#forklift lights safety

Explore tagged Tumblr posts

Text

The Complete Guide to Red & Blue Forklift Safety Lighting

Forklift accidents can occur in industrial environments for various reasons, including limited visibility, crowded workspaces, blind spots, and more. Let's explore each light individually to understand how blue and red forklift safety lights can address such challenges, their features, and other specifications.

Blue Forklift Safety Lights

Forklifts are a primary cause of 10% of workplace accidents - including forklift overturns, collisions, falling loads, pedestrian accidents, and more. Several reasons can contribute to these accidents, including:

Operator’s inability to spot the approaching intersection

Visual inaccessibility due to forklift’s blindspots

Lack of proper monitoring and safety compliance

Inadequate forklift maintenance

Fortunately, installing blue safety lights on forklifts can eliminate most of these challenges. Forklift blue lights are attached to the front and back of the forklift. As the forklift moves, a bright blue light is emitted, visible up to 10 feet from the vehicle. This sharp beam of light warns the pedestrians and other staff members about the speed and direction of the forklift. These lights also alert pedestrians and other drivers to get out of the way when the forklift operator is driving in reverse.

Features of Blue Safety Lights:

Casting Aluminium Alloy Housing

Forklift blue safety lights have robust casting aluminium alloy housing, which helps shield delicate electronic parts of the blue safety light from external impacts, vibrations, moisture, and other environmental hazards. This aluminium casting also ensures optimal heat dissipation and guaranteed longevity and corrosion resistance, keeping your lights functional and shining brightly through the toughest industrial settings.

Tempered Glass Cover

A tempered glass cover makes forklift blue lights resilient, durable, and heat resistant. It adds an extra layer of protection to ensure your lights remain functional under harsh and extreme industrial environments. In case of breakages, tempered glass breaks into small, blunt pieces instead of sharp shards, reducing the risk of injuries.

High Power LED

High-power LEDs enable bright, intense, and concentrated illumination, making them suitable for industries like oil and gas, mining, chemical manufacturing, warehousing, and logistics. Blue Safety lights are high-power LED lights offering a longer operational lifespan and energy efficiency.

IP- 67 rating

IP rating stands for Ingress Protection, which rates the protectiveness of the electric device against dust and water. Our forklift blue safety lights have an impressive IP rating of 67 denoting high protection against solids (dust, dirt, particulates) and water when immersed up to 1 meter.

Red Forklift Safety Lights

According to one of the latest reports, 8% of forklift accidents occur due to forklift turnovers involving workers. To keep workers safe, it's crucial to establish and communicate the correct distance that the crew needs to maintain from forklifts. Red forklift safety lights can help you communicate safe distances and other safety protocols, enhancing workplace safety.

Forklift red lights are often attached to the sides of the vehicle to indicate a safe distance between the pedestrian and the forklift. The red light they emit is also known as a halo zone and marks a two—to five-foot boundary that no one should cross. This distance can be adjusted by angling the light according to your facility space situation.

You can call us at +971-4-454-1054 or mail us at [email protected]

#forklift blue light distance#forklift safety light#forklift lights safety#forklift halo lights#blue lights on forklifts#forklift red lights#forklift blue light#blue light forklift safety#red and blue lighting#blue warning lights on forklifts

0 notes

Text

AgriEyes 9016B Forklift Safety Light

Greetings, comrades of the warehouse! In terms of maintaining safety at work, attention to every small detail is important. This is why we're thrilled to present to you the AgriEyes 9016B forklift safety light. This light serves a dual purpose: enhancing appearance and ensuring safety for you and your coworkers while working. Let's explore the specifics and find out why this safety light is truly authentic.

Superior Quality: Built to Last

To start off, let's discuss the construction quality. The AgriEyes 9016B forklift safety light is built with a durable aluminum alloy casing, a stainless steel bracket that can be adjusted 360°, and a PC lens that is shatterproof. This design guarantees quick dispersal of heat and minimal heat production, ensuring durability and reliability. Having an IP65 waterproof certification allows it to withstand the demands of a bustling warehouse setting.

Enhanced Safety: Keeping Everyone Alert

The AgriEyes 9016B emits a vivid red line on the floor close to the forklift, instructing pedestrians to maintain a secure distance and prevent accidents. This greatly enhances safety in the workplace by decreasing the likelihood of accidents and injuries. It's similar to having a virtual protective area surrounding your forklift!

Wide Applications: Versatility at Its Best

Lighter and more compact than other models, the AgriEyes 9016B forklift safety light is suitable for various settings such as warehouses, stacking yards, loading docks, and enclosed spaces. It's ideal for forklifts in warehouses, farms, trucks, trailers, pickups, excavators, and more. It's like having a Swiss Army Knife of forklift safety lights!

Outstanding Illumination: Clear and Bright

Equipped with customized spot lenses and high-brightness LEDs, the AgriEyes 9016B LED forklift safety light delivers high brightness, clear and bright light beams, and soft, non-glaring light. It provides a more concentrated beam and wider illumination range compared to other forklift lights. It's like having a spotlight that keeps everything in focus!

Wide Voltage: Compatibility Made Easy

The warning light is suitable with the majority of forklifts since it functions within a broad input voltage range of 10 to 80 V. Because it may be used directly without requiring a separate power adaptor, this feature provides convenience. It is similar to having a forklift safety light with a global charger!

Conclusion

So, that's everything for now, everyone! For your job site, the AgriEyes 9016B forklift safety light is the ideal safety accessory. For those who operate forklifts, this safety light is revolutionary due to its superior quality, enhanced safety features, ease of use, outstanding visibility, and compatibility with several voltage levels. The 9016B will suit your demands whether you are operating a forklift on a farm or managing a busy warehouse.

0 notes

Text

A forklift with integrated safety lights and smart sensors. The forklift is parked in a warehouse aisle, and the lights are positioned on the front and rear sections. The smart sensors are not clearly visible in this image.

0 notes

Text

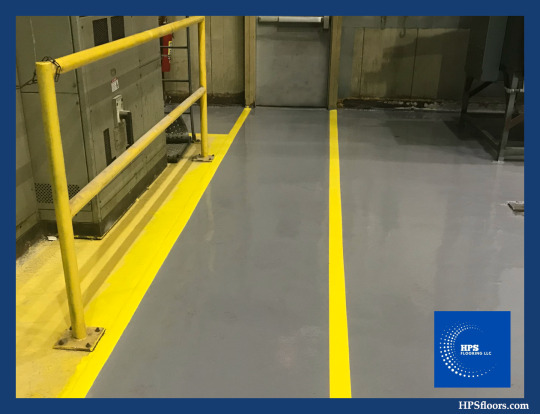

Warehouse Epoxy Flooring: Durable, Safe, and Efficient

When it comes to maintaining a warehouse, the flooring is often an overlooked yet crucial aspect of the facility's infrastructure. The floor must withstand heavy loads, constant foot traffic, and machinery movement while ensuring safety and efficiency. Epoxy flooring is a top choice for warehouses.

What is Epoxy Flooring?

Epoxy flooring is a surface coating created by mixing resin and hardener, forming a durable, seamless layer. This coating bonds exceptionally well to concrete floors, providing an even, resilient surface. The result is a floor that can endure the demanding environment of a warehouse while offering a professional appearance.

Why Choose Epoxy Flooring for Warehouses?

Durability: Warehouses experience high-impact activities, from forklifts carrying heavy loads to constant foot traffic. Epoxy flooring is highly resistant to abrasions, and impacts making it ideal for such environments. Its durability reduces the need for frequent repairs, saving time and costs.

Safety First: Epoxy flooring offers slip-resistant options that can be customized with visible markings for pathways, loading zones, and hazardous areas, improving navigation and reducing accidents.

Easy Maintenance: The seamless nature of epoxy floors makes cleaning and maintenance a breeze. Unlike traditional flooring, there are no cracks or crevices for dirt and debris to accumulate, ensuring a cleaner workspace with minimal effort.

Chemical Resistance: Many warehouses deal with chemicals or materials that can damage conventional flooring. Epoxy floors resist chemical spills, preventing stains and maintaining the floor’s integrity over time.

Cost-Effective: While the upfront cost of epoxy flooring may be higher than some alternatives, its longevity and minimal maintenance requirements make it a cost-effective investment for any warehouse.

Customization Options for Warehouse Needs

Epoxy flooring can be tailored to meet the specific needs of your warehouse. From anti-slip coatings to high-gloss finishes for better lighting, the options are vast. Additionally, color coding and line markings can help organize workflows and improve safety.

Installation and Maintenance

Professional installation is critical for ensuring the longevity of epoxy flooring. The process involves surface preparation, which may include cleaning, repairing cracks, and applying a primer. Once the epoxy is applied, it cures to form a hard, durable surface.

Regular maintenance involves simple sweeping and occasional mopping with mild detergents. For warehouses dealing with heavy traffic or chemical spills, periodic inspections can help ensure the floor remains in excellent condition.

#epoxyflooring#sherwinwilliams#warehousefloorpainting#epoxy floor contractor nj#epoxy flooring#epoxy warehouse flooring#epoxy contractor nj#warehouse floor painting#warehouse epoxy floor#chemical resistant floor#commercial flooring

3 notes

·

View notes

Text

borealis

chapter 1.: for now, it's time to run chapter tags: queer (m/m), sci fi, heists, kidnapping, referenced human experimentation, grumpy x bitchy, angst chapter warnings: implied noncon body modification, technical kidnapping, gun violence, language, mild gore, PTSD word count: 4243 A/N: the first chapter of my baby is here and ready to be shared! this is the first original work i'm posting in more than 5 years so i'm super excited to finally start sharing her with you all!

playlist || pinterest || masterlist

Every time he had to break into a building Dawson was acutely jealous of the shows and movies he’d watched as a kid— his life would be so much smoother if he could just slide through a couple air vents and be done with it! But no, instead here he was, 2am on a Thursday, knee deep in piles of whatever undoubtedly filthy laundry an illegal medical laboratory produced. Not his favorite way to enter a place, but it was one less code to remember— just a single key to lift off of an unaware janitor. The face mask he wore felt inadequate, but it would have to do.

The laundry facilities were on the very bottom floor of the lab, but Dawson’s target was only a few floors up— packed up and ready to be transported for sale tomorrow morning, according to Dawson’s employer. He didn’t know what, exactly, it was that he was stealing, but he wasn’t in any position to turn down a job that paid this much. He made his way swiftly down the hall and up the barren stairwell— which had required a convoluted code to open— in silence. The stairwell opened into a short hallway, only three doors occupying the limited space. He strode towards the 2nd door on the left, as his intel had instructed, and input yet another door code. The little blinking blue light swiftly turned green and the door slid open, bringing a satisfied smirk to the thief’s face. That smirk drops when he takes in the contents of the small room. Whipping his phone out of his breast pocket, he pulls up the single blurry shot of the case he’s supposed to be looking at.

That shitty fucking intel, is all Dawson can think, looking from the picture of his target on his phone back to the large metal crate looking thing that stood in the center of the cargo hold. He was here for a weapon, sure, but a fancy gun or laser sword, not something he would need a damn forklift to move. The crate had a number pad on its side, which would explain the extra passcode he’d been given. He lays his gun down within easy reach inputs the code, wincing as each button press emits a loud ping sound. It’s an obnoxiously long code too, even for some high-tech government laboratory, but finally he types in the last digit and hits enter. The box’s seams glow an ominous red before blinking to green, and there is the hiss of hydraulics before the lid of the box lifts and recedes on its own. Thick clouds of fog rise and quickly dissipate, revealing the contents; his target. It’s not a gun like he had hoped, or a bomb, or even a tiny, mysterious microchip.

It’s a dude. A curled slip of man, nude and nestled into perfectly cut out insulating foam. Dawson inhaled sharply, taking a step back. Because what the fuck. What the fuck was this? Was he stealing a corpse? Apparently not, because just as he goes to step closer, reaching out a hand to check for a pulse, the still form suddenly heaves a ragged breath and flies into a frenzy of movement, flinging himself from the box in a panic. Dawson reaches blindly behind himself for his gun on the table, clicking off the safety and pointing it at the man— fuck the payout, he wasn’t about to be mauled or maimed by some feral lab experiment! The man doesn’t attack though, instead scuttling backwards until he hits the wall, wild gaze flitting about and taking in his surroundings with an expression of pained confusion. When his gaze settles on Dawson the thief clutches his gun tighter and lets out a hissed curse; because those eyes are not human eyes. They shine an unnatural shade of teal, and the pupils shift and dilate like the lens of a camera. Mechanical.

But not one like anything Dawson has seen before, not even the fancy pretty ones the wealthy like to flaunt online. He’s breathing for one, still dragging in labored and brittle breaths, and sweat drips down his face, dampening unkempt curls. There’s an air of humanity to him that shouldn’t be possible in a mechanical.

“Who are you?” Dawson finally grits out, knowing that the clock is ticking and he doesn't really have time for an in-depth interrogation. The man just recoils further against the wall, though his breathing does at last appear to be mellowing out. A glance down at his watch shows that he has exactly 17 minutes to make his escape before the change of the security guards. “Fine, don’t talk. Look, I've got less than 20 minutes to get out of here so it looks like you’re coming with me. I was expecting a nice little carrying case, but I can make this work.” Still no reaction. Dawson feels a little bad for the mech— inhuman or not, the fear in his face and body language is palpable. He lowers his gun with a sigh before coming forward to kneel in front of the man, meeting his gaze with what he hopes is a reassuring expression— he’s not the expert on comforting scared people. There’s a barely audible hum as the mans’ eyes focus on Dawson, repeating that same camera lens effect.

“Look, clearly I don't know what’s going on here and neither do you, but I don't think you want to hang around here— they had you locked in a box in a basement. Something fucked up is happening here, and you can either come with me, or you can stay and try explaining to them how you got out of that box on your own. I don’t think the people here would be very happy with you escaping, do you?” And yeah, maybe it’s cruel to manipulate him like this, but whatever got him off of the floor and got them out of the lab was good enough for Dawson.

“Juno.” he blinks at the abrupt tone, but nods anyway. He— Juno, apparently— could speak, at least.

“Great. Nice to meet you Juno, I’m Dawson. Let’s get the fuck out of here.” And with that, Dawson stands yet again, this time taking Juno by the wrist and pulling him up to stand too. It’s sheer luck that hanging on the back of the chair in the otherwise barren room is an abandoned lab coat— he swiftly covers the mech’s nude form with the white fabric and instructs him to keep close and keep quiet, before leading them out of the room.

The long reaching hall is still blessedly empty as far as Dawson can tell, and it should remain so for the next five minutes— enough time to get them to the ground floor. Gun at the ready he pulls an annoyingly slow-paced Juno along— the smallest thing seems to distract the mech, as if they are not currently trying to escape a life or death (or unpleasant jail time) situation. They reach a fork, the hallway splitting into two identical paths. The map Dawson’s employer had provided said to go to the left, but Juno refuses to follow, digging his bare heels into the ground when Dawson tries to jerk him along.

“Not that way.” the mech unhelpfully says, a mulish expression on his face. He tilts his head in a way that suggests he is listening to something, and that something is evidently not Dawson— or anything Dawson can hear, because both halls are silent. “This way.” and he shifts his hand so he is the one holding onto Dawson now and, much to the thief’s chagrin, tugs him along without any effort, taking the right hall. They come to a stop in front of a closed door, which doesn’t budge when Dawson jiggles the handle.

“A dead end, seriously?” he hisses at the now bored looking mech. “I have been studying the schematics of this building for the last three months, kid, our way out was the other hallway!” He’s about to throw the mech over his shoulder and carry him to the proper exit fireman style, when Juno none too gently shoves him aside and gives the door handle a single firm yank. There is the sharp sound of wood cracking before the door gives way, swinging open, easy as anything now that a skinny little mechanical has just ripped the locking mechanism out of the damn door.

“Faster. And no cameras.” He gently sets the door handle and its guts on the ground, before gesturing for Dawson to lead the way once again. Something was seriously wrong with this mech and the way he functioned, but there was no time for him to ponder that. Quickly familiarizing himself with this portion of the map, Dawson manages to navigate himself and the mech up to the first floor. Which was where things were going to get seriously tricky. Where the bottom levels had been paroled by a barebones crew, the main floors were much more stringently supervised— guards patrolled each end of each level in synchronized pairs, armed to the teeth in the latest tech and paid handsomely enough that there wasn’t much they wouldn’t do for the company. Their escape would have to be timed perfectly, and helpful as he could apparently be, there was no time for deviations from Juno.

“You do what I say from here on out, got it? I’m not about to die because you think you found a shortcut.” The mech nods, but the mulish expression is back— quite the contrast from the trembling, fear filled thing he’d been just a few minutes ago. Time would tell if it was a welcome change. “And— hey, this is important—” he adds sharply, noting the mech’s gaze beginning to wander once again, this time distracted by the rattling of the air con. “If I get shot, or if they catch me? Don’t fucking leave me to die, got it? I am not getting paid enough to die for you. You come back for me.” The mech nods and it’s go time.

Dawson’s favorite kind of jobs were the ones where he got to break out the fancy equipment— harnesses for repelling down buildings, gadgets to disable alarm systems or cut through the glass of windows or display cases. But sadly, this was not that sort of job. Initially, his escape plan was to walk out completely undetected after going back the way he came, but by now someone was sure to have noticed Juno’s little door demolishment; it was only a matter of time before security was alerted of their presence. And unfortunately, he wasn't exactly able to tuck the mech into a backpack or pocket like he could have with his typical targets. So instead they had to do things the much more dangerous, life-threatening way, and tiptoe through the halls just as they emptied of guards, letting the timing of the guards’ schedule do the heavy lifting for them. So long as they didn’t do anything overt or loud, they were in the clear.

So of course. Of course Juno— who walked so silently Dawson could almost forget he was there if not for the bruising grip he had on his hand— slips on the slick tile, letting out a small cry as his ankle twists. It’s faint, but it’s a noise, and that’s all it takes for the sound of boots pounding in their direction to pick up. With a curse Dawson pushes the mech more fully behind him, sandwiched between his back and the wall, and clicks the safety off his gun once again. He can feel the mech breathing harshly against his neck, and thin fingers dig painfully into his hand as two guards come from each direction, cornering them with guns drawn. Dawson notes that they do not aim at them, despite clearly having the upper hand.

“Who are you, how did you get access to this floor?” One guard barks while another approaches, pulling handcuffs from his belt and reaching for Juno. And that, apparently, is the wrong thing to do, because the mech’s gaze snaps to the guard’s hand, and in the space of what can only be a few seconds the mech darts a hand out and grabs the guard, pulling him in close before flinging him bodily towards the other set of guards, sending them all tumbling down into a pile of limbs. The remaining guard, the one with the gun, quickly descends into panic, waving his gun around and shouting. Still, no actual shots are fired. Dawson is torn between trying to talk his way out of this or just knocking him out when Juno makes an executive decision. Hand outstretched like a superhero in one of the old movies Dawson watched as a kid, unnerving gaze glowing, and a little ball of light grows in his hand, giving off sparks and increasing in size until it’s on par with a large marble. The mech— or whatever the hell he actually was because mechanicals couldn’t form matter— closes his hand around it and the light disappears. Juno then opens his hand to reveal a shiny silver ball and Dawson only has a moment to study it before it flies forward and embeds itself in the guard’s chest, punching a hole straight through.

“Jesus Christ!” he exclaims, roughly wiping the blood spray from his face. Juno merely blinks, eerily unaffected, and follows easily when Dawson grabs him and drags him full speed from the scene. Hopefully the shock of their coworker's violent death keeps the other guards off their tail long enough for them to escape.

They make it to the exit, but Dawson would be hard pressed to recall how the hell they did it. After escaping the lab itself, it’s a simple matter of slipping down several tiny alleyways and taking a few twisty little side roads until they reach Dawson’s bike. Which swiftly presents the next dilemma; getting the lab grown superpowered mech onto said bike. Juno accepts the helmet easily enough, and even puts it on himself, though he bats away Dawson’s hands when he tries to adjust the straps. He sits behind Dawson when he says to, wrapping thin arms about the thief’s waist. He’s perfectly compliant until the bike turns on. The second it roars to life the mech is gone, scrambling off of the bike and away from its now offensive form.

“NO!” he yells, pointing an accusing finger at Dawson as he shuts off the bike and tries to approach Juno placatingly. “It’s too loud, I don’t like it!” It’s the most he’s heard from the mech since he opened that damn box. Dawson isn’t keen on having his head exploded or being set on fire, or whatever other powers Juno possessed, and so they are at an impasse.

“What do you want from me here, kid? We need to get out of here, and this is how we do that.” He gestures behind him to the bike. “It’s perfectly safe, I promise.” The mech glares unwaveringly from under stringy curls, and he appears to be shivering— from the cold or from shock, it was hard to tell. Either way, he needed to get him indoors and fast. Could mechs even get sick from exposure?

“Come on, we’ll get you some clothes, something to eat…” The promise of food seems to do the trick, mistrusting gaze softening to something almost hopeful.

“Chocolate, I want chocolate, the shiny ones.” Demanding thing.

“I— Yeah, yeah okay. Get on the bike and we’ll find you some damn chocolate.” He offers his hand again to pull Juno back behind him on the bike, but he’s still a little surprised when icy fingertips graze his own. Again, he wonders if it’s a product of Juno’s inhumanity or the winter temperatures. Dawson guides him onto the bike, holding an arm securely over the thin ones clinging with much more fervor to his waist before starting the bike. Juno gives a little whine of fear but doesn’t run away this time, so Dawson counts it as a win and takes off.

20 minutes later and they pull up to a dark, run-down looking building. Dawson shuts off the bike and after some light jostling manages to get Juno to let go and get off the bike, before leading the mech inside. The interior is just as grim as the exterior— a welcome desk that has sat unoccupied since Dawson moved in fills one corner, while a pile of unusable cleaning supplies from when there was a cleaning crew 10 years ago takes up the lobby. Juno is again taking in his surroundings with all the interest and newness of a child or cartoon alien, running his fingers across a tabletop before grimacing at the thick dust that now clings to them. Dawson wrinkles his nose when the mech absently wipes the grime on his pilfered coat, drawing attention to how out of place he looks outside of the illegal lab setting— barefoot and clad only in a now bloodstained and filthy lab coat, which slides off one shoulder as it has lost several buttons. The dried and flaking blood spatter across what would otherwise be a sweet face completes the upsetting visage.

“Let’s go, we can’t let anyone see you like this.” He takes Juno by the hand and leads him up to his apartment, smirking a little when the mech groans at the sight of several flights of stairs. It was nice to know that there was some humanity programmed into him.

10 floors later and they’re finally there.

“Home sweet home…” Dawson mumbles under his breath, pulling his keys out and opening the door. Juno all but runs inside, leaving the thief alone to lock back up. He kicks off his shoes by the door and then follows the sounds of Juno’s exploring to the living room, where the mech is stroking the blanket strewn carelessly over the back of the couch with reverent hands. Dawson clears his throat, feeling a little bad when he jerks his hands back as if burned.

“There’s a shower through there, go get washed up and I’ll have some clothes ready for you when you’re done.” he points to the doorway on the left. Juno seems to deflate before nodding shortly, stripping off the ruined lab coat right there in the living room, which… Okay, technically Dawson had already seen him nude, but he hadn’t planned on doing it again any time soon. He averts his eyes, and before he can muster up a response, the mech is gone, and the sound of the tub running starts up shortly. Shaking his head, Dawson grabs a trash bag from the kitchen to store the coat for now, planning on burning the thing when he gets the chance rather than risking someone finding it in the trash and poking around. Then he goes to his closet to find the aforementioned clothes he promised Juno.

He doesn’t have much that will fit the slight mech, but he digs up a sweater from an old fling and some shorts with a tie that would work until he could get to a shop. There’s no underwear, but he suspects the mech isn’t used to wearing any anyways. Clothing sorted, Dawson decides to tackle the food problem. He’s not sure what the mech can eat, or, in all honesty, what in his kitchen is still edible.

The fridge is hours away from becoming a biohazard zone, and the fruit bowl on the counter has sat empty since the day his elderly neighbor brought it over as a housewarming gift. The pantry, however, yields a mostly not stale pack of crackers, a jar of pickles, and a half empty bag of halloween candy. He arranges his findings on one of the two plates he owns before checking his watch and frowning. It’s been less than 10 minutes and yet he can already hear Juno turning off the shower. There’s a pleased sound and then the quiet shuffling of someone getting dressed.

Juno emerges not soon after, rubbing a towel aggressively over his head. He has forgone the shorts for some unknown reason, but the sweater does technically cover everything, the hem hanging awkwardly to graze the mech’s bruised knees, and Dawson lets it slide, taking the towel from him before he can drop it carelessly to the ground like he clearly plans to. He takes one of the mech’s eternally cold hands and leads Juno over to sit at the table, setting the plate of food in front of him. Immediately he can tell he’s made some sort of grave error— those unnatural eyes narrow, and the mech pokes at one of the little gherkins with an unimpressed air.

“What… are those?” he asks disdainfully, selecting one of the less offensive crackers to shove into his mouth whole instead.

“They’re pickles, you never seen a pickle before?” Dawson asks defensively, taking one and biting into it with an obnoxious crunch. And maybe it’s a little more sour than usual, what would Juno know about it if it was? The mech just shakes his head, continuing to scarf down crackers whole. He’s a mess of contradiction, equal parts fearful and demanding, knowledgeable and clueless. And then there’s the whole ‘killing people with little balls of light’ thing to consider. Hell, he probably hasn’t ever heard of a pickle before.

“So… What the hell was going on in that lab?” he finally asks. Juno looks up from his food (he has abandoned the plate and is now digging through the Halloween candy bag, pulling everything out and sorting them into piles— the non-chocolate candy is piling up on the floor beside his chair.) with eyes narrowed with distrust. He clearly isn’t about to bring Dawson into the loop, returning back to his candy sorting with an added flair of irritation. “Oh, so I save your skinny ass— nearly die in the process, might I add, take you in and feed and clothe you, but I can’t ask why they had you stuffed into a box? That seems fair.” He rolls his eyes when he is ignored yet again, reaching across the spindly table and grabbing the bag of candy from the mech’s lax grip. Juno hisses in surprise, baring pearly teeth at him— Dawson is pretty sure the mech might really try to bite him. Very animalistic for something so clearly machine.

“Nuh uh, you get these back when you answer my questions.” The little bastard actually has the nerve to snatch for the bag but he easily holds it out of reach. “Are you going to cooperate?” he reiterates once again, shaking the candy enticingly. Juno heaves a beleaguered sigh before giving a single sharp nod. As a token of good faith Dawson chucks a Twix at him— and is a little miffed when the brat catches it seamlessly.

“Good. Let’s start with something simple: why the hell were you in that box?”

“I always sleep in the box, if I’m not in use.”

That's… concerning. Mechs had developed so much in the past decade, it hardly seemed humane to lock them away when they weren’t ‘in use’. And those were just standard mechs, built to be companions, factory workers, and glorified pets. Whatever Juno was, it was clearly nearly human in its’ design, the lab could have at least sprung for a bed for the guy. The mech looks unconcerned though, gnawing at his candy’s wrapper with his teeth.

“What are your prioritized functions?” Some mechs don’t have them preprogrammed, or aren’t allowed to disclose them, but it's worth a shot to ask. Maybe if he knows why the lab was creating hyper realistic mechs, he could better figure out what to do with this one. Again though, Juno just looks confused by his question.

“I don’t know what that means.” It’s said fully deadpan, but Dawson can sense the unspoken disdain.

“Well what the hell are you, then? They obviously built you for something— are you just some sort of fancy weapon?” This, at last, has an actual, visible effect on Juno. And Dawson immediately regrets saying it. Confusion, hurt, and guilt flicker across his face before his expression settles into something supremely pained. Then the tears come, only to be dashed away by the sleeve of Juno’s borrowed sweater before they can fall.

“They didn’t. Build me, I mean. No one did. They just… added things. Removed things.” He’s looking down now, fiddling with the candy he still hasn’t managed to free from its wrapper. “I don’t remember everything, side effect of—” he waves his hand vaguely around his head, “but I was— I guess I was sick, as a kid? Really sick, and my family couldn’t afford the treatment, or maybe I didn’t have a family. The lab was running a trial for some special procedure and they picked me. Fixed me right up. Then they… kept finding new things to fix.” Dawson doesn’t know how he’s supposed to respond. He settles on pushing the candy back across the table, avoiding the unbearable weight of that odd gaze. Silence, for a few moments.

Then rustling sounds pick up.

A package of Skittles hits the linoleum.

#my writing#original work#queer sci fi#queer mystery#queer heists#human x robot#but not#oc x oc#single pov#male oc x male oc#series;borealis#ask to be tagged!#divider source: cafekitsune#special thanks to fanficbarbie for helping with/inspiring my chapter post layout!#spot the community reference lol

4 notes

·

View notes

Text

Heart full of stars chapter one

As Elise Blackmore woke up to the sound of her alarm telling her of all the things she had to do to day. The top of the list was a request from Corey to help repair some of the things in the haunted house that his son Oliver ran and while it is quite unusual for a 10-year-old to be running a haunted house, the fact that it was almost entirely automated, and could be controlled from a control room in the direct center meant that even a five-year-old could do it let alone a 10-year-old with a pension for mischief and a love of scaring people. The reason for the repair was listed as one of the moving walls got stuck along with the fact that some of the decorations needed a new coat of paint.  When Elise got to the haunted house, Oliver was just coming out of the building. He waved to Elise and said I’m going to go looking for that meteorite that crashed down this morning and just like that, he was running off into the jungle. Shortly thereafter, Oliver‘s father Corey ivailo was guiding Elise through the haunted house to the sliding wall that was stuck halfway through its motion. The power to the wall had already been cut, which meant it should have slid back into with the wall in which it was housed, when hiding as part of fire safety after all, despite this haunted house being one of the attractions, it was also used as an actual hotel even if by special appointment only by ghost film Crew and the occasional engineering school that wanted to study the mechanisms used

Oliver waved to Elise and told her that he was going to be looking for the meteorite that had crashed down on their island, while his dad and Elise were fixing up the current stuck wall  and he had already told Luna that he was going to be going out and looking for the meteorite. He had packed a sandwich and some water, and ran down off into the jungle about an hour later into his walk, he saw a blue glow, and getting closer he saw metal and the ruined trail of the meteorite but instead of a rock, it was metal carved with lines of blue light and then he realized it was a spaceship walking around it. He got to the bridge and saw that there. Was someone still inside of it a big someone, but they didn’t look awake and they looked hurt . Oliver knew that he couldn’t get the 7 foot person back on his own so he called his dad and Elise, Luna, and granny opal after all his dad and Elise would be able to get the forklift if nothing else to help move this guy and granny opal as the island doctor would want to take a look at this guy. If he is actually injured and even if granny Opal was fierce in her own way, Luna as head of security would need to be told anyway.

Storm heard a voice it sounded like a little kid. He had just enough strength to lift his head and open his eyes to look there. He saw a really small person and it sounded like they were talking to someone, but there wasn’t anyone there he figured that the kid must’ve had a communication device of some sort, but just as he thought that he blacked out again and when he woke up, he heard more voices He realized that he was on something soft, and he was laying down. When he tried to get up the voices stopped And he managed to open his eyes, and even though the lights were really bright, and they hurt, he still managed to see a little And what he saw was five people all of them smaller than him And from what he could hear through the translator was that he was being urged to lay back down by a small, elderly woman with curly brown hair that was starting to gray from one of the others the girl with long white hair and space buns with icy blue and yellow eyes said granny don’t get too close to them. We don’t know if they’re dangerous or not the elderly woman apparently named granny turned to the girl and said now Luna Skinner, this boy is hurt. He looks like he’ll fall back into unconsciousness if he sits up too fast. Storm processed the girls name Luna. He thought it was beautiful. And that was about the last thought he had before falling back unconscious.

2 notes

·

View notes

Text

Cranky PSA: Children and Hardware Are Unmixy

I never thought I’d have to say this, but apparently some people really haven’t clued in. Hardware stores are not grocery stores. They are not child-safe. They’re barely adult-safe. Do not let your toddlers out of grabbing range.

Ace, Home Depot, Lowe’s, wherever - hardware stores are full of things that even adults have to treat with caution. Kids are ignorant. Kids that can’t read “Danger - Flammable” are in even more trouble.

Start with the hardware. These places are full of shiny things. Nuts, bolts, nails, magnets, bits of railing, you name it. Kids are like ravens, drawn to shiny; and young kids are further drawn to putting everything in their mouths. Picture the large, very large, section of nuts and bolts. Picture them vanishing down a kid’s gullet. It’s happened. Or, and more likely, picture them upending entire drawers to create the ultimate trip hazard. Very possibly yanking them down on their own heads.

Move to the cleaning supplies, many of which are meant for cleaning businesses, and so industrial-strength. As in strong enough and nasty enough stuff you don’t want to handle it without gloves, eye protection, and possibly hazmat clothes. Think muriatic acid. Think pool chlorine tabs. Think ammonia-based cleaners that all say “use with adequate ventilation” at the very least. Think.

Look outside to the plants. Many of them are toxic. Fertilizers can be toxic, or at least harmful to skin and eyes. Herbicides and pesticides are definitely toxic. And they’re all there on the shelves in easy grabbing range.

Let’s not even get into the paints, oils, kerosene, gasoline, and so many sharp objects throughout the entire building. All of which are packaged to be safe to handle... if you don’t drop it. Or puncture it. Or climb on it. Or sling it at someone. What do kids do? Right.

Last but not least, think about the business of the store itself. There is a lot of stock. Much of it is heavy items. All of it has to be stored, and then accessed when customers want it. Which means heavy equipment. Forklifts. Other lifts. Things where the users have to be strapped in, because it’s dangerous to have any part of your body outside. The whole store is outside, and while employees try to set up barriers, they try to keep customers out of hazard zones....

Well. You’ve never seen a toddler scuttle so fast as when they’re scampering right under a safety gate, heading straight for the big black-striped yellow machine with all the blinking lights that can squash them like a watermelon dropped from a hundred feet.

Fortunately she slowed down when I yelled. Fortunately, she listened to her father when he called her to come back out. Absent those two pieces of luck, she was heading right toward a lift that - if something went wrong - could have easily dropped something heavy enough to kill her. And the safety employee wouldn’t have seen her because he was watching for idiot adults trying to come through or around the gates into the working aisle. Not a pink blur at ground level.

These are hardware employees. They’re doing their best, but they’re busy, they’re overworked, and they are not trained to look after children.

If you take your kids into a hardware store, keeping them safe is your job. Think it through. Please.

10 notes

·

View notes

Text

Ugly sweater day at work really be out here making me feel ugly...(ignore the blue light, that's the safety light on my forklift reflecting off the wall behind me)

And what's worse is my binder is making me hella dysphoric...not cuz "omg, flat chest, no!" But cuz ...even wearing it, it is so obvious I am afab and have badonkers.

...I don't pass. I will never pass. Why do I keep trying and playing pretend?

#who am I kidding?#should just accept and deal with the fact I am female and its not gonna change...#gender dysphoria#body dysphoria#low self everything

3 notes

·

View notes

Text

A guide to galactic ships: Millenium Falcon

When it comes to purchasing a starship, safety is of paramount importance. That’s because accidents and malfunctions that happen to starships in space often lead to instantaneous death.

So for those in the market for a cheap ship, the Millennium Falcon is a ship that you definitely want to avoid because of how extremely unreliable it is. Yes, the Millennium Falcon is an unreliable ship, that doesn’t mean however that this isn’t one of the most awesome starships ever built (one of my personal favorites because of how modular it is). These two things can exist in the same vessel. The Millennium Falcon was originally a YT-1300 Stellar Envoy light freighter so it was designed to haul goods and serve as a tugboat for larger containers which is why the cockpit of this ship is offset and there’s a forklift-like area in front of the ship which can be latched onto containers or an escape pod.

The Corellian Engineering Corporation is very well known for creating very affordable and very modular ships that are very good for commerce (or smuggling). They are famous for having a huge third-party aftermarket selection of parts that one could bolt onto their ships. This is usually where a lot of problems start occurring. Aftermarket parts can sometimes improve the performance of a ship but there are oftentimes reliability issues with these additional parts. For the Millennium Falcon, the largest problem was the hyperdrive system. Han Solo had installed the class 0.5 hyperdrive onto the freighter, one of the fastest in the entire galaxy when it worked.

But when the hyperdrive motivator started acting up on the Millennium Falcon, it went immediately from a class 0.5 hyperdrive to a class 10, which makes it one of the slowest ships in the entire galaxy. This is bad when you are on the run for smuggling spice.

Even with the unreliability of the hyperdrive, you can have it fixed or even have it replaced. Overall, this class of ship would be amazing for business or even an everyday ride.

2 notes

·

View notes

Text

Holidays 6.13

Holidays

Beyond the Solar System Day

Dia de Exu (Brazil)

Flag Day (Palau)

International Albinism Awareness Day (UN)

International Axe Throwing Day

International Community Association Managers Day

Inventors’ Day (Hungary)

Jason Voorhees Day

Kitchen Klutzes of America Day

Loeys-Dietz Day of Giving

Miranda Day

National Albinism Awareness Day

National Chamoy Day

National Dance/Movement Therapy Advocacy Day

National Day of Abortion Storytelling Day

National Day of Productive Business Civility

National Doe B Day

National Elderflower Day

National Frances Day

National Jane Day

National Pigeon Day

National Productive Business Civility Day

National Random Acts of Light Day

National Weed Your Garden Day

Outdoor Marketing Day

Random Acts of Light Day

Roller Coaster Day

San Antonio Day (Ceuta, Spain)

Sewing Machine Day

Suleimaniah City Fallen and Martyrs Day (Iraqi Kurdistan)

Swiftie Day

Tench Day (French Republic)

Weed Your Garden Day

The Wicket World of Croquet Day

World Softball Day

Yawn-a-thon

Yeats Day

Food & Drink Celebrations

Cupcake Lover’s Day

National Cucumber Day

Rosé Day [also 2nd Saturday]

2nd Tuesday in June

Broadcast Good Day [2nd Tuesday]

Call Your Doctor Day [2nd Tuesday]

National Forklift Safety Day [2nd Tuesday]

National Time Out Day [2nd Tuesday]

Waldchestag (Forest Day) [Tuesday after Whit Sunday]

World Pet Memorial Day [2nd Tuesday; also 2nd Sunday]

Independence Days

Princian Commonwealth (Declared; 2017) [unrecognized]

Feast Days

Annie Sprinkle Day (Church of the SubGenius; Saint)

Anthony of Padua, Doctor of the Church (Christian; Saint) [Portugal]

Aquilina (Christian; Saint)

Buddha's Parinirvana (Bhutan)

Cetteus (Peregrinus; Christian; Saint)

Damhnade of Ireland (Christian; Saint)

Day of the Living Children of Nut (Ancient Egypt)

Feast of Epona (Celtic; Pagan)

Felicula (Christian; Saint)

Festival of Jupiter Invictus (Jupiter the Unconquered)

G. K. Chesterton (Episcopal Church (USA))

Gerard of Clairvaux (Christian; Saint)

Gin Day (Pastafarian)

Gotthard Graubner (Artology)

Green Day (Pastafarian)

Ides of June (Ancient Rome)

Leon Chwistek (Artology)

Psalmodius (Christian; Saint)

Quinquatrus Minusculae (Old Roman Festival to Minerva)

Ragnebert (a.k.a. Rambert; Christian; Saint)

The Spaniel (Muppetism)

St. Theresa (Positivist; Saint)

Thomas Woodhouse (Christian; Blessed)

Triphyllius (Christian; Saint)

Lucky & Unlucky Days

Butsumetsu (仏滅 Japan) [Unlucky all day.]

Premieres

The Apocalypse Watch, by Robert Ludlum (Novel; 1995)

Back to School (Film; 1986)

Backwoods Bunny (WB LT Cartoon; 1959)

BrainDead (TV Series; 2016)

Day of Infamy, by Walter Lord (History Book; 1957)

Faith and Courage, by Sinead O’Connor (Album; 2000)

Forever Your Girl, by Paula Abdul (Album; 1988)

Hercules (Animated Disney Film; 1997)

How to Train Your Dragon 2 (Animated Film; 2014)

The Incredible Hulk (Film; 2008)

Jagged Little Pill, by Alan’s Morrisette (Album; 1995)

Kind Hearts and Coronets (Film; 1949)

Lolita (Film; 1962)

Make It With You, by Bread (Song; 1970)

Mona Lisa (Film; 1986)

Pat and Mike (Film; 1952)

Post, by Björk (Album; 1995)

The Prince and the Showgirl (Film; 1957)

Prozac Nation (Film; 2003)

Roadie (Film; 1980)

Texas Flood, by Stevie Ray Vaughan (Album; 1983)

22 Jump Street (Film; 2014)

…Very ‘Eavy …Very ‘Umble, by Uriah Heel (Album; 1970)

Vida La Vida, by Coldplay (Song; 2008)

The Washout Chronicle, by John Cheever (Novel; 1957)

Wholly Moses (Film; 1980)

The World is Flat, by Thomas L. Friedman (Economics Book; 2005)

Yodeling Yokels (WB LT Cartoon; 1931)

You Only Live Twice (US Film; 1967) [James Bond #5]

Today’s Name Days

Antonius, Bernhard (Austria)

Antonija, Antun, Toni (Croatia)

Antonín (Czech Republic)

Cyrillus (Denmark)

Monika, Mooni, Moonika (Estonia)

Raila, Raili (Finland)

Antoine (France)

Anton, Antonius, Bernhard (Germany)

Trifilios (Greece)

Anett, Antal (Hungary)

Alice, Antonio (Italy)

Ainārs, Tautvaldis, Tobijs, Uva, Zigfrīds, Zigrids (Latvia)

Akvilina, Antanas, Kunotas, Skalvė (Lithuania)

Tanja, Tone, Tonje (Norway)

Antoni, Chociemir, Herman, Lucjan, Maria Magdalena, Tobiasz (Poland)

Achilina (Rom��nia)

Anton (Slovakia)

Antonio (Spain)

Aina, Aino (Sweden)

Kalyna (Ukraine)

Ivey, Ivy, Lara, Larissa (USA)

Today is Also…

Day of Year: Day 164 of 2024; 201 days remaining in the year

ISO: Day 2 of week 24 of 2023

Celtic Tree Calendar: Duir (Oak) [Day 2 of 28]

Chinese: Month 4 (Ding-Si), Day 26 (Red-Yin)

Chinese Year of the: Rabbit 4721 (until February 10, 2024)

Hebrew: 24 Sivan 5783

Islamic: 24 Dhu al-Qada 1444

J Cal: 14 Sol; Sevenday [14 of 30]

Julian: 31 May 2023

Moon: 20%: Waning Crescent

Positivist: 24 St. Paul (6th Month) [St. Theresa]

Runic Half Month: Dag (Day) [Day 4 of 15]

Season: Spring (Day 85 of 92)

Zodiac: Gemini (Day 23 of 32)

1 note

·

View note

Text

The Complete Guide to Red & Blue Forklift Safety Lighting

According to OSHA, approximately 34,900 serious injuries occur due to forklifts in the United States alone. Despite the advanced safety directives in modern workplaces, forklifts cause 85 deaths and 10,000 accidents every year.

These existing threats call for advanced technological solutions. Proper marking, including safety blue and red lights, is crucial in protecting against these threats. At SharpEagle, we offer a tailored and comprehensive solution for workplace safety, including ATEX-certified, most reliable lighting, cameras, and other solutions. This article will outline how red and blue safety lights can enhance safety at your workplace.

How Red and Blue Forklift Safety Lights contribute to safety

Forklift accidents can occur in industrial environments for various reasons, including limited visibility, crowded workspaces, blind spots, and more. Let's explore each light individually to understand how blue and red forklift safety lights can address such challenges, their features, and other specifications.

Blue Forklift Safety Lights

Forklifts are a primary cause of 10% of workplace accidents - including forklift overturns, collisions, falling loads, pedestrian accidents, and more. Several reasons can contribute to these accidents, including:

Operator’s inability to spot the approaching intersection

Visual inaccessibility due to forklift’s blindspots

Lack of proper monitoring and safety compliance

Inadequate forklift maintenance

Fortunately, installing blue safety lights on forklifts can eliminate most of these challenges. Forklift blue lights are attached to the front and back of the forklift. As the forklift moves, a bright blue light is emitted, visible up to 10 feet from the vehicle. This sharp beam of light warns the pedestrians and other staff members about the speed and direction of the forklift. These lights also alert pedestrians and other drivers to get out of the way when the forklift operator is driving in reverse.

Features of Blue Safety Lights:

Casting Aluminium Alloy Housing

Forklift blue safety lights have robust casting aluminium alloy housing, which helps shield delicate electronic parts of the blue safety light from external impacts, vibrations, moisture, and other environmental hazards. This aluminium casting also ensures optimal heat dissipation and guaranteed longevity and corrosion resistance, keeping your lights functional and shining brightly through the toughest industrial settings.

Tempered Glass Cover

A tempered glass cover makes forklift blue lights resilient, durable, and heat resistant. It adds an extra layer of protection to ensure your lights remain functional under harsh and extreme industrial environments. In case of breakages, tempered glass breaks into small, blunt pieces instead of sharp shards, reducing the risk of injuries.

High Power LED

High-power LEDs enable bright, intense, and concentrated illumination, making them suitable for industries like oil and gas, mining, chemical manufacturing, warehousing, and logistics. Blue Safety lights are high-power LED lights offering a longer operational lifespan and energy efficiency.

IP- 67 rating

IP rating stands for Ingress Protection, which rates the protectiveness of the electric device against dust and water. Our forklift blue safety lights have an impressive IP rating of 67 denoting high protection against solids (dust, dirt, particulates) and water when immersed up to 1 meter.

Red Forklift Safety Lights

According to one of the latest reports, 8% of forklift accidents occur due to forklift turnovers involving workers. To keep workers safe, it's crucial to establish and communicate the correct distance that the crew needs to maintain from forklifts. Red forklift safety lights can help you communicate safe distances and other safety protocols, enhancing workplace safety.

Forklift red lights are often attached to the sides of the vehicle to indicate a safe distance between the pedestrian and the forklift. The red light they emit is also known as a halo zone and marks a two—to five-foot boundary that no one should cross. This distance can be adjusted by angling the light according to your facility space situation.

Features that make red forklift safety lights more effective:

Aluminium die-cast housing with a polycarbonate cover

The red safety lights' aluminium die-cast housing has a robust foundation that enables heat dissipation to keep the lights cool even during prolonged usage. This aluminium casting provides durability and resistance to impacts, vibrations, and harsh environmental conditions. The polycarbonate cover offers excellent optical clarity and protection against dust, debris, and minor impacts. These two features create a functional and reliable safety light system capable of handling rigorous and harsh industrial conditions.

Stainless steel bracket

With a stainless steel bracket, these red safety lights offer steadfast mounting support, ensuring secure attachment to the forklift. This feature guarantees stability and reliability, essential for the safety of operators and workers in industrial settings.

10-80V DC operating voltage

To simplify the specifications, the ‘10-80V DC operating voltage’ denotes that the device is built to operate in the 10-80 volts DC (Direct Current) range. This voltage range makes red forklift safety lights compatible with other power sources. The versatile voltage range simplifies installation procedures, allowing you to integrate the lights into their existing setups quickly and efficiently.

High power Osram LED 6pcs*3w with 18 W LED power.

This indicates the configuration and power rating of the LED lighting system, which is six individual LEDs, each rated at 3 watts, providing an 18-watt LED Power. The high-power LED enables bright illumination, allowing you to use red forklift safety lights even in extreme low-light conditions. This light is preferred in industries such as commercial and retail, industrial and manufacturing, and automotive, among others.

Guide To Red And Blue Forklift Lighting Options

Forklift ARC Lights

Forklift ARC Lights come with aluminium alloy housing and rubberized wire for efficient operation under hazardous conditions. They feature a high-power LED, which can project the light all the way to the ground. The tempered glass protects the system from internal damage and makes it water, dust, and shockproof. The forklift ARC lights are also built under an ingress IP-67 protection standard.

Forklift Red Danger Light

Forklift Red Danger Lights are the perfect all-in-one solution to keep pedestrians safe in your facility. Their warning system includes high-power LED security lights in an aluminium die-cast housing, with double-insulated wire and a stainless steel bracket, making it capable of withstanding extreme temperatures.

Forklift Laser Light

Forklift Laser lights come with a strong system equipped with a rugged design and laser beam projection, allowing you to indicate your forklift's exact positioning. This will help increase productivity and safety in your facility, simultaneously reducing transport time and the chances of any damage and collision. The forklift laser lights boast a robust design that ensures durability in demanding industrial environments. Additionally, they are engineered for easy maneuvering and supervision, enhancing their usability and effectiveness in improving safety and productivity within your facility.

Forklift Blue Spot Light

The Forklift Blue Spot Light safety device has a rugged design and is ideal for alerting pedestrians of an oncoming vehicle. It is also a perfect choice for signalling the forklift around the corner with to-the-ground beam projection. This blue light emitter is 100% dust, water, and shockproof. Its aluminium alloy housing reduces and mitigates the effects of heat and fire.

Forklift Blue Arrow Light

The Forklift Blue Arrow Light offers clear blue arrow-shaped lighting, a highly visual light that immediately warns pedestrians and warehouse workers. Ideal for use at the rear to signal a reversing forklift, the product comes with 3W LED lights enclosed in an aluminium housing that reduces heat dissipation. The double-insulated rubberized wire and stainless steel bracket are engineered to endure high and low heat extremes.

Forklift Warning Light

Forklift Warning Light is an ideal device to warn pedestrians during forklift operations and avoid the risk of workplace accidents. Equipped with high-powered LED lights, the device is protected with a durable glass cover and a two-year warranty from SharpEagle. This warning light is also equipped with a quakeproof, waterproof, and dustproof body with aluminium alloy casting for effective extreme temperature resistance.

How to install Red & Blue Safety Lights?

The forklift's Red & Blue Zone lights can be mounted to any desired side. You need one for each side where you want to project a safety zone. The tool-free bracket with the kit makes it simple to mount the light to the forklift's overhead guard.

The installation of red and blue safety lights is easy. These forklift lights come with a tool-free bracket that can be used to mount the light to the forklift's upper guard easily.

To know the complete installation of the Red & Blue Safety Lights for your warehouse or manufacturing plant, follow our step-by-step manual:

Put two-way tape on the bracket's foot. This will reduce the tremors and prevent the lights from rattling.

Position the light close to the rear of the head guard. Ensure the operator can get in and out of the seat without running into the headlight.

Set the red zone light feet in place by encircling the overhead guard with the two clamps.

Using a socket wrench or screwdriver to tighten the clamps.

Remove excess material from the clamp strap.

Place the plastic clamp end piece over the strap's sharp end to prevent sharp edges.

Connect the wire, then use electrical tape to seal the connection.

As needed, wire into the forklift. The light can accept voltages from 10 to 80V DC.

Finally, tilt the light to a suitable distance—2-6 feet, depending on the requirement. Tighten down and lubricate the adjuster to prevent them from loosening.

How Red & Blue Safety Lights are Beneficial for Your Business?

Knowing the benefits of red and blue forklift safety lights will help you make an informed purchase decision. It will also enable you to educate your workers and forklift operators about the importance of using these lights and enhance your safety efforts.

Your forklift operations will be more productive.

Safety and productivity are closely intertwined. With red and blue safety lights, you upgrade the safety at your workplace by minimizing the risk of accidents. When accidents are reduced, there is no disruption in the workflow.

Forklift operators can continue their operations smoothly and move the load effectively at a given time. Hence, your operations remain productive.

You can proactively reduce the risk of legal liabilities.

Accidents involving forklifts can result in severe legal liabilities. Implementing forklift safety solutions is a proactive way to avoid the risk of these liabilities. Red and blue forklift safety lights strengthen your safety efforts by giving you an edge to safeguard your company’s financial interests and reputation.

It will make your workplace OSHA safety-compliant.

OSHA mandates using blue safety lights in dimly lit areas and while operating a forklift at night. Installing these lights in your forklifts means meeting OSHA lighting standards for safety. By adhering to regulatory standards, you mitigate the risk of fines or penalties for non-compliance, thus protecting your employees and assets. Moreover, creating a safety-compliant workspace protects your employees and assets and demonstrates your commitment to responsible business practices. Thus, safety compliance attracts top talent and improves public perception, fosters positive relationships with stakeholders, and aligns your company with valuable core values, further strengthening your brand reputation in the industry.

Driver’s Instructions to Boost Safety with Forklift Safety Lights

Just installing red & blue safety lights is not enough to make your operations safe. Drivers should also know how to use the safety features effectively. Guide the forklift operators with the following instructions to boost safety with forklift safety lights.

Keep the beam of red/blue light on ground level.

While using warning lights, point the beam towards the ground to ensure that your worker’s visibility is not impaired due to the bright light. Maintaining this practice contributes significantly to accident prevention and overall workplace safety standards.

Stay alert and avoid distractions.

Stay aware of the industrial surroundings, especially while driving the forklift through busy work areas. Remember to give visual cues with red and blue safety lights. If the forklift operator does not understand how to operate a red/blue forklift safety light, ensure to train him in its application and create a norm of regularly using it at the workplace. Maintain high alertness and awareness of the risks associated with forklift operations. This will encourage the drivers to carefully assess their routes and adapt their driving techniques to ensure maximum safety.

Do regular maintenance checks.

Inspect the red and blue safety lights regularly to ensure they function correctly. Seek maintenance immediately if you find any issues or malfunctions. Prompt and timely action can prevent mishaps and disruptions. Therefore, implement a regular inspection schedule for the forklifts and ensure timely maintenance to uphold safety standards.

Don’t overload the forklift.

Overloading a forklift is dangerous as it can be risky for the operator and the forklift alike. Sometimes due to overloading, the load could fall off, and the operator could lose control of the forklift. Additionally, it creates a blind spot for the operators. This could be threatening to pedestrians as the forklift might run over them. Moreover, heavy loads can hamper the regular speed of forklifts, and operators may not be able to make accurate judgments. So, follow a standard for loading of forklifts to avoid damage to the forklift and injuries for the operator and pedestrians.

Conclusion

Equipping your forklifts with red and blue safety lights can significantly reduce the risk of accidents in your workplace. These lights enhance visibility and warn pedestrians about the movement of forklifts. However, whether these lights alone are sufficient to prevent accidents depends on your workplace and the nature of your operations.

So, to ensure comprehensive safety in your facility, consider implementing a complete safety solution tailored to your specific needs. At SharpEagle, we offer expert consultation services to help you choose the right safety solutions for your business.

Related FAQs

What are the red and blue lights on a forklift?

The red and blue lights on a forklift are safety lights designed to enhance visibility and prevent accidents in manufacturing units, transportation facilities, construction sites, and industries that use forklifts for daily operations. The blue lights are typically mounted on the front and back of the forklift, while red lights are positioned on the sides. Both the lights enhance workplace safety and reduce collisions occurring due to forklifts.

What lights are required on a forklift?

According to OSHA's powered industrial truck standard, you need headlights, tail, and warning lights. Headlights provide illumination for the operator to see clearly in low-light conditions, while tail lights indicate the rear of the forklift to other workers. OSHA regulations also specify these lights' minimum brightness and placement requirements to ensure adequate safety measures at your workplace.

What does the red light mean on a forklift?

The red light on a forklift indicates a "halo zone" around the vehicle. It means that the workers should not enter that zone as there is a risk of heavy objects falling off the forklift and causing injury. It warns the workers to stay clear of the indicated boundary line. Hence, it reduces the risk of injuries for workers.

You can call us at +971-4-454-1054 or mail us at [email protected]

#forklift blue light distance#forklift safety light#forklift lights safety#forklift halo lights#blue lights on forklifts#forklift red lights#forklift blue light#blue light forklift safety#red and blue lighting#blue warning lights on forklifts

0 notes

Text

Enhance Workplace Safety with the AgriEyes 7008 Forklift Safety Light

In industrial settings where safety and efficiency are paramount, the right equipment can make all the difference. Introducing the AgriEyes 7008 LED Forklift Safety Light, a state-of-the-art safety solution designed to improve visibility and reduce accidents in a variety of work environments. Let's explore how this innovative light can elevate safety standards in your workplace.

Prioritizing Safety with Innovative Design

The AgriEyes 7008 LED Forklift Light is engineered to enhance safety by projecting a bright blue spot on the ground, either in front of or behind the forklift. This vivid warning light serves as a clear signal for pedestrians to maintain a safe distance, significantly reducing the risk of collisions and accidents. By providing a highly visible cautionary marker, the 7008 model ensures a safer environment for both operators and pedestrians.

Robust and Reliable Construction

Quality is at the heart of the AgriEyes 7008. Constructed with a high-quality aluminum alloy housing, this safety light is built to endure the toughest working conditions. The 360° adjustable stainless steel bracket allows for flexible positioning, ensuring optimal light placement. The shatterproof PC lens enhances durability, while the IP65 waterproof rating guarantees protection against dust and water, making it a reliable choice for various industrial applications.

Superior Heat Dissipation

Effective heat management is crucial for the longevity and performance of LED lights. The AgriEyes 7008 is equipped with a large built-in aluminum heat sink that provides excellent heat dissipation. The use of aircraft-grade aluminum as a protective casing further enhances durability and heat management. This robust construction ensures that the light remains cool during operation, prolonging its service life to over 50,000 hours.

Versatile Applications for Diverse Environments

Compact yet powerful, the AgriEyes 7008 LED Forklift Safety Light is designed for versatility. It is ideal for a wide range of vehicles, including forklifts, trucks, trailers, pickups, and excavators. This adaptability makes it perfect for illuminating stacking yards, loading docks, and enclosed spaces, ensuring optimal safety across various industrial settings.

Outstanding Illumination for Better Visibility

The AgriEyes 7008 features tailored spot lenses and high-intensity LEDs, delivering exceptional brightness and clarity. Its non-glaring light beams ensure that the working area is well-lit without causing discomfort to operators or pedestrians. With a concentrated beam and expansive illumination, this safety light surpasses competitors in both brightness and coverage, making it an indispensable tool for enhancing workplace safety.

One-Year Warranty and Dedicated Support

AgriEyes is committed to quality and customer satisfaction. The 7008 LED Forklift Light comes with a one-year warranty, providing peace of mind and assurance of its durability. If any issues arise during use, our dedicated support team is ready to assist you and resolve any problems within 24 hours, ensuring that your operations continue smoothly and safely.

Conclusion

The AgriEyes 7008 LED Forklift Safety Light is an essential addition to any industrial setting, offering enhanced safety, superior construction, and versatile applications. With its innovative design, robust build, and exceptional illumination, it sets a new standard for forklift safety lights. Invest in the AgriEyes 7008 today and experience the difference it can make in improving safety and efficiency in your workplace.

0 notes

Text

Top Quality Forklift Rental Services in Abu Dhabi | Liftronic Machinery And Equipment Rental LLC

landscape of Abu Dhabi, efficient material handling is paramount for businesses aiming to optimize operations and maintain a competitive edge. Central to this efficiency is the utilization of forklifts, indispensable tools for lifting and transporting heavy loads across various sectors. However, acquiring and maintaining a fleet of forklifts can be a significant investment, prompting many businesses to explore rental options. This is where top-quality forklift rental services in Abu Dhabi come into play, offering flexible and cost-effective solutions to meet diverse operational needs.

The Importance of Forklift Rental Services in Abu Dhabi

Abu Dhabi's rapid industrial growth has led to an increased demand for reliable material handling equipment. Forklift rental services provide businesses with access to a wide range of equipment without the substantial upfront costs associated with purchasing. This approach not only conserves capital but also allows companies to scale their operations based on project requirements.

Moreover, rental services often include maintenance and repair, ensuring that the equipment remains in optimal condition and reducing downtime. This is particularly advantageous in industries where operational continuity is critical.

Key Considerations When Choosing a Forklift Rental Service

Selecting the right forklift rental service involves evaluating several factors to ensure it aligns with your operational needs:

Equipment Variety and Quality: A reputable rental service should offer a diverse fleet of well-maintained forklifts, including electric, diesel, and specialized models, to cater to various applications.

Flexible Rental Terms: Flexibility in rental agreements allows businesses to rent equipment for short-term projects or long-term needs, providing adaptability in dynamic market conditions.

Maintenance and Support: Comprehensive maintenance services and prompt technical support are essential to minimize disruptions and maintain productivity.

Competitive Pricing: Transparent and competitive pricing ensures that businesses can manage budgets effectively without compromising on quality.

Liftronic Machinery and Equipment Rental LLC: A Leader in Forklift Rentals

Among the prominent providers of top-quality forklift rental services in Abu Dhabi is Liftronic Machinery and Equipment Rental LLC. With a commitment to excellence, Liftronic offers a comprehensive range of material handling solutions tailored to meet the unique requirements of various industries.

Comprehensive Fleet of Equipment

Liftronic boasts an extensive inventory of forklifts, including electric and diesel variants, as well as specialized equipment like reach trucks, stackers, and power pallet trucks. This diverse selection ensures that clients have access to the right equipment for their specific applications, whether it's navigating narrow warehouse aisles or handling heavy outdoor loads.

Flexible and Customer-Centric Rental Solutions

Understanding that each business has unique operational demands, Liftronic offers flexible rental terms, allowing clients to choose daily, weekly, monthly, or yearly agreements. This adaptability ensures that businesses can efficiently manage their resources and respond to varying project scopes without the burden of long-term commitments.

Emphasis on Maintenance and Safety

At Liftronic, all rental equipment undergoes rigorous pre-inspection to guarantee optimal performance and safety. The company's dedicated maintenance team provides regular servicing and prompt repairs, minimizing downtime and ensuring that operations run smoothly. Additionally, Liftronic offers advanced safety features, such as forklift cameras and warehouse safety lights, to enhance operational safety and efficiency.

Strategic Presence Across the UAE

While headquartered in Dubai, Liftronic extends its top-quality forklift rental services throughout Abu Dhabi and the other Emirates. This strategic presence enables the company to promptly address the needs of clients across the region, providing timely equipment delivery and support.

Client-Centric Approach

Liftronic's business model is designed to enhance client productivity, uptime, and efficiency. By offering expert services, knowledgeable staff, and pre-inspected resources, the company ensures that client operations remain uninterrupted, enabling organizations to achieve their full potential. QU

Conclusion

In the dynamic industrial environment of Abu Dhabi, partnering with a reliable forklift rental service is crucial for maintaining operational efficiency and competitiveness. Liftronic Machinery and Equipment Rental LLC exemplifies top-quality forklift rental services in Abu Dhabi, offering a diverse fleet, flexible rental terms, and unwavering commitment to maintenance and safety. By choosing Liftronic, businesses can confidently navigate their material handling challenges, ensuring seamless and productive operations.

Contact Us: +971-522483348 , +971-565837586

EMAIL ID; [email protected]

ADDRESS; office no 405 Eyal Nassa building. Eyal Nasar, Deira, Dubai, United Arab Emirates.

Visit our website: https://liftronicme.com/

0 notes

Text

Enhance Your Warehouse Efficiency with Epoxy Flooring

Selecting the appropriate flooring for your warehouse is crucial to ensure durability, safety, and cost-effectiveness. Epoxy flooring emerges as a top contender for meeting these demands.

Advantages of Epoxy Flooring:

Exceptional Durability: Epoxy flooring is designed to withstand heavy loads, frequent foot traffic, and the operation of machinery like forklifts, ensuring longevity with minimal wear.

Chemical Resistance: Its non-porous surface offers robust protection against spills, oils, and harsh chemicals, preserving the integrity of your warehouse floor.

Low Maintenance: The seamless finish of epoxy flooring makes cleaning straightforward, requiring only routine sweeping and occasional mopping, thereby reducing maintenance efforts.

Enhanced Safety: With the addition of slip-resistant coatings, epoxy floors minimize the risk of workplace accidents. Additionally, their reflective surfaces improve lighting conditions, contributing to a safer environment.

Considerations:

While epoxy flooring offers numerous benefits, it's essential to be aware of potential drawbacks:

Initial Installation Costs: The upfront investment can be significant, and the installation process may require downtime.

Substrate Sensitivity: Cracks in the underlying concrete can affect the epoxy coating's performance.

Potential Slipperiness: Without proper anti-slip additives, the surface might become slick when wet.

In conclusion, epoxy flooring provides a durable, safe, and low-maintenance solution for warehouses. Assess your specific operational needs and consult with flooring professionals to determine if epoxy flooring is the optimal choice for your facility.

#Epoxy Flooring#Line Marking#Concrete Resurfacing#Epoxy Kitchen Benchtop#Warehouse Epoxy Flooring#Residential Flooring#Industrial Environment Coating System#Workshop Floor Coating#Garage Epoxy Flooring#Commercial Kitchen Flooring

0 notes

Text

Road Corner Guard -Sanocs

Introduction

In busy urban environments, industrial areas, and parking lots, corners and edges of buildings, pillars, and road structures are highly prone to damage from vehicle impacts. Sanocs’ Road Corner Guards are designed to protect both vehicles and infrastructure, reducing the risk of costly repairs and ensuring enhanced safety. Our high-quality road corner guards are made from durable, impact-resistant materials, making them ideal for various applications in India.

Why Choose Sanocs' Road Corner Guards?