#High Speed Automation

Explore tagged Tumblr posts

Text

High-Speed Automation: Key Advantages for Modern Industries

High-speed automation helps modern industries work faster, safer, and more efficiently. By using advanced machines and control systems, companies can increase production, reduce errors, and lower labor costs. Automation ensures consistent quality, saves time, and allows businesses to meet growing demands with ease. It also improves workplace safety by handling dangerous or repetitive tasks. Industries like manufacturing, automotive, food processing, and packaging benefit the most from high-speed automation. As technology advances, adopting fast and reliable automation solutions is no longer optional—it’s essential for staying competitive and profitable in today’s fast-paced industrial world.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#High Speed Automation

0 notes

Text

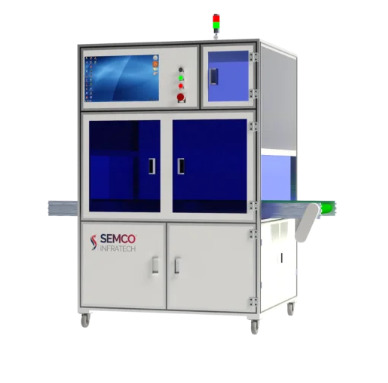

The Semco SI CCD 1220C is a high-precision Charge-Coupled Device (CCD) Polarity Machine designed for accurate testing and sorting in semiconductor manufacturing. It offers fast, reliable, and automated CCD polarity detection for enhanced quality control.

#CCD Polarity Machine#Charge Coupled Device Testing#Semco SI CCD 1220C#CCD Sorting#Semiconductor Inspection#Automated Testing#High-Speed Polarity Detection.

0 notes

Text

Discover Different Sticker Labeling Machines for Industries

Labeling plays a crucial role in various industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. Proper labeling ensures compliance with regulations, enhances brand visibility, and improves efficiency in production lines. With the advancement of automation, sticker labeling machines have become an integral part of industrial packaging. These machines streamline the…

#Ampoule Labeling Machine#Automatic Labeling Machines#Double Side Labeling Machine#Food and Beverage Labeling#High-Speed Labeling Machines#Horizontal Sticker Labeling#Industrial Labeling Equipment#Labeling Machine Selection#Labeling Solutions for Industries#Packaging Automation#Pharmaceutical Labeling#Round Bottle Labeling#Semi-Automatic Labeling#Sticker labeling machines

0 notes

Text

Numerical Relays - Adlite Electricals

Enhance Power System Efficiency with CGI 14N 75-250VDC Relay

For reliable electrical system performance, a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay, available at Adlite Electricals, is designed for superior performance in industrial, commercial, and power utility applications. With its voltage range of 75-250VDC, it ensures stable and efficient operation in electrical protection and automation systems.

What is the CGI 14N 75-250VDC Relay?

The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficiently and enables precise switching for power management.

Key Features of CGI 14N 75-250VDC Relay

This relay offers exceptional advantages, making it an ideal choice for power system applications:

Wide Voltage Compatibility: Operates efficiently between 75-250VDC, making it suitable for diverse electrical systems.

High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.

Rugged and Durable Design: Built for long-term use in demanding industrial environments.

Compact and Easy Installation: Allows seamless integration into various electrical setups.

Reliable Contact Multiplication: Enhances control circuit performance and dependability.

Applications of CGI 14N 75-250VDC Relay

The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency, including:

Power Plants: Assists in relay protection and circuit breaker operations.

Industrial Automation: Enables precise switching in manufacturing processes.

Substations: Supports stable grid management and fault isolation.

Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.

Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?

When it comes to sourcing top-quality electrical protection devices, Adlite Electricals is your trusted provider. Here’s why:

Genuine and Certified Products: Ensuring superior quality and reliability.

Affordable Prices: Get the best value for high-performance electrical components.

Hassle-Free Online Shopping: A seamless purchasing experience with expert support.

Fast and Secure Delivery: Ensuring timely arrival of your relay in perfect condition.

Conclusion

The CGI 14N 75-250VDC Relay is a must-have for industries that require a dependable, high-speed, and durable relay solution. Its wide voltage range and compact design make it ideal for numerous electrical applications.

Order your CGI 14N 75-250VDC Relay today from Adlite Electricals and enhance your system’s efficiency and safety!

Related Products

#CGI 110VDC Master Trip Relay

#CGI 14C 18-52VDC Relay

#CGI 14C 75-250VDC Relay

#CGI 14N 18-52VDC Relay

#CGI 14S 230VAC Relay

#CGI 24C 18-52VDC Relay

#CGI 24C 75-250VDC Relay

#CGXH1 3 Element Aux 110 VDC Relay

#Crompton TCSR Unit 110 VDC Relay

#Megawin M140c Relay

#Megawin MB 140c (Breaker Manager Relay)

#Enhance Power System Efficiency with CGI 14N 75-250VDC Relay#For reliable electrical system performance#a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay#available at Adlite Electricals#is designed for superior performance in industrial#commercial#and power utility applications. With its voltage range of 75-250VDC#it ensures stable and efficient operation in electrical protection and automation systems.#What is the CGI 14N 75-250VDC Relay?#The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficie#Key Features of CGI 14N 75-250VDC Relay#This relay offers exceptional advantages#making it an ideal choice for power system applications:#•#Wide Voltage Compatibility: Operates efficiently between 75-250VDC#making it suitable for diverse electrical systems.#High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.#Rugged and Durable Design: Built for long-term use in demanding industrial environments.#Compact and Easy Installation: Allows seamless integration into various electrical setups.#Reliable Contact Multiplication: Enhances control circuit performance and dependability.#Applications of CGI 14N 75-250VDC Relay#The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency#including:#Power Plants: Assists in relay protection and circuit breaker operations.#Industrial Automation: Enables precise switching in manufacturing processes.#Substations: Supports stable grid management and fault isolation.#Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.#Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?#When it comes to sourcing top-quality electrical protection devices#Adlite Electricals is your trusted provider. Here’s why:

0 notes

Text

Vertical Glue Mixer: Efficient and Uniform Adhesive Mixing for Plywood Manufacturing

In plywood production, efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this production is the Vertical Glue Mixer—a revolution in uniform adhesive mixing for better plywood bonding. If what you're searching for is an advanced glue mixing technology that maximizes productivity and reduces waste, this futuristic machine is a production-line essential.

Why a Vertical Glue Mixer?

A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood, ensuring a consistent glue spread on veneers. Unlike conventional mixers, a vertical mixer offers better blending, reduced glue wastage, and improved bonding strength, making it a preferred choice for modern plywood factories.

Key Benefits of a Vertical Glue Mixer

1. Superior Mixing Efficiency

Vertical design allows for complete and even blending of adhesives, which creates even viscosity and consistency across the batch. This produces improved plywood adhesion, minimizing defects in the finished product.

2. Economical Glue Use

Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality, resulting in extensive cost benefits in the long run.

3. Reduced Production Cycle Times

Using a high-speed mixing device, a vertical glue mixer reduces preparation time, enabling production cycles to be completed quickly and output to be maximized.

4. Minimal Maintenance & Longevity

Designed with robust parts and sophisticated automation, these mixers have negligible maintenance needs, making them a sound long-term investment for plywood production.

5. Eco-Friendly Operations

By minimizing glue waste and maximizing adhesive blending efficiency, a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.

Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

In selecting a Vertical Glue Mixer, there are important considerations to make:

✔️ Mixing Capacity – Select a machine in conformity with your volume of production.

✔️ Automation Features – Choose a model with easy-to-use controls for convenient operation.

✔️ Material Compatibility – Use one that can handle different adhesive types for general applications.

✔️ Manufacturer Reputation – Buy equipment from a reputable plywood machinery manufacturer for guaranteed quality.

A Vertical Glue Mixer is an important investment for plywood plant owners who want to improve efficiency, quality, and cost savings. By adopting this performance-intensive adhesive mixing system into your production process, you can achieve smooth operations, better plywood bonding, and increased profitability.

Want to find the ideal Vertical Glue Mixer for your plywood factory? Contact DNH Engineers a renowned manufacturer of plywood machinery and give your production a boost! Visit www.dnhengineers.com for more details.

#In plywood production#efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this#this futuristic machine is a production-line essential.#Why a Vertical Glue Mixer?#A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood#ensuring a consistent glue spread on veneers. Unlike conventional mixers#a vertical mixer offers better blending#reduced glue wastage#and improved bonding strength#making it a preferred choice for modern plywood factories.#Key Benefits of a Vertical Glue Mixer#1. Superior Mixing Efficiency#Vertical design allows for complete and even blending of adhesives#which creates even viscosity and consistency across the batch. This produces improved plywood adhesion#minimizing defects in the finished product.#2. Economical Glue Use#Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality#resulting in extensive cost benefits in the long run.#3. Reduced Production Cycle Times#Using a high-speed mixing device#a vertical glue mixer reduces preparation time#enabling production cycles to be completed quickly and output to be maximized.#4. Minimal Maintenance & Longevity#Designed with robust parts and sophisticated automation#these mixers have negligible maintenance needs#making them a sound long-term investment for plywood production.#5. Eco-Friendly Operations#By minimizing glue waste and maximizing adhesive blending efficiency#a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.#Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

0 notes

Text

#long roller drilling tufting machine#tufting machine manufacturer#roller drilling tufting machine#industrial tufting machine#automated tufting machine#brush tufting machine#cnc tufting machine#high-speed tufting machine#custom tufting machine#tufting equipment supplier#brush making machine#drilling and tufting machine#precision tufting machine#industrial brush machine#tufting technology manufacturer.

0 notes

Text

Top Benefits of Using a Coin Counter for Your Business

In today’s fast-paced business environment, efficiency is key to staying ahead. For businesses handling a significant volume of coins daily, relying on manual counting methods can be time-consuming, error-prone, and inefficient. That’s where coin counters come into play. This blog explores the top benefits of using a coin counter for your business and why upgrading to one is a smart investment.

1. Time Efficiency

Manually counting coins can take hours, especially for businesses dealing with large amounts of cash. A coin counter—especially a high-speed coin counter—can count thousands of coins within minutes, freeing up your staff to focus on more critical tasks like customer service and sales.

Example: A supermarket can process its daily cash register coins in just 10 minutes, compared to the hours it would take manually.

2. Accuracy

Human errors are inevitable when counting large amounts of coins. Automated coin sorters and counters are designed for precision, ensuring accurate counts every time. This reduces discrepancies in cash management and builds trust among your team and customers.

Pro Tip: Pair your coin counter with regular cash audits for seamless accounting.

3. Cost Savings

Although purchasing a coin counter requires an upfront investment, the long-term savings are significant. By reducing the time spent on manual counting and minimizing errors, businesses save money on labor and avoid potential losses from inaccuracies.

4. Enhanced Security

Handling cash manually increases the risk of theft and fraud. Coin counters reduce direct contact with money, ensuring safer cash handling procedures. Some models even come with lockable compartments to secure sorted coins.

Tip: Opt for a coin counter with advanced security features for added peace of mind.

5. Improved Staff Productivity

When employees aren’t burdened with the tedious task of counting coins, they can focus on activities that drive business growth, such as engaging with customers or improving operational processes.

Case Study: A vending machine operator increased route efficiency by 20% after introducing coin counters to their process.

6. Versatility

Modern coin counters are versatile and suitable for various industries, including retail stores, banks, laundromats, and amusement parks. They handle coins of different denominations, making them a valuable tool for businesses of all sizes.

Example: Automated coin sorters separate and count different coin types, saving time and effort in sorting.

FAQ’s About Coin Counters

1. What types of businesses benefit most from coin counters?

Coin counters are ideal for businesses that handle cash regularly, such as retail stores, banks, vending machine operators, laundromats, and nonprofits.

2. What’s the difference between a coin counter and an automated coin sorter?

A coin counter counts the total value of coins, while an automated coin sorter organizes coins into separate denominations while counting.

3. How fast can a high-speed coin counter work?

High-speed coin counters can process up to 2,000 coins per minute, depending on the model.

4. Are coin counters expensive?

Prices vary based on features and capacity, but many models are affordable for small and medium-sized businesses. The cost is often offset by the savings in time and labor.

5. How do I maintain my coin counter?

Regularly clean the machine to remove dust and debris, and follow the manufacturer’s maintenance guidelines to ensure longevity.

Conclusion

Investing in a coin counter is a game-changer for businesses handling large volumes of coins. By improving efficiency, accuracy, and security, a coin counter not only saves time but also reduces costs in the long run. Whether you’re a retailer, bank, or nonprofit, upgrading to a coin counter is a decision you won’t regret.

Start reaping the benefits of a high-speed coin counter today and elevate your business operations to the next level!

0 notes

Text

High Speed Doors, Rolling Shutters and Automated Gates Manufacturer in India

GATEMAAN, a trademark of Nithyaa Sai Metal Technics LLP (NSMT LLP), stands as a pioneer in introducing world-class automation technologies to India. In collaboration with Efaflex, a global leader in the industry, GATEMAAN specializes in Industrial High-Speed Doors, Gates, Rolling Shutters, Sectional Doors, Dock Levelers, Dock Shelters, and more.

#high speed doors#roller shutters#sliding doors#industrial sectional doors#automated gates#India#Manufacturers in India

0 notes

Text

Valmet's papermaking line for Asia-Pacific customer

Valmet will supply a complete papermaking line from stock preparation to reel and winders with services and a comprehensive automation solution package to one of its major customers in Asia-Pacific. The papermaking line will produce uncoated woodfree grades. The start-up is scheduled for 2026.

The order is included in Valmet's orders received in the fourth quarter 2024. The value of the order will not be disclosed, but such a papermaking line is typically worth between 90 million Euros and 120 million Euros.

This order follows the customer’s previous papermaking line order to the same site, announced in June 2024. “This other fine papermaking line order is strengthening Valmet's position as a supplier for high-speed fine paper machine lines and continues our good co-operation and long-term partnership with the customer,” says Markus Veikkola, Sales Director, China and Asia Pacific, Board and Paper Mills, Paper business line, Valmet.

Delivery’s technical information

Valmet’s delivery will include stock preparation and a high-speed papermaking line from headbox to winders. The delivery also includes a wide range of automation solutions, flow control solutions, Valmet Industrial Internet solutions, paper machine clothing, spare parts, and consumables packages.

#Valmet will supply a complete papermaking line from stock preparation to reel and winders with services and a comprehensive automation solut#The order is included in Valmet's orders received in the fourth quarter 2024. The value of the order will not be disclosed#but such a papermaking line is typically worth between 90 million Euros and 120 million Euros.#This order follows the customer’s previous papermaking line order to the same site#announced in June 2024. “This other fine papermaking line order is strengthening Valmet's position as a supplier for high-speed fine paper#” says Markus Veikkola#Sales Director#China and Asia Pacific#Board and Paper Mills#Paper business line#Valmet.#Delivery’s technical information#Valmet’s delivery will include stock preparation and a high-speed papermaking line from headbox to winders. The delivery also includes a wi#flow control solutions#Valmet Industrial Internet solutions#paper machine clothing#spare parts#and consumables packages.

0 notes

Text

How USB 3.0 Cameras are Revolutionizing Industrial Robot Vision Systems

In the fast-evolving world of industrial automation, USB 3.0 cameras are emerging as pivotal tools that enhance the capabilities of robotic vision systems. With the ability to transmit high-definition video and images at remarkable speeds, these cameras are reshaping how robots perceive their environments. As industries strive for greater efficiency, precision, and productivity, understanding the role of USB 3.0 cameras in industrial robot vision systems becomes essential.

Benefits of USB 3.0 Cameras in Industrial Applications

Enhanced Data Transfer Speeds

One of the most significant advantages of using USB 3.0 cameras is their enhanced data transfer speeds. Unlike previous USB versions, USB 3.0 can transmit data at rates up to 5 Gbps. This speed is crucial for industrial robots that require real-time processing of high-resolution images. Whether it’s for quality control, object detection, or navigational tasks, faster data transfer translates to quicker decision-making, allowing robots to perform tasks more efficiently.

High-Resolution Imaging for Improved Accuracy

USB 3.0 cameras support high-resolution imaging, which is vital for industrial applications where precision matters. With the ability to capture detailed images, these cameras help robots identify components, detect flaws, and ensure that assembly processes meet quality standards. The improved accuracy that comes with high-resolution imaging reduces the risk of errors and minimizes waste, ultimately leading to cost savings for manufacturers.

Compatibility with Advanced Processing Algorithms

Another advantage of USB 3.0 cameras is their compatibility with advanced image processing algorithms. As industries adopt more sophisticated artificial intelligence (AI) and machine learning solutions, the need for cameras that can seamlessly integrate with these technologies becomes paramount. USB 3.0 cameras can easily connect to a variety of image processing software, allowing for enhanced features like real-time analysis, pattern recognition, and object tracking, all of which are essential for intelligent robotic systems.

Versatility Across Multiple Industries

USB 3.0 cameras are not limited to a single industry; their versatility makes them ideal for various applications, including manufacturing, logistics, and healthcare. In manufacturing, they can be used for automated inspection and assembly line monitoring. In logistics, they assist in inventory management and quality checks. In healthcare, these cameras aid in medical imaging and robotic surgeries. This wide range of applications showcases how USB 3.0 technology can cater to diverse industrial needs, enhancing productivity across the board.

Integration Challenges and Solutions

Addressing compatibility issues

While the benefits of USB 3.0 cameras are clear, integrating them into existing systems can present challenges. Compatibility with older hardware or software can be an obstacle. However, many manufacturers now offer USB 3.0 cameras designed to work seamlessly with legacy systems, often through the use of adapters or custom drivers. By ensuring that businesses can upgrade their systems without overhauling everything, USB 3.0 cameras provide a cost-effective solution for enhancing industrial robot vision systems.

Overcoming bandwidth limitations

Another challenge is managing bandwidth limitations in complex industrial environments. High-resolution video streams can consume significant bandwidth, potentially affecting the performance of other connected devices. To mitigate this issue, companies can implement network management strategies, such as prioritizing traffic or using dedicated lines for camera data. This approach ensures that USB 3.0 cameras can operate at optimal performance levels without disrupting other critical operations.

Future Trends in USB 3.0 Camera Technology

Advancements in Imaging Technology

As technology continues to evolve, the future of USB 3.0 cameras in industrial robot vision systems looks promising. Emerging imaging technologies, such as 3D imaging and multispectral cameras, are set to enhance the capabilities of robotic systems even further. These advancements will enable robots to perceive their environments in more complex ways, leading to improvements in tasks such as quality inspection, sorting, and even autonomous navigation.

Growing Adoption of AI and Automation

The need for more sophisticated USB 3.0 cameras will be fueled by the growing automation and artificial intelligence integration in industrial processes. Higher levels of resolution and faster processing power will be required from the cameras that robots rely on as they grow more intelligent and powerful. The way industries approach automation will be redefined by this AI and image technology combination, which will result in even more breakthroughs and efficiencies.

Are you prepared to investigate how your industrial robot vision systems might be improved by USB 3.0 cameras? Visit our website or get in touch with us right now to learn about the newest developments and innovations! Maintain your competitive edge and make sure your business is operating effectively.

1 note

·

View note

Text

High-speed automation is revolutionizing industries by boosting efficiency and productivity. Manufacturing benefits from faster production lines and precise assembly, while logistics sees improved inventory management and quicker delivery times. Retail industries use automation for faster checkout systems and smarter stock management. In healthcare, automation streamlines administrative tasks and enhances patient care. Customer service also improves with AI-powered chatbots, providing instant responses and support. Across these sectors, high-speed automation reduces costs, minimizes errors, and enables businesses to scale quickly, leading to enhanced competitiveness and growth in today’s fast-paced market. Embrace automation for increased efficiency and success in your industry.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#High Speed automation

0 notes

Text

Automatic Double Positioning Rigid Box Making Machine PC-8040A

The Automatic Double Positioning Rigid Box Making Machine is setting new standards in the packaging industry, particularly for businesses that require efficiency and precision in box production. This innovative machine is designed to create two boxes simultaneously, streamlining the manufacturing process and significantly enhancing productivity.

Key Features

The PC-8040A model exemplifies the latest advancements in rigid box making technology. Here are some of its standout features:

Dual Production Capability: The machine can produce two different box types at the same time, which is a game-changer for businesses that need versatility in their packaging solutions.

High-Speed Operation: With the ability to handle double paper feeding, corner pasting, and box forming concurrently, the PC-8040A can produce up to 15-25 pairs of boxes per minute. This high-speed operation is crucial for meeting large orders and tight deadlines.

Precision Engineering: Equipped with a Yamaha robotic arm, the machine ensures high precision in positioning, with an accuracy of ±0.1mm. This level of precision is essential for maintaining quality in packaging, especially for luxury items.

User-Friendly Control System: The machine features a PLC control system that allows for easy adjustments and monitoring of the production process. This digital interface enhances operational efficiency and reduces the likelihood of errors.

#Rigid Box Manufacturing#Automated Packaging Solutions#Double Positioning Technology#High-Speed Box Production#Precision Packaging Machinery

1 note

·

View note

Text

The world of finance has undergone a sea change in the past few years. With the advancement of technology, the world of trading also has revolutionised. Initially, manual trading was the most popular mode. However, with the advent of technology, automated trading came into existence. Now, there is algorithmic trading as well as high-frequency trading, which is increasingly becoming popular among traders globally.

0 notes

Text

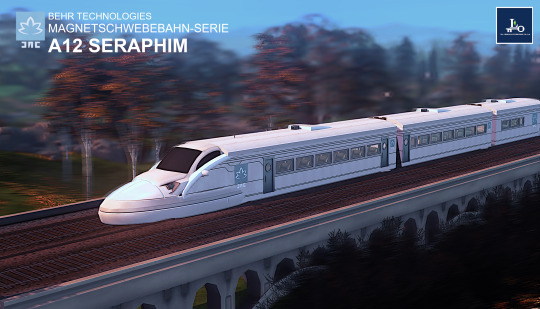

Windslar M-Train Station (NO CC)

Windslar M-Train Station is the northern terminus of the Windslar-Lykke-Britechester line in the Windenbahn high-speed rail network. Originally built in 1998 through a collaboration between Lesmana Enterprise and the Windenburg Royal Ministry of Transport, the station now stands as a state-of-the-art transportation hub. It houses a dedicated maglev rail for the A12 Seraphim, the fastest train in the Western SimWorld, offering seamless, high-speed connections across the region. With premium waiting lounges, a spacious café, a capsule hotel for overnight stays, digital information kiosks, automated ticketing, and high-speed Wi-Fi, Windslar M-Train Station ensures a smooth and comfortable travel experience for all passengers.

New Interior Facelift

The Windslar M-Train Station interior blends modern sophistication with passenger comfort, offering a seamless travel experience. The spacious concourse features sleek ticketing kiosks, automated turnstiles, and a real-time departure board in Simlish for easy navigation. Soft ambient lighting, elegant architectural details, and lush greenery create an inviting atmosphere, while premium seating areas provide relaxation before boarding. A cozy café (POLA Coffee) serves freshly brewed coffee and local delicacies, making it a perfect stop for commuters and travelers alike. With its futuristic design and high-tech amenities, Windslar Station embodies the pinnacle of efficient and luxurious transit in the Windenbahn network.

Windslar Greets You

The peron offers a breathtaking view of the lush countryside, ready to greet travelers with its serene landscapes.

The A12 Seraphim is a masterpiece of speed and comfort, soaring across the landscape at an impressive 510 km/h. Inside, the cabin is designed for both luxury and efficiency.

Seraphim Business Class

Step into the A12 Seraphim Business Class, where elegance meets high-speed innovation. Plush black leather seats with personal entertainment screens ensure a serene and private travel experience. Soft ambient lighting enhances the cabin’s refined atmosphere, while panoramic windows frame breathtaking countryside views at unmatched speeds.

Seraphim Coach Class

For those who seek both comfort and affordability, the Seraphim Coach Class provides spacious seating with deep blue ergonomic chairs designed for long-haul relaxation. Overhead luggage compartments ensure a clutter-free space, while the warm glow of the ceiling lights adds to the welcoming ambiance.

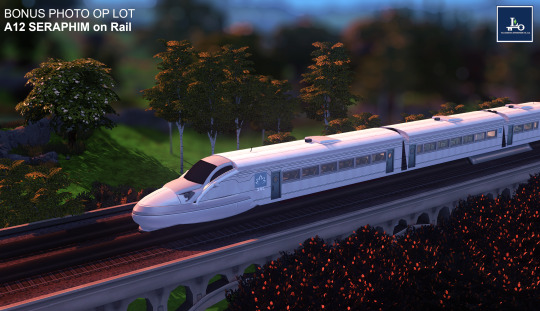

BONUS: A12 Seraphim on Rail, Photo op Lot

Capture the thrill of high-speed travel with the A12 Seraphim on Rail photo op lot! This scenic location is the perfect backdrop for Sim stories, machinima, and breathtaking screenshots.

Positioned along an elegant elevated railway, the A12 Seraphim glides through a picturesque landscape, surrounded by lush greenery and golden-hour lighting that enhances every shot. Whether you're creating a travel blog, showcasing futuristic transportation, or simply looking for a cinematic rail-themed scene, this lot offers stunning views and dynamic compositions.

Set up your Sims for dramatic departures, high-speed action shots, or tranquil countryside journeys—all with the A12 Seraphim as the star.

Techincal Informations

Packs Used

Download via SFS

Windslar M-Train Station : Download A12 Seraphim Photo op : Download

Sul Sul!,

Lesmana Enterprise Co., Ltd.

#simblr#lesmana-enterprise-ltd#sims 4#sims 4 screenshots#sims 4 aesthetic#ts4 simblr#sims 4 build#download#sims 4 no cc#showusyourbuilds#sims 4 tray#travel#station#high speed rail#get together#windenburg#64x64#no cc#maxis match#sims 4 cafe#cafe#train#transportation#airport#sims 4 airport

2K notes

·

View notes

Note

I know you generally work fast but I'm curious on how long on average it takes for you to get out a page of ThUG? I haven't had the opportunity to read it yet (it looks SO good) but I'm making the assumption a page is the size of an average print comic style versus webtoon scroll episode length format. Also curious on what short cuts you might take to get them out faster/more efficiently. I'm currently planning a comic in a similar format and am trying to plan my process ahead.

Thank you!

I don't do whole pages in one go (I do all the thumbnails then all the lineart then all the colour) so it's hard to tell exactly how long but maybe around 3-6h per page? Which makes a chapter (25-30 ish pages) take around 150 ish hours. I definitely prefer this to the webtoon format for a number of reasons, one of which being the satisfaction you get seeing a bunch of panels come together versus having to scroll through them separately.

In terms of speed, my entire process is pretty optimised for it, both in comics and outside. I stick to an A5 format and downsize it further (I tend to work with pages at 1000px width and 300dpi) to keep myself from overworking details. If an eye closeup feels tiring to get right or loses proportion, my resolution is too high

I also use textured brushes and leave the lineart more like a clean sketch, which allows me to not only skip straight from thumbnails to it but also to skip work on backgrounds, objects and figures at a certain distance

The main point of comic work is to convey emotions, movement, etc, not to draw everything accurate all the time, and that's probably the biggest lesson I've learned over the past years. You want your art to evolve in a way that means even without a lot of shading/linework/detail the scene gets properly conveyed, imo

Aside from that, I skip work on SFX and just. Write the sounds down or sketch motion lines as basic as they get. That's a stylistic choice but it works for me. And I have a workspace + automated actions + keyboard shortcuts that are all sort of optimised to make me move as little as possible between tasks and screens etc

251 notes

·

View notes

Text

summary: even with his high profile, alex wasn't above or against using the tube to get around london. this time however, your ride together was a lot more different than usual. rating: nc-17 pairing: f!reader/alex content warnings: established relationship, smut, exhibitionism, sex in a subway (the transportation system not the sandwich franchise !) word count: 0.5k previous one-shot - george r. | next one-shot - fernando a.

“Alex, you’re not minding the gap.”

Though quiet and rather labored, there was a teasing mirth in your voice as you spoke. With the subway car packed to the gills with local commuters and gallivanting travelers from abroad, along with the usual hum of the Tube speeding beneath the nightly bustle of London, you anticipated your words to be drowned out by the surrounding noise.

However, as you continued to face the somewhat worn poster denoting proper public etiquette on the London Underground that was plastered on the wall, your boyfriend proceeded to intrude further into your space in response, eliciting a hushed gasp from your lips while you found yourself ushered further into the corner of the subway car.

“Well, I have to keep close, unless you wanna give a show to everyone on board, darling.”

While you couldn’t look back to face him, you knew fully well that there was a grin that was as wide as could be on his face.

Even as his teeth were clamping down onto his bottom lip in pleasure.

After all, with some sneaky tugs at the front of his jeans and discreet yanks at the hem of your dress, he was happily plugging your cunt full with his cock from behind, his thrusts subtle, slow, yet divinely deep. Paired with the turns, bumps, and stops along the track of the Tube, you were left enthralled in sheer euphoria as you felt his hips rock against your backside.

Tucked away in your own little section of the subway car, locked and engaged together in your own personal debauchery.

Willingly at that.

Though Alex was of mind to dress accordingly–a plain fitted cap tugged down as lowly as possible to shadow over his eyes, a facemask to obscure his trademark smile, clothes that bore not a single designer brand logo–he was still very much the Alex Albon.

Risking the chance of getting caught being intimate with his lover in such a public setting within the capital city of the country he was born in seemed too absurd to even consider in the first place.

However, since recently earning your forgiveness after a nasty spat that saw him accidentally pointing his frustrations from the season towards your direction, he was utterly determined to make things right.

Fulfilling one of your long-harbored fantasies was just one step to achieving that.

Besides, he was more than happy to put his tall, towering stature to use, hiding you behind his frame with ease as he continued to sink his cock deep into the slick heat of your core.

As he choked back a groan as he felt the sweet squeeze of your cunt clamp around his dick, Alex matched your amused tone as he leaned forward to utter out,

“Though, if we had to give everyone a show, we should at least get paid for it, yeah?”

It was then that the automated announcement for the next approaching stop played throughout the subway car, with some passengers preparing their belongings to soon leave while others shifted over in anticipation of freed seats.

For you and Alex however, the two of you weren’t getting off until he successfully got you off.

-----------------------

that's the second stop on the "pole positions" express !!! 🚂💃

maybe i write about running a train with some of the drivers next--

stay tuned for spanish ossan appreciation tomorrow at 11 am est !!! 🙆♀️💚

#alex albon x reader#alex albon x you#alex albon smut#aa23 x reader#aa23 x you#aa23 smut#f1 x reader#f1 x you#f1 smut#formula one x reader#formula one x you#formula one smut#reader insert#Poll Positions

60 notes

·

View notes