#Monel 400 butt weld pipe fittings

Explore tagged Tumblr posts

Text

Monel 400 Butt weld Pipe Fittings manufacturers and suppliers | Metalforgeindia

Monel 400 butt weld pipe fittings are engineered for exceptional performance in corrosive environments, offering superior resistance to pitting and stress corrosion cracking. Manufactured from a nickel-copper alloy, these fittings are ideal for applications in marine, chemical, and oil industries. Their robust construction ensures durability and reliability under high temperatures and pressures. Available in various sizes and configurations, Monel 400 fittings provide seamless integration into piping systems, ensuring optimal flow and efficiency.

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Pipe Tee | Platinex Piping

About Pipe Tee

Stainless steel pipe tee, carbon steel tees and special grade tees are widely supplied by us to many industries such as power generation, petro chemical, shipbuilding, paper Manufacturing, chemical, pharmaceutical, and fabrication.

When the size of the branch is same as header pipes, equal tee is used and when the branch size is less than that of header size, reduced tee is used. The three sizes of a tee are End x End x Center. So if you want a tee that is 1’’ on both ends and 3/4’’ in the center it would be 1’’ x 1’’ x 3/4’’.

Depending on our customer requirements, we can manufacture and offer straight tees and reducing tees in various grades including 202, 304/304L, 904L, 316/316L, Duplex 2205, Alloy 20, Cupro Nickel, Monel Alloy 400, Inconel Alloy 625, Inconel Alloy 600, Hastelloy Alloy C276, and also in various Aluminium Grades.

The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

0 notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

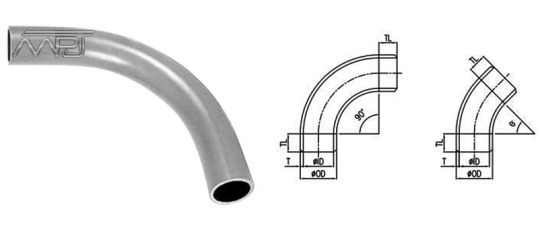

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

C276 suppliers in India

C276 Round Suppliers in India

C276 Round Suppliers in India (by and large called Branch Connection Fittings or Outlet Fittings) which give an outlet from a more prominent funnel to a humbler one (or one of a near size).

C276 Round Suppliers in India are fanning fittings made by biggest producers of metal fittings like us. C276 Round Suppliers in India offer a substitute technique for interfacing into the essential run and don't require fortress or fortification. Krishna Steel & Alloys are pre-formed to the twist of the run pipe. Level based weldolets are open for interfacing with pipe tops and vessel heads.

The chief channel onto which the branch association is welded is generally called the Run or Header measure gauge. The funnel to which the branch alliance or affiliation gives a channel is known as the Branch or Outlet measure. Branch associations are in all sizes, sorts, types, bores, and classes, in an expansive arrangement of treated steel, chrome-molly, and particular amalgams mixes.

C276 Round Suppliers in India are for the most part used for stretching on high weight and high temperature applications. Most extreme acceptable weight of a fitting is same concerning associated straight steady or consistent run channel of proportionate material.

C276 Round Suppliers in India uses Materials and Grades (Weldolets, Threadolets, Sockolets)

1) Stainless Steel Olet Fittings - ASTM/ASME SA 182F GR. 304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316N, 316LN, 309L, 310, 317, 317L, 321, 321H, 347, 347H AND UNS 31254 (254SMO)

2) Carbon Steel Olet Fittings - ASTM/ASME A105/A350 LF2, ASME SA105, A694 - F42, F46, F52, F60, F65, F70, A36, A516 GR. 70, 60

3) Alloy Steel Fittings - ASTM/ASME A182 GR. F1/F5/F9/F11/F22/F91

4) Duplex Steel Fittings - ASTM/ASME SA 182F GR. F44, F45, F51, F53, F55, F60, F61.WERKSTOFF NO. 1.4462

5) Nickel Alloy Steel FittFlangeings - ASTM/ASME SB 256 GR. NICKEL ALLOY 200, NICKEL ALLOY 20, MONEL ALLOY 400, INCONEL ALLOY 600, INCONEL ALLOY 625, INCOLOY ALLOY 800, INCOLOY ALLOY 800H, INCOLOY ALLOY 800HT, INCONEL ALLOY 825, ALLOY 20, HASTELLOY C-276, HASTELLOY C-4, HASTELLOY C-22, ALLOY 6XN

6) Low Temperature Pipe Fittings- A/SA 350 LF2, LF3

C276 Round Suppliers in India is Fittings are likewise accessible in other metal like titanium, aluminum, bronze, Lead, tantalum, zinc, metal and so on.

Application or Uses of Krishna steel & Alloys are are utilized in wide scope of businesses. Some of them are :

· Force Plants

· Water Pipelines

· Treatment facilities

· Nourishment and Beverages

· Pharmaceuticals

· Materials

· Railroads

· Petrochemicals

· Atomic Plants

· Sugar factories

Types of our Products:

1) Brazolet - Brazolet is utilized for the most part and for the most part to interface or partner the continued fittings. Brazolet is same like a weldolet, and is a marvelous fitting for metal channels, copper tubing and iron funnels pipes with metal.

2) Coupolet - Coupolet fittings are gotten ready for use in fire/fire assurance sprinkler structures and other low weight diverting applications.

3) Elbolet - Elbolet is utilized on 90° Long Radius Elbows (can be conveyed for Short Radius Elbows) for thermo well and instrumentation affiliations

4) Flexolet - Flexolets take after weldolets with a minor refinement for example flexolet has straight bore while weldolet has lessened bore.

5) Insert Weldolet - Insert Weldolet is the most extensively seen of all branch affiliations, and is welded onto the outlet pipe.

6) Latrolet - Latrolets are a variety of weldolets. You have to relate it in same manner, anyway these Latrolets make a 45-degree relationship with the standard channel as opposed to a 90 degree.

7) Nipolet - Nipolets is only a blend of olets with pipe areolas. These olets work like the weldolets or threadolets, yet are with areola.

8) Sockolet - Sockolets are in a general sense like weldolets and threadolets; close to the course that in Sockolets there is unique association fit welding.

9) Sweepolet - Sweepolet is a framed, essentially continued; butt-weld branch relationship with a low pressure elevating part for low loads and long consumption or depletion life.

10) Threadolet - Threadolets look like various olets; the essential contrast is that this olet is equipped with female strung affiliation.

11) Weldolet - Weldolets or welding olets or welding branch affiliation fittings are the most comprehended among all the olets. These are for the most used and organized as buttweld fittings, as these are welded into the branch pipe.

Assembling Standards

ASTM A182 - ASME SA182 - Standard Specification

ASME B16.11 - Forged Fittings Socket - Welding and Threaded

1 note

·

View note

Text

How You can Get Best Results with Steel Pipe Fittings?

Butt weld fittings made of stainless steel 304 offered by Seamless Steel Tube manufacturers in India are tiny fittings used for sealing tube ends. It is a phrase that refers to the procedure of butt welding fittings made of 304 stainless steel material in tubes/pipes to avoid leaks. These fittings of SS Seamless Pipe manufacturer in Indiaare relatively affordable and offer excellent resistance to air corrosion. According to industry demand, Hastelloy C276 Plate is made in a range of forms, sizes, grades, and standards.

Fittings of various types:

Though many companies create fittings to the needs of the industries to which they service, other small-scale firms prefer to develop some common fittings that are commonly utilised. The size of the same might range from 1" and 48". These are some important examples of frequent kinds:

45 degree elbow – widely used in the paper, brewing, agricultural, electronics, and food processing sectors.

90 degree elbow – widely used in the oil and gas pipeline, chemical plants, plumbing, and general purpose applications. You can contact with Stainless Steel ERW Pipe manufacturers in Indiafor more information.

Equal Tee - Used in power plants, breweries, and the sugar industry

Concentric reducer - Used in the plumbing and car industries

Inconel 600 Plate fittings are extremely dependable. Stainless Steel 304 has a greater chromium percentage and a lower carbon content. Welding produces less chromium carbide due to lower carbon levels. This steel of SS Square Pipe manufacturer in Indiahas as little as 0.03% carbon, making it less susceptible to intergranular corrosion. This steel can withstand prolonged exposure to temperatures of around 1500°F without deterioration.

Welding a fitting to a pipe with Stainless Steel Conduit Pipe Manufacturers in Indiamakes it permanently leak proof.

The regular metal structure shaped between the fitting and pipe of Duplex Pipe Manufacturers in India adds strength to the system.

A flat and smooth surface and progressive direction changes reduce pressure losses as well as turbulence and minimise the action of corrosion and erosion.

Flanges made of Hastelloy C276

Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Heat Exchangers

Equipment for Sea Water

Condensers

Pulp and Paper Industry

316L stainless steel

Monel 400 Tube Fittings Used in Chemical Procedures

Stainless Steel Pipes of SS Tube Manufacturers In IndiaUsed in the Medical Field

Stainless Steel Tube Fittings Used in Pharmaceutical Plants

Hastelloy C276 Tube Fittings Used in Food Processing Plants

Stainless Steel Pipe Fittings Used during Aviation Engine Components

Because austenitic stainless steel has a low permeability, it is also known as a nonmagnetic material. Steel with a stable sleeve structure, such as 0Cr20Ni10 or 0Cr25Ni20, won't be magnetic although if treated with a considerable quantity of end greater than 80%.

There are several additional applications for Monel 400 Pipe Fittings of Stainless steel heat exchanger manufacturer in Indiain various sectors. You can get suggestions from professional manufacturers and get best option for your industry.

0 notes

Photo

Olets Manufacturers, Olets Exporters, Olets Suppliers, Olets Importers.

Olets Manufacturers in India, Olets Exporters in India, Olets Suppliers in India, Olets Importers in India.

Olets Manufacturers in Mumbai, Olets Exporters in Mumbai, Olets Suppliers in Mumbai, Olets Importers in Mumbai.

The Olets are made utilizing best quality material and are acknowledged for highlights, for example, dimensional precision and superb solidness. These pipe fittings that are particularly utilized as a part of different ventures for various applications. Attributable to erosion and temperature protection, these olets are utilized as a part of high temperature applications in oil and gas industry.

FEATURES:

· Longer service life

· Rust proof

· Sizes available

· Sturdy construction

· Dimensional accuracy

· Corrosion resistance

SPECIFICATIONS OF ASTM A105 OLETS

Stainless Steel ASTM A105 Olets | Carbon Steel ASTM A105 Olets | Nickel Alloys ASTM A105 Olets Size : 1/2'' - 24 Type : Weldolet, Sockolet, Nippolet, Threadolet, Latrolet, Flexolet butt-weld, Flexolet Threaded and Sweepolet

MATERIALS :

Stainless Steel Olets – SS Olets

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Duplex Stainless Steel Olets - Duplex SS Olets

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel Olets – CS Olets

Standard : ASTM / ASME A/SA 105 / 350 LF 2 / A 516 GR.70 / IS 2062

Nickel Alloy Olets :

Standard : ASTM / ASME SB 564 / 160 / 472 Grade : UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

Stainless Steel Olets SS 304 Olets SS 304L Olets SS 304H Olets SS 316 Olets SS 316L Olets SS 316Ti Olets SS 310 Olets SS 310S Olets SS 321 Olets SS 321H Olets SS 317 Olets SS 347 Olets SS 347H Olets

Alloy Steel Olets Nickel Alloys Olets Nickel 200 Olets Nickel 201 Olets Monel 400 Olets Monel 500 Olets Inconel 800 Olets Inconel 825 Olets Inconel 600 Olets Inconel 625 Olets Inconel 601 Olets

Carbon Steel ASTM A 234 Olets Hastelloy C 276 Olets Alloy 20 Olets Titanium Olets Duplex Steel 2205 Olets Copper Alloys Olets Aluminium Olets Copper Olets Brass Olets Gunmetal Olets

Stainless Steel Olets SS 304 Olets SS 304L Olets SS 304H Olets SS 316 Olets SS 316L Olets SS 316Ti Olets SS 310 Olets SS 310S Olets SS 321 Olets SS 321H Olets SS 317 Olets SS 347 Olets SS 347H Olets

Alloy Steel Olets Nickel Alloys Olets Nickel 200 Olets Nickel 201 Olets Monel 400 Olets Monel 500 Olets Inconel 800 Olets Inconel 825 Olets Inconel 600 Olets Inconel 625 Olets Inconel 601 Olets

Carbon Steel ASTM A 234 Olets Hastelloy C 276 Olets Alloy 20 Olets Titanium Olets Duplex Steel 2205 Olets Copper Alloys Olets Aluminium Olets Copper Olets Brass Olets Gunmetal Olets

OUR SUMMARY:

Reviewer

Dipti Metal Industries.

Review Date

6-06-2017

Reviewed Product

Olets

Author Rating

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

0 notes

Text

SS Buttweld Fittings

Stockists, Suppliers, and Exporters of high integrity Buttweld Pipe Fittings, buy Steel Buttweld Pipe Fittings in all Dimensions

We are manufacturing Stainless Steel buttweld fittings in seamless or welded form, it proudly caters the needs of our customers in Oil & Gas, Power Generation, Petrochemical, and Industrial Construction, inclusive of Upstream, Midstream, and Downstream sectors. Our offered Buttweld Pipe Fittings is being developed and designed in accordance by means of the international quality of standards at our infrastructure facility for to attain the highest scales of quality. Buy comprehensive Variety of Butt weld fittings in Stainless Steel, Carbon Steel, Alloy Steel, Hastelloy, Monel, Inconel, Titaniun, Duplex Steel, Super Duplex Steel, Incoloy, Alloy 20, 254 SMO, Copper Nickel Materials.

WHAT IS A BUTTWELD PIPE FITTINGS

A buttweld pipe fittings is designed to be welded on site at its end(s) to connect pipe(s) together and allow change in direction or pipe diameter, or branching or ending.

This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances.

Buttweld Pipe Fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum and high yield material. High yield butt weld carbon steel pipe fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 pipe fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Buttweld Fittings Types:

• 2 Halve Fittings• Cap

• Customised Fittings• Dairy Fittings

• Elbow LR & SR• Mitered Bend

• Nipple Swage• Reducer Eccentric & Concentric

• Return Bends• Stubend Long & Short

• Tee Equal & Barred

Radical Steel & Alloys is counted as one of the privileged manufacturers, stockists, and exporters of an admirable range of buttweld Pipe Fittings. We offer the same in different forms such as Stainless Steel, Carbon Steel, Alloy Steel, Duplex Steel, Super Duplex Steel, and many more.

We are manufacturing buttweld fittings in seamless or welded form, it proudly caters the needs of our customers in Oil & Gas, Power Generation, Petrochemical, and Industrial Construction, inclusive of Upstream, Midstream, and Downstream sectors. Our offered Buttweld Pipe Fittings is being developed and designed in accordance by means of the international quality of standards at our infrastructure facility for to attain the highest scales of quality.

Specifications:Size : 1/8"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Form : Elbow, Tee, Reducer, Cap, Stubend, Bends, Nipple etc. Long radius bends of 2.5 D / 3 D / 5D / 10 D /20D & 22 D for piglaunching steam & General purpose fittings. STAINLESS STEEL BUTT WELD FITTINGS: Range : 1/2"NB TO 48"NB IN SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 Type SEAMLESS / WELDED/ FABRICATED Form Elbows in Long & Short Radius in 45 deg, 90 Deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel Nipple.Standard : ASTM / ASME A/SA 403 GR WP "S" / "W" / " WX" Grade : 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L Value Added Services: Electro Polish Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |DUPLEX STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 Type SEAMLESS / WELDED/ FABRICATED Form Elbows in Long & Short Radius in 45 deg, 90 Deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel Nipple..Standard: ASTM / ASME SA 815 Grade: UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760 Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |CARBON STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 60"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75. Type : SEAMLESS / WELDED/ FABRICATED Form : Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel Nipple.Standard : ASTM A234 WPB / MSS-SP-75, ASTM / ASME A 860, ASTM A 420 WPL6 Type : Grade : WPB, WPC, WPBW, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.Value Added ServicesHot Dipped Galvanizing Epoxy Coating Sand BlastingTest Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |ALLOY STEEL BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 Type : SEAMLESS / WELDED/ FABRICATED Form Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel Nipple.Standard: ASTM / ASME A/SA 234 Grade: WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91 Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B Value Added Services: Hot Dipped Galvanizing , Sand Blasting | Top |NICKEL ALLOY BUTT WELD FITTINGS:Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 Type : SEAMLESS / WELDED/ FABRICATED Form Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel Nipple.Standard : ASTM / ASME SB 336 Grade : UNS 2200 (NICKEL 200 Elbow) , UNS 2201 (NICKEL 201 Elbow) , UNS 4400 (MONEL 400 Elbow) , UNS 8020 (ALLOY 20 / 20) CB 3 , UNS 8825 INCONEL (825 Elbow) , UNS 6600 (INCONEL 600 Elbow) , UNS 6601 (INCONEL 601 Elbow) , UNS 6625 (INCONEL 625 Elbow) , UNS 10276 (HASTELLOY C 276 Elbow) Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |COPPER ALLOY BUTT WELD FITTINGS:Range : 1/2" OD TO 6" OD IN x 18swg, 16swg, 14swg, 12swg, 10swg Type : SEAMLESS / WELDED Copper Buttweld Pipe Fittings Form Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee Bend Reducer Caps Long & Short Stub End. Swage Nipple & Barrel Nipple. Copper Butt Weld Pipe Fitting Grade : De-oxidized & Electrolytic 99.9% Copper Standard: ASTM / ASME SB 111 , ASTM / ASME SB 466 Grade: UNS NO.C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500.UNS NO.C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30) Standard: ASTM / ASME SB 111 / 466 Grade: UNS NO. C 10100, 10200, 10300, 10800, 12000, 12200, 70600 ( CU -NI- 90/10), 71500( CU -NI- 70/30). Test Certificate: Manufacturer Test Certificate as per EN 10204 / 3.1B| Top |MILD STEEL BUTT WELD FITTINGS:Materials : Mild SteelSize : 15 NB to 150 NB, 200 NB to 500 NBClass & Thickness : ‘B’ Class & ‘C’ Class & 6.35mm to 12.7mm ThkType : SEAMLESS / WELDED/ FABRICATED FormElbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & Concentric Reducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel NippleValue Added ServicesHot Dipped Galvanizing Sand Blasting Threading (As per Gauge)Test Certificate: Manufacturer Test Certificate as per IS standards| Top |GALVANIZED STEEL BUTT WELD FITTINGS:Materials: Mild Steel with Hotdipped Galvanized Size: 15 NB to 150 NB, 200 NB to 500 NB Class & Thickness: ‘B’ Class & ‘C’ Class & 6.35mm to 12.7mm Thk Type: SEAMLESS / WELDED/ FABRICATED Form Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg. Equal, Unequal Tee & Barred Tee. Eccentric Reducer & ConcentricReducer. Caps & Crosses. Long & Short Stub End. Swage Nipple & Barrel NippleValue Added Services Hot Dipped Galvanizing Sand Blasting Threading (As per Gauge)Test Certificate: Manufacturer Test Certificate as per IS standards

#ss buttweld fittings#SS Flanges#manufacturers in india#exporters#stainless steel forged fittings#ss 304#ss316#ss316l#ss309#ss 409

0 notes

Link

ASME B16.9 ASTM A403 WP304L Eccentric Reducer DN150 - DN100 SCH10S

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material: 304L

Technics: Cold Forming

Type: 304L Eccentric Reducer

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal, Reducing, etc

Head Code: Round

Standard: ASME B16.9, etc

Size: 6" - 4" (DN150 - DN100)

Surface: Sand Rolling, Sand Blasting, Polishing

Application: Oil, Gas, Etc

Special Desgin: Available

Packaging & Delivery

Packaging Detail:Wooden cases or PPwrapping with bundles as customer's required

Delivery Detail:2 - 10 days

Specifications

ASME B16.9 ASTM A403 WP304L Eccentric Reducer DN150 - DN100 SCH10S

1. Material: 304L 2. Technics: Cold Forming 3. Type: WP304L Eccentric Reducer

4. Size: 6" - 4" (DN150 - DN100)

WT: Sch10S

China Reducer Manufacturer Yaang supplies ASME B16.9 ASTM A403 WP304L Eccentric Reducer, DN150 - DN100, SCH10S.

NPSO.D.

DO.D.

D1Len

H

6*4168.3114.3140

Composition ranges for 304L grade stainless steel

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

304

min.

max.

-

0.08

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

0.10

304L

min.

max.

-

0.030

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

12.0

-

0.10

304H

min.

max.

0.04

0.10

-

2.0

-

0.75

-0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

Mechanical properties of 304L grade stainless steel

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

304

515

205

40

92

201

304L

485

170

40

92

201

304H

515

205

40

92

201

304H also has a requirement for a grain size of ASTM No 7 or coarser.

Physical properties of 304L grade stainless steel in the annealed condition

Grade

Density (kg/m3)

Elastic Modulus (GPa)

Mean Coefficient of Thermal Expansion (μm/m/°C)

Thermal Conductivity (W/m.K)

Specific Heat 0-100°C (J/kg.K)

Electrical Resistivity (nΩ.m)

0-100°C

0-315°C

0-538°C

at 100°C

at 500°C

304/L/H

8000

193

17.2

17.8

18.4

16.2

21.5

500

720

Grade specifications for 304L grade stainless steel

Grade

UNS No

Old British

Euronorm

Swedish SS

Japanese JIS

BS

En

No

Name

304

S30400

304S31

58E

1.4301

X5CrNi18-10

2332

SUS 304

304L

S30403

304S11

-

1.4306

X2CrNi19-11

2352

SUS 304L

304H

S30409

304S51

-

1.4948

X6CrNi18-11

-

-

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

Type

304L Eccentric Reducer

Size

Seamless: 1/2" - 24"; welded: 8" - 100"

Wall thickness

SCH 5,SCH 10,SCH 20,SCH 40,SCH 80,SCH 120,SCH 160,SCH XXS

Standards

ANSI, ASTM,DIN, ASME, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy,

shipbuilding, construction, etc

An eccentric reducer is manufactured with the smaller outlet off center to the larger end, which allows it to align with only one side of the inlet. The eccentric reducer must be installed with straight side up so that it can prevent trapping air at the pump suction. The eccentric reducers allow simple connection of different sized pipes.

Applications of 304L Eccentric Reducer:

Chemical process vessels, piping and heat exchangers

Pulp mill digesters, bleach washers, chip pre-steaming vessels

Food processing equipment

Oil field piping and heat exchangers

Flue gas desulfurization equipment

ASME B16.9 ASTM A403

WP304L Eccentric Reducer

's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.9 ASTM A403 WP304L Eccentric Reducer, DN150 - DN100, SCH10S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]

Related products:

More>>

ASME B16.9 ASTM A815 UNS S31803 90 Degree Elbow LR BE 4 Inch SCH120

butt welding fitting pipe elbow

ASME B16.9 ASTM A403 WP304L Eccentric Reducer DN150 - DN100 SCH40S

A105 Galvanized NPT Threaded Coupling

0 notes

Text

Monel 400 Butt weld Pipe Fittings manufacturers and suppliers | Metalforgeindia

Monel 400 butt weld pipe fittings have an outstanding resistance to pitting and stress corrosion cracking, and they are designed to function exceptionally well in harsh situations. These fittings, which are made of a nickel-copper alloy, are perfect for use in the chemical, oil, and maritime sectors. Even under severe pressure and heat, their robust design ensures dependability and lifespan. For the optimum flow and efficiency, Monel 400 fittings, which are available in a variety of sizes and configurations, fit into piping systems with ease. Our fittings offer a customized solution for your pipeline requirements, coming in a variety of diameters, thicknesses, and combinations. You are selecting quality, dependability, and a partner who is aware of your unique needs when you go with Metal Forge India. Backed by our many years of industry experience, we are dedicated to offering high-quality Monel 400 fittings that satisfy your industrial needs.

0 notes

Text

Piggable bends

M P Jain Tubing Solutions LLP is one of the leading Manufacturer, Stockist, and Exporter of ANSI/ASME B16.9 Piggable Bend in Mumbai, India. We are in this domain since 1972. We are ISO 9001:2015 certified company and most trusted Suppliers of Piggable Pipe Bends. We keep intensive stock of SS Piggable Bend to fulfill urgent requirements of our clients at reasonable prices.

One of the oldest Manufacturer, Stockist, Exporter of ANSI and ASME B16.9 Piggable Bend, Piggable Pipe Bends, Piggable Bend Suppliers at best price in India. We keep the largest stock of stainless steel Piggable bends, carbon steel Piggable bends, nickel alloy Piggable bends, alloy steel Piggable bends, Monel Piggable bends in all dimensions.

Benefits of Butt Weld Pipe Fittings

Butt welding fittings have the following benefits

Welded connection offers more robust connection

Continuous metal structure adds to the strength of the piping system

An option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counterparts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

allow a strong and leak-proof pipe to fitting connection

minimize the pressure drops and the turbulence along the pipeline

have a long service life

are rather cheap to purchase and deploy

Butt weld fittings with matching pipe schedules offer seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

ANSI and ASME B16.9 Piggable Bend Specifications

Type: Butt weld (BW)

Standards: ASME / ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’ ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’

Dimension: A NSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Schedule: Sch 5 TO Sch XXS.

Size: 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”)

ANSI and ASME B16.9 Piggable Bend Material and Grades

Stainless Steel Piggable Bend:

ASTM A403 WP316/316L

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Piggable Bend:

ASTM A234 Gr. WPB

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Piggable Bend:

Monel 400 & 500

Inconel 600 & 625

Incolloy 800, 825

Hastelloy C22, C276

Hastelloy

Nickel

Monel

Inconel

Alloy20

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

Standard:

ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

Alloy Steel Piggable Bend:

ASTM a234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91

As a leading manufacturer, stockist, and exporters of ANSI and ASME B16.9 Piggable bend, we are providing high-quality Piggable bends, SS piggable bend, piggable bend radius at best price in India.

For More Details

Address: 205 Kika Street, Gulalwadi Mumbai, India

Tel: 022-23465538 / 022-23460403

Fax: +91-22-23424250

Mob: +91 9619390230

Email: [email protected]

Visit our site: http://www.mpjainco.com/

0 notes

Text

Exploring the Superior Performance of Monel 400: Flanges and Pipes Introduced

Monel 400 is a popular and versatile nickel-copper alloy known for its exceptional performance in various industrial applications. This alloy offers superior resistance to corrosion, high strength, and excellent mechanical properties. Monel 400 flanges and pipes are widely used in industries such as oil and gas, chemical processing, marine, aerospace, and so on. At Metal Forge India, we take pride in being the leading Monel 400 Alloy Manufacturer, Supplier, Stockist, and Exporter in India. With a strong commitment to delivering high-quality products, we offer a wide range of Monel 400 components, including Monel 400 Pipes, Monel 400 Flanges, Monel 400 Pipe Fittings, Alloy 400 Elbows, Monel 400 Butt weld Pipe Fittings, and Monel 400 Welding Rods and also we do offer them in various sizes, specifications & standards and more so that our customers can choose the one that perfectly suits their project requirements.

In this article, we will explore the key characteristics and advantages of Monel 400 flanges and pipes, highlighting their superior performance and why they are the preferred choice for many critical applications.

Understanding Monel 400

Monel 400 is a solid-solution alloy that consists of approximately 67% nickel and 23% copper, with small amounts of iron, manganese, carbon, and silicon. The unique combination of nickel and copper provides Monel 400 with outstanding resistance to various corrosive environments, including seawater, sulfuric acid, hydrofluoric acid, and alkaline solutions. Additionally, Monel 400 exhibits excellent mechanical properties even at elevated temperatures, making it suitable for high-stress applications.

Exploring the Superior performance of Monel 400 - Pipe - Flanges

Corrosion Resistance

One of the key advantages of Monel 400 flanges and pipes is their exceptional resistance to corrosion. Whether exposed to saltwater, acids, alkaline solutions, or harsh chemicals, Monel 400 remains highly resistant. This property makes it suitable for offshore and marine applications, as well as industries dealing with corrosive substances.

High Strength and Toughness:

Monel 400 offers remarkable strength and toughness, making it ideal for applications that require durability and reliability. It maintains its mechanical properties even at extremely low or high temperatures, ensuring consistent performance in various operating conditions. This strength and toughness make Monel 400 flanges and pipes a preferred choice for critical industrial processes.

Heat and Pressure Resistance:

With its excellent heat and pressure resistance, Monel 400 proves its mettle in high-temperature environments. It can withstand elevated temperatures without losing its structural integrity. Additionally, it maintains its performance under high-pressure conditions, making it suitable for applications that involve fluid transportation and containment.

Excellent Ductility:

Monel 400 exhibits excellent ductility, allowing it to be easily formed and fabricated into different shapes and sizes. This ductility makes it an ideal material for flanges and pipes, enabling easy installation and connection in various industrial systems. Its malleability ensures a secure and leak-free joint, enhancing the overall efficiency of the system.

Wide Range of Applications

The exceptional properties of Monel 400 flanges and pipes make them versatile and applicable in various industries. They are commonly used in chemical processing plants, oil and gas refineries, marine equipment, heat exchangers, seawater systems, and more. Their broad range of applications is a testament to their reliability and performance.

Easy Machinability:

Another noteworthy feature of the Monel 400 is its excellent machinability. Despite its high strength and resistance, this alloy can be easily machined into intricate shapes and parts. The ease of machining simplifies the manufacturing process, reducing production time and costs. This aspect makes Monel 400 a preferred choice for industries that require complex and precise components.

Cost-Effectiveness:

Considering the long lifespan and durability of Monel 400 flanges and pipes, they offer excellent cost-effectiveness in the long run. While the initial investment may be higher compared to other materials, Monel 400's resistance to corrosion and wear minimizes the need for frequent replacements or repairs. This leads to significant cost savings over the equipment's lifespan.

Longevity and Low Maintenance:

Monel 400 flanges and pipes are known for their longevity and low maintenance requirements. They can withstand harsh conditions and continue to perform reliably for an extended period. With minimal maintenance, such as routine inspections and cleaning, Monel 400 components can remain in service for many years, ensuring uninterrupted operations.

Equivalent Material of Alloy 400 Pipe-Flanges

STANDARD

WERKOFF NR.

UNS

JIS

BS

GOST

AFNOR

EN

Monel 400

2.4360

N04400

NW4400

NA13

МНЖМц 28-2,5-1,5

NU-30M

NiCu30Fe

Chemical Equation of Monel DIN 2.4360 Flanges - Pipes

Grade

C

Mn

Si

S

Cu

Fe

Ni

Monel 400

0.30 max

2.00 max

0.50 max

0.024 max

28.00 - 34.00

2.50 max

63.00 min

Mechanical Characteristics of N04400 Flanges - Pipes

Element

Density

Melting Point

Tensile Strength

Yield Strength (0.2%Offset)

Elongation

Monel 400

8.8 g/cm3

1350 °C (2460 °F)

Psi – 80,000 , MPa – 550

Psi – 35,000 , MPa – 240

40 %

Applications of Monel 400 - Flanges and Pipes

Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance, high strength, and good thermal conductivity. It is often used in various industries for its unique properties. When it comes to flanges and pipes, Monel 400 finds applications in several areas:

Marine and Offshore Industry

Chemical Processing Industry

Oil and Gas Industry

Power Generation Industry

Aerospace Industry

Pharmaceutical Industry

Food Processing Industry and so on

Final Thoughts!..

Monel 400 Flanges and Pipes are renowned for their exceptional performance and durability, making them the top choice for demanding industrial applications. With their impressive strength, corrosion resistance, and versatility, they are widely preferred across a range of industries, including marine, chemical processing, oil and gas, and aerospace. As the foremost Monel 400 Alloy manufacturer, supplier, stockist, and exporter in India, we offer an extensive selection to cater to the unique needs of every project.

In addition to their superior qualities, our Monel 400 Flanges and Pipes are accompanied by Material Test Certificates (MTC) compliant with EN 10204 3.1 and EN 10204 3.2 standards. These certificates, along with Test Certificates confirming NACE MR0103 and NACE MR0175 compliance, ensure the highest levels of quality and traceability. We take pride in our expansive export capabilities and widespread customer base, including countries such as the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. Metal Forge India has built a strong reputation for delivering top-notch Monel 400 products worldwide.

To explore our extensive range of Monel 400 products and find the perfect solution for your project needs, visit our website or contact our knowledgeable team today.

0 notes

Photo

Olets Manufacturers, Olets Exporters, Olets Suppliers, Olets Importers.

Olets Manufacturers in India, Olets Exporters in India, Olets Suppliers in India, Olets Importers in India.

Olets Manufacturers in Mumbai, Olets Exporters in Mumbai, Olets Suppliers in Mumbai, Olets Importers in Mumbai.

The Olets are made utilizing best quality material and are acknowledged for highlights, for example, dimensional precision and superb solidness. These pipe fittings that are particularly utilized as a part of different ventures for various applications. Attributable to erosion and temperature protection, these olets are utilized as a part of high temperature applications in oil and gas industry.

FEATURES:

· Longer service life

· Rust proof

· Sizes available

· Sturdy construction

· Dimensional accuracy

· Corrosion resistance

SPECIFICATIONS OF ASTM A105 OLETS

Stainless Steel ASTM A105 Olets | Carbon Steel ASTM A105 Olets | Nickel Alloys ASTM A105 Olets Size : 1/2'' - 24 Type : Weldolet, Sockolet, Nippolet, Threadolet, Latrolet, Flexolet butt-weld, Flexolet Threaded and Sweepolet

MATERIALS :

Stainless Steel Olets – SS Olets

ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Duplex Stainless Steel Olets - Duplex SS Olets

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Carbon Steel Olets – CS Olets

Standard : ASTM / ASME A/SA 105 / 350 LF 2 / A 516 GR.70 / IS 2062

Nickel Alloy Olets :

Standard : ASTM / ASME SB 564 / 160 / 472 Grade : UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

Stainless Steel Olets SS 304 Olets SS 304L Olets SS 304H Olets SS 316 Olets SS 316L Olets SS 316Ti Olets SS 310 Olets SS 310S Olets SS 321 Olets SS 321H Olets SS 317 Olets SS 347 Olets SS 347H Olets

Alloy Steel Olets Nickel Alloys Olets Nickel 200 Olets Nickel 201 Olets Monel 400 Olets Monel 500 Olets Inconel 800 Olets Inconel 825 Olets Inconel 600 Olets Inconel 625 Olets Inconel 601 Olets

Carbon Steel ASTM A 234 Olets Hastelloy C 276 Olets Alloy 20 Olets Titanium Olets Duplex Steel 2205 Olets Copper Alloys Olets Aluminium Olets Copper Olets Brass Olets Gunmetal Olets

Stainless Steel Olets SS 304 Olets SS 304L Olets SS 304H Olets SS 316 Olets SS 316L Olets SS 316Ti Olets SS 310 Olets SS 310S Olets SS 321 Olets SS 321H Olets SS 317 Olets SS 347 Olets SS 347H Olets

Alloy Steel Olets Nickel Alloys Olets Nickel 200 Olets Nickel 201 Olets Monel 400 Olets Monel 500 Olets Inconel 800 Olets Inconel 825 Olets Inconel 600 Olets Inconel 625 Olets Inconel 601 Olets

Carbon Steel ASTM A 234 Olets Hastelloy C 276 Olets Alloy 20 Olets Titanium Olets Duplex Steel 2205 Olets Copper Alloys Olets Aluminium Olets Copper Olets Brass Olets Gunmetal Olets

OUR SUMMARY:

Reviewer

Dipti Metal Industries.

Review Date

6-06-2017

Reviewed Product

Olets

Author Rating

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

0 notes

Photo

Socket Weld Pipe Fittings Manufacturers, Socket Weld Fittings Exporters, Socket Weld Fittings Suppliers, Socket Weld Fittings Importers.

Socket Weld Fittings Manufacturers in India, Socket Weld Fittings Exporters in India, Socket Weld Fittings Suppliers in India, Socket Weld Fittings Importers in India.

Socket Weld Pipe Fittings Manufacturers in Mumbai, Socket Weld Pipe Fittings Exporters in Mumbai, Socket Weld Pipe Fittings Suppliers in Mumbai, Socket Weld Pipe Fittings Importers in Mumbai.

Dipti Metal Industries is driving Manufacturer of stainless steel pipe fittings and stainless steel ribs in INDIA since Five Decades,Dipti Metal Industries positions in Top Ten organization in INDIA occupied with assembling of produced pipe fittings, at Dipti Metal Industries we offers the total scope of fashioned fittings including Socket Weld Fittings, Threaded Fittings, Nipple, Branch Outlet Fittings , Bosses, Union Joint and the sky is the limit from there. we would exporter be able to and provider of fashioned attachment weld fittings fabricated in understanding to ASME B16.11. Produced attachment weld fittings are accessible ex-stock in all real stainless steel grades (ASTM A182 F316L, F304L), carbon steel and combination steel grades. We offer different sorts of attachment weld fittings including attachment weld elbow, attachment weld tees, attachment weld cross, and the sky is the limit from there. Attachment weld fittings are broadly utilized as a part of channeling frameworks crosswise over real ventures, for example, petrochemicals, control age, send building, journal industry, distilleries, squander water treatment, compound, pharmaceuticals and others.

SPECIFICATIONS

Material

Stainless Steel ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L ASTM A312/A403 TP304, TP304L, TP316, TP316L Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB

Dimension

ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Pressure

3000LBS, 6000LBS, 9000LBS

Size

1/8"~4" (DN6~DN100)

FORGED PIPE FITTINGS MANUFACTURING STANDARDS

· ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

· ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

· ASME B16.11 – Socket Welding and Threaded Forged Fittings

· MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications

· MSS SP-95 – Swage(d) Nipples and Bull Plugs

· BS3799 – Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry

Stainless Steel Threaded SS 304 Threaded Fittings SS 304L Threaded Fittings SS 304H Threaded Fittings SS 316 Threaded Fittings SS 316L Threaded Fittings SS 316Ti Threaded Fittings SS 310 Threaded Fittings SS 310S Threaded Fittings SS 321 Threaded Fittings SS 321H Threaded Fittings SS 317 Threaded Fittings SS 347 Threaded Fittings SS 347H Threaded Fittings

Alloy Steel Threaded Fittings Nickel Alloys Threaded Nickel 200 Threaded Fittings Nickel 201 Threaded Fittings Monel 400 Threaded Fittings Monel 500 Threaded Fittings Inconel 800 Threaded Fittings Inconel 825 Threaded Fittings Inconel 600 Threaded Fittings Inconel 625 Threaded Fittings Inconel 601 Threaded Fittings

Carbon Steel ASTM A 234 Threaded Hastelloy C 276 Threaded Fittings Alloy 20 Threaded Fittings Titanium Threaded Fittings Duplex Steel 2205 Threaded Fittings Copper Alloys Threaded Fittings Aluminium Threaded Fittings Copper Threaded Fittings Brass Threaded Fittings Gunmetal Threaded Fittings

OUR SUMMARY:

Reviewer

Dipti Metal Industries.

Review Date

6-06-2017

Reviewed Product

Socket Weld Pipe Fittings

Author Rating

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

http://www.diptimetals.com/socket-weld-and-threaded-pipe-fittings-manufacturers-exporters-suppliers-importers.html

0 notes

Text

Buttweld pipe fittings manufacturers exporters suppliers importers By Dipti Metals

Buttweld Pipe Fittings Manufacturers, Buttweld Pipe Fittings Exporters, Buttweld Pipe Fittings Suppliers, Buttweld Pipe Fittings Importers.

Buttweld Pipe Fittings Manufacturers in India, Buttweld Pipe Fittings Exporters in India, Buttweld Pipe Fittings Suppliers in India, Buttweld Pipe Fittings Importers in India.

Buttweld Pipe Fittings Manufacturers in Mumbai, Buttweld Pipe Fittings Exporters in Mumbai, Buttweld Pipe Fittings Suppliers in Mumbai, Buttweld Pipe Fittings Importers in Mumbai.

Dipti Metals Industries is Manufacturer, Stockists and Supplier of premium quality scope of stainless steel buttweld fittings that are fabricated under the master direction of our persistent workforce. we are 50 years experienced organization in Stainless Steel buttweld fittings. our Stainless Steel buttweld fittings and different items are made utilizing quality material and experience a thorough quality check at all phases of creation to guarantee quality. Outlined in consistence with worldwide quality gauges, these Stainless Steel buttweld fittings are consumption protection, strong and solid. we additionally supply Stainless Steel buttweld fittings in modified size. we are additionally occupied with the produce and conveyance of stainless steel butt welding channel fittings, stainless steel fashioned pipe fittings and stainless steel ribs in India and abroad. we offers a total scope of buttweld and produced pipe fittings, for example, stainless steel reducer, stainless steel elbow, stainless steel tee, stainless steel cross, stainless steel stub closures and stainless steel twists.

SPECIFICATIONS :

· Standards: ASME / ANSI B16.9, ANSI B16.28, MSS-SP-43

· Size: 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

· Thickness : SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS, Custom Thickness.

· Dimension : B16.5, BS 4504, EN-1092

��Stainless Steel Buttweld Pipe Fittings SS 304 Buttweld Pipe Fittings SS 304L Buttweld Pipe Fittings SS 304H Buttweld Pipe Fittings SS 316 Buttweld Pipe Fittings SS 316L Buttweld Pipe Fittings SS 316Ti Buttweld Pipe Fittings SS 310 Buttweld Pipe Fittings SS 310S Buttweld Pipe Fittings SS 321 Buttweld Pipe Fittings SS 321H Buttweld Pipe Fittings SS 317 Buttweld Pipe Fittings SS 347 Buttweld Pipe Fittings SS 347H Buttweld Pipe Fittings

Alloy Steel Buttweld Pipe Fittings Nickel Alloys Buttweld Pipe Fittings Nickel 200 Buttweld Pipe Fittings Nickel 201 Buttweld Pipe Fittings Monel 400 Buttweld Pipe Fittings Monel 500 Buttweld Pipe Fittings Inconel 800 Buttweld Pipe Fittings Inconel 825 Buttweld Pipe Fittings Inconel 600 Buttweld Pipe Fittings Inconel 625 Buttweld Pipe Fittings Inconel 601 Buttweld Pipe Fittings

Carbon Steel ASTM A 234 Buttweld Pipe Fittings Hastelloy C 276 Buttweld Pipe Fittings Alloy 20 Buttweld Pipe Fittings Titanium Buttweld Pipe Fittings Duplex Steel 2205 Buttweld Pipe Fittings Copper Alloys Buttweld Pipe Fittings Aluminium Buttweld Pipe Fittings Copper Buttweld Pipe Fittings Brass Buttweld Pipe Fittings Gunmetal Buttweld Pipe Fittings

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

0 notes

Link

ASTM B366 Alloy 625 Concentric Reducer 21.3x2.6/14x2.5

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Detailed description

Quick Details

Material: Alloy 625 (UNS N06625)

Technics: Cold Formed

Type: Alloy 625 Concentric Reducer

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Packaging & Delivery

Packaging Detail: Plywood case or fumigation woodern case

Delivery Detail: Usually 2-10 days depend on the quantity

Specifications

ASTM B366 Alloy 625 Concentric Reducer

1. Size: 21.3x14 2. Wall thickness: 2.6x2.5

3. Material: Inconel 625 (UNS N06625)

China Concentric Reducer Manufacturer Yaang supplies ASTM B366 Alloy 625 Concentric Reducer, 21.3x2.6/14x2.5.

Composition ranges for Inconel 625 (UNS N06625)

Size:6 Inch - 3 Inch (DN150 - DN80)

Material:

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Standard: ASME/DIN/ISO/, etc

Connection: Welding

Wall thickness:SCH40S

Finish: Mirror polish, semi bright etc

Concentric Reducer

ASTM B366 Alloy 625 Concentric Reducer Concentric Reducer is used to join pipes or tubes sections on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. A Alloy 625 Concentric Reducer can be a single diameter change or a multiple diameter change. The pipes cannot recognize what the outside configuration of the pipe reducer looks like. The pipe flow is affected by the inside diameter conical transition configuration which can be axially moved and externally reconfigured to provide for more economical reducer fittings. Thus, Alloy 625 Concentric Reducer connects pipes of unequal size but have a common centerline. In other words, it is a type of pipe fitting with different size ends to join pipes of different diameter that joins pipe sections on the same axis.

Alloy 625 Concentric Reducer is designed with the small and large diameters on opposite ends and joined by a cone shaped transition section. They are available in both seamless and welded construction.

Use of Alloy 625 Concentric Reducer is as follows:

Alloy 625 Concentric Reducer will transition gracefully between the piping and the pump.

The Alloy 625 Concentric Reducer helps in transporting slurries or abrasive liquids.

They are useful in services where cavitation is present.

When transporting between flanges or pipes of different ratings and wear protection is necessary, concentric reducers are ideal.

Alloy 625 Concentric reducers are used in discharge of the pump.

Application range: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

ASME/ANSI B16.9 321 316L 90 Degree Butt-Welded Stainless Steel Elbows

Stainless Steel Butt Welding Tee Pipe Fittings, Seamless and Welded with 100% X-ray

304L 180D 45D 90D Elbow

MSS SP-97 316L Weldolet 4 Inch X 2.5 Inch Class 3000 Sch160

0 notes