#Construction Applications

Explore tagged Tumblr posts

Text

PVDF material: the choice of environmental protection, high efficiency and sustainable development

In today’s society, with the rapid development of science and technology and the increasing awareness of environmental protection, finding materials that are both efficient and environmentally friendly has become a common goal pursued by all walks of life. Among many materials, polyvinylidene fluoride (PVDF, Polyvinylidene Fluoride) is gradually becoming one of the preferred materials for…

#chemical stability#construction applications#electrical insulation properties#energy applications#environmental protection#high efficiency#mechanical strength#PVDF materials#sustainable development#weather resistance

0 notes

Text

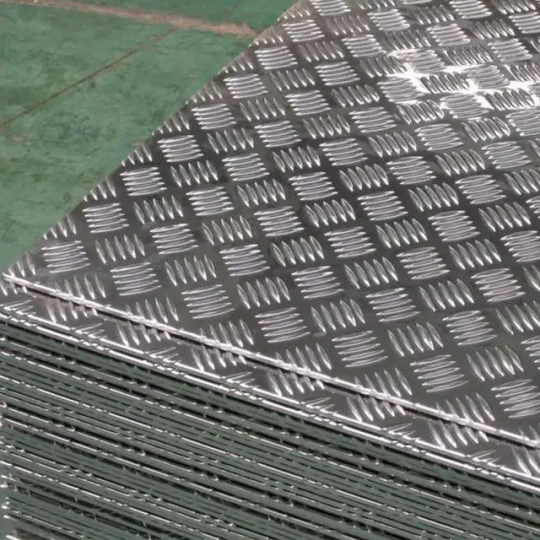

Aluminium 6082 Chequered Plates: Strength, Versatility, and Applications

Aluminium 6082 chequered plates, also known as tread plates or diamond plates, are renowned for their strength, lightweight nature, and corrosion resistance. This blog explores the properties, applications, and benefits of Aluminium 6082 chequered plates, emphasizing their importance in construction, transportation, and manufacturing sectors.

Properties of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several key properties that make them suitable for diverse applications:

High Strength: Provides excellent structural integrity and load-bearing capacity, ideal for heavy-duty applications.

Lightweight: Aluminium's low density makes 6082 chequered plates easy to handle and install, reducing overall structural weight.

Corrosion Resistance: Resistant to corrosion and weathering, ensuring durability in outdoor and marine environments.

Skid-Resistance: Patterned surface design enhances grip and reduces slipping, making them ideal for flooring and stair treads.

Machinability: Easy to fabricate and machine, allowing for precise cutting and shaping in manufacturing processes.

Recyclability: Fully recyclable without loss of properties, supporting sustainability efforts in construction and manufacturing.

Applications of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates find extensive use across various industries and applications:

Transportation: Used in truck beds, trailers, and marine vessels for their durability and skid-resistant properties.

Construction: Ideal for flooring, stair treads, and walkways in commercial buildings, industrial facilities, and outdoor structures.

Manufacturing: Utilized as protective and decorative elements in machinery, equipment, and architectural applications.

Decorative Purposes: Applied in interior design and architectural projects for their aesthetic appeal and functional benefits.

Safety Applications: Employed in industrial settings and public spaces to enhance safety by reducing the risk of slips and falls.

Benefits of Aluminium 6082 Chequered Plates

Aluminium 6082 chequered plates offer several advantages, making them a preferred choice in various applications:

Enhanced Safety: Provides a secure, non-slip surface, improving safety in high-traffic areas and industrial environments.

Longevity: Resistant to corrosion, abrasion, and wear, ensuring extended service life with minimal maintenance.

Versatility: Available in different patterns, thicknesses, and sizes to suit specific application requirements.

Cost-Effectiveness: Lower installation and maintenance costs compared to alternative materials, contributing to overall project savings.

Environmental Sustainability: Fully recyclable and energy-efficient during production, supporting green building initiatives.

Conclusion

Aluminium 6082 chequered plates are essential in industries where safety, durability, and aesthetics are paramount. Their unique patterned surface and robust properties make them versatile for various applications in transportation, construction, manufacturing, and decorative uses. Understanding the properties and benefits of Aluminium 6082 chequered plates underscores their significance in enhancing safety, efficiency, and sustainability across diverse sectors.

#Aluminium 6082 Chequered Plates#Tread Plates#Diamond Plates#Skid-Resistance#Construction Applications#Transportation Industry

0 notes

Text

Water-Based Adhesive Specialty Tapes Market Will Advance at a 6.5% CAGR

The water-based adhesive specialty tapes market will reach USD 9,514.9 million, advancing at a 6.5% compound annual growth rate, by 2030. The progression of the water-based adhesive specialty tapes industry is primarily attributed to the growing automotive sector, advantages offered by water-based adhesive specialty tapes as compared to conventional bonding approaches, and surging demand for…

View On WordPress

#Adhesive tape manufacturers#Construction applications#Construction industry#Eco-friendly tapes#market analysis#Market dynamics#packaging materials#Specialty tape demand#Specialty tape innovations#Sustainable adhesive solutions#sustainable packaging#Water-Based Adhesive Specialty Tapes Market#Water-based adhesive tape technology

0 notes

Text

Global Sanding Block Market Is Estimated To Witness High Growth Owing To Increasing Demand for DIY Home Improvement Projects

The global Sanding Block Market is estimated to be valued at US$ 363.11 million in 2022 and is expected to exhibit a CAGR of 3.50% over the forecast period (2023-2030), as highlighted in a new report published by Coherent Market Insights. Market Overview: Sanding blocks are essential tools used for smoothing and polishing surfaces such as wood, metal, and other materials. These blocks provide better control and even pressure distribution while sanding, resulting in a smooth and polished finish. Sanding blocks are widely used in various industries, including woodworking, automotive, construction, and DIY projects. They offer several advantages such as improved grip, durability, easy handling, and versatility. With the growing trend of DIY home improvement projects and increasing demand for quality finishes, the market for sanding blocks is expected to witness significant growth. Market key trends: One key trend in the sanding block market is the rise in DIY home improvement projects. In recent years, there has been an increase in the number of homeowners opting for DIY projects to enhance the aesthetics of their homes. Sanding blocks play a crucial role in sanding and polishing surfaces before applying paint or varnish. The DIY trend has created a demand for user-friendly tools that provide professional-quality results. Sanding blocks with ergonomic designs and easy-to-use features are gaining popularity among DIY enthusiasts. For example, Festool GmbH, one of the key players in the sanding block market, offers a range of sanding blocks with innovative features such as dust extraction systems and interchangeable sanding pads. These blocks are designed to provide comfort and precision during sanding, making them ideal for DIY projects. PEST Analysis: 1. Political: The sanding block market is not significantly affected by political factors. However, government regulations related to worker safety and environmental concerns may impact the manufacturing and distribution of sanding blocks. 2. Economic: The economic stability and growth of a region directly affect the demand for sanding blocks. A robust economy with increased construction activities and infrastructure development drives the market growth. 3. Social: The growing awareness among consumers about the importance of maintaining and improving the aesthetics of their homes has fueled the demand for sanding blocks. Additionally, the popularity of DIY projects among millennials and Generation Z has created a lucrative market for sanding blocks. 4. Technological: Technological advancements in sanding block manufacturing have resulted in the development of advanced features such as ergonomic designs, dust extraction systems, and interchangeable sanding pads. These technological innovations enhance the efficiency and performance of sanding blocks. Key Takeaways: 1. The Global Sanding Block Market Demand is expected to witness high growth, exhibiting a CAGR of 3.50% over the forecast period, due to increasing demand for DIY home improvement projects. Sanding blocks provide users with professional-quality results and ease of use, making them essential tools for DIY enthusiasts. 2. North America dominates the sanding block market due to the rising trend of DIY projects and increasing renovation activities. The region is expected to maintain its dominance during the forecast period.

#Sanding Block Market#Sanding Block Market Insights#Sanding Block Market Forecast#Sanding Block Market Values#Sanding Block Market Analysis#Sanding Block Market Demand#Sanding Block Market Outlook#woodworking#furniture manufacturing#automotive#construction applications#sanding blocks#Coherent Market Insights

0 notes

Text

disclaimer: these options are based on responses i've heard different people give; they do not necessarily reflect my own personal beliefs

*if you feel comfortable doing so, i would love to hear what passages support your opinion!

please do not use this post for debate. i am genuinely curious what different people's opinions on this idea are. please keep this post friendly, informative, and simply a space to listen and share.

i'd appreciate it if you could reblog if you vote (you don't need to share your answers in your tags if you don't want to!), to get a larger sample size. thank you!

#okay. i have been thinking about some things for about a year/year-and-a-half now#and then a question in sunday school this morning sparked some more thoughts#soooo poll time#stuck the disclaimer there because i do *not* believe gender is a social construct but i tried to provide options that would be#applicable to very different stances#and then i stuck the second bit there bc some horror scenarios flashed before my eyes sdlkjsdglj#elle rambles#polls by elle#also i'm realizing now maybe i should've added two more options of just 'yes for other reasons' & 'no for other reasons' but oops

54 notes

·

View notes

Text

i really enjoy this font

#unfortunately it is hard to read so i will not be spending any more time on this#just saving pics before i return this book to my math department#there is an interesting galois theory application at the end though#about ruler compass constructions#Galois Theory (Notre Dame Mathematical Lectures Number 2) by Emil Artin

30 notes

·

View notes

Text

"Skylab Airlock Module in clean room

St. Louis, MO - The flight version of the Skylab Airlock Module is shown here in a clean room at the McDonnell Douglas Astronautics Co. Faciliy in St. Louis, MO. The flight Airlock Module is 17 feet long and 10.5 feet in diameter at the top, and weighs about 49,000 pounds.

Note: the Gemini door, inverted at center of picture."

Date: January 27, 1972

NASA ID: 72-H-86 aka 72-HC-51

#Skylab Orbital Workshop#Skylab OWS#Skylab#Skylab I#Skylab 1#SL-1#Space Station#NASA#Apollo Program#Apollo Applications Program#construction#McDonnell Douglas#St. Louis#Missouri#January#1972#my post

19 notes

·

View notes

Text

Okay so to get the additive group of integers we just take the free (abelian) group on one generator. Perfectly natural. But given this group, how do we get the multiplication operation that makes it into the ring of integers, without just defining it to be what we already know the answer should be? Actually, we can leverage the fact that the underlying group is free on one generator.

So if you have two abelian groups A,B, then the set of group homorphisms A -> B can be equipped with the structure of an abelian group. If the values of homorphisms f and g at a group element a are f(a) and g(a), then the value of f + g at a is f(a) + g(a). Note that for this sum function to be a homomorphism in general, you do need B to be abelian. This abelian group structure is natural in the sense that Hom(A ⊗ B,C) is isomorphic in a natural way to Hom(A,Hom(B,C)) for all abelian groups A,B,C, where ⊗ denotes the tensor product of abelian groups. In jargon, this says that these constructions make the category of abelian groups into a monoidal closed category.

In particular, the set End(A) = Hom(A,A) of endomorphisms of A is itself an abelian group. What's more, we get an entirely new operation on End(A) for free: function composition! For f,g: A -> A, define f ∘ g to map a onto f(g(a)). Because the elements of End(A) are group homorphisms, we can derive a few identities that relate its addition to composition. If f,g,h are endomorphisms, then for all a in A we have [f ∘ (g + h)](a) = f(g(a) + h(a)) = f(g(a)) + f(h(a)) = [(f ∘ g) + (f ∘ h)](a), so f ∘ (g + h) = (f ∘ g) + (f ∘ h). In other words, composition distributes over addition on the left. We can similarly show that it distributes on the right. Because composition is associative and the identity function A -> A is always a homomorphism, we find that we have equipped End(A) with the structure of a unital ring.

Here's the punchline: because ℤ is the free group on one generator, a group homomorphism out of ℤ is completely determined by where it maps the generator 1, and every choice of image of 1 gives you a homomorphism. This means that we can identify the elements of ℤ with those of End(ℤ) bijectively; a non-negative number n corresponds to the endomorphism [n]: ℤ -> ℤ that maps k onto k added to itself n times, and a negative number n gives the endomorphism [n] that maps k onto -k added together -n times. Going from endomorphisms to integers is even simpler: evaluate the endomorphism at 1. Note that because (f + g)(1) = f(1) + g(1), this bijection is actually an isomorphism of abelian groups

This means that we can transfer the multiplication (i.e. composition) on End(ℤ) to ℤ. What's this ring structure on ℤ? Well if you have the endomorphism that maps 1 onto 2, and you then compose it with the one that maps 1 onto 3, then the resulting endomorphism maps 1 onto 2 added together 3 times, which among other names is known as 6. The multiplication is exactly the standard multiplication on ℤ!

A lot of things had to line up for this to work. For instance, the pointwise sum of endomorphisms needs to be itself an endomorphism. This is why we can't play the same game again; the free commutative ring on one generator is the integer polynomial ring ℤ[X], and indeed the set of ring endomorphisms ℤ[X] -> ℤ[X] correspond naturally to elements of ℤ[X], but because the pointwise product of ring endomorphisms does not generally respect addition, the pointwise operations do not equip End(ℤ[X]) with a ring structure (and in fact, no ring structure on Hom(R,S) can make the category of commutative rings monoidal closed for the tensor product of rings (this is because the monoidal unit is initial)). We can relax the rules slightly, though.

Who says we need the multiplication (or addition, for that matter) on End(ℤ[X])? We still have the bijection ℤ[X] ↔ End(ℤ[X]), so we can just give ℤ[X] the composition operation by transfering along the correspondence anyway. If p and q are polynomials in ℤ[X], then p ∘ q is the polynomial you get by substituting q for every instance of X in p. By construction, this satisfies (p + q) ∘ r = (p ∘ r) + (q ∘ r) and (p × q) ∘ r = (p ∘ r) × (q ∘ r), but we no longer have left-distributivity. Furthermore, composition is associative and the monomial X serves as its unit element. The resulting structure is an example of a composition ring!

The composition rings, like the commutative unital rings, and the abelian groups, form an equational class of algebraic structures, so they too have free objects. For sanity's sake, let's restrict ourselves to composition rings whose multiplication is commutative and unital, and whose composition is unital as well. Let C be the free composition ring with these restrictions on one generator. The elements of this ring will look like polynomials with integers coefficients, but with expressions in terms of X and a new indeterminate g (thought of as an 'unexpandable' polynomial), with various possible arrangements of multiplication, summation, and composition. It's a weird complicated object!

But again, the set of composition ring endomorphisms C -> C (that is, ring endomorphisms which respect composition) will have a bijective correspondence with elements of C, and we can transfer the composition operation to C. This gets us a fourth operation on C, which is associative with unit element g, and which distributes on the right over addition, multiplication, and composition.

This continues: every time you have a new equational class of algebraic structures with two extra operations (one binary operation for the new composition and one constant, i.e. a nullary operation, for the new unit element), and a new distributivity identity for every previous operation, as well as a unit identity and an associativity identity. We thus have an increasing countably infinite tower of algebraic structures.

Actually, taking the union of all of these equational classes still gives you an equational class, with countably infinitely many operations. This too has a free object on one generator, which has an endomorphism algebra, which is an object of a larger equational class of algebras, and so on. In this way, starting from any equational class, we construct a transfinite tower of algebraic structures indexed by the ordinal numbers with a truly senseless amount of associative unital operations, each of which distributes on the right over every previous operation.

#math#the ongoing effort of valiantly constructing complicated mathematical structures with 0 applications#i know i owe you guys that paraconsistency effortpost still#it's coming! just hard to articulate so far#so if you start with the equational class with empty signature your algebras are just sets#the first iteration of the construction gets you the class of monoids#but after that it's what i guess you could call 'near-semirings'?

48 notes

·

View notes

Text

every time i hear anything art-related on tiktok, i immediately get really like... upset? annoyed? idk. unpleasant feeling because it's literally always "we're making fun of this child/beginner for their anatomy or how they color" or whatever else or pretending that an artists deserve to be treated like a piece of corporate media.

i know tiktok is literally the devil and hell incarnate, but i don't think any artist deserves to be targets of mass harassment especially not people who are just starting out (and even more especially not children).

if tiktok was a thing when i was younger and i was posting my art on there, i would never fucking draw ever again. my art career would've ended after a few months of drawing "seriously," and i really do mean it lol. call me sensitive or whatever, but a 13-15 year old does not need to hear whatever criticism you think they need to hear i promise.

#dook dook#the only thing people should be doing is offering actual helpful advice and constructive criticism is only welcome when asked for#but these people never ask for it...#im talking about the 'art lore' stuff or whatever (idk if its called that)#i never kept up with it because 1 i am not on tiktok 2 i am a full grown adult who doesnt care and 3 it just makes me feel fucking awful?#but seriously#beginning artists will not be on the same level as someone whos been drawing for 10+ years#beginning artists will not have 'good' anatomy or know how to color or shade 'properly'#it really pisses me offfff...#if youre a beginning artist the only things you really need to know are: drawing more than 1 body type (please draw fat people. please.)#do not fall for 'dos and donts' types of tutorials#ESPECIALLY ones that are about men vs. women anatomically#take care of your wrists and hands and arms#AND FINALLY: DONT WORRY ABOUT ANY 'RULES' DO WHAT FEELS RIGHT TO YOU#ART CAN LOOK LIKE ANYTHING AND CAN BE MADE USING ANY TECHNIQUE BRUSH APPLICATION WHATEVER!!!#DO NOT FUCKING WORRY ABOUT IT PLEASE

5 notes

·

View notes

Text

had a dream a couple nights ago chris kreider was a panther. the dream was about something entirely different but my subconscious brain was so confused i spent the back half of it post-panther-discovery trying to dig up capfriendly so i could figure out when that fucking happened

#my dream constructing me a reality: yeah so the pizza place accepted your job application. wait here on yr phone. here's a twitter feed.#memes. tweets that are boring but from ppl you follow for hockey so it's ok. memes. hockey photos. hockey photo featuring ck20 as a cat#me (terminally hockeybrained): WHAT??? WHEN??? WHAT WAS THE TRADE RETURN FOR HIM?????#-_-

8 notes

·

View notes

Text

Innovative Application and Prospects of PVDF in the Coatings Industry

At the beginning of the third decade of the 21st century, the global coatings industry is undergoing unprecedented changes and innovations. Among them, PVDF (polyvinylidene fluoride) fluorocarbon coatings have become the focus of industry attention with their excellent performance and broad application prospects. As a high-performance fluoropolymer material, PVDF has shown extraordinary value in…

#automotive applications#chemical applications#chemical resistance#construction applications#corrosion resistance#electrical applications#environmental protection characteristics#PVDF fluorocarbon coatings#weather resistance

0 notes

Text

hi guys....sorry for not posting sherlocktober things....

Here's an artwork I did today to fill out an application for something

Lmk if this seems good!!

Here's the concept description that I wrote that was required

This art piece is based off of an song by Kimya Dawson & Antsy Pants, the name is “Tree Hugger.” In this work I used the sticker notes to write the lyrics. The rattlesnake wants to show affection to the cactus, having the desire to become a man merely to have hands to hug the cactus. Of course the cactus refuses the love and affection that it's been offered because of its spikes that could end up hurting the rattlesnake. Instead, the cactus suggests that the rattlesnake give the flower the cactus has sprouted a hug instead, still only with eyes. This symbolizes a common scenario within many relationships where one person is willing to give the other all the love and respect they deserve, but because of the other's fear of hurting them that person backs away and denies the love. Afraid of making their friend go away, they still accept the minimum amount of affection.

#cactus#rattlesnake#desert#artwork#my art#traditional art#brush pen#watercolor markers#pencil#sticky notes#applications#artists#small artist#artist#artists of tumblr#artists on tumblr#weird art#kimya dawson#antsy pants#feedback#constructive critism welcome#off page#concept art#concept drawing#idk how to tag lol

5 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Seismic Pallet Rack, Racking, new and used, shelving, cantilever rack (concord / pleasant hill / martinez)

#d uprights#8' long x 4#d#GREEN SEISMIC TEARDROP UPRIGHTS. Ask for the innovative uprights that are knocked down for ease of shipping; and are easily set up with nut#Then we have ORANGE BEAMS that are 6'#8'#9'#10'#12' long with capacities from 2200 lbs./pair to 8204 lbs./pair.#Don't forget about the wire decks made necessary by the fire dept. They want you to have “flow through” decks that allow the sprinklers to#the heat to rise#set off the alarm and activate the vents. Call for prices.#We also sell USED PALLET RACK if it is AMERICAN SEISMIC DESIGN. Chinese made and most of the used pallet rack are not seismic design. Chine#increasing the number of connector rivets on the ends of the beams from 2 to 3#and sometimes requiring backers (double columns) on the upright channels to at least the first beam level.#How do you get your forklift from the ground to your dock or the bed of a truck? Use a MOBILE YARD RAMP. They roll around to various locati#Ground-to-trailer application best served with 36' ramp including a 6' level off. Note the lip on the top end that is welded onto a frame f#000 lbs. capacity as opposed to a flimsy hinged steel plate that doesn't have 20#000 lbs. capacity. Other sizes and capacities available.#All steel welded construction. MADE IN AMERICA. Ramps made in China do not have quality control of their steel. Therefore#the capacities cannot be guaranteed.#Add the full undercarriage with solid 18#or 48“ length of forks. We used to sell used pallet jacks but within a few weeks the customer would come back and want to get a refund beca#WHERE-IS#CASH AND CARRY#NO REFUNDS#CREDITS#WARRANTY#EXCHANGES OR RETURNS#Cash and carry

2 notes

·

View notes

Text

Of course the corollary to ‘women writing for women audiences/readers is inherently queer’ is that all other media made by men ostensibly for a male audience is also really fucking queer

#The way I accept that premise#The binary is present but also so ‘constructed’ idk how to say it#the more ppl are aware of it as a construction the more interesting the deconstruction and/or the choice of application maybe?

5 notes

·

View notes

Text

This photograph shows activities during assembly of the Skylab cluster at the Vehicle Assembly/Checkout building. The Saturn V S-IVB stage is shown at left, and right is the Orbital Workshop (OWS) being readied for mating to the thruster. The S-IVB stage was modified to house the OWS, which provided living and working quarters for the Skylab crews. The Marshall Space Flight Center had responsibilities for the design and development of the Skylab hardware, and management of experiments.

Date: 1970

NASA ID: S70-19524

#Skylab Orbital Workshop#Skylab OWS#Skylab#Skylab I#Skylab 1#SL-1#Space Station#NASA#Apollo Program#Apollo Applications Program#McDonnell Douglas#Factory#Lambert Field#St. Louis#Missouri#S-IVB#1970#construction#undated#my post

39 notes

·

View notes