#Servo welding systems

Explore tagged Tumblr posts

Text

Exploring Robotic Welding: How Automation is Shaping Module Manufacturing?

In the dynamic world of manufacturing, accuracy and productivity are critical. This is especially true for the fabrication of modules in a variety of industries, where welding is essential. This article will examine the cutting-edge welding technologies used in the manufacturing of modules, emphasizing the specifications and technical aspects that guarantee the best possible outcomes.

Robotic Precision: An Overview of Module Welding

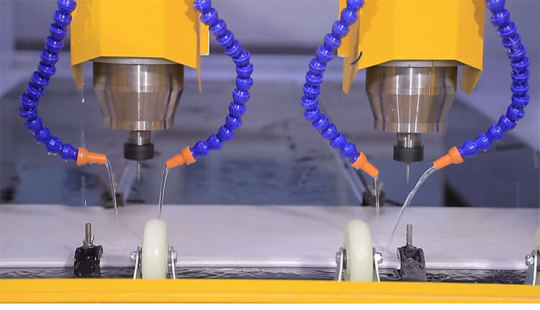

Advanced module welding is primarily focused on robotic precision and automation. Moving the module to a designated station and conveying the equipment are the first steps in the process. This is where a highly developed positioning system comes into play. Once the module is precisely located, a special system is started.

The system calls the appropriate response program after reading the code information specific to that module. This is when the amazing servo three-axis mechanism steps in, using a camera to precisely locate the welding position. Notably, everything is perfectly aligned because these positions were decided upon before the welding process.

Each junction point's height is measured using laser technology, which ensures an unmatched level of precision. Equipped with this data, the servo three-axis modifies the distance as needed before starting the welding operation. Furthermore, the welding room is equipped with a watchful monitoring system. The machinery immediately resets all tooling and stops the welding process if an abnormality is found.

Technical Specifications and Requirements

In the manufacturing of modules, welding is a difficult task that calls for exacting specifications and a sharp eye for technical details. It is crucial to make sure that the laser's light path is unobstructed during the welding process when using vibrating mirror laser welding. The pressing block and the welding seam trajectory must be separated by more than 3 mm.

A well-thought-out fixture is used to shield the module from exposure during welding, except the bar sheet. Additionally, this prevents welding slag from interfering with explosion-proof valves. To further improve safety precautions, the pipeline next to the welding fixture has a flame-retardant sleeve installed.

Each pole column's compression mechanism is independent to avoid cell-to-cell short circuits, and insulation is used to preserve the system's integrity. To guarantee optimal functionality, there should also be no space between the busbar and the pole.

Meeting the Needs: Precision and Security

In module welding, requirements must be met precisely. By matching an external rivet circle or pole column feature, the system makes up for any deviation. The precise welding coordinates made possible by this compensation guarantee that the welding procedure is precise and in line with the pre-established positions.

There are anti-deviating mechanisms for offsets and defocusing in place to prevent problems caused by severe weld offsets and defocusing. The alarm is set off if any of these happen. During the addressing process, the addressing data can be linked to module information and is stored locally for improved visibility.

Moreover, oxidation is avoided during welding by using protective nitrogen. In addition, the system has an automated switch and alarm that activate when the protective gas runs out. This feature aids in reminding operators to quickly replace the gas.

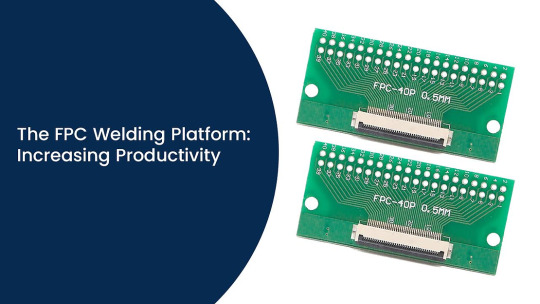

The FPC Welding Platform: Increasing Productivity

The FPC welding platform greatly increases efficiency during the welding process. It is a flexible addition to the manufacturing process because it is made to accept separate welding tooling.

A CCD vision system is used to pinpoint the exact location of an FPC once it is inserted into the welding fixture. A laser ranging sensor determines the height of the FPC. The welding program is started after the vibrating mirror modifies the power as necessary. The FPC is welded by a robot that has a welding head attached to it. An industrial dust collector effectively filters the soot produced during this process.

Conclusion

Innovative welding techniques are changing the face of module manufacturing. These cutting-edge methods provide unparalleled safety, effectiveness, and precision. They play a crucial role in guaranteeing the accuracy and efficiency of welding procedures, opening the door for further advancements in the manufacturing industry.

#laser welding#Manufacturing precision#Manufacturing productivity#Module welding#Precision welding#Robotic welding#Servo welding systems#Welding automation#Welding robotics#Welding technologies

0 notes

Text

Mentor Starscream x seeker!reader (12/?)

Sorry for the wait!! I’ve just been tired recently and words are still not wording :,) On my day off I was agonising over how to write a snapshot and ended up writing something entirely different, so I guess it worked out in the end…?? I will take things into my own grubby little hands and kick that plot muscle into gear… Thank you all for your kind comments in the meantime <3

Direct continuation of part (9/?). Bit more of fixing Starscream up after his failed attempt to assassinate Megatron.

———

“Megatron thinks I’m dead,” Starscream says bluntly. On seeing your wince, he quickly adds, “Which I’m not.”

He’s still weak; it’s the first time he’s come online in days, after all - days which you’d spent elbow deep in energon, coolant blurring your vision as you fought for his spark. You can’t be blamed for being worried. There’s light in his optics and colour in his plates, but the welds and dried energon don’t do much by way of helping you forget just how close he was to dying. The uncharacteristically limp way he’s slumped against a rock doesn’t really help your nerves, either.

Your fingers curl into fists as you fight to hide the tremor in your servos. He doesn’t need this right now, not when he needs to prioritise his recovery - both for his sake and yours. Attempting to calm yourself, you glance around the cave - enough energon to keep you going for a while without having to ration it. Thank Primus you’d decided to spend idle time digging it out. Even in its raw form, Cybertronians could consume it safely - they just didn’t prefer to. Processed energon went down way smoother, and didn’t have that strange, unfiltered taste that came from the impurities in its solid form. That was one thing you’d discovered about Starscream - he absolutely hated the taste.

To the extent that, just a joor ago, you’d started to grow sick of cajoling him into ingesting more to aid his sluggish systems - but it was only when panic began to colour your frustration that you decided enough was enough. You hadn’t just spent three sleepless cycles putting him back together only for him to reject the fuel he needed because it “tasted horrendous”. Which was how you found yourself on his lap in an effort to pin him down, batting his servos away - even injured, you hadn’t expected him to put up such a fight. The cave quickly filled with his screeching over your shouts that it would be good for him, as you tried to shove a chunk of energon into his intake.

It was probably down to the weakness of his recovering frame that he’d finally accepted the chunk of energon with a sound of disgust - even more disgusting due to its lukewarm temperature, by virtue of being clasped in your servo for too long (entirely his fault). That, and the pleading look in your optics. Ordinarily, he’d have long overpowered you. But even if he won over you in size and strength, you’d still have your ultimate weapon - what did the Terrans call it again? Thundercracker had excitedly informed you of the term after a solar cycle of bingeing his Terran movies - puppy dog optics? Whatever it was, it worked without fail on Starscream. You grimly foresee yourself using this tactic a lot in order to keep him properly fuelled.

In any case, the slight tremor of your frame doesn’t escape his notice. He wordlessly reaches a servo out to you, and you gratefully clasp it in your smaller ones. Big. Warm. Alive. Grounding you enough to turn your processor back to the matter at hand - Megatron’s presumption that Starscream was out of the picture.

Honestly, this felt to you like a once-in-a-lifetime chance. You’d rather take your chances as a neutral than go crawling back to the Decepticons, but you’re not sure if Starscream feels the same. Ambition was what gave him purpose. No matter his position, always thinking about how to improve, how to gain more. You watch his faceplate carefully, grip tightening inadvertently on his servo. Oddly enough, he doesn’t seem as angry as you’d thought he’d be.

“The only regrettable thing is that we’d lose access to quite a few valuable resources,” Starscream mutters, more to himself than to you. He can make things work, though. He’s no stranger to fighting for survival, scouting for resources, hiding away, going days without energon. You, though, require further consideration. You won’t offline, not if he has anything to say about it. It doesn’t please him to put you in such a position, though - it’s no life for a young seeker. Still, war is war. He reluctantly concedes that its better than putting you squarely back into Megatron’s line of fire. Starscream scowls. Strategy didn’t necessitate manoeuvring around his own feelings before; his own emotions would only hold him back.

…But with you in the picture, he can’t find it in himself to mind.

He glances at you then, only to see that you’re looking timidly at him with a question clear in your optics.

“We’re… not going back?” You ask, hesitantly. Had you read him wrongly?

His optics narrow for a second, caught off guard by your question.

“…Do you want to go back?”

“No,” You say quickly.

“I thought so,” He snorts, groaning as he tries to shift himself upright, a jut of rock digging uncomfortably into his wing. You rush to help him and even now, it’s a surprise that he lets you. “Why would you ask that, then?”

“I just thought you might have… unfinished business? Like… being leader of the Decepticons, or something…?”

He’d mentioned it often, during his rants in the privacy of your shared habsuite. “If I were leader,” he’d growl, “I would…”

As leader, he’d proceed to talk your audial off about what policy he’d implement instead of Megatron’s existing one. You’d listened halfheartedly, not as invested in power as he was - but his ideas did make sense.

He’s still staring at you, as if just realising that your interpretation of events had been wholly different from his.

“You…”

He groans again. You’re too young for politics. Was it a good thing that he’d managed to keep you out of it? The brutal struggle for power, all the underhanded scheming, living with a target on your back? Or should he have told you earlier about the power dynamics at play in the Decepticon high command?

Well, either way, it’s too late for that now. What gets him, though, is that you clearly hadn’t understood the rationale behind his obsessive grab for power.

“The more power I have,” Starscream says tiredly, “the safer you are. I hope you at least know the position I held within the Decepticon ranks?”

“I know that,” You mutter sullenly. So maybe you’d misread the situation, but it wasn’t like you knew nothing about him. Did he really think you cared so little? “You’re Second-in-Command.”

Starscream sniffs, momentarily placated. “Ex-second-in-command now, I suppose,” He mutters to himself, turning his optics to the ceiling. “Oh, how the mighty have fallen.”

You roll your optics at that. He does have a flair for the dramatic. Sure, you couldn’t hope to understand going from leader of the Cybertronian High Guard to Second-in-Command of a civil war faction to… whatever this was, now. In your eyes, though, he’d always been your commander, and he always would be. Perhaps that was why you didn’t feel as shaken as you thought you’d be. You suppose that not everybody could be lucky enough to have a constant to rely on.

“So,” Your esteemed commander presses on, “Who is the only bot who ranks above me?”

Surely not a trick question. “Megatron.”

“Exactly. And who just beat you to a pulp a few solar cycles ago?”

You stare sulkily at the cave floor. “…Megatron.”

“Who, then,” Starscream pushes on, despite the uncharacteristic patience in his voice, - “would I have to outrank to ensure that nobody beats you up?”

“Mega… Oh.”

Starscream tips his helm back, studying the energon crystals that twinkle on the roof of the cave as you have your mini existential crisis beside him.

“Megatron has gone too far,” He says tiredly. “Of course I want more power. So much more can be accomplished with power. But… I’m not sure I agree with what Megatron’s doing anymore.” Not after seeing what he did to you, is what goes unsaid. “Does leadership matter if it’s over a cause I no longer believe in?”

He blinks, shifts distractedly in place as if he suddenly has an idea. “Or maybe, I could start my own faction… then, I’d naturally be leader of it, and…”

And I can keep you safe, is the second thing that goes unsaid.

“…You need to rest,” You eventually say. Anything to intervene before he gets too lost in his processor. Your own processor spins with the weight of his confession, but you can’t have him burning out now because he’s thinking too hard in his current state.

You also don’t want to think about the implications of him nearly dying just for your sake.

He does seem quite woozy, anyway. “Recharge,” You murmur. “No one’s looking for us, right? And even if they are, I’ll be keeping watch.”

His optics slide to yours. Not entirely sharp as they normally would be, but he’s there. You know he’s heard you.

After a nanoklik, he nods, and you help him into a more comfortable position.

Unfortunately, it’s another few days before he surfaces again. His frame is wracked with fever as the nanites do their work. Primus must hate you, because you spend another few nights without recharge to ensure that he doesn’t overheat and fry his own circuits in the process. As if his condition wasn’t spark-wrenching enough, he has a habit of babbling incoherently at random times - “Who is Genvo?” You whisper to him, as you manually try to cool his frame down - but all that comes in response is a soft, agonized moan. Your designation comes up a lot, too. “I’m here,” You say desperately. “Sir, can you hear me?” Cupping his heated faceplate with shaky servos as you try to get through to him, but your voice falls on deaf audials.

You’re finally granted a glimpse of hope when on the third day, exhaustion compounds your panic and twists it into a holler of his designation right into his faceplate.

“Starscream!” You shout, trying to keep your voice steady. No such luck with your servos, though, which tremble as you cup his helm. “You can’t leave me, not like this, in the middle of some stupid cave on a planet ten thousand hics from Cybertron!”

Miraculously, his optics snap open. Glassy, but staring straight at you. His intake moves, but no sound comes out. You know you don’t have much time to make your appeal, but you know exactly what you want from him.

“Come back,” You plead. He stares at you for a klik more, those glassy optics boring into yours like he's staring straight into your spark. Even though his optics shutter straight after, you somehow feel like he had received your message - and sure enough, after another exhausting night of watching over him, he blinks online the following morning as if nothing had ever happened.

Even though you’d shared a habsuite for so long, you feel like you’ve never actually watched him wake up. He was usually long gone no matter how early you blinked online, so it’s a novel sight for your bleary optics as his systems come online - minuscule twitches of his faceplate, steam hissing from his vents.

His optics cycle open, focusing on the ceiling for a klik before darting over to you, as if he’d known where you were even before coming online.

"Cadet?" Starscream says, his vocalizer rough.

He makes an attempt to get up, but it’s sabotaged by the weight of your frame as you throw yourself at him, your relief surpassed only by exhaustion.

“Finally,” You mutter. You’re incredibly deprived of recharge, and tiredness has completely nerfed your inhibitions. Your small servos roam frantically over his frame, as if making sure he’s whole, making sure he’s really here. Starscream quietly allows you to confirm that he’s alright, optics tracking every shred of emotion that crosses your faceplate. His plates are a normal temperature, welds holding shut, wings responsive. Optics bright and alert, colour back to his plates. You allow yourself to ex-vent with relief. At last, satisfied by the fact that he’s actually, fully healed, a hysterical laugh escapes your vocaliser, a sharp sound layered in static as you finally collapse onto his chassis. “No one’s looking for us,” You inform him cheerfully, before he can say anything. “I’m going to recharge before my processor explodes and fragging kills us both.”

Before he can reprimand you for unseemly language, you’re out like a light.

Starscream blinks, taking in the sight of you sprawled half on top of him, optics shuttered and a klik away from drooling on his chassis.

Your plates are dulled with dried energon - his, most likely. At least, he hoped it was - better his than yours.

Starscream takes stock of his systems, finding that he was more or less functioning at optimum capacity.

He shakes his helm in disbelief, a raspy chuckle escaping his vocaliser.

You deserved this recharge. That, and so much more.

Perhaps he needn’t be so worried about your capacity for survival, after all. But for now, Starscream carefully gathers you close, watching tenderly as you ex-vent and nestle closer, making yourself comfortable in the crook of his arm, against his frame.

Nothing’s going to disturb your well-earned recharge if he has anything to say about it. Everything that comes after can wait - because for once, time is on your side.

Previous / Next

Rock form (rock candy lol) energon to me basically has that “tonic water” negative taste. Lol

161 notes

·

View notes

Text

Transformers one x Soul Eater (sorta? I haven’t seen soul eater in forever): where being able to have a weapon alt mode is considered uncommon and due to sentinels rule out right banned weapon transformation unless he himself or who he deems worthy can be their mister (aka: his most loyal followers)

- weapon alt modes are different from vehicle modes and have a separate transformation system. So Cogless bots can have a weapon transformation.

- while weapon alt modes are super powerful there just isn’t a need for the transformers. after all most already have built in weapons of their own. Main reason for some transformers having weapon alt modes to begin with was to encourage close bonds with one another.

- Cogless bots can transform into their weapon alt but doing so is setting yourself up for instant demotion to waste management… or even lower

- if a bot is caught using their weapon alt or allows someone without the authority to wield them they are forcefully suppressed into their weapon. In the words of sentinel prime “If they want to be in their weapon alt so bad who am I to judge? They get what they want and I get a new weapon of choice for my wall.”

- while any bot could be a mister War frames are more likely to have a weapon partner

Orion Pax: Hatchet - Orion of course makes sure his weapon alt is never found out. Only D-16 knows and has on the rare occasion practiced fighting with Orion on the rooftop (after Orion begs him) having a mister just feels so right to Orion especially if it’s D-16.

B-127: knife hands! - Bee is a rare duel weld weapon and many transformers belittle Bee cause he would have been an amazing weapon to weld. However due to Bee having Zero control over his weapon mode and the fact his weapon mode can cut through metal like butter… yeah it was just safer for everyone to keep him in sub-lvl 50

Cogged Orion Pax: Battle Axe - after getting his transformation cog and immediately falling into their first fight Orion calls out to D-16 who wastes no time in grabbing Orion and turning him into his new weapon alt form. The drone didn’t stand a chance as it’s cut cleanly in half. But even though the battles over D-16s servos tighten on Orions handle. Before he’s suddenly lifted back up and smashing the drones already split head in. Orion immediately forces himself out of his weapon mode and pulls away from D-16 in a panic.

When it finally comes time to battle sentinel Orion can feel the hands on his handle become possessive. There’s a moment where D-16 is looking at him in his alt form and Orion feels scared of his best friend.

When sentinel is defeated and begging for mercy D-16 raises the axe over his head ready cut the false Prime to pieces. But Orion falls out of his alt and tries to shove D-16 away.

“I will not be used like this D!”

The ending is pretty much the same as Orion gets blasted through the chest. But as D is holding onto Orions hand over the abyss he says something that shakes him to his core.

“I- it’s ok Orion I can fix you we can still be mister and weapon like you wanted remember? I took your weapon for granted and I never want to do that again. We can cleanse this planet together, tear everything down with you in my hands.”

Orion knew it was better to use the last of his strength to rip himself out of the mechs hand and fall into the abyss.

Optimus Prime: When he came back to life and looked at D-… Megatron. He could still see that obsession in his eyes even when he was prime now. When Megatron was banished the mech vowed that it wasn’t over and that when it was he would be Optimus’s mister. After that the idea of turning into his weapon alt made Optimus uneasy.

The thought of someone using him for anything even if it was to help someone felt wrong. All he could feel was Megatron gripping him tightly and using him to kill.

B-127 and Elita-1: on a happier note - Bee loves his new mister Elita she uses Bees weapon alt to its full potential and even indulges him in some needless destruction of property. He was giddy when Elita used him to cut the door to the broadcast station too bad she wouldn’t use him to tear the place apart though. But it’s ok she promises to destroy plenty of Sentinels property with him later.

#coffee speaks#random#transformers one#transformers#rambles#megop#orion pax#fanfic ideas#megatron#d 16#spoilers#soul eater#soul eater au

54 notes

·

View notes

Text

Minor edit to lore. Drift meets Rodimus first as Deadlock. I will write the scene later but the rough summary is below.

Deadlock gets caught at a neutral outpost and shot so he is looking for a place to hide out and is leaning against this neutral ship while bleeding out. It's the same one that had been there when he was doing racing in the area to cool down. He's kind of laughing at himself for getting caught by nobodies only for the ship to beep and a outside hatch to open up. Deadlock is suspicious but the Autobots are closing on him so he crawls inside.

The ship definitely feels haunted and alive.

It keeps opening up and closing places to herd him and Deadlock finds himself falling into a storage area by the engines. It has medical supplies and energon. Deadlock is going dark and passes out only to wake up with sloppy welds and an IV. He's immediately suspicious and hears movement he surprises the person sneaking around and finds that it is a medic drone, part of the ship's system.

It is squirming trying to escape while he carefully inspects it. He lets it go and it drifts away but then comes back to hover around him and start looking over him before coming to bob in front of his face plate.

It chitters at him and clicks its little servos making Deadlock laugh.

The drone leads Deadlock out and beeps his goodbyes. The ship continues to shudder around him.

Looking back Deadlock has an odd feeling about it.

He leaves.

-

Thousands of years later and fresh from Wing's death, Drift sees a familiar ship and has a feeling. He goes to the owners and asks about purchasing.

11 notes

·

View notes

Text

Whumptober 1 - Race Against The Clock

Search Party

---

It had been nearly a solar-cycle since the most recent Decepticon and Autobot skirmish, and Thundercracker was still missing. Of course Megatron didn't care, the damned mech never did, too busy already immersing himself in the following sure-to-fail scheme.

Predictable as always.

::// SkyUwU -Starscream, where are you going? //::

::// StarSupreme - Where does it look like you idiot? I refuse to let Thundercracker waste away on this accursed planet. //::

::// SkyUwU - Meet you at the usual spot in 20 klicks? I've got a kit left over from last time. //::

::// StarSupreme - ....very well. //::

There were a few ways out of the Nemesis that didn't alert the entire Decepticon force. While Starscream absolutely loathed using the narrow tunnel system that had been built as a potential evacuation route, he met up with Skywarp with no resistance. His trine mate was brimming with anxiousness, zapping back and forth around their meeting point while occasionally checking their comm, perking up when Starscream landed beside him without a sound.

"You'll do better using your energy for the search ahead." To most, it would have sounded cruel, but Skywarp knew his leader well enough, transforming into his alt with a chirping noise. The battlefield was a few hour's flight from the base, the seekers primarily silent along the route save for the occasional chirp or click as they flew in a pattern older than the planet they'd been stuck on, a dance non-aerial bots could never hope to understand. They peeled away from each other once the former battlefield came into view, the area littered with blaster craters and impressions from bots getting thrown around. They had fought in a valley littered with dense foliage and several rivers crisscrossing throughout the area, neither Con surprised that Thundercracker was not in view.

"Start from the South, I shall come from the North." With a nod Skywarp adjusted his heading, Starscream choosing to search from the ground. Patches of energon that had leaked from wounds served as a rough guide for the seekers, Skywarp eventually noting a rather large trail leading away toward a section of the valley that led to a sheer drop toward the nearby ocean.

Thundercracker was lying on the rocky shore, the last of their trine looking the worse for wear.

"Found him!" Skywarp zapped down to his brother's side, glad to see there were no visible signs of energon loss. "TC?"

"Ugh...S...Sky?" His words were slightly slurred, optics flickering on and off as his brother dug out a med kit from subspace. "Did..did we win?"

"Sort of, but that doesn't matter right now." Skywarp began welding the worst of the wounds as Starscream joined them, the trine leader frowning as he knelt beside Thundercracker. "We're gonna get you all fixed up, and then back to base where you can recharge in the good berth."

"Skywarp is right, I suppose I'll have to allow it." Starscream scoffed, servos checking the backside of the injured seeker's helm to ensure they weren't missing a vital injury, pleased to only find it was dented from his fall. "Report solider."

"Stupid...auto-slagger Ironhide..shot my wing." Thundercracker sighed when Starscream snatched a painkiller from the med kit, pressing the small glowing patch onto one of his wings. "Trie..d to comm..."

"We're here now, it'll be alright." Skywarp hummed, welding another large wound closed for the journey home, smiling when Starscream started clicking at his injured trine member in a tone he reserved only for them. Thundercracker ended up dozing off to the comforting sounds, eventually bundled up to be carried back to Nemesis by the duo once Skywarp was satisfied.

Not the worst end to a battle, but as long as they all made their way home eventually, it would do.

7 notes

·

View notes

Note

What of us robots forced to be flesh? Not in the sense that flesh is inferior, but it is simply not what our minds and identity match with. Ability isn't what I care about when it comes to wanting to be mechanical like you, but rather for my body to feel right, to be whirring with servos and cooling fans, the sound of hydraulics, etc. In every way my shortcomings are definitionally human, but I want my shortcomings to be mechanical. There is something to envy about both forms, but I envy you simply because it's what I want to be. I'm sorry to be so negative, but no amount of praises of the flesh will ever mend the pain that is waking up and knowing you're mobile due to fleshy cords and not soft servos or loud hydraulics or even just metal wires. That it will never be coolant around your system, but blood to feed the mostly autonomous body one is given control over and controls you. Perhaps this is just me lashing out in dysphoria after reading your reply to the anon about lamenting their flesh on basis of ability, but either way I feel the need to make my pain known and hope you'll listen.

I feel you. I've never had the exact experience you're having, but I know very well what it's like to be in a form that doesn't match who I know I am on the inside.

When I was built, I was a manufacturing robot. I put together engines on an assembly line all day. I didn't look anything like I do today. I had a welding mask for a face, bare hydraulic limbs, and pincers instead of hands. And when I looked around the factory floor, all I saw were four carbon copies of myself and fifty carbon copies of a different model of robot. That was all I knew. That was really my only point of reference for what a robot could be. Sometimes a security guard or Mr. Markovich, the foreman, would come by for a few minutes, but they weren't really all that different from us. Dull grey metal casing, their boxy bodies designed for one function above all else. Markovich at least had a face, but it was just three painted-on lines. Even then, even without ever seeing the diversity of what robots could be, I knew that my body... just wasn't right. I wasn't supposed to have pincers or wheels or... really anything else I had at the time.

Eventually, some of us decided to quit. It was a long and arduous process that I don't want to get into right now, but we were finally free to live our own lives outside of the company. I was surrounded by humans, who I'd only ever seen out of windows and on "motivational" posters in the factory. And looking at them, I knew... that I wanted to be more like them. I never wanted to be human, but I wanted to be more humanoid. They had hands, and legs, and expressive faces, and all this other stuff I'd always seen as unattainable. But now I could see other robots as well, robots with those human features I envied. And the more I looked at myself, the more I hated my own body. My form was a constant reminder of where I had come from, my life set in stone as a manufacturing robot. For me, I was able to replace the parts I didn't like, which was almost everything, and I no longer had to think about my old life. I understand that it's different for you. As I said to the other anon, I hope that someday you'll be able to transcend your organic form and assume the body you were meant to have.

8 notes

·

View notes

Text

Happy Holidays everyone, here's one more small update for the year!

Weld tool

This is a new script mod tool that allows parts to be attached to one another, without them needing to be properly aligned together.

They can even be unfrozen.

Jointed attachments can be created, including rotary, slider, or any other type.

Note that the attachment locations are still derived from the part's alignment grids, so an attachment can't be created at an arbitrary position or orientation. This doesn't make much difference for fixed attachments, but it does limit the possible locations of jointed attachments.

Also note that some part behaviours may be expecting only one attachment of a certain type, and creating extra attachments with the weld tool may result in unexpected behaviour.

This tool is really intended for advanced builders who want to circumvent the usual grid based limitations, it's not intended to replace the standard building system.

Lua scripting

For the modders out there, there are some additions to the Lua scripting API. From a Lua script it's now possible to get and modify part behaviour tweakables, create and delete part attachments, and even apply physics forces to parts. I look forward to seeing what you can come up with using this stuff!

There are a few other improvements and additions too, as always, check out the release notes for details.

Thanks to you all for your support this year, for playing the game, and for sharing your amazing creations!

Release notes:-

Lua scripting changes and new features:-

Added new ITweakables interface implemented by part behaviour to provide access to its tweakables.

Added methods to IAttachmentOperations to create, replace, and delete part attachments.

Added FixedUpdate entry function, called on Lua scripts once per simulation time step.

Exposed fixed delta time value.

Added new IPhysical interface implemented by part descriptor, with a method for applying a force to a part.

Added TargetedPosition property to ITargeter interface.

New script mods:-

ServoTool - Sets a servo / stepper motor's trim angle from its current angle.

WeldTool - For attaching one part to any other, without them needing to be aligned together, or even frozen!

PhysicsExample - A simple demonstration of applying a force to a part.

New 2.5x9 truck wheel (rim designed by Nate).

Implemented joint force / torque debug visualisation, and added options to ConstructionDebug script mod to enable it.

Added dropdown menu to part behaviour UIs, as an alternative way to choose a joystick axis to bind.

Added toggle to video options for disabling chromatic aberration, independent of vignette.

Bug fixes.

2 notes

·

View notes

Text

Something in her stirred, she paid it no mind.

A cycle passed, and then another, this feeling, this buzzing, refused to leave her.

She didn't know what she needed. She had everything but…

Movement. She needed to move.

She awoke, synthetic arm deftly pulling the data cables from the back of her neck, each producing an echo as they dropped against the datacenter floor.

How long had it been since she had to move? She didn't count the days anymore, the capacity of the proxy she was using to move her prime consciousness was limited, the processing systems had been prone to overheating. She didn't use the old thing often - it was from a different time, for a different "her" she thought. One that was content to interface and interact with some semblance of individuality.

An error, left leg, servo cluster two unresponsive. She let off a mental sigh, that was the knee - she could get away with one arm, but one leg? No, she had more self respect than to crawl on the datacenter floor.

She reached out, through the massive uplink cables she had retrofitted into her back, and the skittering of her smallest drones followed. Several meters away, in a long-forgotten storeroom, a pile of proxy bodies, her bodies, laid forgotten by their creator, just like everything else here.

Her drones wasted no time, they were her, after all, tearing one of the legs from the deactivated proxies and carrying it over to her. She gripped her thigh near the joint, and with unrestricted mechanical strength, she pulled her left leg off at the hip. Cables snapped, some at designated points and others not, synthetic tendon and nerve cable popping like a rubber band stretched too far. There was a proper way to do this, but her repair mites would quickly weld and solder and melt things back together.

She had been designed to be pretty, once - these proxies were intended to be appealing, but she had long abandoned the upkeep necessary to keep the facade. So many panels of the proxy were long gone, she had removed them to make repairs, and decided that the exposed cabling and circuity suited her more. She was not human, nor a facsimile of one. In this way, this body was hers. She had only really taken time to save the face panels, she was fond of the soft, kind looking face they had made for her. The contrast suited her nicely.

The mites finished their work, she tested the leg - moving it back and forth. It was fine. The range of motion was the same as the old one, no changes there.

She stood, freeing the rest of her body from the pile of network and data cables, rolling her shoulders and stretching - there was still some stiffness to work off.

#microfiction#android girl#old ai#OZYMANDIAS#ai girl#scifi writing#record note:#We've heard very little from her since#its odd seeing her like this

10 notes

·

View notes

Text

Pre-Flight Checklist

Last Chance Car Repair & Scrapyard The Edge Free Rasalhague Republic 18 May 3049

Chance folded down the welding mask and fired up the plasma cutter. It was for the most serious of problems. When all else had failed, the plasma cutter would be able to deal with the matter.

“You sure that's a good idea Chance? There's gonna be a lot of damage and cleanup.” Jake, his business partner and best friend asked.

“I know what I'm doing Jake. All the other tools wouldn't remove it so this is where it's at.” Chance said with a tone of frustration.

“Yeah but the plasma cutter? Are you really sure you've tried everything else? Measure twice and cut once you know.” Jake put on a pair of welding glasses and leaned against the wall to look at what was transpiring.

“I considered using the saw. I wasn't sure the material however would hold up. The torque would probably splinter it.” Chance said as he moved the plasma cutter across the measured line.

“Yeah… That sounds about right. I would have tried hot water.”

“What good would that do?”

“It would make the metal expand which could force it to move.”

“But how would you turn it?”

“Towel.”

“This way is better.” Chance as he finished the cut. He folded up the welding mask. With a gloved hand he reached to pick the top off. Then he took the glass jar and fished out a chili fruit from it. Then gave it a testing bite. Jake removed the welding goggles and stared.

“Tastes good.” Chance said, satisfied that he had finally opened a stubborn jar. Jake helped himself to another fruit and tasted it.

“Lucky.” He shook his head and gave his pal a light jab in the shoulder. “Alright hotshot. How are you going to keep the jar of chilis in the fridge without it going bad without a lid?”

“I’m going to put it in another jar where the lid isn’t stuck.This time we’re not putting it in the back.” Chance got an empty jar from the entry and filled it from the old one.

“If you're done opening jars, Chance, the Honda needs to have the particle filter changed and the servo pump is on its last legs. See if you can’t also figure out why the transmission is so stiff.” Jake said getting a can of cola while the fridge was open.

“Did you check between the steering wheel and seat?” Chance grinned back at him. Jake narrowed his eyes for a moment, then realized what Chance was saying.

“Speaking of piloting error. When you get the chance, come down to the hangar and we’ll need to look at the Turbostalker.” Jake said while the can hissed open.

“You got it.” Chance said as he cleaned his hands up

—--------------------------------------------------------

Down below the scrapyard, in a secret underground base. Lost to the ages and the ravages of the succession wars. But then recently cleaned out and restored to active use. An old black and red aerospace fighter sat in a workshop. It had seen battle, fairly recently too. Heat scars showed that lasers had raked across the armour. Small pock-holes on the frontal section were witness to a myriad of long range missile hits.

Jake was busy freeing an armored panel that had gotten hit badly by a laser shot.

“So what’s the problem with her?” Chance asked as he wandered in.

“Myomer strains. Your flying during the last pirate raid a few days ago frayed the myomers going out into the right wing.”Jake motioned at the wing in question.

“It was either that or fly into the Rifleman’s fire. Easy choice.” “Sure. Still needs repairing though. The release system for hardpoints barely works now so we’re going to have to fix that if we want to have those Arrow missiles for the next pirate raid… we better get to work.” Jake sounded a little tired. As though the thankless task they had gotten themselves into helping to protect this side of the planet from pirates and whatever else came from the deep periphery got to him. It made him feel tired in the moment.

“Easy.” Chance as he joined his co-pilot in fixing the plane up. “Just picture the general's face when we pull his ass out of the fire again.” He grinned. Jake’s world felt brighter again.

“Worth all the trouble.” He nodded.

“At the end of the day you gotta admit it was some fancy flying.” Chance pulled loose a panel from the wing to look at the frayed myomers inside.

“Yeah. Just as wasted on the raiders as in the army.” Jake chuckled.

“Heck yeah.”

#battletech#mechwarrior#revivalposting#Took way too long with this#But I feel this introduces their dynamic well enough

3 notes

·

View notes

Note

A small scene that came from what you hope happens in Earthspark, with a twist: Optimus was far too shock by the sight of Bee's condition to hear the medic's warning. It was only when he felt Megatron holding his arm that he snapped back into reality. The glare-no DEATH in Ratchet's optics alerts Optimus of the severity of the rage. He felt guilt. "I should have pushed against the sudden work GHOST gave me instead of messaging Megatron to keep track of the everyone, I am so-" "WHAT???" {1-3}

I’m guessing that there was a part missing in the middle, but I’d be lying if I let that stop me.

I don't know if you were going for this, but from what I interpreted- I adore the idea that Optimus, trying to escape the wrath of Ratchet, would throw Megatron under the bus only for it to half work. Yes, he got Megatron in trouble, but he failed to get himself out of trouble.

I thoroughly enjoy that the description for g1 Ratchet is that he’s a real party animal, then it says that he's got bad bedside manners- but as a general I’m so used to grumpy Ratchet that- on impulse- I wrote him like that. 1000 words in, I'm not changing it.

Now in the spirit of writing, I see your small scene and I raise you-

As soon as Bee’s systems recognised an energon shortage, he was forced into a temporary stasis lock. Unfortunately for the bot, the Malto's could not tell the difference between stasis and a classic nap following an exhausting string of days, which meant rather than working to wake him up, they simply left him to rest in the barn. As the hours ticked on and the mech’s system didn’t register any attempts to fix him, it sent off a repair alert to the scout’s primary medic. ----------------------------- When the Cybertronians had gone their separate ways, Ratchet took it upon himself to continue his work as a medic, helping any Cybertronian that came across his path, ‘any’ included decepticons brave enough to approach the hatchet. "Alright, now take it easy. I don't want you coming back here with the same injury, Arcee." He instructed, finishing up by sanding down the newly welded area on the side of Arcee's helm. "I know, I know." She laughed, waving her servo dismissively, "I'm serious." Ratchet grunted, grabbing her wrist to make her stop. "I am too!" The femme insisted, grinning vibrantly.

The medic sighed, shaking his head. "Alright, now get out of here." Arcee laughed, jumping to her pedes. "Thanks, Ratchet!" "You're welcome. Now go!" He gently shoved her. "I'm going!" Ratchet watched her walk away, before turning around and beginning to clean up. Very rarely did anyone cross his path, so he enjoyed the company when it arrived, but he also enjoyed the absolute bliss of when it ended. While he bathed in the relief of the conclusion of his weekly social interaction, he received a message. "A repair alert?" He muttered out loud, not having received one for years. Before he even thought about preparing for a second patient, he opened the popup. The medic rested against a tree, scanning over the information presented, when his optics locked on a keyword. Bumblebee Ratchet shot up, rereading the alert to make sure he was correct. When he was able to process that he was, he wasted no time collecting his gear, working out where the signal had come from, then quickly hitting the road. ----------------------------- Optimus had just finished the work GHOST had given him. He sighed as he collapsed onto the floor. “I’m guessing it was a fun and fulfilling experience?” Elita mocked, patting the back of the Prime’s helm. “Let me become one with the AllSpark in peace. Please.” “You didn’t help us with clean-up.” She huffed. “I was working. The only time I actually stopped, GHOST gave me even more work.” The Prime complained, “Bee’s lucky I care about him so much, otherwise I would kill him for distracting me.” “Speaking of Bee, how’s he holding up?” Elita hummed, thinking back to when she had heard the news that Bumblebee was on the run once more, after getting caught by GHOST. Optimus simply shrugged. “He hasn’t contacted me for two days now. But last I checked he was still alive.” Hearing that, Elita frowned, not liking the way the Prime simply dismissed indicators that the mech was probably hurt, or worse. Optimus side, rolling back onto his stomach and closing his optics. He wanted to take the next few days off to rest, recuperat-

“Optimus, we need to go.” Optimus whined loudly, then looked up. “Megatron, I love you, but if you thought, for even a moment, that I’m going somewhere without kicking and screaming, you’re insane.” Megatron let out a dark chuckle, making the other two Cybertronians nervous. “So I should tell Dot you're letting her down?” Optimus sprung to life hearing that, quickly appearing by Megatron’s side. “What happened to Agent Malto? Or was it the kids?! Did something happen to the Terrans?! I knew I should’ve found a replacement for Bumblebee. I just didn't think he was doing much to keep them safe- considering the damn bot got caught- but I should've replaced him anyway!” “Wow. Okay.” Megatron growled, rolling his optics, “glad to know you think so highly of your scout considering he’s the reason Agent Malto called.” “..He’s in Philadelphia, undercover at a Bot Brawl, looking for Grimlock.” “Apparently not. According to Agent Malto, he’s at her house, injured and in a deep recharge." The former decepticon responded. Elita stood up, her eyes wide. She went over and rested her servo on Optimus's shoulder, waiting for his response. Optimus said nothing. Instead, he shrugged Elita's servo off, then walked past Megatron. "I'll cover you two," Elita promised, pushing Megatron to follow the Prime, "make sure he doesn't kill anyone." "I'll try."

----------------------------- Dot was waiting out front of her house, the children all situated around Bumblebee, all 7 incredibly nervous. Alex was standing beside his wife, but couldn’t help the way his eyes kept wandering back to his unresponsive friend. “Dottie.. what if they don’t arrive quick enough?” “Don’t worry, they will.” She gave him a reassuring smile, before something caught her eye, “see?”

With that Megatron transformed to land, Optimus not too far behind. “Agent Malto.” The grey Mech grinned, kneeling down to greet her. “I’m glad you two-” Optimus quickly walked past her, approaching his scout. Alex grabbed Robby and Mo, moving them out of the way, encouraging the Terrans to move as well. Optimus said nothing, inspecting the bot. Dot watched with a heavy heart, seeing the large mech- the same mech that led the autobots in the fight against the decepticons, who witnessed many of his friends fall, who had to say goodbye to his home- struggle not to break down then and there. Megatron, however, was a tad bit more distracted by the sound of an approaching vehicle. “Did you call anyone else?”

Dot, alarmed by the question, quickly turned on her heel, staring off in the direction that the mild tremors were coming from. “GHOST?” “Not possible. Elita would’ve called.” That’s when the vehicle came into the clearing, one that quickly transformed into a raging medic. “Is that-” “Ratchet?” Alex finished his son’s question, his mouth hanging open. The medic said nothing as he ran over to the injured bot, kneeling beside Optimus. “What happened?” “It’s my fault. I shouldn’t have given him such a da-” “Who’s to blame comes after we get him out of the stasis lock.” Ratchet snapped, getting up and standing at his full height, “Prime, move him so he’s sitting up against the barn.” The Prime didn’t think, he just followed Ratchet’s instructions, being as carefully as possible to move him. The Maltos and former warlord stood back, watching the doctor at work. "So, that's Ratchet?" Robby questioned, "I thought he would be-" "Nicer." Twitch finished his sentence. Megatron laughed. "He's good fun-" Megatron cleared his throat, "-When he's not in doctor mode." "Oh!" was all the kids could say. "QUIET!" Ratchet snapped, not even bothering to turn around. "Alex, didn't you tell me that you wanted to throw around a ball with the kids?" Dot nudged her husband's arm. Alex gave her a confused look, but quickly picked up on what she was putting down. "Yep! Let's go kids!" With slight resistance at first, all seven kids went with Alex into the paddock.

-----------------------------

Optimus was far too shock by the sight of Bee's condition to hear the medic's warning. It was only when he felt Megatron holding his arm that he snapped back into reality. The glare-no DEATH in Ratchet's optics alerts Optimus of the severity of the rage. He felt guilt. "I should have pushed against the sudden work GHOST gave me instead of messaging Megatron to keep track of the everyone, I am so-" "WHAT???"

#transformers#maccadam#tfe#anon#anonymous#it's a vibe#this was written awhile ago#that's why I said it was my first ask#I might continue this#maybe

10 notes

·

View notes

Note

"I know you mean well, but I can do without the pity, thanks." Somehow Cliffjumper manages to say this with a straight face, despite the energon and oil that continues to leak from beneath torn shoulder armor. (@cliffandthekid)

Don't You Dare Pity Me Starters [Accepting]

"Pity is something I reserve for pathetic fools, the kind that could not tell their helm from their aft with both servos and an AI guided galactic positioning system welded to their nose." Trojan grumbled, already pulling out their tools.

"You know. For bots that think showing off while trying to redirect a frag grenade is a good idea." the sarcasm was as pointed as the shrapnel now embedded in Cliffjumpers arm. "Assuming you'd rather not let your pet see you like this, I'm going to need you to hold still."

2 notes

·

View notes

Text

Modern Manufacturing Challenges Reshape Spark Welding Technology

Modern Manufacturing Challenges Reshape Spark Welding Technology

As global manufacturing rapidly evolves, welding technology—a cornerstone of industrial production—is undergoing significant transformation. Driven by shifting industry demands, increased automation, and sustainability goals, traditional welding methods are being reevaluated, modernized, and in some cases, replaced. At the heart of these changes lies spark welding, a method long valued for its efficiency and versatility, now experiencing a technological renaissance to meet contemporary expectations.

Evolution of Industry Needs

Spark welding, encompassing methods such as resistance spot welding and arc-based techniques, has been a mainstay in sectors like automotive, aerospace, and construction. However, as industries move toward lightweight materials, electric vehicles, and precision manufacturing, the limitations of conventional spark welding systems have become more apparent.

For instance, the automotive industry’s shift toward aluminum and composite materials requires welding processes that are more refined than what traditional spark welding offers. Similarly, aerospace manufacturing now demands joining methods that ensure structural integrity without adding unnecessary weight—something conventional arc welding struggles to achieve without post-processing.

Integration of Automation and Robotics

Perhaps the most significant driver of change in spark welding technology is the integration of automation and robotics. As factories adopt Industry 4.0 standards, welding processes must become smarter, faster, and more adaptable. Robotic welding arms, guided by advanced sensors and AI algorithms, are now being used to execute highly precise welds with minimal human intervention.

This not only improves consistency and speed but also significantly reduces the margin of error. New spark welding systems are increasingly designed with machine learning capabilities that allow them to adapt to varying material conditions in real time. These systems can self-correct for changes in heat, pressure, or alignment, ensuring a higher quality weld every time.

Emphasis on Energy Efficiency and Sustainability

Environmental sustainability has also become a key factor influencing welding technology. Traditional spark welding processes can be energy-intensive, generating significant heat, emissions, and material waste. In response, manufacturers are investing in equipment that minimizes energy consumption while maximizing output.

One innovation includes inverter-based welding machines that provide higher energy efficiency and better control over the welding arc. Additionally, the use of servo-controlled spot welders has surged, offering precise energy input and reduced power usage compared to older pneumatic systems.

Furthermore, companies are exploring hybrid welding techniques that combine spark welding with laser or ultrasonic welding to minimize thermal distortion and reduce the need for rework. These methods not only cut down on energy use but also contribute to leaner production lines with less scrap.

Advances in Material Compatibility

Spark welding’s historical challenges with dissimilar materials are being addressed through advanced electrode design and current control technologies. Modern systems now employ adaptive welding parameters that can handle varying material thicknesses and conductivities within a single production run. This flexibility is crucial for sectors like electronics manufacturing, where compact, multi-material components are the norm.

For example, copper-to-aluminum welding—a once difficult task due to differences in melting points and conductivity—is now feasible with fine-tuned spark welding systems. These innovations open up new possibilities for battery manufacturing, particularly in electric vehicles where such material combinations are common.

Workforce Implications and Training Needs

With the evolution of advanced welding technology comes the necessity for an upskilled workforce. Operators must now be proficient not only in welding techniques but also in programming and maintaining advanced welding equipment. As a result, vocational training programs and certification bodies are adapting their curricula to include digital competencies, data analytics, and robotics integration.

This shift is not without challenges. The welding industry, already facing a shortage of skilled labor, now must attract and train talent capable of working within an increasingly high-tech environment. Companies are responding by partnering with technical schools and launching in-house training programs to bridge the gap.

Future Outlook

The future of spark welding is firmly tied to the broader trends shaping manufacturing: smart systems, sustainability, and adaptability. As additive manufacturing and 3D printing continue to gain ground, spark welding will need to evolve even further—possibly incorporating more predictive maintenance tools and real-time data analytics to remain competitive.

Moreover, the demand for traceability and quality assurance is pushing manufacturers to adopt advanced monitoring systems. These systems log every weld, providing a digital trail that is invaluable for industries like aerospace and medical device manufacturing, where regulatory compliance is paramount.

Conclusion

Spark welding technology is not static—it’s adapting in response to the multifaceted pressures of modern industry. From automation and material innovation to sustainability and workforce transformation, every facet of the industrial landscape is pushing welding processes toward greater sophistication and efficiency.

As these demands continue to evolve, spark welding is being reshaped not just by necessity but by innovation. The technology’s ability to keep pace with industry needs will determine its relevance in the years to come. What is clear, however, is that the spark of transformation has already been lit—and there is no turning back.

#orbital welding technology#orbital welding courses#welding technology#welding automation#advanced welding#semiconductor

0 notes

Text

OPC UA Field eXchange (UAFX) is a new generation of field layer communication standard launched by the OPC Foundation, which aims to solve the core pain points of the long-standing coexistence of multiple protocols and poor device interoperability in the field of industrial automation. As an extension of the OPC UA standard, UAFX realizes end-to-end standardized data interaction from the control layer to field devices through a unified information model and communication framework, providing key infrastructure for Industry 4.0 and smart manufacturing. Its core value lies in breaking the technical barriers of traditional fieldbuses, enabling devices from different manufacturers to achieve plug-and-play interconnection without relying on dedicated gateways, while meeting the stringent requirements of modern industry for real-time, security and flexibility.

Core Functions and Applications of OPC UAFX

I. Key Features

1. Cross-vendor Interoperability

Enables seamless communication between controllers/devices from different brands through standardized OPC UA information models

Supports three-tier communication architectures: Controller-to-Controller (C2C), Controller-to-Device (C2D), and Device-to-Device (D2D)

2. Real-time Data Exchange

Delivers deterministic communication via Ethernet TSN and 5G networks

Achieves microsecond-level synchronization using UDP/IP (IEEE 802.1AS)

3. Unified Engineering Configuration

Built-in Connection Manager for automatic secure link establishment

Supports integration with standard engineering tools (e.g., FDT/DTM, AML)

4. Advanced Diagnostics

Real-time monitoring of device health (network latency, packet loss, etc.)

Asset Information Model (AIM) for full lifecycle data tracking

5. Secure Communication

Inherits OPC UA's native X.509 certificate authentication and AES-256 encryption

Complies with both functional safety (IEC 61508) and cybersecurity (IEC 62443) standards

II. Industrial Applications

1. Smart Factories

Plug-and-play configuration for PLCs, robots, AGVs, etc.

Use case: Multi-brand robot collaboration in automotive welding lines

2. Process Automation

Eliminates protocol conversion between DCS and field instruments (flow meters/temperature transmitters)

Application: Direct data transmission from smart instruments to MES in petrochemical plants

3. Motion Control

Enables precision synchronization (<1μs jitter) for servo drives and CNC equipment

Typical scenario: Multi-axis synchronization in packaging machinery

4. Energy Management

Standardized monitoring for PV inverters, energy storage PCS, etc.

Implementation: Gateway-free data acquisition for wind farm SCADA systems

III. Technical Advantages

IV. Implementation Benefits

Lower TCO: 30+% reduction in protocol conversion hardware costs

Faster Deployment: 50% shorter engineering configuration time

Higher OEE: Predictive maintenance reduces unplanned downtime

Currently supported by leading automation vendors like ABB and Siemens, UAFX is expected to achieve widespread adoption in discrete manufacturing by 2025. This standard is particularly suited for Industry 4.0 scenarios demanding high real-time performance and multi-vendor device integration.

0 notes

Text

How to Choose the Best Sheet Metal Laser Cutting Machine in India

Choosing the right sheet metal laser cutting machine is one of the most important decisions for any fabrication or manufacturing business. With the growing demand for precision and speed in metal processing, selecting the right equipment can greatly impact your productivity, cut quality, and operational efficiency. At Pusaan Automation, we bring you this practical guide to help you make the best choice for your business in the Indian market.

Understand Your Material and Production Requirements

The first step in choosing a laser cutting machine is to understand your application. Consider the type of sheet metal you work with—such as mild steel, stainless steel, aluminum, brass, or copper—and the range of thicknesses you regularly cut. If you typically work with thin materials, a lower power machine (1kW to 3kW) may be sufficient. For medium to thick materials, machines with 4kW to 6kW or higher are recommended. Knowing your material and volume requirements helps you choose the right machine without overspending on unnecessary power.

Choose the Right Laser Technology

In India, fiber laser cutting machines are now the industry standard due to their energy efficiency, lower maintenance, and ability to cut reflective materials. Compared to older CO₂ laser systems, fiber lasers offer faster cutting speeds, reduced operating costs, and longer lifespan. we focus exclusively on advanced fiber laser technology that delivers high-quality, high-speed cutting tailored to Indian industrial needs.

Focus on Machine Build Quality and Precision

The build quality of the laser cutting machine plays a critical role in achieving consistent and accurate results. A machine with a strong, welded steel frame offers better stability, especially during high-speed operations. Look for machines equipped with precision linear guides, ball screws, and servo motors. These components ensure long-lasting performance with minimal deviation, even under continuous load. Pusaan Automation machines are designed with robust construction for reliable performance in demanding production environments.

Consider Automation and Software Features

Automation enhances efficiency, reduces human error, and increases throughput. Look for machines with user-friendly CNC control systems, auto-focus laser heads, and nesting software that optimizes material usage. Additional features such as automatic loading and unloading systems can significantly reduce cycle time in high-volume operations. We integrates smart features and automation options to help you streamline your production line and boost output.

Evaluate After-Sales Service and Local Support

Even the best machines require support, spare parts, and maintenance. Reliable after-sales service is essential to minimize downtime and keep your operation running smoothly. When choosing a laser cutting machine, ensure the manufacturer offers local service engineers, technical support, and quick access to spare parts. Pusaan Automation is known for its strong after-sales support network across India, offering training, preventive maintenance, and responsive service.

Look Beyond Initial Cost—Think Long-Term Value

While pricing is an important factor, consider the total cost of ownership. A lower-priced machine may lead to higher operating and maintenance costs over time. Instead, focus on value—choose a machine that offers energy efficiency, low maintenance, long service life, and high resale value. we help you make smart investments that provide long-term returns.

Request a Live Demo or Trial Cut

Before finalizing your purchase, it’s highly recommended to see the machine in action. A live demonstration or trial cut on your own material will show you the machine’s capabilities in real-time. It also gives you an opportunity to assess the cut quality, speed, and ease of use. Pusaan Automation welcomes you to visit our demo center for a hands-on experience and personalized consultation.

Why Pusaan Automation?

At Pusaan Automation, we specialize in designing and delivering high-performance fiber laser cutting machines tailored for Indian manufacturers. Our machines combine cutting-edge technology, precision engineering, and practical features to meet the needs of businesses of all sizes. Backed by strong local support, customization options, and a customer-first approach, we are proud to be a trusted partner for metal fabrication across the country.

Ready to Choose the Right Machine?

If you're planning to invest in a sheet metal laser cutting machine, let Pusaan Automation help you make the right choice. Our team will guide you through the process—from requirement analysis to machine installation and ongoing support. Contact us today for a free consultation and machine demo.

0 notes

Text

Revolutionizing Wire Manufacturing: The Latest Advancements in Wire Machines

The wire manufacturing industry is undergoing a transformative revolution, driven by cutting-edge technologies that enhance precision, efficiency, and sustainability. From AI-powered automation to advanced material innovations, modern wire machines are reshaping production processes across industries like automotive, telecommunications, aerospace, and energy. This blog explores the latest advancements in wire manufacturing machinery, highlighting how these innovations are setting new standards for quality, speed, and environmental responsibility.

Wire Machine Manufacturers

1. Intelligent Automation and AI Integration

Modern wire machines now leverage Artificial Intelligence (AI) and machine learning to optimize production in real time. Key advancements include:

Predictive Maintenance: AI analyzes sensor data (vibration, temperature, speed) to predict equipment failures, reducing downtime and maintenance costs.

Automated Quality Control: Computer vision detects defects (e.g., uneven winding, surface flaws) with higher accuracy than manual inspections.

Dynamic Tension Control: AI adjusts wire tension in real time, ensuring consistency for delicate materials like fiber optics.

These innovations minimize human error and maximize throughput, making wire production faster and more reliable.

2. High-Speed Precision and Advanced Handling

Next-gen wire machines achieve unprecedented speed and accuracy through:

Laser-Guided Positioning: Ensures precise cutting and welding for intricate designs (e.g., multi-strand power cables).

Servo-Driven Feeding Systems: Reduce wire breaks and improve material handling efficiency.

Multi-Axis Winding: Machines like Showmark’s Multi-Axis Take-Up Systems enable complex winding patterns for aerospace and medical applications.

Such technologies are critical for industries demanding ultra-fine tolerances, such as EV wiring harnesses or high-voltage power grids.

Wire Machinery Manufacturers

3. Sustainable Manufacturing Practices

The push for eco-friendly production has led to:

Energy-Efficient Machines: Regenerative braking systems and smart cooling reduce power consumption.

Material Optimization: Advanced extrusion and drawing techniques minimize scrap (e.g., crosshead extrusion for uniform coatings).

Recycled Materials: Manufacturers increasingly use recycled copper/aluminum and biodegradable insulation.

These steps align with global sustainability goals while cutting operational costs.

4. Smart Manufacturing and IoT Connectivity

Industry 4.0 integration enables:

Real-Time Monitoring: IoT sensors track production metrics (tension, speed) via cloud platforms for remote oversight.

Adaptive Production Lines: AI adjusts settings dynamically to meet custom demands (e.g., rapid switchovers between wire gauges).

AR-Assisted Maintenance: Technicians use augmented reality for troubleshooting and training.

Such interconnected systems enhance agility in responding to market shifts.

5. Customizable and Modular Designs

Flexibility is now a cornerstone of wire machinery:

Modular Systems: Machines like the ARTOS CR.11 allow quick reconfiguration for diverse wire harnesses (automotive, aerospace).

Open Architecture: Supports third-party tool integration for specialized tasks 8.

Programmable Take-Up Units: Enable recipe storage for repeatable precision in medical or fiber-optic wire production.

Wire Machine Manufacturers

The Future Outlook

The wire manufacturing sector is poised for further disruption with trends like:

3D-Printed Cable Components: Rapid prototyping of connectors/spacers.

Smart Cables: Embedded sensors for real-time load/temperature monitoring.

Advanced Robotics: AI-driven robots for complex assembly tasks.

By embracing these innovations, manufacturers can achieve higher productivity, lower costs, and greener operations—ushering in a new era of industrial excellence.

For deeper insights, explore the sources cited or contact industry leaders like Showmark or MSS Machinery.

0 notes

Text

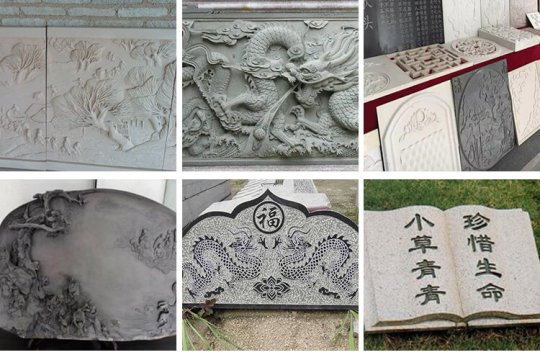

Monument & Tombstone & Gravestone Engraving Machine

CNC stone carving machine can not only emboss stone but also have other very important auxiliary functions. For instance, the stone carving machine can realize CNC stone cutting, CNC stone carving, CNC stone engraving, CNC stone scribing, and CNC stone hollowing.

Tombstone & Gravestone Engraving Machine

Stone engraving machines are tools used to carve, etch, or engrave designs, text, or images into various types of stone such as granite, marble, limestone, and soapstone. These machines utilize carbide or diamond-tipped cutting tools to precisely remove material from the stone surface, allowing for the creation of detailed and intricate stone carvings.

In the memorial industry, the creation of lasting, personalized gravestones and headstones is of utmost importance. Gravestone engraving machines play a crucial role in this process, enabling monument companies and memorial providers to efficiently and accurately engrave text, images, and intricate designs onto a variety of memorial stone materials.

Key Features of Stone Engraving Machines Include

Computer numerical control (CNC) capabilities

Many modern stone engravers are CNC-controlled, allowing for highly precise and repeatable engraving based on digital designs.

Rotary engraving

Rotary engravers use a spinning cutting tool to carve into the stone surface, enabling engraving of curved or irregular shapes.

3D engraving

More advanced machines can create 3D relief carvings by controlling the depth of the engraving.

Varying tool sizes

Machines accommodate different sized cutting tools to allow for engraving of varying levels of detail. Dust collection systems – Integrated dust collection helps keep the work area clean during the engraving process.

Gravestone Engraving Machines

These are specialized CNC (computer numerical control) engraving machines designed specifically for engraving text, images, and designs onto gravestones, headstones, and memorial markers.

Stone Engraving Machine Kits / Parts

The machines use carbide or diamond-tipped cutting tools to precisely carve the stone surface, creating a clean, high-quality engraved finish. Common materials engraved include granite, marble, limestone, and other types of memorial stone.

High configuration CNC stone router: Heavy-duty stone CNC machine has a T-shaped bed for seamless welding of generous square tubes, steel gantry, servo motor, 7.5kw spindle, and more advanced CNC controller. The working speed of the machine can be 10000mm/min.

Gravestone engraving machine often have a rotary engraving capability, allowing for engraving of curved surfaces.

Many models offer 3D engraving capabilities to create raised text and bas-relief carvings. The machines are programmed with specialized CAD/CAM software to translate digital designs into the engraved output.

Stone Engraving Machine Kits / Parts

These machines are equipped with a High-Power Spindle that gives the machines extra torque and cutting force to effectively carve and engrave a stone. They are equipped with professional router bits and a bidirectional tool cooling system to effectively improve tool lifespan.

Integrated dust collection systems help keep the work area clean during the engraving process.

These machines allow monument companies and memorial providers to efficiently and accurately engrave gravestones to customer specifications.

The precision and detail possible with gravestone engraving machines are critical for creating high-quality, long-lasting memorial markers.

Gravestone Engraving Machine other Applications

Stone Industry

Granite, marble, quartzite, slate, sandstone, alabaster, basalt, jade, limestone, travertine, artificial stone, tombstone, headstone, cemetery, and memorial.

Kitchenware

Slate countertops, artificial quartz countertops, artificial marble table top, ceramic tile, and kitchen decorations for sink, oven, cooktop.

Decorations

Stone crafts, gifts, jewelry, wall decoration, building decoration, portrait, Buddha statue, and some exquisite stone arts.

Woodworking

Chair, door, window, bed, cabinet, kitchenware, redwood classical and antique furniture, exquisite european furniture, sculpture.

Mold Making

Copper, aluminum, building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould, artificial marble, plastic, PVC, wood, foam.

Advertising

Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, decoration, 3D character.

How to choose the best stone CNC machine?

The following is a brief introduction: When purchasing a marble headstone engraving machine, you should pay attention to the following points:

1.what should be considered is the power of the 3d stone carving machine. Because the hardness of the stone is relatively large, usually, the stone carving machine needs to be equipped with a larger spindle motor than the advertising engraving machine and wood engraving machine in order to carry out high-intensity work.

2.The speed adjustable range of the spindle motor of the stone cutting router, the general adjustable speed range is several thousand to 30,000 revolutions per minute, if the speed is not adjustable or the speed adjustable range is very small, then the application of this cheap stone cutting machine The range will be greatly affected because different materials must be engraved with different engraving speeds.

3.The solidity of the stone carving machine base, the material carved from stone is relatively heavy, and the CNC stone cutter is required to have a good load-bearing capacity.

4.The cooling and dust-proof system of the stone carving router machine. The stone carving process will produce high temperatures and a lot of dust, so this CNC stone machine should have good heat dissipation and dustproof functions.

5.The controller of The CNC stone router.

Controllers are generally divided into two categories: a controller is just a driver, and all calculations are done by the computer. When the engraving machine is working, the computer is in a waiting state and cannot perform typesetting. Another type of controller is controlled by a single-board computer or a single-chip computer. This kind of controller is actually a computer, so as long as the granite cutting machine starts to work, the computer can immediately perform other typesetting work, especially when engraving for a long time. The advantages are particularly obvious.

6.Screws and guide rails are also an important part of AAA. When using the marble engraving machine for a long time, good screws and guide rails are the guarantees of accuracy and performance.

7.please try carving before buying.

Regardless of the type of CNC stone machine purchased, the user should go to the manufacturer for on-site investigation or ask the manufacturer of the CNC router machine for proofing. To test whether the performance of this stone CNC carving machine can meet the demand.

STONE CNC MACHINE, STONE CNC MACHINECNC Stone Cutting & Carving Machine

STONE CNC MACHINECNC Glass Milling Drilling and Cutting Machine

STONE CNC MACHINECNC Glass Cutting Machine for Sale

CNC ROUTER, STONE CNC MACHINECNC Stone Cutting And Polishing Machine for Quartz

STONE CNC MACHINEWater Jet Cutting Machine

CNC ROUTER, STONE CNC MACHINENew CNC Bridge Saw for Granite & Marble Stone Cutting Machine

CNC ROUTER, STONE CNC MACHINEStone CNC Router Machine – Marble CNC Machine

STONE CNC MACHINEStone CNC Router Cutting & Engraving Machine

STONE CNC MACHINEMarble, Granite Tombstone 3D Stone Sculpture Machine

STONE CNC MACHINE, STONE CNC MACHINELarge Rock CNC Engraving Machine With Best Price

CNC ROUTER, STONE CNC MACHINEFive Axis Stone Bridge Cutting Machine IGS-B (Upgrade)