#Point-of-Use Water Treatment Systems Industry

Text

Point-of-Use Water Treatment Systems Market Growth, Overview with Detailed Analysis 2022-2028

Point-of-Use Water Treatment Systems Market Growth, Overview with Detailed Analysis 2022-2028

This report studies the Point-of-Use Water Treatment Systems Market with many aspects of the industry like the market size, market status, market trends and forecast, the report also provides brief information of the competitors and the specific growth opportunities with key market drivers. Find the complete Point-of-Use Water Treatment Systems Market analysis segmented by companies, region, type…

View On WordPress

#Covid-19 Impact Analysis#Point-of-Use Water Treatment Systems#Point-of-Use Water Treatment Systems forecast#Point-of-Use Water Treatment Systems Industry#Point-of-Use Water Treatment Systems Market#Point-of-Use Water Treatment Systems price#Point-of-Use Water Treatment Systems report#Point-of-Use Water Treatment Systems research#Point-of-Use Water Treatment Systems share#Point-of-Use Water Treatment Systems trends

0 notes

Text

You guys have probably heard that the EPA just set new Maximum Contaminant Levels (MCLs) for the first time in decades for PFAS, which is BIG news in the industry, but not a surprise. I've been in meetings for months hearing about how new PFAS regulations were in the works, and the consensus in the environmental sector is that it's long overdue. But for the rest of you who've never heard of PFAS before I can break down what the big issues are and why they've taken so long to address.

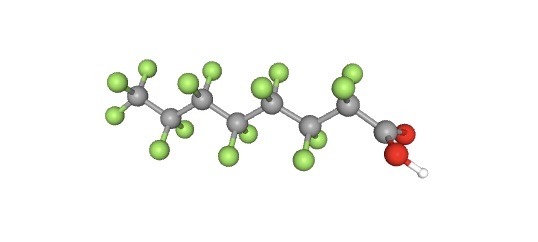

^stolen from pubchem

So PFAS stands for per- and poly- flouroalkyl substances, and it's not one chemical compound, but an entire class of thousands of chemicals that have these chains of Carbon and Flourine atoms. For anybody who doesn't have a chem background fluorine is a nasty atom, it has seven electrons in its valence shell and it will do anything to fill it up to eight, creating incredibly strong bonds.

So you have really strong C-F bonds and these chains of C and F atoms are hydrophobic, which means these compounds are durable and water resistant, which makes them great for all sorts of industrial uses. And we've used them in everything: clothing, fast food wrappers, paints, solar panels, and non-stick pans just to start.

Unfortunately, these wonder chemicals are PBTM- Persistent, Bioaccumulative, Toxic, and Mobile. They don't break down, they build up in the food chain, they have adverse health effects, and even though C-F chains are hydrophobic, additional compounds connected to them can make them soluble in water (so they're in our drinking water). We're starting to realize PFAS can raise cholesterol, inhibit immune response, interfere with your thyroid (part of your hormonal system), cause liver toxicity, is linked to cancer, and more!

At this point you're probably starting to think wtf, how did we allow the continued widespread use of these chemicals? Well, we have phased out quite a few high profile PFAS compounds including PFOA and PFOS, but we still want to regulate and test for them in our drinking water. While PFAS is in many different products, the biggest sources of contamination are industrial runoff, areas where fire fighting foams were tested and used, landfills that leach out PFAS into the surrounding area, and wastewater treatment plants. So don't feel too stressed about eating microwave popcorn or using nail polish.

The reason these regulations took so long to implement was because of how difficult it was to connect such small amounts of PFAS with health hazards. The level of concern for PFAS is extremely low- in the ppt (parts per trillion) range. When I sample for contaminants I'm generally testing in the ppm range and higher, for PFAS we're looking an entire scale lower. We literally did not have the technology before the last few decades to detect PFAS in the ppt range in water, let alone study their effects (you can't just impose massive regulations without any proof to back it up).

States that currently have PFAS limits in drinking water have mostly capped it in the 10-70 ppt range. The new MCLs are 4-10 ppt for the six PFAS compounds the EPA addressed, which are six of the most common and most studied PFAS compounds. Most of the bitching I've seen is about how much this will cost and that the new limits are too low. The conservative take on this is that there isn't enough evidence to support such low MCLs, although most people in the environmental industry feel that more and more research keeps coming out and will keep coming out (remember studying such small amounts of anything is difficult) to support these levels. On the other side of the spectrum, there's the consensus that this is just the beginning and that more and more regulations on PFAS will be needed.

And they're in the works! I saw a proposed rule by the EPA that would ban 12 (already defunct) PFAS substances from pesticides. It wouldn't really affect the current manufacturing of pesticides, but it would be a safeguard from letting them back into the manufacturing process in case of a conservative presidency.

If you're still here I'd like to end on the note that as our science improves, our understanding of how we have impacted the environment and our health will improve. We are constantly going to find out about the adverse effects of new chemicals or things that we may not even produce anymore, and that's a good thing. Over time we are going to make the world a healthier and safer place.

#PFAS#if the boomers were the lead poisoning generation then were the pfas and microplastics generation#chemistry#geology#science#environment#long post

68 notes

·

View notes

Text

Damages to Physical Structures Estimated at $18.5 billion as of end January

WASHINGTON, April 2, 2024 – The cost of damage to critical infrastructure in Gaza is estimated at around $18.5 billion according to a new report released today by the World Bank and the United Nations, with financial support of the European Union. That is equivalent to 97% of the combined GDP of the West Bank and Gaza in 2022.

The Interim Damage Assessment report used remote data collection sources to measure damage to physical infrastructure in critical sectors incurred between October 2023 and end of January 2024. The report finds that damage to structures affects every sector of the economy. Housing accounts for 72% of the costs. Public service infrastructure such as water, health and education account for 19%, and damages to commercial and industrial buildings account for 9%. For several sectors, the rate of damage appears to be leveling off as few assets remain intact. An estimated 26 million tons of debris and rubble have been left in the wake of the destruction, an amount that is estimated to take years to remove.

The report also looks at the impact on the people of Gaza. More than half the population of Gaza is on the brink of famine and the entire population is experiencing acute food insecurity and malnutrition. Over a million people are without homes and 75% of the population is displaced. Catastrophic cumulative impacts on physical and mental health have hit women, children, the elderly, and persons with disabilities the hardest, with the youngest children anticipated to be facing life-long consequences to their development.

With 84% of health facilities damaged or destroyed, and a lack of electricity and water to operate remaining facilities, the population has minimal access to health care, medicine, or life-saving treatments. The water and sanitation system has nearly collapsed, delivering less than 5% of its previous output, with people dependent on limited water rations for survival. The education system has collapsed, with 100% of children out of school.

The report also points to the impact on power networks as well as solar generated systems and the almost total power blackout since the first week of the conflict. With 92% of primary roads destroyed or damaged and the communications infrastructure seriously impaired, the delivery of basic humanitarian aid to people has become very difficult.

The Interim Damage Assessment Note identifies key actions for early recovery efforts, starting with an increase in humanitarian assistance, food aid and food production; the provision of shelter and rapid, cost-effective, and scalable housing solutions for displaced people; and the resumption of essential services.

About the Gaza Interim Damage Assessment Report

The Gaza Interim Damage Assessment report draws on remote data collection sources and analytics to provide a preliminary estimate of damages to physical structures in Gaza from the conflict in accordance with the Rapid Damage & Needs Assessment (RDNA) methodology. RDNAs follow a globally recognized methodology that has been applied in multiple post-disaster and post-conflict settings. A comprehensive RDNA that assesses economic and social losses, as well as financing needs for recovery and reconstruction, will be completed as soon as the situation allows. The cost of damages, losses and needs estimated through a comprehensive RDNA is expected to be significantly higher than that of an Interim Damage Assessment.

34 notes

·

View notes

Text

WASHINGTON, April 2, 2024 – The cost of damage to critical infrastructure in Gaza is estimated at around $18.5 billion according to a new report released today by the World Bank and the United Nations, with financial support of the European Union. That is equivalent to 97% of the combined GDP of the West Bank and Gaza in 2022.

The Interim Damage Assessment report used remote data collection sources to measure damage to physical infrastructure in critical sectors incurred between October 2023 and end of January 2024. The report finds that damage to structures affects every sector of the economy. Housing accounts for 72% of the costs. Public service infrastructure such as water, health and education account for 19%, and damages to commercial and industrial buildings account for 9%. For several sectors, the rate of damage appears to be leveling off as few assets remain intact. An estimated 26 million tons of debris and rubble have been left in the wake of the destruction, an amount that is estimated to take years to remove.

The report also looks at the impact on the people of Gaza. More than half the population of Gaza is on the brink of famine and the entire population is experiencing acute food insecurity and malnutrition. Over a million people are without homes and 75% of the population is displaced. Catastrophic cumulative impacts on physical and mental health have hit women, children, the elderly, and persons with disabilities the hardest, with the youngest children anticipated to be facing life-long consequences to their development.

With 84% of health facilities damaged or destroyed, and a lack of electricity and water to operate remaining facilities, the population has minimal access to health care, medicine, or life-saving treatments. The water and sanitation system has nearly collapsed, delivering less than 5% of its previous output, with people dependent on limited water rations for survival. The education system has collapsed, with 100% of children out of school.

The report also points to the impact on power networks as well as solar generated systems and the almost total power blackout since the first week of the conflict. With 92% of primary roads destroyed or damaged and the communications infrastructure seriously impaired, the delivery of basic humanitarian aid to people has become very difficult.

The Interim Damage Assessment Note identifies key actions for early recovery efforts, starting with an increase in humanitarian assistance, food aid and food production; the provision of shelter and rapid, cost-effective, and scalable housing solutions for displaced people; and the resumption of essential services.

About the Gaza Interim Damage Assessment Report

The Gaza Interim Damage Assessment report draws on remote data collection sources and analytics to provide a preliminary estimate of damages to physical structures in Gaza from the conflict in accordance with the Rapid Damage & Needs Assessment (RDNA) methodology. RDNAs follow a globally recognized methodology that has been applied in multiple post-disaster and post-conflict settings. A comprehensive RDNA that assesses economic and social losses, as well as financing needs for recovery and reconstruction, will be completed as soon as the situation allows. The cost of damages, losses and needs estimated through a comprehensive RDNA is expected to be significantly higher than that of an Interim Damage Assessment.

21 notes

·

View notes

Note

vegan radfems are so annoying I literally do not care

I like that vegans exist. I can also in some cases see the connection to feminism and the treatment of women/female animals as a whole (chauvinist attitudes around meat eating being correlated with misogyny, and how we create constant reproduction in farm animals in a way that is terrible for their bodies), although I don't really think that animal rights is a question for feminism to solve or focus on, rather maybe animal activist sub groups. I've been vegetarian for long periods (several years at a time) and cook vegan meals from time to time. But I can't seem to feel full when I don't eat any meat or fish so I ended up eating way more bread/sugar and gaining weight, and I've also developed some deficiencies (iron, primarily). I know you can avoid a lot of deficiencies even on a vegan diet, but it takes a lot more work and energy.

What I don't like is the aggression and immediate defensiveness. And I don't like the argument that some humans are braindead or have developmental disabilities and if we eat animals because they're "dumber" then nothing should stop us from eating those humans. Because if your point is "we can't eat living beings even if they don't have human intelligence" then what is actually okay to eat? I don't like being met with aggressive and extremely ridiculous arguments like that. And I know it's been said a million times in bad faith, but honestly, why is eating plants okay? We know that plants react to stimuli like light and resources like water, and we also know that many species of plants also react to being damaged. Trees warn each other with stress signals when they're "injured", so is pruning and cutting fruit trees okay just because we can't see these signals of stress without sophisticated technology? How come? If the argument against mine is that we don't kill and eat disabled people even if they're developmentally on the cognitive level of a child or even an animal (for example, pigs are generally thought to have the intelligence level of a 4 year old child), then where is the cutoff? Plants don't have central nervous systems, is that the cutoff? Can we farm and eat insects? Both of these options still have some kind of survival instinct. What makes them okay to eat?

The people who say these things aren't jainists even if they're vegan. I don't like it when vegans make the point that meat eaters are simply making emotional arguments like "I want to keep eating meat because it tastes good" when SOME amount of farming and killing is fine and necessary to vegans too. We're learning new things about animals AND plants every day. Some plants like certain species of fungi even seem to have some sort of reasoning and strategy in their patterns of growth. The arguments for eating plants are also emotional because you need to eat something to survive. What I think is a strong argument is the minimization of suffering, because those stress signals simply aren't as important as the much more obvious and material suffering of mass factory farmed animals. And also minimizing detrimental environmental effects. But that argument requires differentiation between sufferings. You have to recognize, confess almost, that some suffering is worse than other kinds. Which was my point from the beginning, a human can be cognitively aware of certain things in a way that creates terror that simply isn't present in another creature in the same way, which is why I don't think targetting those specific emotions/thoughts in an audience is the smartest idea depending on your goal.

My point has always been that the act of eating in itself can't be unethical. Eating is not morally wrong. We as a species evolved to be omnivores, so it's not unnatural or unethical to eat meat in itself. Many species are predatory. I will never be convinced that meat eating in itself is morally reprehensible. What I think is bad about the meat industry has to do with the treatment of the animals, and the effect such farming has on the environment, and the public health issue of too much meat consumption.

12 notes

·

View notes

Note

What are your opinions on fertilizer runoff from industrial farming? Its ingredients such as phosphate and nitrogen can facilitate algae blooms, which in turn can cause artificial eutrophication, and or release toxins like microcystins.

My opinions are mixed! Also, this is a long post, so I've put the rest under a keep reading. Please do read! I just don't want to fill people's dashes with a long post every time they scroll lol.

Firstly, I need to say that if we were to broadly ban or heavily restrict fertiliser usage in agriculture, it is undeniable that the agriculture economy would collapse. Most industrialised farming is incentivised to sell the 'ideal products' to consumers, which inevitable means a shitload of food production in order to get the highest amounts of 'perfect' product. This requires a lot of fertiliser usage in order to mass produce and harvest monoculture farmland, and also results in a LOT of food waste. Unfortunately, the agricultural economy, combined with the half century of brainwashing by advertising companies telling people that so called 'blemished' food is somehow bad for you, is so based on this excess that if we did immediate drastic action, it would implode and likely send the prospective country into a recession.

With that being said, the system of heavy use of fertiliser is still not good!! Fertiliser runoff causes eutrophication as you point out, and can lead to toxic algal blooms, or even oxygen dead zones further down stream. However, it is not solely the use of fertiliser products that contribute to fertiliser run-off, as contradictory as that sounds. In fact, soil quality has a large part to play in the production of run-off.

For example, most modern agriculture uses monoculture, which is when one plant species is grown in the same place with little to no diversity in the field. A result of this is that only a single type of root system is grown, which is not enough for a healthy layer of topsoil to develop, especially if it is tilled and plowed every season. This means that the soil is very poor at retaining water, meaning that it requires LOTS of irrigation. With lots of irrigation, the fertiliser nutrients can't stay in the soil long enough to be absorbed by the plants fully, and they get washed away and have to be constantly topped up.

If we used less monoculture in our farming, we could use less fertiliser and still gain the same benefit, with also less runoff, which would be ideal!

I would also note a few things, namely that fertiliser runoff is not the only source of nutrient pollution from farming, and especially in places that have heavy cattle farming like my country, nitrates and phosphates from stock effluent is more of a problem. Cows shitting near streams is a big problem, and can be mitigated by proper filtering and nutrient-recovery technologies. One of these that I think is a big winner in terms of green technology wastewater treatment are Floating Treatment Wetlands, which are essentially artificial wetlands that are engineered to be part of wastewater treatment, and also provide habitats for birds and insects at the same time.

17 notes

·

View notes

Text

The “death map” tells the story of decades of sickness in the small northwest New Mexico communities of Murray Acres and Broadview Acres. Turquoise arrows point to homes where residents had thyroid disease, dark blue arrows mark cases of breast cancer, and yellow arrows mean cancer claimed a life.

Neighbors built the map a decade ago after watching relatives and friends fall ill and die.

Dominating the top right corner of the map, less than half a mile from the cluster of colorful arrows [...] : 22.2 million tons of uranium waste left over from milling ore to supply power plants and nuclear bombs. “We were sacrificed a long time ago,” said Candace Head-Dylla, who created the death map with her mother after Head-Dylla had her thyroid removed and her mother developed breast cancer. [...]

Beginning in 1958, a uranium mill owned by Homestake Mining Company of California processed and refined ore mined nearby. The waste it left behind leaked uranium and selenium into groundwater and released the cancer-causing gas radon into the air.

State and federal regulators knew the mill was polluting groundwater almost immediately after it started operating, but years passed before they informed residents and demanded fixes. [...]

---

Uranium mining and milling left a trail of contamination and suffering, from miners who died of lung cancer while the federal government kept the risks secret to the largest radioactive spill in the country’s history. But for four decades, the management of more than 250 million tons of radioactive uranium mill waste has been largely overlooked, continuing to pose a public health threat. [...] At Homestake, which was among the largest mills, the company is bulldozing a community in order to walk away. Interviews with dozens of residents, along with radon testing and thousands of pages of company and government records, reveal a community sacrificed to build the nation's nuclear arsenal and atomic energy industry. [...]

In 2014, an EPA report confirmed the site posed an unacceptable cancer risk and identified radon as the greatest threat to residents’ health. Still, the cleanup target date continued shifting, to 2017, then 2022. Rather than finish the cleanup, Homestake’s current owner, the Toronto-based mining giant Barrick Gold, is now preparing to ask the Nuclear Regulatory Commission, the independent federal agency that oversees the cleanup of uranium mills, for permission to demolish its groundwater treatment systems and hand the site and remaining waste over to the U.S. Department of Energy to monitor and maintain forever. Before it can transfer the site to the Department of Energy, Homestake must prove that the contamination, which exceeds federal safety levels, won’t pose a risk to nearby residents [...].

Part of Homestake’s strategy: buy out nearby residents and demolish their homes. [...] Property records reveal the company had, by the end of 2021, purchased 574 parcels covering 14,425 acres around the mill site. This April, Homestake staff indicated they had 123 properties left to buy. One resident said the area was quickly becoming a “ghost town.”

---

Even after the community is gone, more than 15,000 people who live nearby, many of them Indigenous, will continue to rely on water threatened by Homestake’s pollution. [...]

At the state level, New Mexico regulators waited until 2009, 49 years after first finding water pollution, to issue a formal warning that groundwater included substances that cause cancer and birth defects. [...] Other uranium mines and mills polluted the area’s main drinking water aquifer upstream of Homestake. [...]

More than 500 abandoned uranium mines pockmark the Navajo Nation [...].

Leaders of communities downstream from Homestake, including the Pueblo of Acoma, fear that wishful thinking could allow pollution from the waste to taint their water. The Acoma reservation, about 20 miles from Homestake’s tailings, has been continuously inhabited since before 1200. Its residents use groundwater for drinking and surface water for irrigating alfalfa and corn, but Donna Martinez, program coordinator for the pueblo’s Environment Department, said the pueblo government can’t afford to do as much air and water monitoring as staff would like. [...]

Most days, Billiman contemplates this “poison” and whether she and Boomer might move away from it [...]. “Then, we just say ‘hózho náhásdlii, hózho náhásdlii’ four times.” “All will be beautiful again,” Boomer roughly translated. [...] Now, as a registered nurse tending to former uranium miners, Langford knows too much about the dangers. When it’s inhaled, radon breaks down in the lungs, releasing bursts of radiation that can damage tissue and cause cancer. Her patients have respiratory issues as well as lung cancer. They lose their breath simply lifting themselves out of a chair.

---

Text by Mark Olalde and Maya Miller. “A Uranium Ghost Town in the Making.” ProPublica. 8 August 2022. [Some paragraph breaks and contractions added by me.]

84 notes

·

View notes

Text

I've been thinking about old railway uniforms, and come to the conclusion that the textiles could be INTERESTING in a steampunk world.

If steam power is widespread and commonplace, that means that there's going to be plenty of steam piping and/or boilers around. A lot of it would probably be insulated for safety and efficiency, but that still probably means that a significant part of the population has to work around HOT steam-powered equipment fairly often. I don't think that EVERYONE would necessarily be going around in protective double denim, but I think there'd just be less demand for fabrics with worse heat resistance.

That probably means that textile innovation wouldn't focus so hard on inventing New materials; but rather on improving natural fabrics. With a focus on mechanical innovation, I think your steampunk inventor would have an ENORMOUS array of linkages available to them - for converting a continuous mechanical input to various complicated and adjustable movement patterns. I think that having a lot more workers in hot environments would also lead to wide-spread use of mechanical refrigeration.

I've seen a few videos of industrial fabric-handling machines - they seem to have a Lot spiky metal fingers making repetitive movements. I think a steampunk world would be GREAT at making those little fingers do different, interesting patterns of movement! I recently saw a Matt Parker video about a continuous lattice of 7 different directions of pencil, and there was a cool animation of its cross-section. Imagine the funky patterns you could weave with thread going in more than 2 directions - either coplanar with eachother or in 3d space. All the cool decorative patterns woodworkers can do with plywood and veneer - imagine that with thread!

One of the reasons that a lot of tradespeople wore denim was because the pattern of the fabric obscured oil and grease stains. Could you achieve the same effect with the above funky patterns if they were dense enough? SO many workwear fashion options. And if you've got hot steam on tap as well as decent refrigeration - heat treatment would be easy to incorporate. What sort of interesting features would they be heat-setting into their clothes?

And if you want to build any sort of articulated machine/robot with steam as the power source; you need something to carry that steam - a flexible, high-pressure, heat resistant pipe. That sounds like a braided hose to me - and if you're using more colourful metals than stainless steel, your steam plumbing could get COLOURFUL! You know how we have braided hoses with a red or blue strand for hot or cold water? JUST IMAGINE the industry standard colour coding schemes for different temperatures, pressures, and phases of various fluids they could have!

Colour coded flexible pressure hose reminds me of an electrical system - I wonder how a steampunk world would do mechanical calculation? Did someone say Convoluted Fluid Based Computers?? With advances in textiles, hoses, and ropes - surely at some point they'd invent wire or fibre-wrapped pressure vessels! (Just think what they'd do with carbon fibre!) A society with (admittedly probably building-sized) computers that's used to dealing with high-pressure fluids - SURELY they'd invent jet propulsion? Perhaps not for rockets or aircraft - imagine pressure-jet steampunk ships, submarines even.

Actually where I can see modern-ish chemical rocketry in a steampunk world is in miniature steam generators - either HO bipropellant (your choice of liquid or gaseous) or peroxide monopropellant. A vigorous chemical reaction with hot, fast H2O as the product - sounds like a (rather explosive) portable power source.

Anyways, TLDR i'd LOVE to see what technological innovations a steampunk world would have. What paths they'd go down for research.

2 notes

·

View notes

Text

Sheer Entitlement

Look. I've been called "Boomer", "Coomer" and every other stupid freaking word in the book. However, I'm no boomer, and frankly speaking I think the term "Coomer" is stupid as hell. But I need to discuss this and I know it will not be well received by some people.

Todays generations are royally entitled. And when it comes to Gen Z and Gen A I kind of don't blame them. Because while yes it's f*cked, the reason is because of Gen Y and Gen X. Though not fully.

What we are living through right now is the normalization of Communist ideology. Or rather, the propaganda that leads TO Communism. Which is, "The government should be in charge of everything, and give us everything because EVERYTHING literally is a human right". Except it's not. Your rights stop the moment it requires another persons labor to bring about. What do I mean by this? Scarcity is still a real world issue. And the only reason we have the stores of food we have is due to the labor of SEVERAL different sectors of industry.

The transportation industry. The machining industry. The farming industry, and so on. How do those industries thrive? Due to every other industry that makes it worth their time to do what they do. The local residents that make the water treatment systems work. The people to work on the grid. The people that make the petrol that makes all of that stuff work in general. Our countries require work and industry to survive. If no one works these jobs, there is nothing left. And lest people be FORCED to work these jobs, which under socialism and communism they WOULD be, everything we know and everything we have would crumble.

Frankly speaking, I can't blame the modern generations. We've allowed ourselves to be infiltrated by Commies and Socialists. What's more, it's often people who are well off, like Hasan Piker and his ilk. They complain about "Capitalism" while misrepresenting what it actually is. Every single time, blaming Capitalism for the problems not caused by the system in place, but my the government instead. Which fun fact if the government is the one causing the issue, why EXACTLY do you want more government control when THEY are the ones causing the issues? Then again, I already know why. Many of you assholes have expressed why. And the conversation goes as such:

"We want to turn the system on it's head"

"You realize you view the system as pyramid right? If you turn it on it's head said pyramid will shatter and crumble into a pile "Resembling" a pyramid"

"God your stupid. That's the point. We don't care about the bottom of the system. And people like you that try to view us in good faith are great for us. Of course we want the system to collapse by flipping it on its head. WE want to be on the top. F*ck everyone else."

^Those are the people you support. A system that want to look like this:

This is they system they want. The only grip they have is that not only are they not the ones at the very top, they also don't want mobility for others. They are selfish, greedy, and you prop them up believing "It's for the greater good". And "Oh well it's great to make EVERY THING a "Human Right". Healthcare is not a human right. Food is not a human right. Housing is not a human right. Because all of those things require the labor of others. If you are so pissed off about not having food, grow your own. Buy seeds at Walmart or Lowes. Get in home plants or just get pots to plant stuff in. Put it in the window or hang it outside.

And I've said this before but most people sadly become disillusioned by their friends and family or by social media. Often actually by social media more than not. Basically, a "Victim" of our own success. The better we make things the less effort has to be put into having a decent life. We live vastly better than even Royalty from decades ago. We have indoor plumbing and toilets. We have large refrigerators and freezers. We have strawberries year round. And other foods that would otherwise only exist seasonally. Our great grandparents probably worked 12-16 hr days. Between working on a farm or ranch. Potentially having a day job. Coming home to make repairs without fancy ass tools. Without Amazon. Having to wait for professionals to come out and fix something that could take days or longer. Maybe weeks.

We have it SO GREAT and honestly that might not be a good thing at all. People don't have to try anymore. You can literally make money now a days selling pictures of your f*cking feet. There are people that play games online and attempt to entertain people that make a KILLING. Things are so f*cking easy now. Does that mean it's easy for everyone? No. Does that mean that things are not difficult in their own way? No. But to pretend that the people that preceded us had it easier? They really didn't.

Which leads me to now. I honestly can't stand what we are seeing from people today. Everything is "oppressor" this and "Oppressed" that. It's "woe is me things are so hard". Yeah kindly tell that to some of your parents that worked 2 jobs just so you could turn in to an entitled socialist. And that's what most of the people today are. Even if they don't know it. "Every thing should be free". No. Everything should not be free. People deserve to see the fruits of their own labor. Not to be pressured into giving up what they have for other people who don't WANT to work.

Which leads me to my last point. Stop demanding stuff of free. Start teaching your kids the meaning of work. And it's worth. But more than that, start taking them off social media, and teach them the things you know. Teach them how to cook. Teach them how to clean, teach them how to build things. Teach them how to file taxes. Teach them the things they need to know to be prepared for life in the future. And also. FOR THE LOVE OF GOD, educate your kids on why government interference in the market on BELHALF of multinational corporations is NOT capitalism. It's Corporatism. And when you just fork more and more power to the government you get the picture I posted above.

We need to start sanding down entitled behavior. People need to learn the value of work. They need to realize that. More over, they need to not replace religion in their lives with cult like belief in failed political ideologies. So many of us really have no idea how good we have it. And some of us that do want to see our country crumble because, "We've had it too good for too long". Yeah, I'm actually mostly fine with that. Because if let things crumble, how many people die in that process? Too many. How many people die if we BOW to climate alarmism? Too many. How many people die if we adopt Communism or Socialism? Too many.

And lastly. Teach your kids common sense. And teach them to stop chasing clout. Why? Look at what's going on now. Look at the "Rage" supporting that Palestinian people. Meanwhile the Uighur Muslims are being raped daily, sterilized, beaten, forced into reeducation, and forced to do labor for things coming out of China. NOT! A! F*CKING! PEEP from these same people. Because it's about hate (for a certain group of people) and it's about clout. If nothing else? Teach your kids to be consistent and teach them critical thinking. We really need to offset the current issues we are having today. BADLY. Anyways. I'm done ranting about this. It's already too long.

5 notes

·

View notes

Text

STEPS ON HOW TO SET UP A DIALYSIS CENTER

People often think setting up a Dialysis center is rocket science, even if they have been in the healthcare industry for a long time. Well, I would just say, you need an expert to guide you. Beyond setting up a Dialysis center, you need to be guided on how to stay profitable while offering quality care.

We have managed the set-up of over 60 Dialysis centers in Nigeria, Ghana, and Liberia. I currently have new projects in Zimbabwe, Ethiopia, and Sierra Leon and I can tell you this for free, talk to an expert or consultant. These steps I am giving you will not be enough. The real work will not even be in setting up a Dialysis center but in staying profitable and scaling the business. There are usually so many pros and cons involved, and you need someone to guide you through it all.

THESE ARE THE STANDARD STEPS WE RECOMMEND AT MEDPAU INTERNATIONAL LIMITED

1. Consultation: Whether you are involved in the medical profession, or a business tycoon looking to invest in the healthcare sector, the first step to go about setting up a dialysis center is speaking to an expert consultant. Consulting with a professional would provide you with the necessary guidance to establish a dialysis center of any size, from a single-bed dialysis center to a multiple-bed dialysis center, while considering your budget.

2. Legal requirements: Due to the technicalities involved in running a healthcare business, certain licenses and paperwork are required during the process of registering the business. It is crucial to seek legal counsel to ensure you’re complying with the laid down rules and regulations.

3. Equipment purchase: This is the point where you purchase your dialysis equipment and consumables from a trusted equipment supplier.

4. Equipping & Installation: Next after purchasing your equipment is the setting up of your dialysis center, which includes the installation of dialysis machines, dialysis couches, and other systems like the water treatment plant and a power source. This procedure should be handled by trained installation engineers or technicians.

5. Facility Commissioning: This is the point where all requirements have been met, and your center is ready for business. Commissioning a facility can be done in various styles; whether you choose to throw an opening party, or launch into the streets in a marketing campaign, what matters is that your center is optimally ready to respond to the demands of a dialysis center.

When properly done, owning a Dialysis center is like owning a gold mine. The average cost of each session of Dialysis is about $50 — $100 and patients undergo Dialysis at least twice every week for the rest of their lives or until they get Kidney Transplant.

This will also be a good time for me to advise you to consider using refurbished Dialysis machines especially if you are a private healthcare service provider or in Nigeria, Ghana, Liberia, Ethiopia, Zimbabwe, or any other African country. I will give more information in my next article.

2 notes

·

View notes

Text

Design and Application of the Automatic Instrument in Sewage Treatment

Reading guide: In the new era, water pollution is becoming more and more serious, especially urban and industrial sewage discharge continues to increase, leading to water pollution gradually serious. Our government pays more and more attention to the protection of water resources and takes a series of measures to strengthen the treatment of urban and industrial sewage, promote the sewage treatment process to achieve the best treatment effect, and the treatment equipment can operate normally and stably, thus putting forward higher requirements for automatic instruments in sewage treatment, and relevant enterprises must pay high attention.

Relevant personnel shall monitor the impurities and content parameters in the sewage and take corresponding measures to deal with the problem. At present, in the actual monitoring, because the impurity content of sewage has various and complex characteristics, the manual measurement method not only increases the work amount but also is difficult to achieve the goal of material composition measurement. The automatic instrument design can automatically measure sewage materials, provide accurate sewage material cost, and has been widely used in sewage treatment.

Importance of automatic instruments in sewage treatment

The continuity of sewage treatment is strong, the process is complex, the equipment is numerous, and the management is difficult. In order to achieve the safe and long-term operation of sewage treatment equipment and treatment process, it is necessary to scientifically manage the entire production process of sewage treatment. The important value of automatic control of sewage treatment in today's society is gradually emerging. In the whole process of modern sewage treatment, no matter what method is used, Many parameters of these processes need to be tested.

At this stage, many large-scale process sewage and domestic sewage treatment plants are equipped with automatic instruments such as online total phosphorus, online ammonia nitrogen, online COD, online BOD, redox potential, temperature, pH value, and liquid level difference. Through the use of these automatic instruments, various process parameters are detected, and they are transmitted to the DCS system and other upper computers. Through the upper computer, different process equipment in the process construction is scientifically and effectively controlled, Coordinate the relationship between sewage treatment processes, supply, and demand, and promotes the full and reasonable utilization of different facilities and equipment. At the same time, some important process parameters in the design and application of automatic instruments, such as the measurement accuracy of aeration rate and dissolved oxygen value, are the preconditions for ensuring automatic control.

The measured values of these instruments can automatically control and adjust the process equipment and effectively guide the sewage treatment process. In addition, the automation instrument and DCS system, and other upper computers, can alarm the process in real-time to ensure the safety of equipment and production. It can be seen that the automation instrument plays a very important role in the sewage treatment process.

Importance of automatic instruments in sewage treatment

Specific applications of automatic instruments in sewage treatment

Application of temperature instrument in sewage treatment

Generally, an anaerobic digestion process is required in the process of sewage treatment. This process requires dynamic monitoring with temperature instruments and pressure instruments. The purpose is to facilitate the staff to properly adjust the anaerobic digestion conditions in combination with their dynamics, so as to obtain the best effect. In the application process of temperature instruments, the most commonly used thermal element is a platinum thermistor. However, considering the small number of temperature control points of the platinum thermistor, it is usually necessary to use it together with the temperature transmitter. Through the comprehensive application of the two, the thermal signal can be converted into an electrical signal of 4~20mA, and then connected to the analog module of the electrical signal, so that the data can be extracted and the entire processing process can be simplified.

Application of flow meter in sewage treatment

In sewage treatment, flow meters play a very important role, mainly in the detection of sewage volume, sewage return flow, aeration volume, and other parameters, providing a detailed and reliable basis for the control of sewage treatment operating conditions. At the same time, the flow meter can also reasonably judge the operation of the equipment in sewage treatment. At present, the flow meters in sewage treatment mainly include ultrasonic flowmeters, differential pressure flowmeters, and electromagnetic flowmeters. In the design stage, the most appropriate one should be selected according to the actual needs of the user to ensure the effectiveness of sewage treatment.

The flow meter used by a certain unit is an electromagnetic flowmeter. The working principle of the electromagnetic flowmeter is the electromagnetic induction principle. It measures the flow of the conductive fluid according to the induction electric magnetic field generated by the conductive fluid when the external magnetic field is applied. The characteristics of the flowmeter are that it is not affected by the change in fluid density, temperature, viscosity, and conductivity, and the induced electrical signal of the sensor has a linear relationship with the average flow rate. The measurement has high accuracy, and it is suitable for measuring the fluid with small particles in sewage treatment.

Application of flow meter in sewage treatment

Application of COD analyzer in sewage treatment

Chemical oxygen demand (COD) refers to the amount of strong oxidant required for sewage treatment per unit volume under certain conditions. It is an important part of the indicator system for measuring sewage treatment effects. It can also be used to measure the organic content in sewage. The greater the COD, the higher the organic content in sewage, and the more serious the water pollution. COD measuring instruments are divided into two types: spectrophotometry and electrochemical measurement.

The working principle of spectrophotometry for COD measurement is that when the mixed solution of the water sample, potassium dichromate, catalyst, and concentrated sulfuric acid is put into the digestion tank and heated to a certain temperature, the chromium ion is reduced from tetravalent to trivalent and the color of the liquid changes. The degree of discoloration is opposite to the organic content of the water sample, The instrument changes the COD value by comparing colors and changing colors. In addition, the COD analyzer is a kind of analytical instrument with high precision. Foreign countries are more mature in research, production, production, and technology. To ensure the accuracy of measurement, especially in the case of high process requirements, foreign products should be preferred.

When sewage treatment is carried out, it is necessary to strengthen the determination of the COD index, so as to continuously optimize the sewage treatment process and continuously improve the sewage treatment effect.

Application of ammonia nitrogen online monitor

At present, the methods commonly used for ammonia nitrogen online monitor monitoring in China are spectrophotometry and ammonia gas sensitive electrode method. The spectrophotometry is to mix ammonia in a water sample with potassium iodide and mercury iodide to form an alkaline mixed solution, produce a reddish brown colloidal solution through a chemical reaction, and measure it within the wavelength range of 410~424nm. At the same time, the main interference factor in the process of monitoring is the chemical substances that produce chromaticity and turbidity. In application, most ammonia nitrogen monitors use the ammonia gas-sensitive electrode method.

Application of dissolved oxygen meter in sewage treatment

Dissolved oxygen is closely related to the partial pressure of oxygen in the air, atmospheric pressure, and water temperature. If the dissolved oxygen in pure water is about 9mg/L at 20 ℃ and 100kPa, under the action of aerobic bacteria, the biodegradation of some organic compounds requires the consumption of dissolved oxygen in the water. It is calculated by organic carbon. According to the formula of C+O2=CO2, 12g carbon requires 32g oxygen. In addition, if the dissolved oxygen value in the water drops to 5mg/L, some fish will have difficulty breathing. Generally, there are two sources of dissolved oxygen: first, when the dissolved oxygen in water is not saturated, the oxygen in the atmosphere will seep into the water; Second, plants in water release oxygen through photosynthesis, and the dissolved oxygen in the water will be continuously supplemented with the oxygen dissolved in the air and the photosynthesis of green aquatic plants. However, if the water body is polluted by organic matter, the oxygen consumption is serious, and the dissolved oxygen cannot be supplemented in time, the anaerobic bacteria in the water body will be rapidly propagated, and the organic matter will cause the water body to become black and stinky due to corruption.

At the current stage, the three most widely used methods in sewage treatment are aerobic anaerobic microbial treatment, activated sludge treatment, and biofilm treatment. The content of dissolved oxygen in water plays a decisive role in whether microorganisms can survive in water. Therefore, it is necessary to ensure that there is enough dissolved oxygen in the water to support the activity of microorganisms. The dissolved oxygen meter plays a very important role in dissolution monitoring, The aeration rate can be well adjusted, and the problem of sludge filament bulking in the application of the activated sludge method can also be effectively avoided. Generally, a dissolved oxygen meter is composed of a sensor and a transmitter. Dissolved oxygen sensor includes two types of sensors: coated electrode and filmless electrode, which are both composed of a cathode, anode, and electrolyte. In the specific application, the relevant staff should scientifically and effectively set the installation position of the dissolved oxygen meter according to the actual situation of the sewage and the construction site to effectively avoid electrode scaling and pollution, so as to give full play to the use effect of the dissolved oxygen meter.

Application of dissolved oxygen meter in sewage treatment

Matters need attention in the design of the sewage treatment automation instrument

In the process of applying automatic instruments to sewage treatment, it is very easy to attach some impurities contained in sewage to the surface of the automatic instruments. If this is not handled in the long run, it will have a serious impact on the operation stability of the automatic instruments, thus damaging the accuracy of the instrument detection and measurement data. In the process of automatic instrument design, the problem of instrument cleaning must be solved. First of all, set the automation instrument at a position convenient for disassembly, and the staff can adjust the instrument according to the actual situation. Secondly, scientific and reasonable maintenance measures shall be formulated in combination with the working place and working environment of the automation instrument to make it operate stably for a long time.

Conclusion

To sum up, the automatic instrument plays a crucial role in the sewage treatment process. It is the basic part of the computer and automatic control, which can greatly reduce the workload and improve production efficiency. Relevant enterprises shall select appropriate automation instruments based on the actual situation and design automation instrument systems more perfectly to ensure their reasonable application.

Recourses from https://www.supmeaflow.com/

2 notes

·

View notes

Text

Understanding Instrumentation Valves and Their Types

Instrumentation valves play a crucial role in various industrial applications, especially where precise control of fluids, gases, or pressure is required. These valves are specifically designed to regulate flow and ensure the safety and efficiency of systems. They are vital in industries such as oil and gas, chemical processing, pharmaceuticals, and more. In this article, we’ll take a closer look at some of the key types of instrumentation valves, including their functions, applications, and why Freture Techno Pvt. Ltd. is a trusted provider.

Types of Instrumentation Valves

There are several common types of instrumentation valves used in different industrial settings, each designed to meet specific needs. Here are five prominent types:

1. Double Block and Bleed Valve (DBB Valve)

The Double Block and Bleed Valve is an essential component in many industrial systems that require isolation for safety or maintenance purposes. This valve allows two independent blocks to seal off both sides of the pipeline and a bleed valve in between to vent or relieve pressure.

The DBB valve is widely used in applications where there is a need for safe isolation, such as oil and gas pipelines, chemical plants, and even power generation systems. This design minimizes the risk of leaks and ensures that hazardous fluids or gases are safely contained during maintenance or inspections.

2. Monoflange Valve

Monoflange valves are a compact solution designed to replace traditional assemblies of multiple valves used for isolation, venting, and calibration. They combine the functions of several valves into a single unit, which simplifies installation and reduces weight and space requirements.

Monoflange valves are commonly found in oil and gas industries, offshore platforms, and chemical processing plants. They are ideal for environments where space is limited, yet high performance and reliability are essential. The combination of isolation and venting capabilities within a single valve reduces the potential for leak points, making them a popular choice in critical applications.

3. Ball Valve

Ball valves are versatile, widely used in a range of industries for shut-off and control applications. These valves use a spherical disc (or ball) to control the flow of fluids or gases. When the valve is in the "open" position, the ball's hole aligns with the flow path, allowing fluid to pass through. When it’s in the "closed" position, the ball rotates to block the flow entirely.

Ball valves are known for their durability, ease of use, and ability to provide tight seals even after long periods of disuse. They are often used in water treatment, oil and gas systems, and chemical plants, making them one of the most reliable options for managing flow in instrumentation systems.

4. Check Valve

Check valves, also known as non-return valves, are designed to prevent backflow in a system. They allow fluid to flow in only one direction and automatically close if the flow reverses. This is crucial in protecting equipment and ensuring the safe operation of pipelines or other systems that rely on consistent flow.

Check valves are often used in water systems, fuel pipelines, and air compression systems, where maintaining directional flow is vital. They offer a simple yet effective solution to prevent contamination or damage from reverse flow.

5. Needle Valve

Needle valves are designed for precise flow control in low-flow systems. They have a small, tapered point at the end of a screw, which fits into a similarly shaped seat. As the valve is turned, the point gradually moves out of the seat, allowing more fluid to flow through.

Needle valves are used in applications where accurate flow regulation is critical, such as in hydraulic systems, gas chromatography, and other instrumentation systems. Their design allows for fine-tuned adjustments, making them ideal for systems that require precise control of pressure and flow rates.

Why Buy Instrumentation Valves from Freture Techno Pvt. Ltd.?

Freture Techno Pvt. Ltd. is a leading manufacturer and supplier of high-quality instrumentation valves in Mumbai, India. With years of experience in the industry, Freture Techno is known for producing reliable and durable valves that meet the rigorous demands of various industries.

Here are a few reasons why buying from Freture Techno is a smart choice:

Quality Assurance: All valves are manufactured to meet the highest industry standards, ensuring performance, safety, and longevity.

Wide Range of Products: Whether you need a Double Block and Bleed Valve, Monoflange Valve, Ball Valve, Check Valve, or Needle Valve, Freture Techno offers a comprehensive range to suit any application.

Competitive Pricing: Freture Techno provides competitive pricing, ensuring that you receive top-quality instrumentation valves without breaking the bank. They frequently offer discounts, allowing you to access premium products at reduced prices.

Customization: Freture Techno understands that each industrial application is unique. They offer customization options to meet your specific requirements, ensuring that you get the right valve for your system.

Excellent Support: Freture Techno provides dedicated customer support, helping you choose the right valve and offering guidance throughout the purchasing process.

Conclusion

Instrumentation valves, including the Double Block and Bleed Valve, Monoflange Valve, Ball Valve, Check Valve, and Needle Valve, are essential components in many industrial systems. Each type of valve offers specific benefits and is designed to meet the diverse needs of different applications.

When it comes to sourcing these valves, Freture Techno Pvt. Ltd. stands out as a trusted provider of high-quality, cost-effective solutions. With their extensive range of instrumentation valves and a commitment to customer satisfaction, you can confidently rely on them for all your valve needs.

Take advantage of their discounted prices today and invest in durable, reliable instrumentation valves that ensure the smooth operation of your systems.

#instrumentation valves#high pressure needle valves#high presssure ball valves#high pressure check valves#Double Block and Bleed Valves#Monoflange Valves#Manifold Valves#manufactuers#mumbai#india#freture techno

0 notes

Text

The Economic and Environmental Benefits of Waste Oil to Diesel Conversion

As global energy demands continue to rise and the environmental impact of fossil fuels becomes more apparent, innovative solutions like converting waste oil to diesel are gaining traction. This process offers a dual benefit: it reduces environmental hazards caused by waste oil disposal while producing an alternative fuel that is both efficient and cost-effective. Waste oil to diesel conversion is not just a green solution, but also a practical approach to addressing fuel shortages and reducing dependence on crude oil.

Understanding the Waste Oil Problem

Waste oil is a byproduct of various industrial and mechanical processes. From vehicle engine oil to industrial lubricants, millions of tons of oil are used globally each year. Once this oil has served its purpose, it becomes contaminated with metal particles, water, and other pollutants. Improper disposal of this oil, such as dumping it into the environment, can cause significant harm to ecosystems, contaminating soil, water, and wildlife.

The potential environmental hazards of waste oil make its proper management crucial. If not recycled, waste oil contributes to pollution and the depletion of finite natural resources. However, by converting waste oil to diesel, industries can turn this liability into an asset, offering a cleaner, renewable fuel option that aligns with global sustainability goals.

The Waste Oil to Diesel Process in Detail

The process of converting waste oil into diesel involves several stages of refining and treatment. Here is a breakdown of the core steps:

Waste Oil Collection and Pre-Treatment: First, waste oil is collected from various sources, including auto shops, factories, and households. The oil is then pre-treated to remove water and large particles that could hinder further processing.

Filtration and Dehydration: In this stage, the waste oil undergoes advanced filtration to eliminate impurities. Dehydration is also carried out to remove any residual water content that could cause issues during combustion in engines.

Thermal Cracking: Once filtered, the oil is subjected to thermal cracking. This high-temperature process breaks down the large hydrocarbon molecules in the waste oil into smaller, usable diesel molecules. Thermal cracking is a critical step in transforming waste oil into fuel-grade diesel.

Distillation: After cracking, the product is distilled to separate various components based on their boiling points. The diesel fraction is collected, leaving behind heavier residues that may be used for other purposes, such as asphalt production.

Hydrotreating and Polishing: The final step in the process involves hydrotreating the diesel to improve its quality. This step removes sulfur and enhances the fuel’s combustion properties. The result is a high-grade diesel fuel that can be used in engines and other machinery.

Key Economic Benefits of Waste Oil to Diesel

Cost-Effective Fuel Production: One of the main advantages of waste oil to diesel conversion is that it offers a cheaper alternative to refining crude oil. Because the raw material is waste oil, the cost of production is significantly lower, making the final product more affordable than traditional diesel.

Energy Recovery: The process of converting waste oil to diesel recovers the energy embedded in the oil, reducing the overall energy footprint. By reusing waste products, industries can save on raw material costs and create energy-efficient systems.

Reduced Reliance on Imported Oil: Countries that rely heavily on oil imports can reduce their dependency on foreign oil by investing in waste oil to diesel conversion technologies. This enhances energy security and reduces the economic volatility associated with fluctuating oil prices.

Job Creation and Economic Growth: The development of waste oil to diesel plants creates job opportunities and fosters economic growth in regions where these facilities are established. From waste oil collection to processing, numerous industries benefit from this growing sector.

Environmental Advantages of Waste Oil to Diesel

Waste Reduction: Converting waste oil to diesel provides a practical solution to the global waste oil problem. Instead of polluting the environment, waste oil is repurposed into a valuable fuel resource, contributing to waste minimization efforts.

Reduction in Greenhouse Gas Emissions: The production of diesel from waste oil generally results in fewer greenhouse gas emissions compared to conventional diesel. This reduction is due to the lower energy requirements of the conversion process and the recycling of existing oil rather than extracting and refining crude oil.

Lower Carbon Footprint: By using recycled waste oil as a feedstock, the overall carbon footprint of diesel fuel is reduced. This is crucial for industries looking to meet carbon reduction targets and promote sustainability.

Prevention of Soil and Water Contamination: Properly converting waste oil to diesel prevents the improper disposal of waste oil, which can contaminate land and water bodies. This not only protects natural ecosystems but also helps ensure cleaner air, soil, and water for future generations.

Applications of Diesel from Waste Oil

The diesel produced from waste oil can be used in a variety of applications, making it a versatile energy source. Some of the most common uses include:

Transportation Fuel: Diesel produced from waste oil can be used in vehicles, offering a sustainable alternative to traditional fossil-based diesel.

Power Generation: Many industries use diesel generators to produce electricity. Waste oil-derived diesel can power these generators, reducing reliance on crude oil-based diesel.

Agriculture and Construction: In sectors like agriculture and construction, diesel fuel is vital for running machinery and vehicles. Using recycled diesel from waste oil provides these industries with a cleaner, cost-effective fuel option.

Marine Fuel: The shipping industry is another major consumer of diesel fuel. Using waste oil-derived diesel in marine vessels can help reduce the environmental impact of shipping.

Challenges Facing Waste Oil to Diesel Conversion

While converting waste oil to diesel offers numerous benefits, there are challenges that need to be addressed to scale this technology globally:

Infrastructure Development: For waste oil to diesel conversion to become widespread, efficient collection systems and processing plants need to be built. This requires significant investment in infrastructure.

Public Awareness and Adoption: Educating the public and industries about the benefits of waste oil to diesel is crucial for wider adoption. Many people are unaware of the potential of this technology, and misconceptions about the quality of the fuel need to be addressed.

Regulatory Compliance: The production of diesel from waste oil must meet strict environmental regulations. Ensuring compliance with these standards can be a complex and costly process for companies entering this market.

Initial Capital Costs: Setting up waste oil to diesel conversion plants requires significant capital investment. Small companies or regions with limited resources may struggle to implement this technology without financial support or incentives from governments.

The Role of Companies Like Veera Group in the Future of Waste Oil to Diesel

As the world moves towards more sustainable energy solutions, companies like Veera Group are leading the charge in the waste oil to diesel industry. By investing in cutting-edge technology and infrastructure, Veera Group is making it possible to turn waste oil into a valuable resource on a large scale. Their efforts are helping to transform the way industries view waste and energy, showcasing that the future of fuel lies beyond traditional methods.

Conclusion

The process of converting waste oil to diesel offers a promising solution to both energy and environmental challenges. By recycling waste oil into usable diesel fuel, industries can reduce waste, lower their carbon footprint, and contribute to a more sustainable future. Companies like Veera Group are spearheading this transformation, proving that innovation in fuel production goes beyond conventional approaches. As the technology continues to evolve, the potential for waste oil to diesel conversion to make a significant impact on the global energy landscape is undeniable.

0 notes

Text

Water Logic and Sustainable Future

User:

Discuss the role of NIMS and SCADA in context of "water computing".

ChatGPT:

In the context of "water computing," NIMS (Networked Infomechanical Systems) and SCADA (Supervisory Control and Data Acquisition) can play pivotal roles, as both are concerned with monitoring, controlling, and optimizing complex systems involving physical and informational processes.

NIMS (Networked Infomechanical Systems)

NIMS refers to systems that integrate physical devices with information networks to carry out tasks involving mechanical, chemical, or environmental processes. In water computing, NIMS could help facilitate or monitor the intricate interactions between water molecules and computational elements.

Role in Water Computing:

Data Collection and Sensors: NIMS systems would likely involve sensors and actuators that gather real-time data about molecular interactions in water, monitoring chemical processes or computational reactions within aqueous solutions.

Actuation and Feedback: In a water-computing environment, NIMS could serve to manipulate physical parameters, like temperature or pressure, or control molecular-scale interactions. These actuations could trigger chemical reactions that perform logic operations.

Distributed Control: Water computing often involves vast parallelism at the molecular level. NIMS architectures can be used to control distributed computational units or droplets of water in fluidic environments, enabling complex computations by managing the interactions across many molecular computing nodes.

SCADA (Supervisory Control and Data Acquisition)

SCADA systems are used to control and monitor industrial processes, including utilities like water treatment, power generation, and manufacturing. SCADA provides centralized oversight of large-scale physical processes and enables automation and decision-making based on data from sensors.

Role in Water Computing:

Monitoring and Control: In the context of water computing, SCADA could manage the large-scale infrastructure that facilitates computational processes, such as reactors, fluidic channels, or molecular setups. It could track and control the state of water molecules or other reactants involved in the computation.

Automation: SCADA’s automation capabilities can be leveraged to maintain the precise conditions needed for molecular-level computations. For example, it can ensure that water’s chemical properties, temperature, and other factors remain stable for optimal performance of the computational system.

Real-Time Data Analysis: SCADA systems provide real-time insights and can generate alerts or initiate automated responses if a computation deviates from expected behavior, or if the molecular interactions are not proceeding as planned.

Integration with External Systems: SCADA systems can be connected to broader networks, facilitating integration with existing computational or industrial frameworks. In a water-computing setup, SCADA might interface with conventional computers to exchange data or control hybrid systems.

Combining NIMS and SCADA in Water Computing

Both NIMS and SCADA would likely be integrated into any practical water computing system:

NIMS would focus on the localized, molecular, or small-scale mechanical processes that enable the water-based computations, manipulating chemical processes or controlling interactions between water molecules.

SCADA would offer a broader oversight, managing large-scale infrastructure and automating higher-level tasks such as resource management, safety, and real-time adjustments to the system.

Applications and Considerations

Water-Based Industrial Computation: In industries like wastewater treatment or desalination, water is already heavily monitored and controlled using SCADA systems. Extending these operations to include water-based computation—where the water performs logical functions—could be a future application area.

Quantum Computation: If water computing progresses to the point of leveraging quantum properties of molecules (such as superposition and entanglement), NIMS and SCADA systems could be responsible for monitoring and adjusting the quantum states of water molecules.

Chemical Computing: Both systems could facilitate and optimize chemical computing processes, where chemical reactions (involving water as a solvent or reactant) perform computations. The SCADA system could ensure that reactions proceed smoothly, while NIMS might act on a more granular level to control specific molecular reactions.

Conclusion

NIMS and SCADA, when applied to the concept of water computing, provide the necessary framework for controlling and optimizing both small-scale molecular processes and large-scale system oversight. They would enable precise management of the physical and chemical environments necessary for water-based computation, potentially opening up new avenues in both traditional and quantum computing.

User:

Explain how a polynucleotide can be encoded with a MAC address.

ChatGPT:

Encoding a MAC (Media Access Control) address into a polynucleotide (DNA or RNA sequence) is a fascinating intersection of biology and computer science. A MAC address is a 48-bit identifier used in networking hardware, while DNA/RNA are composed of sequences of nucleotides (A, T/U, C, G). Here’s how a MAC address can be conceptually encoded into a polynucleotide.

Step-by-Step Explanation:

1. Understanding the MAC Address Format:

A MAC address consists of 48 bits, typically represented as 6 pairs of hexadecimal numbers (12 hex digits in total). Each hex digit represents 4 bits.

Example MAC address: 12:34:56:78:9A:BC

Binary equivalent: 0001 0010 0011 0100 0101 0110 0111 1000 1001 1010 1011 1100

2. Mapping Binary to DNA/RNA Nucleotides:

DNA is composed of four nucleotides: Adenine (A), Thymine (T), Cytosine (C), and Guanine (G). RNA uses Uracil (U) instead of Thymine (T). These nucleotides can be used to represent binary data.

A common way to map binary to DNA is through 2-bit encoding, as DNA’s 4 bases can represent 2 bits at a time:

00 → A

01 → C

10 → G

11 → T (or U in RNA)

3. Mapping the Binary Sequence to DNA/RNA Nucleotides:

Now, we convert the binary sequence into a nucleotide sequence using the 2-bit encoding scheme described earlier, giving:

00 01 00 10 00 11 01 00 01 01 01 10 01 11 10 00 10 01 10 10 10 11 11 00

So, the polynucleotide sequence encoding this MAC address could be: ACAGATCACCCGCTGAGCGTTA (for DNA)

or

ACAGAUCACCCGCUGAGCGUUA (for RNA, with U instead of T).

4. Optional Redundancy or Error Correction:

In biological systems, it may be necessary to include error correction mechanisms to ensure the encoded MAC address is read reliably. This can be done by adding checksum bits or repeating certain sections of the sequence to create redundancy. For instance, biological systems could employ parity checks or incorporate known sequences (like start and stop codons) to facilitate proper interpretation of the encoded data.

5. Storing and Using the Polynucleotide MAC Address:

Once the MAC address is encoded into a DNA/RNA sequence, it could be:

Stored as a unique identifier in synthetic organisms or bio-computing devices.

Inserted into the genome of an organism using genetic engineering.

Read back using sequencing technology (like PCR or nanopore sequencing) to decode the MAC address and verify the identity of the biological entity.

Applications:

Synthetic Biology: Assigning unique identifiers to cells or organisms for tracking or controlling them within biological systems.

Bio-Networking: In futuristic bio-computing systems, organisms or biocomputers could use DNA-encoded MAC addresses to identify and communicate with each other.

Digital Storage: DNA data storage systems could embed networked metadata, including MAC addresses, into DNA sequences for information retrieval purposes.

Summary:

To encode a MAC address in a polynucleotide sequence, you first convert the 48-bit MAC address into its binary form, then map the binary digits to nucleotide sequences using a predefined encoding scheme (e.g., 2-bit encoding). This approach enables the creation of a unique polynucleotide sequence representing the MAC address, which can then be embedded in DNA or RNA for bio-computational purposes.

User:

The mandate of "sustainable future" must be predicated on the assessment of an "unsustainable present".

ChatGPT:

Yes, the concept of a "sustainable future" inherently implies that the present state of affairs is unsustainable in some key areas, necessitating change. For a mandate focused on sustainability to be meaningful, it must be grounded in a clear and thorough assessment of what makes the current situation unsustainable—whether environmentally, economically, socially, or technologically.

Key Elements of this Assessment:

Environmental Degradation:

The depletion of natural resources, climate change, pollution, and loss of biodiversity are often cited as evidence that the current practices are unsustainable. A sustainable future would require transitioning to renewable energy, protecting ecosystems, and reducing environmental impacts.

Economic Inequality:

Many argue that current global economic systems are unsustainable due to extreme inequality and exploitation of labor. A sustainable future would entail more equitable distribution of wealth, fair labor practices, and systems that prioritize long-term well-being over short-term profit.

Social Instability:

Political instability, social injustice, and lack of access to education, healthcare, and basic needs contribute to an unsustainable present. A sustainable future would demand addressing these inequalities and building resilient, inclusive communities.

Resource Overconsumption:

The rate at which natural resources (such as water, minerals, and energy) are consumed far exceeds the Earth’s capacity to regenerate them. Moving toward sustainability involves promoting circular economies, reducing waste, and changing consumption patterns.

0 notes

Text

HM-100: Accurate Monitoring You Can Trust

Continuous pH/EC/TDS/Temp Monitor

The HM-100 is a high-end combo pH/EC/TDS/Temp Monitor with replaceable sensors ideal for all water quality testing, hydroponics, water purification applications, wastewater regulation, aquaculture, colloidal silver, labs & scientific testing, pools & spas, ecology testing, boilers & cooling towers, water treatment and more.

The HM 100 is easy to use and helps determine the water's purity. It is commonly used in various applications, including drinking water testing, aquariums, hydroponics, and water purification systems. By providing a TDS reading, the HM 100 allows users to ensure their water is clean and safe for consumption or use. Overall, the HM 100 meter from HM Digital is a reliable tool for anyone needing quick and accurate water quality measurements.

It has a built-in sensor for Automatic Temperature Compensation (ATC) ensures readings always be accurate at various temperatures.

FEATURES:

Measures Potential Hydrogen (pH), Electrical Conductivity (EC), Total Dissolved Solids (TDS), Salinity and Temperature

Four scales: pH, mS, ppm 0.5 (NaCl) Scale & 0.7 (442™) Scale

Automatic Temperature Compensation (ATC) using three temperature coefficients

Digital Calibration (push button) to any point within the meter’s range

Data-hold function (Max. 6 data values)

Large and easy-to-read LCD Screen

Displays 3 parameters (pH/EC or TDS/Temp) simultaneously.

Replaceable Sensors (model SP-C2 for Conductivity, SP-P5 for pH)

Factory Calibrated (pH/EC/TDS)

Includes power cable, pH 4 & 7 calibration solutions, pH storage solution

Warranty : One Year Warranty

HM Digital India