#monel 400 flanges

Explore tagged Tumblr posts

Text

Leading manufacturer of Monel 400 flanges in Saudi Arabia - Metal Forge India

Metal Forge India is a leading manufacturer and supplier of Monel 400 flanges in Saudi Arabia, known for delivering high-quality, corrosion-resistant solutions for various industries. As a trusted name in the market, we specialize in producing flanges that offer exceptional strength, durability, and resistance to seawater, acids, and alkaline environments. Our comprehensive range includes slip-on, weld neck, blind, threaded, and socket weld flanges, catering to the needs of the oil & gas, marine, chemical processing, and power generation sectors. With state-of-the-art manufacturing facilities and stringent quality control processes, we ensure that our products meet international standards such as ASTM B564 and ASME SB564. Visit Metal Forge India to explore our complete product range.

0 notes

Text

Understanding the Basics of monel 400 Socket Weld Flanges.| Anand steels

In the world of business packages wherein robustness and resistance to corrosive environments are paramount, Monel four hundred emerges as a stalwart choice. Among its numerous configurations, Monel 400 Socket Weld Flanges stand out for their versatility and reliability. In this whole manual, we delve into the intricacies of Monel 400 Socket Weld Flanges, exploring their introduction, applications, blessings, and more.

Introduction to Monel four hundred Flanges

Monel 400, a nickel-copper alloy famend for its terrific resistance to corrosion and excessive electricity in the course of a wide variety of temperatures, serves as the foundational cloth for a myriad of business additives. Among those components, Monel 400 Flanges hold a huge position. These flanges are available numerous kinds, consisting of Monel 400 Weld Neck Flanges, Monel four hundred Threaded Flanges, Monel 400 Socket Weld Flanges, Monel 400 Slip On Flanges, Monel 400 Lap Joint Flanges, and Monel four hundred Blind Flanges, each tailor-made to specific application requirements.

Construction and Design

Monel 400 Socket Weld Flanges are meticulously crafted to withstand harsh environments encountered in industries such as chemical processing, marine engineering, and aerospace. The creation usually includes forging Monel 400 alloy into a hoop-formed structure with a socket or hub for welding purposes. This layout ensures a stable and leak-proof connection, making them ideal for high-pressure and high-temperature packages.

Applications of Monel 400 Socket Weld Flanges

The versatility of Monel 400 Socket Weld Flanges renders them vital throughout various industries. From seawater desalination vegetation to oil refineries, those flanges find out software in critical strategies wherein corrosion resistance and reliability are non-negotiable. Their potential to face as much as acidic, alkaline, and saline environments makes them suitable for offshore systems, chemical processing machine, and piping structures managing corrosive fluids.

Advantages of Monel 400 Socket Weld Flanges

Corrosion Resistance: Monel 400 alloy famous fantastic resistance to corrosion, making Socket Weld Flanges product of this material fantastically long lasting in competitive environments.

High Strength: Despite its corrosion resistance, Monel 400 maintains astounding mechanical properties, making sure the integrity and toughness of Socket Weld Flanges beneath high-strain conditions.

Versatility: Monel 400 Socket Weld Flanges are well suited with a extensive variety of piping systems, presenting flexibility in layout and installation.

Ease of Welding: The socket weld layout simplifies the welding manner, facilitating brief and efficient assembly without compromising on electricity or leak-tightness.

Maintenance and Care

Proper maintenance is important to ensure the longevity and overall performance of Monel 400 Socket Weld Flanges. Regular inspections for signs and symptoms of corrosion, erosion, or mechanical harm are imperative. Additionally, imposing corrosion prevention measures consisting of defensive coatings or cathodic protection systems can further enhance their service existence in competitive environments.

Conclusion

In conclusion, monel 400 Blind Flanges epitomize sturdiness, reliability, and corrosion resistance in industrial packages. Whether in chemical processing, marine engineering, or oil and gas exploration, these flanges offer unparalleled performance, safeguarding important tactics in opposition to the deleterious effects of corrosion and high pressures.

For top rate-quality Monel 400 Flanges and different stainless-steel answers, appearance no further than Anand Steel. As a leading importer and exporter of stainless steel merchandise, inclusive of Monel 400 Flanges, Anand Steel boasts years of revel in and expertise in catering to various industry desires. Their commitment to first-class and patron satisfaction is remarkable, making them a depended on companion for all chrome steel necessities.

Contact Anand Steel nowadays to discover a complete variety of stainless-steel products, along with sheets, plates, coils, foils, spherical bars, and more. With their dedication to excellence and huge product portfolio, Anand Steel is poised to fulfill the most traumatic necessities of industries international.

#monel 400 Weld Neck Flanges#monel 400 Threaded Flanges#monel 400 Socket Weld Flanges#monel 400 Flanges#monel 400 Slip On Flanges#monel 400 Lap Joint Flanges#monel 400 Blind Flanges

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Chevron Corporation approved flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C offers a broad assortment of Monel Compound 400 Flanges, where these things that are being introduced by us are made using extraordinary metal. Monel 400 Slip on Flanges (UNS N04400) are areas of strength for a compound that should be hardened by cooling. Welding systems including gas - roundabout section welding, metal - twist welding, gas - metal - bend welding and brought down - bend welding is recommended on these Monel 400 Flanges. Significant machining gear and tooling should be used in Monel 400 Weld Neck Flanges to restrict jabber or work-setting of the blend before the cutting.

Monel 400 Outwardly impeded flanges are embodied by their insurance from attack by acids and stomach settling agents, as well as their high mechanical strength and incredible flexibility. Meanwhile, these Monel 400 Lap Joint Flanges are moreover being introduced in different sizes and shapes to our clients. A totally current compound, these Monel 400 Connection Weld Flanges, is a prevalent show mix that benefits colossally from twofold dissolving through the Electro Slag Refining (ESR) process. Electro Slag Refining (ESR) process ensures the cleanest and most prominent Monel 400 Ring Joint Sort Flanges are given.

There is no requirement for post weld heat treatment in these Monel 400 Exhibition Blind Flangess. Nonetheless, careful cleaning in the wake of welding is basic for ideal consumption obstruction in Monel 400 Nippolet Flanges, or, in all likelihood there is the gamble of pollution and embrittlement.

Monel 400 Pipe Flanges Specifications

Specifications: ASTM B564 / ASME SB564

Size: 1/2″NB TO 60″NB

Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

#Monel 400 Flanges Manufacturers in UAE#Monel 400 Flanges Suppliers in UAE#Monel 400 Flanges Stockists in UAE#Monel 400 Flanges Exporters in UAE#Chevron Corporation Approved Flanges In UAE#Colonial Pipelin UAEe Approved Flanges In UAE#Conoco Philips Approved Flanges In UAE

0 notes

Text

Sankalp Alloys Overseas is driving Manufacturer, Supplier, Exporters and Stockists for amazing Monel 400 Flanges. Isolated from steel, Monel is incredibly difficult to machine as it work-cements quickly. It ought to be turned and worked at slow speeds and low feed rates. Monel 400 Lines and Chambers are for the most part used in various application affiliations like petrochemical plants, petrol treatment work environments, stool plants, and different others.

#"Monel 400 Alloy Flanges Manufacturers#Monel 400 Alloy Flanges Suppliers#Monel 400 Alloy Flanges Stockists#Monel 400 Alloy Flanges Exporters#Monel 400 Alloy Flanges Manufacturers in India

0 notes

Text

Monel Flanges-Buy durable Monel 400/K500 Flanges at Nissan Steel and get the best deals on bulk orders. Our flanges are known for their excellent resistance to corrosion and high strength. Contact us now!

0 notes

Text

Monel K500: Properties, Applications, Composition & More

Introduction to Monel K500

Monel K500 is a nickel-copper alloy that provides the excellent corrosion resistance of Monel 400 with added superior strength and greater hardness. This increased performance is attained by adding small percentages of aluminum and titanium to the base alloy and by using a process known as age hardening (also precipitation hardening). The final material is very desirable for high-demand industrial uses where strength, toughness, and corrosion resistance are paramount.

Monel K500 not only resists corrosion in a wide range of environments including seawater, chemicals, and industrial atmospheres but it also retains its mechanical properties across a broad range of temperatures, from sub-zero to high temperatures.

Key Characteristics of Monel K500

Outstanding Strength: Exceptional Strength: Nearly twice the tensile strength and triple the yield strength of Monel 400.

Enhanced Corrosion Resistance: Excellent protection against saltwater, marine environments, chemicals, and acidic conditions.

Excellent Toughness: Maintains mechanical integrity from cryogenic to elevated temperatures (~480°C / 900°F).

Non-Magnetic Nature: Monel K500 remains generally non-magnetic in its annealed state. However, slight magnetism may develop after age-hardening.

Spark Resistant: Safe for use in explosive environments.

Chemical Composition of Monel K500

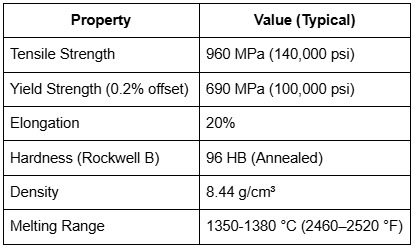

Mechanical Properties of Monel K500

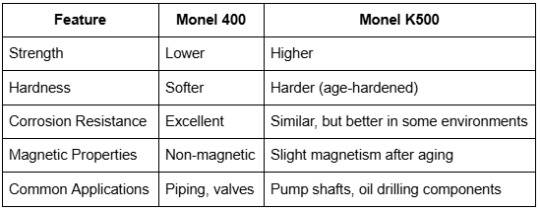

Monel K500 vs Monel 400

Applications of Monel K500

Monel K500 is applied in various industries that require high strength and outstanding corrosion resistance.

Some of the major applications include:

Marine Engineering: Used for propeller shafts, pump shafts, and valves that are subject to seawater.

Oil and Gas Industry: Applied in drill collars, non-magnetic housings, and oil-well tools.

Chemical Processing Equipment: Pumps, valves, and heat exchangers.

Medical Equipment: Specialized surgical instruments and implants.

Defense and Military: Components requiring resistance to corrosive and explosive environments.

Heat Treatment and Hardening

Monel K500 attains its remarkable strength through age-hardening, a process also referred to as precipitation hardening. The typical heat treatment process involves:

Solution Annealing: Heating to about 980°C (1800°F) and rapid cooling.

Aging: Holding the alloy at a lower temperature (~590°C / 1100°F) for several hours to precipitate Ni₃(Al, Ti) particles, which strengthen the matrix.

Proper heat treatment is critical for achieving the best combination of mechanical properties and corrosion resistance.

Corrosion Resistance of Monel K500

Monel K500 offers excellent resistance to:

Seawater: Outstanding for marine applications.

Hydrofluoric Acid: One of the rare alloys that exhibit resistance to hydrofluoric acid.

Alkalis: Strong resistance to caustic solutions.

Salts and Brines: Resistant to various chloride and bromide salts.

Organic and Inorganic Acids: Sulfuric, hydrochloric, and nitric acids in moderate concentrations.

However, it can suffer from stress-corrosion cracking in some conditions, especially in the presence of high concentrations of chlorides.

Forms Available in Monel K500

Monel K500 is available in several product forms, including:

Sheets and Plates

Bars and Rods

Pipes and Tubes

Wires

Forgings

Fittings and Flanges

Fasteners (bolts, nuts, washers)

Conclusion

Monel K500 is the preferred material for applications that demand both high strength and outstanding corrosion resistance. Its unique properties make it indispensable in demanding environments such as marine, chemical processing, aerospace, and oil & gas industries. Though it is more expensive compared to many standard stainless steels, its performance benefits often outweigh the cost in critical applications.

Choosing Monel K500 ensures long-term reliability, fewer maintenance concerns, and superior mechanical performance even under the harshest operating conditions.

FAQs About Monel K500

Q1. Is Monel K500 magnetic?

Monel K500 is non-magnetic in the annealed condition, although it can develop slight magnetism after age-hardening.

Q2. Can Monel K500 be welded?

Yes, but special care must be taken. Welding should ideally be performed using Monel filler metal and proper post-weld heat treatment to prevent cracking.

Q3. What is the maximum temperature Monel K500 can withstand?

Monel K500 can perform reliably at temperatures as high as 480°C (900°F).

Q4. Is Monel K500 expensive?

Yes, Monel K500 is considered a premium material due to its nickel content and specialized manufacturing processes.

Q5. What differentiates Monel K500 from Monel 400?

Monel K500 has higher strength and hardness compared to Monel 400 due to its age-hardening capabilities, while both offer similar corrosion resistance.

#monel#monelfasteners#fasteners#monelk500#monel400#ananka#anankafasteners#articles#blog#fastenersmanuafcturer#manufacturer#supplier#mumbai#tumblr blog#tumblr

0 notes

Text

High - quality Monel 400 flanges Manufacturer & exporter in Turkey | Metalforgeindia

MetalForge India is a trusted manufacturer and exporter of high-quality Monel 400 flanges in Turkey. Our Monel 400 flanges are crafted with precision to deliver excellent performance even in harsh environments. We offer a wide range of Monel 400 flanges, including slip-on, weld neck, blind, socket weld, and threaded types. These flanges are designed to handle high-pressure and high-temperature conditions while ensuring a secure and leak-proof connection. Manufactured in compliance with international standards, our flanges guarantee durability and reliability. Choose MetalForge India for Monel 400 flanges that offer outstanding quality and long-lasting performance.

0 notes

Text

Key Differences Between Monel Weld Neck Flanges and Lap Joint Flanges | Anand steels

In the area of business applications wherein reliability, durability, and corrosion resistance are paramount, the selection of flanges performs a critical function. Among the myriad options available, Monel 400 Weld Neck Flanges, Monel 400 Threaded Flanges, Monel 400 Socket Weld Flanges, Monel 400 Slip-On Flanges, Monel 400 Lap Joint Flanges, and Monel 400 Blind Flanges stand out as stalwarts. Anand Steels, a top of the line importer and exporter of stainless steel and nickel alloys, sheds mild on the key disparities between Monel Weld Neck Flanges and Lap Joint Flanges, illuminating the nuanced variations that can affect choice-making in various industries.

Monel 400 Weld Neck Flanges:

Definition and Construction: Monel 400 Weld Neck Flanges, fabricated from the famend Monel 400 alloy, are characterised by using a long tapered hub, facilitating a clean transition from the flange thickness to the pipe's wall thickness. This design guarantees more desirable electricity and pressure distribution, making them ideal for high-pressure packages.

Usage and Applications: Widely applied in industries consisting of chemical processing, marine engineering, and oil refineries, Monel 400 Weld Neck Flanges excel in environments where resistance to corrosion, erosion, and alkaline solutions is imperative.

Advantages:

Superior Strength and Durability: Monel 400 alloy reveals first-rate mechanical homes, making sure longevity and reliability in annoying conditions.

Corrosion Resistance: With inherent resistance to corrosion and oxidation, Monel 400 Weld Neck Flanges provide robust overall performance in corrosive environments.

High Temperature Stability: These flanges hold their structural integrity even at improved temperatures, ensuring operational protection and efficiency.

Variants: Monel 400 Threaded Flanges and Socket Weld Flanges are alternative configurations catering to unique installation necessities, providing versatility and ease of meeting.

Monel 400 Lap Joint Flanges:

Definition and Structure: Monel 400 Lap Joint Flanges feature a flat face with a radius corner, permitting clean alignment and installation. Unlike Weld Neck Flanges, they do not have a raised face or hub, facilitating speedy disassembly and renovation.

Applications and Suitability: Lap Joint Flanges discover favor in applications in which frequent dismantling and reassembly are predicted, together with piping structures requiring periodic inspection or cleaning.

Advantages:

Easy Installation and Maintenance: The absence of a welded connection simplifies assembly and disassembly, lowering downtime and labor expenses.

Flexibility in Alignment: Lap Joint Flanges provide flexibility at some stage in alignment, mitigating issues related to misalignment and facilitating seamless operation.

Variants: Monel 400 Slip-On Flanges and Blind Flanges are opportunity configurations that cater to particular requirements, imparting adaptability and versatility in various business settings.

Differentiating Factors:

Design and Construction: The number one difference lies within the design and construction of these flanges. While Weld Neck Flanges function as a tapered hub for enhanced strength and strain distribution, Lap Joint Flanges boast a flat face for easy alignment and disassembly.

Application Specificity: The choice between Weld Neck Flanges and Lap Joint Flanges hinges at the specific necessities of the application. Weld Neck Flanges are desired for excessive-stress structures, traumatic advanced power and corrosion resistance, while Lap Joint Flanges excel in packages necessitating frequent preservation and alignment adjustments.

Installation and Maintenance: Weld Neck Flanges offer robustness and stability, ideal for everlasting installations wherein reliability is paramount. In comparison, Lap Joint Flanges prioritize ease of set up and preservation, catering to packages requiring periodic dismantling and reassembly.

Corrosion Resistance: Both types of flanges, crafted from Monel 400 alloy, show off exemplary resistance to corrosion and oxidation. However, the choice among Weld Neck Flanges and Lap Joint Flanges depends on other elements along with structural integrity and simplicity of preservation.

In the end, the choice between Monel 400 Weld Neck Flanges and Lap Joint Flanges involves a cautious attention to the unique necessities and operational nuances of the intended software. While Weld Neck Flanges offer exceptional strength and balance for everlasting installations in excessive-pressure environments, Lap Joint Flanges prioritize ease of protection and alignment flexibility, catering to programs necessitating common dismantling and reassembly.

For top rate first-rate chrome steel and nickel alloy answers, enterprise specialists can depend upon Anand Steels. As a main importer and exporter of stainless steel shims, strips, coils, foils, round bars, and specialized nickel alloys, they pride themselves on turning in excellence and reliability. With a steadfast commitment to first-rate and client delight, they stand as a relied on supplier, offering comprehensive answers tailored to the particular needs of diverse industries. Contact Anand Steels today to explore their sizable range of products and experience unparalleled carrier and understanding.

#monel 400 Weld Neck Flanges#monel 400 Threaded Flanges#monel 400 Socket Weld Flanges#monel 400 Flanges#monel 400 Slip On Flanges#monel 400 Lap Joint Flanges#monel 400 Blind Flanges

0 notes

Text

Understanding Monel 400’s Strength in Extreme Industrial Conditions

Understanding Monel 400’s Strength in Extreme Industrial Conditions

When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Book A Consultation When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Whether in marine, chemical, or high-temperature applications, Monel 400 consistently provides reliable performance. Let’s explore the standout features of the Monel 400, including its composition, density, and industrial uses. What is Monel 400? Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance and durability. It’s made mostly of nickel (around 63%) and copper (roughly 30%), with small amounts of iron, manganese, carbon, and silicon. This combination of metals makes Monel 400 perfect for industries dealing with seawater, extreme heat, or aggressive chemicals. It’s the material of choice when long-lasting performance and reliability are needed in harsh environments. Monel 400 Chemical Composition The unique chemical makeup of Monel 400 is what gives it its impressive strength and corrosion resistance. The high nickel content provides excellent protection against corrosion, while copper enhances its strength. Iron, manganese, and carbon contribute to its mechanical properties. Here’s a simple breakdown of its composition:Nickel: 63% Copper: 28-34% Iron: 2.5% Manganese: 2% Carbon: 0.3%This mix makes Monel 400 highly resistant to stress corrosion cracking, even in harsh environments like seawater and acidic conditions. Monel 400 Density Monel 400 has a density of around 8.8 to 9.0 g/cm³. It is denser than many metals, but its alloy design makes it still light enough for various applications. This makes it perfect for high-stress situations where strength is important, but weight should be kept to a minimum. Monel 400 in Different Forms Monel 400 comes in several forms, each suited for different industrial applications. Here are some of the key options:Monel 400 Plate:

Ideal for heavy-duty applications like tanks and pressure vessels. It works well in environments with both high temperatures and corrosive chemicals.Monel 400 Round Bar: This form is great for parts like valves and pumps, as it can resist extreme temperatures and corrosion.Monel 400 Pipe: Monel 400 pipes are highly resistant to saltwater corrosion and are commonly used in the marine industry and chemical processing plants.Monel 400 Fittings and Flanges:

These are used to connect pipes and other components, offering the same strength and corrosion resistance as other Monel 400 materials.

Why Choose Monel 400?

Monel 400 is a top choice because of its durability and resistance to corrosion. Here’s why it’s relied on in industries that require these qualities:Exceptional Corrosion Resistance: Monel 400 resists corrosion in harsh environments, including seawater and acidic conditions. It also resists stress corrosion cracking, which makes it ideal for industries that need reliable materials in extreme conditions.High Strength in High Temperatures: It performs well even in high-temperature environments, making it suitable for chemical processing plants and power generation systems where heat is a constant factor.Good Workability: Despite its strength, Monel 400 is easy to fabricate, weld, and machine, making it a popular choice for engineers creating custom parts.Versatile Applications: It’s used in a wide range of applications, from pumps and valves to marine equipment and pressure vessels. Its resistance to oxidation and corrosion makes it perfect for environments that would cause other materials to fail.Longevity and Durability: With proper maintenance, Monel 400 components last a long time, saving businesses from frequent replacements. This makes it a cost-effective solution over time.

Common Applications of Monel 400

Monel 400 is used in many industries because of its strength and ability to withstand tough conditions. Here are some key applications:Marine Industry: Its corrosion resistance makes it a go-to material for shipbuilding, offshore platforms, and other vital marine equipment.Chemical Processing: In chemical plants, it’s used for equipment exposed to harsh chemicals, such as tanks, heat exchangers, piping systems, and valves.Aerospace: Its strength and heat resistance make it ideal for aerospace parts, such as aircraft and engine components, which must endure extreme temperatures and stress.Oil and Gas: Monel 400’s resistance to corrosion in saltwater environments makes it a popular choice for the oil and gas industry. It’s found in valves, pumps, and offshore oil rig components exposed to seawater. Monel Alloy: A Versatile Solution Monel alloys are known for their ability to perform in tough environments. While Monel 400 is the most widely used, other alloys like Monel 500 and Monel 405 also offer strong resistance to corrosion. Depending on the specific needs of a project, these alloys may provide extra benefits while still offering the same level of durability. How Does Monel 400 Perform in Extreme Conditions? Monel 400 excels in environments where most metals would break down quickly. It resists seawater corrosion, high temperatures, and harsh chemicals, making it essential for industrial applications that require long-lasting performance. Whether in marine, chemical, or high-temperature industries, Monel 400 ensures that equipment and components remain reliable over time, even under tough conditions.If your industry requires materials that can withstand extreme environments, Monel 400 is the ideal choice. Its impressive properties and performance make it one of the most trusted materials for demanding applications.For more information about Monel 400, including specifications and availability, check out Steelco Metal to learn how this versatile material can meet your industrial needs. FAQ What is Monel metal used for? Monel metal is widely used in marine, chemical, and aerospace industries due to its excellent resistance to corrosion, high strength, and ability to withstand extreme temperatures. It’s ideal for components exposed to harsh environments. What is the difference between Monel 400 and Monel 500? Monel 400 is a nickel-copper alloy known for its corrosion resistance, while Monel 500 contains aluminum and titanium, offering higher strength and better performance at elevated temperatures. Monel 500 is preferred in high-temperature applications. What are the primary uses of Monel 400? Monel 400 is commonly used in marine environments, chemical processing plants, oil and gas industries, and aerospace for components requiring resistance to corrosion, strength, and durability in harsh conditions. Is Monel 400 resistant to seawater corrosion? Yes, Monel 400 is highly resistant to seawater corrosion, making it ideal for marine applications such as propeller shafts, valves, and pumps exposed to saltwater environments. Read the full article

0 notes

Text

High-Quality Inconel 625 Round Bar Supplier in India | OM Export India

Looking for a reliable Inconel 625 round bar supplier? OM Export India offers top-quality Inconel 625 round bars for various industrial applications. Explore our range today for durable, corrosion-resistant solutions!

#flanges#Cupro Nickel 90/10 Sheets & Plates#Monel 400 round bar#astm a350 lf2 class 1#Duplex Steel S31803#SS 316/316L/316Ti Sheets and Plates#Inconel 625 round bar

0 notes

Text

#Monel 400 Flanges Manufacturers in UAE#Monel 400 Flanges Suppliers in UAE#Monel 400 Flanges Stockists in UAE#Monel 400 Flanges Exporters in UAE

0 notes

Text

Monel globe valve

Valves Only stands out as a trusted name in the industry as leading Monel globe valve manufacturers in USA, we specialize in providing premium-quality valves that offer exceptional durability, corrosion resistance, and efficiency in demanding applications. These valves are highly suitable for oxygen services and resistance to corrosion. They are extensively used in steel industry .

What is a Monel Globe Valve?

A Monel globe valve is designed to regulate and control fluid flow within pipelines. Made from Monel, a nickel-copper alloy, Monel alloy valves have excellent corrosion resistance to hydrofluoric acid (HF), uranium fluoride (UF6, UF4), dilute sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, strong alkaline solutions, brine, seawater, and halogen elements, makes them ideal for industries such as marine, chemical processing, power plants, and oil & gas.

Why Choose Monel Globe Valves?

Monel globe valves offer several advantages over conventional materials. Some of the key benefits include:

Corrosion Resistance: Ideal for handling seawater, acids, and harsh chemicals without degradation.

High Strength & Durability: Withstand extreme pressures and temperatures, ensuring long-term reliability.

Superior Flow Control: Designed for precise regulation of fluid flow, reducing pressure loss and enhancing operational efficiency.

Low Maintenance: Due to their resilient construction, Monel globe valves require minimal upkeep, reducing downtime and operational costs.

Applications of Monel Globe Valves

Industries that rely on Monel globe valves include:

Marine & Offshore

Chemical Processing

Oil & Gas

Power Plants

Advantages:

Monel Globe Valve Supplier in Kentucky they are a reliable choice for high-pressure applications.

They have good processing and welding properties.

They have good mechanical properties, even at low temperatures.

They are resistant to corrosion in a variety of environments

Description:

Body: Monel 400, Monel K500, Monel 600, Duplex Stainless Steel, Super Duplex Stainless Steel, Alloy 20, CN7M, Hastelloy, Carbon Steel, WC6, WC9, C5, C12, LCB, CF3M

End Connections: Flanged, Socketweld, Buttweld

Operations: Handwheel Operated, Electric Actuated, Pneumatic Actuated

Nominal Size: DN50 to DN600

Nominal Pressure: PN 1.0 to 25 Mpa, Class 150 to 2500

If you are looking for Monel globe valve manufacturers in USA, trust Valves Only for unparalleled quality and service.

Visit us: https://valvesonly.com/product-category/monel-globe-valve/

0 notes

Text

Monel Flanges - Buy durable Monel 400/K500 Flanges at Nissan Steel and get the best deals on bulk orders. Our flanges are known for their excellent resistance to corrosion and high strength. Contact us now!

https://www.nissansteel.com/monel-400-k500-flanges.php

0 notes

Text

Different Types of Monel Fasteners

Monel Fasteners are high-performance fastening components made from Monel alloys, primarily Monel 400 and Monel K500. Known for their exceptional resistance to corrosion, especially in marine and chemical environments, Monel fasteners are widely used in industries such as marine engineering, chemical processing, aerospace, and oil & gas.

In this blog, we will explore the various types of Monel fasteners, their features, applications, and benefits.

What is Monel?

Monel is a group of nickel alloys, mainly composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. The most commonly used Monel grades include:

Monel 400 – offers excellent corrosion resistance and high strength.

Monel K500 – provides higher strength and hardness due to added aluminum and titanium.

Key Properties of Monel Fasteners

Excellent resistance to seawater, acids, and alkalis.

High strength and toughness.

Superior resistance to corrosion cracking and pitting.

Performs well in high-temperature environments.

Non-magnetic in annealed condition.

Types of Monel Fasteners

Below are the most common types of Monel fasteners used across industries:

1. Monel Bolts

Monel bolts are used for securely fastening materials in highly corrosive environments. These include:

Hex Head Bolts

Heavy Hex Bolts

Socket Head Cap Screws

U-Bolts

Anchor Bolts

Carriage Bolts

Applications: Offshore platforms, marine vessels, pumps, heat exchangers.

2. Monel Nuts

Monel nuts pair with bolts and threaded fasteners. Types include:

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Cap Nuts

Flange Nuts

Wing Nuts

Applications: Chemical plants, pressure vessels, shipbuilding.

3. Monel Screws

Monel screws offer secure fastening with excellent corrosion resistance.

Machine Screws

Self-Tapping Screws

Wood Screws

Socket Set Screws

Sheet Metal Screws

Applications: Aerospace assemblies, instrumentation, defense equipment.

4. Monel Washers

Washers distribute the load of fasteners and protect surfaces.

Flat Washers

Spring Washers

Lock Washers

Fender Washers

Sealing Washers

Applications: High-pressure equipment, marine applications, flanged joints.

5. Monel Studs

Studs are threaded rods used where full thread engagement is necessary.

Fully Threaded Studs

Double End Studs

Tap End Studs

Applications: Heat exchangers, chemical reactors, turbines.

6. Monel Threaded Rods

Threaded rods are ideal for anchoring and structural applications.

Applications: Marine construction, oil rigs, bridge building.

7. Monel Pins

Pins offer precise alignment and fastening in assemblies.

Dowel Pins

Taper Pins

Groove Pins

Split Pins (Cotter Pins)

Applications: Valves, pumps, motors, marine equipment.

Monel Grades Used in Fasteners

✔️ Monel 400 (UNS N04400)

Composition: ~67% Nickel, 30% Copper

Excellent resistance to seawater and acidic environments.

Used in marine and chemical processing.

✔️ Monel K500 (UNS N05500)

Precipitation-hardened alloy.

Higher strength than Monel 400.

Used in pump shafts, oil well tools, and high-torque fasteners.

Industries Using Monel Fasteners

Marine & Shipbuilding

Aerospace

Oil & Gas

Chemical & Petrochemical

Power Generation

Nuclear Industry

Advantages of Monel Fasteners

Long service life even in aggressive environments.

Reduced maintenance cost due to corrosion resistance.

Reliable performance under high mechanical stress.

Excellent for both fresh and saltwater exposure.

Ananka Group – Trusted Monel Fasteners Manufacturer in India

At Ananka Group, we are a leading Monel fasteners manufacturer, supplier, and exporter based in India, delivering premium quality products globally. We provide fasteners in various types, sizes, and Monel grades with international standards such as ASTM, ASME, DIN, and ISO.

Why Choose Us?

In-house manufacturing and quality control.

Wide inventory of Monel 400 and K500 fasteners.

Worldwide shipping and timely delivery.

Custom sizes and coatings available on request.

Standard Specifications

Standard

Description

ASTM B164

For Monel 400 Rods, Bars, and Wire

ASTM B865

For Monel K500 Rods and Bars

ASME SB-164 / SB-865

Boiler and Pressure Vessel Code

DIN / ISO / JIS / BS / EN

Metric Standards for International Use

FAQs

Q1. Are Monel fasteners better than stainless steel? A: Monel offers superior corrosion resistance in marine and acidic environments compared to stainless steel.

Q2. What is the temperature range for Monel fasteners? A: Monel fasteners can typically operate from sub-zero temperatures up to 480°C (900°F), depending on the grade.

Q3. Is Monel magnetic? A: Monel 400 is non-magnetic in the annealed condition, making it ideal for sensitive applications.

Q4. What are the common coatings for Monel fasteners? A: Monel fasteners are usually used without coatings due to their inherent corrosion resistance but can be passivated or coated if required.

Q5. Can Monel fasteners be welded? A: Yes, Monel can be welded using standard welding practices for nickel alloys, but it requires expertise to prevent cracking.

Conclusion

Monel fasteners are a premium choice for demanding applications where corrosion resistance, mechanical strength, and longevity are non-negotiable. From bolts and nuts to studs and washers, Monel alloys like 400 and K500 provide exceptional performance in marine, chemical, and industrial settings.

If you're looking for high-quality Monel fasteners, Ananka Group is your go-to supplier. We offer a wide range of fasteners in various sizes, grades, and finishes to meet your exact specifications.

#ananka#anankafasteners#fasteners#fastenersmanufacturer#monel#monelfasteners#typesofmonel#monelk500#linkedin#articles#blog#manufacturer#supplier#mumbai

0 notes

Text

Monel 400 Flanges Manufacturers in Kuwait – Metalforgeindia

Monel 400 is a high-performance alloy primarily composed of nickel (about 63%) and copper, with small quantities of manganese, iron, and different factors. Known for its notable corrosion resistance, specifically in marine and chemical environments, Monel 400 is broadly used in applications wherein sturdiness and reliability are important. One of the vital issues products crafted from Monel 400 is Monel 400 flanges, which might be vital additives utilized in piping systems to attach, regular, and seal sections of pipe.

In Kuwait, wherein industries together with oil and gasoline, petrochemicals, and marine operations are outstanding, the call for the flanges of Monel 400 is on the rise. As industries in Kuwait require remarkable, corrosion-resistant materials for excessive conditions, Metal Forge India – a relied-on call within the delivery and manufacturing of flanges of Monel 400 – meets the stringent extremely good necessities and might offer pinnacle-notch material.

What Are the Flanges of Monel 400?

To sign up for pipes or connect a pipe to a valve, pump, or different system, flanges are mechanical additions. They encompass blind flanges, weld neck flanges, and slip-on flanges and are packaged in plenty of office work. In addition to its functionality to withstand immoderate temperatures and strain, the alloy used to create Monel's 400 flanges is famed for its terrific resistance to acidic and alkaline environments.

Key Features of Flanges of Monel 400:

Corrosion Resistance: Monel 400 gives first-rate resistance to a huge form of corrosive media, alongside seawater, acids, alkalis, and brine. This makes flanges of Monel 400 nice for use in harsh environments which include offshore drilling structures, marine vessels, and chemical processing flora.

High Strength and Durability: Flanges of Monel 400 maintain high tensile electricity even in severe temperatures, making them alternatively durable below demanding conditions.

Non-Magnetic: Monel 400 is non-magnetic, which is a vital asset for sure packages in which magnetism may want to intervene with operations.

Excellent Weldability: The alloy’s superb weldability makes it appropriate for manufacturing complicated additives, such as flanges, without compromising the material’s features.

Applications of Flanges of Monel 400

Flanges of Monel 400 are utilized in several important industries and applications, way to their notable physical and chemical capabilities. Some of the primary makes use of consist of the following:

Marine and Offshore: Flanges of Monel 400 are extensively implemented in marine applications, collectively with shipbuilding, seawater pumps, and underwater devices. The product's resistance to seawater corrosion makes it superb for those harsh environments.

Chemical Processing: In industries managing acids, alkalis, and different corrosive materials, flanges of Monel 400 are used to make certain that piping structures remain intact and proof in competition to corrosion.

Oil and Gas Industry: Flanges of Monel 400 are crucial in the oil and fuel quarter, wherein they will be used in refineries, pipelines, and offshore structures to move each gasoline and liquid below immoderate stress.

Power Plants: These flanges are also utilized in energy plants, especially human beings with excessive-stress boilers or in systems that address steam and water at severe temperatures.

Why Choose Flanges of Monel 400?

The primary reason to select the flanges of Monel 400 over different substances is their superior corrosion resistance, specifically in environments exposed to seawater, acidic answers, and immoderate-temperature application. Some greater benefits of Monel's 400 flanges encompass:

Cost-Effectiveness: While Monel 400 can be greater expensive than some exclusive alloys, the sturdiness and extended service lifestyles it offers can extensively reduce upkeep and replacement prices through the years.

Long-Lasting Performance: Thanks to their excessive resistance to pressure corrosion cracking, Monel's 400 flanges are carried out reliably over prolonged intervals, even under intense conditions.

Versatility: Monel 400 flanges are flexible for many industries and may be used in several applications, along with pressure vessels, warmth exchangers, and marine systems.

Kuwaiti Manufacturers of Monel 400 Flanges

Finding an issuer that gives remarkable materials and shipping alternatives is crucial when obtaining Monel 400 flanges in Kuwait. We are a trusted issuer of flanges of the Monel 400 and have set up ourselves as a chief manufacturer catering to industries in Kuwait and at some stage in the Middle East. Their commitment to exquisite, precision engineering and customer support guarantees that clients collect only the top-notch.

Why Metal Forge India?

Global Reach: We have a robust distribution community in Kuwait and the Middle East, ensuring nicely timed transport of flanges of Monel 400 and special specialized products.

High-Quality Manufacturing: They observe strict best control procedures, making sure that every flange meets international requirements, providing long-lasting performance and high corrosion resistance.

Customized Solutions: Understanding that precise responsibilities may also moreover require particular specifications, we gives customized flange solutions, ensuring that the material and dimensions meet the appropriate needs of their customers.

We are Your Trusted Partner for Flanges of Monel 400

For industries in Kuwait that demand high-typical performance flanges of Monel 400, we are your dependable associate. Known for its willpower to deliver brilliant products, we provide flanges of Monel 400 to severa sectors in Kuwait, ensuring they meet the very excellent standards of tremendous and basic overall performance. Whether you need fashionable or custom-sized flanges of Monel 400, we have the understanding and stock to meet your dreams.

Conclusion

Monel 400 flanges are vital components in industries that require corrosion-resistant materials and high-electricity overall performance, in particular in tough environments just like the ones located in Kuwait. From marine corporations to grease and gasoline, the flanges of Monel 400 offer advanced protection in the direction of corrosion and excessive situations.

Whether you're looking for a Monel 400 flange manufacturer or a depended-on company in Kuwait, Metal Forge India provides the knowledge, best products, and services you need. By deciding on flanges of Monel 400 from these trusted suppliers, you make sure that your piping structures will perform reliably and adequately inside the harshest conditions, retaining their integrity and lengthening the lifespan of your infrastructure.

For your Monel 400 flange requirements, appearance no further than us for the super products and services tailor-made to fulfill your particular desires.

0 notes