#Latent heat storage

Explore tagged Tumblr posts

Text

Understanding Organic Phase Change Materials: Properties and Applications

In the quest for energy efficiency and sustainable solutions, Organic Phase Change Materials (PCMs) have gained significant attention. These materials play a crucial role in thermal energy storage (TES) systems by absorbing, storing, and releasing heat during phase transitions. This blog delves into the fundamentals of organic PCMs, their practical properties, and their applications across various industries.

What Are Organic Phase Change Materials?

Organic PCMs are substances that undergo a phase transition (solid-liquid or liquid-gas) at specific temperatures, enabling them to store and release latent heat. They are primarily derived from paraffin, fatty acids, and esters, making them ideal for environmentally friendly thermal management. Unlike inorganic PCMs, which often suffer from supercooling and phase separation, organic variants offer superior stability, non-corrosiveness, and recyclability.

Practical Properties of Organic PCMs

To better understand the effectiveness of organic PCMs, let's explore some of their key practical properties:

1. High Thermal Stability

Organic PCMs exhibit excellent thermal stability over multiple heating and cooling cycles. This makes them ideal for long-term energy storage solutions.

2. Non-toxic and Biodegradable

Many organic PCMs, especially bio-based fatty acids, are eco-friendly, biodegradable, and non-toxic, making them safer alternatives for building insulation, textiles, and food preservation.

3. Wide Melting Point Range

Organic PCMs can be engineered to have customized melting points, ranging from low-temperature (below 0°C) to high-temperature (>100°C) applications.

4. High Latent Heat Storage Capacity

They offer efficient heat absorption and release, ensuring optimal thermal regulation in HVAC, solar energy, and thermal packaging systems.

5. Chemical Compatibility and Non-Corrosiveness

Unlike inorganic PCMs (like salt hydrates), organic PCMs do not corrode metals, making them more suitable for integrating heat exchangers and encapsulation systems.

Applications of Organic PCMs

The versatility of organic phase change materials has led to their widespread adoption in various industries, including:

Building & Construction: Used in insulated panels, roofing, and walls to enhance thermal comfort and reduce energy consumption.

Renewable Energy: Integrated with solar power storage systems to store excess heat for later use.

Textiles & Clothing: Embedded in smart fabrics and thermal wear to regulate body temperature.

Pharmaceutical & Food Storage: Maintains temperature-sensitive products, ensuring safe transportation and extended shelf life.

Automotive & Aerospace: Enhances thermal management inelectric vehiclesand spacecraft.

Future Trends in Organic PCM Development

With the rising demand for energy-efficient technologies, research is focused on:

Improving thermal conductivity by integrating nanomaterials.

Enhancing phase stability through advanced encapsulation techniques.

Developing bio-based PCMs for sustainable energy applications.

Conclusion

Organic Phase Change Materials offer a sustainable and efficient solution for thermal energy storage, significantly impacting various industries. Their non-toxicity, stability, and high latent heat capacity make them superior choices for environmentally friendly energy solutions. As advancements continue, organic PCMs will play a pivotal role in shaping the future of sustainable energy management.

#Advanced thermal regulation#Fatty acid PCMs#HVAC energy savings#Latent heat storage#Paraffin-based PCMs#Renewable energy storage solutions#Thermal energy storage

0 notes

Text

MXene-enhanced epoxy promises safer, more durable industrial applications

Two-component epoxies, which require mixing resin and curing agent before use, often suffer from issues such as mixing ratio errors, limited working times, and inconsistent curing. Additionally, they must be used immediately after mixing, leading to wasted residue. To address these challenges, one-component epoxies have gained attention. One-component epoxies come pre-mixed, making them easy to use, reducing processing time, and ensuring consistent quality without mixing. In particular, using latent curing agents allows curing to be triggered only under specific conditions (e.g., heat or UV exposure), significantly improving storage stability. However, conventional one-component epoxies are only stable at room temperature (below 25°C), limiting their storage under high-temperature conditions and making them prone to fire hazards.

Read more.

9 notes

·

View notes

Text

The Forbidden Garden of Leningrad by Simon Parkin

This fascinating history of Nikolai Vavilov and the staff at his plant institute tells a story of almost unbelievable self-sacrifice while under siege during the second world war

Is there any human endeavour as heroic or under-appreciated as plant collecting? When in 1921, at the age of 33, Nikolai Vavilov arrived in Petrograd (now St Petersburg) to take charge of the bureau of applied botany and plant breeding, he found a city racked by hunger. War followed by civil conflict had crippled Russia’s food production and distribution systems – a situation compounded by the seizure of peasants’ grain stores by the Bolsheviks – and Petrograd, once the cradle of the Russian empire, had been transformed into a graveyard. Walking along Nevsky Prospekt, Vavilov was appalled to see starving citizens queueing for mouldy bread. “Westward the sun is dropping,” observed the poet Anna Akhmatova, “and already death is chalking the doors with crosses.”

On entering the bureau, Vavilov was even more dismayed to find the heating pipes had burst and the storage units containing nearly 14,000 varieties of wheat, barley, oat and rye collected by his predecessor had been eaten by famished staff. It was, recorded a member of Vavilov’s team, “a picture of almost complete destruction”.

Yet by 1940, Vavilov had secured new premises in a former tsarist palace in the centre of the city and had amassed the largest collection of seeds in the world. It was a collection brimming with “latent life”, writes Simon Parkin in his riveting account of Vavilov’s plant institute, “a Noah’s Ark of plant matter”. Once cultivated and harvested, the seeds contained sufficient genetic material to feed not only the citizens of Leningrad, as the city had been renamed following Lenin’s death in 1924, but the entire population of the Soviet Union. In the process, Vavilov, a tireless polyglot, would become the most celebrated botanist in the world, feted by scientists from Edinburgh to New York. All the more extraordinary, then, that today he is all but forgotten, a victim of the Soviet state’s desire to erase memories of the siege and the millions who perished in the Nazi onslaught.

Karl Marx wrote that “history repeats itself, first as tragedy, second as farce”. The tragedy is that having amassed a collection with the potential to banish famine, Vavilov was arrested on the eve of war and branded “an enemy of the people”. In this, he appears to have been a victim of a bitter struggle with the peasant-agronomist Trofim Lysenko, who had rejected Mendelian genetics for Lamarckism – the idea that plants and other organisms acquire superior traits from their environments rather than from inherited genetic material. Lysenko believed that through a combination of agronomical knowhow and political will, these traits could be passed down to future generations – a theory that Stalin found appealing.

The result was that when in July 1941, the Soviet authorities began fortifying Leningrad in preparation for the German siege and evacuated precious artworks from the Hermitage, Vavilov’s collection was ignored, though whether this was deliberate or a bureaucratic oversight, Parkin cannot say. What he shows, brilliantly, is how the farce of the seeds’ non-evacuation nearly ended in a second tragedy as Vavilov’s colleagues fought to preserve the collection from raids by starving citizens and their own gnawing hunger. Incredibly, of the 250,000 seeds that Vavilov had amassed at the outbreak of war, the majority survived and by 1967, 100m acres of Russian agricultural land had been planted with material from the institute’s collection. Not only that, but wheat collected by Vavilov in Spain, Japan, Italy and Argentina was crossbred to create high-yielding winter varieties, while potatoes from Bolivia were used to breed hybrids resistant to disease. Today, 90% of the seeds and planted crops in the institute’s collection are found in no other in the world.

Writing in 1737, Carl Linnaeus, the father of modern taxonomy, observed: “When I consider the melancholy fate of so many of botany’s votaries, I am tempted to ask whether men are in their right mind who so desperately risk life and everything else through the love of collecting’ plants.” Imprisoned for the duration of the war, Vavilov would never return to his beloved institute and died of hunger in 1943 at a prison in western Russia. Afterwards, ashamed of their persecution of the world-renowned botanist, the authorities destroyed Vavilov’s case file and did their best to discourage journalists from writing about his achievements. The result was that it was not until the late 1970s that Vavilov’s story and the fate of his employees became more widely known. Even so, Parkin’s is the first book to have been published on the subject outside Russia.

To recreate the story, the author has drawn on the institute’s archives and the diaries and letters of the two-dozen staff to whom it fell to guard the collection during the near-900-day siege, one of the longest of any city in history. In the process, he restores Vavilov and his scientific colleagues to their rightful places in the pantheon of Soviet heroes. But perhaps Parkin’s biggest achievement is to explain how the botanists who sat out the siege resisted the temptation to consume the collection. Instead, he details how they defended the seed bank from looters and braved German bombs to plant potatoes at a field station on the perimeter of the city, thereby ensuring they would produce new tubers that could be stored and preserved for the following year.

In the process, 19 staff died, most of them of starvation while surrounded by containers that could have saved their lives. In this they were guided by the conviction that many of the samples were irreplaceable because of the loss of natural habitats from which they had been collected and that they could contain unrecognised genetic qualities. Their resolve was also a product of their loyalty to Vavilov and their belief in the importance of the scientific endeavour. As one survivor told Parkin: “It was impossible to eat [the collection], for what was involved was the cause of your life, the cause of your comrades’ lives.” Astonishingly, this resolve held despite an explicit order from Moscow to “spare nothing” to save the lives of their fellow citizens.

Although Parkin has done a remarkable job of resurrecting the story of this “forbidden garden”, he admits to frustration that his efforts “could not transport me to the white-hot centre of the story”. It is a frustration this reader shares. Despite a wealth of information about the siege, the thoughts, feelings and cravings of Vavilov’s staff remain tantalisingly out of reach. Instead, Parkin ends on a deflationary note, admitting he has no answer to the question of whether in opting to sacrifice the lives of people in the present for the benefit of future generations, the botanists made the correct moral choice.

Daily inspiration. Discover more photos at Just for Books…?

11 notes

·

View notes

Text

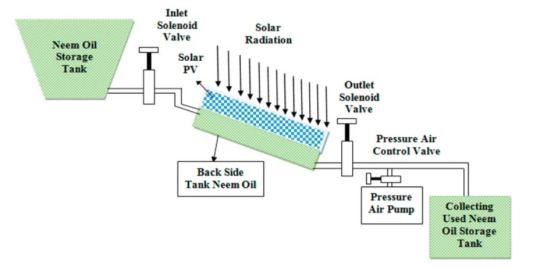

A group of scientists led by Kongu Engineering College in India investigated the use of waste neem oil as a cooling solution for PV modules. Neem oil is extracted from the seeds of the neem tree and is commonly used as a medicine for some skin diseases.

The researchers explained that this oil acts like phase-changing materials (PCMs), which can absorb, store, and release large amounts of latent heat over defined temperature ranges. PCMs have often been used at the research level for PV module cooling and the storage of heat.

“The neem oil has a good thermal range, is physically high in density, is chemically stable and noncorrosive, is environmentally pollution-free, reusable, and recyclable, and is economically low-cost and easy to dispose of,” they added. “Commonly, any PCM used for cooling purposes should have low thermal conductivity, stability, and cycling. The neem oil has fulfilled all the limitations.”

9 notes

·

View notes

Text

On March 27th 1923, Sir James Dewar, the inventor of the vacuum flask, died.

Dewar is probably best known today for his invention of the vacuum flask, which he used in conjunction with extensive research into the liquefaction of gases. He was also particularly interested in atomic and molecular spectroscopy, working in these fields for more than 25 years.

His name is most widely known in connection with his work on the liquefaction of the so-called permanent gases and his researches at temperatures approaching absolute zero. His interest in this branch of physics and chemistry dates back at least as far as 1874, when he discussed the “Latent Heat of Liquid Gases” before the British Association.

About 1892, the idea occurred to him of using vacuum-jacketed vessels for the storage of liquid gases. The Dewar flask (otherwise known as a Thermos or vacuum flask) was the invention for which he became famous for inventing. The vacuum flask was so efficient at keeping heat out, it was found possible to preserve the liquids for comparatively long periods, making examination of their optical properties possible. Dewar did not profit from the widespread adoption of his vacuum flask as he lost a court case against Thermos concerning the patent for his invention. While Dewar was recognised as the inventor, because he did not patent his invention, he was unable to stop Thermos from using the design

10 notes

·

View notes

Text

The GOT Studio Tour has won the UKInbound Sustainable Tourism Provider of the Year award.

While the sets and items on display are themselves impressive, the Earth-friendly HVAC systems for the location are what earned them the award.

Recognised at the tourism industry group’s recent annual convention, Game of Thrones Studio Tour was hailed as a ‘world-class ultra-low carbon visitor attraction’. Located at the principal film studios for Game of Thrones – Linen Mill Studios in Banbridge, Co Down – the immersive tourist destination invites fans of TV and film to go behind the scenes and discover the artistry that went into making the TV phenomenon. [ ... ] The Studio Tour’s priceless original film sets and assets are protected within the 110,000 sq. ft visitor experience by an HVAC system with close temperature and humidity control, sensible and latent heat recovery, free cooling and a modular zero-carbon heating system with energy storage. The UKInbound judging panel were already impressed by many aspects of the Sustainable Management plan at Game of Thrones Studio Tour and the scope of future aspiration. UKinbound CEO, Joss Croft, said: “A key part of our new sustainability strategy, is to showcase our member businesses who are doing great work to reduce energy usage and protect and regenerate the environment. In the future, we will use the practices and initiatives used by Game of Thrones Studio Tour to inspire our other members to take similar action in their businesses.”

In the near future I hope that ultra-low carbon systems such as this will be the norm rather than the exception.

#game of thrones#game of thrones studio tour#northern ireland#county down#ukinbound sustainable tourism provider of the year#ultra-low carbon#gra o tron#trône de fer#kampen om jerntronen#pemainan takhta#jogo dos tronos#juego de tronos#trono di spade#taht oyunları#trò chơi của ngai#cluiche na corónach#valtaistuinpeli#hra o trůny#isang kanta ng yelo at apoy#гра престолів#왕좌의 게임#权力的游戏#ゲームの玉座#صراع العروش#গেম অব থ্রোনস#تخت کے کھیل#गेम ऑफ़ थ्रोन्स#ഗെയിം ഓഫ് ത്രോൺസ്#משחקי הכס#игра престолов

2 notes

·

View notes

Text

A Guide to Understanding the Design and Applications of the Box Type Condenser: An Exploration

The box-type condensers are very essential in the thermal management of various industrial and commercial applications, wherein they are simply referred to as box-type condensers or merely condensers in HVAC systems. Let's find out the features and uses of box-type condensers and why they are important for HVAC systems.

What are box-type Type Condensers? Box-type condensers are modules in air conditioning and refrigeration systems used to abbreviate refrigerant vapor into liquid. They got the name "box type" because of their normally enclosed, small design that wraps up all the parts requisite for concentration and heat exchangers.

How do they function? Heat Exchanger: Box-type condensers work with the principle of heat exchanger. The hot refrigerant vapor from the compressor enters the condenser coils in the box-type unit. Condensation: Depending on the condenser type, heat is lost by the refrigerant vapor while it is traveling through coils and abbreviating into liquid form. Cooling: During condensation, latent heat from the refrigerant is given out and dissipated through the fins or tubes into the condenser. As a result, the refrigerant can be cooled again and set up to start the cycle. Key Features and Components Coils: Inside the condenser box, these are normally copper or aluminum and effectively conduct the heat from the refrigerant to the surrounding medium. Fans of Water Flow: In an air-cooled system, box condensers are fitted with fans that force the ambient air over the coils, while in a water system, they are cooled by having the water flow through the coils. Enclosure: The process guides air or water flow via the condenser coils in a box-type condenser and ensures the enclosure protects all the interior components and promotes effective heat exchanger performance. Applications Box-type condensers for integral components in many HVAC applications include commercial refrigeration. Low-temperature refrigeration systems are used in supermarkets, restaurants, and cold storage facilities. Air conditioning systems form a huge part of domestic and commercial air conditioners, which help make indoor temperatures bearable by extracting heat. It finds applications in chemical processing and manufacturing facilities, and industrial cooling is used where exact temperature control is required in processes. Heat Pumps: Box-type condensers play a crucial role in heat pumps by facilitating the transfer of heat between different environments. Considerations When choosing or maintaining box-type condensers, considerations include: Ensure that the size and capacity suit the air conditioning or refrigeration system in which it is installed. Maintenance: Cleanliness of coils and fans should be ensured to gain maximum heat transfer efficiency and extend the life of the condenser. Environmental Factors: This condenser will work best considering the outside variables like humidity and ambient temperature. Conclusion Box-type condensers have uppermost importance in every HVAC system; in their absence, no effective heat transfer and standard functioning of the air conditioning or refrigeration systems could be sought. Notwithstanding their small size, their efficient heat exchanger properties make them perfect in service for innumerable uses in different sectors of the economy. By selecting the appropriate condenser regarding the requirements and understanding of how it works, a guarantee is given for full, reliable, and efficient operation of the thermal management systems. Rahul Engineering Global Pvt. Ltd. specializes in providing advanced and high-quality box-type condensers in Pune, India, solutions for various industries.

0 notes

Text

Battery pack cooling methods

1. Air cooling

Air cooling uses air as a heat transfer medium and is divided into two methods: passive air cooling and active air cooling. Passive air cooling directly uses external air for heat exchange, has a simple structure, and is low in cost, but has limited cooling effect. Active air cooling pre-processes external air before it enters the battery system, such as heating or cooling, to improve cooling efficiency. However, the thermal conductivity of air cooling is low, and it is difficult to meet the thermal management requirements of high energy density batteries.

2. Liquid cooling

Liquid cooling uses coolant as a heat transfer medium, which is usually circulated in the battery pack through a pump and piping system. According to the contact method, liquid cooling can be divided into direct contact and indirect contact. Direct contact directly immerses the battery pack in the coolant, while indirect contact arranges cooling pipes or jackets between battery modules. Liquid cooling has the advantages of high cooling efficiency and good temperature uniformity, but it has high requirements for the sealing of the system and increases the complexity and weight of the system.

3. Heat pipe cooling

Heat pipe cooling uses the latent heat of phase change materials during evaporation and condensation to transfer heat. The heat pipe consists of an evaporation section, an insulation section, and a condensation section, which can quickly conduct heat and achieve efficient cooling. However, the heat pipe has a complex structure, high manufacturing cost, and the heat transfer performance may decrease after long-term use. It has not yet been widely used in battery thermal management systems.

4. Phase change material cooling

Phase change material (PCM) absorbs or releases a large amount of heat by changing its physical state within a specific temperature range. When PCM is applied to a battery thermal management system, it can absorb heat and reduce the battery temperature when the battery temperature rises. However, PCM has a low thermal conductivity and may have a risk of leakage. It needs to be used in combination with other cooling methods to improve the cooling effect.

5. Immersion cooling

Immersion cooling directly immerses the battery in the coolant, which has the advantages of simple structure, rapid cooling, and good temperature uniformity. Compared with traditional indirect liquid cooling, air cooling, and phase change cooling, immersion cooling shows good application prospects in the thermal management of high power density batteries.

Effective battery pack cooling technology is essential to improve battery performance, extend service life, and ensure safety. As battery energy density and charge and discharge rates increase, a single cooling method is difficult to meet the demand, and composite cooling technology shows broad application prospects. Future research should focus on developing efficient, lightweight, and cost-controlled cooling systems to adapt to the rapid development of electric vehicles and energy storage systems.

0 notes

Text

Exporter of Multi Effect Evaporator in Guinea Drytech Engineering Systems is a leading Manufacturer and Exporter of Multi Effect Evaporator in Guinea.

Drytech Engineering Systems is Multi Effect Evaporator Manufacturer based in Ahmedabad, Gujarat, India.

A Multi-Effect Evaporator is a system that uses multiple evaporation stages arranged in a series. Each stage operates at progressively lower pressures, resulting in more efficient energy usage during evaporation.

The system typically uses steam as the heat source, making it a cost-effective solution for concentrating liquids and recovering valuable products.

Types of Multi-Effect Evaporators: Fully Automatic Multi-Effect Evaporator: Designed for high automation, requiring minimal human intervention during operation.

Semi-Automatic Multi-Effect Evaporator: Offers a balance of automation and manual control, allowing for flexibility in operation.

Working Principle of a Multi-Effect Evaporator: Liquid Introduction: The liquid to be concentrated is introduced into the first effect, typically through a feed pump. The liquid flows through each effect in a controlled manner.

Heat Transfer: The system introduces steam into the first effect. The steam condenses on the heat exchanger surface, transferring latent heat to the liquid. This causes the liquid to evaporate, and the resulting vapor flows to the next effect.

Vapor Recompression: In each subsequent effect, the vapor generated from the previous effect acts as the heating medium.

It condenses on the heat exchanger surface, transferring heat to the liquid in the current effect and causing further evaporation.

Concentrated Liquid Collection: The liquid in the final effect becomes highly concentrated. It is then collected for further processing or storage.

The system condenses the remaining vapor in a separate condenser, forming a distillate that can be recovered or disposed of.

FAQs. How does the multi-effect evaporator conserve energy? The multi-effect evaporator stages the evaporation process, using the vapor generated in one effect to heat the next.

This vapor recycling significantly reduces the amount of fresh steam needed for the process, conserving energy.

What is the expected lifespan of a multi-effect evaporator? With proper maintenance, a multi-effect evaporator can last for several years. Factors like the type of liquid being processed, operating conditions, and maintenance practices determine the lifespan.

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Guinea including locations Conakry, Nzérékoré, Kankan, Manéah, Dubréka, Kindia, Siguiri, Kissidougou, Labé, and Kamsar.

For more information on our multi-effect evaporators and to discuss your specific needs, please contact Drytech Engineering Systems today!

0 notes

Text

Winter-Proof Your Hot Water Supply With Heat Pumps

Many homeowners are struggling to maintain a reliable hot water supply now that winters have arrived. Gas or electric water heaters may be inefficient, particularly in colder climates, and traditional water heaters may find it difficult to meet rising demand. Thankfully, heat pumps are the best option for winters as they offer a steady supply of hot water, while also maximizing energy economy. Let’s discuss below how heat pumps function in colder climates, how to winter-proof your hot water supply, and how to maximize their effectiveness during the winters.

How heat pumps work during winters

It is untrue to say that heat pumps are only effective in warm climates. Even though heat pump efficiency somewhat declines with decreasing temperatures, contemporary systems are prepared to withstand cold weather. Because they use heat from the surrounding air to heat water, they can also work in colder climates by drawing latent heat from the atmosphere, thus bringing about reliable hot water supply along with energy efficiency. Heat pumps are thus a good year-round option for water heating as they can still extract heat from the outside air during the colder months. At lower temperatures, the refrigerant in the system can absorb and transfer heat. A lot of heat pump models are made to work in temperatures as low as -15°C (5°F). Some even include features like defrost cycles, which provide a steady and dependable supply of hot water throughout the winters.

The efficiency of heat pumps during cold weather

The efficiency of heat pumps is one of their primary benefits. Heat pumps only transfer heat from one location to another, in contrast to traditional water heaters that produce heat by burning fuel or utilizing electricity. With some models generating up to four times as much energy as they require, this technique is noticeably more energy-efficient. Heat pumps still consume less energy than traditional systems. Even at low temperatures, modern systems are built to maintain a high coefficient of performance (COP). A heat pump can generate several units of heat for each unit of electricity used, hence the COP provides a gauge of the system’s efficiency. To put this into perspective, a heat pump that runs in the winter can still have a COP of two or three, which means that it generates two to three times as much energy as it uses. Compared to electric resistance heaters, which often run at a COP of 1, this is still a significant gain.

Tips for maximizing heat pump efficiency in winter

Even though heat pumps are made to operate in colder climates, homeowners can take a few precautions to guarantee peak efficiency and performance throughout the winter. These useful pointers will help you get the most out of your heat pump when the weather drops.

Optimize the placement: The effectiveness of your heat pump is strongly influenced by its placement. Make sure your heat pump is positioned to capture as much ambient heat as possible in order to get the most out of it throughout the winter months. Since strong winds might reduce the effectiveness of heat extraction, the unit should ideally be positioned in a well-ventilated region. The outdoor unit should ideally be placed away from places where ice or snow buildup could obstruct airflow, causing frost buildup and decreased efficiency. Maintaining adequate clearance around the unit aids in the system’s ability to continue heating throughout the winter.

Insulate the pipes and tanks: Insulate your storage tanks and hot water pipes to prevent heat loss. Given the lower outside temperatures throughout the winter, this is particularly crucial. Insulation lowers the burden on the heat pump and increases overall energy efficiency by assisting in maintaining the water temperature. Furthermore, confirm that the tank temperature is adjusted to its ideal setting. Setting it too low could result in an inadequate supply of hot water, while setting it too high will waste energy.

Use a timer and smart controls: Energy usage can be reduced by employing smart controls or installing a timer. Numerous heat pump systems have built-in timers and controls that let you plan hot water heating only when it’s needed, saving energy during off-peak hours. You can optimize the heating hours and make sure hot water is available when you need it without the system having to work overtime during periods of low demand by coordinating your heat pump with your household’s routine.

Opt for regular maintenance and cleaning: Heat pumps need routine maintenance to function effectively, just like any other heating equipment. Problems like accumulated dirt, frozen coils, and clogged air filters can be made worse by winter conditions. To guarantee ideal airflow and avoid frost accumulation, check and clean the outdoor unit on a regular basis. Ice may accumulate on the exterior coil of the heat pump throughout the winter. To avoid ice buildup, make sure the defrost cycle is operating correctly. Even though many contemporary heat pumps have automated defrost features, routine maintenance and inspection are still essential to the system’s proper operation.

Choosing the right heat pump for the winters

It’s crucial to pick a heat pump model that can withstand low temperatures when choosing one for colder climates or the winter months. Heat pumps are not all made equal. Numerous manufacturers provide systems with features like variable speed compressors, improved defrost cycles, and more. Consult a reliable specialist to determine the best option for your requirements, and take pleasure in a cozy and warm winter with little effect on the environment. Vindsol’s domestic heat pump in Bangalore is the ideal choice that is made to function best in colder locations, guaranteeing dependable hot water and lower energy usage throughout the winter.

Winter-proofing your hot water supply with a heat pump is a practical and economical way to deal with the colder months. In addition to providing reliable hot water – even in subfreezing temperatures – these systems can lower your home’s carbon footprint while lowering your energy bills.

Resource: Read more

#Vindsol#HeatPumps#EcoFriendly#EcoFriendlyHeatingSolutions#SustainableLiving#HotWaterSolutions#HeatingSolutions#HeatPumpsBangalore#WaterHeater#WaterHeating#CommercialHotWaterHeatPumps

0 notes

Text

Peak Shifting: A Smart Way to Save Energy in Cold Storage, HVAC, and Data Centers

Introduction Energy costs are a big concern for industries like cold storage, HVAC (Heating, Ventilation, and Air Conditioning), and data centers, which require a continuous supply of power to function effectively. These sectors often face high electricity bills, especially during peak hours, when energy demand is at its highest. To combat these rising costs and improve energy efficiency, many companies are turning to a concept called peak shifting. One technology that makes peak shifting possible is Phase Change Materials (PCMs), which are revolutionizing the way energy is stored and used.

In this blog, we’ll explore what peak shifting is, how it can benefit cold storage, HVAC systems, and data centers, and how Tan90’s PCMs—specifically designed to operate at 0°C and -24°C—play a critical role in this energy-saving strategy.

What is Peak Shifting?

Peak shifting is an energy management strategy that involves shifting electricity usage from periods of high demand (known as peak hours) to times when the demand is lower (off-peak hours). Peak hours typically occur during the day, when businesses and households are using the most power. Because energy is more expensive during these times, shifting the demand to off-peak hours can lead to significant cost savings.

For example, instead of running energy-intensive cooling systems during peak hours, businesses can store the cooling energy during off-peak times and use that stored energy during peak hours. This helps balance electricity usage and avoid higher rates charged during peak periods.

Why Peak Shifting is Important for Cold Storage, HVAC, and Data Centers

Industries like cold storage, HVAC, and data centers require round-the-clock cooling, making them large consumers of electricity. Let’s take a closer look at how each of these industries can benefit from peak shifting:

Cold Storage: Cold storage facilities must maintain consistent, low temperatures to prevent spoilage of food, pharmaceuticals, and other perishable goods. Operating refrigeration systems during peak hours is costly. Peak shifting allows cold storage facilities to use PCMs to freeze cooling energy during off-peak hours and release that energy to maintain low temperatures during peak hours, reducing energy costs without compromising product safety.

HVAC Systems: In commercial and residential buildings, HVAC systems regulate temperature, air quality, and humidity. These systems consume a lot of energy, particularly during peak demand times when cooling needs are highest. Peak shifting allows HVAC systems to cool PCMs during off-peak times and use that stored energy during peak hours. This reduces electricity consumption during the day while keeping the indoor environment comfortable.

Data Centers: Data centers are critical to the operation of businesses worldwide, as they store vast amounts of data and require significant cooling to prevent overheating. Running cooling systems continuously can result in high electricity bills, especially during peak hours. By utilizing peak shifting with PCMs, data centers can store cooling energy during off-peak periods and release it during peak hours, keeping server rooms cool without excessive energy use.

The Role of PCMs in Peak Shifting

Phase Change Materials (PCMs) are substances that absorb and release large amounts of heat as they change from one phase to another (for example, from solid to liquid). This ability to store and release thermal energy makes them perfect for peak shifting. PCMs can freeze or melt at specific temperatures, making them ideal for energy storage in cold storage, HVAC systems, and data centers.

Here’s how they work:

During Off-Peak Hours: The PCM is cooled or frozen using the lower-cost electricity available during off-peak times. This stores energy in the form of latent heat.

During Peak Hours: As the temperature rises, the PCM slowly melts, releasing the stored energy and providing the necessary cooling without drawing power from the grid.

This process helps industries maintain stable temperatures and cooling capacity during high-demand periods, significantly reducing energy costs.

Tan90’s PCM Solutions for Peak Shifting

Tan90 offers specialized PCMs designed for peak shifting in various industries. Two of the key products are PCMs that operate at 0°C and -24°C.

0°C PCM

This PCM is ideal for industries that need to maintain temperatures around the freezing point, such as cold storage for food products, medical supplies, and other perishables. During off-peak hours, the PCM freezes, storing energy. During peak hours, it melts, releasing the stored energy to maintain the required low temperatures. This significantly reduces the need for active cooling systems to run during high-cost times.

For example, in a cold storage facility that houses fruits and vegetables, which need to be kept just above freezing, Tan90’s 0°C PCM can store the cooling energy during the night (off-peak) and release it throughout the day (peak hours), ensuring a stable environment for the produce without relying heavily on electricity during peak hours.

-24°C PCM

This PCM is used in deeper freezing applications, such as frozen food storage or pharmaceutical cold chains. At -24°C, this PCM is ideal for products that need to be kept at sub-zero temperatures. It can freeze during off-peak times, storing energy, and then melt during peak hours, providing consistent cooling. This allows for significant energy savings in industries where maintaining freezing temperatures is critical.

In pharmaceutical cold chains, for example, vaccines or biologics need to be kept at extremely low temperatures. Tan90’s -24°C PCM can store cooling energy during the night and release it during the day, reducing the need for constant refrigeration and saving on energy costs.

Advantages of Using PCMs for Peak Shifting

Cost Savings: One of the biggest advantages of peak shifting with PCMs is the reduction in electricity costs. By storing cooling energy during off-peak hours when rates are lower, businesses can avoid using expensive peak-hour electricity.

Energy Efficiency: PCMs improve the overall energy efficiency of cooling systems. By utilizing stored energy, less electricity is required during peak hours, which reduces the load on the grid and lowers overall energy consumption.

Sustainability: Reducing peak-hour energy consumption is not only cost-effective but also environmentally friendly. By using energy more efficiently and reducing reliance on electricity during peak times, businesses can lower their carbon footprint and contribute to a more sustainable future.

Temperature Stability: PCMs help maintain consistent temperatures, which is critical for industries like cold storage and data centers. This ensures that products like food and pharmaceuticals remain safe, and data centers avoid costly downtime due to overheating.

Tan90’s PCM in Shipping: A Real-World Application

PCMs are not just useful for stationary systems like cold storage, HVAC, and data centers; they are also vital in the logistics and shipping industries. During the transportation of temperature-sensitive goods, such as vaccines, Tan90’s PCMs are used in insulated shipping containers to maintain stable temperatures throughout the journey.

The PCM freezes before shipment and then melts during transit, providing consistent cooling without the need for active refrigeration. This method is not only cost-effective but also ensures the safe delivery of products that require strict temperature control.

[Insert Image: PCM used in shipping applications]

Conclusion

Peak shifting, supported by Phase Change Materials, is a powerful strategy for managing energy consumption in cold storage, HVAC systems, and data centers. With Tan90’s innovative PCM solutions, industries can achieve significant cost savings, enhance energy efficiency, and contribute to a more sustainable future.

As energy demands and environmental concerns grow, PCMs offer a practical approach to balancing cost and sustainability. Stay tuned for our next blog post, where we’ll explore more applications of PCMs and their impact on various sectors.

Lear more

0 notes

Text

Boiler Hire: An Essential Service for Industrial and Commercial Needs

Boiler hire is a critical service that supports industries and commercial operations, providing temporary heating solutions during maintenance, breakdowns, or increased demand. Renting boilers offers flexibility, reduces capital expenditure, and ensures continuous operation without disruptions. Whether you require emergency heating solutions, planned maintenance support, or temporary boilers for peak seasons, boiler hire companies deliver bespoke solutions tailored to your specific needs.

This post will dive into the essential aspects of boiler hire, highlighting why it’s an indispensable service, its various applications, and why London Climate Hire is your best choice for boiler hire in the UK.

Why Boiler Hire is a Vital Solution for Industries

For industries that rely heavily on heating systems, such as manufacturing plants, food processing facilities, or construction sites, having a reliable boiler system is essential for uninterrupted operations. Boiler breakdowns can result in costly downtime and even affect product quality. This is where boiler hire becomes an invaluable solution.

Benefits of Boiler Hire:

Cost-Effective: Renting boilers can be far more economical than purchasing a new one, especially for short-term needs. It eliminates the need for hefty upfront investment, maintenance, and storage costs.

Flexible Terms: Boiler hire companies offer a range of options to suit both short-term and long-term projects. This flexibility ensures that businesses pay for only what they need.

Emergency Backup: In case of a sudden boiler failure, a hired boiler can be dispatched and installed quickly, minimizing downtime and keeping operations running smoothly.

Scalability: For industries experiencing seasonal spikes or expanding operations, hiring additional boilers allows them to quickly scale their heating capacity without the need for permanent installations.

Types of Boilers Available for Hire

There is a wide variety of boilers available for hire, ensuring that every business can find the right solution for their specific requirements. Common types of boilers for hire include:

Hot Water Boilers: Ideal for processes that require continuous hot water production, such as hotels, hospitals, and leisure centers. These boilers are available in various sizes and capacities to meet the needs of both small businesses and large industries.

Steam Boilers: These are perfect for industries like manufacturing, food processing, and chemical plants that require steam for their operations. Steam boilers are typically larger and more robust, providing high-pressure steam to meet the rigorous demands of these industries.

Electric Boilers: Environmentally friendly and highly efficient, electric boilers are suitable for areas where gas or oil is not readily available. They produce no emissions and are an excellent choice for companies looking to reduce their carbon footprint.

Condensing Boilers: Known for their energy efficiency, condensing boilers capture the latent heat in the exhaust gases, which would otherwise be wasted, and use it to heat water, reducing energy consumption and costs.

At London Climate Hire, we offer a comprehensive range of these boilers, ensuring that we can cater to any industry or business requirement.

Check our Recent blog on Five Environmentally-Friendly Heating Alternatives to Gas Boilers

Common Applications for Boiler Hire

Boiler hire plays an essential role across various sectors and applications, ensuring that businesses and industries can maintain operations under any circumstance. Below are some of the most common scenarios where boiler hire proves invaluable:

Planned Maintenance and Shutdowns

Industries with high heating demands need to maintain their equipment regularly. During these maintenance periods, temporary boilers are essential to ensure that there are no disruptions in production. By hiring a boiler during planned shutdowns, industries can maintain their operational capacity while carrying out vital maintenance work on their permanent boiler systems.

Construction Projects

Construction sites often require temporary heating solutions, especially during colder months. Boiler hire allows construction firms to maintain the necessary conditions for curing concrete, heating water, or ensuring a comfortable work environment for their employees. By renting a boiler, construction companies can avoid the need to invest in permanent equipment that may only be needed for a few months.

Emergency Situations

When a permanent boiler system breaks down, businesses face the risk of severe financial losses due to halted production. Having access to emergency boiler hire ensures a swift response to any heating failure, allowing operations to resume as quickly as possible. London Climate Hire provides 24/7 emergency services, ensuring that you get a boiler up and running in the shortest time possible.

Seasonal Demand

Many industries experience seasonal variations in their heating requirements. For example, food processing plants may need additional steam during harvest season, or leisure centers may require more heating during the winter months. Hiring a boiler for these periods ensures that businesses have the capacity to meet their seasonal demand without the expense of installing and maintaining additional permanent equipment.

Event Management

Temporary boilers are often required for events like festivals, outdoor exhibitions, or temporary structures such as marquees. These events usually require heating for a short duration, and boiler hire provides an efficient and cost-effective solution.

Why Choose London Climate Hire for Your Boiler Hire Needs?

When it comes to boiler hire, London Climate Hire stands out as a leading provider in the UK. We are committed to delivering top-notch service and reliable, energy-efficient equipment to industries, businesses, and events across the country. Here's why we’re the best choice:

Expertise and Experience

With years of experience in the industry, London Climate Hire understands the unique challenges businesses face when they need temporary heating solutions. Our team of experts is equipped to assess your requirements and provide tailored recommendations to ensure you get the right equipment for your needs.

Comprehensive Range of Boilers

We offer a wide selection of boilers, including hot water, steam, electric, and condensing boilers, available in various sizes and capacities. This ensures that no matter the scope or scale of your project, we have the right boiler for you.

Fast and Reliable Service

We pride ourselves on our quick response times and efficient installation services. Our 24/7 emergency support team ensures that you can rely on us whenever you need an urgent solution. From initial consultation to delivery, installation, and maintenance, London Climate Hire guarantees seamless service throughout the entire hire period.

Energy-Efficient Solutions

At London Climate Hire, we prioritize energy efficiency, offering boilers that are designed to minimize fuel consumption and reduce carbon emissions. This not only helps our clients save on energy costs but also supports their environmental sustainability goals.

Nationwide Coverage

No matter where your business or project is located in the UK, London Climate Hire provides nationwide delivery and installation services. We ensure that our customers receive prompt and professional service regardless of their location.

Conclusion

Boiler hire is a versatile and cost-effective solution for businesses and industries across the UK. Whether you need temporary heating for planned maintenance, emergency breakdowns, seasonal demand, or specific projects like construction and events, renting a boiler allows you to continue operations smoothly and efficiently.

For businesses that value reliability, flexibility, and sustainability, London Climate Hire is the leading choice for boiler hire in the UK. With our extensive range of boilers, fast response times, and commitment to customer satisfaction, we are dedicated to ensuring that your heating requirements are met without disruption.

Choose London Climate Hire for all your boiler hire needs – your trusted partner for efficient, cost-effective, and reliable heating solutions.

0 notes

Text

Thermal Energy Storage Market Report: Industry Manufacturers Analysis 2020-2027

Thermal Energy Storage Market

The global thermal energy storage market size was valued at USD 4.1 billion in 2019 and is projected to grow at a compound annual growth rate (CAGR) of 9.45% from 2020 to 2027.

Shifting preference towards renewable energy generation, including concentrated solar power, and rising demand for thermal energy storage (TES) systems in HVAC are among the key factors propelling the industry growth. Growing need for enhanced energy efficiency, coupled with continuing energy utilization efforts, will positively influence the thermal energy storage demand. For instance, in September 2018, the Canadian government updated a financial incentive plan “Commercial Energy Conservation and Efficiency Program” that offers USD 15,000 worth rebates for commercial sector energy upgrades.

Gather more insights about the market drivers, restrains and growth of the Thermal Energy Storage Market

The market in the U.S. is projected to witness substantial growth in the forthcoming years on account of increasing number of thermal energy storage projects across the country. For instance, in 2018, the U.S. accounted for 33% of the 18 under construction projects and 41% of the total 1,361 operational projects globally. Presence of major industry players in the country is expected to further propel the TES market growth in the U.S.

The U.S. Department of Energy (DoE) evaluates thermal energy storage systems for their safety, reliability, cost-effective nature, and adherence to environmental regulations and industry standards. It also stated that Europe and the Asia Pacific display higher fractions of grid energy storage as compared to North America. Rising need for a future with clean energy is prompting governments across the globe to take efforts towards developing innovative energy storage systems.

The primary challenge faced by the thermal energy storage sector is the economical storage of energy. An important advancement in this sector has been the usage of lithium-ion batteries. These batteries exhibit high energy density and long lifespans of 500 deep cycles, i.e. the number of times they can be charged from 20% to their full capacity before witnessing a deterioration in performance. They can also be utilized in electric vehicles, district cooling and heating, and power generation.

Thermal Energy Storage Market Segmentation

Grand View Research has segmented the global thermal energy storage market report on the basis of product type, technology, storage material, application, end user, and region:

Product Type Outlook (Revenue, USD Million, 2016 - 2027)

Sensible Heat Storage

Latent Heat Storage

Thermochemical Heat Storage

Technology Outlook (Revenue, USD Million, 2016 - 2027)

Molten Salt Technology

Electric Thermal Storage Heaters

Solar Energy Storage

Ice-based Technology

Miscibility Gap Alloy Technology

Storage Material Outlook (Revenue, USD Million, 2016 - 2027)

Molten Salt

Phase Change Material

Water

Application Outlook (Revenue, USD Million, 2016 - 2027)

Process Heating & Cooling

District Heating & Cooling

Power Generation

Ice storage air-conditioning

Others

End-user Outlook (Revenue, USD Million, 2016 - 2027)

Industrial

Utilities

Residential & Commercial

Regional Outlook (Revenue, USD Million, 2016 - 2027)

North America

US

Canada

Mexico

Europe

UK

Russia

Germany

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Middle East and Africa (MEA)

Saudi Arabia

Browse through Grand View Research's Power Generation & Storage Industry Research Reports.

The global energy storage for unmanned aerial vehicles market size was estimated at USD 413.25 million in 2023 and is expected to grow at a CAGR of 27.8% from 2024 to 2030.

The global heat recovery steam generator market size was estimated at USD 1,345.2 million in 2023 and is projected to reach USD 1,817.0 million by 2030 and is anticipated to grow at a CAGR of 4.5% from 2024 to 2030.

Key Companies & Market Share Insights

Industry participants are integrating advanced technologies into the existing technology to enhance the product demand through the provision of improved thermal energy management systems. Furthermore, eminent players are emphasizing on inorganic growth ventures as a part of their strategic expansion. Some of the prominent players in the global thermal energy storage market include:

BrightSource Energy Inc.

SolarReserve LLC

Abengoa SA

Terrafore Technologies LLC

Baltimore Aircoil Company

Ice Energy

Caldwell Energy

Cryogel

Steffes Corporation

Order a free sample PDF of the Thermal Energy Storage Market Intelligence Study, published by Grand View Research.

0 notes

Text

The global thermal energy storage market size was valued at USD 4.1 billion in 2019 and is projected to grow at a compound annual growth rate (CAGR) of 9.45% from 2020 to 2027.

Shifting preference towards renewable energy generation, including concentrated solar power, and rising demand for thermal energy storage (TES) systems in HVAC are among the key factors propelling the industry growth. Growing need for enhanced energy efficiency, coupled with continuing energy utilization efforts, will positively influence the thermal energy storage demand. For instance, in September 2018, the Canadian government updated a financial incentive plan “Commercial Energy Conservation and Efficiency Program” that offers USD 15,000 worth rebates for commercial sector energy upgrades.

Gather more insights about the market drivers, restrains and growth of the Thermal Energy Storage Market

The market in the U.S. is projected to witness substantial growth in the forthcoming years on account of increasing number of thermal energy storage projects across the country. For instance, in 2018, the U.S. accounted for 33% of the 18 under construction projects and 41% of the total 1,361 operational projects globally. Presence of major industry players in the country is expected to further propel the TES market growth in the U.S.

The U.S. Department of Energy (DoE) evaluates thermal energy storage systems for their safety, reliability, cost-effective nature, and adherence to environmental regulations and industry standards. It also stated that Europe and the Asia Pacific display higher fractions of grid energy storage as compared to North America. Rising need for a future with clean energy is prompting governments across the globe to take efforts towards developing innovative energy storage systems.

The primary challenge faced by the thermal energy storage sector is the economical storage of energy. An important advancement in this sector has been the usage of lithium-ion batteries. These batteries exhibit high energy density and long lifespans of 500 deep cycles, i.e. the number of times they can be charged from 20% to their full capacity before witnessing a deterioration in performance. They can also be utilized in electric vehicles, district cooling and heating, and power generation.

Thermal Energy Storage Market Segmentation

Grand View Research has segmented the global thermal energy storage market report on the basis of product type, technology, storage material, application, end user, and region:

Product Type Outlook (Revenue, USD Million, 2016 - 2027)

• Sensible Heat Storage

• Latent Heat Storage

• Thermochemical Heat Storage

Technology Outlook (Revenue, USD Million, 2016 - 2027)

• Molten Salt Technology

• Electric Thermal Storage Heaters

• Solar Energy Storage

• Ice-based Technology

• Miscibility Gap Alloy Technology

Storage Material Outlook (Revenue, USD Million, 2016 - 2027)

• Molten Salt

• Phase Change Material

• Water

Application Outlook (Revenue, USD Million, 2016 - 2027)

• Process Heating & Cooling

• District Heating & Cooling

• Power Generation

• Ice storage air-conditioning

• Others

End-user Outlook (Revenue, USD Million, 2016 - 2027)

• Industrial

• Utilities

• Residential & Commercial

Regional Outlook (Revenue, USD Million, 2016 - 2027)

• North America

o U.S.

o Canada

o Mexico

• Europe

o U.K.

o Russia

o Germany

o Spain

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

• Middle East and Africa (MEA)

o Saudi Arabia

Browse through Grand View Research's Power Generation & Storage Industry Research Reports.

• The global energy storage for unmanned aerial vehicles market size was estimated at USD 413.25 million in 2023 and is expected to grow at a CAGR of 27.8% from 2024 to 2030.

• The global heat recovery steam generator market size was estimated at USD 1,345.2 million in 2023 and is projected to reach USD 1,817.0 million by 2030 and is anticipated to grow at a CAGR of 4.5% from 2024 to 2030.

Key Companies & Market Share Insights

Industry participants are integrating advanced technologies into the existing technology to enhance the product demand through the provision of improved thermal energy management systems. Furthermore, eminent players are emphasizing on inorganic growth ventures as a part of their strategic expansion. Some of the prominent players in the global thermal energy storage market include:

• BrightSource Energy Inc.

• SolarReserve LLC

• Abengoa SA

• Terrafore Technologies LLC

• Baltimore Aircoil Company

• Ice Energy

• Caldwell Energy

• Cryogel

• Steffes Corporation

Order a free sample PDF of the Thermal Energy Storage Market Intelligence Study, published by Grand View Research.

#Thermal Energy Storage Market#Thermal Energy Storage Industry#Thermal Energy Storage Market size#Thermal Energy Storage Market share#Thermal Energy Storage Market analysis

0 notes

Text

The Complete Guide to Cold Data Storage

What is Cold Data Storage?

Cold capacity empowers you to hold idle information successfully. Normal use instances of cold stockpiling include:

Media records — like pictures and recordings

Repeated information — put away as reinforcement, calamity recuperation, and documented purposes

Consistency information — data expected to keep up with consistency

Since cold information stays dormant more often than not, it is normally more financially savvy than elite execution stores that act as essential vaults. Here are a few rules to involve while planning or picking choices for cold capacity:

Financially savvy

High limit and information strength

Moderately sluggish information recovery and reaction time

Media types like direct tape-open (LTO) tape and hard circle drives (HDDs)

Most of cloud merchants offer choices for cold capacity. Well-known administrations offering low information accessibility at cost incorporate Microsoft Purplish blue Cool Mass Stockpiling, Amazon Ice sheet, and Google Distributed Storage Nearline.

Cold versus Hot Capacity

What is Hot Capacity?

Any information that is much of the time and promptly got to ought to be kept in hot capacity.

Use cases

Commonplace use cases for hot capacity incorporate powerfully changed information, information questioned by clients, information expected for use in continuous work processes.

Attributes

Hot capacity gives dependable prompt access. Information moved from hot capacity storehouses is frequently called "information streams".

Speed

The speed of an information move principally relies upon the number of courses the information needs to go through to get to its objective.

For instance, when information is handled nearer to the source, it can move rapidly. Information that travels through various organizations will show up later, in this situation.

What is Cold Capacity?

Any information that is seldom utilized ought to be kept in a cool capacity.

Use cases

Average use cases for cold capacity incorporate chronicled information, information that can't be utilized because of legitimate complexities, and consistence information.

Attributes

Cold capacity gives a protected area to information that isn't in regular use, similar to old data sets. This information is frequently called "torpid information".

Speed

The recovery of cold information commonly takes more time than the recovery of information from hot capacity. The speed recovery fluctuates and can take between minutes and hours.

At times, cool capacity information recovery could require you to physically look through actual hard drives and interface the plates to a PC.

The Interest in Cold Information Stockpiling

The fame of cold information stockpiling has been expanding lately. This is because of reasons — an outstanding expansion in information, changes away utilization, laid out and arising consistence guidelines, and the low costs of cold stockpiling.

Remarkable Information Development

As indicated by IDC, yearly information development is supposed to surpass 44 zettabytes toward the finish of 2020 and keep on expanding. Most of this information is either latent or every now and again. Over 80% is ascribed to unstructured and machine-created information.

Essential Capacity Utilization

Capacity persistently consumes assets. By and large, information stays in the primary objective for the span of its lifecycle. While essential capacity is in many cases revived, cold information keeps on consuming costly hot stockpiling assets.

Experiences from heat maps show that information stays hot during the initial 72 hours after it is made. Following thirty days, information chills off. Following ninety days, information becomes cold. NAND streak SSD media resources are exceptionally powerful for dynamic information, however a loss on cool information.

There is compelling reason need to involve superior execution for cold capacity. This can prompt above and costly stockpiling charging. However, chilly information consumes immense measures of essential stockpiling, assessed between 75% to 90%.

Administrative Consistence

Late years have seen an expansion in consciousness of private information use. An ever increasing number of guideline substances are made to normalize the utilization of information and guarantee the protection of residents.

The Overall Information Insurance Guideline (GDPR), for instance, expects organizations to fulfill specific guidelines while dealing with the information of residents and associations from

Cost-Adequacy

Cold capacity gives a far lower elective than hot capacity choices. There are many sorts of cold information stockpiling choices, from capacity frameworks and media choices to different cloud administrations. While every chilly stockpiling choice gives one of a kind highlights, most remain financially savvy, empowering organizations to lessen capacity costs.

Instructions to Successfully Oversee Cold Capacity

There are numerous approaches to oversee cold capacity actually. Normal practices incorporate utilizing economical capacity, utilizing cloud cold capacity, assessing cold information utilization every year, and carrying out information capacity mechanization.

Utilize Economical yet Trustworthy Cold Stockpiling

Slow hard drives and tapes are much of the time considered great capacity media types for cold information.

Be that as it may, you actually need to routinely test all circles and tapes, to guarantee the media works appropriately. You ought to likewise take note of the life expectancy of drives and tapes and resign old assets before disappointment. Any other way, you could endanger your information. While it's chilly information, it actually should be protected.

Consider Cloud-Based Cold Capacity

There is a wide variety of cold stockpiling choices in the cloud, which could more readily suit your motivations than on-prem choices. Now and again, distributed storage can lessen costs and give you controls for security and consistency. In different cases, you may be expected to use on-premise assets to meet consistence necessities. Evaluate each cloud choice cautiously prior to moving to the cloud.

Perform Yearly Assessments of Cold Stockpiling Information

Not all cool information ought to be put away forever. To guarantee you are effectively utilizing your assets, every year assess your information. End client faculty and legitimate offices can join the evaluation to figure out which information to hold and which shouldn't. A yearly assessment can assist with guaranteeing assets are designated by obvious requirements.

Use Information/Stockpiling Mechanization

Most stockpiling sellers work with layered information capacity utilizing computerized reasoning (artificial intelligence). Commonly, the shopper can characterize rules and triggers, which the artificial intelligence programming utilizes to appropriate information away.

This is the way a level procedure normally works:

In-memory capacity and strong state drives are in many cases utilized as the essential level for putting away often utilized information.

An optional level is utilized for putting away irregularly utilized information on more affordable drives.

One more level is committed to putting away chilly information on savvy slow-circle drives and tapes.

Mechanizing information levels guarantee information is persistently enhanced and appropriated to guarantee ideal outcomes at the most minimal potential expenses.

0 notes