#Point of Use Water Treatment Systems Industry

Explore tagged Tumblr posts

Text

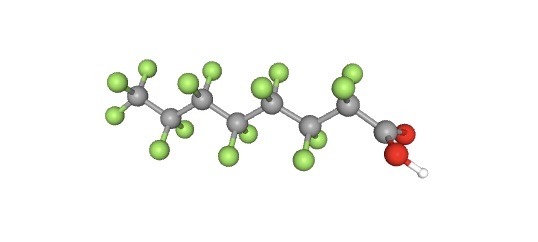

You guys have probably heard that the EPA just set new Maximum Contaminant Levels (MCLs) for the first time in decades for PFAS, which is BIG news in the industry, but not a surprise. I've been in meetings for months hearing about how new PFAS regulations were in the works, and the consensus in the environmental sector is that it's long overdue. But for the rest of you who've never heard of PFAS before I can break down what the big issues are and why they've taken so long to address.

^stolen from pubchem

So PFAS stands for per- and poly- flouroalkyl substances, and it's not one chemical compound, but an entire class of thousands of chemicals that have these chains of Carbon and Flourine atoms. For anybody who doesn't have a chem background fluorine is a nasty atom, it has seven electrons in its valence shell and it will do anything to fill it up to eight, creating incredibly strong bonds.

So you have really strong C-F bonds and these chains of C and F atoms are hydrophobic, which means these compounds are durable and water resistant, which makes them great for all sorts of industrial uses. And we've used them in everything: clothing, fast food wrappers, paints, solar panels, and non-stick pans just to start.

Unfortunately, these wonder chemicals are PBTM- Persistent, Bioaccumulative, Toxic, and Mobile. They don't break down, they build up in the food chain, they have adverse health effects, and even though C-F chains are hydrophobic, additional compounds connected to them can make them soluble in water (so they're in our drinking water). We're starting to realize PFAS can raise cholesterol, inhibit immune response, interfere with your thyroid (part of your hormonal system), cause liver toxicity, is linked to cancer, and more!

At this point you're probably starting to think wtf, how did we allow the continued widespread use of these chemicals? Well, we have phased out quite a few high profile PFAS compounds including PFOA and PFOS, but we still want to regulate and test for them in our drinking water. While PFAS is in many different products, the biggest sources of contamination are industrial runoff, areas where fire fighting foams were tested and used, landfills that leach out PFAS into the surrounding area, and wastewater treatment plants. So don't feel too stressed about eating microwave popcorn or using nail polish.

The reason these regulations took so long to implement was because of how difficult it was to connect such small amounts of PFAS with health hazards. The level of concern for PFAS is extremely low- in the ppt (parts per trillion) range. When I sample for contaminants I'm generally testing in the ppm range and higher, for PFAS we're looking an entire scale lower. We literally did not have the technology before the last few decades to detect PFAS in the ppt range in water, let alone study their effects (you can't just impose massive regulations without any proof to back it up).

States that currently have PFAS limits in drinking water have mostly capped it in the 10-70 ppt range. The new MCLs are 4-10 ppt for the six PFAS compounds the EPA addressed, which are six of the most common and most studied PFAS compounds. Most of the bitching I've seen is about how much this will cost and that the new limits are too low. The conservative take on this is that there isn't enough evidence to support such low MCLs, although most people in the environmental industry feel that more and more research keeps coming out and will keep coming out (remember studying such small amounts of anything is difficult) to support these levels. On the other side of the spectrum, there's the consensus that this is just the beginning and that more and more regulations on PFAS will be needed.

And they're in the works! I saw a proposed rule by the EPA that would ban 12 (already defunct) PFAS substances from pesticides. It wouldn't really affect the current manufacturing of pesticides, but it would be a safeguard from letting them back into the manufacturing process in case of a conservative presidency.

If you're still here I'd like to end on the note that as our science improves, our understanding of how we have impacted the environment and our health will improve. We are constantly going to find out about the adverse effects of new chemicals or things that we may not even produce anymore, and that's a good thing. Over time we are going to make the world a healthier and safer place.

#PFAS#if the boomers were the lead poisoning generation then were the pfas and microplastics generation#chemistry#geology#science#environment#long post

70 notes

·

View notes

Text

Damages to Physical Structures Estimated at $18.5 billion as of end January

WASHINGTON, April 2, 2024 – The cost of damage to critical infrastructure in Gaza is estimated at around $18.5 billion according to a new report released today by the World Bank and the United Nations, with financial support of the European Union. That is equivalent to 97% of the combined GDP of the West Bank and Gaza in 2022. The Interim Damage Assessment report used remote data collection sources to measure damage to physical infrastructure in critical sectors incurred between October 2023 and end of January 2024. The report finds that damage to structures affects every sector of the economy. Housing accounts for 72% of the costs. Public service infrastructure such as water, health and education account for 19%, and damages to commercial and industrial buildings account for 9%. For several sectors, the rate of damage appears to be leveling off as few assets remain intact. An estimated 26 million tons of debris and rubble have been left in the wake of the destruction, an amount that is estimated to take years to remove.

The report also looks at the impact on the people of Gaza. More than half the population of Gaza is on the brink of famine and the entire population is experiencing acute food insecurity and malnutrition. Over a million people are without homes and 75% of the population is displaced. Catastrophic cumulative impacts on physical and mental health have hit women, children, the elderly, and persons with disabilities the hardest, with the youngest children anticipated to be facing life-long consequences to their development.

With 84% of health facilities damaged or destroyed, and a lack of electricity and water to operate remaining facilities, the population has minimal access to health care, medicine, or life-saving treatments. The water and sanitation system has nearly collapsed, delivering less than 5% of its previous output, with people dependent on limited water rations for survival. The education system has collapsed, with 100% of children out of school.

The report also points to the impact on power networks as well as solar generated systems and the almost total power blackout since the first week of the conflict. With 92% of primary roads destroyed or damaged and the communications infrastructure seriously impaired, the delivery of basic humanitarian aid to people has become very difficult.

The Interim Damage Assessment Note identifies key actions for early recovery efforts, starting with an increase in humanitarian assistance, food aid and food production; the provision of shelter and rapid, cost-effective, and scalable housing solutions for displaced people; and the resumption of essential services.

About the Gaza Interim Damage Assessment Report The Gaza Interim Damage Assessment report draws on remote data collection sources and analytics to provide a preliminary estimate of damages to physical structures in Gaza from the conflict in accordance with the Rapid Damage & Needs Assessment (RDNA) methodology. RDNAs follow a globally recognized methodology that has been applied in multiple post-disaster and post-conflict settings. A comprehensive RDNA that assesses economic and social losses, as well as financing needs for recovery and reconstruction, will be completed as soon as the situation allows. The cost of damages, losses and needs estimated through a comprehensive RDNA is expected to be significantly higher than that of an Interim Damage Assessment.

34 notes

·

View notes

Text

WASHINGTON, April 2, 2024 – The cost of damage to critical infrastructure in Gaza is estimated at around $18.5 billion according to a new report released today by the World Bank and the United Nations, with financial support of the European Union. That is equivalent to 97% of the combined GDP of the West Bank and Gaza in 2022. The Interim Damage Assessment report used remote data collection sources to measure damage to physical infrastructure in critical sectors incurred between October 2023 and end of January 2024. The report finds that damage to structures affects every sector of the economy. Housing accounts for 72% of the costs. Public service infrastructure such as water, health and education account for 19%, and damages to commercial and industrial buildings account for 9%. For several sectors, the rate of damage appears to be leveling off as few assets remain intact. An estimated 26 million tons of debris and rubble have been left in the wake of the destruction, an amount that is estimated to take years to remove. The report also looks at the impact on the people of Gaza. More than half the population of Gaza is on the brink of famine and the entire population is experiencing acute food insecurity and malnutrition. Over a million people are without homes and 75% of the population is displaced. Catastrophic cumulative impacts on physical and mental health have hit women, children, the elderly, and persons with disabilities the hardest, with the youngest children anticipated to be facing life-long consequences to their development. With 84% of health facilities damaged or destroyed, and a lack of electricity and water to operate remaining facilities, the population has minimal access to health care, medicine, or life-saving treatments. The water and sanitation system has nearly collapsed, delivering less than 5% of its previous output, with people dependent on limited water rations for survival. The education system has collapsed, with 100% of children out of school. The report also points to the impact on power networks as well as solar generated systems and the almost total power blackout since the first week of the conflict. With 92% of primary roads destroyed or damaged and the communications infrastructure seriously impaired, the delivery of basic humanitarian aid to people has become very difficult. The Interim Damage Assessment Note identifies key actions for early recovery efforts, starting with an increase in humanitarian assistance, food aid and food production; the provision of shelter and rapid, cost-effective, and scalable housing solutions for displaced people; and the resumption of essential services. About the Gaza Interim Damage Assessment Report The Gaza Interim Damage Assessment report draws on remote data collection sources and analytics to provide a preliminary estimate of damages to physical structures in Gaza from the conflict in accordance with the Rapid Damage & Needs Assessment (RDNA) methodology. RDNAs follow a globally recognized methodology that has been applied in multiple post-disaster and post-conflict settings. A comprehensive RDNA that assesses economic and social losses, as well as financing needs for recovery and reconstruction, will be completed as soon as the situation allows. The cost of damages, losses and needs estimated through a comprehensive RDNA is expected to be significantly higher than that of an Interim Damage Assessment.

21 notes

·

View notes

Note

vegan radfems are so annoying I literally do not care

I like that vegans exist. I can also in some cases see the connection to feminism and the treatment of women/female animals as a whole (chauvinist attitudes around meat eating being correlated with misogyny, and how we create constant reproduction in farm animals in a way that is terrible for their bodies), although I don't really think that animal rights is a question for feminism to solve or focus on, rather maybe animal activist sub groups. I've been vegetarian for long periods (several years at a time) and cook vegan meals from time to time. But I can't seem to feel full when I don't eat any meat or fish so I ended up eating way more bread/sugar and gaining weight, and I've also developed some deficiencies (iron, primarily). I know you can avoid a lot of deficiencies even on a vegan diet, but it takes a lot more work and energy.

What I don't like is the aggression and immediate defensiveness. And I don't like the argument that some humans are braindead or have developmental disabilities and if we eat animals because they're "dumber" then nothing should stop us from eating those humans. Because if your point is "we can't eat living beings even if they don't have human intelligence" then what is actually okay to eat? I don't like being met with aggressive and extremely ridiculous arguments like that. And I know it's been said a million times in bad faith, but honestly, why is eating plants okay? We know that plants react to stimuli like light and resources like water, and we also know that many species of plants also react to being damaged. Trees warn each other with stress signals when they're "injured", so is pruning and cutting fruit trees okay just because we can't see these signals of stress without sophisticated technology? How come? If the argument against mine is that we don't kill and eat disabled people even if they're developmentally on the cognitive level of a child or even an animal (for example, pigs are generally thought to have the intelligence level of a 4 year old child), then where is the cutoff? Plants don't have central nervous systems, is that the cutoff? Can we farm and eat insects? Both of these options still have some kind of survival instinct. What makes them okay to eat?

The people who say these things aren't jainists even if they're vegan. I don't like it when vegans make the point that meat eaters are simply making emotional arguments like "I want to keep eating meat because it tastes good" when SOME amount of farming and killing is fine and necessary to vegans too. We're learning new things about animals AND plants every day. Some plants like certain species of fungi even seem to have some sort of reasoning and strategy in their patterns of growth. The arguments for eating plants are also emotional because you need to eat something to survive. What I think is a strong argument is the minimization of suffering, because those stress signals simply aren't as important as the much more obvious and material suffering of mass factory farmed animals. And also minimizing detrimental environmental effects. But that argument requires differentiation between sufferings. You have to recognize, confess almost, that some suffering is worse than other kinds. Which was my point from the beginning, a human can be cognitively aware of certain things in a way that creates terror that simply isn't present in another creature in the same way, which is why I don't think targetting those specific emotions/thoughts in an audience is the smartest idea depending on your goal.

My point has always been that the act of eating in itself can't be unethical. Eating is not morally wrong. We as a species evolved to be omnivores, so it's not unnatural or unethical to eat meat in itself. Many species are predatory. I will never be convinced that meat eating in itself is morally reprehensible. What I think is bad about the meat industry has to do with the treatment of the animals, and the effect such farming has on the environment, and the public health issue of too much meat consumption.

12 notes

·

View notes

Note

What are your opinions on fertilizer runoff from industrial farming? Its ingredients such as phosphate and nitrogen can facilitate algae blooms, which in turn can cause artificial eutrophication, and or release toxins like microcystins.

My opinions are mixed! Also, this is a long post, so I've put the rest under a keep reading. Please do read! I just don't want to fill people's dashes with a long post every time they scroll lol.

Firstly, I need to say that if we were to broadly ban or heavily restrict fertiliser usage in agriculture, it is undeniable that the agriculture economy would collapse. Most industrialised farming is incentivised to sell the 'ideal products' to consumers, which inevitable means a shitload of food production in order to get the highest amounts of 'perfect' product. This requires a lot of fertiliser usage in order to mass produce and harvest monoculture farmland, and also results in a LOT of food waste. Unfortunately, the agricultural economy, combined with the half century of brainwashing by advertising companies telling people that so called 'blemished' food is somehow bad for you, is so based on this excess that if we did immediate drastic action, it would implode and likely send the prospective country into a recession.

With that being said, the system of heavy use of fertiliser is still not good!! Fertiliser runoff causes eutrophication as you point out, and can lead to toxic algal blooms, or even oxygen dead zones further down stream. However, it is not solely the use of fertiliser products that contribute to fertiliser run-off, as contradictory as that sounds. In fact, soil quality has a large part to play in the production of run-off.

For example, most modern agriculture uses monoculture, which is when one plant species is grown in the same place with little to no diversity in the field. A result of this is that only a single type of root system is grown, which is not enough for a healthy layer of topsoil to develop, especially if it is tilled and plowed every season. This means that the soil is very poor at retaining water, meaning that it requires LOTS of irrigation. With lots of irrigation, the fertiliser nutrients can't stay in the soil long enough to be absorbed by the plants fully, and they get washed away and have to be constantly topped up.

If we used less monoculture in our farming, we could use less fertiliser and still gain the same benefit, with also less runoff, which would be ideal!

I would also note a few things, namely that fertiliser runoff is not the only source of nutrient pollution from farming, and especially in places that have heavy cattle farming like my country, nitrates and phosphates from stock effluent is more of a problem. Cows shitting near streams is a big problem, and can be mitigated by proper filtering and nutrient-recovery technologies. One of these that I think is a big winner in terms of green technology wastewater treatment are Floating Treatment Wetlands, which are essentially artificial wetlands that are engineered to be part of wastewater treatment, and also provide habitats for birds and insects at the same time.

17 notes

·

View notes

Text

The “death map” tells the story of decades of sickness in the small northwest New Mexico communities of Murray Acres and Broadview Acres. Turquoise arrows point to homes where residents had thyroid disease, dark blue arrows mark cases of breast cancer, and yellow arrows mean cancer claimed a life.

Neighbors built the map a decade ago after watching relatives and friends fall ill and die.

Dominating the top right corner of the map, less than half a mile from the cluster of colorful arrows [...] : 22.2 million tons of uranium waste left over from milling ore to supply power plants and nuclear bombs. “We were sacrificed a long time ago,” said Candace Head-Dylla, who created the death map with her mother after Head-Dylla had her thyroid removed and her mother developed breast cancer. [...]

Beginning in 1958, a uranium mill owned by Homestake Mining Company of California processed and refined ore mined nearby. The waste it left behind leaked uranium and selenium into groundwater and released the cancer-causing gas radon into the air.

State and federal regulators knew the mill was polluting groundwater almost immediately after it started operating, but years passed before they informed residents and demanded fixes. [...]

---

Uranium mining and milling left a trail of contamination and suffering, from miners who died of lung cancer while the federal government kept the risks secret to the largest radioactive spill in the country’s history. But for four decades, the management of more than 250 million tons of radioactive uranium mill waste has been largely overlooked, continuing to pose a public health threat. [...] At Homestake, which was among the largest mills, the company is bulldozing a community in order to walk away. Interviews with dozens of residents, along with radon testing and thousands of pages of company and government records, reveal a community sacrificed to build the nation's nuclear arsenal and atomic energy industry. [...]

In 2014, an EPA report confirmed the site posed an unacceptable cancer risk and identified radon as the greatest threat to residents’ health. Still, the cleanup target date continued shifting, to 2017, then 2022. Rather than finish the cleanup, Homestake’s current owner, the Toronto-based mining giant Barrick Gold, is now preparing to ask the Nuclear Regulatory Commission, the independent federal agency that oversees the cleanup of uranium mills, for permission to demolish its groundwater treatment systems and hand the site and remaining waste over to the U.S. Department of Energy to monitor and maintain forever. Before it can transfer the site to the Department of Energy, Homestake must prove that the contamination, which exceeds federal safety levels, won’t pose a risk to nearby residents [...].

Part of Homestake’s strategy: buy out nearby residents and demolish their homes. [...] Property records reveal the company had, by the end of 2021, purchased 574 parcels covering 14,425 acres around the mill site. This April, Homestake staff indicated they had 123 properties left to buy. One resident said the area was quickly becoming a “ghost town.”

---

Even after the community is gone, more than 15,000 people who live nearby, many of them Indigenous, will continue to rely on water threatened by Homestake’s pollution. [...]

At the state level, New Mexico regulators waited until 2009, 49 years after first finding water pollution, to issue a formal warning that groundwater included substances that cause cancer and birth defects. [...] Other uranium mines and mills polluted the area’s main drinking water aquifer upstream of Homestake. [...]

More than 500 abandoned uranium mines pockmark the Navajo Nation [...].

Leaders of communities downstream from Homestake, including the Pueblo of Acoma, fear that wishful thinking could allow pollution from the waste to taint their water. The Acoma reservation, about 20 miles from Homestake’s tailings, has been continuously inhabited since before 1200. Its residents use groundwater for drinking and surface water for irrigating alfalfa and corn, but Donna Martinez, program coordinator for the pueblo’s Environment Department, said the pueblo government can’t afford to do as much air and water monitoring as staff would like. [...]

Most days, Billiman contemplates this “poison” and whether she and Boomer might move away from it [...]. “Then, we just say ‘hózho náhásdlii, hózho náhásdlii’ four times.” “All will be beautiful again,” Boomer roughly translated. [...] Now, as a registered nurse tending to former uranium miners, Langford knows too much about the dangers. When it’s inhaled, radon breaks down in the lungs, releasing bursts of radiation that can damage tissue and cause cancer. Her patients have respiratory issues as well as lung cancer. They lose their breath simply lifting themselves out of a chair.

---

Text by Mark Olalde and Maya Miller. “A Uranium Ghost Town in the Making.” ProPublica. 8 August 2022. [Some paragraph breaks and contractions added by me.]

84 notes

·

View notes

Text

MS Eccentric Reducer Manufacturer in Delhi, India: Udhhyog

In industrial piping systems, proper flow control is essential for efficient operations. An MS eccentric reducer plays a critical role in this, ensuring smooth transitions between different pipe sizes while preventing fluid buildup. If you're looking for a reliable MS eccentric reducer manufacturer in Delhi, India, Udhhyog is the trusted name you can count on. We specialize in manufacturing high-quality MS eccentric reducers at competitive prices, making us the go-to supplier for businesses across various industries.

What is an MS Eccentric Reducer?

An MS eccentric reducer is a pipe fitting used to connect pipes of different diameters while maintaining an offset alignment. Unlike concentric reducers, where the centerlines of both pipes are aligned, an eccentric reducer has one side flat, which helps avoid fluid accumulation at the lower part of the pipe. This feature is especially useful in applications where liquid buildup could create blockages or inefficiencies.

Key Features and Benefits of MS Eccentric Reducers

Optimized Fluid Flow: By maintaining an offset alignment, MS eccentric reducers ensure smooth transitions between pipes while preventing fluid or gas pooling at the bottom of the pipeline.

Cost-Efficient Solution: Made from mild steel, these reducers offer a budget-friendly solution for industries that need reliable and durable pipe fittings.

Durability: MS eccentric reducers are highly durable, capable of withstanding high pressure, extreme temperatures, and corrosion when coated properly.

Ideal for Horizontal Piping Systems: The eccentric design is particularly beneficial in horizontal piping systems, as it prevents liquid from settling at the pipe's lowest point.

Versatile Applications: MS eccentric reducers are widely used across several industries, including oil and gas, water treatment, chemical processing, and HVAC systems.

Applications of MS Eccentric Reducers

Oil and Gas Pipelines: In industries where fluid buildup can cause issues, MS eccentric reducers are essential for maintaining efficient fluid flow.

Water Treatment Systems: These reducers ensure that water flows smoothly without pooling in pipelines, reducing the chances of blockages.

Chemical Processing: In chemical industries, MS eccentric reducers are crucial for preventing unwanted fluid accumulation in pipelines.

HVAC Systems: MS eccentric reducers play a vital role in balancing airflow in heating, ventilation, and air conditioning systems by ensuring a steady flow in ducts of different sizes.

Why Choose Udhhyog as Your MS Eccentric Reducer Manufacturer?

At Udhhyog, we take pride in being one of the leading MS eccentric reducer manufacturers in Delhi, India. Here’s why businesses trust us for their industrial steel product needs:

Top-Notch Manufacturing Process: We use advanced manufacturing techniques to ensure that all our products, including MS eccentric reducers, meet industry standards for durability and performance.

Competitive Pricing: As a leading manufacturer, we provide high-quality products at the lowest prices in the market, helping businesses reduce their procurement costs.

Customized Solutions: At Udhhyog, we offer customized solutions tailored to meet the specific needs of our clients, ensuring the perfect fit for your piping system.

Extensive Product Range: Apart from MS eccentric reducers, we offer a wide range of other pipe fittings, flanges, and valves, making Udhhyog a one-stop shop for all your industrial steel needs.

Timely Delivery Across India: Based in Delhi, we cater to businesses all over India, ensuring quick and reliable delivery of products to industrial hubs and MSMEs alike.

Buy MS Eccentric Reducers from Udhhyog

Whether you're in need of MS eccentric reducers for oil and gas, water treatment, or HVAC applications, Udhhyog offers the best quality at the lowest prices. Our dedication to quality manufacturing, combined with our customer-first approach, ensures that you get the best value for your investment. Contact Udhhyog today for more information on our MS eccentric reducers and other pipe fittings.

#MSEccentricReducer#MSReducerManufacturer#IndustrialFittings#DelhiManufacturer#Udhhyog#BestPriceIndia#PipeFittings#SteelReducer#B2BManufacturer#EccentricReducerIndia

2 notes

·

View notes

Text

I've been thinking about old railway uniforms, and come to the conclusion that the textiles could be INTERESTING in a steampunk world.

If steam power is widespread and commonplace, that means that there's going to be plenty of steam piping and/or boilers around. A lot of it would probably be insulated for safety and efficiency, but that still probably means that a significant part of the population has to work around HOT steam-powered equipment fairly often. I don't think that EVERYONE would necessarily be going around in protective double denim, but I think there'd just be less demand for fabrics with worse heat resistance.

That probably means that textile innovation wouldn't focus so hard on inventing New materials; but rather on improving natural fabrics. With a focus on mechanical innovation, I think your steampunk inventor would have an ENORMOUS array of linkages available to them - for converting a continuous mechanical input to various complicated and adjustable movement patterns. I think that having a lot more workers in hot environments would also lead to wide-spread use of mechanical refrigeration.

I've seen a few videos of industrial fabric-handling machines - they seem to have a Lot spiky metal fingers making repetitive movements. I think a steampunk world would be GREAT at making those little fingers do different, interesting patterns of movement! I recently saw a Matt Parker video about a continuous lattice of 7 different directions of pencil, and there was a cool animation of its cross-section. Imagine the funky patterns you could weave with thread going in more than 2 directions - either coplanar with eachother or in 3d space. All the cool decorative patterns woodworkers can do with plywood and veneer - imagine that with thread!

One of the reasons that a lot of tradespeople wore denim was because the pattern of the fabric obscured oil and grease stains. Could you achieve the same effect with the above funky patterns if they were dense enough? SO many workwear fashion options. And if you've got hot steam on tap as well as decent refrigeration - heat treatment would be easy to incorporate. What sort of interesting features would they be heat-setting into their clothes?

And if you want to build any sort of articulated machine/robot with steam as the power source; you need something to carry that steam - a flexible, high-pressure, heat resistant pipe. That sounds like a braided hose to me - and if you're using more colourful metals than stainless steel, your steam plumbing could get COLOURFUL! You know how we have braided hoses with a red or blue strand for hot or cold water? JUST IMAGINE the industry standard colour coding schemes for different temperatures, pressures, and phases of various fluids they could have!

Colour coded flexible pressure hose reminds me of an electrical system - I wonder how a steampunk world would do mechanical calculation? Did someone say Convoluted Fluid Based Computers?? With advances in textiles, hoses, and ropes - surely at some point they'd invent wire or fibre-wrapped pressure vessels! (Just think what they'd do with carbon fibre!) A society with (admittedly probably building-sized) computers that's used to dealing with high-pressure fluids - SURELY they'd invent jet propulsion? Perhaps not for rockets or aircraft - imagine pressure-jet steampunk ships, submarines even.

Actually where I can see modern-ish chemical rocketry in a steampunk world is in miniature steam generators - either HO bipropellant (your choice of liquid or gaseous) or peroxide monopropellant. A vigorous chemical reaction with hot, fast H2O as the product - sounds like a (rather explosive) portable power source.

Anyways, TLDR i'd LOVE to see what technological innovations a steampunk world would have. What paths they'd go down for research.

2 notes

·

View notes

Text

Sheer Entitlement

Look. I've been called "Boomer", "Coomer" and every other stupid freaking word in the book. However, I'm no boomer, and frankly speaking I think the term "Coomer" is stupid as hell. But I need to discuss this and I know it will not be well received by some people.

Todays generations are royally entitled. And when it comes to Gen Z and Gen A I kind of don't blame them. Because while yes it's f*cked, the reason is because of Gen Y and Gen X. Though not fully.

What we are living through right now is the normalization of Communist ideology. Or rather, the propaganda that leads TO Communism. Which is, "The government should be in charge of everything, and give us everything because EVERYTHING literally is a human right". Except it's not. Your rights stop the moment it requires another persons labor to bring about. What do I mean by this? Scarcity is still a real world issue. And the only reason we have the stores of food we have is due to the labor of SEVERAL different sectors of industry.

The transportation industry. The machining industry. The farming industry, and so on. How do those industries thrive? Due to every other industry that makes it worth their time to do what they do. The local residents that make the water treatment systems work. The people to work on the grid. The people that make the petrol that makes all of that stuff work in general. Our countries require work and industry to survive. If no one works these jobs, there is nothing left. And lest people be FORCED to work these jobs, which under socialism and communism they WOULD be, everything we know and everything we have would crumble.

Frankly speaking, I can't blame the modern generations. We've allowed ourselves to be infiltrated by Commies and Socialists. What's more, it's often people who are well off, like Hasan Piker and his ilk. They complain about "Capitalism" while misrepresenting what it actually is. Every single time, blaming Capitalism for the problems not caused by the system in place, but my the government instead. Which fun fact if the government is the one causing the issue, why EXACTLY do you want more government control when THEY are the ones causing the issues? Then again, I already know why. Many of you assholes have expressed why. And the conversation goes as such:

"We want to turn the system on it's head"

"You realize you view the system as pyramid right? If you turn it on it's head said pyramid will shatter and crumble into a pile "Resembling" a pyramid"

"God your stupid. That's the point. We don't care about the bottom of the system. And people like you that try to view us in good faith are great for us. Of course we want the system to collapse by flipping it on its head. WE want to be on the top. F*ck everyone else."

^Those are the people you support. A system that want to look like this:

This is they system they want. The only grip they have is that not only are they not the ones at the very top, they also don't want mobility for others. They are selfish, greedy, and you prop them up believing "It's for the greater good". And "Oh well it's great to make EVERY THING a "Human Right". Healthcare is not a human right. Food is not a human right. Housing is not a human right. Because all of those things require the labor of others. If you are so pissed off about not having food, grow your own. Buy seeds at Walmart or Lowes. Get in home plants or just get pots to plant stuff in. Put it in the window or hang it outside.

And I've said this before but most people sadly become disillusioned by their friends and family or by social media. Often actually by social media more than not. Basically, a "Victim" of our own success. The better we make things the less effort has to be put into having a decent life. We live vastly better than even Royalty from decades ago. We have indoor plumbing and toilets. We have large refrigerators and freezers. We have strawberries year round. And other foods that would otherwise only exist seasonally. Our great grandparents probably worked 12-16 hr days. Between working on a farm or ranch. Potentially having a day job. Coming home to make repairs without fancy ass tools. Without Amazon. Having to wait for professionals to come out and fix something that could take days or longer. Maybe weeks.

We have it SO GREAT and honestly that might not be a good thing at all. People don't have to try anymore. You can literally make money now a days selling pictures of your f*cking feet. There are people that play games online and attempt to entertain people that make a KILLING. Things are so f*cking easy now. Does that mean it's easy for everyone? No. Does that mean that things are not difficult in their own way? No. But to pretend that the people that preceded us had it easier? They really didn't.

Which leads me to now. I honestly can't stand what we are seeing from people today. Everything is "oppressor" this and "Oppressed" that. It's "woe is me things are so hard". Yeah kindly tell that to some of your parents that worked 2 jobs just so you could turn in to an entitled socialist. And that's what most of the people today are. Even if they don't know it. "Every thing should be free". No. Everything should not be free. People deserve to see the fruits of their own labor. Not to be pressured into giving up what they have for other people who don't WANT to work.

Which leads me to my last point. Stop demanding stuff of free. Start teaching your kids the meaning of work. And it's worth. But more than that, start taking them off social media, and teach them the things you know. Teach them how to cook. Teach them how to clean, teach them how to build things. Teach them how to file taxes. Teach them the things they need to know to be prepared for life in the future. And also. FOR THE LOVE OF GOD, educate your kids on why government interference in the market on BELHALF of multinational corporations is NOT capitalism. It's Corporatism. And when you just fork more and more power to the government you get the picture I posted above.

We need to start sanding down entitled behavior. People need to learn the value of work. They need to realize that. More over, they need to not replace religion in their lives with cult like belief in failed political ideologies. So many of us really have no idea how good we have it. And some of us that do want to see our country crumble because, "We've had it too good for too long". Yeah, I'm actually mostly fine with that. Because if let things crumble, how many people die in that process? Too many. How many people die if we BOW to climate alarmism? Too many. How many people die if we adopt Communism or Socialism? Too many.

And lastly. Teach your kids common sense. And teach them to stop chasing clout. Why? Look at what's going on now. Look at the "Rage" supporting that Palestinian people. Meanwhile the Uighur Muslims are being raped daily, sterilized, beaten, forced into reeducation, and forced to do labor for things coming out of China. NOT! A! F*CKING! PEEP from these same people. Because it's about hate (for a certain group of people) and it's about clout. If nothing else? Teach your kids to be consistent and teach them critical thinking. We really need to offset the current issues we are having today. BADLY. Anyways. I'm done ranting about this. It's already too long.

5 notes

·

View notes

Text

STEPS ON HOW TO SET UP A DIALYSIS CENTER

People often think setting up a Dialysis center is rocket science, even if they have been in the healthcare industry for a long time. Well, I would just say, you need an expert to guide you. Beyond setting up a Dialysis center, you need to be guided on how to stay profitable while offering quality care.

We have managed the set-up of over 60 Dialysis centers in Nigeria, Ghana, and Liberia. I currently have new projects in Zimbabwe, Ethiopia, and Sierra Leon and I can tell you this for free, talk to an expert or consultant. These steps I am giving you will not be enough. The real work will not even be in setting up a Dialysis center but in staying profitable and scaling the business. There are usually so many pros and cons involved, and you need someone to guide you through it all.

THESE ARE THE STANDARD STEPS WE RECOMMEND AT MEDPAU INTERNATIONAL LIMITED

1. Consultation: Whether you are involved in the medical profession, or a business tycoon looking to invest in the healthcare sector, the first step to go about setting up a dialysis center is speaking to an expert consultant. Consulting with a professional would provide you with the necessary guidance to establish a dialysis center of any size, from a single-bed dialysis center to a multiple-bed dialysis center, while considering your budget.

2. Legal requirements: Due to the technicalities involved in running a healthcare business, certain licenses and paperwork are required during the process of registering the business. It is crucial to seek legal counsel to ensure you’re complying with the laid down rules and regulations.

3. Equipment purchase: This is the point where you purchase your dialysis equipment and consumables from a trusted equipment supplier.

4. Equipping & Installation: Next after purchasing your equipment is the setting up of your dialysis center, which includes the installation of dialysis machines, dialysis couches, and other systems like the water treatment plant and a power source. This procedure should be handled by trained installation engineers or technicians.

5. Facility Commissioning: This is the point where all requirements have been met, and your center is ready for business. Commissioning a facility can be done in various styles; whether you choose to throw an opening party, or launch into the streets in a marketing campaign, what matters is that your center is optimally ready to respond to the demands of a dialysis center.

When properly done, owning a Dialysis center is like owning a gold mine. The average cost of each session of Dialysis is about $50 — $100 and patients undergo Dialysis at least twice every week for the rest of their lives or until they get Kidney Transplant.

This will also be a good time for me to advise you to consider using refurbished Dialysis machines especially if you are a private healthcare service provider or in Nigeria, Ghana, Liberia, Ethiopia, Zimbabwe, or any other African country. I will give more information in my next article.

2 notes

·

View notes

Text

People used to design things to be repaired.

I learned upholstery a few years ago. Not mastered, mind you, but I learned it and had a paying job doing it for a time. But then I also was dismissed from that job because (?) me working there doing that work wasn't turning out profitable/cost effective for my employer in our area.

But what I learned is that people used to make furniture out of solid wood with occasional bits of metal and various finish treatments and many natural cushioning fibers and fabrics.

They looked nice, were functional, and a person could repair and refinish the pieces when they got worn.

It takes effort. Yes. You have to know how to use tools and materials and a few chemical substances. But it can be done and furnishings at the time were constructed in such a way that you could take them apart to do this work, access the needed areas to attach new bits, and then reassemble everything.

In contrast there are some furnishings made today that just are not made to be repaired or recovered.

Like, when I was working in upholstery we'd get one of those "french style" chairs. They could be antique or just from the 80s. The 80s ones would maybe be gum wood or something, and have less reliable spring support systems, but one could still take everything apart and rebuild. You can still make them nice.

But sometimes someone would bring in some contemporary overstuffed armchair or sofa and when you take the fabric off you can see some of them are in no way ever intended to be recovered. They have particle board in the frames, that won't hold staples and/or tacks as well over the years. The frame is unfinished to the point you will get extra cuts and splinters attempting your upholstery. The portion under a skirt is often unfinished so you cannot remove the skirt only to try another style. The frame will have parts that are stapled in atop other upholstery meaning some areas are not accessible without potentially breaking the frame. Most of the shape of the piece comes from foam, like the wooden structure of the piece is not suggesting its shape, the foam largely is.

I could go on about this.

But the point is that we have alternate ways to do these things. And some of them are quite sustainable. Like, why did we stop using horsehair and replace everything with foam? Horses do regrow hair.

SIDE NOTE a lot of upholstery industry issues seem to be related to fire codes, but if you go down the fire regulation rabbit hole you will find that some of it says it's to protect children but was probably as much protect tobacco industry. Like, yes we need safe homes for humans because fires will happen, but if you look into it, it's not some kind of settled science that coating things with flame retardant is the best and or only way to do this. Yes, natural fibers are flammable, but consider that cotton fabric, for example, catches and then quickly turns to ash. It burns, but then the kindling is gone and there's less fuel for the fire. Whereas some synthetic fabrics melt leaving hot bits sticking around to hurt and smolder.

SIDE SIDE NOTE it's like did you get scalded by hot water or did you get scalded by chicken noodle soup? You still got scalded and that is bad, but your burn will look different if noodles and starch got involved.

I feel like something has gone wrong when IKEA particle board furniture is cheaper than everything in the thrift store.

Especially when the stuff in the thrift store is also particle board. It’s just particle board someone’s scuffed up and painted badly with white chalk paint to make it look ‘shabby chic’.

Anyway, you can tell the boho farmhouse trend is dying because the knick-knack aisle was nothing but metal troughs and fashionably distressed white cabinets made of shiplap. I dread the inevitable influx of griege that’ll happen when the sad beige mommy’s decide to redo their houses.

Finding interesting pieces has already gotten harder without adding brown and greige plastic rainbow toys to the mix.

4K notes

·

View notes

Text

Giving Wastewater New Life: The Healing Power of Biocultures

We often think of wastewater as something to be discarded – a dirty byproduct of modern life.But what if we could alter that point of view? What if we could see wastewater not as waste, but as a resource with the potential for renewal? This is where the magic of biocultures comes in.

Biocultures: Nature's Tiny Recyclers

Bio culture for wastewater treatment involves harnessing the power of beneficial microorganisms – bacteria, fungi, and enzymes – to break down pollutants and purify water. These microscopic heroes work tirelessly to consume organic matter, transforming harmful substances into harmless byproducts like water, carbon dioxide, and nitrogen.

Think of it like a microscopic composting system. Just as worms and microbes break down food scraps in your garden, biocultures do the same for wastewater, only on a much larger scale.

The Benefits of Bioaugmentation

Using biocultures in wastewater treatment, a process known as bioaugmentation, offers a host of benefits:

Improved Efficiency: Biocultures enhance the breakdown of organic pollutants, leading to more efficient wastewater treatment. This means cleaner water discharged back into the environment.

Reduced Reliance on Harsh Chemicals: Traditional wastewater treatment often relies on harsh chemicals used in sewage treatment. Some of these could be detrimental to the environment. Biocultures offer a natural and sustainable alternative, reducing the need for these chemicals.

Cost-Effectiveness: Bioaugmentation can be more cost-effective than traditional methods, particularly in the long run. This is because biocultures are self-replicating, reducing the need for continuous chemical additions.

Odor Control: Biocultures can help control unpleasant odors associated with wastewater treatment by breaking down the organic matter that causes them.

Choosing the Right Bioculture Manufacturer

The success of bioaugmentation hinges on selecting the right bioculture manufacturer. A reputable manufacturer will offer:

High-Quality Products: Look for manufacturers who provide biocultures specifically formulated for wastewater treatment, with a proven track record of effectiveness.

Technical Expertise: A good bioculture manufacturer will offer technical support and guidance on selecting the right bioculture blend for your specific needs.

Customization: Different wastewater streams have different compositions. A reliable bioculture manufacturer can customize bioculture blends to target specific pollutants.

Chemicals Used in Sewage Treatment: A Complementary Approach

While biocultures offer a powerful and sustainable solution, they often work best in conjunction with certain chemicals used in sewage treatment. These chemicals can:

Adjust pH Levels: Maintaining the optimal pH level is crucial for bioculture activity. Chemicals can be used to adjust pH as needed.

Provide Essential Nutrients: Some biocultures require specific nutrients to thrive. Chemicals can supplement these nutrients, ensuring optimal performance.

Control Foam: Excessive foam can be a problem in wastewater treatment. Chemicals known as antifoaming agents can help control this issue.

Expanding on the Role of Biocultures

To further enhance this content and reach the desired word count, you could expand on these areas:

Types of Biocultures: Discuss the different types of bacteria, fungi, and enzymes used in wastewater treatment, highlighting their specific roles and benefits.

Applications of Bioaugmentation: Explore the various applications of bioaugmentation in different industries, such as municipal wastewater treatment, industrial wastewater treatment, and agricultural runoff treatment.

Case Studies: Include real-world examples of successful bioaugmentation projects, showcasing the positive impact of biocultures on wastewater treatment.

Environmental Impact: Elaborate on the environmental benefits of using biocultures, such as reduced energy consumption, reduced sludge production, and improved water quality.

Future Trends: Discuss emerging trends in bioaugmentation, such as the use of genetically modified biocultures and the development of new bioaugmentation technologies.

By adding more detail and specific examples, you can create a comprehensive and informative blog post that effectively highlights the power of biocultures in wastewater treatment.

0 notes

Text

Little P.Eng. Engineering: Your Partner in Specialized Engineering Services Across Canada and the United States

Little P.Eng. Engineering is a highly specialized company offering a broad range of engineering services. Our team of experts is committed to delivering precise and reliable solutions in fields such as Piping Stress Analysis, Pipe Design, Structural Engineering, Above Ground Storage Tank Design, Bulk Material Handling, CRN Registration, and Seismic Bracing Design. With a client base that spans across Canada and the United States, we have established ourselves as a trusted partner for industries seeking top-tier engineering expertise. Let’s explore each of our key services in more detail.

Piping Stress Analysis

Piping systems are critical in industries such as oil & gas, petrochemical, power generation, and more. Little P.Eng. Engineering specializes in piping stress analysis, ensuring that pipelines and their components can withstand various operational loads, thermal expansions, seismic activities, and pressure fluctuations. Our team utilizes advanced software tools like CAESAR II to assess stresses and strains, offering designs that comply with international standards such as ASME B31.1 and ASME B31.3. Our stress analysis services help prevent failures, reduce downtime, and ensure long-term safety and efficiency in your piping systems.

Pipe Design

The design of piping systems goes beyond stress analysis. At Little P.Eng. Engineering, our pipe design services include material selection, layout optimization, routing, and support system designs. We integrate both the mechanical and hydraulic considerations necessary to optimize the performance of piping systems, whether for large-scale industrial installations or specialized custom setups. Our designs ensure proper flow rates, pressure control, and thermal behavior, all while adhering to strict safety regulations.

Structural Engineering

In addition to piping services, we offer structural engineering solutions that cover a wide range of industries and applications. Our expertise includes the design of steel and concrete structures for industrial, commercial, and residential projects. Whether you're looking to build plant facilities, heavy-duty industrial supports, or large-scale warehouses, we provide safe, durable, and cost-effective structural designs. We ensure that our structures meet all regulatory codes and can withstand various loads and environmental factors.

Above Ground Storage Tank (AST) Design

Storage tanks are a vital component in industries like petrochemical, water treatment, and food processing. Our team at Little P.Eng. Engineering specializes in above ground storage tank (AST) design, offering complete design services from tank sizing to material selection and safety considerations. We adhere to standards like API 650, ensuring that your storage tanks are capable of withstanding pressures, environmental loads, and operational requirements. We focus on optimizing storage capacity while ensuring structural integrity and regulatory compliance.

Bulk Material Handling

Handling bulk materials efficiently is key to maintaining smooth operational workflows in industries such as mining, agriculture, and manufacturing. We offer specialized bulk material handling engineering services that include the design of conveyors, silos, hoppers, and other mechanical handling systems. Our goal is to design systems that minimize downtime, enhance safety, and improve productivity. By leveraging our expertise, clients can expect seamless operations in moving materials such as minerals, grains, and other bulk goods from point A to point B efficiently.

CRN Registration

The Canadian Registration Number (CRN) is a mandatory certification for pressure vessels, piping, and fittings used in Canada. Little P.Eng. Engineering provides professional assistance in CRN registration for manufacturers, helping them ensure their products meet the required provincial or territorial regulations. We work with regulatory bodies across all Canadian provinces and territories, streamlining the CRN registration process so that your products can be legally sold and operated across Canada. From design reviews to documentation preparation, our team provides comprehensive support in obtaining and maintaining CRN certification.

Seismic Bracing Design

In regions prone to earthquakes, seismic bracing is essential to ensuring the structural safety of buildings and industrial systems. At Little P.Eng. Engineering, we specialize in seismic bracing design for piping systems, equipment, and structural components. Our engineers design bracing systems that safeguard structures from the effects of seismic activities, mitigating the risk of collapse or damage during an earthquake. We ensure that our seismic designs comply with building codes such as the National Building Code of Canada (NBCC) and the International Building Code (IBC) in the United States, providing you with peace of mind in high-risk seismic zones.

Why Choose Little P.Eng. Engineering?

Expertise across multiple sectors: Our team has extensive experience in serving diverse industries such as oil & gas, energy, petrochemicals, mining, and manufacturing.

Compliance with international standards: We adhere to all relevant codes and regulations in Canada and the United States, ensuring your projects meet legal requirements.

Customized solutions: We tailor our services to fit the unique needs of each client, delivering practical and efficient engineering solutions.

Broad geographical reach: Our services are available across Canada and the United States, making us a reliable partner for projects of any size and complexity.

Conclusion

At Little P.Eng. Engineering, we pride ourselves on being a leader in engineering solutions that ensure safety, efficiency, and compliance. Whether you need expertise in piping stress analysis, structural engineering, or CRN registration, our team is here to help. With a proven track record of successful projects across North America, we are your go-to partner for specialized engineering services.

Contact us today to discuss how we can assist you with your next engineering challenge.

Tags:

ASME B31.3

ASME B31.1

Piping stress analysis

CRN registration

Structural integrity

Silo design

Seismic engineering

Pipe design

Pipe support design

Oil and gas engineering

Structural engineering

API 650 tank design

Bulk material handling

Conveyor system design

Piping layout optimization

Concrete structure design

Mining bulk material handling

Industrial piping systems

Pressure vessel CRN

Above ground storage tank design

Energy sector engineering

Steel structure design

Earthquake-resistant bracing

Manufacturing system design

CAESAR II stress analysis

Mechanical engineering services

Industrial storage tank

Seismic bracing design

Hydraulic pipe design

Canadian registration number

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Montréal, Quebec; Houston Texas; Torrance, California; El Segundo, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

0 notes

Text

The Unsung Hero of Clean Energy and Innovation: Methyl Tertiary Butyl Ether (MTBE)

In an era focused on sustainability and efficiency, the chemical industry has brought forth solutions that not only enhance product performance but also contribute to environmental well-being. One such marvel is methyl tertiary butyl ether (MTBE), a versatile chemical that plays a pivotal role in fuel enhancement, pollution reduction, and even medical applications. Its unique properties make it an indispensable compound across industries. Let’s delve into what makes MTBE a chemical of global significance.

Understanding MTBE: A Versatile Compound

Methyl tertiary butyl ether, commonly referred to as MTBE, is a colourless liquid with a distinctive odour. It is formed through the blending of methanol and isobutylene. This compound has a boiling point of 131°F and a flashpoint of 18°F, making it both stable and effective under various conditions.

A defining characteristic of MTBE is its miscibility in water, owing to its lower density compared to water. This property allows MTBE to serve as an excellent octane booster for gasoline, enhancing fuel efficiency and reducing emissions.

Key Applications of MTBE

The multifaceted nature of methyl tertiary butyl ether makes it a cornerstone in diverse industries.

Fuel Additive for Cleaner Energy

Since its introduction in the 1980s, MTBE has revolutionized gasoline formulations. It is primarily used as an octane enhancer, boosting the combustion efficiency of unleaded petrol. By increasing oxygen levels in fuel, MTBE helps reduce harmful emissions, contributing to cleaner air and mitigating environmental pollution.

Medical Applications

Beyond its industrial utility, methyl tertiary butyl ether has notable medical applications. It is used to dissolve gallbladder stones and delivered directly to the gallbladder via surgical tubes for targeted treatment. This innovative use underscores its safety and effectiveness in controlled medical environments.

Solvent for Pharmaceutical Synthesis

In the pharmaceutical industry, MTBE serves as a solvent for synthesizing Active Pharmaceutical Ingredients (APIs). Its ability to facilitate efficient reactions and maintain purity makes it a valuable asset in drug manufacturing.

Role in Chemical Processing

As a non-polar solvent, methyl tertiary butyl ether is employed in various chemical processes, supporting the synthesis of intermediate compounds essential for multiple applications.

Environmental Considerations

Despite its widespread benefits, MTBE poses challenges when mishandled. Leaks from underground storage tanks can introduce methyl tertiary butyl ether into water sources, especially in urban areas. Furthermore, fuel facilities often release MTBE into the air during refuelling activities.

To address these concerns, stringent safety measures and modernized storage systems are now in place. Advanced monitoring techniques ensure that the environmental impact of MTBE is minimized, aligning its usage with sustainability goals.

The Science Behind MTBE

The chemical structure of methyl tertiary butyl ether includes methyl and tert-butyl groups, contributing to its stability and effectiveness as a fuel additive. When blended with gasoline, MTBE enhances oxygen content, leading to more efficient fuel combustion. This reduces the release of carbon monoxide and particulate matter, key contributors to air pollution.

Why High-Purity MTBE Matters

The purity of MTBE directly influences its effectiveness in applications. High-purity methyl tertiary butyl ether ensures optimal performance as a fuel additive and guarantees safety in medical and pharmaceutical uses. Reliable manufacturers prioritize stringent quality control measures, delivering MTBE that meets global standards and fulfils diverse industry requirements.

MTBE in Action: Global Impact

Industries worldwide rely on MTBE for its unparalleled advantages. In North America and Europe, it is a preferred choice for meeting strict environmental regulations on fuel composition. In Asia, its role in advancing clean energy technologies has cemented its place as a chemical of choice. The global adoption of MTBE highlights its relevance in achieving industrial efficiency and environmental responsibility.

Challenges and Innovations in MTBE Production

Producing methyl tertiary butyl ether requires precision and innovation. As its vapours are denser than air and narcotics, safety measures during manufacturing, storage, and transportation are paramount. Modern facilities employ closed systems and advanced automation to ensure worker safety and environmental protection.

Furthermore, innovations in production techniques have enhanced the efficiency and sustainability of MTBE synthesis. By optimizing resource use and reducing emissions, manufacturers are paving the way for greener chemical production.

Methyl tertiary butyl ether (MTBE) stands at the intersection of industrial advancement and environmental stewardship. Its diverse applications in fuel, medicine, and pharmaceuticals underscore its versatility, while its role in reducing emissions reflects its contribution to a sustainable future. Whether powering cleaner energy or driving pharmaceutical innovation, MTBE continues to prove its value across industries.

For those seeking top-quality, high-purity methyl tertiary butyl ether, Vinati Organics Limited is the name to trust. With cutting-edge facilities and a commitment to excellence, Vinati Organics leads the way in providing superior MTBE solutions that meet global standards.

0 notes

Text

Flexible PCB Manufacturer & Assembly Service

Flexible PCB Manufacturer & Assembly – One-stop services

Hitech Circuits Co.,Ltd is a professional flexible pcb, FPC printed circuit board manufacturer, supplier from China, due to its features of bendable, reducing product size, good heat dissipation and solderability, easy assembly and low overall cost etc, it is widely used in mobile phones, wearable smart devices, automobiles, medical treatment, and industrial control etc. If you are looking for a reliable flexible PCB board partner in China, please don’t hesitate to contact [email protected]

SMT: Technical Points for Mounting Flexible PCB

There are many differences between the flexible PCB SMT process and the SMT solution of the traditional rigid PCB. If you want to do the SMT process of the flexible PCB, the most important thing is positioning, because the hardness of the flexible PCB is not enough, it is softer, and if the special carrier is not used, it cannot be fixed and transmitted, and the basic SMT processes such as printing, patch, and furnaces cannot be completed. The key points of pre-processing, fixing, printing, patch, reflux welding, testing, and division plates of flexible PCB in the production of SMT production are specified as below.

1. Flexible PCB pretreatment

The flexible PCB is softer, and it is generally not a vacuum packaging when it leaves the factory. It is easy to absorb the water in the atmosphere during the transportation and storage procedures. You need to prepare pre-baking treatment before the SMT patch process and slowly discharge the water, otherwise, under the impact of reflux welding at high temperatures, the water absorbed by the FPC quickly vaporizes into steam, which can easily lead to poor flexible PCB layer departure and foaming.

Generally, pre-baking temperatures are 80-100℃ for 4-8 hours, however, under the special condition, the temperature can be raised to more than 125℃, but need to shorten the baking time accordingly. Before baking, be sure to take a small sample test to determine whether the flexible PCB can withstand set baking temperatures, you can also consult flexible PCB manufacturers with appropriate baking process. When baking, don’t put too much flexible PCB for one time, 10-20 panels are more suitable. Some flexible PCB manufacturers may put a piece of paper among each flexible PCB to isolate them and at the same time need to check if the paper can bear the baking temperature, if it cannot be, then pull off the paper before baking. After baking, if the flexible PCB does not have the issues like visible change in color, out of shape, and up warp, etc and then need the IPQC to do sampling inspection.

2. Flexible PCB paste printing

The flexible PCB does not have a very special requirement for the ingredients of the weld paste. The size and metal content of the tin ball particles depends on whether there is a fine pitch IC on the flexible PCB, but the printing performance of the solder paste is higher in FPC, welded paste should be easy to print and eliminate modeling and can be firmly stacked to the flexible PCB surface, there will not be adversely obstructing the steel mesh leakage or collapse after printing.

Because the flexible PCB is loaded on the carrier plate, the flexible PCB has a high-temperature resistant tape for positioning to make its plane inconsistent, so the printing surface of flexible PCB cannot be as smooth as rigid PCB, and has same thickness and hardness, therefore, it is not suitable to use metal scraper, but should use the hardness of 80-90 degrees of polyurethane scraper. It is best to have an optical positioning system for tin paste printing machine, otherwise it will have a great impact on the quality of printing. Although the flexible PCB is fixed on the carrier, there will always be some small gaps between flexible PCB and the carrier, this is the biggest difference from the rigid board, so the setting of the machine parameters also has a greater impact on printing effects.

Printing station is also the key station to prevent flexible PCB dirt, workers need to wear finger stall during operation, at the same time to keep the station clean, and often wipe the steel mesh, to prevent solder paste pollution of the gold finger and gold buttons of flexible PCB.

3. Flexible PCB mounting

According to the characteristics of the product, the number of components, and the efficiency of the patch, needs to use the middle and high-speed patch machines to install. Since the optical mark label for positioning is available on each flexible PCB, SMD paste on the flexible PCB is not very different from the installation on the rigid PCB. It should be noted that although the flexible PCB is fixed on the carrier board, its surface cannot be as flat as rigid board, there will definitely be little gap between flexible PCB and the carrier, therefore, the descending height and blowing pressure of the suction nozzle should be set accurately, and the moving speed of the suction nozzle should be reduced. At the same time, the majority of flexible PCB are connected plates, and the finished product rate of flexible is relatively low, so it is normal for the whole panel to contain some defective board, which requires the bad marks recognition function of the SMT machine, otherwise, the production efficiency will be greatly reduced when the production of this kind of non-integrated panel is good.

4. Flexible PCB Reflow soldering

Mandatory hot air convection infrared reflow furnace should be used, so that the temperature on the flexible PCB can be more uniform change, reduce the occurrence of poor welding. If single-sided tape is used, it can only fix the four sides of the flexible PCB, and the middle part is deformed in the hot air condition, so that the welding plate is prone to tilt, and the molten tin (liquid tin at high temperature) will flow and produce air welding, continuous welding and tin beads, so that the process defect rate is high.

(1).Temperature curve test method:

Due to the different heat absorption properties of the carrier plate and the different types of components on the flexible PCB, their temperature rises at different rates after being heated in the reflow welding process, and the heat absorbed is also different, therefore, carefully setting the temperature curve of reflow furnace has a great influence on the welding quality. The relatively safe method is that according to the load interval during actual production, put two pieces carrier plates with flexible PCB on the front and back of the test board, at the same time, a component is installed on the flexible PCB of the test carrier plate, and the test temperature probe is welded to the test point with high temperature solder wire, meanwhile fix the probe wire on the carrier plate with high temperature resistant tape. Note that high-temperature tapes cannot cover the test point, the testing point should be selected at the welded joints and QFP pins near the side of the carrier plate, such test results can better reflect the real situation.

(2).Settings of temperature curve:

In the furnace temperature debugging, because the flexible PCB temperature uniformity is not good, so it is best to use the temperature curve of temperature rise/heat preservation/reflux, so that the parameters of each temperature area is easy to control, in addition, flexible PCB and components are less affected by heat shock, in this way, the parameters of each temperature area are easy to control. In addition, according to the experience, it is best to adjust the temperature of the furnace to the lower limit of the technical requirements of the welding paste, the wind speed of the welding furnace generally uses the minimum wind speed that the stove can be used, the back welding furnace chain should have good stability and cannot be shake.

5. The Test Division of Flexible PCB

Because the carrier plate absorbs heat in the furnace, especially the aluminum carrier plate, the temperature is higher when it comes out of the oven, so it is best to add a forced cooling fan at the furnace to help rapid cooling, at the same time, operators need to wear heat insulating gloves to avoid being burned by the high temperature carrier plate, when taking the finished flexible PCB from the carrier plate, the force should be uniform and cannot use much force to avoid the flexible PCB being torn or generate crease.

Doing visual inspection for the flexible PCB under the 5x magnifying glass, focusing on checking the surface residual gum, color change, golden finger dipping tin, tin bead, IC pin empty welding, and connected welding, because the flexible PCB surface cannot be flat, the misjudgment rate of AOI is high, so flexible PCB is generally not suitable for AOI checks, but through the use of special testing fixtures, flexible PCB can complete ICT and FCT testing.

Because flexible PCBs are mostly connected together, workers may need to do board split before the ICT and FCT testing, although tools such as blades and scissors can also be used to complete the division operations, the work efficiency and the quality of the operation are low and the scrap rate is high. If it is a large quantity of special-shaped flexible PCB, it is recommended to make a special stamping section mold and perform stamping segmentation, which can greatly improve the operating efficiency, meanwhile, the edge of the flexible PCB is neat and beautiful, it can effectively avoid welded tin cracks.

Conclusion

For SMD mounting on the flexible PCB, accurate positioning and fixing of the flexible PCB are the key points, and the key of fixing is to make the appropriate carrier plate; Secondly is the pr -baking, printing, patch and reflux welding of flexible PCB, obviously, the FPC's SMT process is more difficult than the rigid PCB, so it is necessary to accurately set the process parameters and strict production process management is also important. It is necessary to ensure that operators strictly implement every rule of SOP, engineers and IPQC should strengthen inspection, and discover abnormal conditions of production line in time, analyze the causes and take necessary measures, so as to control the defect rate of production line.

0 notes

Text

Marine and Industrial Applications on Control Valves: The Best Guide

In marine and industrial sectors, control valves control the critical flow, pressure of different fluids, and temperatures to ensure the complex systems work proficiently. As automation heightens in these areas, accurate and dependable control valves have become more crucial than ever before. One of the leading companies offering high-quality automation solutions is Dropship Automation, which has a wide range of control valves crafted for demanding conditions in marine or industrial settings. This article focuses on how control valves work the,ir various types and their applications in these areas, helping people make informed choices.

Understanding what Control Valves are.

Control Valves

are devices that regulate fluid flow through varying sizes of flow passages. In doing this, they also manage pressure levels, system temperatures and liquid levels. Actuators operate these valves automatically following signals from a control system. Precisely controlling these parameters becomes crucial for maintaining efficiency, safety and reliability while dealing with marine operations or industrial processes.

Types of Control Valves

Globe Valves:

Functionality: Globe valves perform very effectively in throttling and regulating flow due to their design, which makes them very accurate in such activities.

Applications: Commonly used in marine and industrial settings, globe valves are found in systems requiring precise control, such as fuel oil systems, cooling water circuits, and steam systems.

Ball Valves

Functionality: Durability and sealing are the strong points of ball valves, which can perfectly close even after prolonged use, making them ideal for on/off control rather than throttling.

Applications: Ball valves frequently appear in bilge and ballast systems in marine environments. They are familiar with industrial gas and liquid pipelines that require tight shutoffs.

Butterfly Valves

Functionality: Butterfly valves are a good option for space-limited applications where quick shutoff is needed without spending too much money.

Applications: Besides being used in industrial water treatment plants and HVAC systems, butterfly valves are commonly employed in marine applications such as ballast and cargo systems.

Diaphragm Valves

Functionality: The flow control element in the diaphragm valve allows it to be used in corrosive liquid handling service; it is also an ideal choice for applications needing freedom from contamination.

Applications: They are widely used on ships for water treatment and industries dealing with aggressive chemicals.

Needle valves

Functionality: Needle valves are particular flow control valves used in small systems where fine adjustments are required.

Applications: In marine, they are found in fuel systems, while industrial uses them in instruments and calibration.

Application Areas for Control Valves in Marine and Industrial Sectors

1. Marine Applications:

• Fuel Management: Forcing fuel flow to engines and boilers through a control valve equipped with a fuel oil system is very important. It ensures that burning occurs optimally and that energy becomes efficient.

• Ballast Systems: The inflow and outflow of ballast water that maintains a ship's stability and buoyancy is usually regulated by control valves.

• Cooling Systems: Control valves help keep marine engines and other equipment cool enough so that overheating does not occur. They enable an even flow of cooling water.

2. Industrial Applications:

• Process Control: A chemical manufacturing industry, for instance, will require control valves to regulate the flow rate of raw materials, leading to accurate reactions for specific chemicals while maintaining uniform product quality at all times.