#Steel foundry

Explore tagged Tumblr posts

Text

Rotary kilns under construction at the Vickers-Armstrong Steel Foundry Tynesie, UK (1928)

59 notes

·

View notes

Text

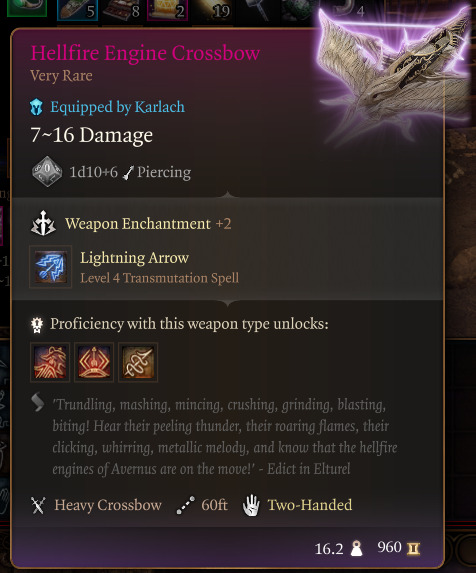

veeeery slowly making my way through the steel foundry... i don't have my usual keyboard, i only have a trackpad for a mouse, and i'm sick, so it's been a time and a half

#we ALL hate it here#but i gotta disassemble these fuckers#so that i can beat gortash to death#i did manage to get the hellfire engine crossbow though#a hellfire weapon for my infernal girl#karlach#astarion#wyll#shadowheart#bg3 act 3 spoilers#steel foundry#bg3#john baldur#nuclear.7z#origin karlach

9 notes

·

View notes

Text

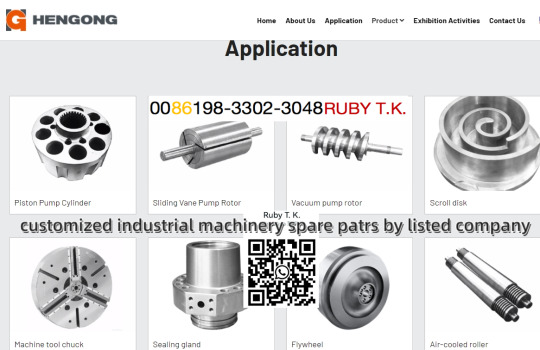

I am from a Chinese listed company HGPE,Asia biggest continuous cast iron bar factory,and we also customized metal parts manufactured by our hundreds of CNC machines and lathes(hydraulic parts,air compressor parts,auto parts,robot parts,reducer parts…),OEM& ODM available.thanks®ards:) 🙏https://www.hengong-bar.com +8619833023048 [email protected]

#casting#iron bars#steel foundry#metalparts#reduceri#hydraulic cylinder#gears#skid and pump#auto parts

0 notes

Text

Uncovering the Materials of Steel: A Comprehensive Guide

Steel, a fundamental material in our contemporary society, is almost everywhere in our surroundings. It serves as the structural backbone of our towering skyscrapers, the sturdy frames of our automobiles, and even the everyday utensils we use in our kitchens.

However, even with its widespread use, a fundamental question often needs to be answered: What steel is made of?

In this article, we will delve into the world of steel and explore its composition, properties, and its crucial role in our daily lives.

The Basic Ingredients of Steel:

Steel is an alloy at its core, which means it is made up of many elements. Steel is made up mostly of iron and carbon. Iron is a naturally occurring element plentiful in the Earth's crust. On its own, it is robust and durable, yet it may be fragile. This is when carbon enters the picture. At the steel foundry, they mix iron with carbon. Iron is fortified with carbon to increase its strength and flexibility, making it more appropriate for various uses.

The Carbon Connection:

The quantity of carbon in steel may vary, giving birth to various steel varieties. Carbon content generally varies between 0.2% and 2.1% by weight. The material is termed low-carbon steel when the carbon content is less than 0.2%. As the carbon percentage rises, it becomes medium-carbon and high-carbon steel. Each kind has its own set of characteristics and uses.

For example, low-carbon steel is well-known for its ductility and ease of shape. It is often used in construction, automobile manufacturing, and even ordinary goods like nails and wire.

Medium carbon steel achieves a good blend of strength and flexibility. It is often utilized to produce equipment, tools, and structural components.

In contrast, high-carbon steel is very strong yet less bendable. It is used in applications with high hardness and wear resistance, such as cutting tools and springs.

But wait, there's another steel player in town: stainless steel. Stainless steel is distinguished by its resistance to rust and corrosion due to the inclusion of chromium during the stainless steel casting. As a result, it has become popular in the culinary world, as well as in medical equipment and many ornamental uses.

Alloying Elements:

While iron and carbon are the fundamental constituents of steel, different alloying elements may be added to improve its qualities. Among the most frequent alloying elements are:

Manganese: This element increases steel's strength and hardenability. It is often used in structural steel and railway rails.

Chromium: Adding chromium improves corrosion resistance, resulting in stainless steel. This steel is often used in kitchenware, medical devices, and architectural projects.

Nickel: In steel foundry, nickel is mixed in steel as it contributes to strength and toughness, making steel suitable for applications like aircraft parts and pipelines.

Vanadium: Vanadium is well-known for increasing steel's hardness and wear resistance. It is often utilized in the manufacture of high-speed equipment and knives.

Molybdenum: Molybdenum enhances steel's heat resistance, making it useful in aerospace and power generation sectors.

Silicon: Silicon aids in the deoxidization of steel and its strength and electrical conductivity. It is often found in electrical steel used in transformers and motors.

The SteelmakingSteelmaking Process:

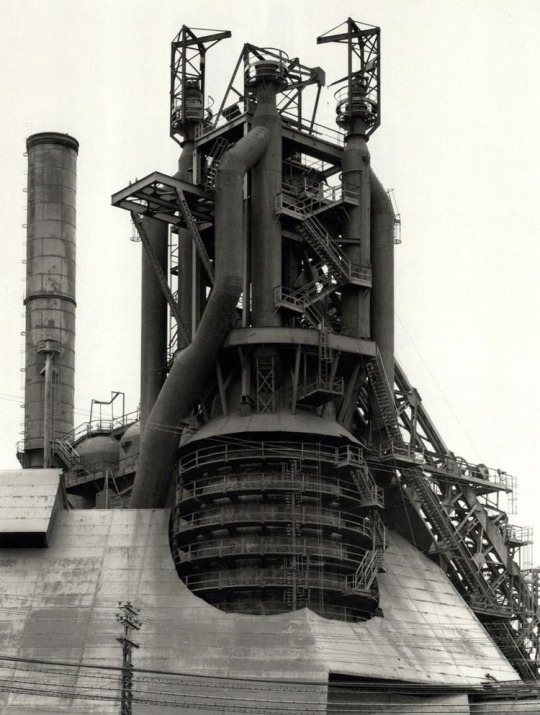

The production of steel involves several steps. It begins with the extraction of iron ore from the Earth's crust. This ore is then smelted in a blast furnace to remove impurities and reduce it to pig iron, which is high in carbon.

Next, the pig iron is refined in a process called "steelmaking." During this phase, the carbon content is carefully controlled by adding or removing carbon and alloying elements. This process can be done through various methods, including the Bessemer, open-hearth, or electric arc furnace processes.

Once the desired composition is achieved, the molten steel is poured into molds to form various shapes, such as sheets, bars, or coils. These shapes are then cooled and solidified, ready for further processing and use in various industries. Many stainless steel casting manufacturers in India are using new methods to create even better products.

Final Thoughts:

In conclusion, steel is a remarkable material that combines the strength of iron with the versatility of carbon and various alloying elements. Its composition can be tailored to suit a myriad of applications, from everyday household items to critical components in aerospace and construction. Understanding steel's basic ingredients and production process sheds light on its importance in our modern world, where it continues to shape our lives in countless ways.

If you need top-quality steel items, check out Sujan Industries. They're known for their excellent steel products and are experts in steel casting.

0 notes

Text

Uncovering the Materials of Steel: A Comprehensive Guide

Steel, a fundamental material in our contemporary society, is almost everywhere in our surroundings. It serves as the structural backbone of our towering skyscrapers, the sturdy frames of our automobiles, and even the everyday utensils we use in our kitchens.

However, even with its widespread use, a fundamental question often needs to be answered: What steel is made of?

In this article, we will delve into the world of steel and explore its composition, properties, and its crucial role in our daily lives.

The Basic Ingredients of Steel:

Steel is an alloy at its core, which means it is made up of many elements. Steel is made up mostly of iron and carbon. Iron is a naturally occurring element plentiful in the Earth's crust. On its own, it is robust and durable, yet it may be fragile. This is when carbon enters the picture. At the steel foundry, they mix iron with carbon. Iron is fortified with carbon to increase its strength and flexibility, making it more appropriate for various uses.

The Carbon Connection:

The quantity of carbon in steel may vary, giving birth to various steel varieties. Carbon content generally varies between 0.2% and 2.1% by weight. The material is termed low-carbon steel when the carbon content is less than 0.2%. As the carbon percentage rises, it becomes medium-carbon and high-carbon steel. Each kind has its own set of characteristics and uses.

For example, low-carbon steel is well-known for its ductility and ease of shape. It is often used in construction, automobile manufacturing, and even ordinary goods like nails and wire.

Medium carbon steel achieves a good blend of strength and flexibility. It is often utilized to produce equipment, tools, and structural components.

In contrast, high-carbon steel is very strong yet less bendable. It is used in applications with high hardness and wear resistance, such as cutting tools and springs.

But wait, there's another steel player in town: stainless steel. Stainless steel is distinguished by its resistance to rust and corrosion due to the inclusion of chromium during the stainless steel casting. As a result, it has become popular in the culinary world, as well as in medical equipment and many ornamental uses.

Alloying Elements:

While iron and carbon are the fundamental constituents of steel, different alloying elements may be added to improve its qualities. Among the most frequent alloying elements are:

Manganese: This element increases steel's strength and hardenability. It is often used in structural steel and railway rails.

Chromium: Adding chromium improves corrosion resistance, resulting in stainless steel. This steel is often used in kitchenware, medical devices, and architectural projects.

Nickel: In steel foundry, nickel is mixed in steel as it contributes to strength and toughness, making steel suitable for applications like aircraft parts and pipelines.

Vanadium: Vanadium is well-known for increasing steel's hardness and wear resistance. It is often utilized in the manufacture of high-speed equipment and knives.

Molybdenum: Molybdenum enhances steel's heat resistance, making it useful in aerospace and power generation sectors.

Silicon: Silicon aids in the deoxidization of steel and its strength and electrical conductivity. It is often found in electrical steel used in transformers and motors.

The SteelmakingSteelmaking Process:

The production of steel involves several steps. It begins with the extraction of iron ore from the Earth's crust. This ore is then smelted in a blast furnace to remove impurities and reduce it to pig iron, which is high in carbon.

Next, the pig iron is refined in a process called "steelmaking." During this phase, the carbon content is carefully controlled by adding or removing carbon and alloying elements. This process can be done through various methods, including the Bessemer, open-hearth, or electric arc furnace processes.

Once the desired composition is achieved, the molten steel is poured into molds to form various shapes, such as sheets, bars, or coils. These shapes are then cooled and solidified, ready for further processing and use in various industries. Many stainless steel casting manufacturers in India are using new methods to create even better products.

Final Thoughts:

In conclusion, steel is a remarkable material that combines the strength of iron with the versatility of carbon and various alloying elements. Its composition can be tailored to suit a myriad of applications, from everyday household items to critical components in aerospace and construction. Understanding steel's basic ingredients and production process sheds light on its importance in our modern world, where it continues to shape our lives in countless ways.

If you need top-quality steel items, check out Sujan Industries. They're known for their excellent steel products and are experts in steel casting.

0 notes

Text

steel foundry slag

Untitled Todd Webb Rhodesia, 1958

599 notes

·

View notes

Text

Oh wow, they made him sound like such an old man.

#rowan rants#baldur's gate iii#bg3#baldur's gate 3#baldurs gate 3#ketheric thorm#bg3 ketheric#high half elf#enver gortash#lord gortash#bg3 gortash#steel watch foundry

1K notes

·

View notes

Text

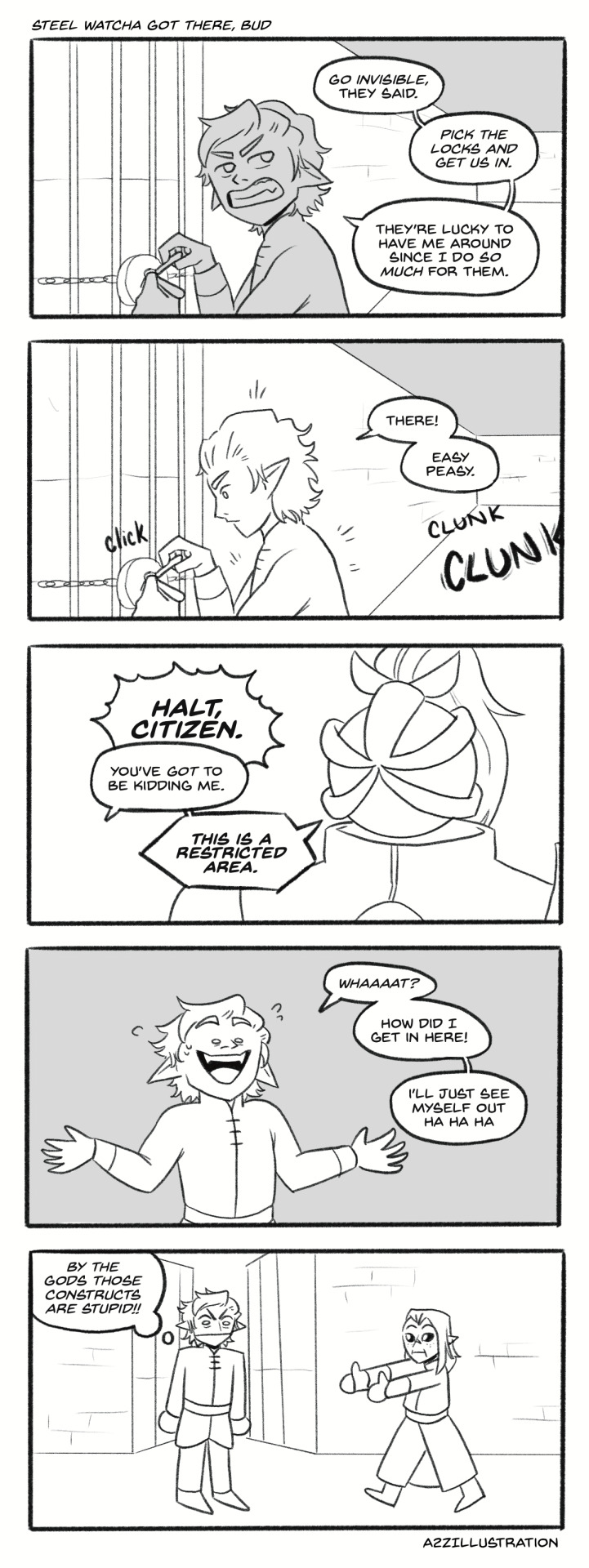

Now we're putting Astarion in Situations™

| First | | Previous | | Next |

[[ All Croissant Adventures (chronological, desktop) ]]

[[ All Croissant Adventures (app) ]]

#the boy really went through it in the foundry lmao#p.s. I'm going to start doing a M-W-F schedule next week#we're approaching endgame and I'm creeping up on my backlog so I want to make sure I have enough time to make some of these longer comics#yes I am already crying about approaching the end of the journey don't worry about it :''''''''''')#bg3#baldur's gate 3#bg3 spoilers#act III spoilers#steel watch foundry#croissant adventures#tav#astarion#steel watch#comics

389 notes

·

View notes

Text

furnace

265 notes

·

View notes

Text

I know these people are smart people who know what they're doing but sometimes it really strikes me. like izzy in burrow's end describing writing as shadows of concepts on surfaces. and ally in nsbu saying out loud they're trying to fail some rolls to get tokens

#not art#nsbu spoilers#technically. very minor spoiler#same as ally saying they sent kristen to the steel foundry bc they wanted to scout that place#its one part these folks being smart and another part like. a kind of confirmation that they're deeply invested in the game's world#and they want to and try to meet it where it is. and when it makes sense its Really good#there is something special abt actual play as a format that lets these kinda moments happen. I really like it

55 notes

·

View notes

Text

Based on a conversation with @doriangaymer in my Discord server. XD

#hector carlisle#karlach#karlach x tav#tav x karlach#karlach cliffgate#the lengths i went to get this screenshot lmao#i didn't keep nearly enough hardsaves on hector's run#i had to redo the iron throne and the steel foundry and the wyrm's rock guard fights for this#but it's so them that i had to XD

72 notes

·

View notes

Text

POV: when you and your friends accidentally broke your neighbours saetillite dish so you run before they can catch you.

(This actually happened to me. I was caught)

#bg3#baldur's gate 3#bg3 bhaalspawn#bg3 durge#enver gortash#steel watch foundry#gondians#shadowheart#laezel#lae'zel#the dark urge#karlach

12 notes

·

View notes

Text

Larian stop being a coward and let me romance Barcus Wroot.

#I finished the Steel Watch Foundry mission#I should’ve yeeted that ungrateful Wulbren into the sea but Barcus would be sad#myisha plays bg3#bg3#barcus wroot

37 notes

·

View notes

Text

The Many Applications of Stainless Steel Investment Castings

Stainless steel investment casting is an age-old technique dating back thousands of years. It has continued to evolve and adapt to modern-day needs, making it a go-to solution for various industries.

What makes stainless steel investing casting different?

The beauty of this method lies in its ability to transform complex designs into high-quality, intricate components with minimal material waste. What to know more about stainless steel casting?

Keep reading.

What is Stainless Steel Investment Casting?

Stainless steel investment casting, also known as the lost-wax casting method, is a venerable technique that dates back thousands of years. The process involves creating wax patterns of the desired component, which are then coated in a ceramic shell to form a mold.

Once the mold is cured, molten stainless steel is poured into the cavity, replacing the wax pattern. After cooling and solidification, the ceramic shell is removed, revealing the final intricately detailed stainless steel component.

Looking for quality casting services? Right from stainless steel casting to steel foundry, get quality services at Sujan Industries.

The Process

Pattern creation: The process begins with creating a wax or thermoplastic pattern replicating the final component's shape.

Mold formation: The pattern is then coated with a ceramic slurry, creating a shell around the pattern.

Dewaxing: The ceramic-coated pattern is heated, causing the wax to melt and drain away, leaving behind a hollow ceramic mold.

Casting: Molten stainless steel is poured into the ceramic mold, filling the void left by the wax.

Cooling and solidification: The mold is allowed to cool and solidify the metal.

Mold removal: The ceramic shell is broken, revealing the finished stainless steel component.

What are Common Applications for Stainless Steel Investment Castings?

Automotive: The automotive industry relies on precision components to ensure safety and performance. Stainless steel investment castings are utilized in critical automotive parts like engine components, suspension systems, and braking components. Their ability to maintain dimensional stability under high-stress conditions ensures optimal performance and longevity.

Food Processing: The food industry demands equipment that is not only hygienic but also capable of withstanding harsh conditions. Stainless steel investment castings are often used in food processing machinery, such as pumps, valves, and fittings. Their corrosion resistance and ease of cleaning make them ideal for maintaining strict sanitation standards.

Medical Equipment: In the medical field, where precision and biocompatibility are paramount, stainless steel investment castings are commonly employed. These castings are found in surgical instruments, implants, and various medical devices, thanks to their biocompatibility and ability to meet strict regulatory requirements.

Marine Applications: The marine environment is one of the most corrosive, with constant exposure to saltwater and harsh weather. Stainless steel investment castings find extensive use in marine equipment, including propellers, fittings, and marine hardware, due to their exceptional corrosion resistance and high strength.

Pipe Fittings: Stainless steel investment castings are used extensively in pipe fittings due to their corrosion resistance and leak-tight properties. These fittings find applications in plumbing, petrochemical, and fluid handling industries, ensuring efficient and safe fluid transportation.

To say, stainless steel investment casting is compatible with a wide range of stainless steel alloys, enabling stainless steel casting manufacturers in india to choose the best material for their specific application, whether it's corrosion resistance, high strength, or temperature resistance.

Over To You

Stainless steel investment castings have proven their worth across diverse industries due to their exceptional versatility and performance. If you’re looking for stainless steel casting services, you can rely on Sujan Industries. With a track record of excellence and a commitment to precision, Sujan Industries has established itself as a trusted name in the world of metal casting.

Want to know more about our services? Visit our website for more information.

0 notes

Text

Baldur's Gate 3 locations 27/?

#steel watch foundry#baldurs gate 3 locations#baldur's gate 3#bg3#bg3 screenshots#baldurs gate 3#bg3 screencaps#virtual photography#chill just a gamer cat

23 notes

·

View notes

Text

I now understand people's hatred for the Iron throne and steel watch foundry.

#I hate it#I'm trying to be good and save everyone#but the gondians keep doing something stupid and end up getting killed#like just run and get out of here#and those damn steel watchers are terrible#and those damn exploding collars#ugh#bg3#baldur's gate 3#feckin gortash#gondians#steel watch foundry#iron throne

20 notes

·

View notes