#Thermal resistance

Explore tagged Tumblr posts

Text

High-Temp Metals: Breaking Down Barriers in Manufacturing

In the fast-paced world of manufacturing, efficiency and durability are paramount. High-temp metals have emerged as game-changers, revolutionizing how industries tackle extreme conditions.

Case Study: Streamlining a Manufacturing Process

A leading aerospace parts manufacturer faced frequent downtime due to component failures in high-temperature environments. By switching to Accromet’s high-temp metals, they reduced component wear by 30%, improved product lifespan, and significantly decreased production interruptions.

Expert Insight: Reducing Downtime with High-Temp Metals

We spoke with John Smith, a materials engineer with 20+ years of experience: "High-temp metals are vital for modern manufacturing. Their exceptional thermal resistance prevents failures in extreme environments, ensuring smooth operations and reduced maintenance costs."

The Numbers Speak for Themselves

25%: Average increase in manufacturing efficiency reported by companies adopting high-temp metals.

40%: Reduction in downtime due to enhanced durability and thermal resistance.

50%: Longer lifespan of components made with high-temp alloys compared to standard materials.

Storytelling: Transitioning to High-Temp Metals

Imagine a small-scale automotive manufacturer struggling with heat damage in their exhaust systems. After integrating high-temp metals into their design, they not only resolved the issue but also improved vehicle performance. Their success story showcases the transformative power of these materials.

Actionable Advice: Steps to Integrate High-Temp Metals

Identify Problem Areas: Pinpoint where thermal resistance is critical in your processes.

Consult Experts: Work with specialists to select the best alloy for your needs.

Test and Iterate: Start with prototypes to ensure compatibility with your manufacturing line.

Train Your Team: Educate staff on handling and maintaining high-temp components.

Visuals: Lifecycle of a High-Temp Metal Component

Let’s Hear From You!

What’s the biggest challenge you face in manufacturing with high-temp materials? Share your thoughts in the comments below and join the conversation!

By incorporating high-temp metals, you can overcome manufacturing barriers and unlock new levels of efficiency and reliability. Let Accromet be your partner in this transformative journey.

#High-temp metals#Manufacturing#Thermal resistance#Heat-resistant materials#High-temperature alloys#Manufacturing efficiency#Durable materials#Metal component lifecycle#Industrial applications#Heat-resistant components

0 notes

Text

Exploring Super Thin Insulation Solutions in the Chemical Manufacturing Industry

In today's rapidly evolving construction and manufacturing sectors, the demand for innovative materials is at an all-time high. One such advancement is the super thin insulation, which is revolutionizing the way we approach energy efficiency and sustainability.

Minmetals East is at the forefront of this transformation, offering high-quality silica products and adhesives that enhance the performance of construction materials. Their super thin insulation not only provides excellent thermal resistance but also contributes to reduced energy consumption, making it an ideal choice for modern building practices.

The versatility of super thin insulation extends beyond construction; it plays a critical role in water treatment processes as well, ensuring that systems operate efficiently while minimizing energy use. With Minmetals East's commitment to quality and innovation, businesses can confidently adopt these advanced materials to improve their operations and environmental impact.

Together, we can build a greener future with superior insulation solutions that meet the needs of various industries. Embrace the change and explore the benefits of super thin insulation today!

#thermal resistance#advanced materials#Minmetals East#energy efficiency#environmental impact#water treatment

0 notes

Text

Laminate Mica Paper: Top Benefits and Industrial Applications Explained - OmkarPaper

Explore the top benefits and industrial applications of laminate mica paper with OmkarPaper. Discover how this versatile material enhances electrical insulation, thermal resistance, and mechanical stability in various industries.

#Laminate mica paper#Electrical insulation#Thermal resistance#Mica paper applications#Industrial insulation materials#OmkarPaper products#Laminate mica benefits#Electrical insulation materials#Mica paper industrial uses

0 notes

Text

nothing "beats walking"

#walking in a storm to get groceries for fun and because i love it#turns out neighbor delivers pizza and was like omg wtf r u doing ill give you a ride and i was like nooooooo i promise im doing this for fun#ive perfected my winter layering i actually getting warm hiking thru the snow#you need only 3 layers. 1) tight thermal layer that traps heat against body 2) cozy warm fluff middle layer 3) hard rain/wet resistant#''shell'' overcoat to keep the elements OUT and the warmth IN#it was great no cars I was like walking on the street and stuff#i really am just like out and about at all hours of the night......hate being in the house#always either walking or on my scooter...... exploring every little bit of like my three mile radius of walking

5 notes

·

View notes

Text

got confirmation the other day that the problems my laptop was having were almost certainly caused by the sims 4 melting the insulation teehee

#the question is. how long can i resist doing it all over again.#okay they did not say this they said they replaced the melted thermal paste and the artifacting and shutting down stopped#and there’s really only 2 games i play that make my laptop overheat like that

10 notes

·

View notes

Text

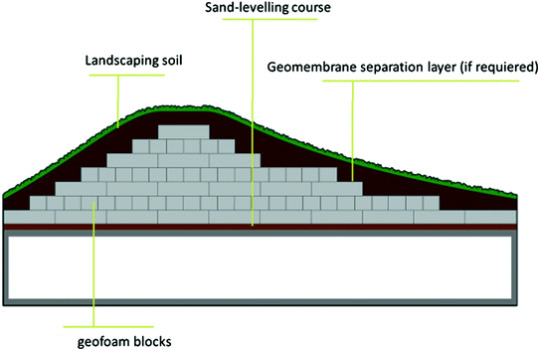

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

12 notes

·

View notes

Text

When someone says 'damn, arnt you cold standing out here, vapeing?'

I'll say 'naw, it's barely brisk' with a straight face, knowing damn well I'm wareing 4 layers. Atleast two of which are fleece lined.

#bek rambles about crap#its a pride thing I think#like naw Im not cold!#I was built for the depths of the english winter!!#grew up with them!#became one with the elements!!!#exept Im wareing a thick top jumper fleecy jacked and winter coat#not to mention the three other pairs of trowsers and thermal socks under my jeans#but no!!!#Im die hard english!!!#fear my cold resistance!!!!!

2 notes

·

View notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

Exploring Calcium Silicate Thermal Insulation in Construction

Welcome to my first post! I wanted to share some insights into the fascinating world of chemical manufacturing, particularly focusing on the role of calcium silicate thermal insulation in construction materials.

As we all know, thermal insulation is crucial for energy efficiency in buildings. Calcium silicate insulation products provide excellent thermal performance while also being environmentally friendly. This makes them a fantastic choice for both residential and commercial construction projects.

Calcium silicate thermal insulation is lightweight, fire-resistant, and has outstanding durability, which means it can significantly enhance the overall performance of building structures.

Moreover, these products are essential for effective water treatment processes, ensuring that we maintain clean and safe water supplies. The versatility of calcium silicate extends beyond just insulation; it's a key component in various industrial applications, showcasing the extensive potential of silica products.

In conclusion, if you're involved in construction or industrial materials, consider exploring innovative solutions in calcium silicate thermal insulation. These products can make a substantial difference in energy efficiency and sustainability for your projects.

Looking forward to discussing more about this topic with everyone!

#fire-resistant#thermal insulation#industrial applications#construction#environmentally friendly#water treatment#durability

1 note

·

View note

Text

How Transparent Thermal Insulation Glass Coating Enhances Comfort

Transparent Thermal Insulation Glass Coating enhances indoor comfort by maintaining consistent temperatures, preventing heat gain in summer and heat loss in winter. This advanced coating reflects infrared rays while allowing natural light to pass through, ensuring a bright and energy-efficient indoor environment. By minimizing heat transfer, thermal insulation coating reduces dependency on heating and cooling systems, lowering energy consumption and utility bills. Ideal for residential and commercial properties, it provides superior comfort, improved energy efficiency, and a sustainable solution for temperature control.

#heat cure glass coating price#transparent heat resistant paint for glass#transparent heat insulation coating for glass#uv protection film for windows#excel staycool - transparent heat resistant paint for glass#thermal coating for glass#window film to block sun heat india#transparent sun protection glass coating price#transparent sun protection glass coating for windows#transparent sun protection glass coating near me#transparent sun protection glass coating india#best transparent sun protection glass coating

0 notes

Text

Heat Resistant & Thermal Insulation Paint For 1800 Deg C- Wb services in pune,india.

Looking for the best Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in Pune and India? Ugam Chemicals brings you an advanced thermal insulation coating designed for high-temperature applications. Our specialized Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB is engineered to withstand extreme heat conditions, making it the perfect solution for industrial furnaces, boilers, ovens, pipelines, and steam pipelines.

Why Choose Our Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB?

High thermal resistance up to 1800°C

Excellent heat insulation properties

Increases energy efficiency by reducing heat loss

Suitable for multiple industrial applications

Long-lasting and durable coating solution

We are a trusted Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB supplier in Pune and India, offering high-quality coatings for industrial needs. Our product is widely used in thermal insulation coating services in Pune and India, ensuring optimal heat resistance for critical equipment.

Applications of Thermal Insulation Coating

Our Thermal Insulation Coating for Furnace in Pune and India is designed to improve the efficiency of high-temperature industrial processes. It minimizes heat loss, ensuring better performance and reduced energy consumption. We also provide Thermal Insulation Coating for Boiler in Pune and India, offering a protective layer to withstand extreme heat.

For industries dealing with steam transportation, our Thermal Insulation Coating for Steam Pipelines in Pune and India ensures enhanced protection against heat dissipation. Whether you need Thermal Insulation Coating for Pipelines in Pune and India, or Thermal Insulation Coating for Ovens in Pune and India, we provide solutions that enhance efficiency and durability.

Contact Us

As a leading Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services provider in Pune and India, Ugam Chemicals guarantees top-quality coatings for industrial applications. Explore more about our Thermal Insulation Coating solutions here: 🔗 https://ugamchemicals.com/heat-resistant-thermal-insulation-paint-for-1800-deg-c-wb.html

For inquiries, contact us today and enhance the thermal efficiency of your industrial equipment! 🚀

#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in india#Thermal Insulation Coating services in pune#Thermal Insulation Coating services in india#Thermal Insulation Coating for Furnace in pune#Thermal Insulation Coating for Furnace in india#Thermal Insulation Coating for Boiler in pune#Thermal Insulation Coating for Boiler in india#Thermal Insulation Coating for Steam Pipe lines in pune#Thermal Insulation Coating for Steam Pipe lines in india#Thermal Insulation Coating for pipe line in pune#Thermal Insulation Coating for pipe line in india#Thermal Insulation Coating for oven in pune#Thermal Insulation Coating for oven in india.

0 notes

Text

Protecting Cement Plant Kilns with Thermal Spray SS 316L Coating: A Game-Changer for Corrosion Resistance

In the demanding environment of cement plants, kilns are the heart of production. These massive structures are exposed to extreme temperatures, chemical reactions, and abrasive materials, making them highly vulnerable to corrosion and wear. One of the most effective ways to extend the lifespan of kilns and improve operational efficiency is through SS 316L coating.

What is Thermal Spray SS 316L Coating?

SS 316L is a low-carbon variant of 316 stainless steel, known for its exceptional corrosion resistance, particularly in aggressive environments. This alloy contains molybdenum, enhancing its ability to resist chloride-induced corrosion and acidic conditions. Its low carbon content minimizes the risk of carbide precipitation during welding, making it highly durable and suitable for industrial applications.

Why Apply SS 316L Coating Inside Kilns?

The interior of a cement plant kiln is continuously exposed to harsh conditions such as high temperatures, sulfur compounds, and alkali materials, which can lead to rapid deterioration of unprotected surfaces. Here’s how Thermal Spray SS 316L coating offers robust protection:

Superior Corrosion Resistance

Protects against chemical attacks from alkalis and sulfates commonly found in cement production.

Minimizes degradation from exposure to aggressive gases.

High-Temperature Strength

Withstands extreme temperatures without compromising structural integrity.

Reduces the risk of material fatigue and failure under thermal stress.

Extended Equipment Lifespan

Reduces frequent repair and replacement costs.

Enhances the durability of kiln linings, ensuring consistent operation.

Improved Energy Efficiency

Provides a smoother internal surface, reducing friction and energy consumption.

Helps maintain optimal heat distribution within the kiln.

Application Process of SS 316L Coating

Applying SS 316L coating inside kilns requires specialized techniques to ensure durability and effectiveness. The process generally includes:

Surface Preparation

Grit blasting or sandblasting is conducted to remove contaminants and roughen the surface for better adhesion.

Coating Application

The SS 316L coating is applied using thermal spray techniques or specialized welding methods.

Inspection and Testing

Post-application inspection ensures the coating adheres properly and meets quality standards.

Benefits for Cement Plants

Reduced maintenance costs due to longer-lasting kiln linings.

Enhanced safety by minimizing unexpected equipment failures.

Improved operational efficiency with reduced downtime.

Protection against costly shutdowns caused by corrosion damage.

Why Choose Cement Plant Painters for SS 316L Coating?

At Cement plant painters, we specialize in advanced corrosion protection solutions for industrial applications. Our SS 316L coating services are tailored to meet the rigorous demands of cement plant operations. With our best-skilled team and cutting-edge technology, we ensure:

High-quality application standards

On-time project completion

Cost-effective solutions that boost operational longevity

Contact Us Today

Protect your kiln and enhance its lifespan with our specialized SS 316L coating services.

Cement Plant Painters Phone: +91-9845063120 Website: https://cementplantpainters.com

Invest in durability, efficiency, and long-term savings today!

#Thermal spray coating#thermal spray ss coting#SS-316L coating#corrosion resistance#corrossion protection#rust prevention

0 notes

Text

Exploring Ceramic Fiber Modules in the Chemical Manufacturing Industry

In the heart of the Chemical Manufacturing and Industrial Materials sectors, Minmetals East stands out for its commitment to quality and innovation. Their ceramic fiber modules are a game-changer in enhancing the efficiency of various applications, particularly in the fields of adhesives, construction materials, and water treatment.

These modules provide excellent thermal insulation, making them an ideal choice for industries that require high-temperature resistance and energy efficiency. With Minmetals East's focus on sustainable practices, clients can trust that they are not only improving their operational performance but also contributing positively to environmental stewardship.

By integrating advanced technology and high-quality materials, Minmetals East continues to lead the way in providing solutions that meet the evolving needs of the marketplace. Embrace the future of industrial materials with Minmetals East and experience the benefits that come with their exceptional ceramic fiber modules!

#construction materials#adhesives#energy efficiency#thermal insulation#high-temperature resistance#industrial materials#sustainable practices#environmental stewardship

0 notes

Text

ABS plastic: a comprehensive analysis from raw materials to products

In the rapidly developing modern industry, the selection and application of materials are directly related to the performance, cost and sustainability of products. ABS plastic, as a thermoplastic widely used in many fields, has become the preferred material in many industries due to its unique chemical structure and superior physical properties. This article will take you to an in-depth…

#ABS plastics#acrylonitrile#automobile manufacturing#butadiene#construction field#corrosion resistance#daily life#easy processing#Electrical Insulation#electronics and electrical appliances#high strength#polymerization#styrene#thermal stability#toughness

0 notes

Text

Green Semi-Gloss HD CAWN 2321: High-Performance Liquid Photoimageable Solder Resist

Discover Green Semi-Gloss HD CAWN 2321, a thermal hardening liquid solder resist designed for superior PCB protection. RoHS and WEEE compliant, UL listed, and REACH-certified, it meets IPC standards and is trusted in industries including automotive and aerospace. Explore its advanced capabilities today.

#Green semi-gloss solder resist#liquid photoimageable solder resist#CAWN 2321#thermal hardening solder mask#IPC standards solder resist#advanced PCB protection#solder resist for automotive#aerospace solder resist solutions#Aqueous Potassium Carbonate processing#Aqueous Sodium Carbonate processing#solvent-processable solder resist#PCB solder mask solutions#A-Gas Electronic Materials

0 notes

Text

Unlocking Energy Efficiency: The Importance of Thermal Insulation in Saudi Arabia

In the heart of Saudi Arabia, where soaring temperatures can lead to soaring energy bills, the need for effective thermal insulation has never been more critical. As energy costs rise and the demand for sustainable living grows, homeowners and businesses alike are turning to innovative solutions to enhance their buildings’ efficiency. This is where RNS KSA comes into play, offering premier insulation services that ensure comfort without compromising on energy savings.

Why Thermal Insulation Matters

Thermal insulation is essential for maintaining comfortable indoor temperatures, especially in the extreme climates of Saudi Arabia. By reducing heat transfer between the outside and inside of a building, insulation helps keep interiors cool during the blistering summer months. This not only enhances comfort but also significantly lowers energy consumption, making it a win-win for both the environment and your wallet.

The construction industry in Saudi Arabia is rapidly evolving, and energy efficiency is now at the forefront of this transformation. High-quality building materials that feature advanced insulation properties are becoming standard in new developments. Investing in effective thermal insulation can lead to substantial savings on air conditioning costs, which are a significant portion of monthly energy bills.

RNS KSA: Your Partner in Energy Efficiency

RNS KSA specializes in providing top-tier thermal insulation solutions that cater to the unique demands of the Saudi Arabian climate. Our commitment to eco-friendly solutions ensures that our products not only enhance energy efficiency but also contribute to a sustainable future. We understand that every building has distinct needs, which is why we offer tailored insulation services that are designed to meet specific requirements.

Our expert team is dedicated to helping you choose the right insulation materials for your project. From spray foam to fiberglass, RNS KSA utilizes only the best products that comply with international standards. By focusing on HVAC efficiency, we help reduce the load on your heating and cooling systems, leading to longer lifespan and lower operational costs.

The Benefits of Investing in Thermal Insulation

Cost Savings: With rising energy prices, investing in thermal insulation can dramatically reduce your energy bills. The initial cost of installation is often offset by the long-term savings achieved through lower energy consumption.

Enhanced Comfort: Proper insulation keeps your indoor environment stable and comfortable. Say goodbye to hot spots and drafty rooms!

Environmental Impact: By improving energy efficiency, thermal insulation helps reduce your carbon footprint. This aligns with Saudi Arabia’s vision for a more sustainable future.

Increased Property Value: Homes and buildings with quality insulation tend to have higher market values. Potential buyers are increasingly aware of energy efficiency, making insulated properties more attractive.

Noise Reduction: Quality thermal insulation not only manages temperature but also absorbs sound, making your indoor spaces quieter and more peaceful.

Choosing the Right Insulation

When it comes to selecting the best thermal insulation for your building project, it’s important to consider factors such as climate, building design, and intended use. RNS KSA’s team of professionals is here to guide you through the selection process, ensuring you choose the right product that suits your needs and budget.

We also provide comprehensive installation services, ensuring that your insulation is applied correctly for maximum effectiveness. Our commitment to excellence means that we stay updated with the latest techniques and materials in the industry, guaranteeing that you receive the best service possible.

Conclusion

In a country like Saudi Arabia, where energy efficiency is not just a choice but a necessity, RNS KSA stands out as a trusted partner in thermal insulation solutions. By investing in quality insulation, you can achieve significant cost savings, enhance indoor comfort, and contribute to a more sustainable future.

Make the smart choice today. Contact RNS KSA to learn more about our thermal insulation services and how we can help you maximize your building’s energy efficiency. Together, let’s create a cooler, more comfortable environment while being kind to our planet.

#thermal insulation#insulation services#energy efficiency#RNSKSA#building insulation#HVAC insulation#industrial insulation#thermal protection#insulation solutions#heat resistance

0 notes