#chemicalindustry

Explore tagged Tumblr posts

Text

🌟 Protect Your Hands, Ensure Your Work Safety 🌟

In high-risk fields such as the semiconductor industry, the chemical industry, and laboratories, using effective chemical-resistant gloves is crucial for operational safety. The HANAKI Strong Acid and Alkali-Resistant Gloves are specifically designed to handle strong acids and alkalis like hydrofluoric acid, nitric acid, and aqua regia, offering exceptional chemical protection.

🔹 Application Scenarios:

Semiconductor manufacturing Chemical production Laboratory research 🔹 Product Features:

Excellent Protection: Resistant to high concentrations of strong acids and alkalis such as hydrofluoric acid, nitric acid, and aqua regia High-Quality Materials: Chlorosulfonated polyethylene (CSM) outer layer, nitrile rubber (NBR) inner layer Multiple Specifications: Available in different lengths and thicknesses to meet various needs Comfortable Fit: Designed specifically for women, providing a comfortable wear and flexible operation 🛡️ Protect you from chemical hazards and ensure your safety! If you engage in high-risk chemical operations, choose HANAKI Strong Acid and Alkali-Resistant Gloves to provide comprehensive protection for your hands!

🔗 Click to learn more: [https://yousuto.com/product/hanaki-strong-acid-and-alkali-resistant-gloves-towa-a-20l-a-22-b-22l/]

#ChemicalResistantGloves#ChemicalProtection#HANAKI#Semiconductor#LabSafety#StrongAcidAndAlkaliProtection#ChemicalIndustry#SafetyFirst

2 notes

·

View notes

Text

SS 316 Blind Flange at the Lowest Price

Looking for a durable and corrosion-resistant flange for your industrial applications? The SS 316 blind flange is your go-to choice, offering superior performance in harsh environments. At Udhhyog, we provide the SS 316 blind flange at the lowest price, making high-quality stainless steel products accessible to all industries. In this article, we’ll explore its key features, benefits, and why Udhhyog is your trusted supplier.

What is an SS 316 Blind Flange?

An SS 316 blind flange is a circular steel plate with all the bolt holes but no central opening, designed to seal off the end of a pipeline or pressure vessel. Made from 316-grade stainless steel, it provides enhanced resistance to corrosion, especially in marine and chemical environments. This makes it ideal for industries dealing with highly corrosive substances.

Key Features of SS 316 Blind Flange

Superior Corrosion Resistance: The addition of molybdenum in SS 316 enhances its resistance to chloride pitting and general corrosion.

High Temperature and Pressure Resistance: Capable of withstanding extreme conditions, making it suitable for high-pressure applications.

Versatility: Available in various sizes and pressure ratings to fit different industrial needs.

Benefits of Using SS 316 Blind Flange

Long-Lasting Durability: The robust structure ensures a longer lifespan, even in challenging environments.

Cost Efficiency: At Udhhyog, we offer the SS 316 blind flange at the lowest price, providing excellent value for your investment.

Safe and Secure: Prevents leaks and ensures safe operation of pipelines and pressure vessels.

Applications of SS 316 Blind Flange

Marine Industry: Resistant to saltwater corrosion, making it ideal for shipbuilding and offshore platforms.

Chemical Industry: Suitable for handling aggressive chemicals and acidic environments.

Pharmaceuticals: Used in sterile and sanitary applications due to its hygienic properties.

Why Choose Udhhyog for SS 316 Blind Flange?

Udhhyog is committed to delivering high-quality industrial products at competitive prices. By choosing us, you benefit from:

Top-Quality Products: We source only the best materials to ensure the highest quality standards.

Affordable Pricing: Get the SS 316 blind flange at the most competitive price in the market.

Exceptional Service: Our team is dedicated to providing the best customer experience.

How to Order

Ordering from Udhhyog is simple. Visit our website and click on SS 316 blind flange lowest price to place your order. We ensure timely delivery and hassle-free service.

#SS316BlindFlange#StainlessSteelFlange#IndustrialFlanges#MarineIndustry#ChemicalIndustry#Udhhyog#FlangeSupplier#LowestPriceFlange

4 notes

·

View notes

Text

Our team will be present at the Asian Chemical Forum (ACF) - 5-6 September 2023. If you will be at the conference, do connect with us. We look forward to the opportunity to understand your requirements and help you in building a safer chemical future! Email us at 📧 [email protected] to schedule a meeting. Eurofins Advinus Agrosciences India offers comprehensive product development services to support your global registration needs. Our team has expertise to assess and prove the safety of your products as per requirements of all international guidelines (OECD, EPA, CIPAC, JMAFF, ICH, SANCO, ABNT etc.) To know more about our services, click on the link - 👉

Agrochemical Development Services

#asianchemicalforum#chemicalindustry#regulations#productdevelopment#pesticides#insecticides#specialitychemicals#cropprotection#EurofinsAdvinus

2 notes

·

View notes

Text

IHF single stage single suction pump PTFE lined pump centrifugal chemical pump is working for highly corrosive mediums between -85°C~120°C (-121°F~248°F), such as arbitrary concentration of vitriol, muriatic acid, hydrofluoric acid, nitric acid, aqua regia, strong base, strong oxidant, organic solvent, reducing agent, etc.

Pump Model: IHF65-50-160

Flow rate:25m3/h

Head:32

Inlet/outlet diameter:65mm/50mm

Seal: single mechancial seal

Motor power:5.5kw/400v/3Ph/50Hz/2900rpm

Pump destination: Vietnam chemical project

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump

If you have any inquiry or question, please feel free to contact me at [email protected] and WhatsApp +86 155 87495056.

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump#jushi

4 notes

·

View notes

Text

#chemicals#chemistry#chemical#chemicalindustry#chemicalbusiness#activecompounds#chemicaltoxins#automotive#health#research

2 notes

·

View notes

Text

At Garg Chemical Industry, we understand the critical role that chemicals play in various industries, ranging from pharmaceuticals to manufacturing. With our extensive range of high-quality chemicals, we cater to a wide spectrum of sectors, ensuring that our clients receive nothing but the best.

3 notes

·

View notes

Video

The 21st China International Foundry Expo

Date: 8-11th May, 2023. Tianjing National Convention and Exhibition Center

3 notes

·

View notes

Text

Plant-based oils in the chemical industry offers a sustainable solution to reduce our dependence on finite resources and tackle environmental issues. Check out this insightful article on the benefits and challenges of this transition.

Read More

#plantbasedoils#chemicalindustry#sustainability#environment#bioplastics#lubricants#polyurethane#renewableresources#greenalternatives#efficiency#climatechange#cleanenergy#sustainablefuture#greenliving#renewableenergy#ecofriendly#zerowaste#recycling#turtletimeline

3 notes

·

View notes

Text

Global Barite Market Research Report 2024(Status and Outlook)

Barite Market Size, Demand & Supply, Regional and Competitive Analysis 2025-2031

The global barite market was valued at USD 991.64 million in 2023 and is expected to reach USD 1,058.92 million by 2029, growing at a CAGR of 1.10% during the forecast period.

The market's expansion is primarily attributed to the steady demand from the oil and gas industry, infrastructure development, and increasing use in the pharmaceutical sector. Despite minor fluctuations in supply due to mining regulations, the long-term outlook remains positive.

Market Size

Barite is a naturally occurring mineral composed of barium sulfate (BaSO4). It is known for its high density, chemical inertness, and ability to absorb X-rays and gamma rays. Due to these properties, barite is widely used in oil and gas drilling as a weighting agent in drilling muds. Additionally, it finds applications in paints, plastics, rubber, medical imaging, and radiation shielding. The demand for barite is largely driven by its indispensable role in the energy sector, particularly in deep-water and unconventional drilling operations.

Download a free Sample Report PDF

Historical Trends and Future Projections

2018-2022: The market witnessed stable growth due to increased offshore drilling activities.

2023-2029: Growth is expected to be moderate due to fluctuating crude oil prices and environmental concerns related to mining activities.

Beyond 2030: Emerging applications in the renewable energy sector and advancements in polymer-based materials may offer new growth avenues.

Global Barite Market Segmentation Analysis

This report provides a deep insight into the global barite market, covering essential aspects from macroeconomic trends to micro-level details. The analysis shapes industry competition and provides strategic insights for businesses to maximize profitability. Additionally, it evaluates key market drivers, challenges, and competitive landscape insights.

Market Segmentation (by Application)

Oil & Gas Industry – The dominant segment, consuming over 70% of global barite production.

Paints & Coatings – Used as a filler to improve durability and brightness.

Rubber & Plastics – Enhances weight and stability in polymer applications.

Medical & Pharmaceuticals – Used in contrast agents for X-ray imaging.

Others – Includes uses in cement, radiation shielding, and electronics.

Market Segmentation (by Type)

White Barite – High-purity variant used in paints, plastics, and pharmaceuticals.

Grey Barite – The most common form, widely used in drilling mud.

Brown Barite – Used in cement and radiation shielding applications.

Key Company

Halliburton

Schlumberger Limited

Excalibar Minerals LLC

Ashapura Group

Guizhou Tianhong Mining Co. Ltd.

Get The Complete Report &TOC

FAQs

1. What is the current market size of the global barite market?

➣The global barite market was valued at USD 991.64 million in 2023 and is projected to reach USD 1,058.92 million by 2029, growing at a CAGR of 1.10%.

2. Which are the key companies operating in the barite market?

➣Major companies include Halliburton, Schlumberger Limited, Excalibar Minerals LLC, Ashapura Group, and Guizhou Tianhong Mining Co. Ltd.

3. What are the key growth drivers in the barite market?

➣The primary growth drivers include rising demand from the oil and gas sector, increasing use in paints and plastics, and advancements in medical imaging applications.

4. Which regions dominate the barite market?

➣Asia-Pacific, led by China and India, dominates the market due to high production volumes and rising industrial demand.

5. What are the emerging trends in the barite market?

➣Key trends include exploring alternative applications in renewable energy, advancements in polymer-based materials, and increased mining investments in developing economies. CONTACT US:203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1(332) 2424 294 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/ About 24Chemical Research:24chemicalresearch was founded in 2015 and has quickly established itself as a leader in the chemical industry segment, delivering comprehensive market research reports to clients. Our reports have consistently provided valuable insights, aiding our clients, including over 30 Fortune 500 companies, in achieving significant business growth.

CONTACT US:203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1(332) 2424 294 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/ About 24Chemical Research:24chemicalresearch was founded in 2015 and has quickly established itself as a leader in the chemical industry segment, delivering comprehensive market research reports to clients. Our reports have consistently provided valuable insights, aiding our clients, including over 30 Fortune 500 companies, in achieving significant business growth.

#BariteMarket#GlobalBarite#MarketResearch#MarketForecast#MiningIndustry#IndustrialMinerals#OilAndGas#DrillingFluids#ChemicalIndustry#MarketTrends#ConstructionMaterials#PaintsAndCoatings#MarketGrowth#AdvancedMaterials#IndustryAnalysis#BariteUses

0 notes

Text

A Trusted Source for Chemical Requirements

When it comes to PTSA, choosing the right PTSA Supplier makes all the difference. We deliver premium PTSA designed for top-tier chemical applications. With rigorous quality control and industry expertise, our PTSA meets the highest standards. Experience superior performance and reliability with the most trusted name in PTSA supply.

#ChemicalIndustry#PTSASupplier#IndustrialSolutions#QualityChemicals#ManufacturingExcellence#ChemicalManufacturing#IndustrialChemicals

0 notes

Text

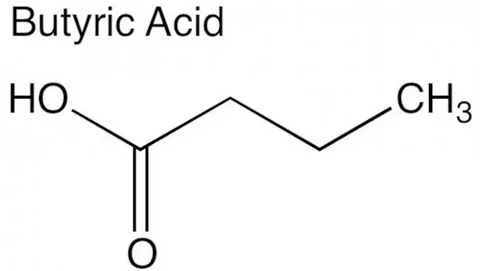

Butyric Acid Market :Growth Driven by Rising Demand in Animal Feed and Pharmaceuticals

1. Growing Demand for Animal Feed Additives

One of the primary drivers of the butyric acid market is its increasing application in animal feed additives. Butyric acid is widely used to enhance gut health and improve digestion in livestock, including poultry, swine, and cattle. The rising global population and increasing meat consumption have boosted the demand for high-quality animal feed, thereby driving the demand for butyric acid. Additionally, the ban on antibiotics in animal feed in several countries has led to a shift towards natural growth promoters, with butyric acid being a key alternative.

2. Expanding Pharmaceutical and Healthcare Industry

The pharmaceutical industry is another significant contributor to the growth of the butyric acid market. Butyric acid and its derivatives are used in medications for gastrointestinal disorders, cancer treatments, and metabolic syndromes. The rising prevalence of chronic diseases, coupled with an increasing focus on gut health, has resulted in greater demand for butyric acid-based products. Ongoing research into the potential health benefits of butyric acid, such as its anti-inflammatory and immune-boosting properties, is further fueling market expansion.

3. Rising Awareness of Functional Foods and Nutraceuticals

The increasing consumer awareness regarding the benefits of functional foods and nutraceuticals is another driving factor for the butyric acid market. Butyric acid is used in dietary supplements and functional food products due to its role in promoting gut microbiota and digestive health. With the growing trend of health-conscious consumers seeking natural and organic food ingredients, the demand for butyric acid in the food and beverage sector is witnessing a significant rise.

4. Growth of the Agricultural Sector

Butyric acid plays a crucial role in agriculture, particularly in the formulation of herbicides, pesticides, and fertilizers. As global agricultural production expands to meet the food demands of a growing population, the use of butyric acid-based products in crop protection and soil health enhancement is increasing. Additionally, sustainable farming practices and organic agricultural trends are driving the demand for natural and biodegradable alternatives, such as butyric acid-based fertilizers.

5. Increase in Bio-Based and Sustainable Chemicals

The shift towards bio-based chemicals and sustainable production methods has positively influenced the butyric acid market. Traditional petroleum-based chemicals are being replaced by bio-based alternatives due to rising environmental concerns and stringent regulations. Butyric acid, which can be produced through fermentation of renewable sources, is gaining traction as an eco-friendly alternative in various applications, including bioplastics, biofuels, and green solvents. This trend is expected to continue as industries strive to achieve sustainability goals.

6. Rising Demand for Perfumes and Flavors

The cosmetics, personal care, and fragrance industries are also contributing to the growth of the butyric acid market. Butyric acid is used in the production of esters that serve as key ingredients in perfumes, flavors, and food additives. The expanding consumer preference for natural and organic fragrances is further propelling the demand for butyric acid-based compounds.

7. Technological Advancements in Production Processes

Innovations in biotechnology and fermentation techniques have significantly improved the efficiency and cost-effectiveness of butyric acid production. Advances in microbial fermentation and genetic engineering have led to increased yields and reduced production costs, making butyric acid more accessible for various industrial applications. Additionally, the development of novel production methods using renewable biomass sources is expected to further drive market growth.

8. Supportive Government Regulations and Policies

Government policies and regulations promoting the use of sustainable chemicals and restricting the use of harmful synthetic additives have positively influenced the butyric acid market. Regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have recognized the safety and benefits of butyric acid in food, feed, and pharmaceutical applications. This has facilitated greater adoption across various industries.

9. Growing Application in the Plastics and Chemical Industry

Butyric acid is increasingly being utilized in the production of cellulose acetate butyrate (CAB), a biodegradable plastic used in coatings, films, and automotive applications. With the rising demand for eco-friendly packaging solutions and sustainable materials, the butyric acid market is expected to benefit from the expanding bioplastics industry. Furthermore, its use as an intermediate in the synthesis of various chemical compounds supports its market growth.

10. Expanding Market in Emerging Economies

Developing countries, particularly in Asia-Pacific, Latin America, and Africa, are witnessing rapid industrialization and urbanization, leading to increased demand for butyric acid across multiple sectors. Rising disposable incomes, changing dietary habits, and growing awareness of health and wellness are fueling the demand for butyric acid-based products in these regions. Additionally, the expansion of the livestock industry in emerging markets is driving the need for high-quality animal feed additives, further propelling market growth.

Conclusion

The butyric acid market is experiencing robust growth due to its diverse applications across industries such as animal feed, pharmaceuticals, food and beverages, agriculture, chemicals, and cosmetics. The increasing shift towards bio-based products, coupled with advancements in production technologies and supportive regulatory frameworks, is expected to drive market expansion in the coming years. As awareness of health, sustainability, and functional benefits continues to grow, the demand for butyric acid and its derivatives is likely to witness sustained upward momentum.

0 notes

Text

Oxalic Acid Market: Steady Growth Driven by Diverse Industrial Applications"

The global oxalic acid market was valued at approximately USD 665.71 million in 2024 and is projected to reach nearly USD 926.61 million by 2032, growing at a compound annual growth rate (CAGR) of 4.22% during the forecast period. This growth is driven by increasing demand in the pharmaceutical sector, particularly for sanitizing equipment, and its applications in cleaning agents, textiles, and metal maintenance. Notably, the Asia-Pacific region dominated the market in 2024, accounting for 48% of total shares, with expectations of continued growth at a CAGR of 4.65%.

0 notes

Text

𝗥𝗲𝘃𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝗶𝘇𝗶𝗻𝗴 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗦𝗮𝗳𝗲𝘁𝘆: 𝗧𝗵𝗲 𝗘𝘅𝗽𝗹𝗼𝘀𝗶𝗼𝗻 𝗣𝗿𝗼𝗼𝗳 𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗢𝗽𝗽𝗼𝗿𝘁𝘂𝗻𝗶𝘁𝘆

The global Explosion Proof Equipment Market size is forecasted to reach $14.5 billion by 2030, growing at a CAGR of 5.7% during the forecast period from 2024-2030.

📥 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝘁𝗵𝗲 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗦𝗮𝗺𝗽𝗹𝗲: 👉 https://lnkd.in/gM39ggDF

🌡️ 𝗞𝗲𝘆 𝗖𝗼𝗼𝗹𝗶𝗻𝗴 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗲𝘀:

𝗥𝗲𝗴𝘂𝗹𝗮𝘁𝗼𝗿𝘆 𝗖𝗼𝗺𝗽𝗹𝗶𝗮𝗻𝗰𝗲 & 𝗥𝗶𝘀𝗸 𝗠𝗶𝘁𝗶𝗴𝗮𝘁𝗶𝗼𝗻:With #international standards such as ATEX, IECEx, and NFPA driving product certification, companies are compelled to #upgrade to advanced explosion-proof #solutions to ensure operational safety and minimize downtime.

𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗰𝗮𝗹 𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻: Advancements in #smart #monitoring, IoT-enabled sensors, and #AI-driven predictive maintenance are redefining explosion proof equipment. These innovations not only enhance safety but also drive operational efficiency and reduce #long-term maintenance costs.

𝗘𝗻𝗵𝗮𝗻𝗰𝗲𝗱 𝗥𝗢𝗜 & 𝗖𝗼𝗺𝗽𝗲𝘁𝗶𝘁𝗶𝘃𝗲 𝗘𝗱𝗴𝗲: Investing in high-quality explosion-proof systems translates into fewer #operational interruptions, reduced liability risks, and improved employee productivity. Forward-thinking companies #leveraging these #technologies set themselves apart as leaders in industrial safety and efficiency.

📊 𝗞𝗲𝘆 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: Emerson | Honeywell | Rockwell Automation

Eaton | Siemens | ABB | Schneider Electric | Parker Hannifin | GE | Johnson Controls | Intertek | Pepperl+Fuchs Group | Bosch Rexroth | Phoenix Contact | Danfoss | Mitsubishi Electric | Fuji Electric Co., Ltd.

Legrand | Baker Hughes | Ingersoll Rand | Cummins Inc. | ITT Inc. | Flowserve Corporation | NOV | Siemens Energy | Dover Corporation

AMETEK | Fluke Corporation | Alfa Laval

📖 𝗚𝗲𝘁 𝗠𝗼𝗿𝗲 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀: 👉 https://lnkd.in/gx8dQNAw

✨ (𝐂𝐫𝐞𝐝𝐢𝐭 𝐂𝐚𝐫𝐝 𝐃𝐢𝐬𝐜𝐨𝐮𝐧𝐭 𝐨𝐟 𝟏𝟎𝟎𝟎$ 𝐨𝐧 𝐚𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐏𝐮𝐫𝐜𝐡𝐚𝐬𝐞𝐬 | 𝐔𝐬𝐞 𝐂𝐨𝐝𝐞: 𝐅𝐋𝐀𝐓𝟏𝟎𝟎𝟎 𝐚𝐭 𝐜𝐡𝐞𝐜𝐤𝐨𝐮𝐭) https://lnkd.in/g6e9u3vX

#ExplosionProof#IndustrialSafety#HazardousEnvironments#ATEX#IECEx#NFPA#OilAndGas#Mining#ChemicalIndustry#PharmaceuticalIndustry#RiskManagement

0 notes

Text

Low-Carbon Ammonia: A Game Changer for the Global Energy Transition

The global ammonia market size is expected to reach USD 313.2 billion by 2030, as per the new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.9% from 2025 to 2030. The growth is majorly driven by rising consumption of ammonia in fertilizers and refrigerants.

As the population of major countries around the world is projected to increase significantly, the demand for food will continue to rise, putting pressure on farmers to adopt more efficient methods of production. Ammonia-based nitrogenous fertilizers are poised to benefit from this trend as they offer increased yield, effective crop protection, and enhanced production cycles, making them a valuable tool for farmers facing the challenge of ensuring food security for an ever-rising global population.

Ammonia Market Report Highlights

The anhydrous segment accounted for the largest revenue market share, 59.8%, in 2024 and is expected to continue to dominate the industry over the forecast period.

The herbicides segment dominated the market with a market share of 78.8% in 2024, during the forecast period. This growth is due to farmers' increasing use of nitrogenous fertilizers.

The Asia Pacific region is expected to grow the fastest growth during the forecast period. The Asia-Pacific region is home to many agricultural countries, including Japan, Thailand, Indonesia, India, and the Philippines.

For More Details or Sample Copy please visit link @: Ammonia Market Report

NH3 is commonly used in large-scale refrigeration plants and is available in various forms such as liquid and gas. The advantage of using NH3 in refrigeration systems is that it costs 10-20% to produce compared to systems that use CFCs. In addition, according to the International Institute of Ammonia Refrigeration, ammonia is an efficient and cost-effective alternative to HFCs and CFCs and considered safe for the environment. Moreover, as per the U.S. Environment Protection Agency, the Global Warming Potential and the Potential of Ozone Depletion rating is almost null for NH3-based refrigerants.

Companies are more inclined toward producing sustainable/green NH3 as it has the potential to be a key component of a more sustainable, low-carbon energy system, as it can be used as a renewable fuel for transportation and power generation, as well as a zero-carbon feedstock for the production of fertilizers and other chemicals.

Moreover, companies like Yara International are focusing on developing sustainable product with the help of green hydrogen along with the production of conventional product. Moreover, the company is actively involved in cooperation with Statkraft & Aker Clean Hydrogen, with a goal of decarbonizing Yara’s NH3 plant by eliminating 800 kilotons of annual CO2 emissions.

List of Key Players in the Ammonia Market

Acron

Koch Fertilizers, LLC

Yara International

CF Industries Holdings, Inc.

Nutrien Ltd.

Qatar Fertiliser Company

Togliattiazot

SABIC

Sumitomo Chemical Co., Ltd.

Mitsui Chemicals, Inc.

BASF SE

Asahi Kasei Corp

We have segmented the global ammonia market on the basis of product, application and region.

#AmmoniaMarket#GlobalAmmonia#ChemicalIndustry#IndustrialChemicals#AmmoniaIndustry#ChemicalManufacturing#IndustrialGases#SyntheticAmmonia#AmmoniaProduction#ChemicalProcessing

0 notes

Text

Global Graphene Paper Market: Forecasted to Reach $139.09 Million by 2032 with 4.70% CAGR

Market Overview:

Graphene oxide paper or graphite oxide paper is a material fabricated from graphite oxide. It is used in various applications such as supercapacitors, batteries, aerospace, biomedical, and others.

Market Analysis:

The global Graphene Paper market size was estimated at USD 92 million in 2023 and is projected to reach USD 139.09 million by 2032, exhibiting a CAGR of 4.70% during the forecast period.

The North America Graphene Paper market size was estimated at USD 25.94 million in 2023, showing a CAGR of 4.03% during the forecast period of 2025 through 2032.

Download FREE Sample of this Report

Market Segmentation:

Market Segmentation (by Application)

Supercapacitor

Battery

Aerospace and Aircraft

Biomedical

Others

Market Segmentation (by Type)

Graphene Oxide Paper

Reduced Graphene Oxide Paper

Key Company

The Graphene Box

JCNANO Tech

Chengdu Organic Chemicals

ACS Material

Graphenea

Techinstro

Stanford Advanced Materials

FAQ

01. What is the current market size of Graphene Paper Market?

Graphene oxide paper or graphite oxide paper is a material fabricated from graphite oxide. The global Graphene Paper market size was estimated at USD 92 million in 2023 and is projected to reach USD 139.09 million by 2032, exhibiting a CAGR of 4.70% during the forecast period. North America Graphene Paper market size was estimated at USD 25.94 million in 2023, at a CAGR of 4.03% during the forecast period of 2025 through 2032.

02. Which key companies operate in the Graphene Paper Market?

Key companies in the Graphene Paper Market include The Graphene Box, JCNANO Tech, Chengdu Organic Chemicals, ACS Material, Graphenea, Techinstro, and Stanford Advanced Materials.

03. What are the key growth drivers in the Graphene Paper Market?

The main factors driving growth in the Graphene Paper Market include industry drivers, restraints, opportunities covered in the study, recent industry trends and developments, competitive landscape & strategies of key players, and potential & niche segments and regions exhibiting promising growth.

Get the Complete Report & TOC

#GraphenePaper#MarketForecast#GrapheneOxide#AdvancedMaterials#CAGR#EnergyStorage#Supercapacitors#Aerospace#Biomedical#TechMaterials#MarketResearch#GrapheneTechnology#GlobalMarket#ChemicalIndustry#MaterialScience

0 notes