#OSHA Safety Regulations

Explore tagged Tumblr posts

Text

Understanding Construction Accident: Causes, and Legal Recourse

Construction accident is a critical concern within the construction industry, often leading to severe injuries or fatalities. With the construction sector consistently ranking among the most hazardous workplaces, understanding the nature of these accidents, their causes, and the legal implications is essential for workers, employers, and legal professionals alike. This article explores the…

#construction accident#construction accident compensation#construction accident lawyer#construction accident legal advice#construction accident prevention#construction accident statistics#construction injury claims#construction injury statistics#construction site hazards#construction site inspections#construction site safety#electrocution in construction#falls in construction#OSHA safety regulations#personal protective equipment#prevent construction accidents#safety gear for construction#struck-by accidents#worker safety training#workplace safety standard

0 notes

Text

In the world of industrial safety, the importance of adhering to safety regulations cannot be overstated. Injuries resulting from workplace accidents can not only cause physical harm to workers but also impact a company's overall productivity and efficiency. This is particularly true in industries where heavy equipment and machinery are used, such as construction and manufacturing. One area of concern is crane operations, which can be especially hazardous if proper safety protocols are not followed. This blog will explore the causes of crane accidents and the importance of complying with OSHA safety regulations. Additionally, we will introduce a solution for improving crane safety in the workplace.

Learn about the common causes of crane accidents and the importance of complying with OSHA safety regulations.

You can call us at +971-4-454-1054 or mail us at [email protected]

#osha crane safety#Crane Accident Injuries#OSHA Safety Regulations#crane safety#Forklift red zone light#Forklift red light#Foklift red zone warning lights#Red-Zone pedestrian Light#forklift warning lights#Forklift safety laser light#Forklift Laser Pedestrian Warning Light#High-Quality Forklift Laser Light#forklift blue spot warning light#Forklift blue light#Forklift blue safety light#Blue lights for forklifts#overhead crane warning lights#overhead crane safety warning lights

0 notes

Text

someone put a glitter cannon within a no party cannon zone and started playing patty cake infront of it smh

#dreamworks trolls#branch#branch trolls#my au#safety rules and osha regulations are very important!#doodle#sketch#shitpost#osha

161 notes

·

View notes

Text

Democratic California is offering protections for workers during extreme heat. Florida, under far right Republican Gov. Ron DeSantis, doesn't care if such workers drop dead. It's bad enough that Republicans are contributing to climate change, they resist your ability to protect yourself against it.

In California, employers will soon have to provide water and air conditioned areas for workers when temperatures inside warehouses rise above 82 degrees. When it goes above 87, workers will get shorter shifts and personal cooling fans. In Florida, when a 95-degree sun bears down on farmworkers, local governments are actually prohibited from making employers supply water or a break in the shade.

People who claim there is no difference between the two parties have their heads up their asses. They are too lazy to think or simply lack the power of cognition entirely.

The split on heat-related labor protections tracks with the scorched-earth feud between the states’ Democratic and Republican governors, Gavin Newsom and Ron DeSantis. This divide on labor protections joins a wide range of differences between blue and red states on basic rights including abortion access, gun regulation and environmental protections. It’s also a reflection of the power dynamics in the coastal states: California is staunchly pro-labor, and Florida is business-dominant. [ ... ] The divergent heat rules are emblematic of a political divide that will only deepen if former President Donald Trump wins reelection, emboldening industry interests over union priorities across the states. [ ... ] On Tuesday, the federal Occupational Safety and Health Administration proposed long-awaited heat regulations for indoor and outdoor workplaces, but they won’t be final until at least 2026, midway through what could be Trump’s second term. OSHA submitted its draft guidelines in June to the White House’s regulatory clearinghouse, but any rule that comes before the election could be overturned by the Congressional Review Act if Republicans retake control of the House in November.

If you don't mind dying on the job so that your oligarch employers can stuff even more money into their pockets, then vote Republican.

#florida#republicans#ron desantis#california#gavin newsom#democrats#work#heat-related fatalities at work#workers' rights#safety on the job#workplace regulations#climate change#osha#election 2024#vote blue no matter who

9 notes

·

View notes

Text

#dammit the AJE app isn't letting me copy paste text from the article#boeing#osha#safety regulations#boeing whistleblower

12 notes

·

View notes

Text

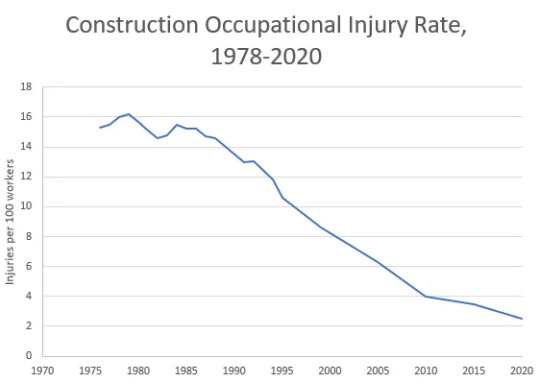

"How much safer has construction really gotten? Let’s take a look.

Construction used to be incredibly dangerous

By the end of the 19th century, what’s sometimes called the second industrial revolution had made US industry incredibly productive. But it had also made working conditions more dangerous...

One source estimates 25,000 total US workplace fatalities in 1908 (Aldrich 1997). Another 1913 estimate gave 23,000 deaths against 38 million workers. Per capita, this is about 61 deaths per 100,000 workers, roughly 17 times the rate of workplace fatalities we have today...

In a world of dangerous work, construction was one of the most dangerous industries of all. By the 1930s and early 1940s the occupational death rate for all US workers had fallen to around 36-37 per 100,000 workers. At the same time [in the 1930s and early 1940s], the death rate in construction was around 150-200 deaths per 100,000 workers, roughly five times as high... By comparison, the death rate of US troops in Afghanistan in 2010 was about 500 per 100,000 troops. By the mid-20th century, the only industry sector more dangerous than construction was mining, which had a death rate roughly 50% higher than construction.

We see something similar if we look at injuries. In 1958 the rate of disabling injuries in construction was 3 times as high as the manufacturing rate, and almost 5 times as high as the overall worker rate.

Increasing safety

Over the course of the 20th century, construction steadily got safer.

Between 1940 and 2023, the occupational death rate in construction declined from 150-200 per 100,000 workers to 13-15 per 100,000 workers, or more than 90%. Source: US Statistical Abstract, FRED

For ironworkers, the death rate went from around 250-300 per 100,000 workers in the late 1940s to 27 per 100,000 today.

Tracking trends in construction injuries is harder, due to data consistency issues. A death is a death, but what sort of injury counts as “severe,” or “disabling,” or is even worth reporting is likely to change over time. [3] But we seem to see a similar trend there. Looking at BLS Occupational Injuries and Illnesses data, between the 1970s and 2020s the injury rate per 100 workers declined from 15 to 2.5.

Source of safety improvements

Improvements in US construction safety were due to a multitude of factors, and part of a much broader trend of improving workplace safety that took place over the 20th century.

The most significant early step was the passage of workers compensation laws, which compensated workers in the event of an injury, increasing the costs to employers if workers were injured (Aldrich 1997). Prior to workers comp laws, a worker or his family would have to sue his employer for damages and prove negligence in the event of an injury or death. Wisconsin passed the first state workers comp law in 1911, and by 1921 most states had workers compensation programs.

The subsequent rising costs of worker injuries and deaths caused employers to focus more on workplace safety. According to Mark Aldrich, historian and former OSHA economist, “Companies began to guard machines and power sources while machinery makers developed safer designs. Managers began to look for hidden dangers at work, and to require that workers wear hard hats and safety glasses.” Associations and trade journals for safety engineering, such as the American Society of Safety Professionals, began to appear...

In 1934, the Department of Labor established a Division of Labor Standards, which would later become the Occupational Safety and Health Administration (OSHA), to “promote worker safety and health.” The 1935 National Labor Relations Act (NLRA), which legalized collective bargaining, allowed trade unions to advocate for worker safety.

Following WWII, the scale of government intervention in addressing social problems, including worker safety, dramatically increased.

In addition to OSHA and environmental protection laws, this era also saw the creation of the Consumer Product Safety Commission (CPSC), the National Highway Traffic Safety Administration (NHTSA), and the National Institute for Occupational Safety and Health (NIOSH).

OSHA in particular dramatically changed the landscape of workplace safety, and is sometimes viewed as “the culmination of 60 or more years of effort towards a safe and hazard-free workplace.”"

-via Construction Physics (Substack newsletter by Brian Potter), 3/9/23

#construction#osha#workplace#workplace safety#workers rights#labor rights#occupational health#nlra#collective bargaining#united states#us history#labor unions#industrial revolution#this is why unions and regulations are so fucking important by the way#if you have not studied late 1800s and early 1900s labor history in the US#you really can't grasp how incredibly dangerous things used to be#and how much proof we have that corporations suck#government regulations

90 notes

·

View notes

Text

So, most Daycares typically look after kids ranging from 1-to-5/6 years old, which means that Sun and Moon aren't just looking after babies. Mans looking after Baby-Babies. At least 10+ of them a day. That makes me wonder what their limit is. Do they have a waitlist for the Daycare?? Did they ever have Daycare assistants?? Or just a daytime security guard who watched from behind the desk? I want to know how the ins and outs of this place worked man!!

#sunnydrop#moondrop#just like having a daycare in what is p much a mall with attractions is so wild to me#that should be a separate building with a yard and multiple rooms for the kids to go into for different activities!!#fuck it we start our own daycare! one that passes osha's safety regulations with flying colors! and has a yard to play in!!#i read a fic similar to this idea once and now I'm obsessed with it#you combine the 'buying the old animatronics post-fire' theme from...fnaf 4? i think?#with making a whole new daycare still using the fazbear 'superstar daycare' branding#but with a lot nore safety and much better quality and care for both you the kids and the animatronics

49 notes

·

View notes

Text

Tumblr brings you face to screen with some wildly stupid people huh!

#Some people would genuinely ask shit like ‘’are women bourgeois’’ and still be incapable of reflecting on how stupid they sound#‘’is osha cops?’’ you’re deeply and seemingly purposefully stupid and I hope you have as little power in matters of public safety#as fucking possible#if u equate safety regulations being upheld with police brutality you need to consider shutting up on the topic dumbass!!! Christ!#also saw some shit excusing male rapists and murderers on some ‘’inherent male nature’’ shit#but bc op said cis that was fucking lost on people apperently

3 notes

·

View notes

Text

sorry, when was this elevator last inspected??

#Hey future elevator tell me how the election goes so I know if I need to move to canada or whatever#Lol what are safety regulations#osha approved

3 notes

·

View notes

Text

all these calls for deregulation astound me. sorry, you hate being safe? you hate having potable water and clean food? you Want to take jobs away from people? you want thousands to die every time there is a flood or a blackout? you WANT your house to be made out of toilet paper and sticks? okaaaaay but thats not my america

#osha exists for YOU#the fda exists for YOU#regulations are in place for YOUR safety#but okaaaaay#shh

30 notes

·

View notes

Note

nikki brewing her gay little potions because you can never have too much of her

its potion time

#jesters art lmao#town of salem 2#i think she wouldnt have like her whole get-up on while potion making due to fire & safety hazards#coven members still have to follow osha regulation#also the goggles stay ON while making potions#& hair tied up obviously (once again. safety hazard)

16 notes

·

View notes

Text

Crane Accident Injuries And OSHA Safety Regulations

In the world of industrial safety, the importance of adhering to safety regulations cannot be overstated. Injuries resulting from workplace accidents can not only cause physical harm to workers but also impact a company's overall productivity and efficiency. This is particularly true in industries where heavy equipment and machinery are used, such as construction and manufacturing. One area of concern is crane operations, which can be especially hazardous if proper safety protocols are not followed. This blog will explore the causes of crane accidents and the importance of complying with OSHA safety regulations. Additionally, we will introduce a solution for improving crane safety in the workplace.

Before discussing this solution, let's examine the common causes of crane accidents and the potential consequences of noncompliance with OSHA safety regulations.

Investigating the Factors Behind Crane Incidents

Crane accidents can stem from various factors, including operator error, environmental factors, and mechanical failure. A combination of these factors can often lead to a crane accident, making it essential to identify and address all potential causes. Among the most common causes of crane accidents is operator error, which may involve improper crane operation, insufficient training, or non-compliance with safety protocols. Mechanical failure is also a leading cause of crane accidents arising from equipment malfunction due to inadequate maintenance or defects.

Environmental factors can exacerbate the risk of crane accidents. High winds, uneven terrain, and electrical hazards, including power lines, pose significant threats to crane operators and workers on the ground. The potential consequences of crane accidents can be severe, ranging from property damage to injuries and even fatalities. Notably, these accidents can lead to lost productivity and revenue for businesses.

Having explored the various causes and impacts of crane accidents, it is crucial to examine the safety regulations set by OSHA to ensure that organizations comply with them, thereby preventing crane accidents.

youtube

Guidelines for Ensuring Safety during Crane Operations as Stipulated by OSHA Regulations

OSHA has set specific safety requirements for crane operations to ensure employees are safe while executing their duties. Inspections of cranes, operator instructions, and safety gear specifications are only a few of these rules. These regulations will reduce the hazards of accidents and injuries at work.

Inspections of cranes are crucial to ensure worker safety. Cranes and the parts that make up employers must frequently inspect to look for flaws or damage that could compromise their safe functioning. Also, operators are required to check their cranes every day before using them.

The safety of cranes must also include operator training. OSHA mandates that crane operators complete rigorous training to guarantee they have the abilities and information required to operate the machinery properly. Operators must receive regular employer exercises to stay informed about current safety standards and laws.

The specifications for safety equipment are still another critical component of crane safety. To reduce the danger of accidents, OSHA mandates that cranes be fitted with special safety equipment, such as anti-two block devices, boom angle indicators, and load moment indicators.

After learning about OSHA's safety requirements for crane operations, let's examine the Forklift Blue Spotlight in more detail to see how it might enhance safety.

The Forklift Blue Spotlight: A Solution for Improving Crane Safety

The Forklift Blue Spotlight by SharpEagle is a premium safety item created to lessen crane accidents and injuries in commercial settings. The crane's immediate surroundings are illuminated by a strong blue LED light, improving visibility and informing employees of the crane's presence.

Every forklift or crane can be equipped with the Forklift Blue Spotlight, which is simple to attach and operate. Blue light is an excellent safety solution for industrial locations with poor visibility because it is visible from a distance, even in low light. Overhead crane lights are essential safety features illuminating the work area and improving visibility for crane operators and workers on the ground. The Forklift Blue Spotlight has many advantages. Enhancing visibility around the crane lowers the possibility of accidents and injuries. As a result of less downtime from accidents and repairs, worker productivity is also increased.

An affordable way to increase crane safety and adhere to OSHA safety rules is the Forklift Blue Spotlight. Businesses that depend on crane operations for their productivity may see long-term benefits from this one-time expenditure. Many clients have already felt the advantages of the Forklift Blue Spotlight. They claim more productivity and safety, fewer accidents and injuries, and better adherence to OSHA safety standards. Consumers also value the product's sturdy construction and superior design.

The Forklift Blue Spotlight is a practical way to increase crane safety in commercial settings. Businesses that depend on crane operations may see long-term benefits from this cost-effective investment. Any company that places a high priority on employee safety and productivity should consider this safety product due to its high-quality design and simple installation.

Enhancing Worker Safety in Crane-Involved Industries through OSHA Regulations and SharpEagle's Forklift Blue Spotlight

It is vital to prioritize worker safety in any workplace, especially in industries that involve heavy machinery such as cranes. Crane accidents can result in severe injuries, loss of productivity, and legal liability. Therefore, it is essential to comply with OSHA safety regulations to prevent crane accidents.

SharpEagle offers the Forklift Blue Spotlight, an innovative solution to improve crane safety. This product illuminates the area around the crane, enhancing visibility and reducing the risk of accidents and injuries. Many customers have already benefited from the Forklift Blue Spotlight, and it is a valuable investment for companies looking to improve their crane safety and comply with OSHA regulations.

The Forklift Blue Spotlight is an excellent solution for preventing crane accidents, and SharpEagle is a reliable provider of industrial safety products. Prioritizing worker safety and complying with OSHA regulations is not only the ethical thing to do but also contributes to increased productivity and profitability.

FAQs

1- What are the OSHA safety regulations for crane operations?

A: OSHA safety regulations for crane operations include regular inspections, operator training, safety equipment requirements, and safety audits to ensure compliance.

2- What are the consequences of noncompliance with OSHA safety regulations?

A: Consequences of noncompliance with OSHA safety regulations include fines, legal liability, and loss of productivity.

3- What are the benefits of the Forklift Blue Spotlight?

A: The benefits of the Forklift Blue Spotlight include improved visibility, increased safety, and reduced accidents and injuries. Customers who have used the product have testified to its effectiveness in enhancing crane safety.

You can call us at +971-4-454-1054 or mail us at [email protected]

#osha crane safety#Crane Accident Injuries#OSHA Safety Regulations#crane safety#Forklift safety light#Forklift Arc Safety Light#Forklift Red Danger Light#Forklift Laser Light#Forklift Blue Spot Light#LED Forklift Safety Lights#LED forklift arc light#Forklift red zone light#Forklift red light#Foklift red zone warning lights#Red-Zone pedestrian Light#forklift warning lights#Forklift safety laser light#Forklift Laser Pedestrian Warning Light#High-Quality Forklift Laser Light#forklift blue spot warning light#Forklift blue light#Forklift blue safety light#Youtube

0 notes

Text

The proposed crackdown on silica follows a fraught history of the mine safety agency's decades of failure to protect miners from the toxic dust. The proposal also overlooks a history of overexposure at coal mines.

Again, this downplays the need and justification for action.

The rule notes that 93% of silica dust samples have been in compliance with existing silica dust limits since 2016. But the remaining 7% of samples amount to 5,300 instances of excessive exposure to the dust based on the newly proposed limit, according to MSHA data analyzed by Louisville Public Media and Public Health Watch.

In the 30 years leading up to 2016, agency data analyzed by NPR and Frontline found 21,000 excessive silica dust samples based on the existing limit. More than twice that many dust samples — 52,000 — exceeded the newly proposed limit.

This means that coal miners worked amid dangerous levels of silica dust — which is easily inhaled, easily lodges in lungs and can lead to severe disease and death — tens of thousands of times in 30 years.

During those three decades, the risk of silica dust exposure increased, as mining consumed the thickest coal seams, leaving thinner seams embedded in rock. Cutting those thinner seams generated more fine silica particles.

Also, during that period, the agency did not respond effectively to the threat.

#black lung#industrial dust inhalation disease#there are as you might expect also massive issues with mine operators cheating on dust samples :D#the current silica exposure limit for miners - whose occupational safety falls under the purview of the MSHA - is double what it is#for every other american worker; OSHA has also lagged behind here - there wasn't a substantial silica standard until 2016#meanwhile coal operators & their doctors spent the 1910s insisting that coal wouldn't make you sick Not Like Silica! so this isn't news#& dust exposure is worse now! both smaller seams & more mechanized mining!#the article is good & you should read it but it's going to call complicated black lung/PMF “incurable”#& i want to be clear: no version of dust disease is curable. once the silica is in it doesn't come out except with a lung transplant#the real problem here is that for various reasons MSHA has undercounted how many people this regulation would protect;#there is substantial opposition from the coal operators & the spineless congressmen they pay;#& we are at best months out from getting a legal standard confirmed - possibly much longer - & if it's not done before 1/25#this regulation will very likely get axed if b/den doesn't get reelected. stupid terrible process!!#every time this comes up i am like. you know the original black lung act in 1971 was meant to end black lung?#it's endable. we know how. we literally know exactly how. but here we are.

8 notes

·

View notes

Text

I really hate how people treat and think about flight attendants. Without getting into the sexism and misogyny of it all, people fundamentally misunderstand their jobs. Flight attendants are not only custom service professionals who serve food and drink. They are first responders. They are trained to fight fires, administer emergency first aid, deal with combative passengers, and help people evacuate the plane. They have a much more dangerous job than police officers—look at their rate of injury and compare that across other private industry. Their job is complex and dangerous and they deserve your respect.

#flight attendants#worker industrial safety and health#this is a marketing problem. if I had photoshop I’d make a bunch of posters about this#I think the reason ppl don’t know is bc airlines don’t want you to think about the dangers of flying#anyway. it really pisses me off#did you know the FAA regulates flight attendant safety and injuries? not OSHA.#and we know the FAA is famously bad at regulation#ugh I’m heated

4 notes

·

View notes

Text

nuclear stuff is so fucking cool. like, horrifying, but also so interesting. maybe in another life i didn’t drop out of high school after flunking out from the lack of accessibility and went into nuclear physics. although, i wasn’t very good at chemistry so that would have been a problem

#been watching a lot of videos on nuclear tragedies#a lot of the most horrible incidents were because of a lack of safety regulations in a new field#or oprhan sources like the goiania incident#and given the fact that i would have also liked to be an osha safety inspector#i would have probably been intrigued by the safety features of a nuclear machine#also we shouldn't have nuclear weapons at all. send tweet.#geralt.txt

3 notes

·

View notes

Text

I think it technically is cop behaviour though, but in a more abstract sense.

OSHA regulations are, at least where I live, anchored in a bunch of federal laws and there are government officials that explicitly have the executive power and duty to enforce them, kind of like cops do (or are supposed to do at least).

Usually, the "victims" of that are the CEOs and employers, when they are forced to fix things up to make their workplace better and safer (who don't deserve much pity). But like all laws, they're a double-edged sword sometimes and they can (depending on the situation) potentially lead to some drawbacks for employees as well.

Still, overall the benefits obviously outshine the negatives, so a great thing to employ and continue to improve on (and not "cop behaviour" in the classical sense).

I’m still thinking about that “is OSHA regulations Cop Behavior” post. Like. You know who thinks regulations are for losers? People who build submersibles out of logitech gamepads and rejected carbon fibre. People who trust starlink as their only surface lifeline.

Do you wanna be like the fine film on the floor of the Atlantic that was once a billionaire? Is that the hill you’re really gonna die on?

We have an expression in my field- “Regulations Are Written In Blood”

People don’t have fucking safety standards as a power trip, we have them because somewhere in the past, NOT having those regulations killed or maimed someone.

A lot of laws out there are bullshit- safety regulations sure as fuck aren’t. I have the literal scars to prove it.

#source: It's kinda what I do for work#just wanted to add something because it's one of those rare cases I'm actually somewhat familiar with the topic#the issues are far too complicated and diverse to explain here but they exist and have to be considerated and discussed everytime#osha#osha regulations#important#work safety

63K notes

·

View notes