#Expanded Polypropylene

Explore tagged Tumblr posts

Text

0 notes

Text

Expanded Polypropylene Foam Market was valued at USD 1125 Million in 2023, and it is expected to reach USD 1725.40 Million by 2030, exhibiting a CAGR of 6.3 % during the forecast period (2024-2030)

#Expanded Polypropylene Foam Market#Expanded Polypropylene Foam Market size#Expanded Polypropylene Foam Market growth#Expanded Polypropylene Foam Market share#Expanded Polypropylene Foam Market demand#Expanded Polypropylene Foam Market analysis

0 notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Text

Discover top-tier EPP manufacturers in India. Innovative EPP packaging, expanded polypropylene protection, and customized solutions for diverse industries. Visit now!

#epp manufacturers#Manufacturers of epp#EPP packaging india#epp packaging#expanded polypropylene protective packaging india#epp material

0 notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Link

#Expanded Polypropylene (EPP) Foam Market size#Expanded Polypropylene (EPP) Foam Market share#Expanded Polypropylene (EPP) Foam Market price

0 notes

Text

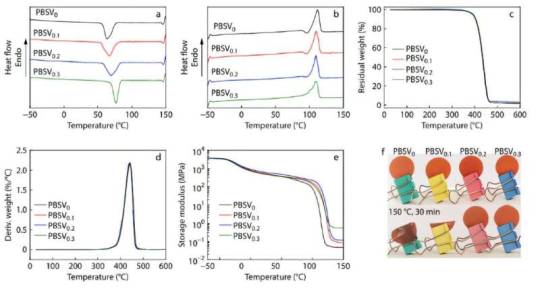

Breaking barriers in polymer tech: PBS vitrimers for greener futures

Poly(butylene succinate) (PBS) has emerged as a viable alternative to conventional plastics due to its biodegradability and similar properties to polypropylene. Under composting conditions, PBS can break down into water, carbon dioxide, and biomass. However, its linear structure has limited its use in key manufacturing processes, such as foaming and film blowing, due to challenges with melt viscosity and mechanical strength. Overcoming these limitations has been a key focus for researchers seeking to expand PBS's potential in sustainable applications. In a significant development, scientists from Southwest University, in collaboration with South China University of Technology, have enhanced PBS's properties by introducing dynamic imine bonds. Their research, published in the Chinese Journal of Polymer Science on May 17, 2024, details the creation of PBS vitrimers (PBSVs) that offer improved thermal, mechanical, and melt characteristics, positioning them as a more versatile material for eco-friendly applications.

Read more.

8 notes

·

View notes

Text

Expanded Polypropylene Foam Market was valued at USD 1125 Million in 2023, and it is expected to reach USD 1725.40 Million by 2030, exhibiting a CAGR of 6.3 % during the forecast period (2024-2030)

#Expanded Polypropylene Foam Market#Expanded Polypropylene Foam Market size#Expanded Polypropylene Foam Market growth#Expanded Polypropylene Foam Market share#Expanded Polypropylene Foam Market demand#Expanded Polypropylene Foam Market analysis

0 notes

Text

Key sectors in KSA manufacturing market:

Here’s a concise overview of the key sectors in Saudi Arabia's manufacturing market:

1. Petrochemicals

- Central to Saudi Arabia's manufacturing, leveraging vast oil and gas reserves to produce chemicals like ethylene and polypropylene.

- Major players include SABIC and Saudi Aramco.

2. Pharmaceuticals

- Rapidly expanding with a focus on local production of generics, vaccines, and biotech products.

- Supported by government initiatives to reduce import dependency.

3. Food and Beverage

- Vital for food security and economic growth, focusing on dairy, processed foods, beverages, and halal products.

- Expanding into regional and international markets.

4. Automotive

- Developing sector with a focus on assembling vehicles, manufacturing parts, and electric vehicles (EVs).

- Growing interest from global manufacturers.

5. Construction Materials

- Driven by mega-projects, producing cement, steel, aluminum, and sustainable materials.

- Key to supporting infrastructure development.

6. Metals and Mining

- Emerging sector with significant resources like gold, phosphate, and bauxite.

- Focus on extraction, processing, and downstream industries like aluminum smelting.

7. Textiles and Apparel

- Small but growing, with potential in high-quality textiles and traditional clothing.

- Opportunities in fashion and design.

8. Renewable Energy Equipment

- Focused on producing solar panels, wind turbines, and related components to support renewable energy projects.

- Significant growth potential aligned with sustainability goals.

9. Packaging

- Expanding due to growth in food, pharmaceuticals, and e-commerce.

- Innovation in sustainable packaging solutions is on the rise.

10. Defense and Aerospace

- Strategic priority with efforts to localize military equipment production.

- Supported by GAMI, focusing on parts manufacturing and maintenance services.

These sectors highlight Saudi Arabia's drive toward economic diversification, with strong government support and strategic investments fostering growth across the manufacturing industry.

#KhalidAlbeshri #خالدالبشري

#advertising#artificial intelligence#autos#business#developers & startups#edtech#education#finance#futurism#marketing

16 notes

·

View notes

Text

#pet acoustic panel#non woven battery gaunlets#light weight insulation#compressor felt#high efficiency media#breather fabric#fiber glass felt#plastic extrusion profile#lint free wipes#pp + pet felt

2 notes

·

View notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Text

Sigma's new enclosure is finished!

well, mostly. I want to get another branch or tube or plant or something in that top right corner to fill in the empty space, assuming the monster dracaena doesn't realize it now has an extra foot of vertical space and decide to conquer it. i'll give it a month or two and see how the dracaena adapts before putting something above it. I also want to see how the new pothos grows in, and how the old philodendron adapts. i actually removed two vines from the philo and cut the remaining two down to size a bit since they took over whatever space the dracaena didn't in the old enclosure, so i'm confident the philodendron will help fill in some of the currently empty space even if the dracaena and pothos decide not to.

for the enclosure itself, it's a Leap Habitats 22"x17"x36" enclosure and hoo boy it has its pros and cons... mostly cons. i haven't seen many reviews for these enclosures that aren't from popular youtubers or reddit threads from over a year ago, so here's my opinions below:

i've moved several times so i greatly appreciate how light the enclosure is even fully planted, and being able to screw branches and tubes and other things into the walls instead of having to use spray foam (and then either silicone or the grout method) to mount them is really nice. both are pluses over the glass exoterra 18"x18"x24" Sig has called home since he was given to me. i loved that enclosure but after moving three times with it (once before i made it bioactive) i was not a fan of the weight.

this doesn't apply to me right now, but i do see it as a plus that they included the little spots in the corners of the top that you can pop out to easily install mister nozzles through. i don't know if these holes fit non-Leap misting systems without modification, but it's certainly simpler than some of the setups i've seen for getting misters installed in traditional enclosures like exoterras.

Sigma is... not a great hunter. his method of hunting black soldier flies, for example, is to slam his face as hard as possible into them. this is another big reason i wanted him out of the glass enclosure-- i'm genuinely worried about him injuring himself with the force at which i've watched him bounce his face off the walls and door of the exoterra enclosure. so the softer, less rigid walls and acrylic door are a plus for that alone.

now for the downsides...

i'm really not a huge fan of how flimsy the acrylic door is. if it was a liiiittle thicker i'd probably like it more. the very simple method for the door hinge also means that when open, the door is misaligned, so i have to remember to slightly lift it when i go to close it so it will fit back in its space and close properly. this could be related to the low quality control that i've heard other people report regarding Leap (and experienced myself further below)

the base also leaks. they do sell external water catch trays in case of leakage, but i feel like they should come with the trays instead of the tray being optional, since the design of these things is basically guaranteed to leak without modification.

i didn't encounter this myself because i'd already seen warnings about this and didn't bother trying, but silicone and expanding foam won't adhere to the sides without help. Leap recommends using wall anchors for the foam to hold onto, but there's no real solution for silicone. this is annoying, because being able to seal the damned thing with silicone would GREATLY help the above leaking problem because you could just silicone around the rivets and internal plastic liner so that the leaking wouldn't be an issue. sealants that do bond to polypropylene don't strike me as being safe for use inside a reptile enclosure, especially a bioactive one.

it was also a BITCH to put together. i sort of expected this because a couple reviews i read before buying stated that the quality control is not the best. Leap has several videos on their youtube showcasing how to assemble the enclosures straight out of the box, and the provided instructions in the box are simple enough to follow, but i had to make some minor modifications in order to get the enclosure together due to ill-fitting pieces (for example, the screen top, which also keeps the walls in shape, did not actually fit on top of the walls like it was supposed to and i had to pry some sections open wide enough to actually get the damned thing in place). the alignment pin that goes in the front right of the base also did not want to be flush with the base like it's supposed to be.

all that being said, right now i would still be willing to get another, smaller Leap enclosure in the future for my mourning geckos or another gecko species. whether i actually do get another of their enclosures will really depend on how this one for Sig holds up. the lightness and ease of customization were the entire reasons i ordered this enclosure instead of a similarly sized (24x"18"x36") glass one, so we'll eventually see if that's truly worth the troubleshooting and outright downsides to these enclosures or not.

11 notes

·

View notes

Text

Cling Film Market Trends, Segmentation, Outlook, Industry Report to 2031

The cling film market is anticipated to grow at a CAGR of 5.2% during the anticipated time frame and reach USD 8.72 billion by 2027. Food items are routinely wrapped and preserved with cling film, a thin plastic sheet also known as plastic wrap or food wrap.

The sector is developing mainly due to rising customer demand for packaged and handy items as well as increased consumer education on food safety and storage. Cling film is frequently used in homes, restaurants, and the food processing and packaging industries to preserve food for a longer period of time.

Low-density polyethylene (LDPE), polyvinyl chloride (PVC), and linear low-density polyethylene (LLDPE) are the three material kinds that make up the market. Because of its exceptional clarity, strength, and flexibility, PVC is the cling film material that is used the most frequently.

For More Insights on this Market, Get A Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-2654

The effects of cling film on the environment, however, are also a worry. In landfills, plastic cling film takes hundreds of years to decompose, which can contribute to environmental contamination. Due to this, there is an increasing need for cling film substitutes like silicone food covers and beeswax wraps.

Overall, it is anticipated that the cling film market will expand over the next few years due to the rising demand for practical and secure food packaging solutions. To fulfil the changing expectations of consumers, the industry will also need to address worries about the environmental impact of plastic cling film and investigate sustainable alternatives.

Market Benefits

The study provides an in-depth analysis of the global Cling Film market along with the current trends and future estimations to elucidate the imminent investment pockets.

The key market players along with their strategies are thoroughly analyzed to understand the competitive outlook of the industry.

An extensive analysis of the market based on application assists in understanding the trends in the industry.

The report presents a quantitative analysis of the market from 2021 to 2031 to enable stakeholders to capitalize on the prevailing market opportunities.

Key Takeaways from the Cling Film Market Study

Polyvinyl chloride is expected to create incremental opportunity of US$ 508.3 million by 2031. It is cost-effective and suitable for recycling processes.

Cling film products up to 9 microns in thickness is estimated to increase 1.7 times by the end of 2031, attributed to clear and transparent packaging for food product displays.

Canada is expected to reflect faster growth in North America, with a 6.5% CAGR due to the presence of key players and the availability of technological advancements.

Germany leads Western Europe accounting for 26% of the value share by 2031, owing to relatively higher production capacity.

China will continue to dominate APEJ holding over 40% of the market through 2031, supported by a large base of end users and manufacturers.

Are you looking for customized information related to the latest trends, drivers, and challenges? @ https://www.futuremarketinsights.com/customization-available/rep-gb-2654

Competitive Landscape

Berry Global Group, Inc.

Intertape Polymer Group (IPG)

Gruppo Fabbri Vignola S.p.A

Kalan SAS

Fine Vantage Limited

Rotofresh – Rotochef s.r.l.

Manuli Stretch S.p.A.

Cling Film Market by Category

By Material type:

Polyethylene

Low Density Polyethylene (LDPE)

High Density Polyethylene (HDPE)

Linear Low Density Polyethylene (LLDPE)

Bi-axially Oriented Polypropylene (BOPP)

Polyvinyl Chloride

Polyvinylidene Chloride

Others

Speak to Our Analyst @ https://www.futuremarketinsights.com/ask-the-analyst/rep-gb-2654

By Thickness:

Up to 9 micron

9 to 12 micron

Above 12 micron

By End Use:

Food

Meat

Seafood

Baked Foods

Dairy Products

Fruits & Vegetables

2 notes

·

View notes

Link

#adroit market research#expanded polypropylene foam#epp foam market#epp foam market 2020#epp foam market size

0 notes

Text

Just some brief and basic facts about the most common types of implants above.

And info on some more unusual past and future types of augmentations below:

String expansion is no longer carried out due to safety concerns. Saline is the only current way of creating huge sizes, whether through overfilling standard shells or expanders (the latter being very prone to infection though as we fill with saline). One type that may be more common in the future are air expanders 😉

2 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Why are you choosing YANCI bed risers? A wide range of applications, including bed, sofa, wardrobe, refrigerator, washing machine, and other kinds of furniture. Expand your space, increased space can store sundries, but also convenient for your cleaning work.This blue bed riser can be matched with different heights to adapt to furniture legs.Use these risers to effectively utilize under-the-bed storage and safely hoist your beds or furniture to an extra 2". A hassle-free answer for little rooms, apartments, and condos with constrained storage space.Powerful support can support the weight of 10,000 pounds, which can effectively reduce the noise of running the washing machine, and the bottom is TPU non-slip rubber, which can firmly stick to the floor YANCI Square-Shaped Design is Convenient There are 4/8 blue wrapped edges, and 4/8 black single-layer TPU anti-slip silicone. The surface of the grain raised can make your table legs stand firmly, you no longer have to worry about it is not high enough, not stable enough. The bottom side of the black silicone is also a grid design so that it fits better with the bed risers and will not easily fall off, to achieve the effect of repeated use. YANCI is committed to creating beautiful and practical and durable family supplies. The High Grade Material Made using polypropylene PP polymer plastic and TPR soft rubber, which is durable and resistant to high temperature, water and corrosion The Standard Dimension The pads are constructed with the dimension of 7.3 x 7.3 x 3.0 cm, the size which fits to almost all models and offers strong bearing capacity The Multi-Purposive It can be used in refrigerators, washing machines, sofas, beds, tables, dish-washing cabinets, wardrobes and other heavy goods or machines to meet your various needs. [Total weight capacity over 10,000 pounds]: Everyday Adjustable bed risers is suitable for this table leg extenders. The furniture will not shake, no need to worry about the bed post risers being punctured or broken.

[Robust & Duable]: The heavy-duty furniture risers made by durable PP. The internal grid structure maintains the long-term stability of the bed riser, and easily supports your heavy furniture. [Washing Machine Foot Pad]: Washing Machine Foot Support- Simple design is very practical for home, store, hotel, bathroom and some other places use. [Various Occasions]: Bed risers heavy duty can be raise beds, sofas, tables, appliances, giving you the ability to create storage space while still keeping furniture at the right height. (Not suitable for furniture with wheels) [ad_2]

0 notes