#CCD Polarity Machine

Explore tagged Tumblr posts

Text

The Semco SI CCD 1220C is a high-precision Charge-Coupled Device (CCD) Polarity Machine designed for accurate testing and sorting in semiconductor manufacturing. It offers fast, reliable, and automated CCD polarity detection for enhanced quality control.

#CCD Polarity Machine#Charge Coupled Device Testing#Semco SI CCD 1220C#CCD Sorting#Semiconductor Inspection#Automated Testing#High-Speed Polarity Detection.

0 notes

Text

Advanced Arise Web Guide Sensor

Arise is an audited, leading web guiding system manufacturer in China with a professional R & D team. Arise can provide advanced web guide sensor for continuous and accurate edge position control of coil materials.

AE400 CCD Image Sensor

AE400 CCD image sensor adopts an imported CCD sensor and the lens. It can track the edges of various materials with a real-time screen display and an easy full-touch operation.

1. No need for polarity conversion.

When the coil baseline and line asymptotically or the left and right edges are reversed, there is no need to switch the polarity of the control output.

2. No need to re-adjust the gain.

The deviation of the edge from the output voltage is not affected by the width or color of the line. Therefore, once the gain of the controller is set during the test run, there is no need to re-adjust the gain.

3. Position signal hold function.

When a line leaves the field of view and when it returns, the position signal generated immediately before the line leaves the field of view is maintained and output. Therefore, when the web bending speed is fast and the line (edge) will be out of the field of view, the tracking operation will be performed.

4. The line (edge) position is displayed by LED.

The control action, even if the integral action is standard, can also be combined with the position transmitter to perform proportional action. The most suitable control action can be selected according to the machine used.

5. When the detected edge is in the center of the field of view, an LED indicator lights up.

When the device is connected to a controller with a drive lock input, in the case of intermittent lines, when an interruption is detected in the line, the drive is locked and the tracking operation is stopped until the next line appears.

A100 Infrared Edge Sensor For Reading Web Edge

Arise A100 infrared edge sensors are specifically designed to read the edge of webs which has the features of sound-transparent, thick weaves and non-transparent. The web guide sensor uses an infrared LED as the light source. The light is reflected through the material and is then recorded by a CCD line. The CCD elements illuminated in this way in the edge sensor issue a higher signal level. The signal level can be converted into an output value proportional to the web edge position.

Features

1. Adopting high-speed DSP chip, full digital processing, truly no drift, strong anti-interference ability

2. Adopting imported infrared-sensitive components with 0.01mm resolution

3. Fully sealed titanium alloy shell design with special surface treatment, to prevent dust and pollution, anti-corrosion

4. It can detect any material (including mesh material) without adjustment

5. DC12V single power supply, 0-5V analog output, two switch output

6. Easy setup

A200 Ultrasonic Edge Sensor For Precise Web Guiding

In the process of web guiding, the web edge control can be realized by an edge sensor. The ultrasonic web guide sensors are designed for detecting the edges of materials such as paper, a plastic film of any color, with reliable and certain identification of deviations. When the receiver establishes an analog voltage signal that is proportional to the impulse intensity. Then the web reaches the air gap, the impulses are weakened, which makes the sensor to precisely recognize the web edge.

Advantages

1. Adopting high-speed DSP chip, full digital processing, truly no drift, strong anti-interference ability

2. Adopting Japanese Fuji high-precision ultrasonic sensitive components with 0.01mm resolution

3. Fully sealed titanium alloy shell design with special surface treatment, to prevent dust and pollution, anti-corrosion

4. The ambient noise of the workshop has no effect on ARISE's unique ultrasonic technology

5. It can detect any material (including mesh material) without adjustment

6. DC12V single power supply, 0-5V analog output, two switch output

0 notes

Text

UV LED visual inspection

Since the beginning of visual inspection, it has been more than 20 years old. Its function and application range have been gradually improved and promoted with the development of industrial automation, especially the current UVLED visual inspection light source, digital image sensor, CMOS and CCD camera embedded COB LED. With the rapid development of technologies such as technology, image processing and pattern recognition, UVLED light sources UV Curing lamp have greatly promoted the development of machine vision.

Application areas of UVLED visual inspection light source: 1. Food industry: appearance packaging inspection, egg appearance and internal quality inspection, fruit color judgment, food packaging visual positioning, etc.; 2, the electronics industry: semiconductor component surface defect feature detection, character printing defect detection, component damage detection, chip pin package integrity detection, terminals; pin size detection, tape machine component polarity identification, keyboard character detection, etc.; 3. Printing industry: printing quality inspection, printing character detection, color recognition, barcode recognition, two-dimensional code detection, etc.; 4, automotive electronics: panel printing quality inspection, character detection, color recognition, AOI detection system, etc.; 5, the medical industry: drug bottle packaging defect monitoring, tablet package missing detection, capsule packaging quality testing, etc.;

UV LED UV Flashlight visual inspection of the advantages of the light source: 1. Non-contact measurement will not cause any damage to the observer and the observer, thus improving the reliability of the system. 2. It has a wide spectral response range, such as infrared measurement that is invisible to the human eye, which extends the visual range of the human eye. 3, stable work for a long time, it is difficult for humans to observe the same object for a long time, while machine vision can make measurement, analysis and identification tasks for a long time.

0 notes

Text

Understanding the CCD Polarity Tester Machine: Working, Mechanism, and Importance in the Battery Industry

In battery manufacturing, ensuring correct polarity is critical for safety, efficiency, and product reliability. The CCD Polarity Tester Machine is an advanced vision-based system designed to verify the polarity of battery cells, modules, or packs before they proceed to the next stage of production.

By using Charge-Coupled Device (CCD) cameras and image processing technology, this machine detects incorrect battery orientations, preventing assembly errors that could lead to electrical failures, reduced efficiency, or hazardous situations.

This article explores the working mechanism and significance of CCD Polarity Tester Machines in the battery industry, particularly in EV battery manufacturing, consumer electronics, and energy storage systems.

How a CCD Polarity Tester Machine Works?

1. Battery Placement

The battery cell or module is positioned in the testing station.

This can be done manually or through an automated conveyor system for high-speed manufacturing lines.

2. Image Capture Using CCD Camera

A high-resolution CCD camera captures detailed images of the battery’s terminals.

The camera is positioned to get a clear view of polarity indicators, such as symbols, colors, or terminal shapes.

3. Polarity Verification Process

The captured image is processed using machine vision algorithms.

The system compares the terminal orientation with predefined polarity templates stored in its database.

If the polarity matches the expected orientation, the battery is marked as passed.

If the polarity is incorrect, the system flags the battery as rejected.

4. Sorting and Classification

Pass Batteries: Batteries with the correct polarity move forward in the production process.

Reject Batteries: Batteries with incorrect polarity are flagged for correction or removal.

Some systems integrate robotic handling to automatically sort out non-compliant batteries.

Mechanism Behind CCD Polarity Testing

1. Charge-Coupled Device (CCD) Camera Technology

The CCD camera captures high-resolution images of battery terminals.

It offers superior light sensitivity, ensuring clear image detection in varying lighting conditions.

2. Image Processing Software

The system processes images in real time using pattern recognition and AI-based algorithms.

It identifies terminal markings, color codes, or shapes to verify polarity.

3. High-Speed Automated Feedback System

The system immediately classifies the battery as correct or incorrect.

Feedback is sent to the production control system, triggering sorting mechanisms or alerts.

4. Temperature and Lighting Adjustments

Some advanced systems adjust for ambient lighting conditions to improve accuracy.

Temperature variations that might affect image clarity are also compensated for.

Importance of CCD Polarity Testing in the Battery Industry

1. Prevents Assembly Errors

Batteries assembled with the wrong polarity can cause short circuits, device malfunctions, or permanent damage.

Ensuring correct polarity at the early production stage eliminates costly assembly line rework.

2. Enhances Safety

Misoriented batteries can lead to fire hazards, explosions, or system failures.

Particularly crucial for high-energy applications like EVs, medical devices, and energy storage solutions.

3. Improves Production Efficiency

Automated CCD testers reduce manual inspection time, improving throughput.

Early error detection minimizes waste and rework costs.

4. Ensures Compliance with Industry Standards

Battery manufacturers must adhere to safety and quality regulations such as ISO, IEC, and UL standards.

Automated polarity testing ensures compliance without human error.

5. Reduces Costs and Defective Product Returns

Incorrectly oriented batteries reaching the market can lead to warranty claims, recalls, and reputational damage.

CCD polarity testers prevent such failures, saving millions in potential losses.

Applications of CCD Polarity Tester Machines

1. Electric Vehicle (EV) Battery Production

Ensures correct orientation of high-voltage battery cells and modules before pack assembly.

Reduces the risk of electrical failure in EV power systems.

2. Consumer Electronics Manufacturing

Used in battery production for smartphones, laptops, and wearable devices.

Prevents polarity-related malfunctions in sensitive electronic devices.

3. Energy Storage Systems (ESS)

Large-scale battery storage requires precisely matched cells.

CCD testers ensure proper polarity before battery module integration.

4. Aerospace and Défense Batteries

In critical applications, such as satellites and military equipment, battery failures are unacceptable.

CCD testers provide high-precision verification for safety-critical batteries.

Choosing the Right CCD Polarity Tester for Your Needs

When selecting a CCD Polarity Tester, manufacturers should consider:

1. Accuracy and Resolution

High millivolt precision ensures reliable results.

Look for CCD cameras with high pixel resolution for better image clarity.

2. Speed and Automation Level

Automated testers are essential for high-volume battery production.

Look for systems with integrated robotic handling for increased efficiency.

3. Software Integration and AI Capabilities

Advanced systems use AI-powered image recognition to improve accuracy.

Machines that integrate with manufacturing execution systems (MES) enable real-time monitoring.

4. Compatibility with Different Battery Types

The machine should support cylindrical, prismatic, and pouch cells.

Should be adaptable to multiple battery chemistries, including Li-ion, NiMH, and LFP.

5. Temperature and Environmental Adaptability

Choose a tester with adjustable lighting and temperature compensation for reliable readings in different factory environments.

Conclusion

A CCD Polarity Tester Machine is a critical tool in battery manufacturing, ensuring that battery terminals are correctly oriented before further processing. By using high-precision imaging, automation, and AI-based vision systems, these machines eliminate polarity errors, enhance product reliability, and improve overall manufacturing efficiency.

In industries such as EVs, energy storage, and consumer electronics, CCD polarity testing plays a key role in ensuring safety, compliance, and product longevity. As battery technology advances, the demand for high-speed, accurate, and automated polarity testing solutions will continue to grow.

#Automated Polarity Inspection#Battery Assembly Line Testing#Battery Polarity Detection#Battery Polarity Testing Machine#battery testing equipment#CCD Polarity Tester#Lithium Battery Polarity Check#Non-contact Polarity Testing

0 notes

Text

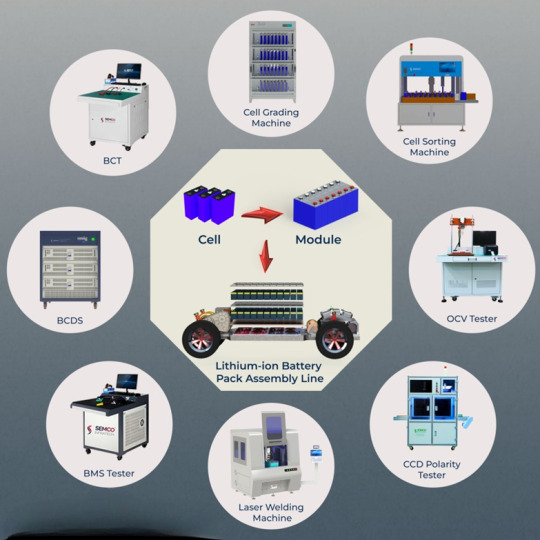

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes