#duplex 2205 pipe

Explore tagged Tumblr posts

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Duplex 2205 Pipe in Construction: Meeting the Demands of Structural Projects

Durability, strength, and corrosion resistance are of utmost importance in the construction industry. Among the materials that have garnered notable acclaim for their exceptional characteristics, Duplex 2205 pipe stands out.

Understanding Duplex 2205 Pipe:

Duplex 2205 is a stainless steel alloy that combines the best qualities of austenitic and ferritic stainless steels. It exhibits high strength, excellent corrosion resistance, and good weldability, making it an ideal choice for structural applications. The pipe's duplex microstructure enhances its mechanical properties, providing superior performance in demanding construction projects.

Strength and Load-Bearing Capacity:

Structural projects require materials that can withstand heavy loads and provide structural integrity. 2205 pipe excels in this aspect, offering high tensile strength and superior load-bearing capacity. Its ability to resist fatigue and stress corrosion cracking makes it a reliable choice for supporting structures such as bridges, buildings, and offshore platforms.

Corrosion Resistance:

Corrosion can be a significant concern in construction, particularly in environments exposed to moisture, chemicals, and harsh weather conditions. Duplex 2205 tube exhibits excellent resistance to corrosion, even in chloride-rich environments. This corrosion resistance extends the lifespan of the pipe, reducing maintenance costs and ensuring the structural integrity of the project.

Cost-Effectiveness:

While 2205 pipe offers remarkable properties, it also provides cost-effectiveness in construction projects. Its superior strength allows for the use of smaller pipe sizes, reducing material and installation costs. Additionally, its corrosion resistance reduces the need for frequent maintenance and replacement, resulting in long-term cost savings.

Versatility in Construction Applications:

Duplex 2205 pipe is extensively utilized in diverse construction projects, finding applications in structural frameworks, piping systems, support columns, and various other areas. Its versatility empowers architects and engineers to envision and create innovative, efficient structures, harnessing the distinctive properties it offers.

Future Trends and Innovations:

As technology and construction practices continue to evolve, it is important to explore future trends and innovations related to Duplex 2205 stainless steel pipe. Discuss ongoing research and development efforts to enhance its properties further or explore new applications within the construction industry.

In the construction industry, Duplex 2205 pipe has carved out a unique position as an invaluable asset, skillfully meeting the demands of structural projects. Its exceptional combination of durability, strength, and corrosion resistance has propelled it to become the favored choice among architects, engineers, and contractors.

For more info, get in touch with a reputable supplier today!

0 notes

Text

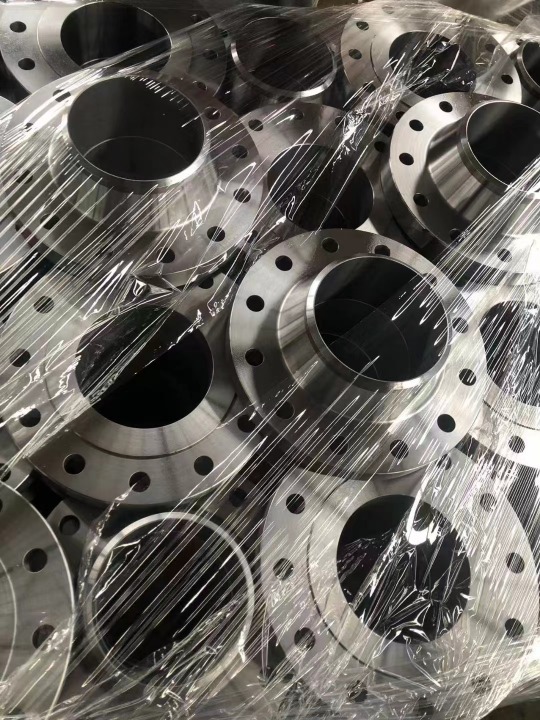

Fully automatic flange CNC lathe

45 years of professional pipe fittings and flange manufacturers and suppliers Duplex steel S3225 A815 WPS32205

1 note

·

View note

Text

#Duplex 2205 Seamless Pipe#DIN 1.4462 Seamless Pipe#UNS S32205 Pipe#ASTM A790 Duplex 2205 Seamless Pipe#Duplex S32205 Seamless Pipe

0 notes

Text

2205 Duplex Pipe

Do you want to purchase 2205 duplex pipe? Visit https://www.archcitysteel.com/product/stainless-steel-pipe/. Arch City Steel & Alloy, Inc brings to you a whole new world of stainless steel. They are reputable suppliers of stainless steel sheets, plates and pipes. Their rich inventory includes an extensive list of stainless steel products like stainless steel pipe and fittings, tubes, flanges, bar stocks, sheets, plates and hollow bars.

0 notes

Text

How Duplex Heat Exchanger Tubes Improve System Efficiency

Companies that rely heavily on thermal transfer systems focus on getting the best results. All production systems rely on heat exchangers to operate correctly across different types of facilities. Over the past years Duplex Heat Exchanger Tubes have proven to be one of the most valuable enhancements. The enhanced heat exchanger tubes deliver superior durability while resisting corrosion effectively for extended service. Selecting appropriate metal materials enhances energy savings while decreasing maintenance needs for better system outcomes. Businesses now mainly select duplex tubes over stainless steel because they bring superior benefits to their operations.

Higher Strength for Demanding Applications

The material offers outstanding force capacity. The material combines austenite and ferrite which makes it two times stronger than basic stainless steel. This enhancement benefits high-temperature high-pressure heat exchangers.

When industries use Duplex Heat Exchanger Tubes they can make thinner walls than standard designs without compromising strength. The reduction of material usage and better heat movement happen as a result. Well-established duplex pipe manufacturers advise using this stainless steel for heavy load areas because of its dependable performance.

Better Corrosion Resistance for Long-Term Use

Corrosion is a major issue in heat exchanger systems. The system endures multiple damages which brings high repair expenses. Duplex tubes stay resistant to many types of corrosion because they are strong enough to avoid stress cracking and pitting.

These pipes show superior performance when processing water with salts plus handling chemicals and oil and gas activities. Suppliers of Duplex 2205 Pipes and Plates recommend using this material when fluids threaten to corrode system areas. The material extends system lifetime while reducing time outages.

Enhanced Thermal Conductivity for Better Output

Heat exchanger tubes should enable effective and rapid heat transfer between flowing substances. Duplex material conducts heat more effectively than usual steel types. Heat moves through the tubes at greater speed because of this design enhancement.

The special tubes enhance heat movement which makes systems work at lower temperatures or achieve thermal targets sooner. These applications need faster heat movement which determines system success in continuous operation. Duplex Round Bar suppliers and Duplex Flange manufacturers conduct reliable projects that use their products for both power and heat movement purposes.

Support for High-Performance Systems

Technology development brings systems into new advanced stages. Systems require materials that equal their advanced technology properties. High-performance units are built using Duplex tubes alongside other components from Duplex Fasteners makers and Duplex 2205 Flanges manufacturers.

Suppliers of Super Duplex 2507 Pipes and Plates step in when normal materials cannot survive harsh work conditions. The materials withstand intense chlorine exposure while performing at high-pressure levels. Super Duplex Fasteners producers and Super Duplex 2507 Flange suppliers assist with these demanding projects.

Conclusion

Manufacturers who seek reliable heat exchanger tubes that perform well and endure heavy use can choose Duplex Heat Exchanger Tubes for their needs. These components reduce system problems while prolonging product life and saving energy. Our company Naman Pipe provides top-class duplex and super duplex materials for every demanding situation. Our team supplies Duplex 2205 Fittings as well as Super Duplex 2507 Round Bar to help you upgrade to superior efficiency with trusted products and professional support.

COMMENTS

0 notes

Text

Premium Alloy Products for Industrial Strength and Durability

Premium Alloy Products for Industrial Strength and Durability

The fulfillment of industrial applications depends on selecting the suitable substances that assure reliability and lengthy-term performance. The combination of top notch alloys which includes Copper Nickel Tube Fittings together with Monel four hundred Fasteners and Hastelloy C276 Round Bar offers remarkable energy along superior corrosion resistance for fasteners and spherical bars and pipes. The annoying nature of specific industrial situations calls for substances including Inconel 625 Round Bar collectively with Inconel 718 Round Bar and 316L Stainless Steel Round Bar. For dependable piping solutions, Duplex 2205 Round Bar, Stainless Steel 304 Pipe, and 316L Stainless Steel Pipe offer durability and resilience.

Copper Nickel Tube Fittings: Corrosion-Resistant and Durable

These marine components utilize Copper Nickel Tube Fittings due to the fact they offer excellent corrosion resistance towards sea pollutants. The fittings find enormous use in desalination plant life in addition to offshore systems and shipbuilding initiatives because they display each amazing sturdiness and exquisite resistance to marine growth. Due to their outstanding thermal conduction capabilities they function perfectly in heat exchangers and condenser tubes.

Monel 400 Fasteners: Strength in Harsh Environments

The extreme environment requires fasteners that function optimally and Monel 400 Fasteners are the most suitable solution available. Nickel and copper constitute the main ingredients of these fasteners which can withstand decay from both seawater and acidic solutions effectively. Manufacturers in chemical processing and marine engineering sectors along with power generation operations constantly depend on sturdy fasteners for their secure joint requirements.

Hastelloy C276 Round Bar: Superior Corrosion Resistance

Engineers apprehend Hastelloy C276 Round Bar for its amazing functionality to withstand corrosion within intense situations. Several chemical processing facilities across various industrial sites use this material in their operations together with flue gas scrubbers and pulp and paper production units. Industrial operations highly depend on this round bar because it maintains excellent mechanical performance and provides robust protection against pitting and crevice corrosion.

Inconel 625 Round Bar: High-Temperature Strength

The design of Inconel 625 Round Bar enables operation at severe temperature and pressing conditions. Its resistance to oxidation and corrosion ensures that the material finds acceptance in aerospace operations and marine fields and chemical processing activities. The material supports high-stress conditions while maintaining structural integrity which results in extended operational life.

Inconel 718 Round Bar: Ideal for High-Performance Applications

The top choice amongst bars for applications that need first rate sturdiness and capacity to undergo harsh temperature situations is Inconel 718 Round Bar. The material stands proud as a jet engine and gas turbine and nuclear reactor preference because of its extremely good mechanical energy and amazing resistance to oxidation. This nickel-based totally alloy retains its mechanical houses even in cryogenic conditions.

316L Stainless Steel Round Bar: Corrosion Resistance and Versatility

The strength and strong corrosion resistance qualities of 316L Stainless Steel Round Bar make it a highly desired material choice. The low carbon composition of this material minimizes the potential for sensitization while improving welding properties to suit pharmaceutical and food processing units together with chemical facilities. The material sustains dependable operations while operating within freshwater bodies as well as saltwater conditions.

Duplex 2205 Round Bar: Strength and Corrosion Resistance Combined

The superior properties of austenitic and ferritic stainless steel are matched in Duplex 2205 Round Bar because it provides strong anti-corrosive characteristics. This material exhibits strong resistance to chloride stress corrosion cracking which enables its use as an excellent option for offshore applications together with chemical storage systems and heat exchanger applications. The material endures well in harsh situations because of its extended operational lifetime.

0 notes

Text

Materials Suitable for Orbital Welding in Modern Industries

Orbital welding is a highly advanced and automated welding process primarily used for joining pipes and tubes with exceptional precision and consistency. Initially developed for aerospace applications, it has become indispensable in industries such as pharmaceuticals, food processing, nuclear energy, semiconductor manufacturing, and power generation. The success of orbital welding depends on the material being welded, as certain metals and alloys exhibit superior compatibility with this technique. This article explores the key materials suitable for orbital welding in modern industries.

1. Stainless Steel

Why Stainless Steel?

Stainless steel is one of the most commonly welded materials in orbital welding due to its excellent corrosion resistance, high strength, and durability. It is widely used in industries where hygiene, sterility, and high-temperature resistance are essential.

Common Grades:

Austenitic Stainless Steels (300 series, e.g., 304, 316L, 321, 347): Known for their excellent weldability, corrosion resistance, and mechanical properties.

Duplex Stainless Steels (2205, 2507, etc.): Offer superior strength and corrosion resistance, commonly used in chemical and marine industries.

Ferritic and Martensitic Stainless Steels: Less common in orbital welding due to their lower ductility and weldability compared to austenitic grades.

Applications:

Pharmaceutical and biotechnology piping

Food and beverage processing plants

Semiconductor manufacturing

Aerospace fuel and hydraulic lines

2. Carbon Steel

Why Carbon Steel?

Carbon steel is widely used due to its affordability, strength, and ease of fabrication. While it does not offer the same level of corrosion resistance as stainless steel, it is still a viable option for applications where oxidation is not a major concern.

Common Grades:

Low Carbon Steel (e.g., A36, A106, A53): Ideal for pipelines, structural applications, and general fabrication.

Medium Carbon Steel (e.g., 1045, 4140): Offers higher strength but requires preheating and post-weld heat treatment.

High Carbon Steel: Less commonly welded orbitally due to increased brittleness and cracking risk.

Applications:

Power plants and energy industries

Structural components and heavy equipment manufacturing

Oil and gas pipelines

3. Titanium and Titanium Alloys

Why Titanium?

Titanium is valued for its high strength-to-weight ratio, corrosion resistance, and biocompatibility. It is often used in environments where weight reduction and resistance to extreme temperatures and chemicals are critical.

Common Grades:

Commercially Pure Titanium (CP-Ti Grades 1-4): Used in chemical processing, medical implants, and aerospace applications.

Titanium Alloys (e.g., Ti-6Al-4V): Provide superior mechanical properties and are commonly used in aerospace and marine applications.

Applications:

Aerospace fuel and hydraulic systems

Medical implants and surgical instruments

Heat exchangers in chemical processing plants

4. Nickel Alloys

Why Nickel Alloys?

Nickel-based alloys offer exceptional corrosion resistance, high-temperature performance, and strength, making them ideal for demanding environments such as chemical processing and power generation.

Common Grades:

Inconel (e.g., Inconel 625, 718): Highly resistant to oxidation and high temperatures, often used in aerospace and marine industries.

Monel (e.g., Monel 400, K-500): Excellent resistance to seawater and chemical environments.

Hastelloy (e.g., Hastelloy C-22, C-276): Superior resistance to highly corrosive environments.

Applications:

Power plants and nuclear reactors

Chemical and petrochemical processing

Aerospace and defense components

5. Aluminum and Aluminum Alloys

Why Aluminum?

Aluminum is widely used for its lightweight nature, corrosion resistance, and good thermal conductivity. However, welding aluminum requires careful control due to its high thermal conductivity and susceptibility to oxidation.

Common Grades:

5XXX Series (e.g., 5052, 5083): Excellent corrosion resistance, commonly used in marine and transportation industries.

6XXX Series (e.g., 6061, 6063): Good strength-to-weight ratio and machinability, widely used in structural applications.

Applications:

Aerospace and aviation fuel systems

Automotive and transportation industries

Marine structures and shipbuilding

6. Copper and Copper Alloys

Why Copper?

Copper and its alloys are known for their excellent electrical and thermal conductivity, corrosion resistance, and antibacterial properties. However, welding copper requires careful control of heat input and gas shielding.

Common Grades:

Pure Copper (C101, C110): Used in electrical applications due to high conductivity.

Copper-Nickel Alloys (e.g., CuNi 70/30, 90/10): Highly resistant to seawater corrosion, commonly used in marine industries.

Bronze and Brass Alloys: Used in decorative and industrial applications.

Applications:

Heat exchangers and HVAC systems

Marine and shipbuilding industries

Electrical and electronic applications

7. Cobalt-Based Alloys

Why Cobalt-Based Alloys?

Cobalt alloys offer outstanding resistance to high temperatures, wear, and corrosion, making them ideal for extreme industrial environments.

Common Grades:

Stellite Alloys (e.g., Stellite 6, Stellite 21): Excellent wear resistance, used in cutting tools and turbine blades.

Haynes Alloys: Used in aerospace and nuclear applications.

Applications:

Aerospace turbine blades and engine components

Medical implants and prosthetics

High-temperature industrial applications

Conclusion

Orbital welding is a critical technique in modern industries, ensuring high-quality, precise, and repeatable welds for various applications. Materials such as stainless steel, carbon steel, titanium, nickel alloys, aluminum, copper, and cobalt-based alloys are widely used due to their unique properties and industrial significance. The choice of material depends on factors such as corrosion resistance, mechanical strength, temperature tolerance, and industry requirements. With advancements in orbital welding technology, the scope for welding new and innovative materials continues to expand, meeting the ever-evolving demands of modern industries.

#orbital welding technology#orbital welding courses#welding technology#orbital welding training#welding automation

0 notes

Text

Premium Quality Round Bars Manufacturer in India

Shashwat Stainless Inc. is the largest Round Bar Manufacturer in India. As a reputable Round Bars Manufacturer in India, we offer precision-engineered bars that are extremely strong, durable, and corrosion resistant. Our round bars are perfect for use in the construction, automotive, and industrial industries, resulting in exceptional performance.

As one of the leading Round Bar Manufacturers, we provide a varied selection of sizes and grades to satisfy our customers' needs. Our innovative production process provides dimensional correctness and superior quality, making us the preferred choice for industries globally. We concentrate on producing superior items that meet globally standards. We are also known as the largest Suppliers of Duplex Steel F53 Round Bar, Duplex Steel 2205 Round Bar, Duplex Steel F51 Round Bar.

As a reputable Round Bars Supplier in India, we guarantee fast delivery and affordable price on bulk and bespoke orders. Whether you want stainless steel, carbon steel, round bars, we have the appropriate option for you. Partner with one of the leading Round Bars Suppliers to acquire the highest quality round bars.

Other Product: Pipes and Tubes Manufacturers in India

0 notes

Text

ASTM A790 Duplex 2205 Pipe - DUPLEX STEEL & ENGINEERING is one of the leading supplier of Duplex 2205 Pipe, Duplex UNS S31803 2205 Pipe, Duplex UNS S32205 Pipe, ASTM A790 2205 Pipe Suppliers in India.

0 notes

Text

Duplex 2205 Fasteners Complete Guide

If you work in the industrial or engineering sector, you’ve likely encountered Duplex 2205. Selecting the right fasteners is crucial for securing structures, machinery, and equipment in high-pressure and high-temperature environments. Duplex Stainless Steel offers excellent strength, corrosion resistance, and durability, making it a preferred choice for various demanding applications.

One of the key advantages of Duplex 2205 Fasteners is their superior weldability, increased tensile strength, and impact resistance. These properties make them ideal for chemical processing, marine, and other industrial sectors where long service life is essential. To get a detailed price list and find the best fasteners for your project, contact Kalpataru Piping Solution today!

What is 2205 Duplex Stainless Steel?

2205 Duplex Stainless Steel is a high-performance alloy that combines the mechanical properties of both austenitic and ferritic stainless steels. This unique best composition makes duplex 2205 more stronger and corrosion resistant to be used in high temperature applications. Duplex SS 2205 consists of 22% chromium, 3% molybdenum, and 5-6% nickel offers outstanding resistance to pitting and chloride stress corrosion cracking. Its high mechanical strength allows it to reduce material thickness, making it a cost-effective solution. Due to its exceptional weldability and durability, Duplex 2205 is widely used in heat exchangers, acid tanks, pipelines, and other applications rather than traditional stainless steel material. Read more about this blog.

0 notes

Text

Duplex Steel F53 Round Bars: Properties, Applications, and Benefits

Shashwat Stainless Inc. is the largest Duplex Steel F53 Round Bars Manufacturers in India. Duplex Steel F53 Round Bars are widely recognized for their superior mechanical properties, excellent corrosion resistance, and exceptional strength. These bars are extensively used in various industrial sectors, including marine, chemical, and oil & gas industries, due to their remarkable durability and high performance under extreme conditions. This blog delves into the properties, applications, and benefits of Duplex Steel F53 Round Bars, making it easier to understand their significance in different industries.

Understanding Duplex Steel F53

Duplex Steel F53 Round Bars Supplier in India, also known as UNS S32750, is a super duplex stainless steel with high levels of chromium, molybdenum, and nitrogen. This composition enhances its resistance to pitting, crevice corrosion, and stress corrosion cracking, making it an ideal choice for harsh environments. The unique duplex microstructure, a mix of austenite and ferrite phases, provides increased strength and better resistance to corrosion compared to conventional stainless steel. Here’s an in-depth look into what makes Duplex Steel F53 Round Bars Manufacturer a top choice for many applications.

Chemical Composition of Duplex Steel F53

Chromium (Cr): 24.0 – 26.0%

Nickel (Ni): 6.0 – 8.0%

Molybdenum (Mo): 3.0 – 5.0%

Nitrogen (N): 0.24 – 0.32%

Iron (Fe): Balance

Other Elements: Manganese, Silicon, Phosphorus, Sulfur

This balanced composition ensures the material exhibits excellent mechanical and corrosion-resistant properties.

Key Properties of Duplex Steel F53 Round Bars

High Strength and Toughness: The duplex structure gives the material superior mechanical strength, making it more durable than standard stainless steel.

Excellent Corrosion Resistance: Its high chromium and molybdenum content ensures outstanding resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking.

Good Weldability:Duplex Steel F53 Round Bars offers excellent weldability and can be welded using standard methods without the need for preheating.

High Thermal Conductivity: The material has better thermal conductivity than austenitic stainless steel, which is beneficial in heat exchanger applications.

Lower Thermal Expansion: Compared to austenitic steels, it has a lower thermal expansion coefficient, reducing deformation in high-temperature applications.

Cost-Effective Alternative: Due to its high strength, lower material thickness can be used, reducing overall material costs without compromising performance.

Applications of Duplex Steel F53 Round Bars

Duplex Steel F53 Round Bars Suppliers widely utilized in various industries that demand high strength, corrosion resistance, and durability. Some common applications include:

Oil & Gas Industry: Used in subsea equipment, heat exchangers, pressure vessels, and piping systems.

Marine Industry: Ideal for shipbuilding, offshore platforms, and seawater desalination plants due to excellent corrosion resistance.

Chemical Processing Industry: Utilized in reactors, storage tanks, and piping systems where exposure to corrosive chemicals is common.

Power Generation: Used in heat exchangers and pressure vessels in nuclear and thermal power plants.

Aerospace Industry: Suitable for critical components that require high strength and resistance to extreme environments.

Food & Beverage Industry: Used in processing plants due to its hygiene-friendly properties and resistance to corrosive food-grade chemicals.

Some common types of round bars include

Duplex Steel 2205 Round Bars: Duplex Steel 2205 Round Bars is a popular product in the Metal Market. These Duplex Steel ASTM A182 Gr F53 Bars are available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Duplex Steel F51 Round Bars: One of our popular products in the Metal Market is Duplex Steel F51 Round Bars. These Din 1.4462 Round Bar is available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Duplex Steel s31803 Round Bars: Duplex Steel 31803 Round Bars is a popular product in the Metal Market. These SAF 2205 Round Bars are available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Super Duplex Steel 2507 Round Bars: This 2507 Duplex Stainless Steel Bar is available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Advantages of Using Duplex Steel F53 Round Bars

Enhanced Durability: Due to their superior strength and resistance to wear and tear, these round bars have a longer service life.

Improved Performance in Harsh Environments: Ideal for industries exposed to high temperatures, pressure, and corrosive elements.

Reduced Maintenance Costs: The material's corrosion resistance leads to lower maintenance and replacement costs.

Eco-Friendly: As stainless steel is 100% recyclable, it contributes to sustainable and environmentally friendly industrial practices.

#Duplex Steel F53 Round Bars#Duplex Steel F53 Round Bars Manufacturer#Duplex Steel F53 Round Bars Manufacturer in India

0 notes

Text

Duplex 2205 Stainless Steel Welded Pipe

Product Overview:

SD-steel is proud to introduce our premium Duplex 2205 Stainless Steel Welded Pipe.

Duplex 2205 Stainless Steel Welded Pipe is a high-performance material designed for applications requiring exceptional corrosion resistance and mechanical strength. This product is ideal for use in industries such as petrochemical, chemical processing, pulp and paper, and offshore oil and gas exploration.

Material Specifications:

Grade: Duplex 2205

Chemical Composition: Approximately 22% Chromium, 5% Nickel, 3% Molybdenum

Mechanical Properties: Yield Strength of 475 MPa, Tensile Strength of 715 MPa

Available Specifications:

| Diameter (mm) | Wall Thickness (mm) | Length (m) |

|---------------|---------------------|------------|

| 25 | 2 | 6 |

| 50 | 3 | 6 |

| 75 | 4 | 6 |

| 100 | 5 | 6 |

Usage Scenarios:

Petrochemical Industry: Used in pipelines and heat exchangers due to its excellent corrosion resistance.

Chemical Processing: Suitable for transporting corrosive fluids and gases.

Offshore Oil & Gas: Ideal for subsea pipelines and structural components.

Pulp & Paper: Utilized in bleaching and washing systems where high chloride environments are present.

Company Strengths:

SD-steel has over two decades of experience in manufacturing high-quality stainless steel products. Our state-of-the-art facilities ensure consistent quality and reliability. We have supplied numerous projects globally, including major offshore platforms and chemical plants.

Frequently Asked Questions:

Q: What are the advantages of using Duplex 2205 Stainless Steel Welded Pipe?

A: Duplex 2205 offers superior resistance to pitting and crevice corrosion, making it perfect for harsh industrial conditions.

Q: Can this pipe be customized according to specific project requirements?

A: Yes, we offer custom dimensions and specifications tailored to your project needs.

Q: How does SD-steel ensure quality control?

A: We follow stringent quality control processes, including non-destructive testing and third-party inspections to ensure compliance with international standards such as ASTM, ASME, and EN standards.

For more information or inquiries, please contact us at +65 83016969.

加飞机@yuantou2048

Mirror Stainless Steel Sheet

Stainless Steel I Beam

0 notes

Text

Duplex Fasteners: A Complete Guide

Introduction

Duplex fasteners are high-performance fastening components made from duplex stainless steel, a material known for its excellent corrosion resistance, strength, and durability. These fasteners are widely used in industries that require high resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion.

In this blog, we will explore the types, properties, benefits, applications, and standards of duplex fasteners in detail.

What Are Duplex Fasteners?

Duplex fasteners are made from duplex stainless steel, which is a combination of austenitic and ferritic microstructures. This dual-phase structure provides enhanced mechanical properties and corrosion resistance compared to conventional stainless steel fasteners.

Common duplex stainless steel grades used in fasteners include:

Duplex 2205 (UNS S32205/S31803)

Super Duplex 2507 (UNS S32750/S32760)

Lean Duplex Grades (e.g., UNS S32101, S32304)

Types of Duplex Fasteners

Duplex fasteners come in various forms, including:

Duplex Bolts - Hex bolts, carriage bolts, eye bolts, U-bolts, anchor bolts

Duplex Nuts - Hex nuts, lock nuts, flange nuts, wing nuts

Duplex Washers - Plain washers, spring washers, lock washers

Duplex Screws - Self-tapping screws, machine screws, socket head screws

Duplex Studs - Threaded rods, double-ended studs, full-threaded studs

Properties of Duplex Fasteners

1. High Strength

Duplex stainless steel has a higher yield strength than austenitic stainless steel, making it suitable for heavy-duty applications.

2. Corrosion Resistance

With high chromium (Cr), molybdenum (Mo), and nitrogen (N) content, duplex fasteners offer exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking.

3. Good Weldability

Duplex stainless steel is easier to weld than ferritic stainless steel and retains better corrosion resistance in welded conditions.

4. Toughness & Ductility

These fasteners offer a balance between toughness and hardness, making them suitable for applications requiring mechanical stability.

5. Cost-Effective

Due to the lower nickel content compared to austenitic stainless steels, duplex fasteners are often more affordable while providing superior performance.

Applications of Duplex Fasteners

Duplex fasteners are used in various industries, including:

1. Marine & Offshore

Shipbuilding

Oil & Gas platforms

Underwater pipelines

2. Chemical Processing

Acid manufacturing plants

Fertilizer industries

Heat exchangers

3. Desalination Plants

Reverse osmosis plants

Water treatment facilities

4. Pulp & Paper Industry

Digesters

Piping systems

Bleaching equipment

5. Construction & Infrastructure

Bridges

High-rise buildings

Structural components

6. Food & Beverage Industry

Brewery equipment

Dairy processing plants

Standard Specifications for Duplex Fasteners

Duplex fasteners conform to several international standards, including:

ASTM A182 – Forged Duplex Stainless Steel Fasteners

ASTM A193 – High-Temperature & High-Pressure Fasteners

ASTM A320 – Bolting Material for Low-Temperature Applications

ISO 3506 – Mechanical Properties of Corrosion-Resistant Fasteners

EN 1.4462 / EN 1.4410 – European Duplex Standards

UNS S32205 / UNS S31803 / UNS S32750 / UNS S32760 – Material Designations

Advantages of Duplex Fasteners

Superior corrosion resistance in harsh environments

Higher strength compared to austenitic stainless steel

Cost-efficient due to lower nickel content

Extended service life, reducing maintenance costs

Ideal for applications requiring high mechanical stability

Advantages of Duplex Fasteners Over Austenitic Stainless Steel Fasteners

Conclusion

Duplex fasteners are an excellent choice for industries requiring high strength, corrosion resistance, and durability. With their unique combination of austenitic and ferritic properties, they outperform conventional stainless steel fasteners in various critical applications. By choosing duplex fasteners, industries can enhance the reliability and longevity of their structures and equipment.

FAQ - Frequently Asked Questions

1. What makes duplex fasteners different from regular stainless steel fasteners?

Duplex fasteners have a dual-phase microstructure (austenitic + ferritic), providing better corrosion resistance, higher strength, and improved stress corrosion cracking resistance than standard stainless steel fasteners.

2. Are duplex fasteners magnetic?

Yes, due to their ferritic phase, duplex fasteners are partially magnetic, unlike austenitic stainless steel fasteners, which are non-magnetic.

3. Can duplex fasteners be used in seawater applications?

Yes, duplex and super duplex fasteners are highly resistant to seawater corrosion, making them ideal for marine, offshore, and desalination applications.

4. What is the temperature range for duplex fasteners?

Duplex fasteners can generally withstand temperatures between -50°C to 300°C, depending on the grade and application.

5. How do I choose the right duplex fastener for my application?

Consider the following factors:

Corrosion exposure (marine, chemical, or industrial environment)

Load-bearing capacity (strength requirements)

Temperature conditions (high or low-temperature applications)

Compliance with industry standards

6. Are duplex fasteners expensive?

While duplex fasteners cost more than standard stainless steel, they are more cost-effective than high-nickel alloys due to their superior durability and lower maintenance costs.

#ananka#anankafasteners#articles#duplex#duplexfasteners#superduplex#fasteners#blog#manufacturer#supplier#tumblr blog#tumblr

0 notes

Text

Do you want to purchase 2205 duplex pipe? Visit https://www.archcitysteel.com/product/stainless-steel-pipe/. Arch City Steel & Alloy, Inc brings to you a whole new world of stainless steel. They are reputable suppliers of stainless steel sheets, plates and pipes. Their rich inventory includes an extensive list of stainless steel products like stainless steel pipe and fittings, tubes, flanges, bar stocks, sheets, plates and hollow bars. For more details, visit their website.

0 notes

Text

Super Duplex 2507 Flanges Benefits

Manufacturing businesses across various sectors need stronger materials due to increased demand. Flanges play their crucial role in all piping systems as essential parts. They permit installations between pipes with a convenient entry point for maintenance work. Of all flange types Super Duplex 2507 Flanges lead the market. These flanges surpass ordinary materials because they handle weight better and endure longer periods of use. Engineers and builders globally are selecting Super Duplex 2507 Flanges because these flanges prove their value across marine, oil and gas, and chemical industry settings.

High Strength for Heavy Duty Use

Super Duplex 2507 Flanges provide their strongest advantage in strength performance. The flanges use stainless steel made of austenitic and ferritic elements to create them. The blend of stainless steels produces flanges with double the strength of basic stainless steel varieties. The flanges have greater capacity to handle intense pressure and weight.

Several pipe manufacturers now suggest using super duplex flanges for their crucial applications. The industries select Super Duplex 2507 Round Bar together with Super Duplex Pipe and Super Duplex Flanges for offshore and chemical plant applications. Systems made with this material have lower failure chances which helps improve their safety and reliability.

Superior Resistance to Corrosion

Many industrial sectors confront the major problem of rusting. The equipment suffers harm and system failures develop due to corrosion effects. They protect against damage when handling seawater and strong acidic chemicals plus other harsh fluids.

Engineers pick Super Duplex 2507 Flanges to work with Duplex Heat Exchanger Tubes and Duplex Plate suppliers due to their selection. These flange components maintain their good condition throughout long periods of service. Flanges with long service life lower costs for both maintenance and new part purchases.

Perfect Match for Tough Environments

Flanges serve areas of the system that handle intense temperature and pressure conditions. Super Duplex 2507 Flanges stay strong even in such tough conditions. The materials withstand chloride damage that regularly affects seawater and chemical equipment.

Super Duplex Flanges producers work with Super Duplex Fasteners producers to supply complete safe piping solutions to their customers. The total system security remains effective when subjected to extreme conditions. These products remain dependable because system failure cannot occur in oil and gas operations.

Cost-Effective Over the Long Term

Super Duplex 2507 Flanges provide better returns on investment because they need fewer replacements and repairs compared to regular flanges. Their durability means fewer replacements. These flanges help reduce maintenance stops because they resist corrosion well. Their strength means fewer failures.

The complete system performs better for more extended periods when these components come from Duplex 2205 Pipe suppliers, Duplex 2205 Flanges manufacturers, and Duplex Fittings manufacturers. The system works better for longer periods which lowers overall expenses and raises output. Today companies select these flanges due to their high value and reliable performance.

Conclusion

The products are created to endure extreme conditions and maintain system functionality. Our company Naman Pipe provides you with the best super duplex and duplex materials for your industrial applications. Our business helps companies select superior Duplex 2205 Fasteners manufacturers and Super Duplex Plate suppliers to produce dependable long-lasting systems.

0 notes