#Forklift red zone danger area warning light

Explore tagged Tumblr posts

Text

Alert Pedestrians Instantly: Blue Spotlight & Red Zone Lights

Safety is paramount in industrial environments, especially given the prevalence of forklift trucks, which often pose risks to pedestrians. To address this concern, safety managers are increasingly turning to innovative solutions like Blue Spotlights and Red Zone forklift lights. These LED safety lights serve a crucial role in alerting pedestrians to the presence of forklifts and preventing collisions. The Blue Spotlight projects a distinct blue spot on the ground, while the Red Zone light creates a visible danger zone around the forklift.

Let’s dive into the nuances of both in more detail!

What are Blue Spotlights and Red Zone Forklift lights?

There is a frequent episode that the crew encounters where someone is walking through your factory or warehouse staring at their smartphones or wearing earbuds, unaware of what’s happening around them.

Blue Spotlights and Red Zone forklift lights are essential safety devices designed to enhance visibility and prevent accidents in industrial environments.

The Blue Spotlight projects a prominent blue spot on the ground, serving as a clear indicator of an approaching forklift. It alerts pedestrians to the presence of the forklift, prompting them to adjust their path to avoid potential collisions. By effectively signalling the forklift's location, the Blue Spotlight significantly reduces the risk of pedestrian-forklift accidents.

On the other hand, the Red Zone Forklift Light creates a designated no-go zone around the forklift by projecting two straight red beams onto the ground. This illuminated area serves as a visible danger zone, indicating that the forklift is in motion or actively stacking goods. Pedestrians are thus alerted to keep a safe distance from the vehicle, minimising the risk of accidents caused by inadvertent crossings.

Blue Spotlights

Blue spot lights are a vital safety feature in industrial environments, particularly in warehouses where forklifts are commonly used. These spotlights serve as proactive warning signals for pedestrians, alerting them to the presence of forklifts and helping them avoid potential accidents.

Illuminating the Path for Pedestrians

Mounted on the overhead guard of the forklift, a blue spotlight emits a bright blue spot on the ground, typically extending 10-20 feet in front or behind the forklift. This illuminated path serves as a visual cue for pedestrians, signalling the approach of the forklift and allowing them to adjust their movements accordingly.

By highlighting the forklift's trajectory, the blue spotlight enhances pedestrian awareness and facilitates safe navigation around the vehicle.

Benefits of Using Blue Spot lights

Enhanced Visibility: Blue spotlights significantly improve visibility in busy industrial settings, especially in areas with low lighting or obscured sightlines. Pedestrians can easily spot the distinctive blue spot, even from a distance, enabling them to steer clear of oncoming forklifts preemptively.

Reduced Accidents: By providing advanced warning of forklift movements, blue spotlights help prevent collisions between pedestrians and forklifts. This proactive safety measure minimises the risk of accidents and injuries in the workplace, fostering a safer environment for all personnel.

Increased Awareness: Blue spotlights raise awareness among pedestrians about potential hazards posed by forklifts, encouraging them to remain vigilant and exercise caution in shared work areas. This heightened awareness promotes a safety-conscious culture and reduces the likelihood of complacency or oversight.

Improved Efficiency: Fewer accidents and disruptions caused by pedestrian-forklift collisions can increase productivity levels as workflow remains uninterrupted. Blue spot lights contribute to the smooth operation of industrial facilities by mitigating safety risks and optimising work processes.

Red Zone Forklift Lights

Red zone forklift lights also known as Red Danger Lights are essential safety devices designed to enhance visibility and prevent accidents in industrial environments, particularly in areas where pedestrians and forklifts interact. These lights serve as proactive warning indicators, delineating a safety perimeter around the forklift to alert pedestrians and other workers of potential hazards.

Overview and Functionality

Mounted on the sides of the forklift's overhead guard, red zone lights project two straight red beams onto the ground, creating a visible safety zone or "no-go zone" around the vehicle. The illuminated area serves as a clear boundary that pedestrians are advised to avoid, signalling the presence of an operational forklift and the potential dangers associated with its movement.

Better Visibility and Safety for Pedestrians

Red zone warning lights significantly improve pedestrian visibility and safety by providing a visual indication of the forklift's operating area and potential hazards. The bright red beams are easily discernible even in busy or dimly lit environments, alerting pedestrians to the forklift's presence and prompting them to maintain a safe distance.

Creating a Visible Safety Zone

The primary function of red zone lights is to create a visible safety zone around the forklift, delineating an area that pedestrians should avoid to minimise the risk of accidents or collisions. By projecting clear red beams onto the ground, these lights define the boundaries of the forklift's operational space, enabling pedestrians to navigate around it safely.

The interesting aspect of the red zone forklift safety light is that the driver does not have to worry about the estimation the pedestrians have to make to keep themselves away from the lift truck. They need to see the danger line, and that’s it.

Benefits of Red Zone Lights

Enhanced Safety: Red zone lights provide a proactive safety measure by clearly defining the forklift's operating area and alerting pedestrians to potential dangers. This helps reduce the risk of accidents and injuries in the workplace.

Improved Awareness: By creating a visible safety zone, red zone lights increase awareness among pedestrians about the presence and movement of forklifts, encouraging them to exercise caution and remain vigilant in shared work areas.

Reduced Collisions: The clear delineation of a safety perimeter around the forklift helps minimise the likelihood of collisions or accidents involving pedestrians. Red zone lights serve as a visual cue for pedestrians to stay clear of the forklift's path, preventing potentially hazardous situations.

Compliance: Implementing red zone lights demonstrates a commitment to workplace safety and regulatory compliance. These lights align with safety standards and guidelines, contributing to a safer work environment and mitigating liability risks.

Read More : Alert Spectators with Forklift Red Danger & Laser Light

Advantages of Blue Spotlight and Red Zone Lights

The key factor is to create a safe working atmosphere around the forklift. The warning lights play an important role in:

• Blind intersections or corners where approaching vehicles or pedestrians can be difficult to spot.

• Reducing the chances of the pedestrians hitting by the rear end swing of a moving or turning forklift truck.

• Providing a safety cover against other speeding forklifts that may collide with the one having loads of goods.

• Enhancing productivity and efficiency, as fewer accidents mean fewer chances of distractions of fellow workers and uninterrupted workflow.

• Making your company compliant with the latest safety standards, also means the betterment of the brand value.

Forklift Safety Lights – A commitment toward a safer and promising business

Blue Spotlights and Red Zone forklift lights are indispensable safety tools that play a vital role in enhancing visibility, reducing accidents, and promoting a safer work environment in industrial settings. By illuminating the path for pedestrians and creating visible safety zones around forklifts, these lights help prevent collisions and minimise the risk of injuries.

At SharpEagle, we understand the importance of workplace safety and are committed to providing high-quality safety solutions to our customers. With years of experience in the industry, SharpEagle has established itself as a trusted provider of forklift safety lights, including Blue Spotlights and Red Zone lights. Our products are designed to meet the highest standards of quality, durability, and performance, ensuring reliable protection for both workers and equipment.

Ensure the safety of your workplace by investing in SharpEagle's forklift safety lights today. Visit our range of products and solutions or contact us directly for personalised assistance.

Let SharpEagle be your partner in creating a safer and more productive work environment.

You can also call us at +971-45549547 or mail us at [email protected]

#Forklift Blue Spot Light#forklift blue safety lights#forklift red zone light#forklift safety lights red#blue forklift safety light#Forklift Red danger light#forklift blue light installation#red zone danger area warning light#Blue lights for forklifts#why do forklifts have blue lights#red zone light for forklift#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

Top Forklift Safety Accessories for Workplace Security

Forklifts play an indispensable role in material handling operations, making tasks like lifting, transporting, and organizing materials faster and more efficient. However, their operation comes with significant safety risks. To mitigate these risks and ensure workplace security, forklift safety accessories are essential tools that every business owner should consider. These accessories enhance operator safety and contribute to the overall efficiency of material handling tasks.

This article will explore the top forklift safety accessories, delve into their benefits, and discuss how incorporating them into material handling equipment strategies can boost workplace safety and productivity.

Importance of Forklift Safety Accessories

Forklift safety accessories prevent accidents and protect employees, equipment, and inventory. According to workplace safety statistics, many incidents involving forklifts occur due to preventable hazards, such as poor visibility, unstable loads, or operator errors. By integrating the right safety tools, businesses can minimize these risks and create a safer working environment.

Moreover, including forklift safety accessories in your operations aligns with broader material handling objectives. These tools support efficient workflows, reduce downtime, and ensure compliance with safety regulations—key factors that every business owner values. Let’s explore the most impactful accessories and their role in enhancing workplace security.

Top Forklift Safety Accessories for Every Workplace

Visibility Enhancements for Forklifts

LED Forklift Lights

LED lights improve visibility for forklift operators, particularly in dimly lit warehouses or outdoor environments. They help illuminate pathways, alert pedestrians, and prevent collisions.

Forklift Backup Alarms

Backup alarms alert nearby workers when the forklift is reversing, reducing the risk of accidents in crowded or noisy workplaces.

Forklift Mirrors

Convex and panoramic mirrors provide operators with a wider field of view, ensuring they can see blind spots and potential obstacles.

Warning Spotlights

Blue or red spotlights project onto the floor, creating a visible safety zone around the forklift to warn pedestrians of its presence.

Load Handling Accessories

Fork Extensions

Fork extensions are vital for handling longer or bulkier loads. They stabilize materials and reduce the chances of accidents caused by unstable cargo.

Load Backrests

These attachments prevent materials from falling backward onto the operator, offering extra safety during lifting.

Pallet Stoppers

Pallet stoppers help secure loads on the forks, ensuring materials remain in place during transportation.

Load Weighing Systems

Integrated weighing systems allow operators to measure loads in real time, preventing overloading and ensuring compliance with weight limits.

Operator Safety Features

Operator Restraint Systems

Seat belts and harnesses keep operators secure in their seats, minimizing injuries in case of sudden stops or tipping accidents.

Anti-Slip Steps

Anti-slip steps provide operators with stable footing, reducing the risk of slips and falls when entering or exiting the forklift.

Overhead Guards

Overhead guards protect operators from falling objects, such as pallets or tools, that could cause serious injuries.

Emergency Stop Buttons

Easily accessible emergency stop buttons allow operators to quickly halt the forklift in dangerous situations, averting potential accidents.

Environmental Safety Enhancements

Forklift Speed Limiters

Speed limiters ensure forklifts operate at safe speeds, especially in areas with high pedestrian traffic or narrow aisles.

Noise-Reduction Systems

Noise-reduction systems minimize forklift operational noise, creating a safer and more comfortable working environment.

Emission Control Devices

For indoor operations, emission control devices reduce harmful emissions from diesel-powered forklifts, ensuring compliance with air quality standards.

Pedestrian Awareness Systems

These systems combine sensors and alarms to detect nearby pedestrians and alert operators, preventing collisions.

Material Handling Equipment Benefits for Business Owners

Material handling equipment goes beyond forklifts to include tools like warehouse loading tools, industrial lifting machines, and cargo moving devices. These systems streamline operations and provide a competitive edge for business owners. Here’s how:

Improved Efficiency Material handling equipment, such as heavy-duty conveyor belts and automated storage systems, reduces the time spent on manual tasks, allowing employees to focus on higher-value activities.

Enhanced Workplace Safety Incorporating tools like crane hoisting mechanisms and pallet stacking equipment ensures secure handling of heavy or awkward loads, reducing the risk of injuries.

Cost Savings Investing in ergonomic handling solutions prevents damage to inventory and reduces the need for costly repairs or replacements.

Regulatory Compliance By integrating advanced safety features, business owners can meet regulatory standards and avoid penalties.

Employee Satisfaction A safe and efficient workplace improves morale and productivity, making it easier to retain skilled employees.

Key Forklift Safety Accessories Checklist

For Enhanced Visibility

LED lights

Warning spotlights

Backup alarms

For Load Stability

Fork extensions

Load backrests

Pallet stoppers

For Operator Protection

Restraint systems

Overhead guards

Emergency stop buttons

For Environmental Safety

Speed limiters

Noise-reduction systems

Emission control devices

Forklift safety accessories are essential for creating a secure and productive workplace. From visibility enhancements to operator protection features, these tools prevent accidents and improve efficiency and compliance. For business owners, incorporating advanced material handling equipment—like industrial lifting machines, ergonomic handling solutions, and cargo moving devices—offers significant benefits, including cost savings and improved employee satisfaction.

By prioritizing workplace safety and leveraging the right accessories, businesses can achieve long-term success while ensuring the well-being of their workforce. Investing in these tools is more than a compliance requirement; it’s a commitment to operational excellence.

1 note

·

View note

Text

FORKLIFT SIGNS

59B Ash Rd, Wiri,Manukau Auckland,2104, New Zealand

Electronic Equipment

Variable-message signs, or VMS, are electronic equipment which may display different traffic messages consistent with the requirements of a selected road. Permanent VMS displays are mounted on large sign structures overhead or alongside the road. These devices are often placed on urban freeways which have traffic problems. Portable CMS (PVMS) panels are usually mounted on trailers, although some could also be carried by trucks. they're often utilized in work zones or other events that disrupt .

A traffic signal , also referred to as traffic light , stop light, stop-and-go lights, may be a device positioned at a road intersection, zebra crossing , or other location so as to point when it's safe to drive, ride, or walk employing a universal code (and a particular sequence, for that are colors blind).Nowadays, a red light meant traffic altogether directions had to prevent . A traffic light meant cross-towntraffic would need to slow and a green light would to travel or proceed.

Traffic Lights are wont to control the vehicle traffic . within the era , everyone has differing types of vehicles leading to rise to the numbers of vehicles. That’s why traffic lights are mandatory to avoid the traffic jams and accidents. There are three lights within the traffic light , having different message for the drivers. Red light (upper one) asks the driving force to yield at the intersection, green light (last one) gives the driving force freelicense to drive through the intersection ...Traffic flow radar uses a "side-fire" technique to seem across all traffic lanes during a narrow band to count the amount of passing vehicles and estimate traffic density. For stopped vehicle detection (SVD) and automatic incident detection, 360 degree radar systems are used as they scan all lanes along large stretches of road. Radar is reported to possess better performance over longer ranges than other technologies.

The Electronics Industry is comprised of organizations that fabricate, plan, make, gather, and administration electronic items. These items comprise of materials, parts, segments, subassemblies, and hardware that utilization the standards of gadgets to play out their major functions.The gadgets industry arose in the twentieth century and is today one of the biggest worldwide enterprises. Contemporary society utilizes an immense range of electronic gadgets worked in computerized or semi-robotized production lines worked by the business. Items are essentially amassed from metal-oxide-semiconductor semiconductors and incorporated circuits, the last basically by photolithography and frequently on printed circuit sheets. The size of the business and the utilization of harmful materials, just as the difficultn gadgets industry, the Consumer Electronics fragment (incorporates Mobile Phones and Home Appliances, viz., Refrigerator, Washing Machine, Air Conditioner and Microwave Oven and so forth) with creation of INR 205,524 crore (~25.5 bn euros) is the head of industry and has piece of the pie of 53%. As of FY18,In the course of the whole creation cycle, an electronic gadget is taken care of by a scope of assembling gear. The consistently expanding intricacy of electronic congregations and the scaling down of segments have improved the interest for cutting edge and solid assembling equipment.Vehicles are recognized electronically with no money exchanges occurring out and about or roadway.

Forklift signs are designed with bright colors and enormous , easy-to-read font to assist catch the eyes of passerby. Floor signs are made with industrial-grade, low-profile vinyl which will withstand forklift traffic, and are immune to chemicals, water, and anything you'll throw their way.Our standard and ANSI Z535.2-compliant forklift traffic signs and forklift warning signs

are available various materials, sizes, colors, and designs , including ANSI Safety - Danger Forklift Traffic Area, Forklift parking lot - Keep Clear Forklift Traffic, ANSI Multi-Message - Caution Forklift Area Look Both Ways, and Illuminated Warehouse Safety - Caution Look Out For Forklift safety signs.Forklift Floor Signs Forklifts are liable for many workplace injuries. Ensure your staff and drivers are conscious of one another with Forklift Floor Signs. improve communication within the workplace, keeping your staff and employees safe

CONTACT US :

59b Ash Road, Wiri, Auckland

0 notes

Text

Alert Spectators with Forklift Red Danger & Laser Light

Grabbing the attention of workers and other pedestrians in a buzzing warehouse isn’t an easy task. With just a little time to react, you need a reliable and sturdy lighting solution. And this is where SharpEagle’s Forklift lighting solutions come into play.

When the phrase “forklift safety” comes to mind, one of the first things that usually springs to people's minds is how easily serious and potentially fatal accidents can happen. To help warehouse managers and business owners ensure that their employees stay safe when operating machinery such as forklifts, it is important to utilise all available methods for controlling potential hazards and communicating warning messages quickly.

One effective way of doing this is using Red Danger Zone Warning lights or Laser Lights on a forklift to grab onlookers' attention in an instant.

Today, we’re going to look at the Red Danger Light and Laser Lights, which are the most effective ways to signal a safe distance and catch the spectators' attention!

The Significance of Forklift Safety

Forklift operation within bustling warehouse environments presents inherent hazards and risks that require meticulous attention and proactive safety measures. Let's explore the critical significance of forklift safety and the imperative need for robust safety protocols:

Potential Hazards and Risks

Operating forklifts in busy warehouse settings entails navigating through narrow aisles, congested pathways, and around stacked inventory—all of which pose potential hazards to both operators and pedestrians. The combination of limited visibility, heavy loads, and fast-paced operations increases the risk of collisions, falls, and material handling accidents. Not to mention the presence of varying floor conditions, such as uneven surfaces or spills, further amplifies the danger associated with forklift operation.

Without adequate safety measures in place, these hazards can lead to serious injuries, fatalities, and costly property damage. Read more: Forklift Safety Solutions - Tips To Avoid Injuries

Importance of Implementing Robust Safety Measures

Given the gravity of the risks involved, it is paramount for warehouse managers and business owners to prioritise the implementation of robust safety measures to mitigate accidents and injuries. This includes investing in advanced safety technologies such as forklift red danger lights and laser lights, which serve as proactive warning systems to alert both operators and pedestrians of potential dangers in real-time.

By incorporating these lighting solutions into forklift operations, businesses can enhance visibility, establish clear safety zones, and minimise the likelihood of accidents occurring.

On top of that, comprehensive safety protocols should encompass rigorous training programs for forklift operators, emphasising safe operating practices, load handling techniques, and awareness of surrounding hazards. Regular maintenance and inspection of forklifts are also essential to ensure optimal performance and identify any potential mechanical issues that could compromise safety.

Want to read more about safety measures? This guide has all the answers.

Red Danger Lights and Forklift Lasers — The Perfect Safety Combo

Forklift Red Danger Lights and Forklift Laser Lights on forklifts have quickly become an industry standard for safety. Danger lights typically feature a bright, flashing red light that illuminates the area to draw immediate attention in a moment of emergency.

With laser lights, you can project lines onto walls, floors, or any other surface to mark out designated paths, while installing red danger lights and laser lights on a forklift can be a great way to quickly grab attention, especially when in tight spaces with limited visibility.

These are powered by their own independent energy sources, making them ideal for mobile machinery. In combination with red lights, you can also implement blue safety lights. If you want to know more, this guide is the one to read.

But, let’s get into more specifics of these lights and what makes them a great safety option!

Understanding Red Danger Light

Red is considered a symbol of danger and will easily catch the attention of walkers who’ll instantly keep safe from an impending collision. What is great with our red danger Warning lights is that they emit a line of red lights on the sides of the vehicle, marking the safety zone that pedestrians shouldn’t cross!

Key Features

Red lights by SharpEagle are a perfect way to keep pedestrians safe from collisions or getting their feet injured. This system comes with LED lights of the highest power and aluminium housing for the lights’ safety. Double-insulated rubber wire ensures that the electricity supply is uninterruptedly flowing to the lights.

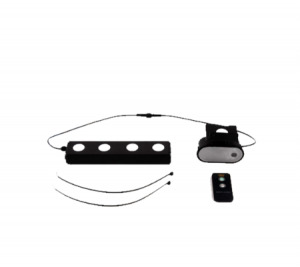

Our Forklift Red Danger Zone Warning Lights:

Have 6 pieces of 18W Osram LED lights

Operating voltage range of 10-80V

Double-insulated silicon rubberized wire able to bear high temperatures

Aluminum Die-Cast Housing

Stainless Steel Bracket Cover

1-year Warranty

Laser Light

The laser light beams help bring attention to the pedestrians by emitting strong laser light in their direction, boosting their focus and helping them get more alert. This light also has the function of establishing fork proximity for faster and easier transport and loading and unloading of goods!

youtube

Key Features

This system indicates the exact position of the fork, increasing productivity and reducing transportation time and chances of damage to the product. The light source is a rechargeable battery that’s remotely controlled and has a laser wavelength of 100mW and 650mm!

SharpEagle’s Foklift Laser Lights:

Are suitable for Class 1,2,3, and 4

Are operated by a remote control switch

Use a rechargeable battery, taking 8 hours to recharge

70 hours of battery lifetime

Laser wavelength of 650mm (red light) and 100mW power, with safety class of IIB

1-year warranty

Laser lights are great attention-grabbers! More on them you can read in this guide.

Added Benefits of Combining Red Danger Lights and Laser Lights

The integration of both Forklift Red Danger Lights and Forklift Laser Lights creates a synergistic safety system that offers comprehensive protection for both operators and pedestrians in warehouse environments.

Enhanced Visibility and Awareness

Red Danger Warning Lights serve as prominent visual indicators, signalling potential hazards and establishing clear safety zones around the forklift. The bright, flashing red light immediately draws attention, alerting nearby personnel to exercise caution and maintain a safe distance. By illuminating the surrounding area with a conspicuous warning signal, Red Danger Safety Lights improve visibility and enhance situational awareness, reducing the risk of accidents and collisions.

Forklift Laser lights, on the other hand, complement the functionality of Red Danger Lights by providing additional visual cues and guidance. By projecting lines onto floors, walls, or other surfaces, laser lights delineate designated pathways and highlight safe areas for pedestrians and operators to navigate. These laser projections serve as proactive reminders of spatial boundaries and potential danger zones, prompting individuals to remain vigilant and adhere to established safety protocols.

Comprehensive Safety System

When used in conjunction, Forklift Red Danger Lights and Forklift Laser lights create a multifaceted safety system that addresses various aspects of forklift operation and pedestrian safety. Red danger lights excel in signalling immediate danger and establishing exclusion zones around the forklift, while Laser Lights contribute to proactive hazard mitigation and spatial awareness.

For example, in scenarios where a forklift is manoeuvring through congested aisles or tight spaces, red danger lights illuminate the immediate surroundings, alerting pedestrians to maintain a safe distance and avoid potential collisions. Simultaneously, laser lights project clear lines on the floor, guiding pedestrians along designated pathways and highlighting safe areas for passage. This dual approach ensures comprehensive coverage and maximises visibility, minimising the risk of accidents and injuries.

With these tips in mind, you can confidently and safely use your forklift!

Conclusion

Forklift safety lights come as an added bonus in your business that mitigates risks of injuries and fatalities. SharpEagle is a leading end-to-end safety consultant in the GCC and UK. Our experts assist you with the best lighting solutions for your forklift operating needs, so that you can invest in a high-quality option for your safety protocols.

Visit our website to know more about Forklift Red Danger Lights and Laser Lights. Connect with our experts today for customised forklift safety lighting solutions.

You can also call us at +971-45549547 or mail us at [email protected]

#forklift laser safety lights#forklift red zone light#forklift safety laser light#forklift safety lights red#Forklift Red danger light#Forklift Laser Light#red zone danger area warning light#red zone light for forklift#forklift indicator lights#Forklift Laser Pedestrian Warning Light#best forklift laser safety lights#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light#Youtube

0 notes

Text

Alert Pedestrians Instantly: Blue Spotlight & Red Zone Lights

Safety is paramount in industrial environments, especially given the prevalence of forklift trucks, which often pose risks to pedestrians. To address this concern, safety managers are increasingly turning to innovative solutions like Blue Spotlights and Red Zone forklift lights. These LED safety lights serve a crucial role in alerting pedestrians to the presence of forklifts and preventing collisions. The Blue Spotlight projects a distinct blue spot on the ground, while the Red Zone light creates a visible danger zone around the forklift.

Let’s dive into the nuances of both in more detail!

What are Blue Spotlights and Red Zone Forklift lights?

There is a frequent episode that the crew encounters where someone is walking through your factory or warehouse staring at their smartphones or wearing earbuds, unaware of what’s happening around them.

Blue Spotlights and Red Zone forklift lights are essential safety devices designed to enhance visibility and prevent accidents in industrial environments.

The Blue Spotlight projects a prominent blue spot on the ground, serving as a clear indicator of an approaching forklift. It alerts pedestrians to the presence of the forklift, prompting them to adjust their path to avoid potential collisions. By effectively signalling the forklift's location, the Blue Spotlight significantly reduces the risk of pedestrian-forklift accidents.

On the other hand, the Red Zone Forklift Light creates a designated no-go zone around the forklift by projecting two straight red beams onto the ground. This illuminated area serves as a visible danger zone, indicating that the forklift is in motion or actively stacking goods. Pedestrians are thus alerted to keep a safe distance from the vehicle, minimising the risk of accidents caused by inadvertent crossings.

Blue Spotlights

Blue spot lights are a vital safety feature in industrial environments, particularly in warehouses where forklifts are commonly used. These spotlights serve as proactive warning signals for pedestrians, alerting them to the presence of forklifts and helping them avoid potential accidents.

Illuminating the Path for Pedestrians

Mounted on the overhead guard of the forklift, a blue spotlight emits a bright blue spot on the ground, typically extending 10-20 feet in front or behind the forklift. This illuminated path serves as a visual cue for pedestrians, signalling the approach of the forklift and allowing them to adjust their movements accordingly.

By highlighting the forklift's trajectory, the blue spotlight enhances pedestrian awareness and facilitates safe navigation around the vehicle.

Benefits of Using Blue Spot lights

Enhanced Visibility: Blue spotlights significantly improve visibility in busy industrial settings, especially in areas with low lighting or obscured sightlines. Pedestrians can easily spot the distinctive blue spot, even from a distance, enabling them to steer clear of oncoming forklifts preemptively.

Reduced Accidents: By providing advanced warning of forklift movements, blue spotlights help prevent collisions between pedestrians and forklifts. This proactive safety measure minimises the risk of accidents and injuries in the workplace, fostering a safer environment for all personnel.

Increased Awareness: Blue spotlights raise awareness among pedestrians about potential hazards posed by forklifts, encouraging them to remain vigilant and exercise caution in shared work areas. This heightened awareness promotes a safety-conscious culture and reduces the likelihood of complacency or oversight.

Improved Efficiency: Fewer accidents and disruptions caused by pedestrian-forklift collisions can increase productivity levels as workflow remains uninterrupted. Blue spot lights contribute to the smooth operation of industrial facilities by mitigating safety risks and optimising work processes.

Red Zone Forklift Lights

Red zone forklift lights also known as Red Danger Lights are essential safety devices designed to enhance visibility and prevent accidents in industrial environments, particularly in areas where pedestrians and forklifts interact. These lights serve as proactive warning indicators, delineating a safety perimeter around the forklift to alert pedestrians and other workers of potential hazards.

Overview and Functionality

Mounted on the sides of the forklift's overhead guard, red zone lights project two straight red beams onto the ground, creating a visible safety zone or "no-go zone" around the vehicle. The illuminated area serves as a clear boundary that pedestrians are advised to avoid, signalling the presence of an operational forklift and the potential dangers associated with its movement.

Better Visibility and Safety for Pedestrians

Red zone warning lights significantly improve pedestrian visibility and safety by providing a visual indication of the forklift's operating area and potential hazards. The bright red beams are easily discernible even in busy or dimly lit environments, alerting pedestrians to the forklift's presence and prompting them to maintain a safe distance.

Creating a Visible Safety Zone

The primary function of red zone lights is to create a visible safety zone around the forklift, delineating an area that pedestrians should avoid to minimise the risk of accidents or collisions. By projecting clear red beams onto the ground, these lights define the boundaries of the forklift's operational space, enabling pedestrians to navigate around it safely.

The interesting aspect of the red zone forklift safety light is that the driver does not have to worry about the estimation the pedestrians have to make to keep themselves away from the lift truck. They need to see the danger line, and that’s it.

Benefits of Red Zone Lights

Enhanced Safety: Red zone lights provide a proactive safety measure by clearly defining the forklift's operating area and alerting pedestrians to potential dangers. This helps reduce the risk of accidents and injuries in the workplace.

Improved Awareness: By creating a visible safety zone, red zone lights increase awareness among pedestrians about the presence and movement of forklifts, encouraging them to exercise caution and remain vigilant in shared work areas.

Reduced Collisions: The clear delineation of a safety perimeter around the forklift helps minimise the likelihood of collisions or accidents involving pedestrians. Red zone lights serve as a visual cue for pedestrians to stay clear of the forklift's path, preventing potentially hazardous situations.

Compliance: Implementing red zone lights demonstrates a commitment to workplace safety and regulatory compliance. These lights align with safety standards and guidelines, contributing to a safer work environment and mitigating liability risks.

Read More : Alert Spectators with Forklift Red Danger & Laser Light

Advantages of Blue Spotlight and Red Zone Lights

The key factor is to create a safe working atmosphere around the forklift. The warning lights play an important role in:

• Blind intersections or corners where approaching vehicles or pedestrians can be difficult to spot.

• Reducing the chances of the pedestrians hitting by the rear end swing of a moving or turning forklift truck.

• Providing a safety cover against other speeding forklifts that may collide with the one having loads of goods.

• Enhancing productivity and efficiency, as fewer accidents mean fewer chances of distractions of fellow workers and uninterrupted workflow.

• Making your company compliant with the latest safety standards, also means the betterment of the brand value.

Forklift Safety Lights – A commitment toward a safer and promising business

Blue Spotlights and Red Zone forklift lights are indispensable safety tools that play a vital role in enhancing visibility, reducing accidents, and promoting a safer work environment in industrial settings. By illuminating the path for pedestrians and creating visible safety zones around forklifts, these lights help prevent collisions and minimise the risk of injuries.

At SharpEagle, we understand the importance of workplace safety and are committed to providing high-quality safety solutions to our customers. With years of experience in the industry, SharpEagle has established itself as a trusted provider of forklift safety lights, including Blue Spotlights and Red Zone lights. Our products are designed to meet the highest standards of quality, durability, and performance, ensuring reliable protection for both workers and equipment.

Ensure the safety of your workplace by investing in SharpEagle's forklift safety lights today. Visit our range of products and solutions or contact us directly for personalised assistance.

Let SharpEagle be your partner in creating a safer and more productive work environment.

FAQs

How do Blue Spotlight and Red Zone warning lights improve safety?

Blue Spotlight and Red Zone warning lights enhance safety by increasing visibility and marking safe areas around forklifts. The Blue Spotlight makes forklift movements more noticeable, especially in noisy or visually cluttered environments, while the Red Zone warning lights visually delineate safe distances, preventing pedestrians from getting too close to the moving vehicle. These lights help minimise the risk of accidents in industrial settings.

Can these lights be used on all types of forklifts?

Yes, these lights can be retrofitted on almost any type of forklift, including counterbalance forklifts, reach trucks, and more specialised types like rough terrain forklifts.

What should be considered when choosing these lights?

Factors such as brightness, durability, ease of installation, compatibility with the forklift model, and compliance with safety regulations should be considered. Additionally, assessing the specific operational environment and the visibility needs of pedestrians can help determine the most suitable lights for the forklift.

You can also call us at +971-45549547 or mail us at [email protected]

#red zone danger area warning light#red zone light for forklift#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

Importance of Red Zone Danger Area Warning Lights

Forklifts serve a vital role in many industries for material handling and transportation. These versatile machines are used in warehouses, factories, construction sites, and many other settings to lift and move heavy loads from one location to another. Forklifts are equipped with long, metal prongs called forks, which lift and move pallets, crates, and other packaged goods. The forks are mounted on a mast, which can be raised and lowered using hydraulic controls. The operator sits in a cab at the front of the forklift and uses powers to manoeuvre the vehicle and manipulate the forks.

However, forklifts are not devoid of safety threats to the goods, equipment, pedestrians, and the operator. OSHA records 34,900 fatal and 61,800 non-fatal injuries caused by forklifts annually. Below listed are the primary hazards that forklifts pose across different industries.

Safety Hazards of Forklifts in Industries

Forklifts are prone to several hazards due to their size and working conditions, as listed below:

Collisions

Forklifts can collide with other vehicles, pedestrians, or stationary objects, which can cause serious injuries or fatalities. Operators should be trained to avoid collisions by paying attention to their surroundings and following safety protocols.

Falls

Falls from a forklift can occur if the operator loses control or if the forklift overturns. Operators should be trained appropriately to use the forklift safely. The forklift should be maintained in good working order to reduce the risk of falls.

Struck-by accidents

Forklifts can cause injuries if workers are struck by the vehicle or by objects being moved by the forklift. Operators should be trained to use caution while operating the forklift and to be aware of their surroundings at all times.

Caught-in/between accidents

Workers can be injured if they are caught between the forklift and another object or if they are caught in moving parts of the forklift. Operators should be trained to keep their hands and feet clear of moving parts and to use caution when driving the forklift.

Eradicating Low-Light Forklift Hazards

One of the common factors in the hazards listed above is the lack of visibility and proper warning signs for the crew, compromising the safety of on-ground pedestrians. This is where the LED lights for forklifts come in. Forklift safety lights are an essential safety feature that can help improve visibility and reduce the risk of accidents on the job. These lights are often used on forklifts, material handling equipment, and other industrial vehicles to improve visibility and alert other workers to the car's presence.

Primarily used in industries like logistics and large-scale warehouses, there are several different types of forklift safety lights, including headlights, tail lights, turn signals, and warning lights. Forklift safety lights are essential in low-light or poorly-lit environments, such as warehouses and factories. They can help improve visibility and make it easier for operators to navigate the workplace. They can also help alert other workers to the presence of the forklift, which can help reduce the risk of collisions and different types of accidents.

In addition to improving visibility and safety, forklift safety lights can also help improve efficiency on the job. By making it easier for operators to see their surroundings and navigate the workplace, safety lights can help reduce the risk of delays and accidents, which can help improve overall productivity.

Thereby, LED lights for forklifts are an essential safety feature that can help improve visibility and reduce the risk of accidents on the job. Employers should ensure that their forklifts are equipped with appropriate safety lights, and workers should be aware of the importance of using them to improve workplace safety and efficiency.

Introducing the Forklift Red Zone Light

Red Danger Warning Light creates a safety perimeter around the forklift to reduce the risk of foot injuries and collisions. These lights are mounted on either side of the vehicle. They project a bright red beam around the forklift, providing a visual cue to the crew and pedestrians to keep safe distance from an operating forklift to avoid accidents and injuries.

Technical Specifications of SharpEagle’s Forklift Red Zone Warning Lights

Enhanced safety signalling with potent red LEDs

Optional line beam for versatile lighting.

Waterproof, dustproof, and quakeproof protection

Durability with aluminium die-cast housing and stainless steel bracket.

Double-insulated silicon rubberized wire for safety.

High-Power LED Array: Osram LED 6pcs*3w

Ground Illumination: 200lux @2.5m

Voltage Options: 10~80V DC or 10-110V DC (Customised)

Long Lifespan: 50,000 hours

Colour Choices: Blue or Red

Working Temperature Range: -40°C ~ 80°C

Compact Design: 150*60*57mm

Importance of Forklift Red Zone Light for Your Industry

Prevents Forklift Accidents

The red danger light prevents forklift accidents by providing warning to the pedestrians from any direction. This is particularly useful in multiple blind corners and behind structures in busy workplaces. Primarily, these lights are useful in providing safety against collisions with the forklift's rear-end swing. Beside securing pedestrians and protecting them from being run-over, these forklift warning lights also secure the goods and merchandise transported with the forklift.

Clear Visibility Over Long Distances

Owing to the working conditions in industries and large warehouses, the workers might encounter several blindspots. Due to the sharp turns in several industries, pedestrians might fail to notice an approaching forklift before the intersection. Furthermore, workers are used to working in extremely noisy conditions, due to which a warning alarm might often be ineffectual. In such cases, the bright LED light used in the forklift red zone warning lights can serve as a reliable visual cue for an approaching forklift. The colour red is proven to scatter the least and is hence visible over long distances to warn the pedestrians.

Increased Productivity

Assured protection from forklifts allow workers to move heavy loads quickly and efficiently, significantly increasing productivity. Thus, forklift red danger lights improve the efficiency of material handling and transportation processes, which is especially important in fast-paced industry environments.

Employers should ensure that their forklifts are equipped with appropriate red danger lights, and workers should be aware of the importance of using them to improve workplace safety and efficiency. Proper use of forklift red danger lights can help reduce the risk of accidents and injuries on the job and can help improve overall safety in the workplace.

Partner with SharpEagle for Smart Safety Solutions for Your Forklift Operations

The benefits discussed above highlight the importance of investing in a good and reliable model of red zone danger light for your workplace. SharpEagle is a leading safety and efficiency solutions provider in the GCC and the UK. We are end-to-end safety consultants for your company. Our experts offer services like site inspection for customised forklift safety and lighting solutions. Our forklift red danger light undergoes severe tests to ensure its reliable performance. We constantly keep updating the model with the latest technological trends to optimise the safety standards for your crew, goods, and the forklift itself. Beside manufacturing and installation, our team also conducts maintenance checks for warranted safety in your forklift operations.

To know more about our forklift red zone light, visit our website or book a free consultation call with our experts to optimise your forklift safety today!

Related FAQs

How do Red Zone Warning Lights improve workplace safety?

Red Zone Warning Lights enhance safety by providing a clear, visible indicator of the forklift’s danger zone. By creating a safety perimeter using powerful red LED lights. It helps prevent pedestrians from accidentally coming too close to moving forklifts, which can significantly reduce the likelihood of collisions and injuries in busy industrial environments.

Where should Red Zone Warning Lights be installed on a forklift?

Red Zone Warning Lights are typically installed on the front, back, or sides of a forklift. This positioning ensures that the red safety boundary is projected on the floor around the forklift, creating a clear visual cue for any pedestrian nearby to maintain a safe distance and avoid injury from an operational forklift.

Can Red Zone Warning Lights be used in conjunction with other safety devices?

Yes, Red Zone Warning Lights can be used alongside other safety devices such as blue spot lights, warning alarms, and forklift cameras. Combining multiple safety features can provide a more comprehensive safety system, further minimising the risk of workplace accidents involving forklifts.

You can also call us at +971-45549547 or mail us at [email protected]

#red zone light for forklift#red zone danger area warning light#Forklift Red danger light#forklift safety lights red#forklift red zone light#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

The Complete Guide to Red & Blue Forklift Safety Lighting

According to OSHA, approximately 34,900 serious injuries occur due to forklifts in the United States alone. Despite the advanced safety directives in modern workplaces, forklifts cause 85 deaths and 10,000 accidents every year.

These existing threats call for advanced technological solutions. Proper marking, including safety blue and red lights, is crucial in protecting against these threats. At SharpEagle, we offer a tailored and comprehensive solution for workplace safety, including ATEX-certified, most reliable lighting, cameras, and other solutions. This article will outline how red and blue safety lights can enhance safety at your workplace.

How Red and Blue Forklift Safety Lights contribute to safety

Forklift accidents can occur in industrial environments for various reasons, including limited visibility, crowded workspaces, blind spots, and more. Let's explore each light individually to understand how blue and red forklift safety lights can address such challenges, their features, and other specifications.

Blue Forklift Safety Lights

Forklifts are a primary cause of 10% of workplace accidents - including forklift overturns, collisions, falling loads, pedestrian accidents, and more. Several reasons can contribute to these accidents, including:

Operator’s inability to spot the approaching intersection

Visual inaccessibility due to forklift’s blindspots

Lack of proper monitoring and safety compliance

Inadequate forklift maintenance

Fortunately, installing blue safety lights on forklifts can eliminate most of these challenges. Forklift blue lights are attached to the front and back of the forklift. As the forklift moves, a bright blue light is emitted, visible up to 10 feet from the vehicle. This sharp beam of light warns the pedestrians and other staff members about the speed and direction of the forklift. These lights also alert pedestrians and other drivers to get out of the way when the forklift operator is driving in reverse.

Features of Blue Safety Lights:

Casting Aluminium Alloy Housing

Forklift blue safety lights have robust casting aluminium alloy housing, which helps shield delicate electronic parts of the blue safety light from external impacts, vibrations, moisture, and other environmental hazards. This aluminium casting also ensures optimal heat dissipation and guaranteed longevity and corrosion resistance, keeping your lights functional and shining brightly through the toughest industrial settings.

Tempered Glass Cover

A tempered glass cover makes forklift blue lights resilient, durable, and heat resistant. It adds an extra layer of protection to ensure your lights remain functional under harsh and extreme industrial environments. In case of breakages, tempered glass breaks into small, blunt pieces instead of sharp shards, reducing the risk of injuries.

High Power LED

High-power LEDs enable bright, intense, and concentrated illumination, making them suitable for industries like oil and gas, mining, chemical manufacturing, warehousing, and logistics. Blue Safety lights are high-power LED lights offering a longer operational lifespan and energy efficiency.

IP- 67 rating

IP rating stands for Ingress Protection, which rates the protectiveness of the electric device against dust and water. Our forklift blue safety lights have an impressive IP rating of 67 denoting high protection against solids (dust, dirt, particulates) and water when immersed up to 1 meter.

Red Forklift Safety Lights

According to one of the latest reports, 8% of forklift accidents occur due to forklift turnovers involving workers. To keep workers safe, it's crucial to establish and communicate the correct distance that the crew needs to maintain from forklifts. Red forklift safety lights can help you communicate safe distances and other safety protocols, enhancing workplace safety.

Forklift red lights are often attached to the sides of the vehicle to indicate a safe distance between the pedestrian and the forklift. The red light they emit is also known as a halo zone and marks a two—to five-foot boundary that no one should cross. This distance can be adjusted by angling the light according to your facility space situation.

Features that make red forklift safety lights more effective:

Aluminium die-cast housing with a polycarbonate cover

The red safety lights' aluminium die-cast housing has a robust foundation that enables heat dissipation to keep the lights cool even during prolonged usage. This aluminium casting provides durability and resistance to impacts, vibrations, and harsh environmental conditions. The polycarbonate cover offers excellent optical clarity and protection against dust, debris, and minor impacts. These two features create a functional and reliable safety light system capable of handling rigorous and harsh industrial conditions.

Stainless steel bracket

With a stainless steel bracket, these red safety lights offer steadfast mounting support, ensuring secure attachment to the forklift. This feature guarantees stability and reliability, essential for the safety of operators and workers in industrial settings.

10-80V DC operating voltage

To simplify the specifications, the ‘10-80V DC operating voltage’ denotes that the device is built to operate in the 10-80 volts DC (Direct Current) range. This voltage range makes red forklift safety lights compatible with other power sources. The versatile voltage range simplifies installation procedures, allowing you to integrate the lights into their existing setups quickly and efficiently.

High power Osram LED 6pcs*3w with 18 W LED power.

This indicates the configuration and power rating of the LED lighting system, which is six individual LEDs, each rated at 3 watts, providing an 18-watt LED Power. The high-power LED enables bright illumination, allowing you to use red forklift safety lights even in extreme low-light conditions. This light is preferred in industries such as commercial and retail, industrial and manufacturing, and automotive, among others.

Stay away from the 85 forklift deaths that occur each year! Make your workplace safer right now by outfitting your forklifts with red and blue lights.

Reach Out to Us

Guide To Red And Blue Forklift Lighting Options

Forklift ARC Lights

Forklift ARC Lights come with aluminium alloy housing and rubberized wire for efficient operation under hazardous conditions. They feature a high-power LED, which can project the light all the way to the ground. The tempered glass protects the system from internal damage and makes it water, dust, and shockproof. The forklift ARC lights are also built under an ingress IP-67 protection standard.

Forklift Red Danger Light

Forklift Red Danger Lights are the perfect all-in-one solution to keep pedestrians safe in your facility. Their warning system includes high-power LED security lights in an aluminium die-cast housing, with double-insulated wire and a stainless steel bracket, making it capable of withstanding extreme temperatures.

Forklift Laser Light

Forklift Laser lights come with a strong system equipped with a rugged design and laser beam projection, allowing you to indicate your forklift's exact positioning. This will help increase productivity and safety in your facility, simultaneously reducing transport time and the chances of any damage and collision. The forklift laser lights boast a robust design that ensures durability in demanding industrial environments. Additionally, they are engineered for easy maneuvering and supervision, enhancing their usability and effectiveness in improving safety and productivity within your facility.

With a 90% chance of forklifts being involved in fatal accidents, it's time to act! Install SharpEagle's safety lights and cut down on thousands of yearly accidents.

Get Free Expert Consultation

Forklift Blue Spot Light

The Forklift Blue Spot Light safety device has a rugged design and is ideal for alerting pedestrians of an oncoming vehicle. It is also a perfect choice for signalling the forklift around the corner with to-the-ground beam projection. This blue light emitter is 100% dust, water, and shockproof. Its aluminium alloy housing reduces and mitigates the effects of heat and fire.

Forklift Blue Arrow Light

The Forklift Blue Arrow Light offers clear blue arrow-shaped lighting, a highly visual light that immediately warns pedestrians and warehouse workers. Ideal for use at the rear to signal a reversing forklift, the product comes with 3W LED lights enclosed in an aluminium housing that reduces heat dissipation. The double-insulated rubberized wire and stainless steel bracket are engineered to endure high and low heat extremes.

Forklift Warning Light

Forklift Warning Light is an ideal device to warn pedestrians during forklift operations and avoid the risk of workplace accidents. Equipped with high-powered LED lights, the device is protected with a durable glass cover and a two-year warranty from SharpEagle. This warning light is also equipped with a quakeproof, waterproof, and dustproof body with aluminium alloy casting for effective extreme temperature resistance.

How to install Red & Blue Safety Lights?

The forklift's Red & Blue Zone lights can be mounted to any desired side. You need one for each side where you want to project a safety zone. The tool-free bracket with the kit makes it simple to mount the light to the forklift's overhead guard.

The installation of red and blue safety lights is easy. These forklift lights come with a tool-free bracket that can be used to mount the light to the forklift's upper guard easily.

To know the complete installation of the Red & Blue Safety Lights for your warehouse or manufacturing plant, follow our step-by-step manual:

Put two-way tape on the bracket's foot. This will reduce the tremors and prevent the lights from rattling.

Position the light close to the rear of the head guard. Ensure the operator can get in and out of the seat without running into the headlight.

Set the red zone light feet in place by encircling the overhead guard with the two clamps.

Using a socket wrench or screwdriver to tighten the clamps.

Remove excess material from the clamp strap.

Place the plastic clamp end piece over the strap's sharp end to prevent sharp edges.

Connect the wire, then use electrical tape to seal the connection.

As needed, wire into the forklift. The light can accept voltages from 10 to 80V DC.

Finally, tilt the light to a suitable distance—2-6 feet, depending on the requirement. Tighten down and lubricate the adjuster to prevent them from loosening.

How Red & Blue Safety Lights are Beneficial for Your Business?

Knowing the benefits of red and blue forklift safety lights will help you make an informed purchase decision. It will also enable you to educate your workers and forklift operators about the importance of using these lights and enhance your safety efforts.

Your forklift operations will be more productive.

Safety and productivity are closely intertwined. With red and blue safety lights, you upgrade the safety at your workplace by minimizing the risk of accidents. When accidents are reduced, there is no disruption in the workflow.

Forklift operators can continue their operations smoothly and move the load effectively at a given time. Hence, your operations remain productive.

You can proactively reduce the risk of legal liabilities.

Accidents involving forklifts can result in severe legal liabilities. Implementing forklift safety solutions is a proactive way to avoid the risk of these liabilities. Red and blue forklift safety lights strengthen your safety efforts by giving you an edge to safeguard your company’s financial interests and reputation.

It will make your workplace OSHA safety-compliant.

OSHA mandates using blue safety lights in dimly lit areas and while operating a forklift at night. Installing these lights in your forklifts means meeting OSHA lighting standards for safety. By adhering to regulatory standards, you mitigate the risk of fines or penalties for non-compliance, thus protecting your employees and assets. Moreover, creating a safety-compliant workspace protects your employees and assets and demonstrates your commitment to responsible business practices. Thus, safety compliance attracts top talent and improves public perception, fosters positive relationships with stakeholders, and aligns your company with valuable core values, further strengthening your brand reputation in the industry.

Driver’s Instructions to Boost Safety with Forklift Safety Lights

Just installing red & blue safety lights is not enough to make your operations safe. Drivers should also know how to use the safety features effectively. Guide the forklift operators with the following instructions to boost safety with forklift safety lights.

Keep the beam of red/blue light on ground level.

While using warning lights, point the beam towards the ground to ensure that your worker’s visibility is not impaired due to the bright light. Maintaining this practice contributes significantly to accident prevention and overall workplace safety standards.

Stay alert and avoid distractions.

Stay aware of the industrial surroundings, especially while driving the forklift through busy work areas. Remember to give visual cues with red and blue safety lights. If the forklift operator does not understand how to operate a red/blue forklift safety light, ensure to train him in its application and create a norm of regularly using it at the workplace. Maintain high alertness and awareness of the risks associated with forklift operations. This will encourage the drivers to carefully assess their routes and adapt their driving techniques to ensure maximum safety.

Do regular maintenance checks.

Inspect the red and blue safety lights regularly to ensure they function correctly. Seek maintenance immediately if you find any issues or malfunctions. Prompt and timely action can prevent mishaps and disruptions. Therefore, implement a regular inspection schedule for the forklifts and ensure timely maintenance to uphold safety standards.

Don’t overload the forklift.

Overloading a forklift is dangerous as it can be risky for the operator and the forklift alike. Sometimes due to overloading, the load could fall off, and the operator could lose control of the forklift. Additionally, it creates a blind spot for the operators. This could be threatening to pedestrians as the forklift might run over them. Moreover, heavy loads can hamper the regular speed of forklifts, and operators may not be able to make accurate judgments. So, follow a standard for loading of forklifts to avoid damage to the forklift and injuries for the operator and pedestrians.

Conclusion

Equipping your forklifts with red and blue safety lights can significantly reduce the risk of accidents in your workplace. These lights enhance visibility and warn pedestrians about the movement of forklifts. However, whether these lights alone are sufficient to prevent accidents depends on your workplace and the nature of your operations.

So, to ensure comprehensive safety in your facility, consider implementing a complete safety solution tailored to your specific needs. At SharpEagle, we offer expert consultation services to help you choose the right safety solutions for your business.

Enhance Safety with Every Turn - Choose SharpEagle's Forklift Lighting Solutions!

Talk to our experts

Related FAQs

What are the red and blue lights on a forklift?

The red and blue lights on a forklift are safety lights designed to enhance visibility and prevent accidents in manufacturing units, transportation facilities, construction sites, and industries that use forklifts for daily operations. The blue lights are typically mounted on the front and back of the forklift, while red lights are positioned on the sides. Both the lights enhance workplace safety and reduce collisions occurring due to forklifts.

What lights are required on a forklift?

According to OSHA's powered industrial truck standard, you need headlights, tail, and warning lights. Headlights provide illumination for the operator to see clearly in low-light conditions, while tail lights indicate the rear of the forklift to other workers. OSHA regulations also specify these lights' minimum brightness and placement requirements to ensure adequate safety measures at your workplace.

What does the red light mean on a forklift?

The red light on a forklift indicates a "halo zone" around the vehicle. It means that the workers should not enter that zone as there is a risk of heavy objects falling off the forklift and causing injury. It warns the workers to stay clear of the indicated boundary line. Hence, it reduces the risk of injuries for workers.

You can call us at +971-4-454-1054 or mail us at [email protected]

#forklift red zone light#forklift safety lights red#blue led forklift safety light#forklift blue arrow light#Forklift Red danger light#Forklift blue safety light#blue safety lights for forklifts#red zone danger area warning light#red zone light for forklift#Forklift Red zone warning light#Forklift Red zone Pedestrian safety warning light#LED Forklift red zone warning light#Forklift red zone danger area warning light

0 notes

Text

Complying efficiently with OSHA lighting standards for safety

OSHA has established lighting standards for workplaces to ensure adequate lighting is provided for workers to perform their tasks safely and accurately, including LED lights for forklifts. Proper lighting prevents accidents, reduces eye strain, and improves worker productivity. This article will elaborate on a few crucial things to know about OSHA lighting standards for safety in facilities.

OSHA Lighting Safety Requirement

1. General Illumination Requirements

OSHA requires that workplaces be adequately illuminated to ensure that workers can perform their tasks safely and accurately. General illumination must be provided with at least 10-foot candles (FC) for most general areas, with specific exceptions for certain areas such as emergency exit signs and stairways. Foot candles measure the amount of light falling on a surface and can be measured with a light meter.

2. Task Lighting Requirements

In addition to general illumination, OSHA requires task lighting to be provided for areas where workers perform specific tasks that require extra illumination. Task lighting must provide at least 30 fc of illustration and must be directed to minimize glare and shadows. Lamps, overhead fixtures, or portable lights may provide task lighting.

3. Emergency Lighting Requirements

OSHA requires emergency lighting to be provided in case of a power failure or other emergencies. Emergency lighting must provide at least one illumination for at least 90 minutes and must be located in areas where workers may need to navigate to safety in an emergency.

4. Lighting Maintenance Requirements

OSHA requires that lighting fixtures be maintained to ensure that they provide adequate illumination. Burned-out bulbs and other defects must be repaired promptly, and fixtures must be cleaned regularly to remove dirt and dust that can reduce illumination levels.

5. Lighting Design Requirements

OSHA recommends that lighting be designed to minimise glare, shadows, and reflections that can cause eyestrain and visual fatigue. Lighting should be distributed evenly throughout the workplace to prevent dark spots and provide uniform illumination. Lighting should also be shielded to avoid direct exposure to the eyes.

Improve workplace safety and productivity with efficient OSHA-compliant safety lighting. Don’t compromise with safety standards!

Connect with Us

Why Should Your Company Follow OSHA Lighting Requirements?

Several areas can be hazardous to a worker in a work environment, which has specially made LED lights for forklifts important. Lighting becomes a risk factor, especially when the labour is mostly manual and physical. Thus, protection is key, and OSHA lighting requirements are a fundamental protective measure. Some of the important reasons why your company should follow OSHA requirements are:

a) Workplace Safety:

The primary purpose of OSHA lighting standards is to promote workplace safety by ensuring that workplaces are adequately illuminated to prevent accidents and injuries. Proper lighting can help workers to identify and avoid hazards, such as obstacles, spills, and equipment malfunctions.

b) Compliance with Regulations:

Compliance with OSHA lighting standards is mandatory for most workplaces, and failure to comply can result in citations, penalties, and legal liabilities. Employers who comply with OSHA lighting standards can avoid these risks and ensure their workplaces are safe and compliant with regulations.

c) Employee Comfort and Well-being:

Adequate lighting is essential for employee comfort and well-being. Poor lighting can cause eyestrain, headaches, and visual fatigue, decreasing worker productivity and increasing the risk of accidents. Compliance with OSHA lighting standards can promote worker comfort and well-being, increasing job satisfaction and reducing turnover.

d) Improved Productivity:

Proper lighting can improve worker productivity by allowing workers to perform their tasks more accurately and efficiently. Adequate lighting can reduce errors and mistakes, saving time and reducing the need for rework.

e) Cost Savings:

Compliance with OSHA lighting standards can result in cost savings for employers. Adequate lighting can reduce the risk of accidents and injuries, resulting in lower workers' compensation costs and reduced liability insurance premiums. Proper lighting can also reduce energy costs by using more efficient lighting systems.

How Do OSHA Lighting Standards of Safety Protect Workers?

OSHA lighting standards for safety protect workers by ensuring that workplaces are adequately illuminated to prevent accidents and injuries. Here are some of how OSHA lighting standards protect workers:

i) Identification of Hazards:

Adequate workplace lighting helps workers identify and avoid hazards such as obstacles, spills, and equipment malfunctions. Proper lighting can also help workers to identify and respond to emergencies quickly and safely.

ii) Prevention of Accidents and Injuries:

Insufficient lighting can increase the risk of accidents and injuries by making it difficult for workers to see and navigate their surroundings. OSHA lighting standards ensure that workplaces are adequately illuminated to prevent accidents and injuries.

iii) Reduction of Eyestrain and Fatigue:

Insufficient lighting can cause eyestrain, headaches, and visual fatigue, which can decrease worker productivity and increase the risk of accidents, especially in the absence of forklift safety lights. OSHA lighting standards ensure that workplaces are adequately illuminated to reduce these risks and promote worker comfort and well-being.

iv) Compliance with Regulations:

Compliance with OSHA lighting standards is mandatory for most workplaces, and failure to comply can result in citations, penalties, and legal liabilities. Employers who comply with OSHA lighting standards can avoid these risks and ensure their workplaces are safe and compliant with regulations.

In conclusion, proper lighting is essential for workplace safety and productivity. OSHA has established lighting standards to ensure that workplaces provide adequate lighting for workers to perform their tasks safely and accurately. Employers should ensure that their facilities comply with OSHA lighting standards to protect workers and avoid potential OSHA citations and penalties.

How Can Your Company Comply With OSHA Lighting Guidelines With SharpEagle?

Managing and following the OSHA lighting guidelines can be tough and not very profitable, which is one of the major reasons why companies fail to do so. According to reports by ILO, a specialized agency of the UN, low light can cause eye strain and headaches, which reduces productivity and creates more scenarios where someone can get hurt.

SharpEagle understands the gravity and the need for the OSHA lighting guidelines and thus has been successful in creating products that help your company comply with these guidelines. Linear lights, LED lights, work lights, forklift safety lights, and HID lights are our best products that help companies create a safe work environment.

You can also call us at +971-45549547 or mail us at [email protected]

#Forklift Arc Safety Light#Forklift blue safety light#LED Crane Safety Lights#blue safety lights for forklifts#fork truck warning lights#warning light for forklift#overhead crane warning laser#forklift blue light installation#blue spot safety light forklift#overhead crane warning light#light duty overhead crane#red zone danger area warning light#forklift safety lighting

0 notes

Text

Forklift Safety Lights: You Must Choose but Choose Wisely

The forklift safety lights can bring a massive difference to the operational safety at industries and increase the efficiency of workplaces. These tools have a robust built and are tailor-made to mitigate the odds of forklift accidents and thrust productivity. Any good forklift safety solution provider must extend a complete range of safety tools under one roof to ensure all-round security of its client business, just as UAE’s number safety ranger SharpEagle does. Keep reading today’s blog to know all about forklift safety lights!

➢ Why Is Forklift Safety Light a Must for Your Business?

Forklifts have been a savior for the construction industry. However, it can prove to be a bane instead of a boon if it keeps causing huge losses in a million for the multiple accidents at the workplace. The trouble must end or else your business can never see the face of profit with the increased operational efficiency that forklifts bring. SharpEagle has manufactured and curated well-researched and advanced, premium quality forklift safety solutions to create a safe ecosystem for various industrial sectors globally. The vast range of products includes safety surveillance devices, anti-collision solutions, radar devices, fork view surveillance devices, and many advanced tools to ensure uninterrupted industry activities.

The right tools imply growth in production manifold and create a safe zone for workers and heavy machines even in rugged and combustible factories. Reports show how forklift safety lights have brought down accidents substantially, preventing collision between pedestrians/ operators and forklifts, and have helped promote a secure and healthy work culture, yielding higher profit!

➢ Forklift Safety Lights: Catalogue

Forklifts brought a revolution to many industries but with it came along the deadliest industrial accidents in history. SharpEagle created a vast range of Forklift safety lights to prevent every possibility of injuries and accidents. Their high-tech devices ensure all-round safety at the workplace. These lights have been engineered to provide maximum visibility to the operators and pedestrians. Better visibility not only ensures security but can also double up productivity in a couple of weeks post-installation.

The premium pocket-friendly products by SharpEagle that can give your business the safest ecosystem are:

• Forklift ArcLight:

The arc lights at SharpEagle are manufactured using rubberized wires made of silicon that works well in extreme temperature fluctuations. These devices last long owing to their robust built. The casts are made of an aluminum alloy, and the housing prevents the light from damages or corrosion. The other best feature of the Forklift Arclight is tempered glass which is water, dust, and quakeproof. All devices use high-power LED lights with minimal power consumption.

• Forklift Red Danger Light: