#Machine Maintenance

Explore tagged Tumblr posts

Text

Now that I own a sewing machine, I think I better understand, like, backyard automobile maintenance hobbyists.

I opened up my sewing machine to do a bit of maintenance on it, just some cleaning and light oiling*. And it was incredibly satisfying--especially being able to hear and feel the difference after the cleaning!

I could see myself standing proudly next to my machine and boasting, "Boy she sure runs smooth now!" or whatever.

This sewing machine was given to me by my partner's mother (it was her spare after she upgraded).

Model: Brother CE8080PRW (Project Runway)

* I understand that this machine is not meant to be oiled by the user, according to the manual. I oiled it anyway.

#sewing machine#sewing machine maintenance#maintenance hobby#machine maintenance#not auto maintenance#brother sewing machine#project runway

4 notes

·

View notes

Text

#HighPressureGrease#Industrial Grease#Lubrication#HeavyMachinery#Machine Maintenance#Grease Lubrication#SyntheticGrease#LithiumGrease#PolyureaGrease#CalciumGrease#ConstructionMachinery#MiningEquipment#ManufacturingSolutions#NextOilSolutions#EquipmentCare#LubricantSolutions#IndustrialLubricants#PreventiveMaintenance#MechanicalEngineering#GreaseSupplier

0 notes

Text

How Not to Break Your Sewing Machine

I work in a shop where we repair sewing machines (a LOT of sewing machines), and unsurprisingly we see a lot of the same problems over and over again, so I'm here with some advice on how to keep your machine running longer.

When you break a needle, dig around until you have found the broken piece. If you leave it in there, it can end up in the wrong place at the wrong time and break something vital.

SLOW DOWN. The function of your sewing machine depends on the different moving parts ending up in the right place at the right time. Having to go through a lot of/heavy material slows the needle down, but it doesn't slow down the mechanism underneath the needle plate. If you try to go your usual speed, the needle will arrive too late and collide with something it shouldn't, breaking either the needle or the bobbin case. If the material is especially heavy (say you're sewing several layers of denim, or sewing webbing onto canvas), take your foot off the pedal and turn the machine by hand.

Clean out the bobbin area after each project. Really. Your machine comes with a little brush for this purpose. If it doesn't, a little dollar-store paint brush will work just fine. Remember what I said above about things being in the right place at the right time? Everything needs to be able to move freely for this to work. I know it looks like it's just a little dust and fluff, but it will jam up your machine eventually.

If you can, get your timing adjusted by a professional. I know most people don't have a sewing machine repair shop in their neighbourhood, but if you can do this, it's worth it. If the machine's timing is good, then you're more likely to have a little leeway for heavier fabric or a lintier bobbin case. When the timing is just a bit off, it takes less of an obstacle to put the needle in a place it shouldn't be.

If you can, buy a machine built before 1980. If it's still working 50 years after it was made, it's gonna keep working. Those older machines are made with metal gears and therefore weigh a ton, so they're definitely not a good choice if you don't have a permanent setup for your machine, but it means they basically last forever. Newer machines are made with plastic parts, and no matter what you do, they will break.

Don't buy a Singer Heavy Duty. I'm sure those machines have their benefits, but they are absolutely not heavy duty. We repair more Singer Heavy Dutys than any other single model of sewing machine. If you're already stuck with a Heavy Duty, then follow my advice above even more scrupulously, and start shopping around for a replacement if you can. You can get a used sewing machine of better quality for significantly less than a new Heavy Duty.

To keep things working properly, make sure you're:

threading your machine properly

using the right kind of bobbin

adjusting your tension properly

and using the right kind of needle for the fabric you're sewing!

(These things are unlikely to break your machine, but they will keep it from sewing properly.)

Other than that, get your hands on your machine's manual and read it carefully. If you can, bring your machine in for a cleaning and adjustment now and then. Your machine will need repairs every once in a while: it's a lot of little moving parts! But these are some basic precautions you can take to avoid some common problems.

#sewing machines#sewing#sewblr#sewing machine#i imagine most of you already know this stuff#but many of our customers do not#sewing machine psa#sewing machine maintenance

8K notes

·

View notes

Text

Safeguarding Yourself During Machinery Operation: Essential Tips

Operating machinery, whether you're a seasoned machine builder, involved in Heavy Equipment Repair, or tasked with industrial maintenance, always carries with it a certain level of risk. Mistakes with industrial machinery, no matter how small, can lead to significant accidents, endangering operators and bystanders. But don't worry! By following some important safety tips, you can greatly reduce these risks and keep yourself and others safe.

This blog post provides useful tips for ensuring safety and efficiency at work. Keep in mind that safety is of paramount importance, whether you're repairing equipment or doing routine inspections.

Let's explore these lifesaving tips together and make sure machinery operation is as safe as can be!

Brief overview of the importance of safety during machinery operation

Operating heavy machinery is an integral part of various industries, from construction to manufacturing. However, working with or around these powerful machines comes with significant risks. Every year, many workplace accidents and injuries are attributed to machinery operation mishaps. Many of these incidents could be prevented with proper safety measures in place.

Keeping safe during machinery operation not only protects operators but also boosts productivity by reducing downtime from accidents. Recognizing the usual dangers and understanding the importance of a detailed risk assessment is the first step to creating a safer workplace.

Identifying common hazards in machinery operation

Operating heavy machinery comes with its fair share of risks. These risks include entanglement, cuts from moving parts, eye injuries from flying debris, and crushing or impact injuries due to machine malfunctions or tip-overs. Also, long-term exposure to loud machinery noise can harm your hearing. Knowing these risks is essential for staying safe and acting carefully.

Highlighting the importance of risk assessment

Risk assessment plays a pivotal role in machinery safety. It involves systematically identifying hazards associated with specific machinery or operations and evaluating how likely these hazards are to cause harm. This process helps in determining the necessary preventive measures to minimize risks, such as modifying equipment, implementing safety protocols, or providing specialized training. An effective risk assessment is not a one-time activity but must be regularly updated to adapt to any changes in the work environment or machinery.

Essential Safety Tips for Safeguarding Yourself

To minimize the risks involved in machinery operation, several key safety tips should be observed.

Proper training and certification for machinery operation

Correct operation is fundamental to machine safety. Operators should undergo comprehensive training specific to the machinery they will be using. This training should cover the machine's operating procedures, emergency stop mechanisms, and potential hazards. Additionally, obtaining certification where required ensures that operators have met a recognized standard of competence.

Using personal protective equipment (PPE)

Personal Protective Equipment (PPE) is your last line of defense against injuries. Depending on the machinery and operation, PPE could include safety goggles, hard hats, hearing protection, gloves, and steel-toed boots. Ensuring that PPE is properly fitted, in good condition, and used at all times during operation can significantly reduce the risk of injury.

Maintaining a safe working environment

A safe working environment encompasses proper Machine Maintenance, a clean and organized workspace, and clearly marked hazard and emergency areas. Regular maintenance checks and timely repairs prevent machinery malfunction, a common cause of accidents. Keeping the workspace free of clutter reduces the risk of tripping or collision. Signage and floor markings help guide operators and alert them to potential hazards. Establishing and enforcing safety protocols promotes a culture of safety that protects everyone in the workplace.

Operational Best Practices

When working with machinery, safety isn't just a recommendation—it's a necessity. Following the rules can greatly lower the chances of accidents and injuries. Let's explore these guidelines more deeply.

Following machinery operating instructions

Every piece of machinery comes with its own set of operating instructions, and for good reason. Whether it’s your first or hundredth time using a machine, always review the manual and adhere to the manufacturer’s guidelines. This ensures not just your safety but also the longevity of the equipment.

Regular equipment inspections and maintenance

Routine checks can catch potential hazards before they become dangerous. Develop a schedule for inspecting and maintaining machinery, focusing on areas prone to wear and tear. Machinery repair and industrial maintenance are key to preventing unexpected failures and costly downtime.

Emergency Preparedness

Being prepared for emergencies is as crucial as preventing them. Know the risks associated with each piece of machinery and plan accordingly.

Developing and practicing emergency response plans

Create clear, accessible emergency response plans detailing what to do in case of machinery failure, accidents, or injuries. Regularly practice these scenarios with your team to ensure everyone knows their role during a crisis.

First aid training for machinery-related injuries

Knowing first aid is crucial for dealing with workplace injuries. It equips employees with the necessary skills to provide immediate care before professional help arrives, which could save lives and avoid further damage. It's not enough to just be careful around machinery; safety needs to be a constant priority. The safety tips we have shared are easy ways to make the workplace safer. Following these guidelines every day can lead to big improvements.

At the Hamilton Machine, safety is integral to all we do. Our safety measures surpass standard industry practices for the protection of our employees and clients. We include comprehensive training, strict protocols, and ongoing risk monitoring, all to create a secure work environment. We provide thorough training, enforce strong guidelines, and constantly monitor any risks to maintain a safe workplace.

Count on a trusted industry leader who prioritizes quality, safety, and customer satisfaction. Contact us today to learn more about how Hamilton Machine can support your business needs.

0 notes

Text

Can Preventive Maintenance Services Enhance Equipment Lifespan?

In today's industrial landscape, maintaining equipment reliability and longevity is crucial for maximizing operational efficiency and minimizing downtime. Preventive maintenance services have emerged as a proactive approach to equipment management, aiming to identify and address potential issues before they escalate into costly breakdowns. The question arises: Can preventive maintenance services truly enhance equipment lifespan? Let's delve into the significance of preventive maintenance and its role in prolonging the lifespan of machinery and assets.

Preventive maintenance involves scheduled inspections, routine upkeep, and timely repairs aimed at preserving equipment functionality and performance. Unlike reactive maintenance, which addresses problems after they occur, preventive maintenance focuses on proactive measures to prevent failures and extend equipment lifespan. By adhering to a structured maintenance schedule, organizations can detect and rectify issues early, thereby reducing the likelihood of unexpected breakdowns and associated production interruptions.

One of the primary ways preventive maintenance enhances equipment lifespan is by mitigating wear and tear. Machinery subjected to continuous operation experiences gradual degradation due to friction, vibration, and environmental factors. Regular maintenance tasks such as lubrication, cleaning, and alignment adjustments can significantly reduce the rate of deterioration, thereby prolonging the usable lifespan of equipment components. By addressing minor issues before they escalate, preventive maintenance helps preserve the integrity of critical machinery parts, extending their operational longevity.

Furthermore, preventive maintenance facilitates the early detection of potential faults or abnormalities. Through systematic inspections and diagnostic tests, maintenance technicians can identify subtle signs of wear, corrosion, or malfunction that may go unnoticed during regular operation. By promptly addressing these issues through preventive measures such as part replacement or recalibration, organizations can prevent catastrophic failures and costly repairs down the line. This proactive approach not only safeguards equipment integrity but also minimizes the risk of unscheduled downtime, thereby optimizing overall productivity and efficiency.

Another key benefit of preventive maintenance is the optimization of equipment performance and energy efficiency. Over time, mechanical components may experience deviations from optimal operating parameters, leading to decreased efficiency and increased energy consumption. By conducting regular tune-ups and performance evaluations as part of preventive maintenance routines, organizations can ensure that equipment operates at peak efficiency levels. This not only extends equipment lifespan by reducing strain and excessive wear but also results in significant cost savings through lower energy bills and improved operational performance.

Moreover, preventive maintenance fosters a culture of reliability and accountability within organizations. By prioritizing equipment upkeep and investing in proactive maintenance strategies, businesses demonstrate a commitment to operational excellence and customer satisfaction. Employees are encouraged to take ownership of equipment maintenance tasks and report any issues promptly, thereby fostering a collaborative environment focused on continuous improvement and risk mitigation.

In conclusion, the implementation of preventive maintenance services can indeed enhance equipment lifespan and optimize operational performance. By adopting a proactive approach to equipment management, organizations can mitigate wear and tear, detect potential faults early, and optimize energy efficiency, thereby prolonging the usable lifespan of machinery and assets. However, to fully realize the benefits of preventive maintenance, organizations must partner with reliable and experienced service providers like Nanoprecise. With their expertise in predictive maintenance technologies and advanced diagnostics, Nanoprecise offers tailored solutions designed to maximize equipment reliability, minimize downtime, and extend lifespan. By leveraging innovative maintenance strategies and cutting-edge technology, Nanoprecise empowers organizations to achieve sustainable operational excellence and unlock the full potential of their assets in today's competitive marketplace.

Know more: https://nanoprecise.io/

Contact number: +91 080 48811211 ,

Email: [email protected]

0 notes

Text

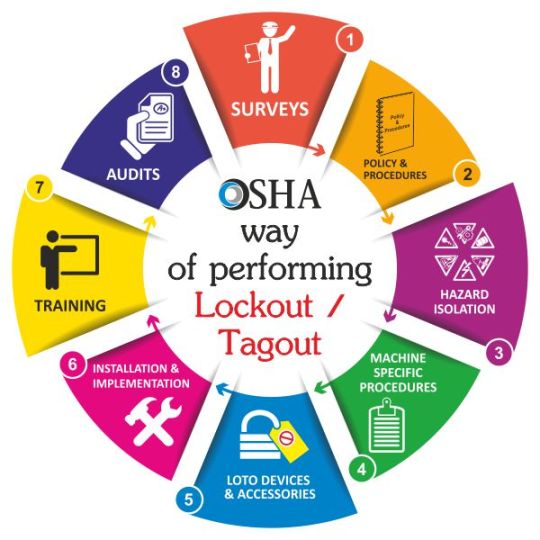

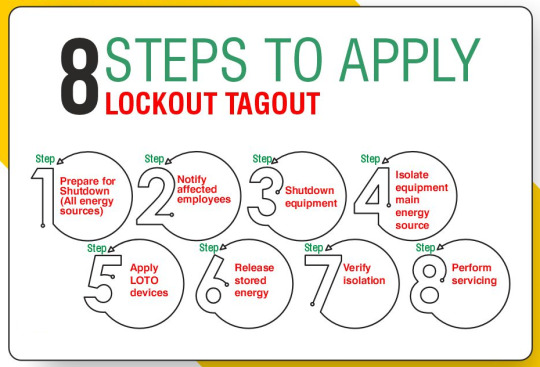

Ensuring Workplace Safety: No Shortcuts in Lockout Tagout Procedures - Follow Established Protocols

Progressing technologies and globalisation have not only changed the way the work is done in industries but also expanded the borders for machine productivity and innovation. The growing globalised world encompasses high-speed machine production techniques, with every company chasing increasing profits. This pursuit of development has had negative and positive effects on employees working in such industries.

World economy liberalisation, rapid technological advancement, significant improvements in basic infrastructure, changing employment trends, adjustments to work organisation procedures, size, structure, and developmental stages of businesses, can all lead to the creation of new types of hazards, exposures, and risks. Workers performing operations, specified procedures, and regular maintenance or installation on machines or equipment face special hazards due to the nature of their work.

The scope of controlling hazards in the workplace has been evolving slowly but surely thanks to social, economical and technological changes. Occupational Safety and Health is the prediction, identification, analysis, and management of occupational hazards that might harm employees' health and well-being while taking into consideration any potential effects on nearby communities and the natural environment in general.

Occupational Safety and Health has been a part of many safety organisations such as OSHA, NIOSH and ILO for years, with continuously improving regulations. OSH is necessary to create a solid and effective workplace environment by developing a culture of personal preventative measures.

It is every employer’s duty to develop, enforce and guide employees on occupational safety protocols to ensure workers’ health, safety and welfare at work. But, the most lengthy and rigorous safety procedures are pointless if the employees and employers do not create a safe work culture wherein every employee wants to implement safety measures to protect himself and others around him.

Unfortunately, many employees and businesses don’t understand the importance of safety procedures. They are always ready with excuses like “we had to restart production and didn’t have enough time”, “we didn’t know about these procedures”, or “I am experienced in this; I have done this countless times”. All these excuses do not exempt workers from the compliances related to Occupational Health and Safety or safeguard them in case of an accident.

In 80% of all accidents, the individual responsible was a part of the production/maintenance activity. Most workers are in a hurry to get the work done, especially when facing pressure from top management. More experienced and older employees feel that applying safety measures like machine guards or Lockout Tagout takes away from production time when they could simply perform the task safely like they have done before. Regrettably, far too many workers and managers want to find "solutions" or justifications for the incident rather than focusing on its primary cause, which almost always involves individuals acting dangerously. More accidents and injuries result from risky and careless behaviours than from harmful surroundings.

“Shortcuts cut your life short” is an infamous quote about life, especially when it comes to safety. Every day employees take certain actions to make their job easier and more efficient without thinking about the negative consequences of such actions. Workers working on heavy machinery tend to use shortcuts while performing tasks to avoid ‘wasting time on burdensome safety procedures’, for instance - using a pipe or a log to erect or stabilise a machine part, cleaning equipment without shutting it off, using a hand or leg to push materials down a hatch. Their reason for utilising such methods vary from ‘not having the correct knowledge to implement effective measures’ to ‘alternative measures are just as effective’.

At the corporate, federal, and international levels, the financial costs of these accidents and fatalities are enormous. Intentionally neglecting to follow safety regulations might jeopardise the authorised employee and his coworkers. Assessments of these damages are typically set at about 4% of global GNP annually, taking into account employee reimbursement, missed work time, disruption of business, training and retraining, hospital expenses, and other costs.

While the majority of workers are fortunate enough to get away with operating unprotected equipment for long periods, it's rather alarming to consider how quickly someone may sustain a significant or drastically life-altering injury. Workers and supervisors might offer several explanations for not enforcing and implementing safety procedures, but it is the duty of top management to make sure that all employees not only follow the established guidelines but also show concern towards their own health and safety. Alongside enforcing protocols, safety programmes should educate workers on the risks and present concrete examples of workplace risk exposure. Both employees and employers are required to be aware of their actions at all times. When each of them operates safely, then everyone will be able to return home in the same condition every day.

#Lockout Tagout#Safety#Lockout Tagout Procedures#LOTO Accidents#OSHA#Workplace Safety#Workers Safety#Avoid Shortcuts at Workplace#Machine Maintenance

0 notes

Text

Navigating the 4M Changes in the Workplace: A Comprehensive Guide

Every workplace undergoes changes, and how we manage them can significantly impact our operations’ success. The 4M changes—Man, Machine, Material, and Method—are critical areas where alterations might occur. Today, we dive into a detailed work instruction (WI) sheet designed to navigate these changes effectively. Man Changes in personnel, whether due to leaves, new operators, or job rotations,…

View On WordPress

#4M changes#containment action#dimensionality check#machine maintenance#manufacturing#material sourcing#method alteration#operational management#Operator training#planned change#process deviation#process parameters#Quality Assurance#record keeping#retrospective inspection#set-up approval#unplanned change#Visual Inspection#work instruction

0 notes

Text

Unlocking Efficiency and Purity: Exploring the Range of Shree Vishwakarma Magnetic Separators

Shree Vishwakarma Magnets, a reputable producer, manufactures high-quality, customizable Magnetic Separators including Wet Magnetic Separator, Overband Magnetic Separator, Hump Magnetic Separator, and Roller Type Magnetic Separator. Magnetic separators play a pivotal role in ensuring efficiency, purity, and quality. They're renowned for quality and customer satisfaction, delivering efficiency and purity to industries. This magnetic separator not only enhances the overall efficiency of numerous operations but also extends the life of machinery and equipment. Contact us for bulk orders and optimize your processes.

#Magnetic Separators#Industrial Equipment#Efficiency#Quality Control#Manufacturing#Customization#Bulk Orders#Machinery#Industrial Solutions#Purity#Magnetic Technology#Customer Satisfaction#Production Efficiency#Magnetic Innovation#Machine Maintenance#Process Optimization#Industry Solutions#Magnetic Performance#Reliability#Shree Vishwakarma Magnets#Wet Magnetic Separator#Overband Magnetic Separator#Hump Magnetic Separator#Roller Type Magnetic Separator

1 note

·

View note

Text

youtube

Another teardown video! This time, this machine is going to a new owner! The new recipient of this well loved machine will be @theshitpostcalligrapher for their future sewing shenanigans!

Watch as I go through parts, try to locate where a mystery part goes, and strugglebus through taking apart a Singer Esteem II, and putting it all back together, while adjusting the needle arm for smoother stitches!

#sewing#youtube#diy#do it yourself#sewing machine#singer#singer sewing machine#repair#maintenance#sewing machine maintenance#Youtube

254 notes

·

View notes

Text

Floating Stasis.

Now available for purchase on INPRNT

#lab#laboratory#stasis#floating#pool#machine#operator#surgery#liquid#cyberpunk#android#cyborg#cables#regular#recall#maintenance#deep#feels#suspension#system#illustration#digitalartwork#digitalart#digitaldrawing#digitalsketch#drawing#scifi

2K notes

·

View notes

Text

been thinking about something wicked a little too much lately. no harm in romanticizing the ominous dreadful unstoppable force

#ultrakill#v1#v1cked#<- unsure if ive ever officially decided that was the tag id be using but i dont recall anyone else having an idea for it#v1 and something wicked... ouhehehe#in a game like this... with conflict and violence and unceasing demand for a spectacle it is a step back to have v1 find themselves in a-#dark and quiet labyrinth belonging to a force that scares even them#idk. i think about it. its so unlike everything v1 has gone through thus far (though albeit not much as 0-S is in prelude. but i assume-#-there was some killing before they decided to drop down)#maybe it reminds them of their home? where they were built? light humming of wicked passing feels like the buzzing of bright artificial-#-lights that were routinely shined down on them for maintenance#a strange but welcome connection...#and something wicked is very lonely. i dont think it has much of an issue with this seeing as it knows its maze so so well.. im sure it-#-cares for it extensively. but a machine? coming here? i wonder if something wicked has the ability to interact with the terminals at all#terminals do really only talk to machines#but this one seems quite lonely. i dont think itd mind if something wicked happened to take a look#ok im done#gen art

566 notes

·

View notes

Text

hey remember when you were feeling anxious, frustrated, panicked, whatever that emotion was, and then

you set a timer for 30 minutes and stretched and worked out aerobically? and while the core struggle isn't gone, it didn't feel so scary anymore?

this is your reminder that it helped. you should probably do it again, and give yourself a sticker about it

#this is @ me but maybe it will help you too#reminders#self maintenance#i literally do have a little sticker book of stars that is taped on my rowing machine. i love it

685 notes

·

View notes

Text

from “Rethinking High Maintenance: The Queer Fat Femme Guide to Not Blaming It on the Fact That You Don’t Like High Femmes” by Bevin Branlandingham

published in Persistence: All Ways Butch & Femme, ed. Ivan E. Coyote & Zena Sharman (2011)

Backstage at a show I was hosting, burlesque legend World Famous *BOB* told me a story about how a (now former) beau had called her high maintenance.

“I called my drag mom and asked if she thought I was high maintenance. She said ‘Of course you are, but you maintain yourself. You’re like a classic car; if someone is going to drive a ’66 Caddy, they will. If they want a Honda, they should drive a Honda.’”

The rhetoric of what is considered “high maintenance” in our community is judgmental and unfairly targets femmes.

The definition of high maintenance I am working from is something, much like the aforementioned classic car, that takes a lot of work to keep in running order. This can be aesthetic work—makeup, hair care, attention to fashion—or emotional, physical, or intellectual expectations that need to be met in order for the person who is high maintenance to be running in top condition.

In the queer community, there seems to be a very negative value judgment on the so-called high-maintenance feminine aesthetic. There are hundreds of stories of femmes coming out of the closet only to be shamed into an androgynous or butch appearance because they wanted to fit into the lesbian or queer community, but femmephobic people called them not queer enough. There is nothing in my lipstick case that prevents me from being queer, and realizing that took an entirely separate coming-out process.

We should remove the value judgment from the phrase high maintenance, since it should have nothing to do with anyone other than the person being maintained. Everyone can be high maintenance in their own ways; it’s all just a matter of whether or not one person’s maintenance is compatible with another person’s.

#femme#high femme#queer femme#bevin branlandingham#high maintenance#quotes#image described#mac’s bookshelf#twin high maintenance machines#everything goes back to femme#frogging#she steals the show (she is the show of difference)

156 notes

·

View notes

Text

Getting into the nooks and crannies with mineral spirits this morning. Every key that was previously sticking is now smooth as butter

#olivetti#lettera 22#Typewriter#1950s#restoration#machines#maintenance#underwood-olivetti#hobbies#tinkering#ASMR

68 notes

·

View notes

Text

i wish i had a robotic body and wires and PCBs and all that. there's something so romantic about laying in bed and being caressed while someone plugs in your power cord (not even live, just to connect you to ground) and gently and lovingly performs maintenance on your body. spraying wd40 in any creaky joint, cleaning your fans, removing dust from your insides. running her hands through your hair as she closes you back up and a quick kiss to the cheek as she flips the switch back on, allowing you to charge

yes i'm the kind of girl that straddles her pc when working on her.

#i know you don't use wd40 for pc maintenance but i was talking about my hypothetical robot body here#eroticism of the machine#(??)#robot girl

680 notes

·

View notes