#Inconel 200 Flanges

Explore tagged Tumblr posts

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Haynes 188 Sheet Suppliers in India

Haynes 188 Sheet in Mumbai, Haynes 188 Sheet Importers in Mumbai, Haynes 188 Sheet Suppliers in Mumbai, Haynes 188 Sheet Exporters in Mumbai, Haynes 188 Sheet Stockists in Mumbai.

HAYNES 188 Sheets is a cobalt-nickel-chromium-tungsten alloy that may be readily fabricated for aerospace and commercial gas turbine engine applications, including combustion cans, flame holders, liners, transition ducts, and afterburner parts. HAYNES 188 Coils is generally found in hot sections of engines in burner cans, ducting and afterburner components. In recent years, Udimet 188 Coils has been eclipsed by Alloy 230 for many applications due to improved properties. Udimet 188 Plates has good forming characteristics and is capable of being forged, hot worked or cold worked, although it does work-harden very rapidly so frequent intermediate annealing treatments are recommend for complex forming operations. Buy Alloy 188 Plates at reasonable price from us.

What are Haynes 188 Plates?

Haynes 188 Plate is a cobalt-based alloy that is composed of nickel, chromium, tungsten, and molybdenum, along with other elements. It is known for its excellent high-temperature strength, resistance to corrosion and oxidation, and good weldability.

What are the properties of Haynes 188 plates?

Haynes 188 plates have excellent high-temperature strength, good oxidation resistance, and good resistance to corrosion and erosion. They also have good weldability and formability, making them suitable for a wide range of industrial applications.

What are the applications of Haynes 188 plates?

Haynes 188 plates are commonly used in high-temperature applications, such as gas turbine components, exhaust systems, and heat exchangers. They are also used in chemical processing, power generation, and aerospace applications.Specifications:AMS 5608 / AMS 5609Standard:AMS, AMS and APISpecialize:Shim Sheet, Perforated Sheet, B. Q. Profile.Size:0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTHForm:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange)Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.Grade:Haynes 188 (UNS R30188)

Haynes 188 Plates Equivalent Grades

STANDARDWERKSTOFF NR.UNSHaynes 188–R30188

188 Haynes Plates Chemical Composition :

GradeCMnpSSiCrNiCoBFeLaWHaynes 18805-151.25 max020 max.015 max20-.5021.0 -23.020.0 -24.0Bal.015 max3.0 max03-1513.0 -15.0

Special Products

Haynes 188 Sheet

Alloy 188 Sheet

Conicro 4023 Sheet

2.4683 Sheet

Uns R30188 Sheet

Cobalt Alloy Haynes 188 Sheet

AMS 5772 Sheet

Cobalt Nickel 188 Sheet

Stellite 188 Sheet

Haynes 25 Sheet

L605 Sheet

Udimet L605 Sheet

Stellite 25 Sheet

UNS R30605 Sheet

2.4964 Sheet

AMS 5537 Sheet

Ams 5759 Sheet

HS25 Sheet

Cocr20w15ni Sheet

Cobalt Alloy Haynes 25 Sheet

Cobalt L605 Sheet

Inconel X750 Sheet

X750 Sheet

Haynes X750 Sheet

Nicrofer 7016 Sheet

Udimet X750 Sheet

Pyromet X750 Sheet

Superimphy 750 Sheet

2.4669 Sheet

UNS N07750 Sheet

Nickel Alloy X750 Sheet

NiCr15Fe7TiAl Sheet

Nickelvac X750 Sheet

AMS 5699 Sheet

Alloy X750 Sheet

Nimonic C263 Sheet

Nickel Alloy C263 Sheet

UNS N07263 Sheet

Haynes 263 Sheet

2.4650 Sheet

NiCo20Cr20MoTi Sheet

AMS 5872 Sheet

Hastelloy C263 Sheet

Nicrofer 5120 Coti Sheet

Nicrofer 5120 Coti Round Bar

Inconel 945 Round

Inconel 945 Bar

UNS N09945 Round

Inconel 945X Round

2 notes

·

View notes

Text

SS Long weld Flange | Duplex Steel Flange | Monel 400 Flange.

Exporter Of High Quality Long Weld Flanges-Inconel 600, 601, 625, 718 Flanges, Incoloy 800, 800H, 800HT Flanges, Monel 400 ,Nickel 200 Flanges, Duplex Steel Flanges.

0 notes

Text

Designing For The Extremes – Gasket Innovations For Cryogenic And

Supercritical Systems

In the realm of sealing technology, conventional standards are no longer sufficient. As industries like aerospace, energy, and cryogenics evolve, gaskets must now endure extreme conditions, ranging from cryogenic temperatures near absolute zero, to sealing components in supercritical systems that operate under significant pressure and heat. This shift necessitates innovative advancements in gasket materials and designs. In this blog, we delve into how engineers are addressing these extreme conditions, the challenges they face in such environments, and how state-of-the-art solutions are transforming sealing capabilities.

Understanding extreme conditions

Cryogenic environments

Cryogenic systems function at temperatures typically below -150°C (-238°F), commonly encountered in liquefied natural gas (LNG) transport, medical applications involving liquid oxygen or nitrogen, and space exploration. These frigid temperatures introduce distinct sealing challenges, such as material contraction, which can lead to compromised seal integrity due to severe shrinkage; embrittlement, where certain materials lose their elasticity and become fragile at low temperatures; and issues of outgassing and leakage, where gasket materials must maintain tightness even in vacuum conditions or when gas permeability is elevated.

Supercritical systems

Supercritical fluids, like supercritical CO₂, exist above their critical point and display characteristics of both gases and liquids. These fluids are utilized in processes such as extraction, power generation, and enhanced oil recovery, often at temperatures exceeding 350°C (662°F) and pressures above 3,000 psi (200+ bar), along with exposure to corrosive or reactive substances. Such extreme environments demand specialized gasket solutions engineered to endure high pressures, elevated temperatures, and chemical reactivity, ensuring dependable sealing performance in essential applications.

Challenges in gasket design for extreme applications

Gasket design for demanding applications encounters numerous challenges, such as thermal cycling, which requires seals to withstand repeated expansion and contraction without suffering damage. This can lead to issues like gasket relaxation or compression set, increased flange movement that heightens the risk of leaks, and mechanical fatigue. Another significant concern is material degradation, as extreme temperatures can hasten chemical breakdown; for instance, elastomers may become rigid in cryogenic environments, while organic compounds in supercritical systems may decompose or become reactive. Furthermore, mechanical stresses from high pressure and clamping forces can cause problems like creep, extrusion, or blowouts if the material or gasket design is not adequately optimized for these conditions.

Materials leading the charge

Metals: Metallic gaskets are known for their exceptional structural integrity, making them suitable for high-pressure and high-temperature applications. They can be customized with soft fillers such as graphite or PTFE and perform effectively in cryogenic environments when constructed from materials like Inconel or stainless steel.

PTFE: Polytetrafluoroethylene (PTFE) is recognized for its outstanding chemical resistance, low permeability, and durability at extremely low temperatures, making it ideal for cryogenic applications. It can withstand temperatures up to 260°C in supercritical systems and is resistant to corrosive substances. Variants like filled PTFE (with materials such as glass or graphite) enhance its mechanical strength.

Elastomers: Certain elastomers, including specific fluorosilicates and perfluoro elastomers, provide improved flexibility at low temperatures, although they typically have limitations in extreme cryogenic conditions.

Graphite: Graphite can endure temperatures exceeding 500°C while maintaining seal integrity during thermal cycling due to its compressibility and ability to recover. It is inert to most substances, including supercritical fluids, ensuring dependable performance in extreme settings.

Composite materials: Composite materials, which integrate metal cores with non-metallic sealing surfaces, are increasingly favored for their enhanced stress distribution capabilities, customized performance across diverse temperature and pressure conditions, and their resistance to mechanical creep and blowout.

Design innovations in extreme gasket applications

Low-temperature seal design

In cryogenic settings, the design of low-temperature seals is refined to ensure consistent compression despite material contraction. This involves the use of thicker cross-sections, spring-energized seals that retain their force even as temperatures decrease, and specially designed grooves that mitigate thermal contraction, thereby guaranteeing a dependable seal in harsh environments.

Gaskets for supercritical applications

Gaskets intended for supercritical applications are engineered to withstand blowout and creep under high pressure. This is achieved through the implementation of reinforced graphite gaskets featuring metallic tang layers, as well as spiral-wound gaskets that utilize optimized winding tension and carefully selected fillers, ensuring effective sealing in high-pressure and high-temperature scenarios.

Finite Element Analysis

Finite Element Analysis (FEA) tools are employed to model pressure distribution across flanges, assess material deformation due to thermal and mechanical stresses, and evaluate long-term relaxation and creep characteristics. This allows engineers to validate gasket designs digitally prior to physical testing, ensuring enhanced performance in extreme conditions.

The process of designing gaskets for cryogenic and supercritical systems has evolved beyond mere pressure sealing; it now focuses on engineering resilience at the molecular level. Utilizing materials such as graphite and PTFE, along with advanced composites and intelligent sensors, gasket technology is evolving to meet the challenges of contemporary industry. Whether it involves sealing a cryogenic storage tank or managing a high-pressure extraction system, gaskets play a crucial yet often overlooked role. As industries continue to explore extreme conditions, it is evident that the future of sealing will hinge not only on strength but also on intelligence, adaptability, and innovation.

Looking for gasket solutions built for extremes? Get in touch with Vrushabh Engineering, one of the top gasket manufacturers in India, to discover custom gasket options specifically crafted for cryogenic, high-temperature, and high-pressure applications. Whether you need gaskets for demanding environments such as LNG transport, space exploration, or supercritical systems, Vrushabh Engineering delivers bespoke solutions that guarantee durability and performance in the toughest situations. Emphasizing high-quality materials and innovative designs, these gaskets are engineered to offer exceptional sealing capabilities, preventing leaks and ensuring dependable operation across various industries.

0 notes

Text

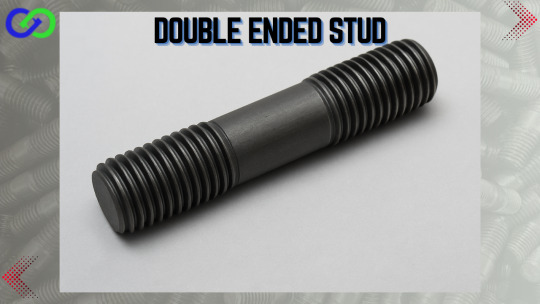

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

Stainless Steel 321 Flanges Suppliers

Introduction:-

Stainless Steel 321 flanges are widely used in high-temperature and corrosion-resistant applications due to their excellent mechanical properties and oxidation resistance. Manufactured from ASTM A182 F321 stainless steel, these flanges contain titanium, which stabilizes the alloy and prevents carbide precipitation, making them ideal for applications requiring resistance to intergranular corrosion.

Stainless Steel 321 flanges are essential components in industrial piping systems, known for their excellent high-temperature strength, oxidation resistance, and corrosion resistance. These flanges are manufactured using ASTM A182 F321 stainless steel, a titanium-stabilized alloy that prevents carbide precipitation and enhances intergranular corrosion resistance, making them ideal for applications in extreme environments.

Product Overview:-

We are a leading manufacturer of stainless steel flanges in various qualities, scales, shapes and standards. We specialize in manufacturing 321 stainless steel flanges with a yield strength of 320 ksi and a tensile strength of over 75 ksi. The nominal inside diameter size of our flanges ranges from 1/2 inch to 48 inches. Additionally, our company manufactures his 321 stainless steel blind flanges. This is used to close the flow at the end of the pipe, making cleaning and maintenance easier.

We manufacture slip-on flanges from 321 stainless steel that are used in low pressure environments where the risk of leakage is minimized. We offer a selection of affordable ASTM A182 F321 flanges that can be customized to meet your specific requirements. We also offer affordable and high quality material, No. 1.4541 Orifice Flange, and other flanges, which can be delivered to your doorstep.

Specifications:-

Stainless Steel 321 FlangesTechnique Use In Forging

Forged, Heat treated,& machined Flanges Top 4 TypesScrewed / Forged/ Threaded / PlateMostly Use TypesLap Joint, Threaded, Weld Neck, Blind, Slip-On, Socket-WeldIndustries UseWaterworks & Municipal Pipe Systems Nuclear Power And The Power Plants Industry Food Processing & Manufacturing High TemperatureAbove 400°C (750°F) And Above 200°C (400°F) For 150LBLow TemperatureAbove -29 °C (−20°F)JIS Standards5K To 63KManufacturing Flange FaceLap-Joint Face, Large Tongue & Groove And Small Tongue Groove, RTJ, FF, Raised Face, Large Male-Female And Small Male-FemaleSize1/2 Inch To 48 InchWe Manufacturer This MaterialsCarbon Steel, Inconel, Hastelloy, Copper Nickel, Stainless Steel, Cast Iron, Duplex Steel & Super Duplex Steel, Wrought Iron, Alloy Steel, Mild Steel.Thickness SizeNormal Pipe Size ≤ 18Bore DiameterNPS ≤ 10RPF India Manufacturer Below StandardsUNI, EN-1092, ANSI/ASME B16.5, B16.47 Series A & B, BS1560-3.1, API7S-15, ASME B16.48, AWWA C207, IS 2062, EN1092, API7S-43, MSS S44, ISO70051, ASME B16.36, DIN, API, ISO, API605, BS4504Pressure Ratings150 To 2500

Benefits:-

Our 321 SS weld neck flange can withstand hazardous conditions such as high temperatures and large pressure fluctuations. We also manufacture large diameter stainless steel 321 flanges, which are metal rings used to connect valves, pipes, and other equipment to pipelines. Here, you can get different types of flanges all from one source. Our UNS S32100 socket weld flanges are made from Alloy 321, a titanium-stabilized true stainless steel with excellent resistance to intergranular corrosion.

Conclusions:-

Manufacturers employ advanced forging, machining, and heat treatment techniques to ensure precision, durability, and compliance with international standards such as ASME B16.5, ANSI, and DIN. SS 321 flanges are widely used in industries like petrochemicals, aerospace, power generation, and marine applications, where reliable performance under high temperatures and aggressive conditions is crucial. Leading manufacturers focus on quality assurance through rigorous testing methods, including ultrasonic testing, hydrostatic testing, and PMI (Positive Material Identification), to deliver high-performance flanges for critical industrial applications>

Email Id:[email protected]

Contact Number:-88797-09191

0 notes

Text

Spiral Wound Gaskets vs. Other Gasket Types: A B2B Comparison

In industries where maintaining a leak-free system is critical, gaskets play a vital role in sealing connections between components. The choice of gasket can significantly affect the performance, safety, and cost-efficiency of a business's operations. For manufacturers, suppliers, and B2B professionals, understanding the differences between various gasket types is essential for making informed decisions.

In this article, we'll take an in-depth look at spiral wound gaskets and compare them with other popular gasket types, including ring-type joint gaskets, rubber gaskets, and metallic gaskets. We'll explore their design, advantages, disadvantages, and best-use scenarios to help you decide which gasket type suits your specific needs.

What Are Spiral Wound Gaskets?

Spiral wound gaskets are a type of metallic gasket that consist of a combination of metallic and filler materials, wound in a spiral form. This design creates a highly effective seal that can withstand extreme temperatures, high pressures, and chemical exposure. The metal provides structural strength, while the softer filler material enhances sealing capabilities by filling surface imperfections on flange faces.

Key Features of Spiral Wound Gaskets:

Materials: Typically made of stainless steel or other high-grade alloys combined with flexible graphite, PTFE (polytetrafluoroethylene), or other filler materials.

Design: The spiral construction allows for flexibility and resilience, enabling the gasket to conform to flange faces under pressure.

Temperature and Pressure Resistance: Capable of handling temperatures from -200°C to over 500°C and pressures up to 250 bar, making them ideal for critical applications.

Best Use Cases:

Spiral wound gaskets are widely used in the petrochemical, oil and gas, power generation, and chemical processing industries. They are particularly suited for applications involving extreme temperature fluctuations, high-pressure steam, and corrosive media.

Comparing Spiral Wound Gaskets to Other Gasket Types

Now that we’ve established the basics of spiral wound gaskets, let’s compare them with other common gasket types, highlighting the differences in performance, durability, cost, and applications.

1. Spiral Wound Gaskets vs. Ring-Type Joint (RTJ) Gaskets

Ring-Type Joint (RTJ) gaskets are solid metallic gaskets primarily used in high-pressure applications such as oilfield and pipeline systems. They are often made from materials like carbon steel, stainless steel, or inconel.

Comparison:

Design and Structure:

Spiral wound gaskets feature a flexible, layered design, whereas RTJ gaskets are solid metal rings that rely on compression to form a seal.

Sealing Capabilities:

Spiral wound gaskets offer better performance in systems where there are uneven surfaces or minor imperfections on flange faces due to their filler material, while RTJ gaskets work best in applications with smooth, precise flange surfaces.

Pressure and Temperature:

Both gasket types can withstand extreme pressures and temperatures, but RTJ gaskets are generally used in the most high-pressure environments, such as valve bonnets and flange assemblies in the oil and gas industry.

Installation and Maintenance:

Spiral wound gaskets are relatively easier to install due to their ability to adjust to flange imperfections. RTJ gaskets, being solid metal, require perfect alignment and tighter bolting, making installation more challenging.

Cost:

RTJ gaskets tend to be more expensive due to their solid metal construction, but they offer excellent durability in highly demanding environments. Spiral wound gaskets, while still robust, tend to be more cost-effective for applications requiring frequent maintenance or replacement.

Best Use Cases:

Choose spiral wound gaskets for systems with fluctuating pressures and uneven flange surfaces. Opt for RTJ gaskets in high-pressure, precision applications like subsea pipelines and oil drilling.

2. Spiral Wound Gaskets vs. Rubber Gaskets

Rubber gaskets are made from elastomeric materials such as neoprene, EPDM, silicone, and nitrile. These gaskets are widely used in less demanding applications such as water systems, HVAC units, and general industrial processes.

Comparison:

Design and Structure:

Rubber gaskets are soft and flexible, whereas spiral wound gaskets have a more complex, resilient metallic design. Rubber gaskets are highly compressible and can conform to most surfaces but lack the durability of spiral wound gaskets.

Sealing Capabilities:

While rubber gaskets are effective at sealing under low-pressure conditions, spiral wound gaskets provide superior sealing under high temperatures, high pressures, and harsh chemicals.

Temperature and Pressure:

Rubber gaskets are generally limited to lower temperature ranges (typically -40°C to 120°C) and cannot handle the extreme pressure environments that spiral wound gaskets can withstand.

Durability and Longevity:

Rubber gaskets degrade over time when exposed to extreme temperatures, oils, and chemicals. In contrast, spiral wound gaskets are designed to resist such conditions and have a longer service life in harsh environments.

Cost:

Rubber gaskets are significantly cheaper than spiral wound gaskets, making them a cost-effective solution for non-critical applications. However, frequent replacement may be required, driving up the long-term costs.

Best Use Cases:

Rubber gaskets are ideal for low-pressure applications, such as plumbing, HVAC systems, and food processing equipment. Spiral wound gaskets should be used for more demanding applications that require resilience against temperature, pressure, and chemicals.

3. Spiral Wound Gaskets vs. Metallic Gaskets

In addition to spiral wound gaskets, the term metallic gaskets encompasses other types of gaskets made entirely from metal, such as corrugated metal gaskets, jacketed gaskets, and metal-reinforced gaskets.

Comparison:

Design and Structure:

Spiral wound gaskets are a hybrid of metallic and non-metallic materials, while other metallic gaskets are typically all-metal or have metal jackets with soft filler cores.

Sealing Capabilities:

Spiral wound gaskets offer greater flexibility due to their mixed material design. Other metallic gaskets provide less flexibility and may not conform as well to imperfect flange surfaces.

Temperature and Pressure:

Both spiral wound and metallic gaskets can endure extreme temperatures and pressures, but spiral wound gaskets tend to perform better under fluctuating conditions due to their layered construction.

Installation and Maintenance:

Spiral wound gaskets are easier to install and can recover from stress and pressure cycles more effectively. All-metal gaskets are less forgiving and require more precise installation techniques.

Cost:

Depending on the type of metal and complexity of the design, metallic gaskets can range in cost. Spiral wound gaskets tend to be moderately priced but offer a higher degree of versatility and performance.

Best Use Cases:

Choose spiral wound gaskets for systems subject to frequent pressure and temperature changes. Metallic gaskets are better suited for static sealing applications where durability and resistance to high stress are essential.

Key Considerations for Choosing the Right Gasket

When selecting a gasket for your business, consider the following factors:

Application Requirements: Understand the temperature, pressure, and chemical exposure levels in your system.

Cost vs. Longevity: While cheaper gaskets like rubber may seem economical upfront, they may lead to higher costs due to frequent replacements. On the other hand, higher-performance gaskets like spiral wound gaskets offer longer service life in demanding environments.

Installation and Maintenance: Consider the ease of installation and the required maintenance. Spiral wound gaskets, for example, offer easier installation compared to solid metallic gaskets but still perform under harsh conditions.

Conclusion: Why Spiral Wound Gaskets Stand Out

In a B2B context, selecting the right gasket type can significantly impact operational efficiency, safety, and cost management. Spiral wound gaskets stand out for their versatility, durability, and excellent performance in high-temperature, high-pressure, and corrosive environments. While RTJ gaskets provide unparalleled strength in precision applications, and rubber gaskets are cost-effective for less demanding uses, spiral wound gaskets offer the best of both worlds with their unique combination of metal and filler materials.

Whether you're in the oil and gas sector, chemical processing, or general manufacturing, spiral wound gaskets provide the reliability and resilience that businesses need to maintain seamless operations, reduce downtime, and improve system longevity.

0 notes

Text

Spiral Wound Gasket Materials- A Comprehensive Guide to Superior Sealing Solutions

Spiral wound gaskets are renowned for their outstanding sealing capabilities, especially in applications that involve extreme temperatures, high pressure, and aggressive chemicals. The secret behind their exceptional performance lies in the unique combination of materials used in their construction. Designed for use in critical industrial sectors like oil and gas, petrochemical, power generation, and pharmaceuticals, spiral wound gasket provide a versatile solution for preventing leaks and ensuring system integrity. In this article, we will explore the various materials used in spiral wound gaskets and their significance in different industrial applications.

The Structure of Spiral Wound Gaskets

Spiral wound gasket consist of a combination of metallic and non-metallic materials. The gasket is formed by winding alternating layers of a metallic strip and a soft filler material in a spiral manner. This design allows the gasket to be both flexible and robust, making it ideal for handling the most demanding sealing applications.

Metallic Materials Used in Spiral Wound Gaskets

The metallic component of a spiral wound gasket provides structural integrity and strength, allowing it to withstand high pressures and temperatures. Common metals used include:

Stainless Steel:

The most widely used metal for spiral wound gaskets, stainless steel (grades such as 304, 316, and 321) offers excellent corrosion resistance and mechanical strength. This material is suitable for most applications involving exposure to chemicals, steam, and corrosive environments.

Monel:

Monel, a nickel-copper alloy, is known for its superior resistance to acids, alkalis, and seawater. Gaskets made from Monel are ideal for use in marine environments and chemical processing industries where harsh chemicals are present.

Inconel:

Inconel is a high-strength nickel-chromium alloy that excels in high-temperature and high-pressure environments. This material is used in applications where extreme heat, such as in power generation plants and refineries, can degrade other metals.

Titanium:

For applications requiring resistance to both high temperatures and aggressive chemicals, titanium is an excellent choice. Its lightweight yet durable properties make it ideal for use in aerospace and chemical processing industries.

Filler Materials in Spiral Wound Gaskets

While the metal provides strength and durability, the filler material ensures effective sealing. The choice of filler material depends on the application’s specific requirements, such as temperature, chemical exposure, and operating pressure. Common filler materials include:

Flexible Graphite:

Flexible graphite is known for its excellent thermal conductivity and chemical resistance. It can handle temperatures up to 450°C (850°F) and is used in applications involving high temperatures, such as in steam systems, boilers, and heat exchangers. It also resists oxidation and can withstand exposure to a wide range of chemicals.

PTFE (Polytetrafluoroethylene):

PTFE is one of the most chemically resistant materials available. It provides exceptional resistance to corrosive chemicals and solvents, making it suitable for gaskets used in chemical processing and pharmaceutical industries. PTFE can operate in temperatures ranging from -200°C to +260°C (-328°F to 500°F), making it highly versatile for both high and low-temperature applications.

Mica:

Mica is a naturally occurring mineral known for its high heat resistance. It can withstand temperatures up to 1000°C (1832°F) and is primarily used in applications involving extreme heat, such as power generation and high-temperature industrial furnaces.

Additional Components: Inner and Outer Rings

Spiral wound gaskets also incorporate inner and outer rings made from materials like carbon steel or stainless steel. These rings provide stability, help center the gasket within the flange, and prevent over-compression during installation. The rings also protect the sealing element from the corrosive environment and enhance the gasket’s longevity.

Inner Ring: The inner ring prevents the filler material from being exposed to the inner media and maintains gasket integrity under high pressure.

Outer Ring: The outer ring is used for accurate centering in the flange and to protect the spiral wound element from excessive tightening forces.

Advantages of Spiral Wound Gasket Materials

High Durability:

The combination of metallic and non-metallic materials ensures that spiral wound gasket materials can withstand extreme operating conditions without deteriorating or losing sealing performance.

Versatility:

By selecting different combinations of metals and fillers, spiral wound gasket can be customized to meet the specific needs of any industrial application, from cryogenic temperatures to high-temperature steam systems.

Resilience:

Spiral wound gasket maintain flexibility, allowing them to adapt to flange imperfections and provide a secure seal even when there are changes in pressure and temperature.

Excellent Chemical and Thermal Resistance:

The use of high-quality filler materials like PTFE and flexible graphite ensures resistance to a wide range of chemicals, high temperatures, and pressure fluctuations, making spiral wound gasket suitable for diverse applications.

Common Applications of Spiral Wound Gaskets

Oil and Gas:

Spiral wound gaskets are widely used in pipelines, refineries, and offshore platforms where high pressure, extreme temperatures, and corrosive chemicals are common.

Power Generation:

Power plants utilize spiral wound gasket in boilers, heat exchangers, and steam turbines, where they are exposed to high-temperature steam and varying pressure conditions.

Chemical Processing:

The chemical industry benefits from the chemical resistance of spiral wound gasket, using them in reactors, pumps, and pipelines carrying aggressive chemicals.

Petrochemical:

Refineries and petrochemical plants rely on these gaskets to seal joints in process equipment that handles corrosive chemicals and extreme heat.

Conclusion

Spiral wound gaskets, with their combination of durable metals and flexible filler materials, provide an unmatched sealing solution for the most challenging industrial environments. The versatility of material options ensures that spiral wound gasket can be tailored to meet the specific demands of any application, whether in the oil and gas sector, chemical processing, or power generation. The right selection of metallic and filler materials guarantees long-lasting performance, cost-efficiency, and safety, making spiral wound gasket a preferred choice for industries worldwide.

Original Source: Spiral Wound Gasket Materials

0 notes

Text

Welded Flanges Exporters in India

We are broadly known for manufacturing and supplying an extensive variety of high quality of Welded Flanges. These flanges are welded to the end of pipe so that the pipe can be bolted to another pipe with a same flanges. Complying with the characterized parameters of the business, these offered welded flanges hold a few properties, such as,Epoxy Coating, Longer service life, Hot Dip Galvanizing, Resistance against corrosion, Dimensions stability, Compressive strength.SPECIFICATION

Size:

1/2" NB TO 60"NB.

Class:

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS DIN Standard ND-6,10, 16, 25, 40 Etc.

Nickel Alloy Socket Weld Flange:

ASTM / ASME SB 564 / 160 / 472.

UNS 10276 -HASTELLOY C 276 Socket Weld Flange

UNS 2200 -NICKEL 200 Socket Weld Flange

UNS 2201 -NICKEL 201 Socket Weld Flange

UNS 4400 -MONEL 400 Socket Weld Flange

UNS 8020 -ALLOY 20 Socket Weld Flange

UNS 8825 -INCONEL 825 Socket Weld Flange

UNS 6600 -INCONEL 600 Socket Weld Flange

UNS 6601 -INCONEL 601 Socket Weld Flange

UNS 6625 -INCONEL 625 Socket Weld Flange

Copper Alloy Socket Weld Flange:

ASTM / ASME SB 61 / 62 / 151 / 152.

C 70600 (CU -NI- 90/10)/Cupro Nickel Socket Weld Flange

C 71500 (CU -NI- 70/30)/Copper Nickel Socket Weld Flange

UNS NO. C 92200, UNS NO. C 83600, UNS NO. UNS NO C 10100,

C 10200, C 10300, C 10800, C 12000, C 12200

Duplex Steel Socket Weld Flange:

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Stainless Steel Socket Weld Flange/SS SWRF Flange:

ASTM A182 Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Alloy Steel Socket Weld Flange/AS SWRF Flange:

ASTM SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel Socket Weld Flange/CS SWRF Flange:

ASTMA 105 Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel Socket Weld Flange/LTCS SWRF Flange:

A350 LF2/A350 LF3, Value Added Services, Hot Dip Galvanizing, Epoxy Coating,, Test Certificate, Mill Test Certificate as per EN 10204 / 3.1Bc

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

A Comprehensive Overview of High-Pressure Pipe Fittings Hastelloy C276 Pipe Fittings

By joining valves, pipes, pumps, and other machinery using bogus fittings, a pipeline system can be constructed with a diameter ranging from 2 to 4 inches. They are basically the high-pressure pipe fittings and the Hastelloy C276 flanges which are made of stainless steel are durable, long-lasting, and realistically priced. On the other hand, stainless steel's reduced oxidisation resistance could make it incompatible for some applications. Hence, the Nickel Alloy Pipe Fittings are very sustainable as well as wonderful to use for commercial as well as the residential purpose.

It is also important to note that the Nickel 200 Pipe Fittings is well constructed from solid steel blocks that are machined to shape according to specifications, it meets all applicable standards. The device can endure pressures up to the highest class, which is Stainless Steel High Pressure Pipe Fittings as well as also known as Inconel 625 Pipe Fittings. Extreme tension Forged fittings are made by joining two pipe fittings and sealing them with a gasket.

On the other hand, the Incoloy 825 pipe fittings and the Forged fittings come in two varieties: threaded and socket-weld. The pipe is screwed into threaded fittings, whereas the pipes are filledet-welded into socket-weld fittings.

Why High-Pressure Fittings Are Necessary

In many cases, high-pressure fittings are the best option for fluids. They can be found in the following systems and machines:

Skids and panels for gas and oil control

Chemical injection skids

Equipment that uses hydraulic power

Using water jets for cleaning and cutting

Fittings for Stainless Steel Pipes

Fittings of the same or different diameters are used to create couplings, which link two male terminals.

Crosses—The Hastelloy pipe fittings allow you to attach four identical connections to a line of tubing.

Elbows are fittings that join two pieces of tubing at a right angle to one another, allowing the line to be extended.

Nipples are used to join two common male tubing ends when using threaded or coned tubing of varying common lengths.

Reducing Adapters for SS To accommodate fittings and pipes of varying sizes, adapters are manufactured to modify the one end of a pipe. It usually has a male and a female end and is also called diminishing coupling.

Tees—Three identically sized standard connections used to lengthen a tubing line—are the fittings in question.

Advantages of Clamps for High-Pressure Pipes

If a complex threaded connection is required in an industrial setting, these fittings are the way to go. In addition, structural hydrodynamics testing can be done using it.

Chemical fertilizer manufacturing, nuclear power plants, heat exchangers, petroleum gas industries, medical and pharmaceutical sectors, water gas pipe systems, and petrochemical refineries are just a few of the numerous places you could find their use.

A high-pressure pipe fitting is an essential component in numerous applications that demand elevated temperatures. Transporting gases or fluids at high pressure is its primary function.

Read More :-https://www.pipingmaterial.ae/stainless-steel-ferrule-fittings/

0 notes

Text

Orifice Flanges

We are worked in get-together five star need nature of Orifice Flanges The principal clarification behind a hidden Flanges is to offer interest to a line for metering of fluids or gasses. A hidden plate is squashed between several Flanges when it is being showed up in a line and the whole collecting is shown as a hole Flanges mixing. Jack-fixes the party make a short summit of the hidden plate. In the meantime, the hole plate, which is the metering contraption, joins a powerless plate by structures for a square edge, concentric, and round opening in inside point. Two weight tap-openings are other than penetrated in each Flanges for to gage weight limit totally through the hole.

Orifice Flanges are utilized as a decision of the standard line Flanges when stream spout or hole plate is utilized. The hole plate is a general scattered thing and isn't being sold as a touch of the Flanges gathering. These Flanges are for the most part utilized as a scramble of various applications industry. They are sensible in various sizes, focal centers, examinations and thickness as appeared by the client's necessities, and are proposed to driving costs in march.

Hole Flanges are utilized with Opening meters to check the stream advancement of either fluids or gases in the particular pipeline. Sets of weight "Tappings", everything thought about on 2 sides, unequivocally change one another, are machined into the hidden Flanges. This makes separate opening carriers or tappings in the line divider senseless.

Orifice Flanges Specifications:

Standards: ANSI B16.47 Series A & B, ANSI B16.5, API-605, MSS SP44, ASA, EN1092, BS 4504, DIN Type: Orifice Flanges Size: ½” (15 NB) to 48″ (1200NB) Class : 150 Class, 300 Class, 400 Class, 600 Class, 900 Class, 1500 Class, 2500 Class, PN6, PN10, PN16, PN25, PN40, PN64 etc. Material: Stainless Steel, Duplex, Super Duplex, Nickel Alloys, Alloy Steel, Carbon Steel, Low temperature Steel Material Grade: Stainless Steel Orifice Flanges: ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L Duplex & Super DuplexSteel Orifice Flanges: ASTM A182 / ASME SA182, F 44, F 45, F51, F 53, F 55, F 60, F 61 Carbon Steel Orifice Flanges: ASTM A105 / ASME SA105, ASTM A350 / ASME SA350, ASTM A181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70 Low Temperature Carbon Steel Orifice Flanges (LTCS): Flange, A350 LF2/A350 LF3 Alloy Steel Orifice Flanges: ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91 Nickel Alloy Orifice Flanges: ASTM / ASME SB 564 / 160 / 472, UNS 2200 ( Nickel 200 ), UNS 2201 (Nickel 201 ), UNS 4400 (Monel 400 ), UNS 8020 ( Alloy 20 / 20 CB 3, UNS 8825 Inconel (825), UNS 6600 (Inconel 600 ), UNS 6601 ( Inconel 601 ), UNS 6625 (Inconel 625), UNS 10276 ( Hastelloy C 276 )

We Offer The Following Types :

Slip on threaded ring joint corner tap weld neck orifice flanges Raised Face slip-on orifice flange manufacturers Ring-Type joint weld neck orifice flanges Corner tap orifice flanges Raised Face weld neck orifice flanges

0 notes

Text

Blind Flange | Blind Pipe Flange.

Stainless Steel ASTM A182 F316/316L/316H Blind Flange, Monel 400, Inconel 600, Nickel 200, Hastelloy C22, Duplex Steel S31803 Blind Flange, Supplier Mumbai India.

0 notes

Text

Designing For The Extremes – Gasket Innovations For Cryogenic And Supercritical Systems

In the realm of sealing technology, conventional standards are no longer sufficient. As industries like aerospace, energy, and cryogenics evolve, gaskets must now endure extreme conditions, ranging from cryogenic temperatures near absolute zero, to sealing components in supercritical systems that operate under significant pressure and heat. This shift necessitates innovative advancements in gasket materials and designs. In this blog, we delve into how engineers are addressing these extreme conditions, the challenges they face in such environments, and how state-of-the-art solutions are transforming sealing capabilities.

Understanding extreme conditions

Cryogenic environments

Cryogenic systems function at temperatures typically below -150°C (-238°F), commonly encountered in liquefied natural gas (LNG) transport, medical applications involving liquid oxygen or nitrogen, and space exploration. These frigid temperatures introduce distinct sealing challenges, such as material contraction, which can lead to compromised seal integrity due to severe shrinkage; embrittlement, where certain materials lose their elasticity and become fragile at low temperatures; and issues of outgassing and leakage, where gasket materials must maintain tightness even in vacuum conditions or when gas permeability is elevated.

Supercritical systems

Supercritical fluids, like supercritical CO₂, exist above their critical point and display characteristics of both gases and liquids. These fluids are utilized in processes such as extraction, power generation, and enhanced oil recovery, often at temperatures exceeding 350°C (662°F) and pressures above 3,000 psi (200+ bar), along with exposure to corrosive or reactive substances. Such extreme environments demand specialized gasket solutions engineered to endure high pressures, elevated temperatures, and chemical reactivity, ensuring dependable sealing performance in essential applications.

Challenges in gasket design for extreme applications

Gasket design for demanding applications encounters numerous challenges, such as thermal cycling, which requires seals to withstand repeated expansion and contraction without suffering damage. This can lead to issues like gasket relaxation or compression set, increased flange movement that heightens the risk of leaks, and mechanical fatigue. Another significant concern is material degradation, as extreme temperatures can hasten chemical breakdown; for instance, elastomers may become rigid in cryogenic environments, while organic compounds in supercritical systems may decompose or become reactive. Furthermore, mechanical stresses from high pressure and clamping forces can cause problems like creep, extrusion, or blowouts if the material or gasket design is not adequately optimized for these conditions.

Materials leading the charge

Metals: Metallic gaskets are known for their exceptional structural integrity, making them suitable for high-pressure and high-temperature applications. They can be customized with soft fillers such as graphite or PTFE and perform effectively in cryogenic environments when constructed from materials like Inconel or stainless steel.

PTFE: Polytetrafluoroethylene (PTFE) is recognized for its outstanding chemical resistance, low permeability, and durability at extremely low temperatures, making it ideal for cryogenic applications. It can withstand temperatures up to 260°C in supercritical systems and is resistant to corrosive substances. Variants like filled PTFE (with materials such as glass or graphite) enhance its mechanical strength.

Elastomers: Certain elastomers, including specific fluorosilicates and perfluoro elastomers, provide improved flexibility at low temperatures, although they typically have limitations in extreme cryogenic conditions.

Graphite: Graphite can endure temperatures exceeding 500°C while maintaining seal integrity during thermal cycling due to its compressibility and ability to recover. It is inert to most substances, including supercritical fluids, ensuring dependable performance in extreme settings.

Composite materials: Composite materials, which integrate metal cores with non-metallic sealing surfaces, are increasingly favored for their enhanced stress distribution capabilities, customized performance across diverse temperature and pressure conditions, and their resistance to mechanical creep and blowout.

Design innovations in extreme gasket applications

Low-temperature seal design

In cryogenic settings, the design of low-temperature seals is refined to ensure consistent compression despite material contraction. This involves the use of thicker cross-sections, spring-energized seals that retain their force even as temperatures decrease, and specially designed grooves that mitigate thermal contraction, thereby guaranteeing a dependable seal in harsh environments.

Gaskets for supercritical applications

Gaskets intended for supercritical applications are engineered to withstand blowout and creep under high pressure. This is achieved through the implementation of reinforced graphite gaskets featuring metallic tang layers, as well as spiral-wound gaskets that utilize optimized winding tension and carefully selected fillers, ensuring effective sealing in high-pressure and high-temperature scenarios.

Finite Element Analysis

Finite Element Analysis (FEA) tools are employed to model pressure distribution across flanges, assess material deformation due to thermal and mechanical stresses, and evaluate long-term relaxation and creep characteristics. This allows engineers to validate gasket designs digitally prior to physical testing, ensuring enhanced performance in extreme conditions.

The process of designing gaskets for cryogenic and supercritical systems has evolved beyond mere pressure sealing; it now focuses on engineering resilience at the molecular level. Utilizing materials such as graphite and PTFE, along with advanced composites and intelligent sensors, gasket technology is evolving to meet the challenges of contemporary industry. Whether it involves sealing a cryogenic storage tank or managing a high-pressure extraction system, gaskets play a crucial yet often overlooked role. As industries continue to explore extreme conditions, it is evident that the future of sealing will hinge not only on strength but also on intelligence, adaptability, and innovation.

Looking for gasket solutions built for extremes? Get in touch with Vrushabh Engineering, one of the top gasket manufacturers in India, to discover custom gasket options specifically crafted for cryogenic, high-temperature, and high-pressure applications. Whether you need gaskets for demanding environments such as LNG transport, space exploration, or supercritical systems, Vrushabh Engineering delivers bespoke solutions that guarantee durability and performance in the toughest situations. Emphasizing high-quality materials and innovative designs, these gaskets are engineered to offer exceptional sealing capabilities, preventing leaks and ensuring dependable operation across various industries.

Resource: Read more

0 notes

Text

High Nickel Fasteners Manufacturer, Supplier & Exporter

Introduction

High Nickel Fasteners are highly durable and corrosion-resistant fastening solutions that find applications in extreme environments. These fasteners are made from nickel and nickel alloys, offering superior strength, oxidation resistance, and heat tolerance. They are widely used in industries such as aerospace, marine, chemical processing, and power generation.

As a leading High Nickel Fasteners Manufacturer, Supplier, and Exporter, we at Ananka Group specialize in producing high-quality fasteners that meet international standards and cater to the diverse needs of industries worldwide.

As a leading High Nickel Fasteners manufacturer, supplier, and exporter, we provide high-quality products to clients worldwide, including locations such as the USA, UK, Canada, Germany, Australia, UAE, and more.

Types of High Nickel Fasteners

High Nickel Fasteners come in various forms, including:

Bolts – Hex bolts, carriage bolts, anchor bolts, flange bolts, etc.

Nuts – Hex nuts, lock nuts, coupling nuts, dome nuts, etc.

Washers – Flat washers, spring washers, lock washers, etc.

Studs – Threaded rods, double-end studs, and full-threaded studs.

Screws – Machine screws, self-tapping screws, socket head cap screws, etc.

Threaded Rods – Used in construction, marine, and industrial applications.

Features of High Nickel Fasteners

High Nickel Fasteners possess unique features, making them ideal for demanding environments:

Corrosion Resistance – Exceptional resistance to oxidation, rust, and acids.

High Strength – Superior mechanical properties, even at elevated temperatures.

Excellent Durability – Withstands harsh chemical exposure and extreme pressure.

Non-Magnetic Properties – Ideal for specific applications in electronics and aerospace industries.

High Temperature Resistance – Suitable for use in heat-intensive environments.

Common Nickel Alloys Used in Fasteners

Some of the commonly used nickel alloys in fasteners include:

Inconel (Alloy 600, 625, 718, etc.) – Known for oxidation resistance and high strength.

Monel (Alloy 400, K500) – Offers excellent corrosion resistance, especially in marine environments.

Hastelloy (C22, C276, etc.) – Provides superior resistance to acids and harsh chemicals.

Nickel 200/201 – Pure nickel fasteners with excellent mechanical properties and electrical conductivity.

Alloy 20 – Designed for resistance to sulfuric acid and other aggressive chemicals.

Applications of High Nickel Fasteners

High Nickel Fasteners are used in a wide range of industries, including:

Aerospace Industry – High-performance fasteners for aircraft and spacecraft.

Marine Industry – Resistant to seawater corrosion, ideal for shipbuilding and offshore structures.

Chemical Processing Plants – Used in reactors, heat exchangers, and chemical storage tanks.

Oil & Gas Industry – Essential for drilling platforms, pipelines, and refineries.

Power Generation – Employed in nuclear, thermal, and renewable energy plants.

Automotive & Defense – Critical for military vehicles, submarines, and high-performance engines.

Manufacturing Process of High Nickel Fasteners

The production of high nickel fasteners involves multiple steps to ensure precision and durability:

Raw Material Selection – High-grade nickel alloys are chosen based on application requirements.

Forging & Machining – Fasteners are shaped and processed to attain the desired dimensions.

Heat Treatment – Enhances strength and corrosion resistance.

Threading & Surface Finishing – Threads are cut, and coatings are applied for improved durability.

Quality Testing – Fasteners undergo rigorous testing for mechanical and chemical properties.

Packaging & Dispatch – Proper packaging ensures safe transportation to global destinations.

Why Choose Us as Your High Nickel Fasteners Manufacturer?

As a reputed High Nickel Fasteners Manufacturer, Supplier, and Exporter, we provide:

Premium Quality – Manufactured using high-grade nickel alloys with precise engineering.

Global Reach – Supplying to industries in the USA, UK, Europe, Middle East, and Asia.

Customization Options – Tailored fasteners based on size, grade, and specifications.

Competitive Pricing – Cost-effective solutions with bulk order benefits.

Certifications & Compliance – Products adhere to ASTM, DIN, ISO, and other international standards.

High Nickel Fasteners Available in Different Locations

We supply High Nickel Fasteners to various international locations, including:

USA: New York, Texas, California, Florida, and more.

Canada: Toronto, Vancouver, Montreal, and other cities.

UK: London, Manchester, Birmingham, and more.

Germany: Berlin, Hamburg, Munich, Frankfurt.

Australia: Sydney, Melbourne, Brisbane, Perth.

UAE: Dubai, Abu Dhabi, Sharjah.

India: Mumbai, Delhi, Chennai, Bangalore.

Saudi Arabia: Riyadh, Jeddah, Dammam.

South Africa: Johannesburg, Cape Town, Durban.

Other Locations: Mexico, Oman, Singapore, Kenya, Ireland, Sweden, Europe, Iran

Conclusion

High Nickel Fasteners play a crucial role in industries that require extreme strength, corrosion resistance, and temperature stability. Choosing the right fastener manufacturer ensures reliability and long-term performance. At Ananka Group, we are committed to providing top-quality nickel fasteners that meet global industry standards.

Frequently Asked Questions (FAQs)

Q1: What are high nickel fasteners used for?A1: They are used in aerospace, marine, chemical processing, oil & gas, and power generation industries due to their high strength and corrosion resistance.

Q2: What are the advantages of nickel alloy fasteners?A2: They offer excellent corrosion resistance, high-temperature stability, and superior mechanical properties, making them ideal for harsh environments.

Q3: Do you provide customized high nickel fasteners?A3: Yes, we manufacture custom fasteners based on client specifications, including size, grade, and coatings.

Q4: What certifications do your high nickel fasteners comply with?A4: Our products meet ASTM, DIN, ISO, and other international standards to ensure quality and reliability.

Q5: Do you supply High Nickel Fasteners worldwide? A5: Yes, we supply High Nickel Fasteners to countries including the USA, UK, Canada, Germany, Australia, UAE, and many more.

#Nickel#Nickelfasteners#Articles#Blog#Monel#Monelfasteners#Ananka#Anankafasteners#manufacturer#fasteners#supplier#mumbai#tumblr#blog tumblr

1 note

·

View note