Don't wanna be here? Send us removal request.

Text

Forklift Arc Lights: Improved Visibility & Safety

Forklifts are essential for efficiently moving materials in warehouses and industrial settings. However, their operation carries inherent risks, including collisions and accidents. In fact, the National Safety Council reports nearly 85 deaths and 34,900 serious injuries involving forklifts annually in the United States alone.

Forklift arc lights are an innovative solution designed to mitigate these risks by enhancing safety and awareness within industrial environments. These lights, often part of a broader pedestrian warning system, create a visual safety boundary around the forklift, alerting both operators and pedestrians to potential hazards.

How forklift arc lights work

Forklift arc lights utilize a specialized projector to cast a clearly visible arc of light onto the ground surrounding the forklift. This illuminated arc serves as a dynamic safety zone, signaling the forklift’s presence and direction of movement.

Benefits of implementing forklift arc lights

Enhanced Visibility: Arc lights significantly improve visibility, especially in low-light conditions prevalent in many warehouses and industrial settings. This increased visibility helps prevent collisions by alerting pedestrians and other vehicles to the forklift’s presence and path.

Improved Worker Safety: By clearly delineating a danger zone, arc lights reduce the risk of accidents and injuries by ensuring workers maintain a safe distance. This is particularly crucial in noisy environments where auditory warnings may be less effective.

Compliance with Safety Regulations: Implementing forklift arc lights demonstrates a commitment to workplace safety and helps businesses comply with relevant safety regulations, potentially reducing the risk of fines and legal issues. Forklift Arc lights can meet and even exceed OSHA requirements for visibility and accident prevention.

Cost-Effectiveness: Investing in forklift arc lights is a cost-effective solution, as the initial installation cost is minimal compared to the potential financial implications of accidents and injuries, including medical expenses, workers’ compensation claims, and lost productivity.

Durability and Easy Maintenance: Arc lights are built to withstand harsh industrial environments, often boasting features like robust construction, water, dust, and impact resistance (e.g., IP67 rating). Their minimal maintenance requirements and long lifespan further contribute to cost savings.

Read more: Benefits of Installing Forklift Arc Safety Lights

Types and features

Forklift arc lights are commonly available in red or blue, with red often being associated with danger. However, the choice of color is largely based on user preference and environmental factors, such as the type of flooring (blue is reportedly highly visible on concrete).

Installation and maintenance

Installation is generally straightforward and involves securely mounting the lights onto the forklift, often utilizing existing mounting points or brackets. Proper positioning is vital to ensure the projected arc is clearly visible from all necessary angles, and the recommended mounting height is typically between 2.0m and 2.5m.

Regular maintenance is crucial to ensure the lights remain functional, including cleaning the lens to prevent obstruction and periodically checking wiring and connections for damage.

Complementary safety measures

While arc lights significantly enhance safety, they are most effective when integrated with a holistic approach to workplace safety. This includes comprehensive operator training on the proper use of arc lights and other safety equipment, maintaining clear walkways, enforcing speed limits, and utilizing additional safety technologies such as:

Blue Spot Lights: Project a blue spot in front or behind the forklift, warning of its presence.

Red Zone Lights: Create a perimeter on the ground around the forklift, indicating a “no-go” zone for pedestrians.

Collision Avoidance Systems: Utilizing sensors and alarms to detect potential collisions and alert operators.

AI-Powered Systems: Employing artificial intelligence and cameras to detect and track pedestrians, even in challenging conditions.

Read more: Forklift Safety Solutions for forklift safety

By implementing forklift arc lights and combining them with a robust safety program, businesses can create a significantly safer and more efficient work environment for everyone. Prevent accidents and protect your team. Get a free quote for forklift safety lighting.

#Safety Light for Forklift#Blue spot Light for Forklift#Forklift Beacon Light#Forklift Light#Red Zone Light#Red Zone Warning Light#Red Beacon light#Forklift Arc Light#Forklift arc safety lights#Forklift Arc Safety Light#LED forklift arc light#arc safety solutions

0 notes

Text

Forklift safety lights: Enhancing visibility and preventing accidents

Forklift safety lights are essential accessories designed to increase visibility and warn pedestrians and other operators of a forklift’s presence and intended movement in warehouses, industrial settings, construction sites, and other areas where forklifts are used.

Key benefits

Improved visibility and situational awareness: Safety lights, especially in conjunction with headlights and tail lights, illuminate the forklift’s path, making it easier for operators to navigate and spot potential hazards.

Preventing collisions and accidents: By clearly outlining the forklift’s presence and danger zones, safety lights help pedestrians and other vehicles maintain a safe distance, significantly reducing the risk of collisions and injuries, including those caused by rear-end swings and blind spots.

Demarcating safe zones: Certain types of safety lights, like the red zone lights, create a visible perimeter around the forklift, indicating areas that pedestrians should avoid.

Compliance with safety regulations: Implementing forklift safety lights can help businesses meet and exceed OSHA standards and other applicable workplace safety regulations, potentially mitigating legal liabilities and enhancing brand reputation.

Increased productivity: Reduced accidents and improved safety translate to less downtime, fewer injuries, and more efficient material handling operations.

Read more: How Does the Forklift Safety Lights Improve Forklift Safety?

Types of forklift safety lights

Blue Spotlights/Arrow Lights: Project a bright blue spot or arrow onto the ground, signaling the approach and direction of the forklift.

Red Zone Lights: Create a red line or “halo zone” on the ground around the forklift, marking a safe distance that pedestrians should maintain.

Arc Lights: Project a bright arc light in the direction of travel, serving a similar purpose to danger zone lights.

Laser Lights: Project a visible laser line or pattern onto the floor, helping operators delineate a secure path and enhancing navigation in confined spaces.

Strobe Lights/Beacon Lights: Emit a bright, flashing signal to attract attention and warn nearby personnel of the forklift’s presence and potential danger.

Warning Lights: These lights, including flashing headlights and Forklift beacon lights, are highly visible and serve as a general warning signal.

Read more: 7 Types of Forklift Safety Lights and their functions

Installation and maintenance

Proper Positioning: Ensure red lights are mounted on the sides to create a clear safety zone, while blue lights are placed at the front and back to project a visible warning spot on the floor. The angle and distance should be adjusted for optimal visibility without being a distraction.

Regular Checks: Inspect the lights before each shift, checking for damage, secure mounting, and functionality. Replace faulty bulbs or lights as needed.

Cleanliness: Keep the light lenses clean to ensure maximum brightness and effectiveness.

Conclusion

Forklift safety lights play a crucial role in creating a safer and more efficient work environment. By increasing visibility, warning pedestrians, and marking safe zones, these lights help reduce the risk of accidents and injuries, ultimately contributing to a safer and more productive workplace.

Upgrade your forklifts with high-quality safety lights from Sharpeagle, your trusted partner in workplace safety solutions.

Get a free consultation today!

#Forklift blue light OSHA#Forklift blue light distance#Forklift blue Safety light#beacon light#Forklift Arc Light#forklift blue light#forklift blue safety lights#forklift light#Forklift arc safety lights#forklift safety laser light#forklift safety light#overhead crane warning lights#Forklift safety lights#blue spot light for forklifts#Forklift Arc Safety Light#blue forklift safety light

0 notes

Text

Forklift Safety Lights – Maximise Forklift Safety at Your Workplace

Introduction

Forklifts are essential in warehouses, construction sites, and manufacturing plants, but they also pose significant safety risks. Collisions, pedestrian accidents, and blind-spot incidents are common hazards. One effective way to enhance safety is by using forklift safety lights. These lights improve visibility, alert workers, and reduce accidents.

In this blog, we’ll explore how forklift safety lights work, their benefits, and why your workplace should consider installing them.

What Are Forklift Safety Lights?

Forklift safety lights are LED or laser-based devices that project bright warning signs or beams onto the floor around a forklift. They help pedestrians and other workers see the forklift’s path, even in noisy or low-visibility environments.

Common Types of Forklift Safety Lights:

Blue Spot Lights – Project a bright blue spot a few feet ahead of the forklift, indicating its direction of travel.

Red Zone Lights – Create a red perimeter around the forklift, marking its danger zone.

Strobe Lights – Flashing lights that enhance visibility in busy or dimly lit areas.

Laser Guide Lights – Display a clear path or boundary line to warn pedestrians.

Why Are Forklift Safety Lights Important?

1. Prevent Pedestrian Accidents

Many forklift accidents involve pedestrians who don’t see or hear the forklift approaching. Safety lights create a visible warning zone, reducing collision risks.

2. Improve Visibility in Low-Light Areas

In warehouses with poor lighting or outdoor sites at night, safety lights make forklifts more noticeable.

3. Reduce Blind Spot Incidents

Forklift operators have limited visibility. Safety lights alert workers when a forklift is turning or reversing.

4. Comply with Safety Regulations

OSHA and other workplace safety organizations recommend using visual warnings to enhance forklift safety. Installing these lights helps meet compliance standards.

5. Enhance Operator Awareness

Operators become more cautious when they know their forklift’s path is clearly marked for others.

Where Should You Install Forklift Safety Lights?

Warehouses & Distribution Centers – High-traffic areas with pedestrians.

Manufacturing Plants – Noisy environments where horns may not be heard.

Construction Sites – Uneven terrain with limited visibility.

Retail & Cold Storage Facilities – Busy loading docks and tight spaces.

Choosing the Right Forklift Safety Lights

When selecting safety lights, consider: ✔ Brightness & Visibility – Ensure they are bright enough for your workspace. ✔ Durability – Look for weatherproof and shock-resistant models. ✔ Ease of Installation – Some lights are wireless and easy to mount. ✔ Battery Life – Opt for long-lasting or rechargeable options.

Conclusion

Forklift safety lights are a simple yet powerful way to reduce accidents, protect workers, and improve efficiency in your workplace. By investing in these lights, you create a safer environment for both forklift operators and pedestrians. Contact SharpEagle for more details

#beacon light#Forklift Arc Light#forklift blue light#forklift blue safety lights#forklift light#Forklift arc safety lights#forklift safety laser light#forklift safety light#overhead crane warning lights#Forklift safety lights#blue spot light for forklifts#Forklift Arc Safety Light#blue forklift safety light#forklift laser safety lights#forklift led safety light#blue led forklift safety light#forklift safety warning lights

0 notes

Text

Get the Best Forklift Safety Light System in the Dubai, UAE

If you operate a forklift, you must be aware of the dangers of using big machinery. Forklifts are amazing machines that help transport goods and materials over short distances. While they are necessary to build and create numerous projects, it doesn't remove the risks. After all, accidents can and do happen. The most an industry can do to avoid accidents is to take safety precautions. You may have heard that companies are more and more interested in installing forklift safety lights for their machines. We will decipher whether forklift safety lights are worth your money or not.

A forklift offers a pretty open view to the person operating it. However, many crucial viewpoints are blocked off from the driver's point of view when using it. This can lead to risky situations that can cause accidents. Forklift safety lights are used to keep a close eye on these blind spots and shed illumination. In addition, drivers often have to work in places with dim or little-to-no lights. In these situations, forklift safety lights are a savior. Our verdict on whether the forklift safety light system is a fad or a necessity? An absolute requirement, of course! These safety lights can help you reduce and even avoid serious injuries for workers on the clock.

➢ Types of Forklift Safety Light Systems for Your Use

Which forklift safety lights by SharpEagle will offer you the best deal? Keep reading to know more!

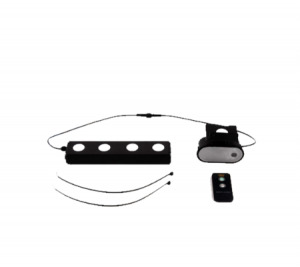

• Forklift Arc Light

Get a high-power LED with a beam projection on the ground. The tempered glass cover offers you dual protection from any external damage. The forklift arc light is also 100 percent dust, water, and quakeproof.

• Forklift Red Danger Light

The Red Danger Light is a gamechanger. It helps pedestrians steer clear of` the dangerously swinging movements of a forklift. Avoid countless injuries with this hefty piece of innovative technology. The alert set system offers high-power LED lights and the ability to withstand extreme temperatures.

• Forklift Laser Light

Get laser beam projection that indicates the exact fork position. You get to increase workers' productivity who will work better in a safe and secure environment. That is a win-win for sure!

• Forklift Blue Spot Light

The Blue Spot Light is ideal for alerting other cars and pedestrians. It also offers a much better perspective on blind spots.

• Forklift Blue Arrow Light

The Blue Arrow Light offers 3W LED lights to protect bystanders and drivers from engaging in accidental maneuvers with the forklift.

• Overhead crane light

SharpEagle's overhead crane light ensures that the hook is in the right spot. This helps bystanders stay safe when the crane is moving. The 72 W overhead crane light serves the purpose effectively even in extreme temperatures.

• Forklift warning light

The high-power Forklift warning light (Forklift beacon light), protected with a durable glass cover and a two-year warranty, offers protection to both pedestrians and operators.

Read More : 10 principles of Forklift operational safety

➢ Why You Should Go for SharpEagle for All Your Safety Light Requirements

Are you looking for a trustworthy organization that understands and implements safety systems as a principle? Then, you have come to the right place! SharpEagle is the one-stop for all things safety and security. If you are looking for top-notch forklift safety lights in the market, look no further. SharpEagle's products lay waste to any who dare to compete with them. Expect only the best with the most modern, up-to-date mechanisms and complex safety measures. SharpEagle is the go-to shop for all corporations that require safety lighting systems. They understand your need to cover all blind spots to avoid accidents. Companies swear by SharpEagle products for safekeeping their workers from all possible bodily injuries. You can choose from an array of forklift safety light systems to suit your needs. From unique designs to workability, all products by SharpEagle are unparalleled by its competitors. So you can safely trust this organization with all your needs.

➢ Opt for a Safe and Secure Warehouse Today

Industries should employ all safety regulations possible. It will help ensure that every one of your workers feels secure when they operate big machinery like forklifts. You should alleviate your worries by choosing nothing but the best. SharpEagle's range of products will ensure that you can avoid all liabilities on the site. Always encourage a safe and nurturing place of business with premium safety products from SharpEagle.

#Forklift Arc Light#forklift red zone light#forklift safety lights red#Forklift arc safety lights#Forklift Red danger light#Forklift Arc Safety Light#red zone danger area warning light#red zone light for forklift#LED forklift arc light#arc safety solutions#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

Importance of Red Zone Danger Area Warning Lights

Forklifts serve a vital role in many industries for material handling and transportation. These versatile machines are used in warehouses, factories, construction sites, and many other settings to lift and move heavy loads from one location to another. Forklifts are equipped with long, metal prongs called forks, which lift and move pallets, crates, and other packaged goods. The forks are mounted on a mast, which can be raised and lowered using hydraulic controls. The operator sits in a cab at the front of the forklift and uses powers to manoeuvre the vehicle and manipulate the forks.

However, forklifts are not devoid of safety threats to the goods, equipment, pedestrians, and the operator. OSHA records 34,900 fatal and 61,800 non-fatal injuries caused by forklifts annually. Below listed are the primary hazards that forklifts pose across different industries.

Safety Hazards of Forklifts in Industries

Forklifts are prone to several hazards due to their size and working conditions, as listed below:

Collisions

Forklifts can collide with other vehicles, pedestrians, or stationary objects, which can cause serious injuries or fatalities. Operators should be trained to avoid collisions by paying attention to their surroundings and following safety protocols.

Falls

Falls from a forklift can occur if the operator loses control or if the forklift overturns. Operators should be trained appropriately to use the forklift safely. The forklift should be maintained in good working order to reduce the risk of falls.

Struck-by accidents

Forklifts can cause injuries if workers are struck by the vehicle or by objects being moved by the forklift. Operators should be trained to use caution while operating the forklift and to be aware of their surroundings at all times.

Caught-in/between accidents

Workers can be injured if they are caught between the forklift and another object or if they are caught in moving parts of the forklift. Operators should be trained to keep their hands and feet clear of moving parts and to use caution when driving the forklift.

Eradicating Low-Light Forklift Hazards

One of the common factors in the hazards listed above is the lack of visibility and proper warning signs for the crew, compromising the safety of on-ground pedestrians. This is where the LED lights for forklifts come in. Forklift safety lights are an essential safety feature that can help improve visibility and reduce the risk of accidents on the job. These lights are often used on forklifts, material handling equipment, and other industrial vehicles to improve visibility and alert other workers to the car's presence.

Primarily used in industries like logistics and large-scale warehouses, there are several different types of forklift safety lights, including headlights, tail lights, turn signals, and warning lights. Forklift safety lights are essential in low-light or poorly-lit environments, such as warehouses and factories. They can help improve visibility and make it easier for operators to navigate the workplace. They can also help alert other workers to the presence of the forklift, which can help reduce the risk of collisions and different types of accidents.

In addition to improving visibility and safety, forklift safety lights can also help improve efficiency on the job. By making it easier for operators to see their surroundings and navigate the workplace, safety lights can help reduce the risk of delays and accidents, which can help improve overall productivity.

Thereby, LED lights for forklifts are an essential safety feature that can help improve visibility and reduce the risk of accidents on the job. Employers should ensure that their forklifts are equipped with appropriate safety lights, and workers should be aware of the importance of using them to improve workplace safety and efficiency.

Introducing the Forklift Red Zone Light

Red Danger Warning Light creates a safety perimeter around the forklift to reduce the risk of foot injuries and collisions. These lights are mounted on either side of the vehicle. They project a bright red beam around the forklift, providing a visual cue to the crew and pedestrians to keep safe distance from an operating forklift to avoid accidents and injuries.

Technical Specifications of SharpEagle’s Forklift Red Zone Warning Lights

Enhanced safety signalling with potent red LEDs

Optional line beam for versatile lighting.

Waterproof, dustproof, and quakeproof protection

Durability with aluminium die-cast housing and stainless steel bracket.

Double-insulated silicon rubberized wire for safety.

High-Power LED Array: Osram LED 6pcs*3w

Ground Illumination: 200lux @2.5m

Voltage Options: 10~80V DC or 10-110V DC (Customised)

Long Lifespan: 50,000 hours

Colour Choices: Blue or Red

Working Temperature Range: -40°C ~ 80°C

Compact Design: 150*60*57mm

Importance of Forklift Red Zone Light for Your Industry

Prevents Forklift Accidents

The red danger light prevents forklift accidents by providing warning to the pedestrians from any direction. This is particularly useful in multiple blind corners and behind structures in busy workplaces. Primarily, these lights are useful in providing safety against collisions with the forklift's rear-end swing. Beside securing pedestrians and protecting them from being run-over, these forklift warning lights also secure the goods and merchandise transported with the forklift.

Clear Visibility Over Long Distances

Owing to the working conditions in industries and large warehouses, the workers might encounter several blindspots. Due to the sharp turns in several industries, pedestrians might fail to notice an approaching forklift before the intersection. Furthermore, workers are used to working in extremely noisy conditions, due to which a warning alarm might often be ineffectual. In such cases, the bright LED light used in the forklift red zone warning lights can serve as a reliable visual cue for an approaching forklift. The colour red is proven to scatter the least and is hence visible over long distances to warn the pedestrians.

Increased Productivity

Assured protection from forklifts allow workers to move heavy loads quickly and efficiently, significantly increasing productivity. Thus, forklift red danger lights improve the efficiency of material handling and transportation processes, which is especially important in fast-paced industry environments.

Employers should ensure that their forklifts are equipped with appropriate red danger lights, and workers should be aware of the importance of using them to improve workplace safety and efficiency. Proper use of forklift red danger lights can help reduce the risk of accidents and injuries on the job and can help improve overall safety in the workplace.

Partner with SharpEagle for Smart Safety Solutions for Your Forklift Operations

The benefits discussed above highlight the importance of investing in a good and reliable model of red zone danger light for your workplace. SharpEagle is a leading safety and efficiency solutions provider in the GCC and the UK. We are end-to-end safety consultants for your company. Our experts offer services like site inspection for customised forklift safety and lighting solutions. Our forklift red danger light undergoes severe tests to ensure its reliable performance. We constantly keep updating the model with the latest technological trends to optimise the safety standards for your crew, goods, and the forklift itself. Beside manufacturing and installation, our team also conducts maintenance checks for warranted safety in your forklift operations.

To know more about our forklift red zone light, visit our website or book a free consultation call with our experts to optimise your forklift safety today!

#Forklift Arc Light#forklift red zone light#forklift safety lights red#Forklift arc safety lights#Forklift Red danger light#Forklift Arc Safety Light#red zone danger area warning light#red zone light for forklift#LED forklift arc light#arc safety solutions#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

How To Enhance Warehouse Traffic Safety with Forklift Safety Solutions

Warehouses are bustling environments with a constant flow and traffic of forklifts, trucks, and pedestrians. This is why increasing warehouse traffic safety has become essential to accident mitigation and maintenance of an efficient workflow. With the right know-how, technologies, and adherence to safety standards, every business can create a secure space — the one that promotes productivity without compromising safety.

As a leader in custom industrial safety solutions, SharpEagle offers innovative tools like advanced cameras and other warehouse traffic systems to address common warehouse hazards effectively. In this guide, we’ll explore the importance of traffic safety in warehouses, common challenges, and actionable solutions.

Importance of Traffic Safety in Warehouse

Traffic safety in warehouses is about more than compliance with OSHA standards; it’s about protecting lives and ensuring operational efficiency.

Accidents caused by poor traffic control and failing to implement forklift safety regulations can lead to serious injuries, equipment damage, and financial losses.

1. Injuries : Fractures, head trauma and even fatalities can occur as a result of poor warehouse traffic management. Such injuries disrupt not only the lives of the affected workers but also the productivity and morale of the entire team. Recovery times and medical treatments can extend over weeks or months, causing significant workforce challenges and strains to cover for the missing workforce.

2. Equipment Damage : Damaged equipment often leads to expensive repairs or replacements. Such incidents happen as a result of collisions or improper use, directly affecting operational capacity. From the operational perspective, there are also delays and increased downtime, further hampering efficiency.

3. Financial Losses: The financial repercussions of accidents in a warehouse can be far-reaching. Expenses related to medical care, equipment repairs, and potential legal claims can strain budgets. Prolonged downtime caused by accidents further amplifies losses, reducing the overall profitability of the operation. These factors highlight the critical need for stringent traffic safety measures in warehouses.

Hazards in the Warehouse

Warehouses are filled with potential hazards, especially when it comes to traffic management. Common risks include:

Blind spots: Collisions occur due to limited visibility around corners and shelves.

Pedestrian and forklift interactions: A lack of defined pathways increases the risk of accidents.

Poor lighting: Dimly lit areas can obscure obstacles, leading to mishaps.

Key Risks and Hazards of Warehouse Traffic

1. Blind Spots and Collisions: Blind spots around shelving units and corners often lead to collisions. This risk can be mitigated with tools like SharpEagle’s Safe Zone Corner Guard, which enhances visibility at blind corners.

This device provides visual and audio warnings triggered when motion is detected on both sides of the corner. Its easy snap-on installation and customisable audio settings make it the perfect safeguard for blind corners. Equipped with loud, distinct audio alerts and high-intensity LED lights, the Safe Zone Corner Guard ensures maximum visibility and awareness, making it a comprehensive solution for collision detection and avoidance.

2. Pedestrian and Forklift Interactions: Forklifts and pedestrians share warehouse spaces, creating significant risks. SharpEagle addresses these challenges with innovative solutions like advanced cameras and pedestrian warning systems. Without defined pathways and effective warning mechanisms, the potential for accidents rises sharply.

3. Poor Visibility in Dimly Lit Areas: Inadequate lighting reduces visibility, increasing the risk of errors and collisions. Proper lighting solutions, like SharpEagle’s high-intensity forklift traffic LED lights, ensure a safer work environment.

Ways to Improve Your Warehouse Traffic Safety

Enhancing traffic safety in a warehouse involves implementing strategic measures tailored to address specific risks.

1. Prioritising Path Design and Layout : Efficient warehouse design is fundamental to traffic safety. Ensure clearly marked, one-way pathways for forklifts and pedestrians. Integrate designated crossing zones to minimise accidental interactions and streamline traffic flow.

2. Traffic Signs, Signals, and Safety Equipment : Employ reflective signs, LED indicators, and physical barriers to enhance navigation. Strategically place these tools in high-risk areas to ensure they’re easily visible to all workers.

3. Warehouse Traffic Flow: Optimise traffic flow by strategically positioning loading and unloading zones near operational hotspots. This reduces unnecessary forklift travel, minimising congestion and risk.

4. Blind Spots: SharpEagle’s Safe Zone Corner Guard is an ideal solution for mitigating risks associated with blind corners. This innovative device provides synchronised audio and visual alerts when motion is detected on both sides of a corner. High-intensity LED lights and customisable sound settings ensure maximum awareness, significantly reducing collision risks.

OSHA’s Guidelines for Warehouse Traffic Safety

Adhering to OSHA standards is crucial for maintaining a safe and compliant warehouse environment. These guidelines provide a structured approach to minimising risks and ensuring the safety of workers, equipment, and goods. Below are key warehouse safety rules OSHA recommends:

Clear Marking of Aisles and Pathways: All aisles and pathways should be visibly marked to guide forklift operators and pedestrians effectively. This reduces confusion and the risk of accidents.

Regular Maintenance of Forklifts: Ensuring forklifts are in good working condition is vital. Routine inspections can identify potential issues before they become major problems, aligning with OSHA’s focus on preventive measures.

Operator Certification Programs: Only trained and certified operators should be allowed to use forklifts. OSHA mandates proper training to ensure operators are equipped to handle equipment safely and efficiently.

Proper Use of Safety Equipment: Equip forklifts with necessary safety tools like cameras, warning lights, and alarms. OSHA encourages the integration of advanced safety technologies to address modern workplace challenges.

Defined Traffic Management Plans: Implement traffic rules within the warehouse, such as speed limits and right-of-way protocols. These guidelines help in creating a more organised and safer environment.

Warehouse Safety Checklist for Forklifts

Operating forklifts safely in a warehouse requires vigilance and adherence to best practices. Here is a warehouse safety checklist to ensure the safety of both operators and pedestrians:

Pay Attention to Forklift Stability: Operate forklifts at moderate speeds and avoid abrupt turns to maintain stability. Instability increases the risk of tipping, especially when carrying heavy loads.

Forklift Operator Certification: Only certified operators should handle forklifts. Certification ensures the operator understands safety protocols and the mechanics of the vehicle.

Pedestrians Have the Right of Way: Establish clearly defined pedestrian zones with proper markings and crossing points to reduce risks of interaction between forklifts and people.

Be Aware of the Lift Capacity: Overloading a forklift compromises its balance and can lead to accidents. Always adhere to the specified lift capacity guidelines.

Know Your Blind Spots: Equip forklifts with SharpEagle’s camera systems, such as the 360-degree Bird-Eye View Camera, to eliminate blind spots and improve situational awareness.

Don’t Travel with an Elevated Load: Always lower loads to improve the operator’s visibility and the forklift’s balance. Elevated loads obscure vision and increase the risk of tipping.

Forklift Speed Needs to be Moderated: Enforce speed limits to prevent reckless operation. Speeding in confined warehouse spaces can lead to catastrophic accidents.

Implement Forklift Marking Systems: Use LED safety lights and warning markers to signal forklift movement, ensuring nearby workers are alerted.

Use a Forklift Safety Checklist: Conduct regular inspections of forklifts to ensure they are in optimal working condition. A checklist helps identify potential issues before they escalate into accidents.

How SharpEagle Forklift Camera and Lighting Solutions Improve Warehouse Safety

How Forklift Safety Lighting Enhances Visibility

SharpEagle’s advanced lighting solutions are specifically designed to tackle the challenges of poor visibility in dimly lit areas. Our high-intensity LED warning lights and spotlights not only illuminate the forklift’s path but also serve as clear visual cues for pedestrians, ensuring their safety. By integrating these lighting solutions into warehouse operations, businesses can significantly reduce collision risks and improve overall efficiency.

Advanced Camera Systems for Forklift Safety

SharpEagle offers a range of camera systems designed for forklift operations:

Forkview Camera System: Ideal for improving visibility during loading and unloading.

360-Degree Bird-Eye View Camera System: Provides a comprehensive view of the forklift’s surroundings, reducing blind spots.

These systems offer real-time monitoring, helping operators navigate safely and efficiently.

Integration with Warehouse Operations

SharpEagle’s safety solutions integrate seamlessly with existing warehouse systems, offering advanced tools like real-time monitoring cameras, pedestrian detection systems, and high-intensity LED lights. These technologies provide real-time data, reduce operational blind spots, and support proactive decision-making to enhance overall safety protocols and operational efficiency.

Why Choose SharpEagle Forklift Safety Solutions?

At SharpEagle, we understand the unique challenges of warehouse traffic management. Our customised solutions, including cameras, lighting, and pedestrian warning systems, are designed to enhance safety and efficiency. With a proven track record and support network across the Middle East, India, and the UK, we’re your trusted partner in safety.

Conclusion

Traffic safety is not just about compliance – it’s about creating a secure, productive environment for your team. With the right tools, strategies, and expert guidance from SharpEagle, you can mitigate risks and optimise operations. Book a free consultation to discuss warehouse safety solutions or visit our product page and to explore advanced forklift safety cameras and lighting systems.

#warehouse traffic safety#traffic safety warehouse#warehouse safety tips#warehouse safety checklist#Warehouse Safety Rules#forklift safety regulations#OSHA standards

0 notes

Text

How To Enhance Warehouse Traffic Safety with Forklift Safety Solutions

Warehouses are bustling environments with a constant flow and traffic of forklifts, trucks, and pedestrians. This is why increasing warehouse traffic safety has become essential to accident mitigation and maintenance of an efficient workflow. With the right know-how, technologies, and adherence to safety standards, every business can create a secure space — the one that promotes productivity without compromising safety.

As a leader in custom industrial safety solutions, SharpEagle offers innovative tools like advanced cameras and other warehouse traffic systems to address common warehouse hazards effectively. In this guide, we’ll explore the importance of traffic safety in warehouses, common challenges, and actionable solutions.

Importance of Traffic Safety in Warehouse

Traffic safety in warehouses is about more than compliance with OSHA standards; it’s about protecting lives and ensuring operational efficiency.

Accidents caused by poor traffic control and failing to implement forklift safety regulations can lead to serious injuries, equipment damage, and financial losses.

1. Injuries : Fractures, head trauma and even fatalities can occur as a result of poor warehouse traffic management. Such injuries disrupt not only the lives of the affected workers but also the productivity and morale of the entire team. Recovery times and medical treatments can extend over weeks or months, causing significant workforce challenges and strains to cover for the missing workforce.

2. Equipment Damage : Damaged equipment often leads to expensive repairs or replacements. Such incidents happen as a result of collisions or improper use, directly affecting operational capacity. From the operational perspective, there are also delays and increased downtime, further hampering efficiency.

3. Financial Losses: The financial repercussions of accidents in a warehouse can be far-reaching. Expenses related to medical care, equipment repairs, and potential legal claims can strain budgets. Prolonged downtime caused by accidents further amplifies losses, reducing the overall profitability of the operation. These factors highlight the critical need for stringent traffic safety measures in warehouses.

Hazards in the Warehouse

Warehouses are filled with potential hazards, especially when it comes to traffic management. Common risks include:

Blind spots: Collisions occur due to limited visibility around corners and shelves.

Pedestrian and forklift interactions: A lack of defined pathways increases the risk of accidents.

Poor lighting: Dimly lit areas can obscure obstacles, leading to mishaps.

Key Risks and Hazards of Warehouse Traffic

1. Blind Spots and Collisions: Blind spots around shelving units and corners often lead to collisions. This risk can be mitigated with tools like SharpEagle’s Safe Zone Corner Guard, which enhances visibility at blind corners.

This device provides visual and audio warnings triggered when motion is detected on both sides of the corner. Its easy snap-on installation and customisable audio settings make it the perfect safeguard for blind corners. Equipped with loud, distinct audio alerts and high-intensity LED lights, the Safe Zone Corner Guard ensures maximum visibility and awareness, making it a comprehensive solution for collision detection and avoidance.

2. Pedestrian and Forklift Interactions: Forklifts and pedestrians share warehouse spaces, creating significant risks. SharpEagle addresses these challenges with innovative solutions like advanced cameras and pedestrian warning systems. Without defined pathways and effective warning mechanisms, the potential for accidents rises sharply.

3. Poor Visibility in Dimly Lit Areas: Inadequate lighting reduces visibility, increasing the risk of errors and collisions. Proper lighting solutions, like SharpEagle’s high-intensity forklift traffic LED lights, ensure a safer work environment.

Ways to Improve Your Warehouse Traffic Safety

Enhancing traffic safety in a warehouse involves implementing strategic measures tailored to address specific risks.

1. Prioritising Path Design and Layout : Efficient warehouse design is fundamental to traffic safety. Ensure clearly marked, one-way pathways for forklifts and pedestrians. Integrate designated crossing zones to minimise accidental interactions and streamline traffic flow.

2. Traffic Signs, Signals, and Safety Equipment : Employ reflective signs, LED indicators, and physical barriers to enhance navigation. Strategically place these tools in high-risk areas to ensure they’re easily visible to all workers.

3. Warehouse Traffic Flow: Optimise traffic flow by strategically positioning loading and unloading zones near operational hotspots. This reduces unnecessary forklift travel, minimising congestion and risk.

4. Blind Spots: SharpEagle’s Safe Zone Corner Guard is an ideal solution for mitigating risks associated with blind corners. This innovative device provides synchronised audio and visual alerts when motion is detected on both sides of a corner. High-intensity LED lights and customisable sound settings ensure maximum awareness, significantly reducing collision risks.

OSHA’s Guidelines for Warehouse Traffic Safety

Adhering to OSHA standards is crucial for maintaining a safe and compliant warehouse environment. These guidelines provide a structured approach to minimising risks and ensuring the safety of workers, equipment, and goods. Below are key warehouse safety rules OSHA recommends:

Clear Marking of Aisles and Pathways: All aisles and pathways should be visibly marked to guide forklift operators and pedestrians effectively. This reduces confusion and the risk of accidents.

Regular Maintenance of Forklifts: Ensuring forklifts are in good working condition is vital. Routine inspections can identify potential issues before they become major problems, aligning with OSHA’s focus on preventive measures.

Operator Certification Programs: Only trained and certified operators should be allowed to use forklifts. OSHA mandates proper training to ensure operators are equipped to handle equipment safely and efficiently.

Proper Use of Safety Equipment: Equip forklifts with necessary safety tools like cameras, warning lights, and alarms. OSHA encourages the integration of advanced safety technologies to address modern workplace challenges.

Defined Traffic Management Plans: Implement traffic rules within the warehouse, such as speed limits and right-of-way protocols. These guidelines help in creating a more organised and safer environment.

Warehouse Safety Checklist for Forklifts

Operating forklifts safely in a warehouse requires vigilance and adherence to best practices. Here is a warehouse safety checklist to ensure the safety of both operators and pedestrians:

Pay Attention to Forklift Stability: Operate forklifts at moderate speeds and avoid abrupt turns to maintain stability. Instability increases the risk of tipping, especially when carrying heavy loads.

Forklift Operator Certification: Only certified operators should handle forklifts. Certification ensures the operator understands safety protocols and the mechanics of the vehicle.

Pedestrians Have the Right of Way: Establish clearly defined pedestrian zones with proper markings and crossing points to reduce risks of interaction between forklifts and people.

Be Aware of the Lift Capacity: Overloading a forklift compromises its balance and can lead to accidents. Always adhere to the specified lift capacity guidelines.

Know Your Blind Spots: Equip forklifts with SharpEagle’s camera systems, such as the 360-degree Bird-Eye View Camera, to eliminate blind spots and improve situational awareness.

Don’t Travel with an Elevated Load: Always lower loads to improve the operator’s visibility and the forklift’s balance. Elevated loads obscure vision and increase the risk of tipping.

Forklift Speed Needs to be Moderated: Enforce speed limits to prevent reckless operation. Speeding in confined warehouse spaces can lead to catastrophic accidents.

Implement Forklift Marking Systems: Use LED safety lights and warning markers to signal forklift movement, ensuring nearby workers are alerted.

Use a Forklift Safety Checklist: Conduct regular inspections of forklifts to ensure they are in optimal working condition. A checklist helps identify potential issues before they escalate into accidents.

How SharpEagle Forklift Camera and Lighting Solutions Improve Warehouse Safety

How Forklift Safety Lighting Enhances Visibility

SharpEagle’s advanced lighting solutions are specifically designed to tackle the challenges of poor visibility in dimly lit areas. Our high-intensity LED warning lights and spotlights not only illuminate the forklift’s path but also serve as clear visual cues for pedestrians, ensuring their safety. By integrating these lighting solutions into warehouse operations, businesses can significantly reduce collision risks and improve overall efficiency.

Advanced Camera Systems for Forklift Safety

SharpEagle offers a range of camera systems designed for forklift operations:

Forkview Camera System: Ideal for improving visibility during loading and unloading.

360-Degree Bird-Eye View Camera System: Provides a comprehensive view of the forklift’s surroundings, reducing blind spots.

These systems offer real-time monitoring, helping operators navigate safely and efficiently.

Integration with Warehouse Operations

SharpEagle’s safety solutions integrate seamlessly with existing warehouse systems, offering advanced tools like real-time monitoring cameras, pedestrian detection systems, and high-intensity LED lights. These technologies provide real-time data, reduce operational blind spots, and support proactive decision-making to enhance overall safety protocols and operational efficiency.

Why Choose SharpEagle Forklift Safety Solutions?

At SharpEagle, we understand the unique challenges of warehouse traffic management. Our customised solutions, including cameras, lighting, and pedestrian warning systems, are designed to enhance safety and efficiency. With a proven track record and support network across the Middle East, India, and the UK, we’re your trusted partner in safety.

Conclusion

Traffic safety is not just about compliance – it’s about creating a secure, productive environment for your team. With the right tools, strategies, and expert guidance from SharpEagle, you can mitigate risks and optimise operations. Book a free consultation to discuss warehouse safety solutions or visit our product page and to explore advanced forklift safety cameras and lighting systems.

#warehouse traffic safety#traffic safety warehouse#warehouse safety tips#warehouse safety checklist#Warehouse Safety Rules#forklift safety regulations#OSHA standards

0 notes

Text

Ultimate Guide to Forklift Truck Accidents and Their Solutions

Forklift truck accidents are a significant concern in industrial settings across the UAE and the United Kingdom. According to the British Safety Council forklift accident statistics, 1,300 individuals are involved in forklift accidents every year in Britain. Addressing forklift safety is important to protect employees and avoid legal and financial issues for businesses. Companies that prioritise safety create trust with their workers and customers while adhering to health and safety standards.

This blog aims to highlight 10 fatal forklift accident causes and provide precautions to prevent such mishaps.

Understanding Forklift Accidents

What Are Forklift Accidents?

Forklift accidents refer to incidents involving forklifts that result in injuries or fatalities, often occurring in industrial settings such as warehouses and construction sites. These accidents can occur due to a variety of factors, including operator error, mechanical failure, or unsafe working conditions. The most common types of forklift accidents include rollovers, pedestrian collisions, mechanical failures, and falling loads.

Statistical Overview

Forklift accidents are a major safety concern worldwide, with OSHA estimating 35,000 to 62,000 injuries annually. Serious injuries involving pedestrians account for 34,900 or 36% fatalities every year. The manufacturing sector has the highest fatality rate at 42.5%, followed by construction at 23.8%. Other high-risk industries include transportation and warehousing, where nonfatal incidents are common due to the frequent use of forklifts for moving goods.

Common Causes of Forklift Accidents

Operator Error is one of the leading causes of warehouse forklift accidents, often resulting from distractions, poor judgement, or failure to follow safety protocols.

Mechanical Failures can occur due to inadequate maintenance or faulty equipment, leading to unexpected malfunctions that compromise safety during operation.

A Poorly Designed Workplace Layout can create hazards such as narrow aisles, insufficient signage, and obstacles, increasing the risk of collisions and accidents.

Insufficient Training and Lack of Supervision can leave operators unprepared to handle the complexities of forklift operation, contributing significantly to the likelihood of accidents.

Pedestrian Impacts

Pedestrian impacts are frequently caused by operator inattention, poor warehouse layout, and a lack of clear pedestrian pathways.

To prevent this:

Implement physical barriers to separate pedestrian walkways from forklift paths

Use blue spotlights or warning light signal

Ensure operators receive thorough training on pedestrian awareness

Additionally, installing forklift cameras can enhance visibility and safety for both operators and pedestrians.

Lack Of Operator Training

Insufficient training often leads to improper handling of forklifts, increasing the likelihood of accidents. Operators may not be aware of safety protocols or how to manage loads effectively.

Providing comprehensive training programs is essential, which include:

Safe operation practices

Load management

Emergency procedures

Regular refresher courses can help reinforce safety knowledge and skills among operators.

Falling Loads

Falling loads typically result from improper loading techniques, unsecured loads, or moving with an elevated mast.

To prevent falling loads:

Ensure that all loads are properly secured and balanced before movement

Avoid raising the load unnecessarily

Tilt the mast back when transporting items

Truck Falling Off A Trailer Or Dock

Trucks can fall off docks or trailers due to improper loading practices, lack of safety barriers, or operator error during loading and unloading processes.

To prevent trucks from rolling off docks:

Install dock plates and barriers

Implement strict loading protocols

Ensure that operators are trained in safe loading practices

Personnel Falling From Forks

Personnel falling from forks often occurs when workers ride on the forks or platforms without proper safety measures in place.

Implement forklift accident prevention like

Establishing a strict policy against riding on forks

Providing adequate training on safe working practices

Blocked Field of View for the Operator

A blocked view can occur when loads are too high or when the operator's line of sight is obstructed by equipment or materials.

To avoid a blocked field of view for the operator:

Operators should be trained to keep loads as low as possible while driving

Use spotters when visibility is compromised

Installing forklift safety cameras and mirrors can also improve visibility in low-light conditions or blind spots.

Mechanical Failures

Mechanical failures may result from inadequate maintenance, worn-out parts, or failure to conduct regular inspections.

To prevent mechanical failures:

Regular maintenance schedules should be established, including pre-shift inspections and routine servicing of forklifts

Operators should be trained to identify potential mechanical issues before they lead to accidents

Emissions Poisoning

Emissions poisoning can occur in poorly ventilated areas where forklifts emit harmful gases such as carbon monoxide.

To avoid emissions poisoning:

Ensure proper ventilation in work areas where forklifts operate

Use electric forklifts instead of gas-powered ones

Crushed By Forklift

Being crushed by a forklift usually happens due to operator error, lack of awareness around moving equipment, or inadequate safety measures in place for pedestrian protection.

To avoid these tragic accidents:

Implement strict safety protocols that include designated pedestrian pathways

Use warning signals for moving forklifts

Ensure operators are trained in situational awareness

Impact Of Forklift Accidents

Warehouse forklift accidents have significant impacts on workplace safety and operations. They can result in fatalities and serious injuries, affecting not only the individuals involved but also their families and coworkers. The economic consequences are substantial, leading to increased costs for businesses due to medical expenses, legal fees, and lost productivity.

Additionally, pedestrian safety is a major concern, as many accidents involve individuals who are not operating the forklift. Regulatory compliance becomes more challenging following accidents, often resulting in investigations and potential fines. Furthermore, the need for comprehensive training and awareness programs is critical, as many accidents could be prevented with better education on safe operating practices.

Overall, the repercussions of forklift truck accidents highlight the necessity for stringent safety measures in industrial environments.

Preventative Measures For Forklift Accidents

Operator Training And Certification

Ensuring that forklift operators are thoroughly trained and certified is critical for maintaining safety in environments where explosion-proof equipment is necessary. Compliance with regulatory requirements is essential for effective training. SharpEagle recognises the importance of such comprehensive training programs that not only meet regulatory requirements but also equip operators with the skills to effectively utilise advanced Forklift Safety Solutions.

Equipment Maintenance

Establish regular inspection schedules to pick up and address potential issues with forklifts. Common maintenance checks should include brakes, tires, lights, and safety features to ensure optimal performance.

Workplace Design And Layout

Design the workplace with clear pathways and appropriate signage to guide operators and pedestrians. Establish dedicated zones for forklifts and pedestrians to minimise collision risks.

Technology-Based Solutions

Implement safety cameras and sensors on forklifts to enhance visibility. Utilise real-time monitoring systems to track operations and alert supervisors to unsafe behaviours or conditions. A few technology-based products include:

Forklift Cameras

The forklift camera systems can be mounted in various locations on the forklift, such as the overhead guard or the carriage, allowing operators to see their forks and loads more clearly. The system is equipped with advanced features, including high-resolution imaging, a wide temperature range, wireless operation, and many more. A standout product for real-time monitoring is SharpEagle's Forkview Camera System, which significantly enhances operator visibility, particularly in blind spots.

Forklift Lights

Forklift safety lights are engineered to improve visibility and awareness in busy work environments. Notably, the Arrow Light projects a bright directional arrow onto the ground to indicate the approach of a forklift. Visual cue by these lights enhance pedestrian awareness and helps prevent collisions.

Other Forklift Safety Solutions

Other safety solutions, like the forklift anti-collision system, offer automatic warnings to avoid collisions during operations. Regular safety training further reinforces best practices, creating a safer workplace overall.

Conclusion

Addressing forklift safety is pivotal for protecting employees and preventing serious accidents that can lead to injuries and financial costs for businesses. Implementing comprehensive training, regular equipment maintenance, optimised workplace design, and technology solutions can significantly reduce accident risks. Companies must adopt proactive measures like installing reliable forklift camera systems to create a culture of safety, ensuring the well-being of all workers.

For the best forklift camera solutions, partner with SharpEagle, the most trusted partner in the UAE. Our technology-based forklift safety solutions are meticulously designed to enhance operational safety in industrial environments. By integrating advanced products like SharpEagle’s forkview camera system, and safety lights into their operations, companies can significantly mitigate risks associated with forklift usage. Schedule a free consultation with SharpEagle’s experts for custom forklift safety solutions today!

#forklift truck accidents#forklifts accidents#forklift accident causes#Forklift Accident Statistics#forklift truck accident warehouse#forklift accident prevention#warehouse forklift accidents

0 notes

Text

Ultimate Guide to Crane Operation Safety

Cranes play a pivotal role in construction and industrial operations - these machines often operate in complex environments where safety is paramount. Crane operation safety policies not only protect workers but also enhance productivity and reduce costly disruptions.

At SharpEagle, we offer innovative safety solutions through which businesses can address critical safety challenges effectively.

In this guide we’ll explore the best practices, common hazards, and cutting-edge solutions to improve safety during crane operations.

Introduction to Crane Operation Safety

Cranes are indispensable tools for lifting and moving heavy loads across construction and industrial sites. However, improper handling of these powerful machines can result in severe accidents, injuries, and even fatalities.

According to the U.S. Bureau of Labor Statistics (BLS), between 2011 and 2021, an average of 44 crane-related fatalities occurred annually in the United States alone. A significant portion of those were caused by crane collapses, contact with power lines, and improper load handling.

Furthermore, the Occupational Safety and Health Administration (OSHA) reports that violations related to crane safety frequently rank among the most cited in workplace inspections. These statistics underscore the critical need for stringent safety measures and comprehensive training programs.

By prioritizing crane operation safety, businesses can protect lives, adhere to regulatory compliance, and ensure seamless and efficient workflows, ultimately fostering a safer and more productive work environment.

Common Hazards in Crane Operations

Understanding the risks associated with crane operations is critical for implementing effective safety measures. Cranes are powerful machines, but they can pose significant dangers when hazards are not properly managed.

Let’s explore the most common hazards and their potential impact:

Blind Spots

Restricted visibility is one of the leading causes of accidents in crane operations. Operators often struggle to see nearby personnel or equipment, increasing the likelihood of collisions. Blind spots can be particularly dangerous in crowded or high-activity areas where the risk of inadvertent contact is elevated.

Overloading

Exceeding the crane's load capacity is a common yet avoidable hazard. Overloading can lead to catastrophic consequences, such as the crane tipping over or structural failure. These incidents not only endanger the operator but pose significant risks to on-ground staff and surrounding equipment too.

Mechanical Failures

Cranes are complex pieces of machinery that require regular maintenance to function safely and efficiently. Neglecting routine inspections or ignoring minor issues can result in mechanical failures, such as hoist malfunctions, broken cables, or faulty brakes. These failures can lead to dropped loads, equipment damage, and serious injuries.

Environmental Factors

External conditions, such as adverse weather or uneven terrain, can severely compromise crane stability. High winds, heavy rain, or icy surfaces increase the risk of accidents by reducing traction and making it harder to maintain control. Uneven ground can cause the crane to tilt, further jeopardizing its stability.

Types of Cranes and Their Specific Safety Considerations

Mobile Cranes: Require stable ground and careful load balancing.

Tower Cranes: Need secure assembly and wind resistance checks.

Overhead Cranes: Demand clear pathways and reliable hoisting mechanisms.

Why Crane Safety is Critical

Investing in crane safety minimizes risks and ensures seamless operations. Key benefits include:

Reduced Accidents: Proper safety measures protect workers and equipment.

Regulatory Compliance: Adhering to OSHA and ANSI standards will prevent legal penalties and save lives.

Enhanced Efficiency: Safe operations minimize downtime and increase productivity.

OSHA guidelines emphasize the importance of clearly marked pathways, certified operators, and regular equipment inspections, particularly for suspended loads.

In this guide, you can find out all about crane accident prevention!

Best Practices for Crane Operation Safety

There are some necessary steps every company should undertake to achieve optimal safety.

Pre-Operation Checklist

Before commencing any crane operation, it is crucial to conduct a thorough pre-operation inspection. This includes:

Crane Inspection: Examine the crane for any signs of wear, damage, or mechanical issues. Check cables, hooks, brakes, and other components to ensure they are in optimal condition.

Environmental Assessment: Evaluate the work area for potential hazards, such as overhead power lines, uneven terrain, or obstructions. Clear the workspace of unnecessary personnel and equipment.

Load Capacity Verification: Confirm that the crane’s load capacity is suitable for the intended operation. Ensure the load weight does not exceed the crane’s rated capacity.

Operator Training

Certified and experienced operators are the backbone of safe crane operations. To maintain high safety standards:

Ensure all crane operators undergo comprehensive training and certification programs.

Provide refresher courses to keep operators updated on the latest safety protocols and technology advancements.

Conduct regular skill assessments to verify competency and adherence to safety guidelines.

Establish Clear Communication Protocols

Effective communication is vital to prevent misunderstandings and accidents. Key measures include:

Standardized Signals: Use universally recognized hand signals and gestures for crane operations.

Reliable Tools: Equip operators and ground personnel with radios or other reliable communication devices.

Clear Instructions: Ensure all team members understand the operation plan and their respective roles.

Regular Maintenance

Preventive maintenance is a cornerstone of crane safety. Establish a routine maintenance schedule that includes:

Lubricating moving parts to reduce wear and tear.

Inspecting hydraulic systems, electrical components, and structural elements for integrity.

Addressing minor issues promptly to prevent larger mechanical failures.

Safe Load Handling Techniques

Proper load handling techniques are essential to avoid accidents and equipment damage. Follow these guidelines:

Avoid overloading the crane by adhering strictly to load capacity limits.

Use appropriate rigging techniques, ensuring slings, hooks, and other equipment are securely fastened.

Balance loads to prevent shifting during lifting and transport.

Environmental Awareness

External conditions significantly impact crane stability and safety. To mitigate environmental risks:

Monitor Weather Conditions: Avoid operations during high winds, heavy rain, or storms, as these can compromise crane stability and visibility.

Assess Ground Stability: Ensure the ground is level and firm enough to support the crane’s weight and movement.

Adjust Operations as Needed: Modify procedures to account for changing environmental factors, such as reduced visibility during fog or glare from direct sunlight.

Now we’ve covered the basics, but is there anything else that can get you further in your safety efforts? The answer may lie in the safety tech being used.

Let’s see how Sharp Eagle can help!

Spotlight on SharpEagle's Overhead Crane Safety Light

SharpEagle’s innovative Overhead Crane Safety Light is tackling visibility challenges with precision and efficiency. Designed for high-demand industrial environments, this safety tool offers unparalleled features to ensure secure and efficient crane operations.

Key Features of SharpEagle’s Overhead Crane Safety Light

High-Intensity LED Lights: These lights project clear, sharp lines on the ground, creating well-defined load boundaries and safety zones. This feature ensures workers can identify hazardous areas at a glance.

Collision Prevention: By clearly marking crane movement paths, the light helps alert workers to the crane's position, significantly reducing the risk of accidents and collisions.

Enhanced Low-Light Performance: SharpEagle’s lights are specifically designed to perform in dimly lit and high-activity environments, ensuring safety even in challenging lighting conditions.

Durability and Energy Efficiency: Built with robust materials, the lights are resistant to industrial wear and tear while consuming minimal energy, making them a sustainable safety solution.

Want to know more about overhead crane safety? This guide may prove useful!

Complementary Products from SharpEagle

SharpEagle offers a comprehensive range of products that can be used to further enhance crane operation safety.

Explosion-Proof Camera Systems: Ideal for hazardous environments, these cameras provide real-time monitoring, helping operators maintain situational awareness and prevent accidents.

Forklift Safety Solutions: SharpEagle’s anti-collision sensors and camera systems enhance safety by reducing blind spots and ensuring the operator has a clear view of their surroundings.

Zone Safety Lighting: These LED safety lights illuminate designated zones, guiding ground staff and minimizing risks associated with overhead crane operations.

Equip your workplace with SharpEagle’s innovative safety solutions today to create a safer, more productive environment. Visit our product pages and explore the full range of products designed to redefine industrial safety.

Choosing the Right Crane Safety Lights

When selecting crane safety lights, consider factors like:

Durability: Ensure lights can withstand tough industrial conditions.

Brightness: Opt for high-intensity LEDs for maximum visibility.

Ease of Installation: Choose solutions that integrate seamlessly with existing systems.

If you need more help on choosing the right lights, this article has a few more knowledge points!

Enhancing Safety with Cameras and Additional Tools

Advanced cameras complement crane safety by providing real-time monitoring and eliminating blind spots. SharpEagle’s solutions, such as 360-degree cameras and warning lights, create a safer workplace by enhancing operator awareness and improving communication during operations.

Crane operation safety is an investment in your team’s well-being and your business’s success. Enhance your safety protocols with SharpEagle’s cutting-edge crane safety lights and cameras. Contact us today for a free consultation and discover how our solutions can transform your operations.

#overhead crane safety#crane operation safety#Crane safety#overhead crane operation safety#crane operation safety rules#overhead crane operation safety rules#Crane Lifting Hazards#crane warning lights#led crane lights

0 notes

Text

Type and functions of Forklift Safety Lights

Transporting heavy loads can be conducted securely and efficiently through the assistance of forklifts, which serve as vital instruments of efficiency across various industries. Nevertheless, their usage in congested warehouses or industrial structures can pose hazards.

Among the array of safety features integrated into forklifts, safety lights are particularly crucial. This post will delve into seven specific types of forklift safety lights, elucidating their role in enhancing worker safety.

7 Types of forklift safety lights and their uses

Presented below are seven categories of forklift safety lights, each with its distinct functions. Understanding the purposes of these lights empowers operators and pedestrians to steer clear of accidents and injuries, promoting secure navigation around forklifts.

1. Forklift Arc Light

The forklift arc light is one of the prevalent safety lights incorporated into forklifts. Typically affixed to the front or rear of the forklift, this light emits a vibrant spot onto the ground, aligning with the forklift's travel direction.

The primary role of the forklift arc light is to notify pedestrians and fellow workers about the presence of an approaching forklift. The projector spot on the ground functions as a visual alert, signaling the proximity of a forklift and urging caution. This proactive measure helps avert unintended collisions and ensures that workers remain cognizant of their surroundings.

Product Features:

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 year

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Casting Aluminum Alloy Housing, the suitable design for heating elimination.

2. Forklift Red Danger Light

Forklifts come equipped with a vital safety feature known as the red danger light. Typically positioned on the front, back, or sides of the forklift, it comprises one or more conspicuous red lights. Designed for enhanced visibility, especially in low-light conditions.

The red hazard light serves as a clear warning signal, alerting individuals to the presence of the forklift. This is particularly crucial when the forklift is moving in reverse or operating in poorly lit areas. By notifying bystanders and other workers to steer clear of the forklift's path, this light significantly reduces the risk of accidents and mishaps.

Product Features:

Light source: High-power Osram LED 6pcs*3w

Operating Voltage:10-80V DC

LED power:18W

Double insulated silicon rubberized wire, Which can bear very low & high temperatures.

Material: Aluminium Die-Cast Housing, PC

Cover, Stainless Steel Bracket

Optional beam: line beam

Warranty: 1 year

3. Forklift Laser Light

Forklift laser lights represent a cutting-edge safety feature found in certain forklift models. These lights project a visible laser line or pattern onto the floor, aiding in delineating a secure path for the forklift's movement.

The forklift laser safety lights provide a precise visual reference for operators by indicating the exact path the machine's wheels will traverse. This feature facilitates precise forklift positioning, assists in avoiding obstacles, and enhances navigation in confined spaces. Additionally, it reduces the likelihood of accidents by signaling bystanders and other workers about the forklift's intended route.

Every year, forklift accidents lead to the tragic loss of approximately 75 to 100 workers, with an average of around 87 fatalities annually.

Product Features:

Suitable for Class 1,2,3 and 4

Type: Red laser alignment system

Remote control switch

Laser Light/Battery

Power Source rechargeable battery

Full Recharge time 8 Hours

Use time per recharge 50-70 hours

Laser Wavelength 650mm (red)

Laser power 100mw

Laser safety class IIB

Warranty: 1year

Boost your forklift's visibility and reduce collision risks by 60%. Tap into our 7 unique safety light solutions now!

Reach out to Us

4. Forklift Blue Spot Light

Similar to the forklift arc light, the forklift blue spotlight serves the purpose of creating a visible warning zone around the forklift. It emits blue light, outlining the forklift's perimeter and signalling its presence to others.

The incorporation of forklift blue safety lights contributes to overall safety by clearly delineating the area surrounding the forklift. This innovative feature significantly diminishes the risk of accidents and injuries by alerting workers and pedestrians who might unintentionally enter the forklift's operational zone. These safety lights become especially advantageous in environments with simultaneous operation of multiple forklifts, such as densely packed warehouses or bustling loading docks.

The forklift's spotlight casts a bright beam to alert pedestrians when the forklift manoeuvres through blind intersections or crosses busy aisles. It serves as a proactive warning, enhancing safety and awareness in dynamic work environments.

Product Features:

Casting Aluminum Alloy Housing, the suitable

Design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 Year.

5. Forklift Blue Arrow Light

Forklift blue arrow lights are similar to the forklift blue spotlight but come with an additional feature – they function as LED forklift lights, projecting directional arrows onto the ground to signify the forklift's planned path or direction of movement.

The blue arrow light not only serves as a warning to pedestrians about the forklift's presence but also communicates its intended route. This feature facilitates pedestrians in anticipating the forklift's movements, enabling them to choose optimal spots for walking or standing. This is particularly beneficial in scenarios where forklifts frequently change directions or execute turns.

Product Features:

Casting Aluminum Alloy Housing, the suitable

Design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Double insulated silicon rubberized wire, which can bear very low & high temperatures.

Beam: Projector spot on the ground.

Ingress protection: IP-67

Warranty: 1 Year.

6. Forklift Warning Light

The forklift beacon light, also known as a strobe light or warning beacon, is a highly visible flashing light affixed to the forklift's roof or other conspicuous locations.

Functioning as a strobe light, the forklift warning light emits a bright, flashing signal from the forklift's roof or another prominent location.

Product Features:

Casting Aluminum Alloy Housing, the suitable design for heating elimination.

Tempered Glass Cover.

High power LED with High quality.

The high performance of 100% waterproof, dustproof & quakeproof.

Ingress protection: IP - 65

Warranty: 2 years.

Light source: High - power Osram LED 5pcs*1w

Operating Voltage: 10 - 110V DC

Colour: Amber, Red, Green, Blue & Purple

Pattern: Rotating, Flashing (Once, Twice), Solid (No Pattern)

Material: aluminium die - cast housing, Hard glass cover, stainless steel bracket

Working environment: - 40° - 80°

Elevate your forklift operations with lights that cut down hazard rates by half. Unveil the power of our safety lights today!

Talk to our Expert

7. Overhead Crane Light

While not limited to forklifts, facilities utilising both forklifts and overhead cranes employ overhead crane lights. These lights project a distinct, visible signal onto the ground, indicating the position of the overhead crane's load.

In facilities housing both types of machinery, overhead crane lights play a vital role in ensuring security. These lights aid forklift operators and other workers in accurately determining the position of the overhead crane's load, contributing to the safety and avoidance of potential hazards. This preventive measure helps mitigate accidents and collisions between forklifts and overhead crane loads.

Product Features:

Power: 72 Watts

Current: 2.3A @24V Blue, 1.4A @24V RED

Voltage: 9-48 Volts DC

Lumens: 12,000 lumens(each light creates one line)

LEDs: 24

LED colour: Blue Or Red

Beam Type: Line Beam or Spot Light

Working life: Up to 50,000 hours