#IPC standards solder resist

Explore tagged Tumblr posts

Text

Green Semi-Gloss HD CAWN 2321: High-Performance Liquid Photoimageable Solder Resist

Discover Green Semi-Gloss HD CAWN 2321, a thermal hardening liquid solder resist designed for superior PCB protection. RoHS and WEEE compliant, UL listed, and REACH-certified, it meets IPC standards and is trusted in industries including automotive and aerospace. Explore its advanced capabilities today.

#Green semi-gloss solder resist#liquid photoimageable solder resist#CAWN 2321#thermal hardening solder mask#IPC standards solder resist#advanced PCB protection#solder resist for automotive#aerospace solder resist solutions#Aqueous Potassium Carbonate processing#Aqueous Sodium Carbonate processing#solvent-processable solder resist#PCB solder mask solutions#A-Gas Electronic Materials

0 notes

Text

PCBA Through Hole Components New Assembly Way: Paste-In-Hole

Past-In-Hole (PIH) is to print solder paste directly on plated through holes (PTH, Plated Through Hole) of the PCB (Print Circuit Board), and then put the traditional plug-in/through-hole component directly inserted into the plated through-holes that have been printed with solder paste. At this time, most of the solder paste on the plated through-holes will stick to the solder feet of the plug-in components. These solder pastes are reflowed the high temperature of the soldering furnace will re-melt, and then the components will be soldered on the circuit board.

The above method is also called "pin-in-paste", "intrusive reflow soldering" and "ROT(reflow of through-hole), etc.

Speaking of the advantages of this method (Paste In Hole): It can not only eliminate the process of manual soldering or wave soldering but also save labor hours. Apart from that, it can also improve the quality of soldering and reduce the chance of solder short.

However, this method (Past In Hole) has the following inherent limitations:

1. The heat resistance of traditional components must meet the temperature requirements of reflow soldering. General plug-in components usually use materials with lower temperature resistance than reflow soldered components. Because the PIH(Past In Hole) method requires traditional components to be reflowed together with general SMT components, and which must meet the temperature resistance requirements of reflow. Lead-free components are now required to be able to withstand 260°C for 10s.

2. It’s better to have tape-on-reel packaging (tape-on-reel) and enough flat surface to put it on the circuit board (PCB) through the SMT pick and place machine. If it doesn’t work, just it is necessary to consider sending an additional operator to manually place the parts manually. At this time, the required working hours and quality instability must be measured, because the manual plug-in may touch other components that have been placed and positioned due to careless operation. .

3. The solder pads of the component body and PCB must have a standoff (elevated) design. Generally, the PIH process will print the solder paste larger than the outer frame of the solder pad. This is to increase the amount of solder paste to achieve 75% of the through hole filling requirement. If there is no standoff between the component and the solder pad go through Reflow, the molten solder paste will travel along the gap between the component and PCB, resulting in excess tin slag and tin beads, which will affect the electrical quality in the future.

4. Traditional components are best printed on the second side (if there are two-sided SMT). If the components have been printed on the first side, and when SMD is continued on the second side, the solder paste may flow back into the traditional components, causing the possibility of internal short circuits, especially the connector, must be careful.

In addition, the amount of solder is the biggest challenge of this method. The acceptable standard of IPC-610 for through-hole solder joints must be more than 75% of the thickness of the carrier board, and some require 50%. (Please refer to the figure below, please refer to IPC-610 section 7.5.5.1 for detailed specifications)

As for the calculation of the amount of solder paste, you can subtract the smallest diameter of the pin from the maximum diameter of the through hole, and then multiply it by the thickness of the circuit board to get it. Remember to x2 again, because the flux in the solder paste accounts for 50%, that is After reflow, that is to say, the volume of solder paste will only be left half of the original printed solder paste.

The required solder paste volume ≧ [(Maximum diameter of the through hole/2)2-Minimum diameter of the pin/2)2]× π × thickness of the circuit board × 2

How to increase the amount of solder for through-holes? The following methods are provided for your reference:

1. Reserve enough space near the through hole (PTH) of the circuit board for overprinting.

Discuss with the Layout Engineer (PCB layout engineer) to make more space for printing solder paste near the through-holes that need paste-in-hole. That’s to say, try not to place other pads (welding pads) or other non-products nearby. Solder through holes are required to avoid short circuits during overprint.

It should be noted that the flat space of solder paste printing cannot extend out indefinitely, and the cohesion ability of the solder paste must be considered, otherwise the solder paste will not be able to fully retract the solder pads and form solder beads.

In addition, consider that the direction of solder paste printing must match the direction in which the solder pads extend.

2. Reduce the diameter of the through hole on the circuit board.

Just like the above [Calculation of the amount of solder paste required], the larger the diameter of the through hole, the more the amount of solder paste required, but at the same time, it should be considered that if the diameter of the through hole is too small, the component will be inserted into the through hole. .

3. Use step-up (partial thickening) or step-down (partial thinning) stencil.

This kind of stencil can forcibly increase the thickness of the solder paste locally, which can also increase the amount of solder paste, thereby achieving the purpose of filling the through holes with solder. However, this stencil is about 10% more expensive than ordinary stencil on average.

4. Adjust the proper solder paste, the speed and pressure of the printing machine, the type and angle of the squeegee, etc.

These parameters of the solder paste printer will more or less affect the solder paste printing volume, and the solder paste with lower viscosity will have more solder paste volume.

5. Add some solder paste.

You can consider using a dispenser to add solder paste to the Paste-in-Hole pads to increase the amount of solder paste. Since almost no automatic dispenser is available in the current SMT production line, you can also consider manual dispensing , but must increase the working hours of an operator.

6. Use solder preforms

https://www.grande-pcba.com/

0 notes

Text

What are BGA PCB Soldering Joints

The underside of the chip pronounced. BGA PCB has many compared to wired IC advantages such as: • Smaller housing • Higher packing density • Higher pin density • Improved signal transmission properties • Better thermal coupling to the circuit board

Latest forms of these components, such as which enable VFBGA (Very Fine BGA) meanwhile several thousand connection pins with a pitch of less than 0.5mm. The BGA PCB components are assembled in a corresponding soldering process, with many factors play a role. The result of this process is usually a matt.

• High level of liability between the ball and circuit board • High mechanical long-term stability • The high structural integrity of the ball body • High conductivity • High electrical signal integrity • High insulation resistance to neighboring pins

At this point the interaction between the physical states and the resulting electrical properties clearly. The reference model shows the structural relationships in a simplified manner. It is based on a static, directional signal with simple ohmic. The conditions prevailing in the chip (bond wires, etc) are neglected as well known.

Static reference model between the mechanical and the electrical level during the soldering process, the solder of the balls melts with the solder paste and it forms a chemical reaction with the surface of the circuit board an intermetallic zone. Also, there is an intermetallic zone between the chip and the ball body, which, however, is pronounced at the chip manufacturer and must also be checked by him. This should normally be between the transmitter and the receiver should be stable at the milliohm level.

But all theory is gray because in practice both systematic and random occur errors and these lead to greatly changed electrical parameters and also one shiny solder joint is by no means a guarantee of freedom from errors. They range from visible deformations of the solder body in the senses of lean or fat solder joints, where there is electrical contact, up to optically well-defined solder joints with no, or sporadically falling electrical contact.

The standard IPC-A-610E plays an important role in the evaluation of a BGA PCB soldering joint role. It specifies the acceptance criteria for electronic assemblies and also specifies criteria for BGA PCB components. So for a production system solutions are necessary which ensure the conformity of the solder joints to this standard can demonstrate. This also causes structurally unstable solder joints where it is underneath mechanical stress to break and thus to loss of electrical conductivity comes avoided. However, it remains to be noted that many errors, the shape of the solder body regarding, only have electrical effects at extreme values.

Worth mentioning here are the "Head in Pillow" and "Black Pad “known phenomena. With the former effect, the solder does not melt with the solder paste and a quasi-barrier layer is formed. However, the optics of the solder joint reveal this typically not. The main causes, in this case, are contamination of the ball surface.

The problem with the black pad is more towards the circuit board. Here the reacts ball with the solder paste but below it also creates a layer with reduced or complete lack of conductivity.

Overview of typical error categories for BGA PCB soldering joints

However, they do lower resolution and thus problems in the detection of liability weaknesses in the intermetallic zones. AXOI devices combine AXI and AOI in one system

They are also capable of failing BGA PCB soldering joints on incorrectly placed chips due high-density BGA assemblies with conductor tracks completely embedded in the circuit board are pushing against it.

Put reliable methods like ICT and FPT aside for years. As groundbreaking the so-called boundary scan method, which is based on IEEE1149.x is standardized and works without an adapter. Starting from the discussed production requirements, crystallize for complex BGA assemblies focus on two technologies - X-ray systems in the form of AXI / AXOI and as an electrical test device boundary scan system. Both procedures are examined in more detail below.

Make full use of X-Ray's potential even if X-ray technology is basically able to use the BGA. Looking at balls is just a necessary technical basis. The actual customer benefit is primarily defined by technological device design.

X-ray systems are used in modern SMD production either directly in or next to the production line for fully automatic X-ray inspection (AXI) used. In summary, AXI systems for use in SMD production lines at BGA Assemblies meet a number of basic criteria, such as: • Complete inspection according to IPC-A-610E • Low slip • Low rate of ghost errors (false alarms) • Throughput in the area of the beat rate of the production line (in-line operation) • Automatic error detection • Simple program generation • Intuitive user guidance • Support for Statistic Process Control (SPC)

The IPC-A-610E addresses criteria such as those related to the BGA PCB components solder ball offset, solder ball distance, solder ball shape and pores (air pockets) in the soldering.

Particularly efficient to meet the requirements of the IPC-A-610 3D AXI systems based on tomosynthesis are to be checked, e.g. the OptiCon X-Line 3D from GÖPEL electronic.

OptiCon X-Line 3D with integrated AOI option (AXOI)

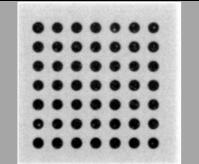

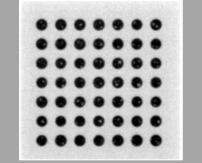

Well soldered BGA ball, Roundness OK Area OK Gray value OK

Badly soldered balls Roundness NOK Area NOK Gray value OK

Measurement of good and bad solder joints

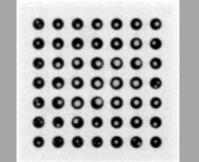

The examples in Figure 3 show an example of a ball and its ball image processing evaluation. The pictures show the section through the middle of the BGA soldering balls. The example below shows that the amount of solder applied has an influence on void formation.

BGA - 50% solder volume, low voiding

BGA - 100% solder volume, low voiding, light larger ball area

BGA - 200% solder volume, strong voiding recognizable

Representation of voids

Typically, the void test does not use the volume, but the void area certainly. Mainly the void area is related to the ball area and thus the void percentage issued.

The lower left example shows the automatic void determination. The IPC-A610E limit for the maximum proportion of void in the total solder joint is 25 percent.

Automatic determination of the proportion of void area to BGA area; Voiding = 27.4%; Measuring plane = ball center

Automatic determination of the proportion of void area to BGA area; Voiding = 27.4%; Measuring plane = ball center

Short circuits between two balls; these can also by means of an electrical test can be detected

Representation of void components, short circuits, and non-planar BGA

In addition to assessing the shape, presence, and pores of the solder balls, according to Figure 5 also short circuits between the solder balls are evaluated. If this BGA PCB is mechanically or thermally stressed, it will be expected to fail. Such an inclined position can include: stray components are caused that come to rest under the BGA. The error scenario of the "head-in-pillow" effect has already been discussed. It is also known under the synonym "trailer". One way of this failure scenario safely and to be able to test reproducibly is the use of a “tear-drop” pad design. in this connection, the connection pads of the BGA PCB are not circular, but tear-shaped.

X-ray image of a BGA with tear-drop design; the round pronounced soldering are trailers

X-ray image of a BGA with tear-drop design; the round pronounced soldering are trailers

Detection of trailers by tear-drop design

If a ball melts and combines with the solder paste underneath, it is shaped the typical teardrop shape. If no connection is established, the ball retains its circular shape and can be measured such as roundness, axis ratio or ball are abe sorted out.

The teardrop shape reduces the distance between two pads and it can cause injury of the minimum electrical insulation distance.

Now, a ball shape assessment is often not enough to make it bad differ. If there are assemblies on one side, you can use high-resolution 2.5D x-ray oblique radiation examined the transition between pad and solder ball become. If the constriction is recognizable here, this is an indication of a trailer.

ScopeLine MX-1000 for semi-automatic BGA analysis (MXI)

It’s better without needles This is a complementary partner for X-ray inspection of complex BGA assemblies Boundary scan procedure first choice.

This design-integrated test electronics is serialized via a so-called test bus driven. The virtual needles are actually boundary scan cells, which are in form a shift register (boundary scan register) can be interconnected. By the electrical test of BGA soldering joints succeeds in the synchronous handling of the problems of the cell. However, the fault location cannot be used for directional connections to be determined exactly, then processes such as MXI are required again.

Connection test of two BGA pins via boundary scan

With multi-point connections, e.g. Bus structures, on the other hand, is a pin accurate fault diagnosis completely given. But the charm of the boundary scan process is also its high test speed and flexibility when testing prototypes. Sophisticated system solutions such as the software platform SYSTEM CASCON ™ [6] from GÖPEL electronic offer automatic test pattern generators (ATPG) which thousands of test the solder joints in parallel in a few seconds and with automatic pin error diagnosis can, without the need for an adapter. It can hardly be more cost-effective. Boundary scan is a structural process and independent of that in the chip integrated functional logic. The bottom line is that each pin is individual and can be tested independently. This also makes the process very easy to use combine stress tests in which e.g. due to thermal stress in a climatic chamber attempts are made to cause defective solder joints to fail. It also offers for this GÖPEL electronic pre-assembled hardware modules, such as the TIC03 from the SCANFLEX series. But Boundary Scan also has its strengths in the laboratory. For quick prototype verification targeted check of certain signals is often relevant for the designer. Here graphic tools like Scan Vision ™ achieve the best results.

Representation of layout and schematic for interactive pin toggling

They not only allow cross-referencing between layout and schematic but also the activation of the boundary scan cells by simply clicking on the corresponding pin. The resulting logical signal states are then transferred from the user definable color schemes visualized. Special packages such as the PicoTAP Designer are also available for the introduction of Boundary Scan studio [8] from GÖPEL electronic available. They already contain all the tools including ATPG and debugger, as well as the necessary hardware to get started immediately. This also includes a hardware module for testing I / O signals. The special charm these packages are of course their extremely good price/performance ratio.

Components of the complete package PicoTAP Designer Studio

The very existence of the technologies and system solutions discussed so far is enough for one manufacturing with the highest quality standards is not enough. Rather, the use of X-ray systems and boundary scan systems in the production of BGA PCB assemblies a thorough analysis of the entire manufacturing situation. Above all, they play precise knowledge of the errors to be combated and their statistical distribution authoritative role. In total there are over 100 parameters that define an influence the optimal inspection and test strategy. In this respect, it is at this point impossible to name "the" strategy. But the fact is that the combination of AXOI and Boundary Scan at BGA provides 100 percent error coverage can guarantee and the greater the proportion of BGA is the more important precisely these techniques. From today's perspective, they are for high-density assemblies in perspective the only solution. What a process line looks like for such situations could be seen.

Example of using AXOI, MXI and Boundary Scan in a BGA PCB assembly line

The basic idea is to establish a sensor behind each process step and the statistical error information holistically on the processes fed back. The AXOI system can due to its high inspection speed qualify the module according to IPC-A-610E and, for example, also the inner meniscus measured by TQFP components. The still missing mechanical fault coverage is ensured by the integrated AOI system. MXI is used for precision analysis commitment. The sensors shown in blue are all in the GÖPEL product portfolio electronic included.

Summary and conclusions

BGA components are an important component of complex circuit boards and enable ever higher integration densities and improvements in the electrical parameters. The continuously decreasing access makes the use more appropriate countermeasures in the form of alternative inspection and test procedures are essential. In practice, 3D-AXOI machines, in particular, have a combined AXI / AOI system and Boundary Scan as the electrical test method for the greatest potential Solve the access problems. Both methods complement each other perfectly enable fault coverage against 100% for BGA soldering joints. It also offers boundary-scan fundamental future security as it progresses on standardization within the framework of the IEEE. That from GÖPEL electronic the developed concept of embedded system access (ESA) involves these standards and complements them with further technologies to extend the fault coverage [11]. Thereby the combination becomes even more attractive. For optimal use of the discussed system solutions, however, there is one in the first place accurate analysis of the process situation is essential because if the buggy bride is not dancing want to help all technology fiddling nothing.

https://www.mokotechnology.com/fr4-thermal-conductivity/

0 notes

Text

circuit building

This is a beginner's guide to building circuits that will talk about the "proper" way to install components (resistors, ICs, capacitors, etc), and also a little bit about soldering. It'll cover things like recommended tools, how far and which direction components should be inserted, pre-bending and clinching leads along with some tips and tricks. We'll be using a power supply kit made by David at uCHobby.com that plugs into a bread board for demonstration. Yep, we're commercial and sell all this stuff, but the advice should apply equally well to anyone's tools and circuits.- Soldering iron and solder: Just about any 25-30 Watt soldering iron will do. Ideally, the temperature of you iron would be between 600-700 degrees F (for lead-free solder, 700-800 is recommended). How temperature relates to wattage depends a lot on the iron (watch a video testing the temperature of cheap RadioShack irons), and some high wattage irons have too high of a temperature. Avoid "solder guns" as these are meant for pipe soldering. Not only can these be too hot, but they work by running high current through a resistive heating element, and this could apply dangerous voltages to your circuit.For solder, we recommend starting out with a lead-based solder, usually called 63/37 (63% tin, 37% lead by weight) or 60/40 rosin cored solder. Get whatever's cheaper; there's unnoticeable difference in hand soldering between 63/37 and 60/40. The rosin is a flux that cleans parts so solder will bond with them. Avoid solid wire (no flux core) and acid cored solder (for plumbing, too aggressive for circuits). We recommend solder that's about .031" in diameter for most through-hole components. Water-soluble flux is much more aggressive than rosin, and these residues must be cleaned. Lead-free solder melts at a higher temperature, and doesn't wet or spread out as readily, so it will be slightly harder to use.- Needle Nose Pliers: Useful for pre-bending leads, pulling out components during de-soldering, and a lot of other things.- Wire Strippers: Two types are shown: the yellow ones can be adjusted to strip any size wire (good for small 28-30 AWG ribbon cable wires) whereas the red handled ones have several fixed hole sizes.- Flush Cutters: Used to trim leads close to the board after soldering .- Clamps: Oftentimes just resting your board on a table will be fine, but the clamps are especially helpful when desoldering parts or soldering wires together.- Solder Sucker and Solder Wick: Both are inexpensive ways to remove solder. The sucker is a spring loaded tube that vacuums out solder and the wick is a fine braid of flux coated copper that soaks up solder.- Multimeter: Some multimeters have a continuity check that beeps if there is a complete circuit. This is very useful for making sure parts are connected or disconnected when there're a lot of wires and parts.-Pink Erasor: (not shown) A pink eraser can be used to rub off oxides from older components and boards without risking damage to the parts.Most people advise to start with the shorter components first, and add more by height from there. This has two benefits: - If there are tall components right next to shorter ones, you avoid having to bend already-installed taller components out of the way while inserting shorter ones later on.- One of the best ways to hold a component in place is to insert it, and then lay the board upside down so the table surface keeps the component in place. If you install shortest to tallest, the tallest component will always be the one you're currently working on.It's also helpful to install components so that the value can be read in the same direction as the surrounding text. For instance, install all the resistors with their tolerance bands on the right so that all the values can be read without having to rotate the board.Make sure the notch on ICs matches the notch on the board.To avoid stressing the holes and junction between the resistor body and its lead, pre-bend the leads before inserting the part. To do this, line up the resistor on it's board location, grip the lead a little inside with needle nose pliers and then fold the lead over the pliers. The pliers prevent stress from reaching the the connection point between body and lead. You can also use something called a christmas tree to quickly form both leads to the correct size. Just fyi, for sensitive circuits (ie, military, space), serrated pliers aren't allowed because they might create a divot in the lead that could weaken and fail from vibration. The "right" way aside, just bending the leads with fingers can work well, tooClinching means bending the lead slightly on the other side of the board to hold the part in place. For ICs, bend two opposite corners outwards. The only downside is that parts can be harder to remove later. Other methods to hold things in place while you flip the board over include just having the table surface hold it in place, and also using tape. For instance, header pins can't be bent, so the table is used to hold them up in the last picture. You can also place some solder on one empty pad, and then reheat that pad while pressing the part through to get started.In industrial manufacturing processes, parts are either held in place by a small drop of adhesive (for surface mount) or by clinching the leads. Boards are then transported via conveyor over molten fountains of solder (google wave soldering).The longer lead on electrolytic capacitors (the cylinder ones) and LEDs is positive. Insert most components until they lie flat on the board for extra stability unless they have a metal casing that could cause a short circuit. it's OK if the yellow plastic on ceramic capacitors (disc shaped) goes beneath the top level of the board and touches the solder, it just can't show through to the other side (according to IPC, the industry's soldering standards organization).You've probably heard that solder should melted on the parts and not the iron tip. The catch is that a dry tip will not transfer heat very well. You need to have a little solder, called a heat bridge, between the iron tip and parts. Do this by either melting a small amount of solder on the tip before soldering ("tinning" the tip) or adding some solder at the junction between tip and work. Then melt solder on the opposite. It should spread out towards the iron tip and heat. A video is available with many more details.Usually people say that joints should come out looking shiny, but this is only true for lead-based solder. Lead-free joints will have a duller surface finish, but still be perfectly fine joints. With either type, the solder should cling to or wet the surfaces, and not just sit on top of them. It should form a smooth ramp and feather out across the pad. The above link also has some galleries of good and bad joints.It's a good idea to check the part for correct alignment after soldering one pin. Adjustments can easily be made at this point by reheating that one pin, but once multiple pins have been soldering, the part may need to be completely removed to adjust it.Flush cutters are useful for trimming leads close to the surface. Regular diagonal cutters can work, also. Safety goggles are actually a good idea for this step as the leads can fly off quickly. We usually like to hold on to the lead while clipping. Helping our customers manage document workflow and increase efficiency through best-in-class resistive heating element and services. Fostering the growth and development of our employees.

0 notes

Text

circuit building

This is a beginner's guide to building circuits that will talk about the "proper" way to install components (resistors, ICs, capacitors, etc), and also a little bit about soldering. It'll cover things like recommended tools, how far and which direction components should be inserted, pre-bending and clinching leads along with some tips and tricks. We'll be using a power supply kit made by David at uCHobby.com that plugs into a bread board for demonstration. Yep, we're commercial and sell all this stuff, but the advice should apply equally well to anyone's tools and circuits.- Soldering iron and solder: Just about any 25-30 Watt soldering iron will do. Ideally, the temperature of you iron would be between 600-700 degrees F (for lead-free solder, 700-800 is recommended). How temperature relates to wattage depends a lot on the iron (watch a video testing the temperature of cheap RadioShack irons), and some high wattage irons have too high of a temperature. Avoid "solder guns" as these are meant for pipe soldering. Not only can these be too hot, but they work by running high current through a resistive heating element, and this could apply dangerous voltages to your circuit.For solder, we recommend starting out with a lead-based solder, usually called 63/37 (63% tin, 37% lead by weight) or 60/40 rosin cored solder. Get whatever's cheaper; there's unnoticeable difference in hand soldering between 63/37 and 60/40. The rosin is a flux that cleans parts so solder will bond with them. Avoid solid wire (no flux core) and acid cored solder (for plumbing, too aggressive for circuits). We recommend solder that's about .031" in diameter for most through-hole components. Water-soluble flux is much more aggressive than rosin, and these residues must be cleaned. Lead-free solder melts at a higher temperature, and doesn't wet or spread out as readily, so it will be slightly harder to use.- Needle Nose Pliers: Useful for pre-bending leads, pulling out components during de-soldering, and a lot of other things.- Wire Strippers: Two types are shown: the yellow ones can be adjusted to strip any size wire (good for small 28-30 AWG ribbon cable wires) whereas the red handled ones have several fixed hole sizes.- Flush Cutters: Used to trim leads close to the board after soldering .- Clamps: Oftentimes just resting your board on a table will be fine, but the clamps are especially helpful when desoldering parts or soldering wires together.- Solder Sucker and Solder Wick: Both are inexpensive ways to remove solder. The sucker is a spring loaded tube that vacuums out solder and the wick is a fine braid of flux coated copper that soaks up solder.- Multimeter: Some multimeters have a continuity check that beeps if there is a complete circuit. This is very useful for making sure parts are connected or disconnected when there're a lot of wires and parts.-Pink Erasor: (not shown) A pink eraser can be used to rub off oxides from older components and boards without risking damage to the parts.Most people advise to start with the shorter components first, and add more by height from there. This has two benefits: - If there are tall components right next to shorter ones, you avoid having to bend already-installed taller components out of the way while inserting shorter ones later on.- One of the best ways to hold a component in place is to insert it, and then lay the board upside down so the table surface keeps the component in place. If you install shortest to tallest, the tallest component will always be the one you're currently working on.It's also helpful to install components so that the value can be read in the same direction as the surrounding text. For instance, install all the resistors with their tolerance bands on the right so that all the values can be read without having to rotate the board.Make sure the notch on ICs matches the notch on the board.To avoid stressing the holes and junction between the resistor body and its lead, pre-bend the leads before inserting the part. To do this, line up the resistor on it's board location, grip the lead a little inside with needle nose pliers and then fold the lead over the pliers. The pliers prevent stress from reaching the the connection point between body and lead. You can also use something called a christmas tree to quickly form both leads to the correct size. Just fyi, for sensitive circuits (ie, military, space), serrated pliers aren't allowed because they might create a divot in the lead that could weaken and fail from vibration. The "right" way aside, just bending the leads with fingers can work well, tooClinching means bending the lead slightly on the other side of the board to hold the part in place. For ICs, bend two opposite corners outwards. The only downside is that parts can be harder to remove later. Other methods to hold things in place while you flip the board over include just having the table surface hold it in place, and also using tape. For instance, header pins can't be bent, so the table is used to hold them up in the last picture. You can also place some solder on one empty pad, and then reheat that pad while pressing the part through to get started.In industrial manufacturing processes, parts are either held in place by a small drop of adhesive (for surface mount) or by clinching the leads. Boards are then transported via conveyor over molten fountains of solder (google wave soldering).The longer lead on electrolytic capacitors (the cylinder ones) and LEDs is positive. Insert most components until they lie flat on the board for extra stability unless they have a metal casing that could cause a short circuit. it's OK if the yellow plastic on ceramic capacitors (disc shaped) goes beneath the top level of the board and touches the solder, it just can't show through to the other side (according to IPC, the industry's soldering standards organization).You've probably heard that solder should melted on the parts and not the iron tip. The catch is that a dry tip will not transfer heat very well. You need to have a little solder, called a heat bridge, between the iron tip and parts. Do this by either melting a small amount of solder on the tip before soldering ("tinning" the tip) or adding some solder at the junction between tip and work. Then melt solder on the opposite. It should spread out towards the iron tip and heat. A video is available with many more details.Usually people say that joints should come out looking shiny, but this is only true for lead-based solder. Lead-free joints will have a duller surface finish, but still be perfectly fine joints. With either type, the solder should cling to or wet the surfaces, and not just sit on top of them. It should form a smooth ramp and feather out across the pad. The above link also has some galleries of good and bad joints.It's a good idea to check the part for correct alignment after soldering one pin. Adjustments can easily be made at this point by reheating that one pin, but once multiple pins have been soldering, the part may need to be completely removed to adjust it.Flush cutters are useful for trimming leads close to the surface. Regular diagonal cutters can work, also. Safety goggles are actually a good idea for this step as the leads can fly off quickly. We usually like to hold on to the lead while clipping. As manufacturers we are determined to be the very best in resistive heating element, regardless of the size, pedigree or inclinations of our competitors.

0 notes

Text

Guidelines To Choose A Reliable PCB Manufacturer

Printed circuit boards or PCBs is an integral part of all electronic devices. There is an upsurge in the number of electronic devices that are being used today and each one them has a printed circuit board inside. Starting from electronic devices to high-performance servers, PCB or printed circuit board exists in every sphere of an individual’s life. There is hardly any electronic device without PCBs. It is used to connect various electronic parts through the designed pathways and provide the components with physical support.

Though there is a surge in the number of printed circuit board manufacturers, choosing one of them can be a tough task. However, choosing the top company will be a good decision because they are a leading PCB manufacturer providing high-quality PCBs. Below are some guidelines to choose the right printed circuit board maker that will make things easier for you.

Choosing the right printed circuit board maker Quality

Quality is perhaps the most important measure to select the right PCB manufacturer and they fulfill certain criteria in order to qualify as a good printed circuit board maker. These criteria are high-density design, high-speed communication lines, good conductivity, and long term durability. Another metric to judge the quality is the final E-test. One needs to check, if the supplier under consideration meets the requirements. Certifications

The manufacturers are strictly required to comply with UL, ISO, and IPC quality standards. One thing that must be taken into account while buying the circuit board is the UL 94V-0 fire resistance certification. You should make a wise decision to choose a PCB manufacturer which is quality compliant. Meeting deadlinesMost PCBA companies require the circuit boards within a given timeframe. It is also important to have the capability to supply the circuit boards with a fast turnaround. When selecting a circuit board supplier one must make sure that the deadlines are met consistently. Experience

Experience matters a lot and you need to ensure that the service provider has previous experience in servicing customers in your industry. An experienced manufacturer has the ability to adapt and innovate over changing course of modern technology and understands the requirements of customer requirements.

Customer support

An important success factor for printed circuit board manufacturers is customer satisfaction. They should promptly respond to queries, resolve issues, and should be open to customer suggestions and discussions. Cost

The cost varies depending on quality and design. Variation in the base material or the material of solder mask makes a difference in the cost of PCBs. Therefore, it is important to make sure that the quality matches the price. Final wordsA bad quality circuit board design can really impact your printed circuit board business. To avoid such situations, it is important to find a design that is of best quality. The aforesaid guidelines will help you to make the right selection. The reliable printed circuit board maker and supplier have consistently provided their customers with high-quality printed circuit boards with excellent performance and speed.

Blog Resource https://greatpcbsmt.blogspot.com/2019/04/guidelines-to-choose-reliable-pcb.html

0 notes

Text

Factors Affect PCB

PCB processing is part of customer OEM products, different customized products are not the same, there is little sharing products, on the other hand, in consideration of the quality, some of our customers may also specify a vendor of substrate, ink, etc., in order to achieve quality and cost control requirements, process price is volatile.

As one most professional China PCB manufacturer, ALLPCB can help you quickly proof the sample and detect if there is any problem with the prototype board, so that it can be modified in time to save time. The prototype board allows you to verify that your design is working according to the original file most gerber file.

ALLPCB,who is a typical fast pcb prototype manufacturer in China and with many experience of board manufacturing and protection, for handling and storage. No matter which board finish you are using, there are a few steps that will help extend the life of the board and making the PCBs working for much longer life and could be more functional.

PCB price is consisted of the following multiple factors:

PCB materials difference will cause price diversity.

Take the ordinary double-layer PCB for example, generally the material is FR-4, CEM-3, etc., the thickness ranges from 0.6mm to 3.0mm, copper thickness changes from 1Ooz to 3Ooz, all of which cause huge price difference at the aspect of material; for the solder resist inks or oils, there are some prices difference between common thermosetting oil and photosensitive green oil, so different materials cause the price diversity.

Different production processes adopted by PCB will cause the price diversity.

Different production processes will result in different costs, such as immersion gold PCB and Immersion tin plate, the milling board and beer board making the outline, using screen printing wires and dry film wire, etc. will form different cost and cause price diversity.

PCB itself difficulty cause price diversity.

Even if the same material, the same process, but with different PCB itself will also cause different costs. For example, there are 1000 holes on two kinds of circuit board, a plate aperture greater than 0.6mm and the other plate pore size of less than 0.6mm will form different drilling costs; the same as the other two kinds of circuit boards, but the line width different a are greater than 0.2mm, less than one kind of 0.2mm, can also cause different production costs, because of the higher difficulty of plate scrap, inevitably increase the cost and cause the price of diversity.

Different customer requirements will result in different prices.

Customer requirements will directly affect the panel factory yield, such as one kind of board of IPC-A-600E, class 1 required 98% proficiency, but class3 may be requested of 90%, resulting in different panel factory costs, leading to volatile commodity prices.

PCB manufacturers difference cause price diversity.

Even if the same product, because the process equipment and skill levels of different manufacturers is different, it will form a different cost, nowadays many manufacturers like to produce immersion gold board, because the process is simple, cost is low, but discard amount is rising, resulting in higher costs, so they prefer to produce Immersion tin board, so they offer the immersion-tin board price lower than the immersion gold board.

Different payment method cause price differences.

Currently PCB panel factory usually adjust the PCB price according to the different payment method, the range is frome 5% to 10%, thus resulting in a price difference.

Regional diversity cause different price

As for PCB material, factors affecting price mainly the following points:

a. Board material, b. Board thickness and c.Raw material suppliers and so on.

PCB industry cost calculating is the most special, the most complex in all industries, from board cutting, plate forming, to the FQC, packaging, warehouse completion, according to the input material costs, labor costs, manufacturing costs of each step, etc. according to the product order batch calculate the cumulative cost. And for different types of products, the processing standard cost rates will be different.

0 notes

Text

Wire Harness Manufacturing Terms, Tools, and Tips of the Trade

Steps for Wire Harness Manufacturing Success

Superior Quality

Maintaining Impeccable Customer Scorecards

Fast Turnaround Times

Also, Competitive Prices

Highly Skilled and Seasoned Staff

FREE Estimates (click here)

High Productivity

Agility and Flexibility

Company Culture Dedicated to Customer Satisfaction

Lastly, a Commitment to Safety

Helpful Guide of Wire Harness Manufacturing Terms, Tools and Tips

Are you new to the Wire Harness process? Our team created a helpful guide below.

The Wire Harness Manufacturing Guide includes:

Wire Harness Terms

Tools

Tips of the Trade

Additionally, the list below includes a number of Wire Harness Manufacturing Terms and definitions.

Wire Harness Manufacturing IPC/WHMA-A-620 Standard

All of the Wire Harness Manufacturing Terms below are from the IPC/WHMA-A-620. This serves as an industry standard. Therefore, providing criteria for commonly used wire harness assemblies. Consequently, the standard sets a “collection of visual Quality Acceptability Requirements for Cable, Wire and Harness Assemblies.”

To learn more about the IPC/WHMA-A-620, click here.

A standard system for designating wire diameter. Primarily used in the U.S.

The raised portion at the front and/or back of the wire barrel crimp that provides a gradual entrance and exit for the wire strands without causing damage.

Wire Strands that have separated from the normal lay of the wire.

Woven bare metallic or tinned copper wire used as shielding for wires and cables and as ground wire for batteries or heavy industrial equipment. Also, a woven fibrous protective outer covering over a conductor or cable.

A group of individually insulated conductors in the twisted or parallel configuration under a common sheath.

A cable with plugs or connectors attached.

An uninsulated wire or the conductor of an insulated wire suitable for carrying electrical current.

A tube in which insulated wires and cables are passed.

A device used to physically and electrically join two or more conductors.

The conducting part of a connector that acts with another such part to complete or break a circuit.

A continuous path for the flow of current in an electrical circuit.

Final configuration of a terminal barrel formed by the compression of terminal barrel and wire.

The measurement of the overall wire barrel height after crimping the terminal.

Total current is the combination of resistive and capacitive currents. Resistive current is present in both AC and DC DWV tests. Additionally, the capacitive current is present only with fluctuations in applied voltage (Ex: AC testing).

Any insulating medium that intervenes between two conductors.

The process of two or more mechanical crimping operations on the same location in a single terminal.

A short tube. Used to make solderless connections to shielded or coaxial cable. Also, a terminal crimped onto the stranded wire to allow insertion into terminal blocks.

A rubber seal used on the cable side of multiple contact connector to seal the connector against moisture, dirt or air.

A group of wire and cables, usually made with breakouts. Furthermore, with a rubber or plastic sheath tie them together. A harness also provides interconnection of an electric circuit.

A material that offers high electrical resistance making it suitable for covering components, terminals, and wires. This material also helps to prevent the possible future contact of adjacent conductors and a resulting short circuit.

Area of a terminal, splice or contact formed around the insulation of the wire.

An outer covering, usually nonmetallic, mainly used for protection against the environment.

A device attached to certain connectors that permit uncoupling and separation of connector halves by a pull on a wire or cable.

A combination of two or more conductors cabled together and insulated from one another and from sheath or armor where used.

A mechanical arrangement of inserts and/or shell configuration that prohibits the mating of mismatched plugs and receptacles.

Connector used for connecting or terminating coaxial cable.

A flat cable of individually insulated conductors lying parallel and held together by means of adhesive film laminate.

A technique or item which reduces the transmission of mechanical stresses to the conductor termination.

A predetermined amount of slack to relieve tension in component or lead wires.

A device designed to terminate a conductor that is to be affixed to a post, stud, chassis, another conductor, etc., to establish an electrical connection. Some types of terminals include ring, tongue, spade, flag, hook, blade, quick-connect, offset and flagged.

A tube of extruded non-supported plastic or metallic material.

Slender rod or filament of drawn metal.

The overall conductor plus insulation thickness.

Types of Wire Terminals

The definition of a terminal is:

A device designed to terminate a conductor that is to be affixed to a post, stud, chassis, another tongue, etc., to establish an electrical connection.

Wire Terminals come in many different shapes and sizes. This is due to the size of the wire and screw. Also, there are several types of terminals.

Wire Harness Manufacturing Terminals Include:

Ring

Spade

Hook

Quick-disconnect

Bullet

Butt terminals

Flagged

Wire terminals are available in insulated and non-insulated. The insulation provides a protective cover. Therefore, serving as a non-conductor. Furthermore, the type of project that is being done will determine if you need insulated or non-insulated terminals.

The insulation spares the wire from water and moisture as well. Also, it protects against extreme heat or cold. Wire insulation is typically available in vinyl, nylon and heat shrink. Non-insulated terminals provide much more economic value with its low cost. Also, they are commonly used when extra protection is unnecessary.

When purchasing various Types of Wire Terminals, make sure that your purchase meets industry standards as well as project requirements.

Wire Terminals

A ring terminal is a round-ended terminal that easily allows a screw or stud to be attached. Ring terminals also called ring connectors, come in various sizes. It is crucial that the ring terminal is compatible with the wire gauge and stud size. Ring Terminals are either crimped or soldered to the wire. Available in insulated or non-insulated.

Spade Terminals are also called spade connectors or fork terminals due to the shape of the terminal. A spade terminal is available in various sizes depending on the gauge of the wire and stud size. Additionally, the open-ended spade terminal is convenient to use allowing easy attachment or removal from the screw. Especially for wire harness projects that are tight on space for installation. They are also available in insulated or non-insulated.

Similar to the Spade Terminal, Hook Terminals are convenient to use with an open end (imagine a tiny version of Captain Hook). These terminals are produced as insulated or non-insulated. Hook Terminals offer a simplistic yet durable connection for a variety of projects.

A quick-disconnect terminal provides convenient and reliable usage while also offering an easy connect and disconnect between two wires. They are commonly found in auto, industrial and consumer products. Products can be insulated or non-insulated. Quick-Disconnect Terminals additionally deliver a stable and durable connection.

Bullet Terminals (also called bullet terminals) make an easy, reliable and secure connection. It is simple to disconnect as well. Bullet terminals also connect with the male and open-ended round female connectors creating a high-quality connection. Therefore, the connection with bullet terminals helps prevent corrosion and other potentially harmful materials from entering a wire harness.

A Butt Terminal connects or terminates single or multiple wires. Butt Terminals help prevent abrasion and cutting. Additionally, this extra protection helps keep out moisture, corrosion, and other negative elements. Butt Terminals serve as a simple solution to extend wires due to the ability to mate and connect wires. Simply install each wire on the open end of the connector, then crimp both ends of the terminal to secure the connection.

Flag Terminals also called flag connectors to offer a convenient and secure connection. Flag terminals work well in tight spaces as well as when a quick-disconnect is too large. Provides a quick and easy connection and disconnect. Also available in insulated and non-insulated.

Wire Insulation

Wires can be found… seems like… everywhere. Any electrical product that demands a current flowing will typically require a wire (or cable). Even when you hear something is “wireless”. In this instance wires power the device sending a signal. Electricity traveling through wires bring each of us tremendous joy and pleasure.

Examples of electronics containing wires:

Computers

Internet routers

Also, music players (MP3 and iPods)

Communication devices (Cell Phones)

Vehicles

Appliances

Actually, can you imagine surviving a single day without electricity? Well, in the early stages, electricity did not travel so safely through wires. Thankfully electricity travels safe and sound through wires protected with wire insulation.

The explosive growth of electrical products well over a century ago drastically increased the use of wires carrying electricity. Unfortunately, uncovered or exposed wires were responsible for dangerous situations.

Furthermore, exposed wires led to electrical shocks or fire. However, the addition of a non-conductive cover was a brilliant move to protect and strengthen wires. The application of Wire Insulation protects wires greatly reducing potential hazards and threats.

You can take a look at wire insulation in the 19th century.

Check out this cool video on porcelain insulators. Thanks to Thomas Edison Tech Center.

https://youtu.be/x8ekfxijhuA

Wire Insulation Evolution

Due to increasing demand, electrical products require a solution to protect wires. The solution is affordable and efficient. Also, with the early growth in popularity, wire harness assembly has become necessary. It is much more efficient in harnessing loose wires. This is opposed to a "free for all". Especially for electrical consumer goods and the auto industry. Both of which have exploded since the early 20th century.

Insulation serves as a non-conductor. The Insulation also separates and protects wires within a wire harness assembly. Especially since it is a nasty world out there with many detrimental elements that can cause harm to non-insulted wires.

To save the day, an insulated jacket protects each wire from the elements keeping the wire cozy and safe. Like insulated terminals, wire insulation also protects from moisture and extreme temperatures.

Thankfully wire insulation today is much more efficient. It is also, effective and affordable. For example, thermoplastic high heat-resistant nylon coated wire (THHN wire) is low in cost. It is also lightweight. Due to these factors, it is an extremely popular wire insulation option.

Now that you know all about terminals and wires you need to know how they come together to create a wire harness.

Crimping Tools

We have over 30 years of wire harness manufacturing experience. Also, we here at Falconer Electronics have accumulated an impressive arsenal of crimping tools. When crimping wires and cables for our customers we have to utilize the proper tools. These allow our team to execute jobs with accuracy and efficiency. As well as, in a safe manner.

Many projects require crimping wires by hand. When producing wire assemblies for prototypes and small volume runs, handheld crimping tools sure come in…well... handy.

It is extremely important to look over the entire assembly when selecting the proper tool. For example, a basic pliers-style crimp tool can fit various wires, connectors, and terminals. Also, matching the right size tool is imperative when terminating wires.

A great brand is Molex. They are a global leader in the manufacturing of high-quality electrical tools. They are also a leader in components and other equipment. Falconer Electronics hax relied on Molex for many years. We trust their products.

The team at Molex declares they solve challenges “through our collaborative process, we take a multi-dimensional approach that brings together engineers, product designers, and manufacturers to ensure the design cycle is smooth and seamless.”

Below is one of the “Bad Boys” from Molex that our team loves to use when tackling tough projects:

Pneumatic Crimping Tool

Not interested in crimping wires by hand? Or do you have a large amount to crimp? No problem. Pneumatic crimping tools are extremely beneficial and efficient. Additionally, a pneumatic tool allows you to work hands-free due to air power. These tools are also fast and accurate. All qualities that will drastically increase your production.

We recently welcomed a new addition to our team. The Pneumatic Crimping Press pictured below. The “Plug’n Play” Pneumatic Press looks fierce, doesn’t it? It is ready and raring to CRIMP!! Especially ideal for wires requiring interchangeable crimping dies:

Tips for Successful Wire Harness Manufacturing

The crimp does not break the insulation.

Also, the crimp fully wraps around and supports insulation (also cannot expose an opening greater than 45 degrees).

Insulation does not have puncturing to the point where tabs penetrate the wires.

Crimp tabs are in contact with the top of the insulation.

Insulation is flush with the crimped wire.

Additionally, identifying damaged insulation that reveals wires.

The wire, connector, assembly process, as well as insulation, are all compatible.

Wire Harness Manufacturing: Crimping Wires Do’s & Don’ts

The IPC/WHMA-A-620 standard provides the necessary guidance on crimping wires. Consequently, this standard shows what is acceptable along with what is considered defective. Here are a few examples of Do’s and Don’ts:

Do’s

Insulation crimp tabs fully wrap and support insulation

Additionally, the insulation fully enters and extends past the insulation crimp tabs

Wires must be in solid working condition – also cannot have scrapes, nicks, severing or other damages

The connector retains the wires

Center the crimp indent

Insulation crimp must provide a minimum side report of 180 degrees

Don’ts

Wires should not have deformities- Flattening untwisting, buckling, or kinking

Insulation should not show any signs of pinching, pulling, fraying, discoloration, or charring

Also, the insulation crimp needs to fully support and wrap insulation without causing any damage or breaking the insulation

No broken insulation- This can expose wires causing safety issues and potential hazards

Wire not secured by crimp

Contact has visible cracks and fractures

Also, no Birdcaging – Wire Separation

These are just a handful of the requirements.

To learn more about the Wire Harness Manufacturer’s Association and A-620 Standards, please click here.

Wire Harness Manufacturing Quality Control

Wire Harness Quality Control is paramount at Falconer Electronics. We perform testing on cables and wire harness assemblies for every order. Therefore, quality control strongly impacts the bottom line with the wire harness assembly process. Also, our well-guided wire harness quality control and a solid test system prevents unnecessary errors, stress and lost profits.

High accuracy during the assembly process is the key to maintaining competitive pricing and reliability. We take every step to ensure accuracy at the time of assembling and producing the wires. Instituting a strict wire harness quality control system during production brings significant benefits to our customers.

Wire Harness Manufacturing Testing Check List

Safety First! Wire Harness Testing requires extreme caution. This is due to it involving live wires. Unfortunately, electric shock and burns can turn a great day into a really bad day quickly. It is mandatory to use personal protective equipment on the job such as safety glasses when testing a wire assembly.

When performing Wire Harness Testing, our quality control department strictly follows the IPC/WHMA-A-620 Standard. This standard is a collection of visual Quality Acceptability Requirements for Cable as well as Wire and Harness Assemblies.

Wire Harness Manufacturing Checklist for Testing Wires:

Accurate Labeling

Check for Damaged Insulation or Defective Wires

Continuity

Correct Wire Gauge

Also, Check for Proper Crimps

Free of Moisture and Corrosion

Optimum Wire Placement Within Connectors

Pull Test

Test for Broken Wires

Finally, Test for Shorts

Deming Values for Continual Improvement

Going old school, we are big fans of 20th-century management guru Dr. Deming. Dr. W. Edwards Deming created 14 points for management with a quest for continual improvement. We give credit to Dr. Deming for being the master of quality improvement. Particularly with his work in Japan during the 1950’s.

The Deming Institute continues the incredible legacy of Dr. Deming.

Furthermore, one of the core values at the Deming Institute states:

We are dedicated to the Deming philosophy and the belief that working together, with humility, we can make a difference in the quality of life for everyone.

This is a truly inspiring message!

According to Dr. Deming, implementing the 14 points is a philosophical way of conducting business with an unwavering quest for continual improvement. In addition, new tactics and behaviors become habits. Furthermore, those habits eventually form into the core beliefs and culture of a company.

Two particular interesting points from Dr. Deming's 14 points that help drive our wire harness quality control:

1. Create constancy of purpose toward improvement of product and service, with the aim to become competitive and to stay in business, and as a result to provide jobs.

5. Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

Consequences when continual improvement and quality are NOT the top priority:

High defect rates

Underutilized equipment

Poor productivity

Poor inventory management

Safety concerns

Finally, low morale with employees

Wrapping it Up

Thank you for reading our post on Wire Harness Manufacturing Terms, Tools, and Tips of the Trade.

Also, for more information on Wire Harness Manufacturing, click here:

For additional information click on the links below:

Build Your Business Tips: Selecting a Wire Harness Manufacturer

Ground Straps: What Are They And What Are They Used For?

Wire Harness Estimator

Ground Strap Express

0 notes

Text

Imagecure IMC 6002R: High-Performance Solder Resist for LED Lighting Applications.

Explore Imagecure IMC 6002R, a high-performance solder resist designed for LED lighting applications. Compliant with RoHS, WEEE, and REACH regulations, this UL-listed product offers exceptional durability and meets IPC standards. Contact A-Gas Electronic Materials for advanced solutions.

#Imagecure IMC6002R#solder resist for LEDs#LED lighting applications#RoHS compliant#WEEE compliant#REACH regulations#UL listed solder resist#thermal hardening photoimageable resist#aqueous processing#IPC standards#NASA approved solder resist#automotive solder resist#A-Gas Electronic Materials

0 notes

Text

Why Does Most PCB Assembly Adopt SMT Assembly?

Everyone knows that most of the circuit board asembly now adopts SMT assembly, Why? What is SMT chip processing? What are the advantages?

What is SMT Assembly?

SMT Assembly means surface mount technology assembly. The specific content refers to the placement of schistose-shaped components or miniaturized components suitable for surface assembly on the surface of PCB as required, and then solder them using reflow soldering and other soldering processes to complete the technology of electronic components assembly. On the SMT circuit board, the solder joints and components are on the same side of the board, so on the PCB board processed by the SMT Assembly, the through holes are only used to connect the wires on both sides of the circuit board, and the number of holes is much less, so does the diameter of the hole. Furthermore, such a design can greatly improve the mounting density of PCB components.

Advantages of SMT Assembly

1. Miniaturization

The size and volume of chip components used in SMT Assembly are much smaller than those of traditional plug-in components, which can generally be reduced by 60% to 70%, or even by 90%. The weight is reduced by 60% to 90%, which cater for the development of miniaturization of electronic products.

2. High signal transmission speed

The PCB board processed processed by SMT Assembly has a compact structure and high mounting density, which can achieve the effect of short connection and low delay, and thus achieve high-speed signal transmission. At the same time, electronic products can be more resistant to vibration and shock.

3. High frequency characteristics

The components processed by SMT Assembly are generally leadless or short leads, which reduces the distribution parameters of the circuit and thus reduces radio frequency interference.

4. Conducive to automated production

SMT Assembly components have multiple characteristics such as size standardization, serialization and uniform welding conditions, which is able to make SMT Assembly a high degree of automation.

5. Low material cost

The packaging cost of most PCBA SMT Assembly components is already lower than that of plug-in processing components of the same type and function.

6. High production efficiency

SMT placement technology simplifies the production process of electronic products and reduces production costs. In addition, the entire PCBA production process is shortened as well as the production efficiency is improved.

SMT Assembly Capability

1. The largest board: 310mm*410mm (SMT);

2. Maximum board thickness: 3mm;

3. Minimum board thickness: 0.5mm;

4. The smallest Chip components: 0201 package or parts above 0.6mm*0.3mm;

5. The maximum weight of the mounted parts: 150 grams;

6. Maximum part height: 25mm;

7. The largest part size: 150mm*150mm;

8. Minimum lead components spacing: 0.3mm;

9. The smallest spherical components (BGA) spacing: 0.3mm;

10. The smallest spherical components (BGA) diameter: 0.3mm;

11. Maximum component placement accuracy (100QFP): 25um@IPC;

12. Mounting capacity: 3 to 4 million points/day

http://www.58pcba.com/index.php?id=1075

0 notes

Text

PCB Assembly No Further A Mystery