#Thermal Insulation Coating services in india

Explore tagged Tumblr posts

Text

#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in india#Thermal Insulation Coating services in pune#Thermal Insulation Coating services in india#Thermal Insulation Coating for Furnace in pune#Thermal Insulation Coating for Furnace in india#Thermal Insulation Coating for Boiler in pune#Thermal Insulation Coating for Boiler in india#Thermal Insulation Coating for Steam Pipe lines in pune#Thermal Insulation Coating for Steam Pipe lines in india#Thermal Insulation Coating for pipe line in pune#Thermal Insulation Coating for pipe line in india#Thermal Insulation Coating for oven in pune#Thermal Insulation Coating for oven in india

0 notes

Text

What Are the Ways to Choose Aluminium Windows and Doors?

Choosing the right aluminium windows and doors for your home or commercial space is crucial for aesthetics, durability, and functionality. Aluminium is a preferred material due to its strength, low maintenance, and modern appeal. As the best system aluminium windows and doors supplier in India, GREFET provides high-quality solutions tailored to your needs. Here’s a guide to help you make the best choice.

Consider the Type of Aluminium Windows and Doors There are various styles of aluminium windows and doors to suit different needs: • Aluminium Sliding Doors – Ideal for maximizing space and providing seamless indoor-outdoor connectivity. • Casement Windows – Open outward for excellent ventilation and a classic look. • Fixed Windows – Perfect for spaces where natural light is needed without ventilation. • Bi-Fold Doors – Great for larger openings, offering flexibility and style. • Tilt and Turn Windows – Provide dual functionality for better ventilation and security.

Assess the Quality of Aluminium Window Frames The durability and performance of aluminium window frames depend on their quality. When selecting aluminium frames, consider: • Thickness – A minimum thickness of 1.2mm is recommended for residential applications, while 2mm or more is suitable for commercial spaces. • Powder Coating or Anodizing – A high-quality finish ensures resistance to corrosion and weather conditions. • Thermal Break Technology – Enhances energy efficiency by reducing heat transfer.

Choose the Right Glass for Energy Efficiency Aluminium windows and doors are often paired with glass, so choosing the right type is essential: • Double or Triple Glazing – Provides better insulation and noise reduction. • Low-E Glass – Enhances energy efficiency by minimizing heat loss. • Tinted or Frosted Glass – Offers privacy while maintaining aesthetic appeal.

Check for Security Features Security is a key consideration when selecting aluminium windows and doors. Ensure they come with: • Multi-point locking systems • Toughened or laminated glass for added security • Reinforced aluminium window frames for structural strength

Look for Weather Resistance and Durability Since aluminium windows and doors are exposed to various weather conditions, check for: • Water Resistance – Proper drainage systems prevent water accumulation. • Wind Load Capacity – Essential for high-rise buildings and coastal areas. • UV-Resistant Finishes – Protects against fading and discoloration.

Customization Options GREFET offers a wide range of aluminium sliding doors, windows, and aluminium window frames in various colors, designs, and finishes to match your architectural style. Customization ensures that your installations complement the aesthetics of your space.

Installation and After-Sales Service Professional installation is crucial for the longevity and performance of aluminium windows and doors. GREFET provides expert installation services and excellent customer support to ensure hassle-free maintenance. Conclusion Choosing the right aluminium windows and doors requires careful consideration of style, quality, security, and durability. As a leading supplier in India, GREFET ensures that you get the best solutions tailored to your needs. Whether you’re looking for aluminium sliding doors, sturdy aluminium window frames, or energy-efficient solutions, GREFET has you covered. Contact us today to explore our range of premium aluminium products!

#aluminium windows and doors#aluminium windows#aluminium sliding doors#aluminium window frames#best aluminium window company in india

0 notes

Text

The Rise of FRP Pipes: Strength, Durability, and Versatility

D Chel Oil & Gas is an experienced FRP pipe manufacturer in India. FRP pipe is corrosion-resistant, simple to construct and carry, has a long service life, and needs little maintenance. It delivers sewage and wastewater from households and businesses. Our FRP pipe performs effectively under a wide range of soil and weather conditions. When placed in difficult locations, they may have to operate at high temperatures and pressures. FRP pipes are widely used in a variety of industries, including power generation, irrigation, gas, and chemical plants.They are often recognised as the most successful petrochemical industry commodity solutions.

What Are FRP Pipes?

FRP pipes are made from a composite material that combines a polymer matrix reinforced with fibers, typically glass or carbon. The polymer matrix acts as a binder, while the fibers provide structural integrity and strength. This combination results in a lightweight, yet incredibly strong material that can withstand harsh environmental conditions.

The manufacturing process often involves filament winding, pultrusion, or centrifugal casting, each tailored to specific performance requirements. The versatility of FRP pipes in terms of customization makes them suitable for a wide range of industries.

Key Benefits of FRP Pipes

Corrosion Resistance One of the most significant advantages of FRP pipes is their resistance to corrosion. Unlike traditional materials such as steel or concrete, FRP pipes are unaffected by exposure to chemicals, salts, and water, making them ideal for chemical plants, desalination facilities, and wastewater treatment systems.

Lightweight and Easy Installation FRP pipes are significantly lighter than materials like steel or concrete. This reduces transportation and handling costs and simplifies the installation process. The reduced weight also minimizes the need for heavy machinery during installation, saving time and labor costs.

High Strength-to-Weight Ratio Despite their lightweight nature, FRP pipes offer exceptional strength. This makes them suitable for high-pressure applications and ensures long-term performance in demanding environments.

Longevity and Low Maintenance The durability of FRP pipes ensures a long service life, often exceeding 50 years. Their resistance to wear, tear, and environmental factors means they require minimal maintenance, reducing lifecycle costs.

Thermal and Electrical Insulation FRP pipes provide excellent insulation properties, making them suitable for applications involving high-temperature fluids or environments requiring non-conductive materials.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

The versatility of FRP pipes allows their use across various industries, including:

Oil and Gas: Transporting corrosive fluids, including crude oil and natural gas, in offshore and onshore applications.

Chemical Processing: Handling aggressive chemicals and acids without the risk of material degradation.

Water and Wastewater Management: Used for desalination plants, potable water supply, and sewage systems due to their resistance to corrosion and biofouling.

Power Generation: Cooling water systems and chimney liners in power plants often utilize FRP pipes for their durability and performance under extreme conditions.

Marine and Offshore: FRP pipes are widely used in marine applications for their resistance to saltwater corrosion.

Design and Customization

FRP pipes can be designed to meet specific requirements, including:

Pressure Ratings: Tailored to handle low, medium, or high-pressure applications.

Diameter and Length: Customizable to suit various installation scenarios.

Lining and Coating: Additional linings can enhance chemical resistance or provide smooth flow for specific fluids.

Considerations for Using FRP Pipes

While FRP pipes offer numerous benefits, there are considerations to address:

Initial Cost: Although FRP pipes may have a higher upfront cost compared to traditional materials, their long-term benefits often outweigh this.

Specialized Installation: Proper installation by trained professionals is essential to ensure optimal performance and longevity.

Temperature Limitations: While FRP pipes are resistant to many conditions, extremely high temperatures may affect their performance. Proper material selection is crucial for such scenarios.

The Future of FRP Pipes

As industries continue to prioritize sustainability, efficiency, and cost-effectiveness, FRP pipes are poised to become a go-to solution. Advances in manufacturing processes and material science are further expanding their capabilities, making them an even more attractive option for diverse applications.

FRP Pipe Manufacturers in India

India is home to several well-known FRP pipe manufacturers who develop high-quality goods that match international standards.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that customers receive long-lasting and effective pipe systems. These manufacturers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the result of cutting-edge production procedures and rigorous quality control measures. We are also one of the major FRP grating manufacturers in India.

#FRP Pipe Manufacturers in India#FRP pipe manufacturers#FRP Pipe Suppliers in India#FRP Grating Manufacturers in India

0 notes

Text

VEKA uPVC doors improve thermal insulation at home

The gratification of entering the home after a long day’s work is something, we all look forward to each day. What if it becomes easier to glide inside the calm indoors just by unlocking and the door open? It is a relief to walk inside the cool interiors in summers and experience the warmth in winters. This is a prime advantage of uPVC doors thermal conductivity of an urban home. This insulation is the key to adaptability when seasons change.

Advantages of uPVC Doors by VEKA for homes

The following information is curated by our experts to explain energy-saving with uPVC doors. VEKA is a manufacturer of the best uPVC doors in India. We are reputed worldwide for our capability to assemble door profiles that stack up in tight city spaces.

Interested in this wonderful and amazing entrance option for your apartment?

Why are doors assets in crowded cities?

Space is premium and energy efficiency is paramount in Indian cities. Having uPVC doors which do not take up space is valued. Sleek and stylish doors offer a perfect blend of aesthetics and security. With thermal insulation, they are ideal entrances for modern homes. In locations where the weather dictates living conditions, the advantages of uPVC door’s insulation cannot be ignored.

Importance of thermal conductivity

When the climate changes according to seasons, we normally modify the clothes we wear or the food we eat. But how many people realise that making changes in the home also matters? Our homes need alternative solutions like uPVC doors with energy efficiency which comes with thermal conductivity. The superior thermal insulation of uPVC doors lies in their construction.

Where does the secret lie?

The frames and panels of these doors are typically made from sturdy uPVC. It is a durable and thermally efficient material. VEKA guarantees the profiles prepared in the factory are engineered to withstand seasonal changes with impeccable sheathing properties.

For apartments, precise measurements are taken to verify a perfect fit. Our doors prevent gaps that could compromise thermal efficiency. The experts assess the specific insulation needs of your home to recommend the most suitable uPVC door configuration.

Significant gateway to a healthy environment

Doors are the gateways to your home. They play a crucial role in maintaining comfortable indoor temperatures. With thermal insulation, they can resist the transfer of heat. Reducing energy consumption creates a better living environment. Traditional doors allow heat to escape, leading to higher energy bills and discomfort.

If you choose VEKA uPVC doors it will impact thermal efficiency positively. They are designed to minimise heat transfer. They keep the space warm in winter and cool in summer if made by the right manufacturer.

A design before assembling the best uPVC doors in India

The factory assembly

Our experts put together different materials and components of an uPVC door in the factory. The process involves multiple layers and chambers that work together to prevent heat transfer. The glass panes used in these doors are energy-efficient, featuring low-E coatings that reflect heat into the room. They are combined with the insulating properties of uPVC frames and panels. It generates a robust barrier against heat loss or gain depending on the weather conditions.

The uPVC doors thermal conductivity is particularly beneficial in homes located in regions with extreme temperatures. Whether you’re battling scorching summers or freezing winters, they maintain a comfortable indoor climate. Your reliance on heating and cooling systems is minimal.

Choosing a vendor for uPVC doors

Look for a manufacturer offering high-quality products and excellent customer service. This investment reduces noise pollution and minimises maintenance requirements. Consult VEKA experts, to select the right size, style, and features for your apartment.

uPVC doors are a smart choice for homeowners seeking alternatives to traditional solutions of thermal efficiency. Their superior construction, durable materials, and innovative features make them valuable. Invest in a trusted vendor like VEKA to enjoy all the seasons wherever you reside. Allow us to show our selection of uPVC door styles this winter.

0 notes

Text

Electrical Steel Coatings Market — Forecast(2024–2030)

Electrical Steel Coatings Market Overview

As industries increasingly prioritize energy efficiency, there’s a growing demand for coatings that enhance the performance of electrical steel used in transformers and motors. Recent innovations focus on developing materials with superior insulation properties, corrosion resistance, and improved thermal conductivity. These advancements not only contribute to reducing energy losses in electrical devices but also align with global efforts toward sustainability. The Electrical Steel Coatings Market is undergoing a significant transformation with the rise in renewable energy infrastructure. As the world increasingly embraces renewable energy sources like wind and solar power, the demand for electrical steel coatings is surging. These coatings play a vital role in manufacturing components such as transformers essential for renewable energy systems. The trend underscores the industry’s pivotal role in supporting the global shift towards sustainable energy. The report covers various segments of the Electrical Steel Coatings Market and analyze the market landscape, drivers, and challenges within the forecast period.

COVID-19 Impact

During the COVID-19 Pandemic, many industries had suffered a tumultuous time, and it was no different for the Electrical Steel Coatings Market. Many governments across the globe implemented lockdown regulations and factories & production facilities in many sectors came to a halt. The supply chain was greatly disrupted as many businesses followed the lockdown protocols. Some integral industries that use motors and transformers are the automotive industry, aerospace and defense, and the electrical industry. During the pandemic, automotive production was greatly reduced as many production facilities shut down. However, many governments have relaxed lockdown procedures as the public is being vaccinated and industries are resuming production. As such, the Electrical Steel Coatings Industry is expected to grow tremendously during the forecast period of 2024–2030.

Market Snapshot:

Report Coverage

The report: “Electrical Steel Coatings Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Electrical Steel Coatings Market.

By Type: C0, C2, C3 (C3A), C4 (C4A, C4AS), C5 (C5A, C5AS), C6.

By Coating Technique: Electroless plating, Physical Vapor Deposition, Chemical Vapor Deposition.

By Electrical Steel Type: Grain-oriented Electrical Steel, Non-oriented Electrical Steel (Non-oriented semi-processed Electrical Steel, Non-oriented fully processed Electrical Steel).

By Application: Static Machines (Power & Distribution Transformers, Welding Transformers, Audio Transformers, Current Transformers, Others), Rotating Machines (Electrical vehicle driving motors, Hermetic motors, AC motors, Intermittent service motors), Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East and Africa).

Request Sample

Key Takeaways

The Asia-Pacific region holds the largest share in the Electrical Steel Coatings Market due to advancements in their Industrial, Automotive, and Energy sectors.

C5 type of electrical steel coating is the most commonly used electrical steel coating in the Electrical Steel Coatings Market.

The growth of industries like the Automotive industry and the Electrical industry are key drivers for the Electrical Steel Coatings Market.

Electrical Steel Coatings Market Analysis — By Type

The C5 coating type holds the largest share of around 38% in the Electrical Steel Coatings Market during the forecast period of 2024–2030. C5 coating type is a high-resistance insulation coating formed by a chemical treatment with the addition of an inorganic filler to enhance its electrical resistance. C5 coatings provide excellent surface resistivity both before and after stress relief annealing (SRA). The presence of organic parts ensures improved punch and die life during stamping operations. The C5A variant of C5 has a thinner coating thickness while C5AS is used primarily for preventing sticking of semi-processed non-oriented electrical steel and cold-rolled motor lamination steel during quality anneals. Some other types of electrical steel coatings are C0, C2, C3, C4, and C6 coatings. Their wide variety of applications in transformers and motors is one of the driving factors for the growth of this segment.

Electrical Steel Coatings Market Analysis — By Electrical Steel Type

Grain-oriented electrical steel is estimated to hold the largest share more than 50% in the Electrical Steel Coatings Market during 2024–2030. Grain-oriented electrical steel is an important material that can generate magnetic flux without rotation at a stationary state. As such, grain-oriented electrical steel is ideal for use in transformers. It is often used in the form of lamination, wound, or punched sheets. Transformers are essential power-generating devices used practically in every industry. Some of the core industries that use transformers are the industrial sector and power & energy sector. According to the National Informatics Centre (NIC) of India, India Sees an 11.5% Increase in Mineral Production. Another type of electrical steel that is used primarily in motors, is the non-oriented electrical steel. The growth in various sectors globally is projected to promote the growth of this segment and the Electrical Steel Coatings Market within 2024–2030.

Electrical Steel Coatings Market Analysis — By Geography

The Asia-Pacific region holds the largest share of 46% in the electrical steel coatings market during the forecast period of 2024–2030. This is because the region accounts for substantial growth in the industrial sector and different industries like the automotive industry, the electrical industry, and the power & energy sector have observed an increase in demand. According to IEA, in 2023, there will be close to USD 2.8 trillion invested in energy. Clean energy, which includes nuclear power, storage, grids, low-emission fuels, renewable energy, efficiency upgrades, end-use renewables, and electrification, will cost more than USD 1.7 trillion. These booming industries in the Asia-Pacific region prove to be a great driver for the global Electric Steel Coatings Market within the forecast period of 2024–2030.

Inquiry Before Buying

Electrical Steel Coatings Market Drivers

The exponential growth of end-use industries such as automotive and electrical Industry

As mentioned above, some of the key applications of transformers and motors are in the automotive industry and electrical industry among others. As such, the growth in these industries proves to be a great driver for the Electrical Steel Coatings market. According to IEA, Coal supply investment is currently significantly higher than it was prior to the pandemic and is predicted to increased by 10% in 2023. As per Acara Solutions India, India is a major auto exporter in the fiscal year 2023, the country’s auto exports increased by 15%. These factors are ideal for the growth of the Electrical Steel Coatings Market within 2024–2030.

Electrical Steel Coatings Market Challenges

Regulations against Energy Consumption and Pollution for various Industries:

One of the main constraints for the Electrical Steel Coatings market is the various regulations and laws that are put in place to limit and reduce energy consumption and pollution. For example, in Switzerland, The Federal Energy Law envisages measures to reduce energy consumption and regulate the energy consumption of installations, vehicles, and equipment. This is done so to ensure an economic and environmentally friendly supply of energy. While such regulations don’t directly affect the Electrical Steel Coatings market, they affect the primary end-users of electrical steel applications, namely the energy sector and the automotive sector. These regulations are only becoming more stringent as many countries and governments are adopting measures to make energy consumption as environmentally friendly as possible. As such, this proves to be a challenge for the Electrical Steel Coatings market within 2024–2030.

Buy Now

Electrical Steel Coatings Industry Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in this market. Electrical Steel Coatings top 10 companies include:

Axalta Coating Systems

Chemetall GmbH

ArcelorMittal

Dorf Ketal

PPG Industrial Coatings

Valmont Coatings

Silco Tek

JFE Steel Corporation

Novolipetsk Steel

Nippon Steel Corporation

Recent Developments

In April 2023, an industry leader in steel processing and technology, Fives has launched and supplied thermal sections for two new annealing and coating lines (ACL) and a new annealing and pickling line (APL). The performance and quality of electrical steel are largely dependent on the thermal section.

In May 2022, The Precoat Metals business division of Sequa Corporation, a portfolio company of international investment firm Carlyle, has been acquired by AZZ Inc., a global provider of welding solutions, specialty electrical equipment, galvanizing and metal coating solutions, and highly engineered services for maintaining and building critical infrastructure. The acquisition was completed as previously announced, with a purchase price of approximately $1.28 billion.

0 notes

Text

Electrical Cables Fireproof Coatings services in pune | Ugam Chemicals

Are you searching for reliable solutions to protect your surfaces from extreme heat and harsh chemicals?

At Ugam Chemicals, we understand the need for top-quality industrial coatings that not only perform well but also stand the test of time. Founded with a mission to provide innovative coating solutions, Ugam Chemicals specializes in a wide range of high-performance coatings, including heat-resistant paints, fireproof coatings, chemical-resistant coatings, and thermal insulation paints. Our products are designed to protect structures from intense heat, chemical exposure, and environmental wear, ensuring durability and enhanced performance.

But why choose Ugam Chemicals?

Our expertise and dedication to quality set us apart. We use advanced technology and research-driven processes to develop coatings that meet the highest industry standards. Whether you're dealing with high-temperature environments or corrosive chemicals, our coatings are formulated to provide optimal protection for your assets. Additionally, our products are environmentally friendly, ensuring safety without compromising on effectiveness.

Choosing Ugam Chemicals means choosing a partner that prioritizes your needs. Our team of experts is always ready to offer personalized advice and solutions tailored to your specific requirements. We are committed to delivering consistent results, backed by excellent customer service and continuous innovation.

Need a reliable coating solution? Look no further—Ugam Chemicals has the answer to all your industrial coating challenges.

0 notes

Text

Importance Of Glass Facade Contractors!

Glass façade contractors play a crucial role in modern architecture, especially in the construction of commercial and residential buildings. Here’s why the importance of Glass Facade Contractors In Mumbai cannot be overstated:

1. Expertise in Design and Engineering

Specialized Knowledge: Glass façade contractors possess deep knowledge of the design, engineering, and installation processes required for glass facades.

Customization: They can tailor designs to meet the specific architectural and functional needs of a building, including considerations for climate, light, and energy efficiency.

2. Safety and Compliance

Building Codes: Glass façade contractors ensure that the installation meets all relevant building codes and safety standards. This includes using the right type of glass (e.g., tempered or laminated) and ensuring proper load distribution.

Wind and Weather Resistance: They design facades to withstand environmental factors such as wind loads, seismic activity, and weather conditions, reducing the risk of damage or failure.

3. Energy Efficiency

Insulation: Properly designed and installed glass facades can significantly improve a building’s thermal insulation, reducing energy consumption for heating and cooling.

Solar Control: Contractors can incorporate advanced glazing technologies, such as low-E coatings or double-glazing, to control solar heat gain, enhance daylighting, and reduce the building’s carbon footprint.

4. Aesthetic Appeal and Brand Image

Modern Design: Glass facades give buildings a sleek, modern appearance, enhancing their visual appeal. This is especially important for commercial buildings, as it can help create a strong, positive first impression.

Transparency and Light: Glass facades allow for natural light to penetrate deep into the building, creating a bright and welcoming environment. This transparency also promotes a connection between the interior and exterior spaces.

5. Innovative Solutions

Advanced Technologies: They stay updated with the latest advancements in materials and technologies, such as smart glass or dynamic facades, offering innovative solutions that enhance the building’s functionality and sustainability.

Sustainable Materials: Contractors can source and recommend sustainable materials and systems that contribute to green building certifications like LEED.

6. Durability and Maintenance

High-Quality Installation: Proper installation by experienced contractors ensures the durability of the façade, reducing the need for frequent repairs or replacements.

Maintenance Planning: Contractors often provide maintenance services or guidance to ensure the façade remains in optimal condition over time, preserving its appearance and functionality.

If you are searching for Glass Facade Contractors In Navi Mumbai, then you don’t have to look for them because we are your destination.

About Alu Mine Fabricators India Pvt. Ltd.

Alu Mine Fabricators India Pvt. Ltd. is one of the leading names because it offers a wide range of sales and installation of custom high-performance building facades. To avail of the service, you can connect with them today.Source: https://penzu.com/p/e05c42050de495a7

1 note

·

View note

Text

Aluminium Sliding Window Fabricators

In the bustling metropolis of Mumbai, where every square foot counts, the choice of windows can significantly impact the functionality and aesthetics of a space. Among the myriad options available, Aluminium Sliding Windows stand out as a versatile and practical choice. And when it comes to fabricating these windows with excellence, one name shines brightly: Bhavani Metal India.

A Legacy of Quality: Bhavani Metal India has cemented its position as a premier Aluminium Sliding Window Fabricator not just in Mumbai, but across India. With a reputation built over years of dedicated service, we take pride in offering windows that surpass ordinary aluminium windows in multiple aspects.

Craftsmanship and Innovation: What sets our Aluminium Sliding Windows apart is our unwavering commitment to quality and innovation. Crafted from 6063 T5/T6 Grade virgin or non-recycled metal, with increased sheet thickness, our windows boast unparalleled strength and durability. The choice of 5 mm hardened glass and robust metal profiles ensures resilience against even the most challenging weather conditions, especially in Mumbai's high-rise areas.

Beyond Durability: But our commitment to excellence doesn't end with durability. Our windows feature high-grade elastic gaskets, ensuring both leakage-proofing and superior thermal insulation. The powder coating of 60-80 microns, coupled with meticulous craftsmanship, gives our windows a flawless finish. Rust-proof and equipped with top-notch retractable mesh and hardware, our windows demand minimal maintenance, offering hassle-free usage for our valued clients.

Tailored Solutions: At Bhavani Metal India, we understand that every space is unique, and thus, offer customization options in terms of size, design, and color. Whether it's for a residential apartment, a commercial complex, or an institutional building, our Aluminium Sliding Windows can be tailored to suit the specific requirements of each project.

Client-Centric Approach: With a focus on client satisfaction, we go beyond just fabricating windows. Our team of experts is always on hand to offer valuable advice, recommend suitable products, and address any concerns or questions our clients may have. Our goal is not just to meet but exceed our clients' expectations with every project we undertake.

In Conclusion: In the dynamic landscape of Mumbai, where space is at a premium, the choice of windows can make all the difference. With Bhavani Metal India as your Aluminium Sliding Window Fabricator, you can rest assured that you're not just getting windows; you're getting quality, innovation, and excellence that will enhance your space for years to come.

For more information

Visit our website : https://bhavanimetal.com/

Email ID : [email protected]

Contact no: 932-357-3032

0 notes

Text

Polyurea Coatings is Estimated to Witness High Growth Owing toInfrastructure Development

Polyurea coatings are chemical coatings that consist of the reaction product of an isocyanate component and a resin blend component. Polyurea coatings are thermal insulating, corrosion resistant, and tough elastomers known for their high tensile strength and quick-drying qualities. They offer exceptional bonding to surfaces such as wood, concrete, and metal. Polyurea coatings are used as protective linings for infrastructure, including wastewater containers, tanks, pipelines, floors, and parking structures. The global polyurea coatings market is estimated to be valued at US$ 1.32 Mn in 2023 and is expected to exhibit a CAGR of 11% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics: One of the key drivers for the growth of the polyurea coatings market is the increasing investment in infrastructure development projects around the world. Rapid urbanization and industrialization have increased the demand for construction of roads, bridges, buildings, and other infrastructure. Polyurea coatings offer superior adhesion and corrosion resistance properties making them suitable forusage in infrastructure applications such as protective lining for wastewater containers, parking decks, flooring, and pipelines. Additionally, polyurea coatings dry very fast unlike epoxy coatings, reducing curing time and allowing quick re-use of the infrastructure, further driving their demand. While infrastructure development continues to propel the market growth of polyurea coatings, availability of substitute products such as polyaspartic coatings can hinder the market growth. SWOT Analysis Strength: Polyurea coatings have high abrasion and chemical resistance which makes them ideal for various industrial applications. Their fast curing properties allow quick return to service. They form an impermeable membrane providing excellent protection against corrosion under insulation. Weakness: Polyurea coatings have high material costs compared to conventional protective coatings. Their application requires specialized spraying equipment and trained personnel. Opportunity: Growing infrastructure development and repair activities worldwide is driving the demand for durable protective coatings. Polyurea coatings are increasingly used in the construction of bridges, tunnels, and hydraulic structures due to their waterproofing and damage resistance. Rising oil and gas production also offers opportunities for pipeline coating applications. Threats: Strict environmental regulations regarding VOC emissions during coating application pose challenges. Development of alternative hybrid and bio-based coating technologies with better performance could threaten polyurea coatings market shares. Key Takeaways The global polyurea coatings market size is expected to witness high growth at a CAGR of 11% during the forecast period of 2023 to 2030. The market size is projected to reach US$ 1.32 billion by 2024. Regional analysis: North America currently dominates the polyurea coatings market owing to large infrastructure and construction sectors. The region accounts for over 40% of global demand. Growth in Asia Pacific is expected to be the fastest during the forecast period led by China, India, and other developing countries rapidly expanding their industrial and building infrastructure. Key players: Key players operating in the polyurea coatings market are GloboForce Ltd, BI Worldwide, SalesForce.Com, Jive Software, Inc., Aurea, Reffind Ltd, Recognize Services, Inc., Kudos, Inc., Vmware, Inc., Achievers Solutions Inc., and Madison.

Get more insights on this topic: https://www.newswirestats.com/polyurea-coatings-market-size-and-outlook/ Explore more information, Please visit:https://allmeaninginhindi.com/fiber-reinforced-concrete-the-construction-material-of-future/

#Polyurea Coatings#Polyurea Coatings Market#Polyurea Coatings Market size#Polyurea Coatings Market share#Coherent Market Insights

1 note

·

View note

Text

Solar water heater buy online India

Solar water heater buy online India Solar water heaters are a great way to save electricity and reduce your carbon footprint. They use the free and abundant energy from the sun to heat water for your home or business. Solar water heaters are also durable, efficient, and cost-effective in the long run. If you are looking for the best solar water heaters online in India, here are some tips to help you:

Choose the right capacity: The capacity of a solar water heater depends on your daily hot water requirement, the number of people in your household, and the climatic conditions of your location. Generally, a 100-litre solar water heater can provide enough hot water for 3 to 4 people in a moderate climate. You can also use online calculators to estimate the optimal capacity for your needs. Choose the right type: There are two main types of solar water heaters: flat plate collectors (FPC) and evacuated tube collectors (ETC). FPCs are more expensive, but they are more durable and perform better in cold and cloudy weather. ETCs are cheaper, but they are more prone to breakage and may not work well in hard water areas. You can choose the type that suits your budget and water quality.

Solar water heater buy online India

Compare the features and prices: You can compare the features and prices of different solar water heater models online from various brands and sellers. You can also check the reviews and ratings of other customers to get an idea of the quality and performance of the products. Some of the features to look for are the inner tank material, the outer coating, the insulation, the warranty, and the after-sales service. Look for discounts and offers: You can also look for discounts and offers on solar water heaters online from various platforms and sources. You can use coupons, cashback, EMI, exchange, and other schemes to get the best deals on your purchase. You can also check the eligibility and availability of government subsidies and incentives for installing solar water heaters in your area. To help you with your search, I have found some of the best online platforms where you can buy solar water heaters in India:

Jupiter Solar Water Heater: Jupiter Solar is a leading brand of solar heater in India. It offers a wide range of solar water heaters with different capacities, types, prices and features. You can buy solar water heaters in India from Jupiter Solar online from their official website or from authorized dealers and distributors.

Power of Solar Water Heaters: A Comprehensive Guide

In the realm of sustainable energy solutions, solar water heaters have emerged as a cutting-edge technology that not only reduces carbon footprints but also promises substantial cost savings. At Jupiter Solar,www.jupitersolars.in we delve into the intricacies of solar water heaters, aiming to provide you with a comprehensive guide that goes beyond the basics.

Solar Water Heaters

Solar Water Heater Technology Demystified Solar water heaters harness the inexhaustible power of the sun to generate hot water for residential and commercial purposes. Our cutting-edge technology employs solar collectors and thermal panels, ensuring an eco-friendly and efficient alternative to traditional water heating methods.

Types of Solar Water Heaters Passive Solar Water Heaters Passive systems are cost-effective and low-maintenance, utilizing natural convection and gravity to circulate water through the system. This makes them an ideal choice for those seeking simplicity without compromising efficiency. Active Solar Water Heaters Active systems, on the other hand, incorporate pumps to circulate water, offering more control and flexibility. This section delves into the nuances of active systems, providing insights into their advantages and optimal applications.

Advantages of Solar Water Heaters Here is an expanded version of the advantages of solar water heaters:

Environmental Impact Solar water heaters significantly reduce reliance on conventional energy sources, leading to a notable decrease in greenhouse gas emissions. By understanding the environmental benefits, you can make an informed decision that aligns with both sustainability and efficiency.

According to a study by the National Renewable Energy Laboratory (NREL), a typical residential solar water heating system can reduce the annual carbon dioxide emissions of a four-person household by 2,000 kilograms.

Solar water heaters also reduce the consumption of non-renewable resources such as coal, oil, and natural gas, which are often used to generate electricity for conventional water heaters. This helps to conserve these resources for future generations and avoid the environmental problems associated with their extraction and combustion.

Solar water heaters can also contribute to the mitigation of global warming by reducing the demand for electricity from the grid, which may be generated by fossil-fuel power plants. This can lower the amount of greenhouse gases emitted into the atmosphere and slow down the rise of global temperatures.

Cost Savings and Return on Investment (ROI) Explore the financial advantages of adopting solar water heaters. Our detailed analysis delves into initial costs, potential savings, and the impressive ROI that comes with embracing this green technology.

- Solar water heaters can save you money on your energy bills by using the free and abundant energy from the sun to heat your water. Depending on your location, climate, and water usage, you can expect to save between 50% and 80% of your water heating costs with a solar water heater. - Solar water heaters can also increase the value of your property by making it more energy-efficient and attractive to potential buyers. A study by the Lawrence Berkeley National Laboratory (LBNL) found that homes with solar water heaters sold for an average of $4,000 more than comparable homes without them. - Solar water heaters can also provide you with a high return on your investment by paying for themselves in a few years. The payback period of a solar water heater depends on several factors, such as the initial cost, the amount of energy saved, the incentives available, and the maintenance costs. However, according to the U.S. Department of Energy (DOE), the average payback period of a solar water heater in the U.S. is between 4 and 8 years. After that, you can enjoy free hot water from the sun for the rest of the system's lifespan, which is typically 20 to 30 years.

Installation and Maintenance Tips

Professional Installation Guidance For optimal performance, a correctly installed solar water heater is paramount. Our step-by-step guide, supported by diagrams, ensures that your system is installed with precision.

Common Maintenance Pitfalls to Avoid From annual inspections to troubleshooting tips, this section addresses common maintenance pitfalls, empowering users to keep their solar water heaters operating at peak efficiency.

Selecting the Right Solar Water Heater for You

Size Matters: Sizing Your System Dive into the crucial aspect of sizing your solar water heater to meet the unique demands of your household or business. Avoid common pitfalls and make an informed decision based on your specific needs.

Brand Comparison In this section, we conduct an unbiased comparison of leading solar water heater brands, assisting you in making an informed decision that aligns with your expectations of quality and durability.

Conclusion As we conclude our comprehensive guide to solar water heaters, we leave you with the knowledge needed to make an informed decision for a greener, more sustainable future. Embrace the power of solar technology with confidence, and join the ranks of those contributing to a cleaner environment and reaping the financial benefits along the way.

#solar water heater#solar energy#bangalore#india#solar water heaters#solar water heating#solar#bengaluru#solar heater#Solar water heater buy online india#solar water heater 200 ltr price#solar water heater 100 ltr price#solar water heater 25 ltr price#solar water heater price 500 ltr#solar water heater price 50 ltr#solar water heater 1000 ltr price#Selecting the Right Solar Water Heater for You#Cost#buy#online#buy solar water heater#buy solar water heaters#buy solar water heaters online#buy solar heaters

1 note

·

View note

Text

Quality Talc Powder Suppliers in India

Talc, chemically known as magnesium silicate, is a naturally occurring mineral often found alongside metamorphic rocks. Its softness, lubricating properties, and ability to resist heat, moisture, and electricity make it an essential component in several industrial processes. Talc is widely used in the production of ceramics, paints, plastics, cosmetics, and pharmaceuticals. It is a versatile mineral with a wide array of applications in various industries. When it comes to sourcing high-quality talc powder in India, A.N. Enterprises emerge as a trustworthy and dependable Supplier of Talc Powder in India. Their commitment to quality, diverse product range, competitive pricing, and timely delivery make them a top choice for businesses seeking reliable talc powder solutions.

The Significance of Talc Powder

1. Industrial Applications: Talc powder is a critical ingredient in various industrial applications. It acts as an excellent filler material in the manufacturing of ceramics, where it enhances the product's thermal resistance and electrical insulation properties. Moreover, talc is a key component in the production of paints and coatings, improving their viscosity and durability.

2. Cosmetic Industry: The cosmetic industry relies heavily on talc powder due to its silky texture and oil-absorbing qualities. It is a common ingredient in face powders, eyeshadows, and blushes, offering a smooth and matte finish to cosmetics.

3. Pharmaceutical Sector: In pharmaceuticals, talc is used as a pharmaceutical excipient, serving as an essential ingredient in tablet manufacturing. Its role is to prevent tablet sticking during the compression process and enhance the overall quality of the medication.

4. Plastics and Polymers: Talc-filled plastics are known for their improved dimensional stability and stiffness. This makes talc a preferred choice in the production of automotive parts, electrical appliances, and various other plastic products.

A.N. Enterprises - Your Trusted Talc Powder Supplier

A.N. Enterprises is India's leading supplier of talc powder, known for its commitment to quality and customer satisfaction. Here are some reasons why they are the preferred choice for talc powder:

1. High-Quality Products: We pride ourselves on delivering talc powder of exceptional quality. Their talc is sourced from reputable mines and undergoes stringent quality control measures to ensure it meets industry standards.

2. Diverse Product Range: We offer a wide range of talc grades to cater to the diverse needs of different industries. Whether you require talc for cosmetics, pharmaceuticals, or industrial applications, we have you covered.

3. Competitive Pricing: We offer competitive pricing without compromising on quality. Their cost-effective solutions make them an attractive choice for businesses seeking reliable talc suppliers.

4. Timely Delivery: Timeliness is crucial in the business world, and we understand this. They are known for their prompt and reliable delivery services, ensuring your operations run smoothly.

A Commitment to Sustainability

A.N. Enterprises not only excels in providing high-quality talc powder but also places a strong emphasis on sustainability. They are dedicated to environmentally responsible mining practices, ensuring minimal impact on the ecosystems surrounding their operations. By prioritizing sustainability, we demonstrate their commitment to preserving natural resources for future generations and aligning with the global movement towards eco-conscious business practices. Choosing us as your talc powder supplier means not only accessing top-tier products but also supporting a company that values the planet's well-being. Ready to explore the world of high-quality talc powder with a trusted supplier? Contact us today to discuss your specific requirements and discover how our premium talc powder can benefit your business. Whether you're in the ceramics, cosmetics, pharmaceuticals, or plastics industry, we have the right talc solution for you. Don't miss out on the opportunity to elevate your products with the finest talc powder in India. Reach out to us now and let's start a productive partnership!

0 notes

Text

#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB manufacturer in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB services in india#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in pune#Heat Resistant & Thermal Insulation Paint For 1800 Deg C- WB suppliers in india#Thermal Insulation Coating services in pune#Thermal Insulation Coating services in india#Thermal Insulation Coating for Furnace in pune#Thermal Insulation Coating for Furnace in india#Thermal Insulation Coating for Boiler in pune#Thermal Insulation Coating for Boiler in india#Thermal Insulation Coating for Steam Pipe lines in pune#Thermal Insulation Coating for Steam Pipe lines in india#Thermal Insulation Coating for pipe line in pune#Thermal Insulation Coating for pipe line in india#Thermal Insulation Coating for oven in pune#Thermal Insulation Coating for oven in india

0 notes

Text

Best Heat insulation and Roof insulation Services

Heat Insulation

The barrier to the flow of heat between two objects is called thermal insulation. Specially designed processes, special shapes, and selection of suitable materials are very important for the insulation of heat.

When two objects of different temperatures come in direct contact, there must be a transfer of heat between them. But by inserting an insulating material between these two objects, the flow of heat will be less than before.

How much less depends on the thickness of the insulating material, its low thermal conductivity, etc. Similarly, some other methods are adopted to reduce the flow of heat by radiation.

The lower the thermal conductivity of a material, the better it is as an insulator. Other properties of insulating materials in the field of thermal engineering are density and specificity.

What are heat-resistant materials?

It is very important to choose specially designed processes, special sizes, and suitable materials for heat insulation. Tantalum carbide (TaC) and hafnium carbide (HfC) are refractory ceramics, meaning they are exceptionally resistant to heat.

Which is the least heat-resistant metal?

The correct answer is glass. Heat conduction is the reduction in the transfer of heat between objects in thermal contact. In modern times, glass is the most common insulation.

What is the difference between a heat conductor and a heat insulator?

Of heat from a substance goes from one end to the other, it is called a heat conductor. Aluminum, iron, silver, copper, etc. are heat conductors. When there is no transfer of heat from a substance, it is called an insulator. Such as plastic, wood, etc.

Main insulation Material

Fiberglass

Mineral wool

Cellulose

Polyurethane foam

Polyurethane eps

Roof insulation

You can always tell who hasn't insulated their attic because of the pigeons and other birds sitting on the roof and enjoying all the heat coming from the house below. Summer is on the rise and clever birds are quick to take advantage of it.

Other benefits of roof insulation include

Lower heating bills

Improve the energy efficiency of your home

Increase the value of your home

Attic insulation for an average 3-bedroom semi-detached house with gas central heating can start with DIY insulation for around €50 and can take less than a year, reducing energy costs. Know about top insulation and Roof insulation.

What is Roof insulation?

Roof insulation is a barrier of material in your roof space. It can be placed between joists (horizontal joists along the floor of your attic) or rafters (slant joists that support the roof).

Why is roof insulation necessary?

In non-insulated homes, a quarter of the heat lost is dissipated through the roof. Insulating an attic or roof is a great way to increase the comfort of your home. And there's even more good news: It will last more than 40 years and should pay for itself many times over in energy savings since the cost of Roof insulation is relatively low.

Restoration of houses made of non-traditional materials.

If you live in a historic home or a home built from local traditional stone or other materials, use appropriate roof insulation materials and methods. Otherwise, your home may not stay as warm or dry as it should. It may be best to consult or hire local workers trained in the techniques involved.

#Roof Insulation#Heat Insulation#Insulation Material#thermal insulation sheet#insulation manufacturers in india#thermal insulation sheet manufacturers in india#insulation sheet for roof#Insulation Installation Services#aluminium foil insulation#thermal sheeting insulation#Insulation Sheet#thermal insulation materials in buildings#Building Insulation Material#thermal insulation material#Colour Coated Roofing Sheets#Insulated Roofing Sheets

0 notes

Text

Reasons How Rubber Rollers Makes Life Easy For Industries

Rubber Rollers

The rubber roller is one of the most important parts of the manufacturing and processing industry. It’s mainly used in the Textile, steel, paper, and packaging industry. These rollers are crafted according to the industry requirements and offer optimal performance. There are many different kinds of rollers, built according to the requirement of the industry.

Rollers for various industrial use

Silicone rubber rollers

Silicone Rubber rollers come in many different colors & sizes with required hardness (25 to 85 shore) along with surface grinding and suitable Bearing size. It is made up of ultimate quality silicon raw material. This material has an extremely high-temperature range and it is the best electrical insulator too. The silicon rubber roller has a heating base in it. Silicon Rubber Rollers are used for many different applications. It is used for cutting the sealing, hot melt coating, extrusion coating, foil processing, holography, poly coating, heat & press lamination, and thermal lamination to name a few.

Groove rollers

The Groove rollers are manufactured at a very economical price for industry use. These rollers are made by using ultra-modern machinery & ultimate quality raw material that is available in different lengths and diameters. These rollers are known for their effective working & accurate finishing. It has various properties like longer stability, corrosion & moisture resistance. There are many different types of grooves available according to their use like vertical groove, helical groove, screw cut groove, horizontal groove, double-helical groove, diamond cut groove, and all types of grooves. And these grooves are used for sealing machines, pouch machines, and remove all types of wrinkles & slips.

Ebonite Roller

Ebonite roller is manufactured of supreme quality that is designed and fabricated with the use of the latest tools and advanced technology. It is capable of surviving the high temperature of steam and water. That's why it provides excellent performance and long service life. These rollers are available in various sizes.

Ebonite rollers are very easy to install, has precise dimension, long service life with high functionality.

Nips Rubber rollers

Rubber roller made of the different compound as per their use and working environment. Nip Rollers are high-quality rubber rollers, used for the Textile industry. These are used under different working conditions for better Squeezing efficiency. These rollers are chemical resistant, have stable strength and uniform hardness which protects the roller core and shaft. It is used for varied processes like Singeing, DE sizing, Impregnating, Bleaching (PTR), Mercerize Range, Stenter m/c, Washing, and Dyeing, etc. for the textile industry.

Teflon roller

These rollers are Teflon coated, are widely used in the textile industry. The Teflon rollers prevent corrosion and use for non-stick applications. The Teflon coated surface of the rollers provides great resistance against general wear & tear and heat. Teflon roller manufacturers in India export an extremely wide range of industrial rollers, which are designed according to advanced industrial standards. Customization can be done to meet specific dimensions.

Guide rollers

These rollers are installed for direction control of the unit loads. The application of the guide roller is to maintain the guided direction of a moving object like a drawer, door, fence, or tank track. This roller provides easy movement of the objects with less resistance. Guide Rollers allows easy lifting of the object without causing any damage.

Printing rollers

The Printing rollers are assembled with three different rollers. First is the ink ductor roller that first receives the ink. The second is the ink form rollers that give the ink to the printing plate and the third is distributor rollers through which paper comes back after printing. It is used for paper printing or press purposes.

Lamination Rollers

Lamination rollers are used for laminating important stuff like important documents. This roller includes hard chrome plated surface & Rubber roller. lamination rollers mechanism is to apply a thin plastic cover to paper documents with the combination of heat and pressure. Lamination rollers are used for Paper laminators, Printed circuit board laminators, Dry film laminators, Cold lamination, Hot lamination.

With four decades of industry experience in its quiver, Arvind Rub-Web Controls Ltd. has established itself as an industry leader in manufacturing, supplying, and export of a range of industrial rubber rollers!

#Rubber Roller#Silicone Rubber Roller#Groove Roller#Ebonite Roller#Nip Roller#Teflon Roller#Guide Roller#Printing Roller#Lamination Roller#Manufacturers#India

14 notes

·

View notes

Text

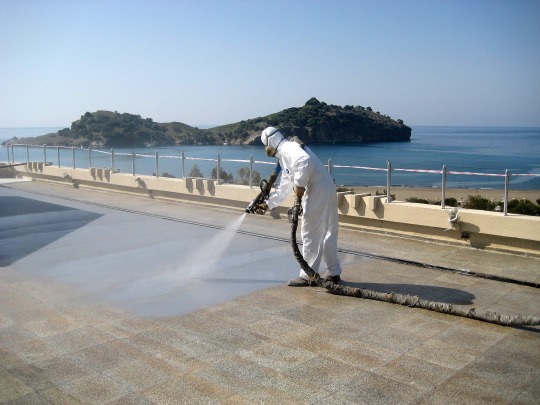

Thermal Spray Gun | Thermal Spray Coatings

Thermal Spray Gun

The thermal spray gun is a coating process in which finely divided metallic or nonmetallic materials. That consists of a heat source and a coating material in a powder. The coating material may be in the form of molten materials, powder, ceramic-rod or wire, which is melted into small droplets and sprayed onto surfaces at large velocity.

Thermal spray coating is normally utilized to metallic substrates, but also can be carried out to a few plastic substrates. This form of coatings uniquely complements and improves the performance of the thing.

Types of Thermal Spray Gun

There are numerous types of processes used to use a thermal spray coating. They may be the following:

· Metalizing Gun

· Flame Spray Gun

· Arc Spray Gun

· HVOF Gun

· Zinc Spray Gun

· Plasma Thermal Spray Gun

Metalizing Gun - In this metalizing gun the metal takes place with the help of heat. In this, heat melts the metal wire into the liquid. Then it is sprayed on the surface of the subject. On part of abrasive media, we can take rod, wire, and powder to feed inside the gun.

Flame Spray Gun – Flame Spray Gun spraying generally requires only low-cost equipment. It is appropriate for single-piece and series production may be used in both stationary and mobile configurations. Its main applications are corrosion and wear protection. The usage of wire or powder relies upon at the material and the application rate. Zinc, aluminum, and molybdenum are mostly sprayed as wire. Most metal and hard alloys are applied as a powder.

Arc Spray Gun – In this gun, two arcs of wire are generating with the help of an electric supply anode and cathode. These wires when touched generate the spark which leads to heat to the two-wire. Melts down and sprayed over the subject.

HVOF Gun - HVOF Gun known as High-Velocity Oxy-Fuel. HVOF Gun is a thermal spray system utilizing the combustion of gases or liquid. Combustion gases such as hydrogen and liquid fuel such as kerosene are used. Fuel and oxygen combine and atomize within the combustion area under conditions that monitor the correct combustion mode and pressure required for coating.

Zinc Spray Gun - In this, different abrasive media can be used for spraying on the subject. Like anti-corrosive abrasive is used for protecting the surface from corrosion. Othertime, Zinc spray gun, the Aluminum spray gun is used.

Plasma Flame Spray Gun - Plasma fire spray gun is utilized for both huge surfaces just as little inward bore widths surface coatings. Plasma spray measure incorporates the spraying of liquid or warm mollified materials onto a surface to give a covering. Plasma spray gun creates adequate energy to liquefy practically any material in powder structure makes them appropriate for an enormous assortment of surface coatings.

Working of Thermal Spray Gun

Thermal Spray coating technology sprinkle can provide you with thick coatings (approx. thickness scope is 22 microns to several mm, depending on the technique and feedstock), over a massive place at a excessive announcement fee compared to more coating strategies including electroplating, physical and chemical vapor declaration. Thermal Spray gadget is ready for thermal sprinkles to encompass metals, ceramics, alloys, plastics, and composites.

Advantages of Thermal Spray Gun

· Wear Resistance – It can improve overall product quality, reduce maintenance costs and downtime, and help improve energy efficiencies.

· Performance Enhancement – It can enhance product performance in a number of ways. A copper-based coating can be used to improve electrical conductivity.

· Extended Life – It can be used to extend the working life of treated parts and components.

Disadvantages of Thermal Spray Gun

· Disguises the substrate – They are so efficient in many cases, what material the substrate was made of after the coating process, unless stringent records are kept.

· Cannot precisely evaluate effectiveness – Once it has been applied it is often difficult to tell exactly how well the coating has gone on.

· Costly set up – It require very expensive apparatus, which can result in a high initial set up cost.

Applications of Thermal Spray Gun

· Wear Resistant Coatings against abrasion, erosion

· Corrosion-Resistant Coatings

· Heat Resistant Coatings

· Thermal Insulation or Conduction Coatings

· Electromagnetic Shielding

· Medical Coatings

Uses of Thermal Spray Gun

Thermal spray coatings are more accepted for electrical purposes. Conductive elements such as copper slag can be applied for conductors. Ceramic elements may be utilized for electrical packing. Conductive metals are more applied to magnetically shield delicate electronics.

Very solid and thick thermal spray deposits have been applied on an innovative basis as cavitations tight materials and in combination with weld overlays as a replacement technique.

Thermal Spray Gun Manufacturer in India

We manufacture the best-designed models for thermal spray gun as per their applications. The prices of thermal spray gun are within the budget of the customers, they can afford them easily. From ordering to delivering, Blast rooms give assurance of providing the best service. The thermal spray guns available here are capable of working on any type of work-piece geometry.

#Thermal Spray Gun Manufacturer in India#Thermal Spray Coatings#Plasma Flame Spray Gun#Zinc Spray Gun#Arc Spray Gun

1 note

·

View note

Text

Best Geysers in India 2020 : (Buying Guide)

Best geyser for homeNow-a-days water warmers have turn out to be one of the need to-have home equipment in our domestic, mainly at some stage in bloodless seasons. Because, traditional methods like heating water over gasoline stoves are not most effective risky however additionally uncomfortable.

Geysers are available in unique models – garage Geysers and Instant Geysers.

When in comparison to immediate geysers, garage water heaters provide warm water with none pause. However, they're bit expensive and take extra wall mounting space.

While shopping a water heater, you need to bear in mind below important points…

Capacity – Usually garage geysers have capacity variety of 6 to 35 liters. If you need to warm water for cleaning kitchen utensils, then 6 to eight liters potential is enough. But for bucket bathing eight to ten liters is sufficient. And for shower bathing, you will require geyser with more than 15 liters’ capability. Water Tank Material – Most common materials used are copper, thermostatic or chrome steel. Stainless steel cloth comes with anti-corrosive and glass coating which prevents corrosion and electrochemical reactions. And insulation is much better and calls for less renovation. Wattage – Most of the electric water heaters found in Indian market have 1500 – 3000 watts range. The thumb rule is – higher the wattage, water gets heated more fast.

While those are the 3 critical factors, there are lots more which you want to consider. We have supplied special records of them in our “Buying Guide“. Apart from that, we have also picked out the pleasant water heaters in India after carefully reading best, durability and service.

Now allow us to soar proper into the reviews. If you have got any questions or queries regarding geysers or water warmers, experience loose to say them in our Comments Section beneath. Our product group is constantly listening and will get returned to you ASAP. Do checkout: Best geyser for home

Top 10 Best Geyser/Water Heaters in India

Storage Geysers Water Tank Capacity Power Conjumption Inner Tank + Warranty Buy Now AO Smith HSE-SDS-15 Water Heater 15 Litre 2000 watts 7+four years Check the Price Bajaj New Shakti GL Water Heater 25 Litre 2000 watts five+ 2 years Check the Price American Micronic AMI WHM3 Water Heater 25 Litre 2000 watts 2 years Check the Price V-Guard Victo Water Heater 15 Litre 2000 watts 2 years Check the Price Havells Monza EC5S Water Heater 15 Litre 2000 watts 6+2 years Check the Price Usha Misty Water Heater 25 Litre 2000 watts 7+2 years Check the Price V-Guard Victo Plus Water Heater 15 Litre 2000 watts 7+2years Check the Price Racold Eterno 2 Water Heater 15 Liters 2000 watts 7+2 years Check the Price Crompton Solarium DLX Water Heater 15 Liters 2000 watts five+2 years Check the Price

Longway Water Heater 25 liters 2000 watts 1+2years Check the Price

Best Water Heater – Geysers Reviews in India 1. AO Smith HSE-SDS-15 Vertical Storage Water HeateraosmithgeyserThe main U.S water heater employer has taken the Indian market by hurricane with this stylish and compact 15 litre water heater. AO Smith is known for its progressive technologies that improve the longevity of the equipment. Available in two models (15 and 25 litre); this water heater comes with five megastar BEE rating making sure its superior best and performance in the direction of power savings. The water heater is satisfactory suitable for Indian water conditions as the municipal water supply in most areas is hard water. And that is it's miles our top pick out on this list.

Its innovative Blue Diamond Glass line technology makes the inner tank stronger and corrosive resistant. The anode rod with a stainless steel center works closer to extending the shelf lifestyles of the tank with the aid of protective it from corrosion by using difficult water. The patented glass covered heating detail prevents limescale buildup inside the tank and guarantees an extended lifestyles for the product. The sublime design of the water heater includes a temperature manage knob at the the front panel. The manipulate knob lets in you to alter the temperature (25-seventy five℃) at which you just like the water to get heated. Auto thermal cut-out works splendidly if and while the water exceeds the highest pre-set temperature. The thermal cut-out shuts off the energy deliver while the water temperature exceeds. Similarly, a protection valve keeps the water pressure in test through routinely relieving water when the strain shoots up a preset restrict.

Notable Features:

15 litre storage tank Blue Diamond Glass line generation Temperature control ( 25-75℃) Auto thermal cutout BEE 5 megastar rating

Verdict:

This small and compact water heater works splendidly with amazing protection features that allow kids to handle it freely. The innovative anti-corrosion technology ensures low protection. It is best proper for our hard water deliver. It comes with an impressive warranty bundle however the after sales provider isn't true. Apart from this small glitch, the water heater scores excessive amongst its opposite numbers. Once heated, the water temperature is maintained for up to 12 hours. Easy dealing with, brief heating function and hassle unfastened protection.

What We Liked:

Comes with a 7-year warranty for the internal tank four-yr extended assurance on the glass lined heating element Energy green (BEE five star) Customizable temperature placing and thermal cutout 15 litre storage capacity Low preservation Super silent What We Didn’t Like:

No unfastened installation Bad after sales carrier Buy Now From Amazon

2. Bajaj New Shakti GL 25-Litre Water HeaterbajajgeyserThis make in India product comes with some marvelous capabilities designed to tackle the hardness of municipal water. The 25-litre garage tank ability works efficiently time and power clever with out causing a good deal subject to you. The features are pretty equal as our topper however this one comes with a commendable 25 litres of capability. It is worth of the second spot at the list.

The vertical water heater comes with a glass lined inner tank that enables in the prevention of limescale buildup inside the tank. The magnesium lined anode rod no longer most effective prevents corrosion however additionally prevents water leakage. The Incoloy heating element ensures a longer shelf lifestyles to the product. The heater is also appropriate for excessive water strain (8Bar) and pressure pump installations. This extremely safe water heater comes with certain safety measures to preserve water from overheating/dry heating. It also can address immoderate water pressures. The cable extension of the heater is likewise fire retardant. The heater has a four star BEE score this means that you may keep numerous money and time. Once heated, the PUF insulation inside the tank captures the heat and maintains the temperature for a longer time frame even when the energy deliver is cut off.

Notable Features:

25-litre storage tank Fire retardant cable extension 4 superstar BEE rating Magnesium covered anode rod Glass coated and PUF insulated inner tank Incoloy heating element

Verdict:

The Bajaj New Shakti water heater is incredibly adaptable to all forms of areas. Whether you want to in shape it within the laundry room or within the toilet, the vertical construct sits perfectly at the wall without taking over lots area. Available for a respectable rate, the water heater has low renovation and excessive protection features. The outer tank is manufactured from metal preventing any external damage to the product and the outer frame is made up of plastic which allows in stopping rust formation. The 3 pin hearth retardant cable extension is an added bonus to this power green heater. Its excessive pressure withstanding function makes it best for high upward thrust flats.

What We Liked:

Large garage capacity four big name BEE score Can face up to high water strain Retains warmth Comes with a 2 year warranty on the general product and five yr guarantee at the internal tank Heats up speedy What We didn’t like:

Pipes and miscellaneous installation add-ons do now not include the package. The temperature display isn't always accurate. Buy Now From Amazon

three. American Micronic AMI WHM3 25-Litre Water HeateramericanmicronicgeyserDesigned with the aid of the American Micronic Instruments, Inc., USA, this water heater is durable, reliable and green. Although it lacks a fashionable design, the water heater comes with a p.C. Of protection and sensible capabilities which are suitable for an Indian surroundings. Its multiple protection systems provide easy handling and carefree surroundings. It comes with functions which includes resistance towards overheating/ dry heating and monstrous water stress. With 25 litres of potential and 5star BEE score, this one rightfully takes the 1/3 spot.

The internal tank is covered with titanium-enamel glass to ensure its durability by stopping corrosion. The 2mm thick metallic inner tank can cope with excessive water pressure (eight Bar) and as a consequence suitable for excessive upward thrust buildings. The inner tank additionally comes with a 42mm PUF insulation which allows in reducing strength consumption and warmth retention. In addition to this, the sus316l heating detail guarantees the lengthy lifestyles of the product The magnesium coated anode rod works toward stopping leakages and metal corrosions. The 3 pin hearth retardant cable also offers a secure environment for the children to be round. Auto cutout, thermostat and stress discharge valve are the opposite few critical features American Micronic offers.

Notable Features:

25-litre garage tank Titanium-enamel glass coated tank PUF insulation Iso 9001:2008 certified Comes with a 2 12 months warranty Verdict:

The water heater without problems tackles the difficult water scale buildup trouble. It has an automatic cut off characteristic that enables in saving strength and cash. The build of the heater is respectable with climate and moisture evidence body. The quality a part of the product is that it comes with a customizable power putting characteristic. Based in your requirement you could set the strength enter (800W/1200W/2000W at 230V).

What We Liked:

Easy set up and handling Impressive protection systems Customizable temperature and energy settings Low maintenance Retains warmth for up to 24 hours Energy green What We Didn’t Like:

Takes a bit longer to warmth up first of all Buy Now From Amazon

4. V-Guard Victo 15 Litre Water Heaterv-guardgeyserThe maximum relied on emblem in India when it comes to electrical home equipment, V-protect brings an stylish and high overall performance water heater to the market. The vertical water heater holds a fifteen-litre large tank made up of high excellent material.

V-defend Victo comes with a 4 layered safety machine that consists of a hello-tech thermostat and thermal reduce off characteristic that guarantees the proper temperature regulation. The multifunctional safety valve presents greatest strain manipulate and protects it from leakages and corrosion. The cylindrical body of the water heater is made up of high satisfactory metallic and is coated with anti-corrosive powder that provides to its toughness. The inner tank is built using thick gauge steel and covered with advanced glass coating via single-line welding era. The tank has a PUF insulation that keeps warmth and minimizes this sort of loss for that reason saving strength. The water heater comes with a BEE five celebrity rating.

Notable Features:

five famous person BEE rating Thermal cutoff characteristic Customizable temperature manage knob Four layered protection system High first-class construct material 15-litre garage ability

Verdict:

The water heater does no longer take an awful lot time to warmth up 15 litres of water. The sleek build of the heater suits into any space without a good deal trouble. The heater weighs about 10 kgs which fits it wall mounting potential. The water heater is electricity green and has low maintenance as soon as hooked up. It is suitable for tough water supply with respectable water stress. The package deal comes at the side of accent gadgets, unlike other brands.

What We Liked:

Energy efficient Comes with a 2 -year guarantee Accessory kit included Low renovation Longer shelf-lifestyles What We Didn’t Like:

Not positive whether or not it withstands excessive pressure. Buy Now From Amazon

five. Havells Monza EC5S 15 Litre Water HeaterhavellsgeyserComing from a first-rate strength distribution equipment manufacturing business enterprise, this 15-litre is the high-quality desire for a visitor bed room. The ergonomic layout makes it not possible for each person to now not notice the water heater. Havells is known for high performance merchandise and this EC 5s water heater lives as much as the expectations.