#Resettable Fuse

Explore tagged Tumblr posts

Text

Same Sky has continually grown over the years is Partner with Future Electronics

Continuity for customers is a key priority for Same Sky and Future Electronics. Outside of the changes above, much will remain the same: model numbers, pricing, supply chain, business processes, quality, customer support, and more will continue under Same Sky as they were under the CUI Devices name.

#Future Electronics#Littelfuse#Resettable Fuse#Electronic Fuse#TVS Diode#ESD#Diode#Electromechanical#Circuit Protection#Gas Discharge Tube#Protection Thyristor

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--electronic-fuses/0466-125nr-littelfuse-2887107

Types of electrical fuses electronic slow blow fuse, high voltage, diode array

466 Series Very Fast-Acting 125 V 0.125 A 1206 Surface Mount Thin Film Fuse

#Circuit Protection Devices#Electronic Fuses#0466.125NR#Littelfuse#electronic slow blow fuse#high voltage#diode array#Slow blow#cooper bussmann#gas discharge tube#Main circuit breakers#Diodes#ESD Protection#resettable#slow blow

1 note

·

View note

Text

Love how back when I was in a&p class joking about the box of spare fuses I found in my Ultra Pup when I 1st started cleaning it to restore and the instructor was like "zomg no, no fuses in aircraft, baaaad" and that's basically the general consensus on the use of fuses used in 99% of aircraft.

Meanwhile today I learned Eurocopter really likes their fuses. Spare and resettable types.

What does this mean? Nothing, my brain is fried from Airbus helicopter anatomy classes and working with too much paint and sealant the last week. :'3

7 notes

·

View notes

Text

botw already had wild mechanics but the new mechanics are like. game designer hell. idk how they made this game there is not one aspect of it that is easy to do at all. like. weapon fuse needs to have a logical combination for about every item that exists. teleporting though ceilings isnt per se THAT hard to do but by god does it have implications for level design. being able the glue everything ever together sounds like hell to make performant. the map is vastly vertical so rendering everything is a huge problem. a TIME RESET mechanic. for a time reset mechanic you basically need to constantly 'record' the last 5000 or so positions and rotations of every resettable object. i have no idea how they actually did it but that approach is really not feasible to put into a game. and they still needed to make a GAME on top of that

88 notes

·

View notes

Text

High-Quality Marine Fuse Holders & Waterproof Fuse Holders for 3-400A Fuses

Welcome to our premium fuses and fuse holder store, your trusted source for high-quality electrical protection components. Whether you're looking for reliable fuses for marine applications or automotive systems, we've got you covered.

We offer a comprehensive selection of marine fuses and marine fuse holders, designed to meet the demanding needs of boat and watercraft electrical systems. Our marine fuses are crafted to withstand harsh environments, ensuring optimal performance and safety in your marine electrical installations. Pair them with our robust marine fuse holders for a secure and reliable connection.

In the automotive sector, we provide both ATO fuses and ATC fuses. These blade-style fuses are essential for protecting your vehicle's electrical circuits from overloads. The ATO fuse and ATC fuse options come in various amperages to suit your specific requirements. With easy installation and high durability, they are perfect for use in cars, trucks, and other vehicles.

For those seeking convenience and reliability, we also offer resettable fuses. Unlike traditional fuses, which need to be replaced after blowing, our resettable fuses automatically reset after the fault condition is cleared, providing long-term protection and reducing downtime. If you prefer manual control, our manual reset fuses are an excellent choice. They allow you to reset the fuse manually once the issue is resolved, giving you greater control over your electrical systems.

At our store, you'll find the perfect fuse holder for every application. Whether you need a standard fuse holder for automotive use or a specialized marine fuse holder, we have the right solution for you. Our fuse holders ensure a secure fit and reliable performance, protecting your circuits from electrical faults.

Browse our extensive selection today and find the best fuses, fuse holders, and related components to keep your electrical systems running smoothly!

2 notes

·

View notes

Text

How to Know When It's Time for an Electrical Panel Upgrade

Knowing when it’s time for an electrical panel upgrade can save you a lot of headaches and ensure your home stays safe, efficient, and ready for modern electrical needs. An outdated or faulty electrical panel doesn’t just affect your electrical appliances—it can be a fire hazard. If you’re unsure whether it’s time to upgrade your electrical panel, here are some key signs to look out for, along with why Leaf Power Design in Manassas, VA, is the best service to handle this critical task.

1. Frequent Circuit Breaker Trips

If your circuit breakers are constantly tripping, it’s often a sign that your electrical panel is struggling to keep up with your home’s electrical demands. Modern households use more electricity than ever, with multiple devices running simultaneously. If your electrical panel is older or undersized for the current load, it can’t distribute power properly, causing the breakers to trip. In some cases, a simple fix could be adding a new breaker or upgrading an individual circuit. But if your entire panel is outdated, a full upgrade is likely the solution.

2. Flickering Lights

Have you noticed your lights flickering when you use multiple appliances or when you turn on a high-power device, like an air conditioner or space heater? This issue points to an electrical panel that may not be able to handle the demand of all your appliances and lighting fixtures. Flickering lights can also be a sign of faulty wiring or connections, which is why it’s essential to have a professional inspect and possibly upgrade your panel to ensure everything is functioning safely.

3. You Have an Old Fuse Box

If your home still has a fuse box instead of a modern circuit breaker panel, it's definitely time for an upgrade. Fuse boxes are outdated and are no longer capable of handling the electrical load that modern homes require. A fuse box relies on fuses that need to be replaced when they blow, whereas circuit breakers are resettable and safer. Upgrading to a new electrical panel can also provide you with more capacity, which is essential for modern homes.

4. Your Electrical Panel is Over 25 Years Old

Most electrical panels last anywhere from 20 to 30 years. If your electrical panel is older than that, it’s a good idea to have it inspected by a licensed professional. Older panels may not meet the latest safety codes or be able to supply enough power for modern electrical needs. An electrical panel upgrade can ensure that your home meets safety regulations and has enough power to support all of your appliances, electronics, and gadgets.

5. You’re Adding New Appliances or Renovating

When you’re adding major appliances—like a new oven, dryer, or air conditioner—or doing a home renovation, your electrical system may need to be upgraded to handle the increased load. Similarly, if you’re converting a basement or attic into living space, the electrical demands could change. An electrical panel upgrade will ensure you have enough circuits and capacity to safely accommodate your home’s new needs.

6. Burning Smells or Discoloration

If you smell burning or notice any discoloration around your electrical panel or outlets, this is a serious red flag. This could indicate overheating, which might be due to overloaded circuits or faulty connections. It’s essential to call an electrician immediately if you notice these symptoms. In many cases, the issue can be traced back to the panel itself, requiring an upgrade to meet safety standards and prevent dangerous electrical fires.

Why Choose Leaf Power Design for Your Electrical Panel Upgrade?

If any of the signs mentioned above sound familiar, it’s time to call a professional to evaluate your electrical panel. Leaf Power Design in Manassas, VA, offers expert electrical panel upgrades to ensure your home stays safe and efficient. With years of experience and a team of certified electricians, they provide top-notch service tailored to your specific needs.

Whether you’re upgrading to accommodate a growing household or to make sure your electrical system is up to code, Leaf Power Design is the trusted choice in Manassas, VA. Their commitment to safety, quality, and customer satisfaction makes them the ideal partner for any electrical project, from panel upgrades to complete rewiring.

If you’re ready to make sure your home’s electrical system is safe and efficient, reach out to Leaf Power Design for a comprehensive consultation. Their expert electricians will evaluate your current setup and provide the best solutions for upgrading your electrical panel. Don’t wait for an issue to become a crisis—contact Leaf Power Design today to ensure your home stays powered and protected.

0 notes

Text

0 notes

Text

0 notes

Photo

Best Resettable PTC Fuses for Electronics in the US: Why Choose 1206L? #GEBSKIFuses #ResettablePTCFuses #ElectronicsSolutions #FuseYour... Link: https://mymetric360.com/question/best-resettable-ptc-fuses-for-electronics-in-the-us-why-choose-1206l/?feed_id=295478&_unique_id=6726b10e7c29b

0 notes

Text

MIT team takes a major step toward fully 3D-printed active electronics

New Post has been published on https://sunalei.org/news/mit-team-takes-a-major-step-toward-fully-3d-printed-active-electronics/

MIT team takes a major step toward fully 3D-printed active electronics

Active electronics — components that can control electrical signals — usually contain semiconductor devices that receive, store, and process information. These components, which must be made in a clean room, require advanced fabrication technology that is not widely available outside a few specialized manufacturing centers.

During the Covid-19 pandemic, the lack of widespread semiconductor fabrication facilities was one cause of a worldwide electronics shortage, which drove up costs for consumers and had implications in everything from economic growth to national defense. The ability to 3D print an entire, active electronic device without the need for semiconductors could bring electronics fabrication to businesses, labs, and homes across the globe.

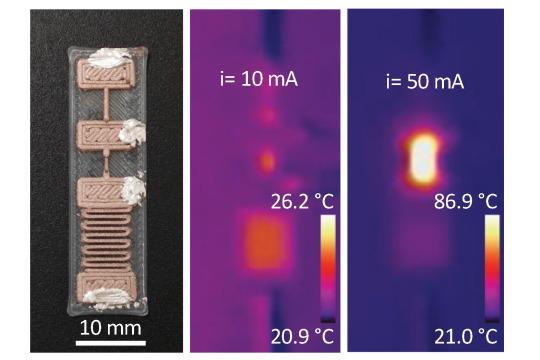

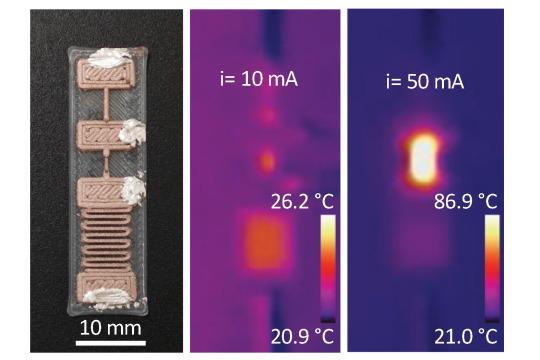

While this idea is still far off, MIT researchers have taken an important step in that direction by demonstrating fully 3D-printed resettable fuses, which are key components of active electronics that usually require semiconductors.

The researchers’ semiconductor-free devices, which they produced using standard 3D printing hardware and an inexpensive, biodegradable material, can perform the same switching functions as the semiconductor-based transistors used for processing operations in active electronics.

Although still far from achieving the performance of semiconductor transistors, the 3D-printed devices could be used for basic control operations like regulating the speed of an electric motor.

“This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing, but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the devices, which appears in Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student.

An unexpected project

Semiconductors, including silicon, are materials with electrical properties that can be tailored by adding certain impurities. A silicon device can have conductive and insulating regions, depending on how it is engineered. These properties make silicon ideal for producing transistors, which are a basic building block of modern electronics.

However, the researchers didn’t set out to 3D-print semiconductor-free devices that could behave like silicon-based transistors.

This project grew out of another in which they were fabricating magnetic coils using extrusion printing, a process where the printer melts filament and squirts material through a nozzle, fabricating an object layer-by-layer.

They saw an interesting phenomenon in the material they were using, a polymer filament doped with copper nanoparticles.

If they passed a large amount of electric current into the material, it would exhibit a huge spike in resistance but would return to its original level shortly after the current flow stopped.

This property enables engineers to make transistors that can operate as switches, something that is typically only associated with silicon and other semiconductors. Transistors, which switch on and off to process binary data, are used to form logic gates which perform computation.

“We saw that this was something that could help take 3D printing hardware to the next level. It offers a clear way to provide some degree of ‘smart’ to an electronic device,” Velásquez-García says.

The researchers tried to replicate the same phenomenon with other 3D printing filaments, testing polymers doped with carbon, carbon nanotubes, and graphene. In the end, they could not find another printable material that could function as a resettable fuse.

They hypothesize that the copper particles in the material spread out when it is heated by the electric current, which causes a spike in resistance that comes back down when the material cools and the copper particles move closer together. They also think the polymer base of the material changes from crystalline to amorphous when heated, then returns to crystalline when cooled down — a phenomenon known as the polymeric positive temperature coefficient.

“For now, that is our best explanation, but that is not the full answer because that doesn’t explain why it only happened in this combination of materials. We need to do more research, but there is no doubt that this phenomenon is real,” he says.

3D-printing active electronics

The team leveraged the phenomenon to print switches in a single step that could be used to form semiconductor-free logic gates.

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch.

While the devices did not perform as well as silicon-based transistors, they could be used for simpler control and processing functions, such as turning a motor on and off. Their experiments showed that, even after 4,000 cycles of switching, the devices showed no signs of deterioration.

But there are limits to how small the researchers can make the switches, based on the physics of extrusion printing and the properties of the material. They could print devices that were a few hundred microns, but transistors in state-of-the-art electronics are only few nanometers in diameter.

“The reality is that there are many engineering situations that don’t require the best chips. At the end of the day, all you care about is whether your device can do the task. This technology is able to satisfy a constraint like that,” he says.

However, unlike semiconductor fabrication, their technique uses a biodegradable material and the process uses less energy and produces less waste. The polymer filament could also be doped with other materials, like magnetic microparticles that could enable additional functionalities.

In the future, the researchers want to use this technology to print fully functional electronics. They are striving to fabricate a working magnetic motor using only extrusion 3D printing. They also want to finetune the process so they could build more complex circuits and see how far they can push the performance of these devices.

“This paper demonstrates that active electronic devices can be made using extruded polymeric conductive materials. This technology enables electronics to be built into 3D printed structures. An intriguing application is on-demand 3D printing of mechatronics on board spacecraft,” says Roger Howe, the William E. Ayer Professor of Engineering, Emeritus, at Stanford University, who was not involved with this work.

This work is funded, in part, by Empiriko Corporation.

0 notes

Text

MIT team takes a major step toward fully 3D-printed active electronics

New Post has been published on https://thedigitalinsider.com/mit-team-takes-a-major-step-toward-fully-3d-printed-active-electronics/

MIT team takes a major step toward fully 3D-printed active electronics

Active electronics — components that can control electrical signals — usually contain semiconductor devices that receive, store, and process information. These components, which must be made in a clean room, require advanced fabrication technology that is not widely available outside a few specialized manufacturing centers.

During the Covid-19 pandemic, the lack of widespread semiconductor fabrication facilities was one cause of a worldwide electronics shortage, which drove up costs for consumers and had implications in everything from economic growth to national defense. The ability to 3D print an entire, active electronic device without the need for semiconductors could bring electronics fabrication to businesses, labs, and homes across the globe.

While this idea is still far off, MIT researchers have taken an important step in that direction by demonstrating fully 3D-printed resettable fuses, which are key components of active electronics that usually require semiconductors.

The researchers’ semiconductor-free devices, which they produced using standard 3D printing hardware and an inexpensive, biodegradable material, can perform the same switching functions as the semiconductor-based transistors used for processing operations in active electronics.

Although still far from achieving the performance of semiconductor transistors, the 3D-printed devices could be used for basic control operations like regulating the speed of an electric motor.

“This technology has real legs. While we cannot compete with silicon as a semiconductor, our idea is not to necessarily replace what is existing, but to push 3D printing technology into uncharted territory. In a nutshell, this is really about democratizing technology. This could allow anyone to create smart hardware far from traditional manufacturing centers,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the devices, which appears in Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student.

An unexpected project

Semiconductors, including silicon, are materials with electrical properties that can be tailored by adding certain impurities. A silicon device can have conductive and insulating regions, depending on how it is engineered. These properties make silicon ideal for producing transistors, which are a basic building block of modern electronics.

However, the researchers didn’t set out to 3D-print semiconductor-free devices that could behave like silicon-based transistors.

This project grew out of another in which they were fabricating magnetic coils using extrusion printing, a process where the printer melts filament and squirts material through a nozzle, fabricating an object layer-by-layer.

They saw an interesting phenomenon in the material they were using, a polymer filament doped with copper nanoparticles.

If they passed a large amount of electric current into the material, it would exhibit a huge spike in resistance but would return to its original level shortly after the current flow stopped.

This property enables engineers to make transistors that can operate as switches, something that is typically only associated with silicon and other semiconductors. Transistors, which switch on and off to process binary data, are used to form logic gates which perform computation.

“We saw that this was something that could help take 3D printing hardware to the next level. It offers a clear way to provide some degree of ‘smart’ to an electronic device,” Velásquez-García says.

The researchers tried to replicate the same phenomenon with other 3D printing filaments, testing polymers doped with carbon, carbon nanotubes, and graphene. In the end, they could not find another printable material that could function as a resettable fuse.

They hypothesize that the copper particles in the material spread out when it is heated by the electric current, which causes a spike in resistance that comes back down when the material cools and the copper particles move closer together. They also think the polymer base of the material changes from crystalline to amorphous when heated, then returns to crystalline when cooled down — a phenomenon known as the polymeric positive temperature coefficient.

“For now, that is our best explanation, but that is not the full answer because that doesn’t explain why it only happened in this combination of materials. We need to do more research, but there is no doubt that this phenomenon is real,” he says.

3D-printing active electronics

The team leveraged the phenomenon to print switches in a single step that could be used to form semiconductor-free logic gates.

The devices are made from thin, 3D-printed traces of the copper-doped polymer. They contain intersecting conductive regions that enable the researchers to regulate the resistance by controlling the voltage fed into the switch.

While the devices did not perform as well as silicon-based transistors, they could be used for simpler control and processing functions, such as turning a motor on and off. Their experiments showed that, even after 4,000 cycles of switching, the devices showed no signs of deterioration.

But there are limits to how small the researchers can make the switches, based on the physics of extrusion printing and the properties of the material. They could print devices that were a few hundred microns, but transistors in state-of-the-art electronics are only few nanometers in diameter.

“The reality is that there are many engineering situations that don’t require the best chips. At the end of the day, all you care about is whether your device can do the task. This technology is able to satisfy a constraint like that,” he says.

However, unlike semiconductor fabrication, their technique uses a biodegradable material and the process uses less energy and produces less waste. The polymer filament could also be doped with other materials, like magnetic microparticles that could enable additional functionalities.

In the future, the researchers want to use this technology to print fully functional electronics. They are striving to fabricate a working magnetic motor using only extrusion 3D printing. They also want to finetune the process so they could build more complex circuits and see how far they can push the performance of these devices.

“This paper demonstrates that active electronic devices can be made using extruded polymeric conductive materials. This technology enables electronics to be built into 3D printed structures. An intriguing application is on-demand 3D printing of mechatronics on board spacecraft,” says Roger Howe, the William E. Ayer Professor of Engineering, Emeritus, at Stanford University, who was not involved with this work.

This work is funded, in part, by Empiriko Corporation.

#000#3-D printing#3d#3D printing#additive manufacturing#Art#author#binary#biodegradable#board#Building#carbon#Carbon materials#carbon nanotubes#chips#computation#computer#Computer Science#consumers#covid#crystalline#data#defense#devices#direction#economic#Electrical engineering and computer science (EECS)#electronic#electronic devices#Electronics

1 note

·

View note

Text

Circuit Breaker And Fuse Market Evaluation and Long-term Growth Strategies 2024 - 2032

The circuit breaker and fuse market is a vital component of the electrical and electronics industry, playing a crucial role in protecting electrical systems from overloads and short circuits. With the increasing demand for reliable electrical solutions across various sectors, this market is experiencing significant growth. This article provides a comprehensive overview of the current state of the circuit breaker and fuse market, including key drivers, challenges, and future trends.

Introduction to Circuit Breakers and Fuses

Circuit breakers and fuses are protective devices designed to interrupt the flow of electricity in the event of an overload or fault. They serve as essential components in electrical systems, ensuring safety and preventing damage to equipment. While both serve similar functions, their mechanisms and applications differ significantly.

What is a Circuit Breaker?

A circuit breaker is an automatic electrical switch that interrupts the flow of current when it detects an overload or short circuit. It can be reset after the fault condition is cleared, making it reusable.

What is a Fuse?

A fuse is a protective device that contains a metal wire or strip that melts when the current exceeds a predetermined level. Unlike circuit breakers, fuses need to be replaced after they have operated.

Market Overview

Current Market Size and Growth

The global circuit breaker and fuse market has witnessed substantial growth, driven by the increasing demand for electrical safety solutions in residential, commercial, and industrial applications. Analysts predict a compound annual growth rate (CAGR) of around 5-7% over the next several years.

Key Segments of the Market

By Type

Circuit Breakers:

Miniature Circuit Breakers (MCB): Used for residential applications, protecting low-voltage circuits.

Molded Case Circuit Breakers (MCCB): Suitable for industrial applications, handling higher currents.

Air Circuit Breakers (ACB): Commonly used in high-voltage applications, providing robust protection.

Fuses:

Cartridge Fuses: Used in industrial and commercial settings for reliable circuit protection.

Blade Fuses: Commonly found in automotive applications due to their compact size and ease of installation.

Resettable Fuses: These fuses can automatically reset after a fault is cleared, ideal for sensitive electronic devices.

By Application

Residential: Protecting household electrical systems and appliances.

Commercial: Safeguarding electrical installations in offices, retail spaces, and public buildings.

Industrial: Used in manufacturing facilities, machinery, and heavy equipment to prevent electrical failures.

By Geography

North America: Leading the market, driven by stringent electrical safety regulations and a robust industrial base.

Europe: Strong focus on energy efficiency and safety driving demand for advanced circuit protection technologies.

Asia-Pacific: Rapid growth in industrialization and urbanization leading to increased investments in electrical infrastructure.

Market Drivers

Increasing Demand for Electrical Safety

As electrical systems become more complex, the need for effective protective devices like circuit breakers and fuses has grown. These devices play a critical role in preventing electrical faults and minimizing the risk of fires, driving market growth.

Growth of the Electrical and Electronics Industry

The expansion of the electrical and electronics industry, particularly in emerging markets, is significantly driving the demand for circuit breakers and fuses. The rise in consumer electronics, appliances, and electrical infrastructure makes reliable protection devices essential.

Technological Advancements

Continuous innovations in circuit protection technologies are enhancing performance, reliability, and safety. Smart circuit breakers with integrated monitoring capabilities are emerging, allowing users to detect faults in real-time and improve overall system safety.

Challenges Facing the Market

Competition from Alternative Technologies

The circuit breaker and fuse market faces competition from alternative protective devices that offer similar functionalities, such as surge protective devices (SPDs) and smart relays. This could impact the demand for traditional circuit protection solutions in certain applications.

Raw Material Price Volatility

The cost of raw materials used in the production of circuit breakers and fuses, such as metals and plastics, can be volatile. Fluctuations in material prices may affect production costs and profit margins for manufacturers.

Regulatory Compliance

Navigating the complex regulatory landscape concerning electrical safety standards can be challenging for manufacturers. Compliance with various national and international standards is critical but can also be resource-intensive.

Future Outlook

Growing Adoption of Smart Technologies

The future of the circuit breaker and fuse market is expected to be heavily influenced by the increasing adoption of smart technologies. Innovations such as IoT-enabled circuit breakers that provide real-time data on current flow and fault conditions will enhance safety and operational efficiency.

Expansion in Emerging Markets

Emerging economies are expected to witness significant growth in the circuit breaker and fuse market due to rising infrastructure development and increasing investments in electrical safety solutions. This presents substantial opportunities for manufacturers to expand their market presence.

Focus on Sustainability

As industries shift towards more sustainable practices, manufacturers of circuit breakers and fuses will need to focus on developing eco-friendly products. This includes using recyclable materials and minimizing waste during production processes.

Conclusion

The circuit breaker and fuse market is poised for substantial growth as the demand for electrical safety solutions continues to rise. With their critical role in protecting electrical systems and enhancing safety, these devices are indispensable in various applications. While challenges related to competition, material costs, and regulatory compliance exist, the outlook remains positive. Stakeholders must leverage emerging opportunities to innovate and drive the adoption of circuit breakers and fuses, contributing to a safer and more reliable electrical infrastructure for the future.

More Trending Reports

Power Battery Management System Market

Well Intervention Market

Diesel Genset Market

Diesel Generator Market

#Circuit Breaker And Fuse Market Size#Circuit Breaker And Fuse Market Trends#Circuit Breaker And Fuse Market Analysis

0 notes

Text

0 notes

Text

Electric Fuses: Key Facts You Should Know

What is the use of Fuses?

Fuses are safety devices in electrical systems. They protect circuits and devices from excess current. Their main job is to stop overheating, fires, and equipment failure. They do this by cutting off electricity when it becomes too high. When too much current flows, a fuse’s metal melts. This breaks the circuit and stops the flow. Thus, it protects devices and prevents hazards. Fuses are vital for the safety and reliability of electrical systems.

What are the advantages of Electric Fuses

Safety: Fuses are essential. They break the circuit in case of overcurrent or shorts. This prevents fires and damage to equipment.

Simplicity: Fuses are simple, with no moving parts. This makes them easy to install and maintain. Their design also lowers the chance of malfunction.

Cost-Effective: Fuses are cheap compared to other circuit protectors. So, they are a cost-effective way to safeguard electrical systems.

Quick Response: Fuses react quickly to overcurrents. They protect the circuit and devices.

No Maintenance Required: Once a fuse blows, it simply needs to be replaced. No need for ongoing maintenance. It simplifies managing electrical systems.

Wide Range of Applications: Fuses can be used in many places. They protect household appliances, cars, industrial machines, and power grids. They offer versatile protection across different environments.

Buying Guide for Electric Fuses

Determine Purpose: Identify if the fuse is for appliances, cars, machinery, or electronics.

Choose Type: Choose from a cartridge, blade, glass tube, or resettable fuses. Use one based on your application.

Current Rating: The fuse’s current rating must match or slightly exceed your circuit’s.

Voltage Rating: Check that the fuse’s voltage rating meets or exceeds the circuit’s.

Response Time: Choose between fast-blow (for sensitive electronics) or slow-blow (for devices with surges).

Environmental Suitability: Consider if the fuse needs to withstand heat or moisture.

Size and Form Factor: Ensure the fuse fits your fuse holder or panel.

Quality: Opt for reputable brands and ensure compliance with safety standards.

Cost and Availability: Balance cost with quality and availability of replacements.

Consult Experts: When in doubt, seek advice from electrical experts or suppliers.

Conclusion

For reliable, high-quality fuses and expert guidance, consider shopping at Vashi Integrated Solutions. Vashi, a top distributor, provides a variety of safe, high-quality fuses. Its expert team helps you choose the best fuse to protect your electrical systems. Shop at Vashi Integrated Solutions. They are committed to quality and satisfaction.

1 note

·

View note

Text

Aupo A-Series Thermal Fuse Is Non Resettable Thermal Protection Device With Plastic Casing

http://dlvr.it/TBgMrj

0 notes

Text

Automotive Resettable PPTC Fuse Market Size, Analyzing Forecasted Outlook and Growth for 2024-2030

On 2024-8-5, the latest report 【Global Automotive Resettable PPTC Fuse Market 2024 by Manufacturers, Regions, Types and Applications, Forecast to 2030】from Global Info Research provides a detailed and comprehensive analysis of the global Automotive Resettable PPTC Fuse market. The report provides both quantitative and qualitative analysis by manufacturers, regions and countries, types and applications. As the market is constantly changing, this report explores market competition, supply and demand trends, and key factors that are causing many market demand changes. The report also provides company profiles and product examples of some of the competitors, as well as market share estimates for some of the leading players in 2024.

Polymer Positive Temperature Coefficient (PPTC) Resettable Fuses are particularly developed to give robust and cost-effective protection and reduce short circuits, especially in a range of demanding settings with high voltage temperatures. These components remove the need for any temperature-based nuisance tripping across all such applications, while offering increased, high resistance protection in space-saving surface mount packages. According to our (Global Info Research) latest study, the global Automotive Resettable PPTC Fuse market size was valued at US$ 139 million in 2023 and is forecast to a readjusted size of USD 288 million by 2030 with a CAGR of 10.6% during review period. This report is a detailed and comprehensive analysis for global Automotive Resettable PPTC Fuse market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided.

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approval.

Automotive Resettable PPTC Fuse market is split by Type and by Application. For the period 2019-2030, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

Market segment by Type: Surface Mount、Radial Leaded、Others

Market segment by Application:Window Lift Motors、Door Lock Actuators、Trunk Actuators、Others

Major players covered:Littelfuse、Bel、Bourns、Eaton、Onsemi、Schurter、YAGEO

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Automotive Resettable PPTC Fuse product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Automotive Resettable PPTC Fuse, with price, sales quantity, revenue, and global market share of Automotive Resettable PPTC Fuse from 2019 to 2024.

Chapter 3, the Automotive Resettable PPTC Fuse competitive situation, sales quantity, revenue, and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Automotive Resettable PPTC Fuse breakdown data are shown at the regional level, to show the sales quantity, consumption value, and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment Automotive Resettable PPTC Fuse the sales by Type and by Application, with sales market share and growth rate by Type, by Application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the Automotive Resettable PPTC Fuse sales data at the country level, with sales quantity, consumption value, and market share for key countries in the world, from 2019 to 2024.and Automotive Resettable PPTC Fuse market forecast, by regions, by Type, and by Application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends, and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Automotive Resettable PPTC Fuse.

Chapter 14 and 15, to describe Automotive Resettable PPTC Fuse sales channel, distributors, customers, research findings and conclusion.

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Automotive Resettable PPTC Fuse

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes