#625 Concentric Reducer

Explore tagged Tumblr posts

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Monel Reducing Flanges Stockists

A Monel reducing flange consists of a flange with one specified diameter having a bore of a different and smaller, diameter. Except for the bore and hub dimensions, the flange will have dimensions of the larger pipe size.

There are several types of reducing flanges including weld-neck reducing flanges, slip-on reducing flanges and threaded reducing flanges. Monel Reducing Flange can be fabricated using a reducing spool with concentric or eccentric reducer & desired flange at each end OR it could be a single flange with internal reduced bore to connect different sized fittings on either sides.

Designed for use in changing diameters in a piping system. A reducing flange consists of a flange with one specified diameter having a bore of a different and smaller, diameter Except for the bore and hub dimensions, the flange will have dimensions of the larger pipe size.

B16.5 ASTM A182 Reducing Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Reducing Flange, ASME B16.5 Dual Monel Reducing Flange, ANSI B16.5 Class 150 Flat Face Reducing Flange, Monel K500/400 30 Inch Reducing Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539) Duplex Steel:Grade: 2205 (1.4507) Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750) Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668) Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT Nickel :Grade: Nickel 200, Nickel 201 Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225) Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

For More information- Visit Our Website – http://www.kobsindia.in/monel-reducing-flange.html Contact Us- 91-9819523999 Email Id - [email protected]

0 notes

Text

Night Shift

Pairing: Young Sub! Joe Elliott x Sassy! Reader

Warnings: 18+ (smut!), light hair pulling, light choking, reader is kinda rude asf towards joe 🤪

Lil Summary: Joe’s your new coworker and things haven’t been going so smoothly, after causing you a considerable amount of stress you finally voice your irritation, which he responds to extremely well.

Requested Tags: @satchie666 @white-lightning-625

Special thanks to @thewritingdoll for forcing me 🔫 to write for the first time in DECADES (bc I never finish anything ☺️)

If you don’t think it’s trash lemme know 💖 I probably won’t add this onto my masterlist until I get my new laptop lol I hate posting on mobile tumblr,, the formatting just makes no sense to me 🥺

——

Working night shift had its perks. The hastle of dealing with the general public was reduced and the atmosphere was a lot more lax. For a while you had a pretty good thing going, being the only employee willing, or needed, to come in at such bleak hours.

Unfortunately, your boss had convinced himself you were in dire need of a workmate in case an incident were to occur, which wouldn’t have been so bad, had the person he hired been anybody else.

Joe was incapable… Really easy on the eyes, but unable to learn even the simplest of tasks. You’d considered having him fired, but couldn’t bring yourself to lodge a complaint. Sure, he’s a little daft, but having him parade into work with a pair of form fitting jeans stretched across his tight figure was almost enough to make up for it, almost.

The undeniable sound of glass shattering detaches you from your salacious thoughts, irritation immediately bubbling throughout your body. Not even an hour into tonight's shift and he’s already managed to turn your mood sour. Dragging your feet across the floor in a huff, you push your way through aisles of snacks and refreshments, stopping to exhale before you enter the room labeled ‘employees only’. The scene you’re met with would have been comical, had similar instances not happened several other times before. With a look of vapid confusion evident on his face, he looks down towards the floor, eyes laid upon the fragments strewn around his feet. The coffee, freshly brewed, had splattered across numerous tiles and up his taut, denim pants.

“Uuhhh, I don’t know how it slipped-”, disorderly grabbing a handful of the nearest napkins, he drops to his knees, further soaking his jeans with the caffeinated beverage while haphazardly mopping up the mess he had created. You’ve made an effort to tightly pinch the bridge of your nose to cease your escalating rage, preventing a full-on outburst. Plastering a forged smile upon your face, you finally gain enough composure to speak, “I’m almost impressed by how clumsy you are”. Looking into your eyes through stray strands of brunette hair, he flashes a vacuous smile, “I’m so sorry, Y/N, I promise I’ll do better… just having a hard time concentrating lately”.

Squinting your eyes in confusion, you’re bewildered by his confession, what exactly did that mean? Pushing all thoughts of perplexity to the side, you chalk it up to nothing, perhaps he was having a difficult time adjusting to night shift. Now feeling somewhat guilty for your attitude towards him, you lower onto your knees to help, carefully picking up rouge pieces of sharp glass.

After a considerable amount of time and effort, the mess is almost entirely taken care of, albeit a few sticky patches here and there. Caught up in cleaning the room around you, you’ve almost forgotten about your uncoordinated coworkers tarnished attire. Wringing out the bottom of his pants, he still manages to hold a delighted smile, as if nothing could ruin his cheerful mood. Maybe he wasn’t as terrible as you were leading him on to be, as you find your cold demeanour now warming up to his rapturous personality.

Simply watching him move was a spectacle of its own. The way he carried himself was .. klutzy, like he was unsure of his next move, allowing his body to haphazardly lead the way. Looking once more in your direction, he flips his hair to prevent it from further blocking his vision, leaving it to cascade down the side of his face. Straightening his frame and leaning against the nearest countertop, he stops to speak, putting on a tone that, if you weren’t mistaken, was slightly apprehensive “hey uh... I know we’ve only known each other for a few weeks, but I’ve been wondering-”, his body seemed to tense with each syllable that crossed his lips, feet unable to stay perfectly grounded. Just as he was about to finish his wavering sentence, his hand slightly slides forward, his large paw knocking a new slew of objects onto the floor.

You watch in vexation as he fumbles once more, like a bull in a china shop, unaware of his lanky stature. As soon as he’d begun to redeem himself, he’d managed to piss you off further. Neither of you had moved, he awaited carefully to gauge your emotions, eyes darting from the broken mug that decorated the floor and your face, now painted with a blank expression. No longer did you possess the patience to babysit a man your own age, every single instance of irritation he’s caused you now bubbling directly to the surface, irritability extremely evident in your voice “Can you do anything right?”.

Scratching the nape of his neck, he goes to shrug, “hey no need to be so-“ stopping him mid-sentence , you interrupt whatever thought he had conjured and thought appropriate to spill from his unoccupied skull, “I’ll speak to you in whatever manner I please, and if you have any ounce of intelligence, you’ll shut up to listen”. Quiet for once, his mouth stays firmly closed for what seems like the first time since you’ve met him. Proud of standing your ground, you begin once more, pushing your limits, “since it’s obvious there’s not a single thought floating through that pretty little head o’ yours, I’ll make this simple, I’m tired of your constant mistakes- it’s not cute, I’m not impressed, and you’re gonna start listening to my instructions or I’ll have you fired”, nibbling on his bottom lip and focusing on every word you speak, he eagerly shakes his head in agreeance, too scared to respond with any other notion.

“Now, I can tell you’ve never had to put on your big boy pants and put any effort into a single task, so this is gonna be rough, but I’m sure if you try really, really hard, you’ll be able to function somewhat decently, ya?”, conjuring up a smile that was sarcastically sweet, you finish, clasping your hands together to signify you’ve made your point. It wasn’t until the red hot rage within you had started to disperse with the end of your speech that you began to notice one unreasonably large elephant in the room; the crotch of his jeans now tighter than usual, a large protrusion begging to spring free from its confines.

Your first reaction was to scoff, you couldn’t believe he’d gotten off on your tangent, excited by your frustration and cruel words. Thoroughly eyeing up his bulge, you slowly trace your sight up to his reddening cheeks, “that’s the type of stuff you’re into?”.

Finally speaking up, his voice seems shakier than ever, shy and wavering, “well uh- fuck, it’s not my fault you look so damn good when you’re mad”, hyper-aware of the confession he begins to jumble his words, “well, I mean you always look good but- oh god I’m sorry I know I shouldn’t speak to you like this-“

Stepping forward and lifting your hand to the bottom half of his face, you cover the entirety of his mouth, “shut up”, using your other hand to trace lines on his stomach, he retracts, surprised by your touch. With a devious look on your face, you provide him with a proposition, “Do you want me to touch you?”. Since you’ve removed his ability to consent verbally, you await a nonverbal cue, one he provides before you’re able to finish your sentence, an undeniable yes given to you via enthusiastic nod.

Laughing at his eagerness to continue, you taunt him, sliding your northernmost hand into his dense locks and pulling on the strands. The hand once dancing on his abdomen now applying pressure on his clothed member. A string of whimpers already begin to fall from his plump lips, he reacts as if he’s barely been touched before. “You’re so..sensitive, does nobody touch you besides yourself?”, looking into your eyes with heavy lids, he begins to grind into your hand, keen for more friction “nobodies ever touched me quite like this”.

Shaking your head, you pull at his hair once more, lavishing in the power you have over him in this moment. “Really? surprised you haven’t been put in your place sooner, guess somebody had to do it”, outlining his rock solid cock with your hand, you begin a rhythm of running your fingers along his covered shaft, moving up and down his length again and again. A few small droplets of sweat begin to form on his skin, the pleasure he was so eager to receive now turning bitter sweet. Huffing out a sigh and continuing to rock his hips with the motion of your wrist, he pleads “can you please touch it, like- really touch it”.

Increasing the pace you’ve set on the outside of his jeans, you get extremely close to his face, so close that he goes in for a kiss, but you make sure to reject it. “I really don’t think you deserve that”.

Grasping the countertop to his side, he clamps down in frustration, looking to prevent himself from going off the deep end, allowing you to break him so easily. “I promise I’ll do anything you want, really I do”, finally releasing your grip on his hair, you move your hand onto his neck, lightly applying pressure and running your thumb along his jugular. “Baby boy, I’m certain you’d do anything I want no matter what”.

The new pet name seems to excite him further, as he’s now reduced himself to a mewling, needy little toy, giving into your cruel pleasure, twitching and jerking with your every touch. Eyes rolling into the back of his head, he sharply inhales, as if he was taken by surprise, “fuck, please don’t y/n”.

Applying much more pressure on his neck, you giggle, breaking him was so easy, and something you’re certain you’ll continue on future occasions. “Let it go, baby”, his orgasm was coming on fast and strong, you could tell from the way he squirmed beneath your unrelenting touch.

With one final thrust against your hand he trembles, a sweet sob leaving his mouth, making you aware that he’d actually came from nothing more than clothed petting. A small wet patch had formed on his crotch, physical evidence that he’d climaxed in his pants.

Standing up straight and composing yourself, you run your hands down your body to rid your attire of any wrinkles or imperfections. You’d been away from the front of the store for so long, you’re certain somebody must’ve been awaiting service and you didn’t want to look disheveled in front of a customer. Turning on your heels, you glance back at him before exiting to attend to your duties, “change the pants, clean up the mess you’ve made and meet me out front when you’re ready to learn”.

#joe elliott#HOE ELLIOTT#def leppard#joe elliott x reader#joe elliott smut#def leppard smut#smut#omg this picture.. of joe#so nervous i accidentally referred to him as joel in this and never noticed#sorry yall this is.. trash

79 notes

·

View notes

Link

ASTM B366 Alloy 625 Concentric Reducer 21.3x2.6/14x2.5

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Detailed description

Quick Details

Material: Alloy 625 (UNS N06625)

Technics: Cold Formed

Type: Alloy 625 Concentric Reducer

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Packaging & Delivery

Packaging Detail: Plywood case or fumigation woodern case

Delivery Detail: Usually 2-10 days depend on the quantity

Specifications

ASTM B366 Alloy 625 Concentric Reducer

1. Size: 21.3x14 2. Wall thickness: 2.6x2.5

3. Material: Inconel 625 (UNS N06625)

China Concentric Reducer Manufacturer Yaang supplies ASTM B366 Alloy 625 Concentric Reducer, 21.3x2.6/14x2.5.

Composition ranges for Inconel 625 (UNS N06625)

Size:6 Inch - 3 Inch (DN150 - DN80)

Material:

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Standard: ASME/DIN/ISO/, etc

Connection: Welding

Wall thickness:SCH40S

Finish: Mirror polish, semi bright etc

Concentric Reducer

ASTM B366 Alloy 625 Concentric Reducer Concentric Reducer is used to join pipes or tubes sections on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. A Alloy 625 Concentric Reducer can be a single diameter change or a multiple diameter change. The pipes cannot recognize what the outside configuration of the pipe reducer looks like. The pipe flow is affected by the inside diameter conical transition configuration which can be axially moved and externally reconfigured to provide for more economical reducer fittings. Thus, Alloy 625 Concentric Reducer connects pipes of unequal size but have a common centerline. In other words, it is a type of pipe fitting with different size ends to join pipes of different diameter that joins pipe sections on the same axis.

Alloy 625 Concentric Reducer is designed with the small and large diameters on opposite ends and joined by a cone shaped transition section. They are available in both seamless and welded construction.

Use of Alloy 625 Concentric Reducer is as follows:

Alloy 625 Concentric Reducer will transition gracefully between the piping and the pump.

The Alloy 625 Concentric Reducer helps in transporting slurries or abrasive liquids.

They are useful in services where cavitation is present.

When transporting between flanges or pipes of different ratings and wear protection is necessary, concentric reducers are ideal.

Alloy 625 Concentric reducers are used in discharge of the pump.

Application range: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

ASME/ANSI B16.9 321 316L 90 Degree Butt-Welded Stainless Steel Elbows

Stainless Steel Butt Welding Tee Pipe Fittings, Seamless and Welded with 100% X-ray

304L 180D 45D 90D Elbow

MSS SP-97 316L Weldolet 4 Inch X 2.5 Inch Class 3000 Sch160

0 notes

Text

What exactly does 316L in stainless steel used for?

Iron ore is first melted to produce steel, then impurities like phosphorus, silica, and sulphur are eliminated. The concentration of carbon in SS round bar made by SS 316L Round Bar suppliers in Indiain the ore is higher than the levels that give steel its special characteristics. As a result, steel producers reprocess the molten metal to lower the carbon content to the necessary level. At this stage, additional components may be added to the iron ore complex that has been smelted to produce the various types of steel. Every form of steel has unique industrial applications ranging from building to strengthening structures. Producers have developed a nomenclature system to keep track of the key characteristics of steel. The demand for Copper Round Bar suppliers in India has also increased. Know about round bars The term "round bar" refers to a long, cylindrical metal bar that Titanium Round Bar suppliers in India produce. There are two steel round bars: hot rolled and cold rolled. In applications like construction where flawless polish and exact dimensions are not essential, a hot rolled round bar is frequently employed. On the other hand, a cold-rolled round bar is utilized in applications that need a superior surface finish and precise measurements. For what purposes are titanium rods used? A titanium rod produced by Titanium Round Bar suppliers in Indiacan be created from pure titanium or from alloys that combine titanium with additional metals like vanadium or aluminum. The metal becomes significantly more vital when alloyed. Doctors and dentists also use surgical devices constructed of titanium rods. Titanium, a material renowned for its tremendous strength and low density, is frequently used in aeronautical equipment, including the construction and skin of airplanes. In this business, titanium rods make durable, dependable equipment that can endure high temperatures and speeds. Application of inconel 625The development of municipal waste-to-energy systems and refuse-derived fuel plants will likely play a significant role in the future development of the global economy as we all work to reduce the environmental impact of producing energy and disposing of waste. This is because INCONEL 625 alloy made by Inconel 625 Round Bar suppliersis likely to do so. In situations with high concentrations of halides, INCONEL 625 pipe with a minimum nickel content of 58% is a good choice because nickel-based alloys are extraordinarily resistant to halogen attack. For this precise reason, alloy 625 has traditionally been the most popular alloy used in trash boilers. The INCONEL 625 alloy is generally believed to outperform steel tubing in these kinds of settings with a minimum factor of 10, with its corrosion rate being less than 0.25mm/y. Know about Monel 400 bars Monel 400 apply produced by Monel 400 Round Bar suppliers is a cold-worked metal that has excellent strength, stiffness, and hardness. The Monel 400 Hex Bar is also resistant to acidic solutions containing salt. Is C276 the same as Hastelloy C? Hastelloy C-276, produced by Hastelloy C276 Round Bar suppliers, is a nickel-molybdenum-chromium wrought alloy that is also marketed under Nickel Alloy C-276. The use of Hastelloy C-276 is ideal when protecting against localized and aggressive corrosion attack is required.

0 notes

Text

Juniper Publishers-Open Access Journal of Environmental Sciences & Natural Resources

Evaluation of Nutrient Stress (Nitrogen, Phosphorus Regimes) on Physio-Biochemical Parameters of Oleaginous Micro algal Strains and SEM Study under Nutrient Stress

Authored by Kulvinder Bajwa

Abstract

The objective of this study was to investigate the accumulation of lipid, biomass, photosynthetic pigment, protein and carbohydrates from various micro algal strains. Algal cultures were grown in BG-11 medium inoculated into nitrogen (N) and phosphorus (P) en rich and stress medium. Three different treatments were set up: N+P+ (control group); (N-P+); (N+P-) respectively for algal growth evaluation in the form of lipid accumulation, biomass yield, protein, carbohydrate and total chlorophyll contents. When the cells were grown in BG-medium under nutrient stress (N,P) for 12 days, in (N+P+) nutrient regime, significant (P≤0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021gL- 1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively. Interestingly, nitrogen deficiency condition promoted (P≤0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. On the other hand, (nitrogen+ phosphorus) condition promoted higher chlorophyll, carbohydrates and protein content in almost all algal species.SEM study also conducted under normal and stress condition for these micro algal strains (Chlorella, Scenedesmus, Nannochloropsis and Chlorococcum). Results showed, cells wall of algal species smooth under normal condition, while under stress condition distorted cell morphology. Thus, this native micro alga strain could be a potent candidate for feed, food or bio fuel production.

Keywords: Microalgae; Nutrient Stress; Biomass; Lipid; Sem; Oleaginous Algae; Nitrogen; Phosphorus Deficiency; Biomass; Lipid; Scanning Electron Microscopy

Introduction

As global population and consequently energy demand increase over time the introduction and commercialization of renewable sources of energy becomes a critical issue. Microalgal biomass as feedstock for bio-energy production is an attractive alternative to bio-energy derived from terrestrial plant utilization [1,2]. Micro algal biotechnology has gained increasing attention over the last few decades as a next- generation driver for obtaining food, feed and bio fuels and to carry out bioremediation of effluents and CO2 mitigation [3]. Oleaginous microalgae are well known as promising candidates for renewable energy production mainly because of high biomass productivity and lipid content Chisti [4,5]. Microalgae, cultivated under specific stress conditions, can accumulate, along with the lipids and carbohydrates, considerable amount of secondary metabolites, whose industrial exploitation strongly enhances a bio-based economy [6].

Nitrogen and phosphorus, as the two main nutrients, are hypothesized to influence the attachment efficiency and growth of microalgae [7,8]. Similarly, phosphorus is an essential nutrient for the growth of microalgae as it plays a significant role in cellular metabolic processes related to energy transfer, signal transduction, photosynthesis and respiration. Studies have shown that the phosphorous deprived conditions responsible for significant lipid accumulation in Chlorella spp. Chaetoceros spp. Phaeodactylum tricornutum, Isochrysis galbana and Pavlovalutheri [9-13]. In addition to these factors, nitrogen deficiency severely affects protein synthesis and reduces photosynthetic rates which result in metabolic flux towards lipid biosynthesis [14,15]. High lipid accumulation was reported under nitrogen deprived conditions in microalgal species viz., Neochloris oleoabundans, Nannochloris sp., Chlorella muelleri and Scenedesmus sp. [16-19]. According to Li, et al. [20] phosphorus strongly influenced Chlorella vulgaris growth but has little influence on lipid accumulation. Anand, et al. [21] revealed that the 2.27-fold increase in lipid yield (226 mg/L) was observed in nitrogen-depleted condition when compared to nitrogen rich condition (99.33 mgl-1). The present study aimed at to evaluate the nutrient stress of Nitrogen and phosphorus, simultaneously scanning electron microscopy study of various micro algal species viz. Chlorella, Nannochloropsis, Chlorococcum, Scenedesmus sp. Under nutrient stress.

Materials and Methods

Collection of Water Samples Having Algal Growth

The water samples having algal growth were collected in pre cleaned sterilized plastic containers from different fresh water bodies located in Haryana, Punjab, Rajasthan and Uttarakhand. Marine water samples were collected from Mumbai, Maharashtra.

Isolation and Molecular Characterization

The freshwater micro algal species was isolated from the freshwater pond at Shahidawaali village, Dist. Sirsa (Haryana) India. Genomic DNA from micro algal sample was extracted by using cetyl tri methyl ammonium bromide (CTAB) method Scott & Bendich [22]. Polymerase chain reaction (PCR) was analyzed to amplify 18S rRNA gene of microalgae using forward (5”GGGAC C C GTTAC C GTAGGTGAAC CTGC-3”) and reverse primers (5”-GGGATCCATATGCTTACGTTCCGCGGAT-3”). The purified PCR products were sequenced by Amnion Biosciences Pvt. Ltd. (Bangalore, India). Comparisons of nucleotide sequences and statistical significance of matches were carried out with the National Centre for Biotechnology Information (NCBI) nucleotide BLAST program.

Analytical Methods for Physio-Biochemical Parameters

Bligh and Dyer Lipid Extraction Method: The extraction total lipid were carried out by mixing methanol-chloroform (2:1.5 v/v) with the algal samples using slightly modified version of Bligh and Dyer's method Bligh & Dyer [23]. According to Suganya and Renganatha [24] (the oil extraction yield (%w/w) was determined by the following formula:

Dry Biomass estimation: Dry cell biomass was measured as the cell density (dcw) at OD625 of an 11 day old culture at dilutions ranging from 0.2 to 1.0. The dry biomass was calculated using the regression equation as the linear relationship [25].

y = 0.137x + 0.1766, R2 = 0.9859

Extraction and Determination of Photosynthetic Pigment: Chlorophyll content of the algae was estimated spectrophotometrically at 650 and 665 nm. The concentration of chlorophyll was calculated using the formula:

Total chlorophyll (mgmU1) = 2.55 x 10-2E650 + 0.4 x 10-2E665 x 103

Extraction and Determination of Total Soluble Carbohydrate by Anthrone Reagent: Glucose was determined at 625 nm using Anthrone reagent method by Dubois et al. [26]. The sugar content was calibrated against standard curve prepared by using graded conc. of glucose dilution ranging from 0.2 to 1 and expressed in terms of mg ml-1

y = 0.636x + 0.0592, R2 = 0.9595

where y, concentration of glucose, x optical density.

Total Protein Estimation by Lowry Method: The protein content was estimated using Lowry's method. Protein concentration was calculated from the standard curve prepared with bovine serum albumin (BSA) [27].

y = 0.1097x - 0.0005, R2 = 0.9989

Effect of nitrogen and phosphorus stress on physio- biochemical parameters of screened algal strains

To evaluate the ability of screened algal strains to accumulate lipid under phototrophic conditions, screened algal cultures were grown in BG-11 medium inoculated into nitrogen (N) and phosphorus (P) enrich and stress medium. Three different treatments were set up: N+P+ (control group); (N-P+); (N+P- ) respectively for algal growth evaluation in the form of lipid accumulation, biomass yield, protein, carbohydrate and total chlorophyll contents. All the experiments were conducted in triplicate over a cultivation period of 12 days.

Scanning Electron Microscopy (SEM)

In the present study, morphological features and other cellular details of screened algal under nutrient stress (nitrate and phosphate deficient condition) were studied with the help of Scanning Electron Microscope (Carl Zeiss, Model no. SMT EVO 50SEM) as method described by Fowke et al. [28]. Bacterial and algal broths were centrifuged and washed the pellets with phosphate buffer saline for three times and collected the pellet by centrifugation. The fundamental steps for SEM sample preparation are fixing of samples in 0.25% buffered glutaraldehyde (in Sodium phosphate having pH 7.2) and incubated at room temperature for 30 minutes, then freeze dried for 24 hrs, after that fixing is done using tetra oxide of osmium, samples dehydration by different ethanol grading starting; 30%, 50%, 70%, 80%, 90% and 100% and for each ethanol volume incubate for 10 minutes then incubation in 100% ethanol for 1 hour, drying with air dryer, placed in desiccators until constant weight attain, mounting it on stubs using double sided sticky tape coated with carbon. Preparation of SEM stub by applying the adhesive tape and then adding the dried bacterial and algal samples on the tap. The exposed surface was coated with gold with the help of sputter coater device and then the inner surface was scanned at 20 kV potential and various magnifications.

Result and Discussion

Morphological and Molecular Identification of Micro Algal Isolates

Purified algal species were preliminary identified with the help of algal identification guide on the basis of morphological features by using Olympus (CX41) light microscope equipped with digital camera. Microscopic images of these algal strains under (100 x) magnification are depicted in (Figure 1) 18S rRNA sequences of screened algal strains were aligned with global sequence available in Gen bank (NCBI) using the standard nucleotide -nucleotide basic local alignment search tool (BLAST) programme. Sequences alignment outcomes revealed that screened algal strains were exhibiting 100% homology with Chlorococcum aquaticum (Accession No. KT961379), Scenedesmus obliquus (Accession No. KT983434), Nannochloropsis oculata (Accession No. KU160538), Chlorella pyrenoidosa (Accession No. KU236002).

Effects of Nutrient Stress (Nitrogen, Phosphorus Regimes) on Physio-Biochemical Parameters of Algal Strains

To evaluate the ability of screened algal strains to accumulate lipids under nutrient stress conditions, algal cultures were grown in full BG-11 medium were inoculated into nitrogen (N) and phosphorus (P) enrich medium, respectively, with significant (P≤0.05) higher biomass, protein, carbohydrate and total chlorophyll as given in (Figures 2A-2E). Three different treatments were set up: N+P+ (control group); N-P+ (nitrogen deficiency); N+P- (phosphate deficiency). Anova table suggested that significant (P≤0.05) higher lipid content was observed in nitrogen deficiency condition in four algal strains as shown in (Figure 2A). In (N+P+) nutrient regime, significant (P≤0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021 gL-1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively as compared to Scenedesmus obliquus, Chlorococcum aquaticum (Figure 2 B).

The lipid percentage also slightly increases in (N+P+) condition in comparison to other nutrient stress condition in four algal strains. Interestingly, nitrogen deficiency condition promoted (P≤0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa, and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. Similar to biomass yield, (N+P+) regimes condition also responsible for significant (P≤0.05) higher protein content in Nannochloropsis oculata (0.062±0.005 mgmL-1) and Chlorella pyrenoidosa (0.068±0.003 mgmL-1) respectively (Figure 2D) illustrated that Scenedesmus obliquus, Chlorella pyrenoidosa showed significant (P≤0.05) higher carbohydrate content in (N+P+) condition as compared to nitrogen and phosphorus deficient media. In case of total chlorophyll content, nitrogen + phosphorus condition promoted higher chlorophyll content in Chlorococcum aqauticum (13.02±0.037 ngmL-1) Chlorella pyrenoidosa (13.68±0.029 ngmL' 1) as compared to Nannochloropsis oculata, Scenedesmus obliquus as shown in (Figure 2E).

Anand, et al. [21] revealed that the 2.27-fold increase in lipid yield (226 mg/L) was observed in nitrogen-depleted condition when compared to nitrogen rich condition (99.33mgL-1). In this study, it was validated that four algal strains were able to accumulate large quantity of lipid and reached the highest lipid content (25.75%) in Nannochloropsis oculata under N deficiency, which was in agreement with previous report that N-deficiency was an efficient prompted to induce lipid accumulation (particularly triacylglycerols) in many microalgae [29]. It is known that the different nitrogen sources and levels were effective on the growth of microalgae and biochemical composition [30-34]. Our study also showed that P-deficiency was a suitable condition for lipid accumulation in screened experimental cultures as well. This observation is similar to prior reports [35] who proposed that lipid storage in Monodus subterraneus can be increased by P deficiency. Similarly Feng, et al. [36] found that the lipid contents of Chlorella zofingiensis grown in media deficient of nitrogen (65.1%) or phosphate (44.7%) were both higher than that obtained from cells grown in full medium (33.5%).

Usually, the nitrogen deficiency would result in more metabolic flux and to lipid accumulation in algae cells as the synthetic rate of essential cell structures including proteins and nucleic acids lowered Li et al. [37] Kirrolia et al. [38]. According to Li et al., phosphorus strongly influenced Chlorella vulgaris growth but has little influence on lipid accumulation as we found in our study. Higher protein content reported in our study with (N+P+) condition, similar finding has been revealed by Mutlu et al. [39] and found significantly higher protein content in Chlorella vulgaris in nitrogen and phosphorus rich condition. Dortch et al. [40] also observed that the proteins associated with the chlorophyll-protein complex decreased in nitrogen starved cultures. Smit et al. [41] reported a positive relationship between protein and chlorophyll a. Chlorophyll a is one of the most important nitrogen pools in algae: the pigment may reduce nitrogen limitation. Similar to our study, observed that chl a content of Chlorella vulgaris decreased and also, a yellowish colour was recorded under N-starvation condition.

Scanning Electron Microscopy

Scanning electron micrographs of four algal species of Chlorellapyrenoidosa, Chlorococcum aquaticum, Nannochloropsis oculata and Scenedesmus obliquus under normal as well as stress conditions were taken at potential of 20 kV and under various magnifications. Scanning electron micrographs of Chlorella pyrenoidosa having cell size 2μm revealed that cells of Chlorella pyrenoidosa in normal stage was smooth and compacted as well as covered with irregular network of subtle ribs (Figure 3 A,B) whereas in nutrient stress conditions cells become dispersed with rough cell wall (Figures 3C & 3D). Under nutrient stress no longer smooth surface of algal cells walls and outer region was irregular and cell wall roughly folded. Similar to our present work Kirrolia also found striking changes in cell morphology in Chlorella sp. under nutrient stress condition. Similar to our findings, [42] observed smooth cell wall in scanning electron micrographs of Chlorella sp. in normal condition but cell wall of Chlorella species no longer remained smooth after absorption of metal ions Cu+2 and Ni+2 . Similarly Scanning electron micrographs of Scenedesmus obliquus under normal and stress condition showed characteristics colonies of cells, usually round in shape with prominent nucleus. Under normal conditions, Scenedesmus obliquus cells are compactly arranged in two or four cells and are non-fragmented wheareas, under stress conditions there is fragmentation and separation of Scenedesmus cells (Figure 4 A-D). Kirrolia [43] also observed distorted morphology under stress condition in Scenedesmus quadricauda. Chlorococcum aquaticum is green microalgae having cell size 2 μm round elongated shape with smooth lines over cells walls in normal condition, whereas in stress conditions cell walls distorted with no smooth coverage of fine lines on cell wall (Figures 5A-5D).

Nannochloropsis oculata showed intact structure with no cell lyses. Whereas in stress condition in normal condition, disrupted morphology of micro algal structure and appeared completely broken cells under Scanning Electron Microscope (Figures 6A- 6D). Similar results have been found in Nannochloropsis oculata in normal condition. In addition, acid treatment 1M HCl totally disrupted the morphology of micro algal structure appearing completely broken cells under Scanning Electron Microscope Surendhiran and Vijay [44-46].

Conclusion

Nutrient stress variables for enhancement of micro algal performance towards sustainable biodiesel synthesis could be effectively optimized in (N+P+) nutrient regime; significant (P≤0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021gL-1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively. Interestingly, nitrogen deficiency condition promoted (P≤0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. On the other hand, (nitrogen+phosphorus) condition promoted higher chlorophyll, carbohydrates and protein content in almost all algal species. It is meaningful to examine the cellular morphology to further understand the cell disruption under nutrient stress. Scanning electron micrographs (SEM) was found to be efficient tool for characterization of change in cell morphology under normal and stress condition in selected indigenous algal strains. The cellular morphology of micro algal strains was investigated by scanning electron microscope (SEM) which certified that the cells damage was caused by both nitrogen and phosphorus stress.Nutrient stress variables for enhancement of micro algal performance towards sustainable biodiesel synthesis could be effectively optimized in (N+P+) nutrient regime; significant (P≤0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021gL-1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively. Interestingly, nitrogen deficiency condition promoted (P<0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. On the other hand, (nitrogen+phosphorus) condition promoted higher chlorophyll, carbohydrates and protein content in almost all algal species. It is meaningful to examine the cellular morphology to further understand the cell disruption under nutrient stress. Scanning electron micrographs (SEM) was found to be efficient tool for characterization of change in cell morphology under normal and stress condition in selected indigenous algal strains. The cellular morphology of micro algal strains was investigated by scanning electron microscope (SEM) which certified that the cells damage was caused by both nitrogen and phosphorus stress.Nutrient stress variables for enhancement of micro algal performance towards sustainable biodiesel synthesis could be effectively optimized in (N+P+) nutrient regime; significant (P<0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021gL-1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively. Interestingly, nitrogen deficiency condition promoted (P<0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. On the other hand, (nitrogen+phosphorus) condition promoted higher chlorophyll, carbohydrates and protein content in almost all algal species. It is meaningful to examine the cellular morphology to further understand the cell disruption under nutrient stress. Scanning electron micrographs (SEM) was found to be efficient tool for characterization of change in cell morphology under normal and stress condition in selected indigenous algal strains. The cellular morphology of micro algal strains was investigated by scanning electron microscope (SEM) which certified that the cells damage was caused by both nitrogen and phosphorus stress.Nutrient stress variables for enhancement of micro algal performance towards sustainable biodiesel synthesis could be effectively optimized in (N+P+) nutrient regime; significant (P≤0.05) higher biomass yield 1.129±0.036 gL-1 and 1.115±0.021gL-1 have been reported in Nannochloropsis oculata, Chlorella pyrenoidosa respectively. Interestingly, nitrogen deficiency condition promoted (P≤0.05) significant higher lipid accumulation 25.75%, 23.78% and 20.26% in Nannochloropsis oculata, Chlorella pyrenoidosa and Scenedesmus obliquus respectively as comparison was made with other nutrient stress. On the other hand, (nitrogen+phosphorus) condition promoted higher chlorophyll, carbohydrates and protein content in almost all algal species. It is meaningful to examine the cellular morphology to further understand the cell disruption under nutrient stress. Scanning electron micrographs (SEM) was found to be efficient tool for characterization of change in cell morphology under normal and stress condition in selected indigenous algal strains. The cellular morphology of micro algal strains was investigated by scanning electron microscope (SEM) which certified that the cells damage was caused by both nitrogen and phosphorus stress.

To know more about Juniper Publishers please click on: https://juniperpublishers.com/manuscript-guidelines.php

For more articles in Open Access Journal of Environmental Sciences & Natural Resources please click on: https://juniperpublishers.com/ijesnr/index.php

#Juniper Publishers Review#Juniper Publishers PubMed Indexed Journals#Ecological psychology#Environmental Chemistry#Geo Morphology#Geodesy

0 notes

Text

Features of Inconel pipe

Inconel 600 is a nickel-chromium alloy with excellent resistance to oxidation at high temperatures and excellent resistance to carburizing and chloride-containing environments.

Inconel 600 Bolts is a nickel-chromium alloy designed for use from very low temperatures to high temperatures in the 2000 ° F (1093 ° C) range. The high nickel content of the alloy allows it to maintain considerable strength under reducing conditions and is resistant to corrosion by many organic and inorganic compounds.

With a strong oxidizing solution such as hot concentrated nitric acid, the resistance of Inconel 600 is low. Alloy 600 is not attacked by most neutral and alkaline salt solutions and is used in some caustic environments. This alloy is resistant to vapours and mixtures of vapours, air, and carbon dioxide.

Alloy 600 is non-magnetic, has a combination of excellent mechanical properties and high strength, and excellent workability, making it easy to weld. Inconel 625 Tube exhibits cold-forming properties typically associated with chrome-nickel stainless steel.

Typical applications for corrosion include titanium dioxide formation (chloride pathway), perchloroethylene synthesis, vinyl chloride monomer (VCM), and magnesium chloride. Alloy 600 is used in food and chemical treatments, heat treatments, phenolic capacitors, soap making, plant and fatty acid containers, and more.

Feature

Resistant to a wide range of corrosive media: Chromium content provides better resistance than alloys 200 and 201 under oxidizing conditions, and high nickel content provides better resistance under reducing conditions. It is substantially resistant to chlorine ion stress corrosion cracking. It is sufficiently resistant to organic acids such as acetic acid, formic acid, and stearin.

Excellent resistance to the high-purity water used in primary and secondary circuits of pressurized nuclear reactors: Dry gases such as chlorine and hydrogen chloride cause little or no attack at ambient and high temperatures. At temperatures up to 550 ° C in these media, this alloy has proven to be one of the most powerful of the common alloys. At high temperatures, annealed and solution annealed alloys show excellent resistance to scale formation and high strength.

Inconel 718 Bolts is also resistant to atmospheres containing ammonia, nitrogen, and fuel gases. Under alternating oxidation and reduction conditions, alloys are subject to selective oxidation.

Application

Generation of caustic alkali, especially in the presence of sulfur compounds. Reactor vessels and heat exchange tubes are used in the production of vinyl chloride. Process equipment used to produce chlorinated and fluorinated hydrocarbons. In nuclear reactors, it is used for parts such as short control rod inlet tubes, reactor vessel parts and seals, steam dryers, and boiling water reactor separators. In pressurized water reactors, it is used for steam generator control rod guide tubes and baffle plates. Furnace retort seals, fans, and accessories. Roller floors and radiation tubes, especially in carbon nitride processes.

Manufacture of INCONEL Alloy 600

Inconel 600 Pipe is non-magnetic, has a combination of excellent mechanical properties and high strength and excellent workability, and is easy to weld. Alloy 600 exhibits cold-forming properties typically associated with chromium-nickel stainless steel.

Six hundred sheets and plates are supplied almost exclusively annealed. Before performing a pitching operation, it may be necessary to reduce the stress on the bar or annealed material.

0 notes

Link

ASTM B366 Inconel 625 Concentric Reducer 6 Inch - 3 Inch SCH40

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material: Inconel 625 (UNS N06625)

Technics: Cold Formed

Type: Inconel 625 Concentric Reducer

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Packaging & Delivery

Packaging Detail:Plywood case or fumigation woodern case

Delivery Detail:Usually 2-10 days depend on the quantity

Specifications

ASTM B366 Alloy 625 Concentric Reducer

1. Size: 6 Inch - 3 Inch (DN150 - DN80) 2. Wall thickness: SCH40

3. Material: Inconel 625 (UNS N06625)

China Concentric Reducer Manufacturer Yaang supplies ASTM B366 Inconel 625 Concentric Reducer, 6 Inch - 3 Inch, SCH40.

Composition ranges for Inconel 625 (UNS N06625)

Size:6 Inch - 3 Inch (DN150 - DN80)

Material:

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Super Duplex Stainless Steel: S32750/2507, UNS32760, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Standard: ASME/DIN/ISO/, etc

Connection: Welding

Wall thickness:SCH40S

Finish: Mirror polish, semi bright etc

NPSO.D.

DO.D.

D1Len

H

6*3168.388.9140

Concentric Reducer

ASTM B366 Alloy 625 Concentric Reducer Concentric Reducer is used to join pipes or tubes sections on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. A Alloy 625 Concentric Reducer can be a single diameter change or a multiple diameter change. The pipes cannot recognize what the outside configuration of the pipe reducer looks like. The pipe flow is affected by the inside diameter conical transition configuration which can be axially moved and externally reconfigured to provide for more economical reducer fittings. Thus, Alloy 625 Concentric Reducer connects pipes of unequal size but have a common centerline. In other words, it is a type of pipe fitting with different size ends to join pipes of different diameter that joins pipe sections on the same axis.

Alloy 625 Concentric Reducer is designed with the small and large diameters on opposite ends and joined by a cone shaped transition section. They are available in both seamless and welded construction.

Use of Alloy 625 Concentric Reducer is as follows:

Alloy 625 Concentric Reducer will transition gracefully between the piping and the pump.

The Alloy 625 Concentric Reducer helps in transporting slurries or abrasive liquids.

They are useful in services where cavitation is present.

When transporting between flanges or pipes of different ratings and wear protection is necessary, concentric reducers are ideal.

Alloy 625 Concentric reducers are used in discharge of the pump.

Application range: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

Stainless Steel Elbow 90 Degree DN15 - DN2500

long neck lap joint stub end

F304 Eccentric Swaged Nipple PBE 2 Inch X 1 Inch 40S/80S

CHINA Stainless Steel 90 degree Elbow

ANSI B16.9 A815 UNS S32750 2507 Seamless Equal Tee 2 Inch Sch80

90 Degree Stainless Steel Threaded Elbow

Lap Joint Stub Ends

ANSI B16.9 WP321 Stainless Steel Equal Tees

0 notes

Text

Things you need to know about Corrosive Service Ball Valves today.

Corrosion is a moderate material loss due to chemical or physical reaction with the process fluid; based on the concentration, temperature and pressure fall, exposed liquid surfaces can cause severe harm to the valve order unless the right sort of valve and equipment are chosen.

Aggressive impurities or solid particles may be present in the process fluid typically recognised as corrosive & dirty applications.

Sulfuric acid (H2SO4), chlorides, moist acid gas and dry sour gas are all corrosive process ingredients.

Corrosion-resistant alloy (CRA) products, overlays on exposed stress bearing and maintaining parts should be regarded to avoid valve continuity and minimize the likelihood of failure and leakage. Source materials should also observe with NACE MR0175 (ISO 15156) or NACE MR0103 when indicated for pipeline.

High Alloys, Nickel Alloys, Duplex and Superduplex can be provide according to corrosion resistance requirements as per special material standards.

Besides Electroless Nickel Plating (ENP) and Alloy 625 weld overlay are always used to grow corrosion resistance of balls, seats, stems, seat pockets and stem sealing areas, in corrosive service.

Exceptional designs for grinding mediums, slurry, scaling, fouling and solidifying facilities are included in the our Corrosive service ball valves range.

Ball valves are chiefly used for controlling the flow of liquids in industrial and commercial piping systems. The tight close down feature of Corrosive Service Ball Valves makes them particularly suited for flow control applications in high pressure and high temperature conditions. They are chiefly used in fuel reforming, refining, power, marine, petrochemical, and process industries. Design engineers design valves for challenging applications should match the performance of the valve's component elements with the needed flow, temperature, and pressure conditions. The cavity diameter of a Corrosive Service Ball Valves is called its port size.

Full Port Design

The port size of a full port ball valve is approximately the same as the pipeline's inner diameter. These designs are worthy for applications that warrant minimum resistance to flow of fluids.

Regular Port Design

Correlated to full port designs, the hole diameter of regular port ball valves is small and shows increased resistance to fluid flow..

Reduced Port Design

The hole diameter of a lower port ball valve is just about equal to 60% of the valve's inner diameter. This ball valve design is suitable for small, end-loaded valves that need small-diameter balls.

0 notes

Text

How Wetlands Can Protect Coastal Communities

[By Gan Xiaojing and Shi Jianbin]

In 2005, Hurricane Katrina struck the Mississippi delta in the state of Louisiana. The severe flooding that followed led to the death of 1,800 people. Over a million were displaced and the direct economic losses reached more than $100 billion. One of the worst natural disasters in US history was made much worse by long-term destruction of the delta wetlands, which would otherwise have absorbed much of the seawater that surged into the city of New Orleans.

In response to the disaster, Congress authorized a $14 billion reconstruction of the New Orleans flood defenses, including a levee system strong enough to withstand once-in-a-century floods.

But in May 2018, just 11 months after those levees were completed, the US Army Corps of Engineers warned that rising sea levels and subsidence in the soft ground meant they may only last for another four years. It later called for an additional $3.2 billion to reinforce the levees.

While acknowledging the importance of this work, some local environmental groups have argued that the levees will remain at risk regardless of their height. They cannot be the sole solution, they say.

Research is increasingly showing the promise of another approach: restoring wetlands to make coastal areas more robust and resilient to flooding. As we will see, China in particular could benefit greatly from this approach.

Natural coastal defenses

As early as the 1970s, people were aware that Louisiana was losing over 100 square kilometers of its coastal wetlands every year. Restoration schemes only started in the late 1990s, however, with the state government launching the Coast 2050 plan. This recommended spending $14 billion on the regeneration of coastal wetland ecosystems over the following 30 years. But due to a lack of funding and a succession of replacement schemes, Louisiana’s wetlands continued to decline. Meanwhile, federal funds for coastal protection were used to strengthen and maintain engineered flood defenses such as levees, sea walls, breakwaters and riprap.

Can natural coastal defenses compete with engineered solutions in the face of a threat like Hurricane Katrina? In 2011, a team lead by Rachel K Gittman of the University of North Carolina tried to answer that question by studying the damage done by another devastating hurricane, Irene. The worst-affected area was the Outer Banks, a long thin strip of islands stretching much of the way along the North Carolina coast. Many properties there were protected by bulkheads – sea walls typically concrete and about two meters high. Gittman found three quarters of these had been damaged by the hurricane. Meanwhile, the marshes that extend up to 40 meters into the sea had lost no sediment or elevation. Some of the marsh vegetation was damaged, but it had all grown back by the following year. A survey of 689 waterfront properties found that the 41% protected by bulkheads suffered 93% of the damage. Moreover, annual maintenance costs for bulkheads were four times those for the natural defenses.

More and more evidence like this is showing that “living coastlines” made up of salt marshes, mangrove forests, oyster reefs and shallow-water coral reefs are better able to resist storms and flooding. Oyster and coral reefs are natural breakwaters, with rough surfaces that absorb the power of waves, weakening floods and reducing coastal erosion. Meanwhile, vegetation in salt marshes and mangrove forests sap energy from storm surges. After a survey of damage caused by Hurricane Sandy in 12 eastern US states, scientists calculated that despite retaining only 10-40% of their natural wetlands, this was enough to reduce the economic damage of the hurricane by $625 million.

While restoring natural wetlands require investment, it may be much better value for money than artificial defenses. The six-meter-tall levees being built to protect properties in Louisiana cost $33,000 a meter, but research suggests they will only reduce losses from storms by a quarter of that amount, representing a return of just $1 for every $4 spent. Meanwhile, calculations show spending $1.3 billion on restoring an oyster reef could prevent $9.7 billion in damages. And spending $2 billion on restoring a salt marsh could prevent $18.2 billion in damage.

Restoration costs are coming down as techniques improve. Scientists have discovered that salt marsh vegetation grows three times faster when planted in clumps, and natural enemies of herbivorous crabs can be introduced to further aid growth. Restoration of oyster reefs also helps to protect the salt marshes.

The US air force searching for survivors in the aftermath of Hurricane Katrina (Image: Master Sgt. Bill Huntington/U.S. Air Force)

Coral reefs are another effective natural flood defense, able to absorb 97% of wave energy, with relatively cheap restoration costs. On average, a meter of coral reef can be restored for $1,300, compared to $20,000 to build a meter of breakwater. In the US, coral reefs help avoid $1 billion in damages every year; in Mexico, Malaysia, Indonesia and the Philippines, the figure is over $400 million for each country. Some insurance companies are realising that restoring mangrove forests and coral reefs offers better value than building artificial defenses. For example, Swiss Re and the Nature Conservancy have worked together on a Coastal Zone Management Trust in Yucatan, Mexico, where income from tourism is used to fund regular maintenance of reefs and to take out insurance on those reefs. That insurance then funds protection and restoration work on the reef if it is damaged by a storm.

Better late than never

While climate change has seen hurricanes in the North Atlantic intensify, things are even more worrying on the other side of the world. China is especially vulnerable to climate change – its sea levels have risen by more than the global average over the last 30 years, and typhoons that reach land have become stronger since the mid-1990s. China’s economic activity and populations are also concentrated on its coast, increasing the damage caused by storms. In 2018, Typhoon Mangkhut affected three million people across southern China, with 1.6 million evacuated, over 1,200 buildings destroyed, and 1.7 million hectares of crops damaged. Up to $120 billion of damage may have been caused across Asia as a whole.

In the wake of Mangkhut, experts warned that China would see more frequent and more powerful typhoons making landfall. It was estimated that 2020 would see 25-28 tropical cyclones form in the western Pacific and South China Sea, with six to eight making landfall in China. In August, three typhoons reached mainland China, with Zhejiang, Fujian and Guangdong provinces suffering damage worth 12.44 billion yuan (US$1.8 billion).

Since antiquity, those who live and work by the coast in China have built flood defenses, and today levees and other coastal protections are key to disaster prevention efforts. But as experience in the US has shown, artificial defenses have only limited effectiveness and require expensive annual repairs and maintenance.

Research shows that from the 1950s to the 2000s, China lost 53% of its temperate coastal ecosystems, 73% of its mangrove forests, and 80% of its coral reefs, mainly because of huge levels of development and land reclamation. As such, the country’s coastline has lost much of its capacity to resist increasingly intense storms.

But it is not yet too late. There is an ever-clearer awareness of the value of the ecological services provided by China’s coastal wetlands, and protection and restoration is now on the agenda for policymakers. In April 2017, President Xi said mangrove forests must be safeguarded while inspecting some in Guangxi. In July 2018, the State Council published a notice on better protection of coastal wetlands and tougher regulation of land reclamation projects. In June of this year, a 15-year plan for protecting and restoring key ecosystems was published – future work will focus on saving and regenerating coastal vegetation such as mangrove forests, seagrass meadows and coral reefs. Then, in August, the Ministry of Natural Resources and the State Forestry Administration published a detailed 2020-2025 plan for protecting and restoring mangrove forests.

The ministry’s National Marine Hazard Mitigation Service is leading development of a system to assess and categorize the protection offered by coastal wetlands. Trial results indicate that mangrove forests with a width of 150 meters can reduce the height of a storm surge by 80%, while a belt of salt marsh vegetation 30 meters wide can reduce wave energy by 70%, and a 100-meter-wide grassy marsh reduces their energy by 90% – proving how effective these wetlands are as barriers against the sea. In response to these findings, the ministry has led the drafting and release of a series of standards for the surveying, assessment, restoration and management of coastal ecosystems. While these standards are not binding, they are a positive step.

Given all these developments, it seems likely that the government will increase protection and restoration of coastal wetlands in the upcoming 14th Five Year Plan period (2021-2025).

Making use of coastal wetlands as a natural “green infrastructure” – working with nature rather than against it – to reduce threats facing humanity is, perhaps, a welcome return to rationality.

Gan Xiaojing is a conservation program manager at the Paulson Institute supporting the institute's wetland conservation and restoration projects. She holds a Ph.D. in ecology from Fudan University.

Shi Jianbin is an associate professor at the School of Environment at Beijing Normal University and an advisor to the Paulson Institute, in charge of wetland conservation-related projects and initiatives. He holds a Ph.D. in animal ecology from the University of Liverpool.

This article appears courtesy of China Dialogue Ocean and may be found in its original form here.

from Storage Containers https://www.maritime-executive.com/article/how-wetlands-can-protect-coastal-communities via http://www.rssmix.com/

0 notes

Text

week4

(1)Advantages and disadvantage of virtual exhibition:

Advantages:

1. It’s green:

Virtual exhibition eliminate the transport of artifacts and materials, which could reduce the carbon footprint of an event and also save big money for other good use.

2. It’s time-saving and long-lasting:

Virtual exhibition not only allow visitors to save time on travel, many also keep the virtual space for a long time after the actual event as a long-term display platform.

3. It’s available for more visitors:

Digital strategy includes virtual tours to allow rural, interstate and international audiences to the exhibitions without regional restriction. Besides, since a virtual space has no boarder it could contain more guests as long as the server is stable

4.It’s easier to track visitors’ interest:

Digital platforms make it easy to record users’ data and provide the museum an overall assessment.

Disadvantages:

1. It’s not exactly exciting:

With virtual exhibition, the audience doesn’t have all the excitement that goes along with a live event, so they’re not necessarily as engaged. The point is the curator has to work harder to catch the attention of attendees because they are not immersed in an atmosphere of enthusiasm and excitement as they are in a real space.

2. It’s technically vulnerable:

Virtual display may meet a lots of problems such as trouble connecting at the time of the show and page crash when overloading too many users…The museum needs to hire extra professional computer engineers to manage the online platform.

3. It’s relatively distracting:

When we’re attending an event in person, there is not many things to distract you. However, when we are visiting a museum online, it’s easier to get distracted by the web ads or other messages.

4. It’s not friendly to those who can’t afford a laptop:

(2) Examples of collections:

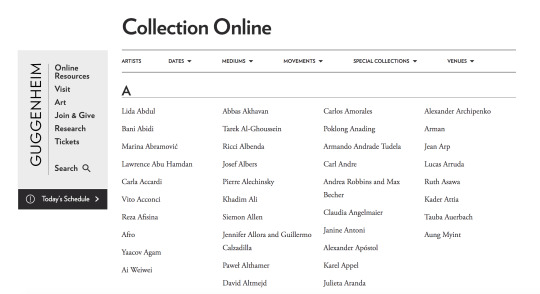

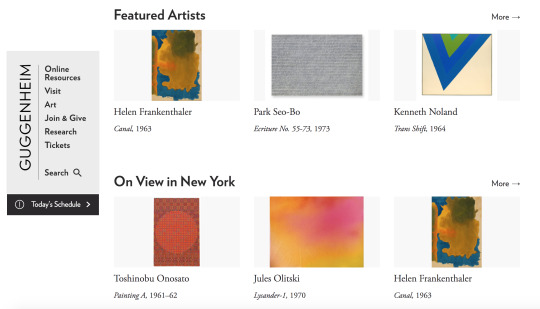

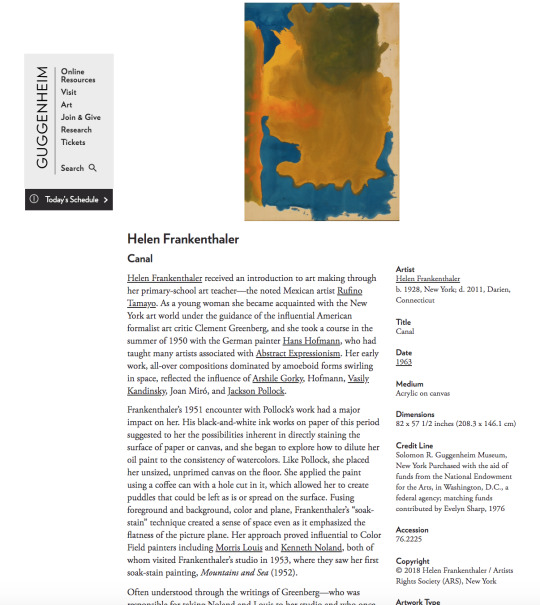

1.THE SOLOMON R. GUGGENHEIM MUSEUM:

Advantages:

Rich Collections: Featuring over 1,700 artworks by more than 625 artists, the Collection Online presents a searchable database of selected artworks from the Guggenheim’s permanent collection of approximately 8,000 artworks. The selection reflects the breadth, diversity, and tenor of the Solomon R. Guggenheim Foundation’s extensive holdings from the late 19th century through the present day.

Detailed Searching Categories: The search engine is perfect and the visitors could easily find their favorite artworks divided by by artist, date, medium, movement, and venue.

Disadvantages:

The online exhibition is only pictures with text description, and it is very difficult for visitors to immerse themselves in the virtual space since there is no where for them to explore. Personally, it makes me feel more like doing research or going through beautiful pictures rather than visiting a museum. Besides, the only medium is photography. There is no extra video, 3d maps or audio and to be honest it’s a little boring.

2.THE LOUVRE:

Advantages:

The excellent 3 dimensional map allows all online visitors to feel like they really engage in the collections since everybody could talk a virtual walk at the real museum.

Disadvantages:

Poor web design: The visual effect of the website looks very outdated, like it was designed in the last century. On the contrary, GUGGENHEIM MUSEUM’s website is very clear, stylish and modern. Plus, the interface of the searching page is also a little bit unfriendly. There are only few categories and they are not that specific.

Lack of description: Although the 3d immersed map is very engaging and the viewer could click and zoom artifacts during the tour, there is no explanation of the displays when you click the work. It’s a single picture with no artist’s name and necessary information. It’s hard to leave an impression by just display a photo since the audience could not understand the purpose and the worldview behind it.

3.NASA:

Advantages:

Vivid combination of text, picture and video provide the viewers with a relatively comprehensive understanding and it’s more interesting and attractive than boring text description.

Handy: The Space Center Houston also has an app that provides virtual tours, augmented reality experiences, and videos and audio stories about space exploration.

Disadvantages: Their web pages is loading at a very slow speed and occasionally suffer from freezing, which greatly affects the user experience. People usually browse the web very quickly, and an unsmooth experience will make the visitors impatient and less concentrated.

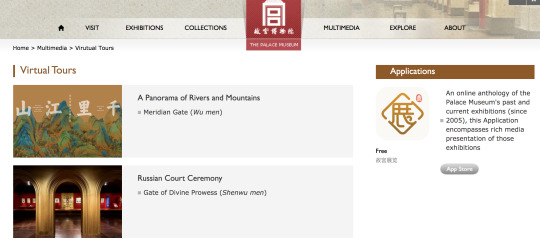

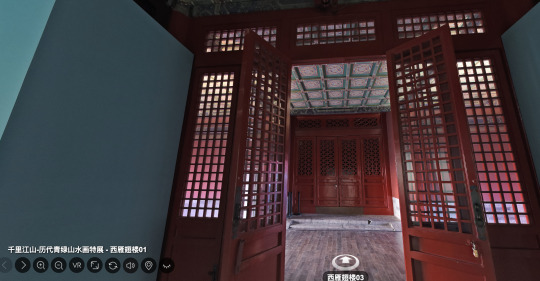

4.The Palace Museum:

Assistance functions:

Advantages:

The online Palace Museum provides its visitors almost the best visiting experience they could achieve based on high technological support. Although it shares a similar 3d map with the LOUVRE, it has more assistant options to help their audience to engage in the collections, which include VR mode, full screen mode, automatic rotation (so that the visitors could follow the lead and won’t get lost ), related background music and detailed floor map.

Personally I like to hear matching background music when visiting the exhibition since it could help me relax and provoke some emotional feelings. So I’m very glad to find out that the curators of the Palace Museum considered that part and set a button so that those who prefer a quiet visiting time could also close the music and enjoy their time.

The rotation speed of the map is a bit fast, which can easily cause 3d dizziness.

Although the audiences can zoom in to view the introduction of exhibits, they cannot click on the specific artifact. Some paintings are in a really huge scale and it’s difficult for the audience to see the overall appearance of the work.

I think it’s better to combine the advantages of the Louvre with the Palace Museum that the viewer can not only zoom in to view the pictures, but also see the relevant notes.

(3) Reading Reflection:

In Rodney’s opinion, it’s very different to appreciate the artifacts through its actual presence from experiencing it through the mediation of a screen (unless on purpose). Setting up in the physical environment, the audiences are more able to measure their own body against a display. The artwork could either remind them of some remarkable memories or some unforgettable experiences. Therefore, by occupying the same space and time, the visitors could create some special connection and meaningful memories with the displays and other viewers. In short, seeing art through screen does not allow the viewer to take his own measure and do no benefits for building up intimate relations to make visitors more engaged.

Ask questions of the work:

-The theme/purpose of the exhibition:

What is happening here? If the viewer could not find the answer during their visiting, it’s hard to provoke their further interest to investigate the artifacts. We need to communicate with them, to make ourselves present to the art even as it is present with us the moment we make visual contact.

“How did this come about? What kind of care had to be taken to make this thing? How long did this take and what else besides physical labor did it require of the maker?”

2. Imagine the worldview that brought the work about.