#Fiberglass Reinforced Plastic

Explore tagged Tumblr posts

Text

YAMAHA Mundur Dari Bisnis Kolam Renang Pool

YAMAHA Mundur Dari Bisnis Kolam Renang ., salam pertamax7.com, YAMAHA Mundur Dari Bisnis Kolam Renang Pool Link ponsel pintar ( di sini ) Salam Yamaha Mania. Ada info resmi dari Iwata Japan hari ini, Selasa, 3 Juli 2023. Yamaha Motor Co., Ltd. (Tokyo: 7272) hari ini mengumumkan bahwa Perseroan telah memutuskan untuk menyelesaikan aktivitas penjualan pada akhir Maret 2024 dan menarik diri dari…

View On WordPress

0 notes

Text

0 notes

Text

Plasticair Environmental: Leading Ventilation Fan Solutions

Plasticair Environmental specializes in high-performance air filtration solutions, including Horizontal Packed Bed, Fume Hood, Chrome, Vertical Packed Bed, Venturi scrubbers, and Mist Eliminators. Trusted by Plasticair Inc.

#plasticair#plasticair enviromental#Fiberglass-Reinforced Plastics (FRP)#Corrosion Resistance#Fiber Reinforced Plastics#Reinforced Thermoset Plastic (RTP)#Reinforced Thermoset Resin (RTR)#Glass-Reinforced Plastic (GRP)#Hand Lay-up Fabrication#Resin Transfer Molding#Corrosion Barrier Coating#Plasticair FRP Fans#Cost-Effective Solution#Industrial Applications#Quality Control in FRP#Resin Brand Importance#Durability of FRP#Thermoplastics vs. Thermosets#Fan Specifications#Acid Scrubbers#Alkaline Scrubbers#Odor Scrubbers#Odour Scrubbers#Chlorine Scrubbers#H2S Scrubbers#SO2 Scrubbers#Wet Scrubbers#Chemical Scrubbers#Fume hood scrubbers#Venturi scrubber

2 notes

·

View notes

Text

Summary of 25 plastic reinforced modification formulas and 20 key points involved

There are many common plastic modification technologies, mainly reinforcement technologies, including fiber reinforcement, self-reinforcement, and molecular reinforcement; toughening technology; filling modification; blending and plastic alloy technology; flame retardant technology; nanocomposite technology; reaction grafting modification; aging resistance; functional modification, including…

View On WordPress

#Antistatic glass fiber reinforced PA6 impeller#Chopped glass fiber reinforced PP#Compatibilizer#Composite reinforced PP#Engineering plastic reinforced formula#Enhanced PF for chemical anti-corrosion pipelines#Epoxy fiberglass#Epoxy phenolic fiberglass#Flame retardant and antistatic reinforced PA6#Flame retardant glass fiber reinforced PA6 impeller#GF enhanced RJM-PU#Glass fiber reinforced PP#Glass fiber reinforced PVC#Glass fiber reinforced PVDC special-shaped components#High performance glass fiber reinforced PP#High strength unsaturated polyester board#Long glass fiber reinforced PA6#Mica reinforced PP#No. 771 unsaturated polyester fiberglass#plastic modification technologies#plastic reinforced modification formulas#PS coloring formula#thermoplastic reinforced formulations#Thermoset reinforced formulations#Transparent glass fiber reinforced PC#UHMWPE/carbon fiber composite materials#Wollastonite fiber-filled reinforced PP

0 notes

Text

Fiber-Reinforced Plastic Roofing Sheet in Indore - Vaishnow FRP Products

#Fiber Reinforced Plastic Roofing Sheet#FRP Fiber Sheet#FRP Roofing Sheet Manufacturer#Fiberglass Sheet Products#Air Ventilator in Indore#Air Ventilator Indore#Air Ventilator Manufacturer#Air Roof Ventilators#Indore Air Roof Ventilators#Industrial Roof Ventilator

0 notes

Text

Keiichi Tanaami (1936-2024) — Dream of Human Metamorphosis [fiberglass reinforced plastics, iron, acrylic and urethane paint, gold plating, 2014]

114 notes

·

View notes

Text

Fiberglass Recycling

Fiberglass is a type of composite that consists of a polymer material reinforced with glass fibers. Because of the nature of many composites, and the separation that recycling would entail, fiberglass is not often recycled and is considered to be difficult to recycle. This is particularly the case if thermoset polymers are used (as opposed to thermoplastic polymers), which cannot currently be recycled. Typically, when fiberglass is recycled, it is ground down before separation occurs between the plastic and glass components, and only the glass is often recycled. It should be noted that fiberglass is often made from recycled glass as a raw material to begin with. As the demand to recycle fiberglass increases, interest also grows in developing the infrastructure and policies needed to do so.

Sources/Further Reading: (Image source - ThePaGerS) (Composites World) (2022 article) (Wikipedia)

#Materials Science#Science#Glass#Composites#Fiberglass#Glass fibers#Recycling#Waste#2024Daily#WasteWednesday

20 notes

·

View notes

Text

kinktober #7

7. Magic Mirror 🪞 / Donut Devotee 🍩

“Uh, yeah,” says Raleigh, surveying the mess of damp drywall, fiberglass, and insulation strewn across what used to be Dr. Mori’s desk. “This is gonna take a while. You probably shouldn’t even be in here, you know.”

Dr. Mori shakes her head, the blue tips of her razor-sharp black bob whispering against the white N95 mask obscuring the lower half of her face. Her arms are folded across her chest, and she’s planted protectively in front of the one corner of her office untouched by disaster. Clustered on a stack of books is an entire animal shelter’s worth of little plastic cat figurines in various positions, some wearing costumes, some wrapped into sushi — he wants to say something about them, but he’s afraid she’ll think he’s making fun of her. She’s piled another stack of thick textbooks onto a folding chair — spines out so Raleigh can see that they’re all robotics-adjacent — and her slim silver laptop is perched at the top in a precarious attempt at a standing desk. A line of small robots and action figures, presumably previously housed on the shelves that got taken out when her ceiling caved in, are lined up on either side of the folding chair like knights ready to do her bidding. It’s honestly kind of an impressive setup, if he ignores the myriad of safety hazards.

“It’s okay,” she says. “I can use this part just fine.”

Raleigh raises an eyebrow. “It’s going to get worse in here before it gets better. I’m gonna have to redo most of the ceiling. And fix that pipe, and the water damage in the wall. Not to mention the wiring.”

Dr. Mori’s unfazed. “That’s fine. I have headphones.”

“Okay,” says Raleigh dubiously. “Up to you. I’m gonna have to come back later today and get some measurements, see what’s going on in there. Will you be here around two?”

She nods.

“All right, well — be careful in here. I dunno the last time the insulation got replaced up there, it’s probably full of asbestos.” He gives her a little salute and goes to step out of the office, but as he’s passing the threshold, she reaches out and taps his arm, drawing her hand back as quickly as if he’d burned her.

“I want a bookshelf.” Her dark eyes are intense over the top of her mask, her eyebrows sharp and precise. “And better wattage in the outlets. And more outlets.”

Stepping carefully over the debris on the floor — she’s wearing what look like military surplus boots with her smart skirt and sweater — she indicates the space behind her desk. “Bookshelf here. Short is okay.” She holds her hand about three feet from the floor. “Outlets here and here. The shelves can stay where they were, but I would like them reinforced.”

Raleigh leans against the doorframe, trying not to smile. “Anything else?”

Dr. Mori considers. “Can you soundproof?” she asks, and Raleigh laughs.

Her eyes curve into a smile above her mask. Raleigh makes some notes, flashes her a thumbs-up. “I’ll see what I can do, Dr. Mori.”

She pauses for just a second too long, then dips her head. “Call me Mako.”

—

Mako lets out a huge breath the moment the facilities guy is gone. She’s also aware that she probably shouldn’t be working in her destroyed cubicle, but she just got her own office and she refuses point-blank to go back to sharing space with the Hansens and pretending she can’t hear the father-son duo sniping back and forth at each other every waking moment. They’ve been in the field a long time and she respects their work, but given the choice between the two of them and the potential asbestos, well, at least she can wear a respirator to shield herself from one of those.

But the facilities guy didn’t blink when she made her requests, even though they technically exceed what could be considered necessary repairs for the caved-in ceiling. She hopes he’s the one who comes back to do the work. She hadn’t expected him to be cute, even though she really doesn’t have time to deal with him being cute. But strong and soft is an easy way to her heart, and if he has to be in her space for the next couple of weeks, well, she might as well enjoy it.

Her last lecture of the day ends at quarter of two, and she hurries back to her office afterward, unwilling to miss her chance to supervise any remodeling plans. The Hansens have a whole wall of bookshelves in their office. Mako has resorted to piling her books on the floor behind her desk and using them as auxiliary shelf space.

She opens her laptop at her makeshift desk and tries to look busy when the guy shows up. He’s right on time, which she appreciates, and he knocks before coming in, even though her door is open.

“Hey,” he says. He’s got a respirator around his neck, which makes her smile a little. “All right, I ran everything by my supervisor and it should be all right. I really emphasized how much your stuff had been ruined, you know, your bookshelves and all. And how the water got into some of your outlets, so those’ll need to be replaced. Might even have to add a few, just to be safe.” He grins, shoves his hands into his pockets. “You mind if I poke around? I’ll stay out of your way, I promise.”

“No, that’s fine,” she says, closing her laptop. “I was actually thinking about going to the cafe across the street. Would you like anything? My treat.”

“Oh, you don’t have to —” he starts, but Mako’s eyebrows must say she’s not taking no for an answer because he backtracks, “Uh, yeah, a tea would be great, actually. Green, hot, no milk or sugar. Thanks.”

She repeats it back to him and pulls her coat off the back of the folding chair. “I’m sorry, I didn’t get your name.”

He lifts his chin and smiles. “Raleigh.”

“Raleigh,” she echoes. “I’ll be right back.”

“Take your time,” he says, pulling the respirator over his nose and mouth. “This is gonna take a while.”

Mako is categorically incapable of taking her time when she’s excited; efficiency is both her blessing and her curse. She crosses the street to the cafe at a light jog, frightens everyone in line with her because she’s still wearing her own respirator, and has to repeat her order three times because she’s speaking too quickly. One green tea, hot, no milk or sugar. One matcha latte, hot, with oat milk and strawberry syrup. And six of the doughnuts on display: roasted cherry, brown butter passion fruit, chocolate sprinkle, vanilla cardamom, lychee rose, and chai apple cider.

Raleigh’s up on a ladder, a toolbox sitting open at its base, when she gets back, and he’s reaching up into the crumbling ceiling, a headlamp on his hard hat beaming into the detritus. He’s several inches taller than Mako even without the ladder, sturdily built, and she thinks the green cargo pants he’s wearing shouldn’t do nearly as much for his backside and legs as they do. His gray t-shirt rides up as he raises his arms, and Mako nearly drops both teas and the doughnut box at the bit of stomach he’s inadvertently revealed. His midsection is heavily scarred, gnarled ribbons of raised tissue disappearing up toward his ribcage, and a soft roll of belly sits precariously over his belt, like just the slightest bit more might tip it into sagging.

Mako is so, so glad that she’s still got the respirator on.

Biting her tongue, she drags in a chair from the department’s kitchenette and sets down both teas and the doughnuts out of harm’s way. Then she opens her laptop back up and stares at the screen, unseeing, the afterimage of Raleigh’s pudgy, torn-up torso burned into her vision.

Finally he hops down from the ladder and dusts off his hands, doffs his mask around his neck. “It’s bad up there,” he confirms. “Probably a couple weeks’ worth of work, at least.”

Mako nods slowly, lowering her own mask to sip her latte. “Okay. I can handle that.”

Raleigh pops the lid off his tea and leans against the wall. He shifts the cup to his right hand and slowly moves his left shoulder in small circles.

Mako gestures to the box sitting on the chair. “Please,” she says. “Help yourself. It’s my thank-you for honoring all of my requests.”

He sets his tea down and opens the box. Mako asked the barista to write the names of each flavor on the top so she wouldn’t have to stumble through them all one more time, and Raleigh takes his time deciding.

“I’m sorry if this is too forward,” he says finally, and it’s not at all what Mako is expecting. She inhales sharply. “But you have excellent taste in doughnuts.”

Oh. She exhales in a shaky laugh. “Thank you. Theirs are the best I’ve had. Have as many as you’d like; I’ll put the rest in the kitchen.”

“Is there one in particular I should save for you?”

She nods and points to the lychee rose. “Perfect,” says Raleigh, taking the brown butter passion fruit. “Rose tastes like soap to me, but, you know, I respect it. Takes all kinds.”

She surreptitiously watches him eat the doughnut over the rim of her cup. Then she fires her laptop back up and watches him dip back into her periphery for another. Twenty long minutes of staring at her lines of code in R and then he’s back again, and finally she gives in to the instinct to turn and look at him.

“Sorry,” he says sheepishly, and it tugs at something deep and tender inside her. “Am I distracting you? I’m realizing now that I missed lunch.”

“Don’t worry,” she manages. “I got them for you.”

—

Raleigh comes back every day. He’s easygoing and affable, and Mako knows for sure he’s won her over when he steps in one day with his ladder, toolbox, and kneepads and says, “What’s up with the Australian meathead?”

Mako laughs before she can stop herself. “Junior or senior?”

He makes a face. “There’s two?”

As quietly as she can, she closes her office door. “I know you have work to do,” she says. “But this is crucial information. Those are the Hansens, and it is vital that you do not make me go back to sharing their office.”

Raleigh scoffs. “I hear you. Crocodile Dundee out there just made a big show of muscling his way out of the elevator in front of me. Didn’t hold a single door either. Man, you can see that I’m carrying shit.” He shakes his head. “Don’t you worry. You’ll lose this office over my dead body.”

She smiles. “Thank you. Please, let me offer you a token of my gratitude.”

Doughnuts again. Raleigh eats four.

—

Mako finds out what kind of green tea Raleigh likes, buys a box, and assigns him one of the random university-branded mugs in the kitchenette. She vents to him after a department meeting in which Herc — ostensibly an impartial party, as department head — backs up Chuck’s insistence on keeping his programming course in MatLab rather than R, even though MatLab is expensive and slightly old-fashioned while R is open-source and far more accessible to students. But of course, Herc taught all of his coding in MatLab when he came up through this program and god forbid anything change, ever! God forbid anything inconvenience the Hansens!

Raleigh listens with his head in her ceiling as he fiddles with the pipes, and when she stops to draw breath, he says, “Shouldn’t you all be encouraging open-source stuff anyway? Isn’t that, like, the future?”

“Yes!” Mako practically bellows. “But of course that’s too easy! There’s no gatekeeping, so clearly it’s unsuperior.” She realizes too late that it’s the wrong word, then has the worse realization that she waited a beat out of habit for someone to correct her. Raleigh doesn’t. “I mean inferior,” she continues with renewed zeal. “How dare anyone be able to access this information without a legacy in this program for the last forty years!”

Raleigh descends his ladder and winces. There’s an indistinct shape under the chest of his t-shirt that she’s spent days puzzling out — a binder? some kind of medical port? a particularly traumatic continuation of his scarring? — but she sees now, as he rolls back his t-shirt sleeve to adjust it, that he’s wearing a brace around his left shoulder, fastened across his sternum.

“I have aspirin,” she says. “If you need some.”

“That would be great,” says Raleigh, relief smoothing his face. She hands him the bottle from her backpack and he shakes a few into his hand, washing them down with a gulp of tea. She went too late to the cafe today, delayed by the department meeting, and had to get muffins rather than doughnuts. Raleigh doesn’t seem bothered. He went for the miso white chocolate chip first, then the ube, and now he peels the wrapper from the double chocolate matcha. “That’s bullshit,” he says, covering his mouth as he chews. “Must be exhausting to be so obsessed with being right.”

Mako nods vigorously. “Thank you. I don’t understand it.”

“Yeah, that’s because you seem like a reasonable person.” He balls up the muffin wrapper and shoots it across the room into her wastebasket, missing it by inches. She golf-claps politely anyway, and he flashes her a sheepish grin. As he bends to retrieve it, he braces a hand against his belly where Mako knows it almost pooches out over his belt, and he stifles a burp as he straightens up. “Sorry. Getting a little too used to these pastries.”

If Mako ever wins a Nobel Prize or something, the first entity she thanks in her speech will be her box of N95s. She owes her entire working relationship with Raleigh to being able to hide her furious blushing behind them. “I can stop,” she offers. “I just wanted to make sure you knew I appreciated your work.”

“Oh, I won’t ask you to stop,” says Raleigh with a laugh. He palms his belly beneath his t-shirt. “Even if I probably should. By the time I finish up in here I’m not going to fit through those ceiling tiles.”

On one hand, it’s probably a good thing Mako has to leave for an afternoon of meetings so she doesn’t combust. On the other, she processes absolutely none of what is said to her for the next few hours. Her mind is solely on Raleigh, adding up the various baked goods she’s brought him and applying them to his waistline with the concentration she usually reserves for coding. In the notebook where she draws designs and diagrams for new projects, she sketches the shape of his body, the jags of his fluffy blond hair, the N95 hanging around his neck, the folds of his utility pants, the forking bolts of scar tissue reaching up to his chest.

While she’s out, Raleigh builds her a bookshelf that spans an entire wall.

—

Her office is coming together. The ceiling is once again intact, not a hint of water damage remaining. Raleigh spent the last few days drilling while Mako sat contentedly in the corner with the giant gaming headphones one of her mentors, Dr. Choi, sent her for the holidays a few years ago. The vague screech of metal on drywall that filters through her shibuya-kei playlist is a welcome reminder of Raleigh’s continued presence. There are three more outlets than she started with, all with a higher output capacity than she probably needs. Now it’s just the finishing touches that are left, and she should be glad for that. A few more days and she’ll have her space back entirely. Her office will be hers again, new and improved.

But she’s not ready to lose Raleigh.

The time he spends in her office grows shorter and shorter, and she hopes against hope that he’s intentionally drawing it out. She keeps the baked goods coming; today she got a half dozen doughnuts free after filling up her punch card. She tells Raleigh to take the rest when he goes; there are too many for just her and she refuses to share with the Hansens. Raleigh tells her he can share them with his team. She thinks they both know he won’t.

Because Raleigh has spent a fair bit of time painting the new walls and ceiling this week, and Mako’s been gathering data every time he reaches above his head with the roller. His belly pooch has reached its tipping point, rolling an inch or two over his belt. She can see the shape of his stomach through his t-shirts now, can see the shadow of his navel and the push of his flesh against the fabric. He keeps tugging his shirts down, and Mako sits on her hands and pretends not to see and pretends not to know how this could have possibly happened.

And then one day he declares that he’s done, and he gives Mako a sad little smile and tells her he hopes he’ll see her around campus sometime, and he scrawls his number on a sticky note in case she needs anything else from facilities.

She tries to enjoy being alone in her office, she really does. She sets up her cat figurines around her new computer monitor and arranges her books on the new shelving. She returns her robots to their place of honor above her desk. And then she picks up the phone.

“Hey,” says Raleigh when he picks up. She thinks she can detect a thread of delight in his voice. “What’s up?”

“It’s all the new outlets,” she says. “They work fine, I’m very happy with them. But I was wondering if you have one of those mats I could put over all the wires so no one trips.”

“No problem,” says Raleigh. She thinks he’s smiling. “I’ll come by later and drop one off.”

The next day Mako’s phone rings just as she’s brewing her morning tea. “Hello?”

“Hey, it’s Raleigh. I think I might have left some tools in your ceiling. Okay if I come up and check?”

Mako’s heart backflips. “Yes. If you wait half an hour I’ll have doughnuts to give you.”

Raleigh waits half an hour. There’s nothing in the ceiling.

“I could use an ethernet cable,” she says as his mouth is full of roasted cherry. “Just in case. Sometimes the Wi-Fi is spotty up here.”

“You got it,” he says, and he comes back the next day with an ethernet cable.

“Hey,” he says, leaning in the doorway with his hands in his pockets as she carefully coils the cable and stores it in her desk drawer. “Weird question. I heard you on the phone one day while I was up here with my head in the ceiling — you speak Japanese, right?”

She nods.

“Well, here’s the thing,” says Raleigh. “I’m actually starting a Japanese class soon, and I could use a conversation partner, if you have time.”

“That’s lucky,” says Mako. “I could use a lunch partner.”

“Yeah,” says Raleigh. His smile spreads all the way across her new office like sunlight. “That is lucky.”

#feedist kinktober#feedist kinktober 2024#my fic#my writing#pacific rim#chubby raleigh#mako x raleigh#listen i know NOTHING about robotics this is purely for entertainment purposes

18 notes

·

View notes

Text

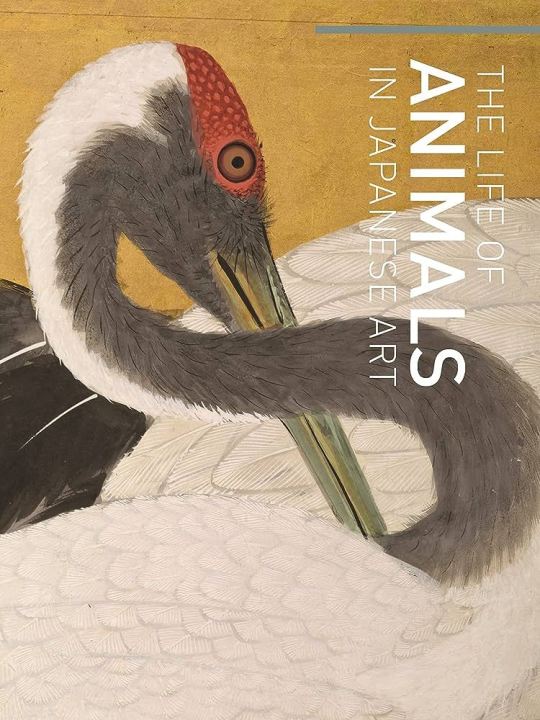

Happy 95th birthday to Yayoi Kusama, born #OTD 22 March 1929! Here are a trio of colorful canines from The Life of Animals in #JapaneseArt exhibition at National Gallery of Art (2019).

1 Megu-chan, 2014

2 Toko-chan, 2013

3 Sho-chan, 2013

fiberglass-reinforced plastic, paint

“The Japanese titles of these sculptures refer to affectionate nicknames for childhood friends.”

The Life of Animals in Japanese Art exhibition catalog

#animals in art#museum visit#dog#dogs#canine#canines#dogs in art#sculpture#trio#Yayoi Kusama#contemporary art#2010s#Japanese art#East Asian art#Asian art#pop art#National Gallery of Art DC#exhibition#The Life of Animals in Japanese Art#polka dots#birthday#OTD#women artists

23 notes

·

View notes

Text

Fiberglass in humans has been found to cause:

Skin, eye and upper respiratory tract irritation in humans

Lung disorders and

Increased risk for certain cancers

It also hurts the shellfish ability to digest food and reproduce, alongside causing inflammation

Fiberglass is a type of plastic material that is made stronger by having little fibers of glass woven into it.

Classified as marine debris, man made materials are polluting the world’s oceans.

Mussels and oysters are commonly used to study microparticle contamination of the aquatic environment and their consequent biological effects.

10 notes

·

View notes

Text

Here's the 1954 Plymouth Belmont Concept.

(See if you can spot the antenna.)

The Belmont was the first plastic-bodied (reinforced fiberglass) Chrysler 'idea car', an experiment in new materials and design.

It had a 150-horsepower, 241-cubic inch, 3.9 liter, V8.

It was made for the 1954 Chicago Auto Show by Briggs Manufacturing and designed in the Advanced Styling Studio, under the supervision of head stylist Virgil Exner.

❤️🚘❤️🚘❤️🚘❤️🚘❤️🚘❤️🚘❤️🚘❤️🚘❤️

2 notes

·

View notes

Text

Character bio of the Asian Pasifika demigod and Afro Latine Native alien hybrid superhero main character part 13

Alien Hybrid Costume:

First costume:

Letterman jacket, hoodie, fingerless gloves, black jeans, black and red wide width high top sneakers with white laces

Domino mask, face mask, & bandana

Second costume:

Spandex and kevlar costume that comes with a utility belt and gadgets

Stretchy and made of mesh to be extra flexible

Has a cape that allows user to glide for a short period of time

Bio mask with eye lenses that comes with built in headset

Warps light and sound to make wearer temporarily invisible

Third costume:

Fourth costume:

The black and blue alien hybrid suit with a black domino mask, a red bio mask, red gloves, black pants, & red boots. The alien hybrid suit armored version would be the same as earlier but with power armor strapped to it. Made up of human and alien metal. The crimson, silver, & obsidian power armor is more streamlined and sleek. The chest, the helmet, arms, legs, & and shoulders of the power armor suit has gold and silver decals and emblems.

Fifth costume:

Current costume:

Red and black tactical costume with nanites and nanomachines that allow the suit to appear and disappear into a metal neck choker for easy access and storage.

Black domino mask, red bandana, a black facemask, red breath mask, & red bio mask

Comes with built in headset for communication with lenses that boosts their ability to sense throughout the electromagnetic spectrum

Vibranium and adamantium like reinforced titanium combat armor

Titanium reinforced nanocomposite Kevlar and ceramic bodysuit

Enhances strength, speed, senses, flexibility, durability, reflexes, intelligence, perception, endurance, agility, etc.

Never gets dirty

Repairs, customizes, and upgrades itself thanks to nanites and cybernetic and bionic technology

Comes with wrist computer for hacking

Celestial steel metal plated fingerless (for clawed hands with opposable thumbs) combat gloves

Stellar titanium metal plated steel toed (can transfigure open for clawed feet with opposable toes) combat boots.

Divine iron and heavenly bronze like metal claw gauntlets that are attachable to gloves and boots.

Future costume:

Tactical domino mask, balaclava, bio mask, & bandana. They come with reactive layering, with shock absorbent composite layering, with thermoregulation, reinforced, composite coated, fireproof, padded, with titanium micro plate mesh, with reinforced plastic, with insulated lining, anti shrapnel, has coprocessor function, has hardened leather, has nanotubing, waterproof, windproof, bulletproof, reinforced cotton, durable nanofiber, hydrophobic, antibacterial lining, with strengthened polyamide fibers, carbon fiber, durable, with micro fleece lining, sturdy, reflective, reinforced silk weave, with breathable lining, elastic, carbon reinforced, anti UV coating, with built in neuron circuitry, with light armor layer, with reinforced seams, with protective rubber inset, reinforced lining, with digital camouflage, & with 4K resolution holographic display.

Comes with reinforced lenses, tempered lenses, with protective techno polymer goggles, holo tinted goggles, hardened fiberglass, coated glass, with UV filter, anti glare, bulletproof, scratch resistant, polarized lenses that let them sense throughout the full electromagnetic spectrum.

Comes with communication built in headset, built in camera, & built in microphone. The mask had built-in headset, earpieces, cameras, microphone, speakers, and radio systems. The lens was able to analyze the environment, spot enemies through walls, and track vapor trails. The mask contains shifting lenses that identify the enemy’s identities. The mask has lenses that identifies enemies weak points through an artificial intelligence and a database. The user was able to tag enemies and allies with markers. The mask has defense mechanisms such as electric shock, sleeping gas, or stun gas in order to prevent unauthorized removal.

Reinforced puncture resistant tear proof, flame resistant fireproof, hydrophobic waterproof, hypoallergenic, windproof, dustproof, anti viral, anti chemical, anti corrosive, oil resistant, abrasion resistant, stain resistant, bulletproof, stretch fabric, antiseptic membrane, anti viral membrane, protective membrane, high utility, nylon lining, quick dry, foam cushioning, discreet bullet proof lining, titanium inserts, breathable, armor coated, with armor layer, compressible, insulated, anti shrapnel, bioplastic fur, form fitting, copper microfiber, bronze microfiber, micro fiber, welded hems, gold inlay, fitted, tailored, silver inlay, bio synthetic giant spider silk, space fabric, composite lined, durable synthetic, eco friendly, carbon reinforced, cushion insert, hybrid lining, fortified threading, silver nano inlay, slim fit, titanium micro plating lining, ultrasonic quilting, nano layer, high alloy steel, carbon fiber lined, durable synthetic silk, synthetic padding, Kevlar thread, carbon nanotube fibers, reactive layer, Egyptian cotton, protective mesh, tech membrane, plastic weave, nano weave, bulletproof weave, ultra weave, fiberglass weave, carbon composites, lightweight metal polymers, reinforced synthetic fiber weave, armor weave, technology advanced, armored costume. Comes with cargo pockets, crystalline protective sleeves, detachable hood, detachable collar, taped seams, reinforced bodice, elastic cuffs.

Comes with reinforced, cushioned, synthetic, extra durable soles, practical, with sole support, anti puncture, tear proof, nano weave, heat resistant, fireproof, waterproof, breathable lining, reinforced stitching, resistant materials, reinforced lining, multilayered protection, tactical fiber, hybrid fabric, with protective inserts, armor coated, shock absorbent, rubber reinforced, athletic, with protective insoles, high top sneakers. Comes with reinforced dress shoes with reinforced soles, with sole support, reinforced seams, with metal inserts, & cushioned composite insoles. Comes with durable bio leather, puncture resistant, waterproof, fireproof, hardened leather, hardened with composite inserts, & steel toe combat boots.

Comes with a utility belt full of gadgets and tools housed in mechanical compartments and armored fabric pouches. Stretchy and made with mesh to be extra flexible. Comes with gloves, pants, & boots. Has a cape to glide for several minutes and fly for a few minutes. Warps light to make its user invisible and hushes sound to make its wearer quiet with noise dampening to allow for better sneaking.

Has an electrical system that can shock, stun, & knockout assailants. Made out of nanites and nano machines that allow the suit to be easily accessible. Is made with alien and human reinforced metal. The gloves and boots come with retractable metal claws. Clawed hands and clawed feet are diamond tipped. Comes with combat gloves with titanium knuckles for punching and combat boots with steel toes for kicking. Repairs, customizes, & updates itself thanks to cybernetic and bionic technology.

Comes with a wrist computer for hacking. The suit also has on-board sensors for complete vicinity readings. Has radio transmission scanners and receivers. Has multiple biological sensors such as EKG (readings, pulse rates, etc.). Has multiple electromagnetic spectrum vision settings. The reinforced armor comes with a material to dampen shocks and impact. It can absorb small firearms and reflect large caliber firearms up to a certain point before needing to be repaired. Has force fields plasma shields, laser shields, energy shields, and hard light shields that can absorb and reflect damage before needing to be recharged.

It has limited hover, flying, & gliding capabilities. It has built in thrusters integrated into the boots for launch. Has grafted metal armor on the forearms, elbows, shoulders, hips, knees, and lower legs. Has four retractable metal arms to traverse environments including walls. Enhances and augments wearer or users strength, perception, awareness, durability, constitution, endurance, stamina, intelligence, senses, reflexes, agility, flexibility, & speed. Also has a built-in feature for the costume to change its appearance at the user's will. This was an ideal feature since the wearer never has to worry about trying to hide their suit in public.

Divine costume:

First costume: It is a basic clothed armor made out of animal hide and quilted linen. It comes with animal hide, leather, & wooden round shield.

Second costume: It is a basic metal armor made out of iron, bronze, copper, and dragon studded leather. It comes with an iron, bronze, & copper round shield.

Third costume: It is made out thick, multilayered of threads of giant spider silk, studded dragon leather, wood, & quilted linen, hardened plastic. It comes with a metal ballistic shield.

Fourth Costume: The amour is also part of their manifestation as the deity of storms. When he/she/they shifts into this form the armor forms around him/her/them. Borrowing from the motif of mist gathering itself into the form of the armor. When the mist is fully concentrated into the correct shape the armor manifests itself. This happens as they move. The whole transformation can be seen to take place over a few steps, one form dropping away and dissolving into mist/fog with the mist/fog then coalescing into Kana’i/Ataahua with the manifestation of the cloak and armor lagging slightly behind the manifestation of his/her/their body. The leather parts of the armor is the same color of the Pacific sea during an ‘ino (dark greens and purples merging together to form an almost-dark gray color when viewed at a distance.) His/her/their cloak is a manifestation of their powers. It is a constantly shifting concentration of storm clouds that fade to clouds then to fog and then cycles back up, with that happening in a gradient across the cloak. So in some places on the cloak the storm clouds will fully be in effect while elsewhere the cloak looks like fog.

Fifth Costume: It is a metal armor made of chainmail and steel modular plate armor. It has a gorget (that protects the chest), a bevor (protecting the lower face, neck, chin, & throat) a breastplate or chestplate (that protects the chest), backplate, pauldrons (that protect the shoulders), plackart (that protected the lower half of the torso), cuirass (that protected the front of the torso), culet (that protects the small of back and the buttocks), couters (that protects the elbows), poleyns (that protected the knees), faulds (to protect the waist and hips), gauntlets (that protect the forearms to the hands), gardbraces (to protect the armpits), vambraces (that protect the elbow to the forearm), sabatons (that protect the feet), cuisses (to protect the thighs), tassat (that protect the groin, upper thighs, & pelvis), & greaves (that covered from the shin to the knee). It comes with a knight helmet. It is based on knight armor and paladin armor. It comes with a red cape. It comes with a silver diamond shield, a gold rectangular shield, & platinum war door shield.

Current costume:

Asian and European inspired red and black full plate armor. It is made of divine metals forged by god smiths of divine pantheons. It was forged with divine elements that acts as a conduit to supercharge any elemental and divine magic used by the wearer. It is also a modernized helmet that protects them and hides identity but also allows them to see than a typical knight or spartan like helmet.

It has a gorget (that protects the chest), a bevor (protecting the lower face, neck, chin, & throat) a breastplate or chestplate (that protects the chest), backplate, pauldrons (that protect the shoulders), plackart (that protected the lower half of the torso), cuirass (that protected the front of the torso), culet (that protects the small of back and the buttocks), couters (that protects the elbows), poleyns (that protected the knees), faulds (to protect the waist and hips), gauntlets (that protect the forearms to the hands), gardbraces (to protect the armpits), vambraces (that protect the elbow to the forearm), sabatons (that protect the feet), cuisses (to protect the thighs), tassat (that protect the groin, upper thighs, & pelvis), & greaves (that covered from the shin to the knee).

It was made out of mithril, adamantine, and orichalcum. It has a red and gold cape. East Asian, Southeast Asian, & European inspired full plate armor made out of celestial steel. It comes with a steel and titanium shield.

Future costume:

Asian and European inspired red and black full plate armor. It is made of divine metals forged by god smiths of divine pantheons. It was forged with divine elements that acts as a conduit to supercharge any elemental and divine magic used by the wearer. It is also a modernized helmet that protects them and hides identity but also allows them to see than a typical knight or spartan like helmet.

It has a gorget (that protects the chest), a bevor (protecting the lower face, neck, chin, & throat) a breastplate or chestplate (that protects the chest), backplate, pauldrons (that protect the shoulders), plackart (that protected the lower half of the torso), cuirass (that protected the front of the torso), culet (that protects the small of back and the buttocks), couters (that protects the elbows), poleyns (that protected the knees), faulds (to protect the waist and hips), gauntlets (that protect the forearms to the hands), gardbraces (to protect the armpits), vambraces (that protect the elbow to the forearm), sabatons (that protect the feet), cuisses (to protect the thighs), tassat (that protect the groin, upper thighs, & pelvis), & greaves (that covered from the shin to the knee).

It was made out of mithril, adamantine, and orichalcum. It is made out of chain mail, celestial steel, & stellar titanium. The armor was composed of large steel plates that were linked by loosely closed rivets and by internal dragon stuffed leathers to allow the wearer maximum freedom of movement. It is reinforced with precious metals (like divine iron, heavenly bronze, divine silver, celestial gold). East Asian, Southeast Asian, & European inspired full plate armor made out of celestial steel. It is a magical powered armor suit.

It is decorated with precious gemstones (like pearls, amethyst, sapphire, ruby, emerald, jade, & diamonds). The armor was elaborately gilded, etched, and embossed with fine decoration. It is carved with magical symbols and emblems. It is engraved with magical runes and sigils. It has a red and gold cape.

Holstered to the armor are small wooden, leather, and animal hide shields. Holstered to the armor are medium iron, bronze, & copper shields. Holstered to the armor are medium gold, silver, & platinum shields. Holstered to the armor are large steel, titanium, & tungsten shields.

Strapped to the armor are throwing knives, combat daggers, combat knives, tonfas, escrima sticks, nunchucks, two short handled war hammers, two short axes, two sword swords, a broadsword, a longsword, a two handed spear, a bojutsu bo staff, a two handed battle axe, a two handed sledgehammer, & a two handed great sword.

Strapped to the armor are two magical quadruple barrel flintlock pistols, a magical tri barrel flintlock rifle, a magical double barrel blunderbuss, a magical six shot revolvers, a magical ten shot lever action repeating rifle, a magical carbine, a magical bolt action sniper rifle, a magical combat shotgun, a magical submachine gun, a magical light machine gun, a magical medium machine gun, & a magical Gatling Gun.

For combat in melee combat, ranged combat (like bows and guns), and unarmed combat the Asian Pasifika demigod and Afro Latine Native alien hybrid superhero main character deals fire (fire, magma, lava) incineration damage, lightning shock damage, water drench damage, ice (snow, ice, frost) frozen damage, earth (earth, stone, metal & sand) physical damage, wind (air, wind, smoke, & fog), nature (plants, wood, nature) ensnare damage, poison toxic damage, and acid corrosive status and damage effects.

There is also light holy damage, dark necrotic damage, magic arcane damage, aether and nether esoteric damage, spiritual soul damage, & psionic mental damage, temporal time damage, quantum dimensional damage, nuclear radioactive damage, chaos damage, and void reality warping damage. This armor can supercharge those attacks to a certain point before needing to be recharged. This armor can also take attacks with status effects to a certain point before needing to be repaired.

#indigenous#indigenous artist#indigenous writer#indigenous art#indigenous creator#indigenous rep#indigenous character#native rep#native artist#native art#native writer#native character#native tag#queer creator#queer representation#queer artist#queer writer#queer character#trans creator#trans character#trans writer#trans representation#trans artist#disabled creator#disabled writer#disabled representation#disabled art#disabled artist#disabled character

2 notes

·

View notes

Text

Nail Technician Nail Extension Methods: Understanding different methods of nail extensions.

Understanding different methods of nail extensions is crucial for nail technicians to offer a variety of options to their clients. Here are some common nail extension methods:

1. Acrylic Extensions:

Acrylic extensions involve applying a combination of liquid monomer and powdered polymer to create a durable and long-lasting artificial nail.

The nail technician applies the acrylic mixture onto the natural nail or a nail form, shaping and sculpting it to the desired length and shape.

Acrylic extensions can be customized with various colors, designs, and finishes.

2. Gel Extensions:

Gel extensions are created by applying a gel product directly onto the natural nail or a nail form, which is then cured under a UV or LED lamp to harden.

The gel is usually applied in several layers, building up the desired length and shape.

Gel extensions provide a more flexible and natural-looking result compared to acrylic extensions.

3. Fiberglass or Silk Wrap Extensions:

Fiberglass or silk wrap extensions involve using a thin, flexible material (fiberglass or silk) to reinforce and extend the natural nail.

The material is applied using an adhesive or resin, providing added strength and support.

This method is suitable for clients who prefer a more natural-looking extension.

4. Polygel Extensions:

Polygel extensions combine the best qualities of acrylic and gel systems.

Polygel is a hybrid product that comes in a tube, which the nail technician dispenses onto the natural nail or nail form.

It requires a special slip solution to shape and sculpt the extension before curing it under a UV or LED lamp.

Polygel extensions offer a lightweight and durable option with excellent flexibility.

5. Press-On Nail Extensions:

Press-on nail extensions are pre-made artificial nails that come in various sizes and designs.

These nails typically have adhesive tabs or glue on the back, allowing them to be easily applied and removed.

Press-on extensions are a convenient and temporary option for clients who want a quick nail enhancement without the commitment.

6. Nail Tips and Overlay:

Nail tips are pre-formed plastic extensions that are applied to the natural nail to add length.

The tips are glued to the natural nail, trimmed to the desired length, and then overlaid with acrylic, gel, or another overlay product.

This method is popular for clients who want to extend the length of their nails without sculpting or building from scratch.

It's essential to stay updated yournailsupplier with the latest techniques and trends in nail extension methods and choose the method that best suits your client's preferences and needs. Proper application techniques and adherence to hygiene and safety protocols are crucial for providing high-quality nail extensions.

#nailstyle#painted nails#naildesign#manicure#nailpolish#pretty nails#nail#nail polish#nails#nail art

4 notes

·

View notes

Text

The Bahco Ergo Bypass Pruner PX-M2

Every gardener needs a trusty tool to make their gardening life easier. Let’s talk about “The Bahco Ergo Bypass Pruner PX-M2” today.

The Bahco Ergo Bypass Pruner PX-M2 is a game-changer for any gardener, whether you're a professional or a home gardener. Its professional-grade, ergonomic design is specifically crafted to reduce wrist and arm strain, making pruning tasks much more comfortable and efficient. The medium-sized handles are perfect for those with medium-sized hands, and the soft grip cover provides even more comfort during use. The medium-sized blades coated with Xylan can cut branches up to 3/4 inch thick with ease, and the fiberglass-reinforced plastic handles make this tool durable and long-lasting. Plus, with virtually every part available on Amazon, this pruner is a wise investment for any gardener looking for a reliable and efficient tool.

View the product here

There are more “Hand Pruning Shears” product suggestions you can check here

If you have found this post helpful, please share the post with others. And visit www.yardener.com for more information that is available for fully free.

#gardeningtools#gardenlife#yardener#gardeninginformation#garden#gardening#gardendesign#gardeningtips

1 note

·

View note

Text

Affordable 250 Liter RO Plant Price for Commercial Use

If you're looking for a 250 litre RO plant for your commercial needs, the 250 LPH RO Plant - Blue Color FRP Material from Indian RO and AC Service Center offers an ideal solution. Not only does it provide reliable water filtration, but its cost-effective pricing makes it a top choice for businesses with moderate water demands.

Key Features of the 250 LPH RO Plant

Durable FRP Material: The plant is made with FRP (Fiberglass Reinforced Plastic), ensuring both durability and resistance to corrosion. This makes it perfect for use in high-demand commercial environments.

Compact and Efficient Design: With a 250 LPH capacity, this RO plant is ideal for small to medium-sized businesses. It provides sufficient purified water for various commercial purposes, such as in restaurants, offices, or small manufacturing units.

Affordable Pricing: The 250 LPH RO plant price is competitive and offers an excellent return on investment for businesses seeking an affordable water filtration solution without compromising on quality.

Ease of Use: This RO plant is user-friendly, with easy installation and maintenance, making it perfect for businesses that require reliable, hassle-free water purification.

Why Invest in a 250 Litre RO Plant?

Cost-Effective Water Solution: Save on bottled water expenses while ensuring your business always has access to purified water.

Reliable Filtration: The advanced filtration system ensures that harmful contaminants are removed, providing high-quality water for consumption and other uses.

Compact Size: Its compact design allows for installation in small spaces, making it a great option for businesses with limited space.

For more information on the 250 LPH RO Plant - Blue Color FRP Material, visit the product page to discover how this affordable and efficient system can meet your commercial water purification needs.

0 notes