friendly surface treatment, sustainable manufacturing, blasting technology trends, industrial carbon neutrality, ESG compliance

Data Sources: Grand View Research, Frost & Sullivan, European Environment Agency, China Ministry of Ecology and Environment. Further Reading:

2024 Global Surface Treatment Technology White Paper

Pathways to Carbon Neutrality in Manufacturing: Starting with Blasting Processes

2 notes

·

View notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

TOKYO, Sept 7 (Reuters) - Japan launched its lunar exploration spacecraft on Thursday aboard a homegrown H-IIA rocket, hoping to become the world's fifth country to land on the moon early next year.

Japan Aerospace Exploration Agency (JAXA) said the rocket took off from Tanegashima Space Center in southern Japan as planned and successfully released the Smart Lander for Investigating Moon (SLIM).

Unfavourable weather led to three postponements in a week last month.

Dubbed the "moon sniper," Japan aims to land SLIM within 100 metres of its target site on the lunar surface.

The $100-million mission is expected to start the landing by February after a long, fuel-efficient approach trajectory.

"The big objective of SLIM is to prove the high-accuracy landing ... to achieve 'landing where we want' on the lunar surface, rather than 'landing where we can'," JAXA President Hiroshi Yamakawa told a news conference.

The launch comes two weeks after India became the fourth nation to successfully land a spacecraft on the moon with its Chandrayaan-3 mission to the unexplored lunar south pole.

Around the same time, Russia's Luna-25 lander crashed while approaching the moon.

Two earlier lunar landing attempts by Japan failed in the last year.

JAXA lost contact with the OMOTENASHI lander and scrubbed an attempted landing in November.

The Hakuto-R Mission 1 lander, made by Japanese startup ispace (9348.T), crashed in April as it attempted to descend to the lunar surface.

SLIM is set to touch down on the near side of the moon close to Mare Nectaris, a lunar sea that, viewed from Earth, appears as a dark spot.

Its primary goal is to test advanced optical and image processing technology.

After landing, the craft aims to analyse the composition of olivine rocks near the sites in search of clues about the origin of the moon. No lunar rover is loaded on SLIM.

Thursday's H-IIA rocket also carried the X-Ray Imaging and Spectroscopy Mission (XRISM) satellite, a joint project of JAXA, NASA and the European Space Agency.

The satellite aims to observe plasma winds flowing through the universe that scientists see as key to helping understand the evolution of stars and galaxies.

Mitsubishi Heavy Industries (7011.T) manufactured the rocket and operated the launch, which marked the 47th H-IIA rocket Japan has launched since 2001, bringing the vehicle's success rate close to 98%.

JAXA had suspended the launch of H-IIA carrying SLIM for several months while it investigated the failure of its new medium-lift H3 rocket during its debut in March.

Japan's space missions have faced other recent setbacks, with the launch failure of the Epsilon small rocket in October 2022, followed by an engine explosion during a test in July.

The country aims to send an astronaut to the moon's surface in the latter half of the 2020s as part of NASA's Artemis programme.

https://www.reuters.com/technology/space/japan-launches-rocket-carrying-moon-lander-slim-after-three-delays-2023-09-06/

youtube

Japan launches 'Moon Sniper' mission | AFP

7 September 2023

Japan's "Moon Sniper" mission blasted off Thursday as the country's space programme looks to bounce back from a string of recent mishaps, weeks after India's historic lunar triumph.

#H-IIA rocket#Japan#lunar exploration spacecraft#SLIM#moon sniper#Japan Aerospace Exploration Agency (JAXA)#Tanegashima Space Center#Smart Lander for Investigating Moon#Hiroshi Yamakawa#Hakuto-R Mission 1 lander#ispace#Mare Nectaris#X-Ray Imaging and Spectroscopy Mission (XRISM) satellite#JAXA#NASA#European Space Agency#Mitsubishi Heavy Industries#Artemis#space#space rocket#Youtube#Chandrayaan-3 mission#Luna-25 lander#India#Russia#moon#moon landing

25 notes

·

View notes

Text

In the realm of space exploration, carbon fiber composites have emerged as a vital component, offering lightweight yet robust solutions for aerospace applications. The Asia-Pacific space carbon fiber composite market was valued at $91.1 million in 2023 and is projected to reach $351.0 million by 2033.

#APAC Space Carbon Fiber Composite Market#APAC Space Carbon Fiber Composite Report#APAC Space Carbon Fiber Composite Industry#Aerospace#BISResearch

0 notes

Text

What are the Key Mechanical Properties of Solids?

Mechanical properties of solids refer to the characteristics that define how a material responds to external forces, such as stress, strain, and deformation. These properties include elasticity, plasticity, hardness, toughness, strength, and ductility, among others. They are fundamental in determining a material’s suitability for various applications, influencing its behaviour under different conditions.

The significance of mechanical properties spans numerous fields. In engineering, these properties ensure the safety and durability of structures like bridges, buildings, and dams. In construction, they guide the selection of materials for specific purposes, such as load-bearing or flexibility. Material science relies heavily on these properties to develop innovative materials that meet evolving industrial demands.

This article aims to delve into the science behind mechanical properties, their key characteristics, real-world applications, and their indispensable role in innovation and progress.

The Science Behind Mechanical Properties

Stress and Strain: Fundamentals

Stress is the force per unit area exerted on a material. It can be mathematically expressed as:

where is the applied force and is the cross-sectional area of the material. Strain, on the other hand, measures the deformation caused by stress. It is defined as the ratio of the change in length to the original length: where is the change in length and is the original length.

Types of Stress and Strain

Tensile Stress and Strain: Occurs when forces act to stretch a material. Examples include the stretching of rubber bands and cables.

Compressive Stress and Strain: Results from forces that compress or squeeze a material. Concrete in buildings often experiences compressive stress.

Shear Stress and Strain: Arises when forces are applied parallel to a surface. Scissors cutting paper is an example of shear stress in action.

Hooke’s Law and Elasticity

Elasticity is the ability of a material to return to its original shape and size after the removal of stress. Hooke’s Law describes this behaviour:

where is the Young’s modulus, a measure of a material’s stiffness. Elasticity is crucial for applications requiring temporary deformation, such as springs.

Plasticity and Permanent Deformation

When stress exceeds a material’s elastic limit, it undergoes plastic deformation, leading to permanent changes in shape or size. Metals like aluminium and copper exhibit plasticity, making them ideal for moulding and shaping processes.

Key Mechanical Properties

1. Young’s Modulus (Stiffness)

Represents a material’s resistance to deformation under tensile stress.

Example: Steel has a high Young’s modulus, making it ideal for construction.

2. Shear Modulus and Bulk Modulus

Shear Modulus measures resistance to shape changes under shear stress.

Bulk Modulus evaluates a material’s response to uniform compression.

Applications include hydraulic systems and pressure vessels.

3. Poisson’s Ratio

Describes the ratio of lateral strain to longitudinal strain. Materials with low Poisson ratios, like cork, are used for sealing applications.

4. Strength

Includes tensile, compressive, and shear strength. Determines how much load a material can bear without failure.

Example: Carbon fiber composites are used in aerospace for their high strength-to-weight ratio.

5. Ductility and Malleability

Ductility is the ability to be stretched into a wire. Copper’s ductility makes it suitable for electrical wiring.

Malleability is the ability to be hammered into sheets. Gold’s malleability is utilized in jewellery making.

6. Brittleness and Toughness

Brittleness: Materials like glass break without significant deformation.

Toughness: Measures a material’s ability to absorb energy before fracturing. Rubber is an example of a tough material.

7. Hardness

Resistance to indentation or scratching. Hardness tests include the Mohs scale and the Brinell test.

Example: Diamond, the hardest known material, is used in cutting tools.

Applications in Engineering and Design

Civil Engineering

Bridges: Steel and reinforced concrete combine high strength and ductility to withstand loads.

Buildings: Materials like concrete and glass are chosen based on compressive strength and aesthetic appeal.

Aerospace and Automotive Industries

Lightweight yet strong materials like titanium alloys ensure efficiency and safety in aircraft.

Automotive components use materials with high impact resistance, such as advanced polymers.

Manufacturing Tools and Machinery

Machine tools rely on hard materials like tungsten carbide for durability and precision.

Conveyor belts require toughness and flexibility to handle wear and tear.

Product Design and Safety Analysis

Consumer goods, such as smartphones, use materials that balance hardness and toughness.

Safety-critical systems, like helmets and airbags, are designed with energy-absorbing materials.

Material Science and Advancements

Developing New Materials

Nanomaterials and composites offer superior strength and lightweight properties.

Innovations like graphene enhance conductivity and mechanical strength.

Sustainability and Recycling

Recyclable materials, such as aluminium, reduce environmental impact.

Bio-based polymers provide eco-friendly alternatives for packaging and construction.

Future Trends

Smart materials, such as shape-memory alloys, adapt to environmental changes.

Research focuses on enhancing the durability of materials under extreme conditions.

The mechanical properties of solids are the backbone of modern engineering, construction, and material science. They ensure the safety, functionality, and efficiency of structures and products. By understanding and leveraging these properties, we can drive innovation, create sustainable solutions, and meet the challenges of an ever-evolving world.

As we continue to explore new materials and techniques, the importance of mechanical properties will remain at the forefront of progress, shaping a future of resilience and ingenuity.

For more simplified explanations like the one above, visit the physics blogs on the Tutoroot website. Elevate your learning with Tutoroot’s personalised Physics online tuition. Begin your journey with a FREE DEMO session and discover the advantages of online tuitions.

2 notes

·

View notes

Text

Scientists develop 3D printing technique using microwaves for faster, versatile manufacturing

- By Nuadox Crew -

Researchers at Lawrence Livermore National Laboratory (LLNL) have developed a new 3D printing technique called Microwave Volumetric Additive Manufacturing (MVAM), which uses microwave energy to cure materials.

This approach allows for a wider range of materials, including opaque and composite resins, compared to traditional light-based methods. MVAM overcomes the limitations of Volumetric Additive Manufacturing (VAM), which is restricted to transparent resins, by enabling microwaves to penetrate deeper into materials. The technique promises faster curing times and the ability to produce larger, complex parts, potentially transforming industries like aerospace, automotive, and healthcare.

The team has demonstrated the ability to cure various resins and developed a computational model to optimize the process. While existing microwave hardware can cure resins in minutes, the model suggests that curing could be reduced to mere seconds at higher power levels. Despite the promise of faster and more versatile production, researchers face challenges such as the high cost of microwave devices. Future work will focus on reducing costs, scaling up production capabilities, and refining the process for broader industrial use

Image: Proposed MVAM system: Energy from the antenna array beams is focused at specific locations through superposition, allowing for complex patterning. Credit: Additive Manufacturing Letters (2024). DOI: 10.1016/j.addlet.2024.100209

Read more at LLNL

Scientific paper: Saptarshi Mukherjee et al, Towards microwave volumetric additive manufacturing: Generation of a computational multi-physics model for localized curing, Additive Manufacturing Letters (2024). DOI: 10.1016/j.addlet.2024.100209

Other recent news

Photosynthesis in Arctic Algae: Researchers have discovered that Arctic algae can thrive with just 100,000th of daylight, showcasing a remarkable adaptation.

#microwave#3d printing#engineering#materials#arctic#biology#plants#oceanography#light#photosynthesis#algae#manufacturing

2 notes

·

View notes