#Chemical Process Equipment

Explore tagged Tumblr posts

Text

Chemical Industry: Supporting Agrochemicals, Polymer Consumption, and Emerging Market Growth

India is currently 3rd in agrochemicals production & polymer consumption and an emerging player in specialty chemicals. Idex provides services for Chemical industry in India. Check out our products here. IDEX India offers innovative products tailored to the chemical industry, including solutions for agrochemicals and polymer consumption. As an emerging player in the market, IDEX India provides cutting-edge equipment that enhances production efficiency, safety, and sustainability, helping businesses stay competitive and compliant with industry standards.

#Chemical Process Equipment#leading valves manufacturer#Industrial Compressor#Industrial Fire Fighting#Pump and Valves#IDEX India

0 notes

Text

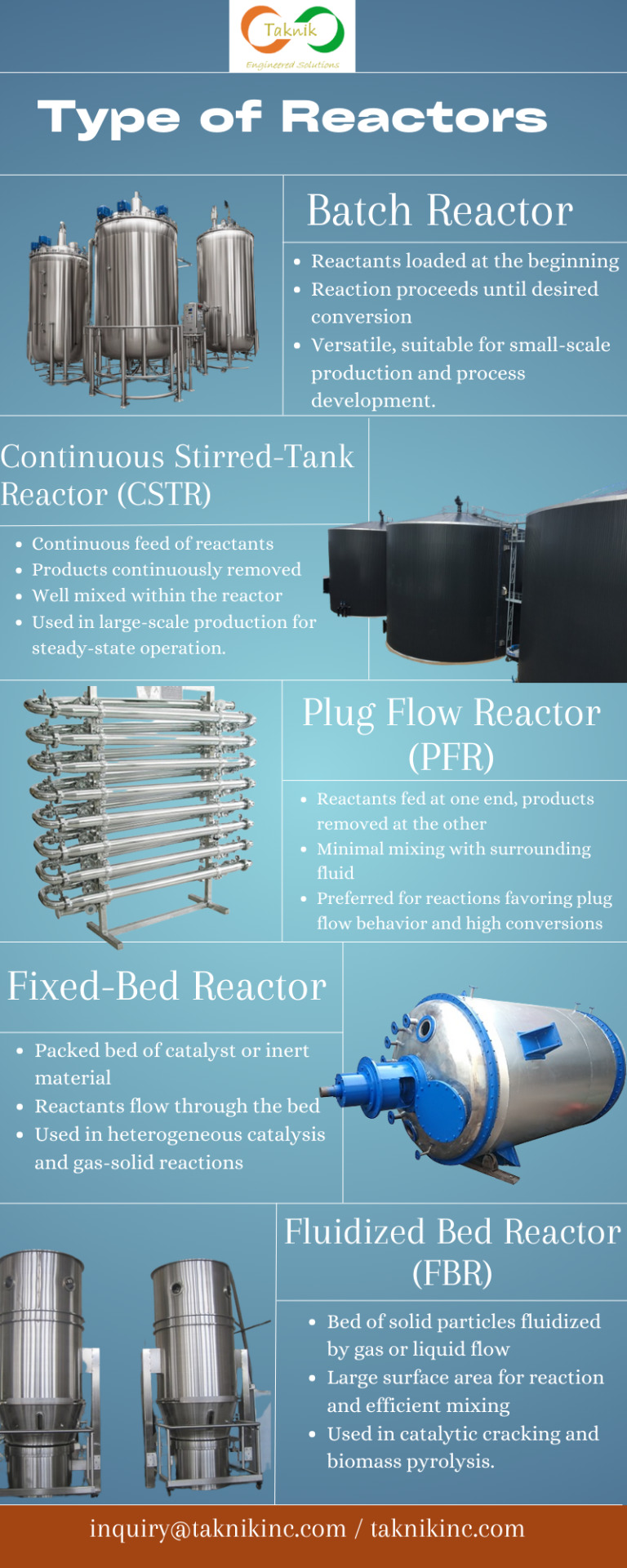

Taknik Inc is an Engineering Consultant it is a leading provider of Engineering design & Consultancy Services solution in India.

We Provide Process Equipment for the Manufacture Industries ,all kind of Matallic and non Metallic Equipment ,Reactor,HDPE Sprial Tank Blower Scrubber, Heat Exchanger, Storage Tank, Pressure Vessel etc .

for more details you can contact us

9510430147

or

email Id- [email protected]

#taknikinc#engineering#consultant#services#manufacturingindustry#manufacturer#metallic#Reactor#solutions#process#equipment#production#chemicals#tank#bharuch#gujarat

4 notes

·

View notes

Text

U.S. Chemical Safety Board Announces New Safety Product to Provide the Public with More Information about Serious Chemical Incidents Reported to the Agency

Reports Cover Incidents in California, Colorado, Georgia, Illinois, Iowa, Kentucky, Louisiana, Massachusetts, Minnesota, New Mexico, North Carolina, North Dakota, South Carolina, Tennessee, and Texas Washington, D.C. January 14, 2025 – Today, the U.S. Chemical Safety and Hazard Investigation Board (CSB) announced that it is launching a new initiative to give the public more details about the…

View On WordPress

#Business#Chemical Safety#CSB#Employment#News#Occupational safety and health#Personal protective equipment#Process Safety#Safety News#U.S. Chemical Safety and Hazard Investigation Board#United States#Workplace Fatality#Workplace Safety

0 notes

Text

Trusted Chemical and Process Equipments Supplier UK Since 2014

PPEC Ltd. is one of the well-known chemical companies UK that has been operating since 2014. We have built a solid foundation for commercial and domestic clients by complying with our core values of integrity, transparency, quality, and affordable prices. Our team is committed to offering exceptional chemical products to customers in a variety of industries while maintaining high quality.

#chemical#chemicalindustry#organic chemicals#research chemicals#supplements#process equipments#process engineering#vitamins

1 note

·

View note

Text

Top Dairy Industry Cleaning Supplies | Pure Clean Supplies

Explore our extensive range of cleaning supplies specifically designed for the dairy industry. From sanitizers to specialized detergents, Pure Clean Supplies offers high-quality products to ensure a clean and safe environment. Perfect for farms, processing plants, and dairy facilities. Shop now for the best in dairy cleaning solutions!

#Dairy cleaning products#Dairy farm sanitation#Dairy equipment cleaner#Food-safe cleaning supplies#Industrial cleaning chemicals#Dairy hygiene products#Sanitizers for dairy industry#Effective dairy cleaning solutions#Commercial dairy cleaning#Milk processing cleaning supplies

0 notes

Text

Diesel Fired Thermic Fluid Heater

Introducing our cutting-edge Diesel Fired Thermic Fluid Heater – an epitome of innovation in industrial heating solutions. This advanced heater redefines heat transfer, offering a seamless blend of speed, reliability, durability, and precision temperature control for diverse industrial applications.

Key Features:

Experience the efficiency of quick and uniform heat transfer using thermic fluid with Avon engineering Diesel Fired Thermic Fluid Heater. Rapid Heat Transfer ensures a reliable exchange of heat for various operational needs. Additionally, it adeptly converts diesel fuel into heat, providing seamless and efficient energy utilization.

Moreover, Powered by Reliable Diesel Fuel, our heater harnesses the reliability of diesel fuel as an energy source. It utilizes this dependable fuel type, offering continuous and dependable heat for a wide range of applications, ensuring uninterrupted operation.

Furthermore, Designed with longevity in mind, our heater boasts Durable Construction for Lasting Use. Its robust construction can withstand the demands of industrial environments, ensuring consistent performance and reliability over time.

Lastly, Achieve accurate temperature control within your processes with our product. Precise Temperature Control is enabled through its advanced control systems, allowing you to maintain desired temperature ranges crucial for applications requiring specific heat levels.

#Diesel fired thermic fluid heater#Thermic fluid heater#Diesel heater for heat transfer#Rapid heat transfer fluid heater#Efficient diesel-fired heater#Industrial thermic fluid heater#Uniform heat transfer heater#Reliable diesel fuel heater#Durable construction heater#Precise temperature control heater#Process heating solutions#Heat exchange equipment#Thermic fluid heating system#Quick heat transfer heater#Uniform heat distribution heater#Reliable diesel fuel utilization heater#Robust construction for industrial use#Accurate temperature control heater#Dependable heat source heater#Energy-efficient heating solution#Industrial-grade thermic fluid heater#Long-term reliability heater#Versatile heat transfer equipment#Industrial heating solution for manufacturing#Heater for process industries#Heat transfer equipment for textile industry#Heater for food processing#Heater for pharmaceutical industry#Heater for chemical industry#Benefits of diesel-fired thermic fluid heaters

0 notes

Text

When it comes to procuring top-tier process equipment in the UK, discerning businesses turn to trusted suppliers known for their reliability and quality. These suppliers offer a comprehensive range of equipment tailored to various industries, including pharmaceuticals, food and beverage, chemicals, and more. With a commitment to innovation and customer satisfaction, they provide state-of-the-art solutions designed to enhance efficiency, productivity, and safety in manufacturing processes. From precision-engineered machinery to cutting-edge technologies, these suppliers ensure that their clients have access to the latest advancements in process equipment, supported by expert guidance and unparalleled service. Trusted by leading companies nationwide, these suppliers play a pivotal role in driving the success and competitiveness of the UK's industrial landscape.

0 notes

Text

chemical process equipment’s manufacturers | Mathesis

Our chemical Process equipments manufacturers ,are custom-built, entirely indoor, and provided in a safe and secure manner. These are manufactured at our facilities, sent to client sites in India, installed, and then safely commissioned.

For more information visit: https://www.mathesis.co.in/index.php

Plot No. B-35, BHEL-AIE, Ramachandrapuram, Hyderabad – 502032

+91 98857 04874

0 notes

Text

Driving Efficiency and Precision: Exploring the Metering Pumps Market

In the intricate landscape of industrial processes, where accuracy and efficiency are paramount, metering pumps play a pivotal role. These precision instruments are designed to deliver fluids with absolute consistency, making them indispensable across various sectors such as chemical processing, water treatment, and pharmaceuticals.

The metering pumps market is witnessing steady growth, fueled by the increasing demand for accurate and reliable fluid delivery systems. As industries strive for higher productivity and tighter quality control, the need for precise metering solutions becomes more pronounced.

One of the key drivers of metering pumps market is the expanding scope of applications. Metering pumps are not limited to a specific industry; rather, their versatility allows them to be deployed in diverse settings. Whether it's adding precise amounts of chemicals in industrial processes or delivering medications in healthcare settings, these pumps offer unmatched reliability and control.

Moreover, advancements in technology are further propelling the growth of the metering pumps market. Manufacturers are constantly innovating to enhance the precision, efficiency, and durability of these pumps. From sophisticated electronic controls to improved materials and designs, the latest generation of metering pumps sets new standards for performance and reliability.

Another factor driving market growth is the increasing emphasis on sustainability and resource optimization. Metering pumps enable precise dosing, minimizing wastage of chemicals, water, and energy. This not only reduces operational costs but also aligns with environmental regulations and sustainability goals.

Furthermore, the integration of automation and digitalization is transforming the metering pumps market. Smart metering solutions equipped with sensors and connectivity features enable remote monitoring, predictive maintenance, and real-time optimization. This enhances operational efficiency while minimizing downtime and maintenance costs.

In conclusion, the metering pumps market is poised for significant growth as industries continue to prioritize efficiency, precision, and sustainability in their operations. With ongoing technological advancements and expanding applications, metering pumps are set to play an increasingly indispensable role across various sectors, driving productivity and innovation.

Contact us for more information.

#Metering Pumps#Industrial Equipment#Chemical Processing#Precision Engineering#Fluid Dynamics#environmental sustainability#innovation#sustainability#technology#augmented reality#immersive experiences#additive manufacturing#ai#aiincelltherapy#compliance

0 notes

Text

Fully Automatic Lami / Plastic Tube Filling, Sealing, Coding and Cutting Machine, Mumbai, India

Manufacturing of Pharmaceutical Machinery, Tube Filling Machinery, Tube Sealing Machinery, Soft Drink Filling Machinery, Container Filling Machinery, Pharmaceutical Equipments, Food Processing Machinery, Chemical Equipment, Mumbai, India.

Pharmaceutical Machinery, Tube Filling Machinery, Tube Sealing Machinery, Soft Drink Filling Machinery, Container Filling Machinery, Pharmaceutical Equipments, Pharmaceutical Machine, Food Processing Machinery, Chemical Equipment, Plastic Tube Filling Machinery, Multi Head Container Filling Machine, Cone Blender, Volumetric Bottle Filling, Filtration Unit, Rotary Bottle Washing, Rubber Bung Washing Machine, Storage Tank, Pressure Vessel, Cosmetic Filling Machinery, High speed Multi Head Container Filling Machine, Multi Head Container Filling Machine, Plastic Tube Filling Machine, Plastic Tube Sealing Machine, Plastic Tube Coding Machine, Plastic Tube Cutting Machine, Automatic Multi Head Container Filling Machine, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon

#Pharmaceutical Machinery#Tube Filling Machinery#Tube Sealing Machinery#Soft Drink Filling Machinery#Container Filling Machinery#Pharmaceutical Equipments#Pharmaceutical Machine#Food Processing Machinery#Chemical Equipment#Plastic Tube Filling Machinery#Multi Head Container Filling Machine#Cone Blender#Volumetric Bottle Filling#Filtration Unit#Rotary Bottle Washing

0 notes

Text

Rubber Lining Solutions: Enhancing Operational Efficiency

In today's industrial landscape, maintaining operational efficiency is paramount for organizations striving to remain competitive. Amidst the myriad of challenges faced by industrial sectors, ensuring the integrity and longevity of equipment and infrastructure is crucial. This is where rubber lining solutions come into play, offering a versatile and effective method for protecting assets and enhancing operational efficiency.

Understanding Rubber Lining

Rubber lining involves the application of specialized coatings to various surfaces, providing protection against corrosion, abrasion, and chemical exposure. These coatings, typically made from synthetic rubber compounds, create a durable barrier that shields equipment and infrastructure from damage, thereby extending their lifespan and reducing maintenance costs.

Key Benefits of Rubber Lining

Rubber lining solutions offer a multitude of benefits for industrial applications:

1. Corrosion Resistance

One of the primary advantages of rubber lining is its exceptional resistance to corrosion. By creating a protective barrier between metal surfaces and corrosive substances, rubber lining helps prevent degradation and prolongs the lifespan of equipment and infrastructure.

2. Abrasion Protection

In environments where equipment is subjected to abrasive materials or high levels of wear, rubber lining serves as a critical line of defense. The resilient nature of rubber coatings absorbs impact and minimizes abrasion, preserving the integrity of surfaces and components.

3. Chemical Compatibility

Rubber lining solutions are engineered to withstand exposure to a wide range of chemicals, making them suitable for applications where chemical resistance is essential. Whether dealing with acids, alkalis, or solvents, rubber linings provide reliable protection against chemical damage.

4. Flexibility and Adaptability

Rubber linings are highly flexible and adaptable, allowing them to conform to complex shapes and contours. This versatility makes them ideal for lining tanks, pipes, valves, and other equipment, ensuring comprehensive protection across various industrial applications.

Applications of Rubber Lining

Rubber lining finds extensive use across diverse industries, including:

Mining and Mineral Processing: Rubber lining is commonly used to protect equipment such as chutes, hoppers, and conveyor systems in mining operations, where abrasive materials and harsh conditions are prevalent.

Chemical Processing: In chemical plants and refineries, rubber lining provides essential protection for vessels, tanks, and piping systems that handle corrosive chemicals and aggressive fluids.

Oil and Gas Production: Rubber lining plays a vital role in offshore platforms, pipelines, and storage facilities within the oil and gas industry, safeguarding critical infrastructure against corrosion and erosion.

Water and Wastewater Treatment: Rubber linings are utilized in water treatment plants and wastewater facilities to protect tanks, basins, and pipes from corrosion and chemical attack, ensuring reliable operation and compliance with environmental regulations.

Conclusion

In conclusion, rubber lining solutions offer a versatile and effective means of enhancing operational efficiency across a wide range of industrial applications. From protecting equipment against corrosion and abrasion to ensuring chemical compatibility and adaptability, rubber linings provide invaluable benefits for organizations seeking to optimize performance and reduce maintenance costs. By leveraging the advantages of rubber lining technology, industries can enhance asset integrity, prolong equipment lifespan, and achieve greater operational efficiency in today's competitive marketplace.

#industry#technology#manufacturing#rubber products#materials#rubber process#rubber sheets#rubber lining#rubber industry#rubber sheet mixing#rubber lining solution#protective equipment#chemical resistance

0 notes

Text

Spray Dryer manufacturers in India

Ronetech: Leading Spray Dryer Manufacturers in India. Expert solutions for efficient drying processes. Explore now!

https://ronetech.co.in/spray-dryer/

#Spray Dryer#Spray Dryer India#Industrial Dryers#Spray Drying Technology#Indian Manufacturing#Drying Equipment#Chemical Processing#Pharmaceutical Dryers#Food Processing Dryers

0 notes

Text

Taknik Inc manufacture and Provide Process Equipments

for order contact us on

Email Id- [email protected]

Contact no- 9510430147

#taknikinc#process#Equipment#processequipment#storage#tank#storagesolutions#chemicals#liquidgas#solidsurface#solutions#bharuch#gujarat

0 notes

Text

1、 Cutting method

Cutting method is currently one of the most widely used thread machining methods. This method can use cutting tools such as turning tools, cutting cutters, and milling cutters for machining. The cutting method is simple to operate, but requires precise machining equipment and low machining efficiency. In addition, due to the slow relative movement speed of the cutting tool, it may cause the problem of rough machining surface.

2、 Etching method

Etching method is a chemical processing method, which has the advantage of being able to process very small and complex thread shapes. The etching method requires the use of chemicals such as acids and bases for processing, and requires hazardous material management and strict operating procedures. In addition, the etching method also requires the processing of molds, so the cost is relatively high.

3、 Rolling method

Rolling method is a processing method that uses rollers to press the workpiece and convert its shape. Rolling can process the surface of a workpiece into parallel and continuous external and internal threads. Compared to the cutting method, the rolling method has the advantages of high machining efficiency, good surface quality, and high material utilization of workpieces, especially suitable for large-scale thread processing.

4、 Line cutting method

The wire cutting method is a method of using high current discharge to process the spiral shape on the electrode along the workpiece. This processing method can produce very small spiral lines, with high processing accuracy and good surface quality. However, the processing speed of wire cutting method is relatively slow, and it also requires periodic maintenance and upkeep of the processing equipment.

#1、 Cutting method#Cutting method is currently one of the most widely used thread machining methods. This method can use cutting tools such as turning tools#cutting cutters#and milling cutters for machining. The cutting method is simple to operate#but requires precise machining equipment and low machining efficiency. In addition#due to the slow relative movement speed of the cutting tool#it may cause the problem of rough machining surface.#2、 Etching method#Etching method is a chemical processing method#which has the advantage of being able to process very small and complex thread shapes. The etching method requires the use of chemicals suc#and requires hazardous material management and strict operating procedures. In addition#the etching method also requires the processing of molds#so the cost is relatively high.#3、 Rolling method#Rolling method is a processing method that uses rollers to press the workpiece and convert its shape. Rolling can process the surface of a#the rolling method has the advantages of high machining efficiency#good surface quality#and high material utilization of workpieces#especially suitable for large-scale thread processing.#4、 Line cutting method#The wire cutting method is a method of using high current discharge to process the spiral shape on the electrode along the workpiece. This#with high processing accuracy and good surface quality. However#the processing speed of wire cutting method is relatively slow#and it also requires periodic maintenance and upkeep of the processing equipment.

0 notes

Text

Exploring the Benefits of Chemical Process Equipment

High-quality materials and construction contribute to the longevity and durability of chemical process equipment. Equipment that withstands the harsh conditions of chemical processing environments requires less frequent replacement, reducing overall costs.

0 notes

Text

0 notes