#Warehouse Design

Explore tagged Tumblr posts

Text

#new york loft#loft living#loft interior#loft spaces#open space#warehouse#warehouse design#industrial space#interior design#interior ideas#interiors

20 notes

·

View notes

Text

7 Ways to Optimize the Design of a Cold Storage Warehouse

Designing an efficient cold storage warehouse is crucial for businesses that rely on maintaining the quality and safety of temperature-sensitive products. Here are seven strategies to optimize the design of a cold storage warehouse:

1. Strategic Location and Orientation

The location and orientation of a cold storage facility significantly impact its energy efficiency. Position the building to minimize exposure to direct sunlight, particularly on critical walls and windows. Consider prevailing wind patterns for passive ventilation and utilize natural shade from trees or water bodies to maintain a cooler environment around the facility.

2. Utilize Advanced Automation Systems

Incorporating automation into warehouse design can enhance efficiency and reduce labor costs. Selecting an automation system before finalizing the building design allows for better integration, maximizing storage capabilities. Automated systems such as stacker cranes and robotic pallet shuttles can significantly improve retrieval processes and overall throughput.

3. Maximize Vertical Space

Building taller warehouses can help reduce the footprint while increasing storage capacity. High-density storage solutions, such as automated storage and retrieval systems (AS/RS), allow for efficient use of vertical space, minimizing energy consumption associated with cooling larger areas.

4. Implement Effective Insulation

Proper insulation is essential for maintaining temperature control in cold storage facilities. Use high-quality insulation materials to minimize heat exchange between the internal environment and external conditions. This not only helps in maintaining desired temperatures but also reduces energy costs associated with refrigeration.

5. Optimize Temperature Monitoring Systems

Integrating advanced temperature monitoring systems can ensure that products remain within their required temperature ranges. Utilizing IoT sensors allows for real-time tracking of temperature and humidity levels, enabling quick responses to any fluctuations that could compromise product integrity.

6. Design Efficient Loading and Unloading Areas

Loading bays in warehouse design layouts should be spacious enough to accommodate multiple delivery vehicles simultaneously, reducing congestion and improving operational efficiency. Wider doors and lanes facilitate easier access for trucks, allowing for quicker loading and unloading processes, which is vital for time-sensitive deliveries

7. Incorporate Sustainable Practices

Adopting sustainable practices in cold storage design can lead to long-term cost savings and environmental benefits. This includes using eco-friendly refrigerants, optimizing cooling systems for energy efficiency, and implementing renewable energy sources like solar panels. Regular maintenance checks are also necessary to ensure systems operate at peak efficiency.

By implementing these strategies, businesses can create cold storage warehouses and warehouse design layouts that not only meet operational demands but also enhance energy efficiency and sustainability, ultimately leading to improved profitability in the competitive market of temperature-sensitive goods.

0 notes

Text

6 Major Benefits Of Pre-Engineered Metal Buildings In 2024

Pre-engineered metal buildings (PEBs) are revolutionizing the construction industry, offering a dynamic solution that aligns with modern demands. These structures consist of solid, sustainable materials and are composed of steel beams, columns, roofs, and wall panels that are pre-designed and pre-engineered.

Let's dive into the major benefits of pre-engineered metal buildings.

1. Time-Saving

Traditional construction methods are often time-consuming, plagued by delays due to various factors like sourcing materials from different vendors, labor shortages, transportation issues, and adverse weather conditions. In contrast, pre-engineered metal buildings significantly reduce construction time. Once the requirements are gathered, all involved teams work in synchronization to ensure timely and quality deliverance. This efficiency can cut construction time by almost half compared to conventional methods.

2. Cost-Effective

PEB buildings are cost-effective due to their customizable nature and ease of transportation. Many parts can be recycled, which not only saves money but also reduces waste. The assembly process is straightforward, and once the structure is erected, it requires less maintenance than traditional buildings. This cost efficiency allows building owners to expand their market presence without incurring excessive expenses.

3. Fast Construction

For projects that demand quick and efficient completion, pre-engineered buildings are an ideal choice. Their simple implementation process makes them perfect for producing fast results. These structures are commonly used for warehouses, industrial sheds, factory buildings, cold storage, and industrial enclosures.

4. Easy to Adapt

PEB structures offer a high degree of adaptability and are multipurpose. Whether it's a small warehouse or a large manufacturing unit, there's a pre-engineered solution available. Their adaptability makes them a superior alternative to conventional buildings, capable of meeting diverse needs with ease.

5. Profitability

Pre-engineered building manufacturers use high-quality, recyclable materials. If you need to relocate, you can simply dismantle the structure, transport it, and reassemble it at the new site. This eliminates the need for demolition or selling the building based on land value, making PEBs a profitable investment with minimal extra costs compared to conventional structures.

6. Market Growth and Forecast

The demand for PEB structures is expected to grow due to their eco-friendly approach and various advantages. Pre-engineered metal building manufacturers provide comprehensive support, helping clients expand their operations efficiently. Investments in PEB structures offer mobility and flexibility, which can give businesses a competitive edge. The expansion of SEZs, new airports, and cold storage chains further boosts the popularity of PEB structures.

If you’re looking for high-quality pre-engineered metal buildings, EPACK Prefab is a reliable choice. As a leading manufacturer, EPACK Prefab combines precision and passion to deliver outstanding PEB construction. Choose EPACK Prefab for your next project and experience the unparalleled benefits of pre-engineered metal buildings.

Also Read: Pre Engineered Buildings: Components And Advantages

#Pre-Engineered Buildings#PEB#Metal Buildings#Construction Innovation#Sustainable Construction#Building Solutions#Steel Structures#Fast Construction#Cost-Effective Building#Building Adaptability#Eco-Friendly Buildings#Industrial Construction#Warehouse Design#Prefab Construction#EPACK Prefab#Building Efficiency#Modern Construction#Construction Trends#Building Benefits

2 notes

·

View notes

Text

B1 C Warehouse, Lea Bridge, London, United Kingdom,

Courtesy: The Modern House

#art#design#architecture#minimal#interior design#interiors#warehouse#london#lea bridge#atelier#the modern house#B1C#musicien#artist#studio

205 notes

·

View notes

Text

Study room by the Hillside, Taiwan,

Huibo (Shanghai) Architectural Design Office

#art#design#architecture#interior#interiors#bookcases#library#taiwan#warehouse#luxury house#luxury home#huibo#study room

100 notes

·

View notes

Text

Time Travel Question 69: Assorted Performances VIII

These Questions are the result of suggestions from the previous iteration.

Please add new suggestions below if you have them for future consideration.

#Time Travel#Concerts#Performances#The Rocky Horror Picture Show#San Francisco#1979#20th Century#Queer History#Theater History#Canada#Hamlet#Keanu Reeves#Winnipeg#1995#Anne Hathaway#Twelfth Night#Shakespeare in the Park#Shakespeare#Audra McDonald#Chiwetel Ejiofor#Donmar Warehouse#Othello#Ewan McGregor#Tom Hiddleston#Titanic#Broadway#Sweeney Todd#Noël Coward#Design for Living#James Whale

82 notes

·

View notes

Text

"at least, learn the engine first before actually working on the bg-" "no, i must make asset of my own to fully immerse!"

#KArts#you can tell that i have never designed any metroidvania levels until now#first time and also. i prefer dungeon-crawler kind of levels#i also haven't really came up all the lores for this suppose-new-city that randomly pop out of no where#considering that ZX was meant to be a prequel to Legends#i debating to design the city around the playable areas in mml#but i haven't played Legend for so long#also haven't finished mml2#honestly. my first thought was that this city meant to parody the Central Town cyberspace#hence why there would be statue of Falzar and Gregar if anyone go to the outskirt of the town#But feel like that would create too many confusion#so i'm redesigning this area to look like pieces of Gregar and Falzar fused with the lands. (hence the second image suppose to look like-#Falzar wings)#The Giro Express building was some sort of abadoned warehouse that Aile purchased with a very cheap prices.#the place has a whole underground network#“somehow” there is a tunnel connected to area N#actually there are shortcuts to “important places” which beg the question to who was the original owner of this warehouse#sorry for rambling. but also not really. talking about AUs is good for your soul.

22 notes

·

View notes

Text

helena & myka, 2x07 “for the team”

#warehouse 13#wh13edit#myka bering#helena wells#bering & wells#edits#this gifset brought to you by: doing a big giggle at that last shot#hg like i hate to see her go… love to watch her leave….#also the grand gay spirit of adventure. hg couldnt have designed a better date. yk

572 notes

·

View notes

Text

Warehouse Office in Ageo, Japan - Arii Irie Architects

#Arii Irie Architects#architecture#design#building#modern architecture#interiors#minimal#modern#contemporary#contemporary architecture#design blog#cool architecture#cool design#industrial#chic#light#transparent#polycarbonate sheets#metal cladding#steel#aluminium#urban#city#warehouse#office#office design#timber frame#beautiful architecture#japan#japanese architecture

66 notes

·

View notes

Text

i’m sos orry for not drawing lego stuff my brain. for the past few days has just been this

#cursed with my urge to create silly designs and personalities for protags …#player is literally just an oc at this point but idc they’re my little guy i love them with my heart#they work at a warehouse#they’re kinda emmet brickowski coded tbh#i could’ve drawn so much special spaceship …#but look where i am .. drawing a dumb yellow thing for the 50th time#and just poppy playtime rot to be fair#i want to talk about it so much#i hope my lil guy is an actual enjoyable character imm a little scared they aren’t#<:D#don’t want to make them too silly cause they’re like — 30 and in a murder house and i don’t want them to seem unrealistically optimistic#but also i love writing silly characters#an endless peril i face ..

19 notes

·

View notes

Text

#loft area#loft interior#loft spaces#loft ideas#loft inspo#warehouse living#warehouse interiors#loft bed#loft bedroom#brick wall#interior brick#mid century modern#mcm furniture#exposed wood#living room ideas#living room inspo#bed inspo#interior design#interior ideas#interiors#bohemian living#interior decor

117 notes

·

View notes

Text

Warehouse Layout Design: Best Practices, Examples & Ideas

Designing an efficient warehouse layout is crucial for optimizing operations, enhancing productivity, and ensuring safety. This article provides an overview on warehouse layout design, focusing on best practices, real-world examples, and innovative ideas that can help warehouse managers, logistics professionals, and business owners maximize their warehouse spaces.

Understanding Warehouse Layout Design

Warehouse layout design refers to the strategic arrangement of various areas within a warehouse to optimize the flow of goods and information. It encompasses the layout of storage spaces, receiving and shipping areas, and the overall workflow within the facility. A well-planned layout not only improves efficiency but also reduces operational costs and enhances safety.

Key Principles of Warehouse Layout Design

Strategic Layout Planning:

Place high-demand items closer to shipping areas.

Optimize travel paths to minimize congestion.

Design layouts that facilitate quick picking and packing processes.

Utilization of Vertical Space:

Implement storage solutions that utilizes height such as high bay racking.

Maximize storage capacity while maintaining accessibility.

Embracing Technology:

Utilize automated systems such as ASRS and robotic picker. to increase efficiency

Technology can significantly reduce manual labor and errors.

Flexible Storage Solutions:

Use adjustable shelving and modular racks to accommodate varying product sizes.

Adapt storage configurations based on seasonal demand fluctuations.

Employee Training and Well-being:

Invest in employee training on new technologies and best practices.

Create ergonomic workstations to enhance safety and productivity.

Continuous Improvement Culture:

Foster an environment where employees can suggest efficiency improvements.

Regularly evaluate processes to identify areas for enhancement.

Sustainable Practices:

Incorporate eco-friendly materials and energy-efficient technologies in warehouse design.

Scalability and Flexibility:

Design warehouses that can easily adapt to business growth without major disruptions.

Modular designs allow for seamless expansion as needs evolve.

Common Warehouse Layout Types

Choosing the right layout is essential for optimizing space and workflow. Here are three common types:

U-Shaped Layout:

Features shipping and receiving areas adjacent to each other with storage in the middle or at the back of the warehouse.

This design minimizes travel time between these critical areas, reducing bottlenecks.

I-Shaped Layout:

Arranges loading/unloading zones at either ends with storage in the center.

Ideal for high-volume warehouses where products need to travel long distances within the facility.

L-Shaped Layout:

Configures traffic flow in an "L" shape, separating receiving from shipping areas.

This layout maximizes storage space while maintaining efficient workflow.

Best Practices for Optimizing Warehouse Layout

Define Requirements and Objectives: Understand your specific business needs, including inventory types, order volumes, and any special handling requirements.

Optimize Space Utilization: Select appropriate shelving or racking systems based on the products stored, ensuring maximum accessibility while fitting as much inventory as possible.

Implement Clear Signage and Labels: Use signs to guide employees through the warehouse efficiently, reducing confusion and improving operational speed.

Regularly Review and Adjust Layouts: As operations evolve or new technologies emerge, revisit your layout design to ensure it remains effective.

Real-World Examples of Successful Warehouse Designs

Several companies have successfully implemented innovative warehouse layouts:

Amazon's Fulfillment Centers: Utilize advanced robotics alongside traditional shelving systems to streamline order fulfillment processes.

Walmart's Distribution Centers: Employ a combination of U-shaped layouts with automated systems for efficient inventory management.

These examples illustrate how strategic planning can lead to significant improvements in efficiency and productivity.

Conclusion

Effective warehouse layout design is fundamental for optimizing operations in any logistics environment. By adhering to best practices, understanding different layout types, and continuously seeking improvements, businesses can enhance their warehouse efficiency significantly. Implementing these strategies not only maximizes space utilization but also supports future growth while ensuring employee safety and satisfaction.

0 notes

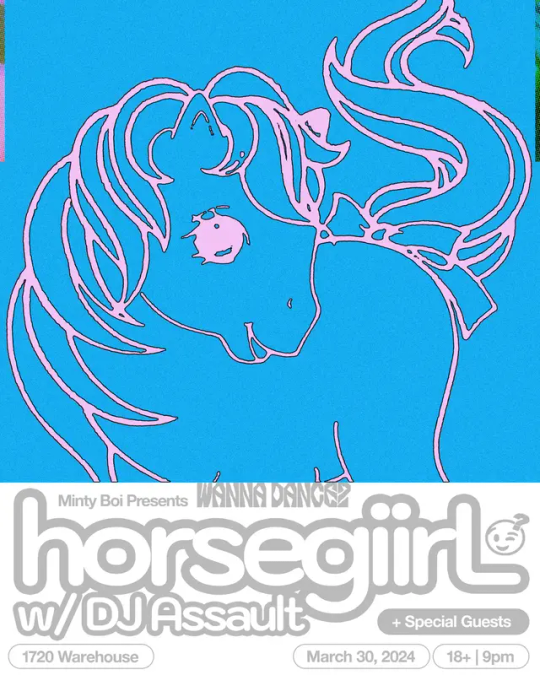

Text

#horsegiirl#minty boi#wanna dance?#1720 warehouse#event#electronic#music#graphic design#poster art#u

118 notes

·

View notes

Text

I've officially started my Chai cosplay :3

#thanks to my grdma's mad sewing skills; a 12€ jacket and some orange fabric#Hi-Fi Rush#cosplay#next step is to make an 808 plushy#i know this sounds like a weird next step but I'm not home for the summer and didn't feel like transporting a warehouse worth of cardboard#for the robot arm#however materials for a plushy took a lot less space#so 808 it is#but i also wanna add a cool little design with fabric paint on the left sleeve instead of the weird grey spot Chai has#gotta settle on a design first#anyway#toodles

40 notes

·

View notes

Text

Magnus Walker's Downtown L.A. Pad, California

#art#design#architecture#minimalism#interior#interiors#luxury house#luxury home#los angeles#magnus walker#downtown#pad#garage#warehouse#converstion#restauration#loft

57 notes

·

View notes

Text

Tattoo commission! This one was the second of a two part Warehouse 13 tattoo, and it was so nostalgic to get to work on this project again :')

129 notes

·

View notes