#Dairy equipment cleaner

Explore tagged Tumblr posts

Text

Top Dairy Industry Cleaning Supplies | Pure Clean Supplies

Explore our extensive range of cleaning supplies specifically designed for the dairy industry. From sanitizers to specialized detergents, Pure Clean Supplies offers high-quality products to ensure a clean and safe environment. Perfect for farms, processing plants, and dairy facilities. Shop now for the best in dairy cleaning solutions!

#Dairy cleaning products#Dairy farm sanitation#Dairy equipment cleaner#Food-safe cleaning supplies#Industrial cleaning chemicals#Dairy hygiene products#Sanitizers for dairy industry#Effective dairy cleaning solutions#Commercial dairy cleaning#Milk processing cleaning supplies

0 notes

Text

How To Balance Your Daytime and Nighttime Activities So That You Don't Burn Yourself Out More Than You Already Have

Dick had to give it to the kid, he'd somehow thought of everything. It was a little concerning, actually, but the kid had brushed off every attempt had probing for answers. Who trained him? If he was trained at all. ...had the kid gone into vigilantism alone? Oh, dear. THat's not good fro Dick's current worries.

Reading the file Danny had handed him, Dick had to wonder how long it had taken him to put together this cover story. Also, where he'd managed to get the equipment to do it. At a glance, the kid didn't seem to have much on him. Not even a phone!

He closed the folder and set it back down on the table. "Really?" he asked, "'Congratulations, it's a boy'?"

Danny's cheeks turned a bit red as his gaze shifted to the folder. "Well, yeah. You're stuck with me now until I can get you into good habits and a healthier schedule."

"That implies that you're planning on leaving."

Danny shrugged, all his confidence now fading away. Is this what he's really like? "Well, I mean, I'm sure you don't want me sticking around at all, let alone for a while."

Dick frowned and looked back at the black folder and the binder sitting on his coffee table. God, his apartment's a mess! He smiled at Danny. "My name's Richard, but everyone calls me 'Dick'. You can stay in the guest room."

Danny lit up like a fucking Christmas tree. "Really?"

"Yep. You went to all this work, it'd be a shame if it all went to waste."

The grin on Danny's face was more than worth the security risk that he now posed. "You won't regret it, Mr. Dick!"

Dick smiled back at him, "Please, drop the formalities. We're cousins, apparently."

Was he attached? No. He wouldn't allow himself to get attached. Sure, maybe he was letting this kid - he really needs to start calling him Danny - stay with him for a while, but he wasn't going to get attached. Getting attached meant losing him. Dick wasn't sure he'd be able to survive if he lost someone again.

...damn it.

***

First order of business, now that Danny was officially Dick's - why would he willingly go by that nickname? - ward/cousin, Danny was going to make sure he got some sleep. Today was Dick's day off, so Danny had sent him to his room to take a much needed nap. The man was basically dead on his feet and Danny would be damned if he let him wander around this mess of an apartment with blurry vision.

The second thing he did, once he was sure Dick was asleep, was start to clean up. The place was a stereotypical bachelor's pad, complete with questionable stains in the carpet, rips in the cushions, dishes piled up in the sink, and old take-out on every table and counter. Gross.

He made quick work of the old take-out by throwing it all away and hitting it with a very small and controlled ectoblast. He was so glad Dick had disposable gloves on hand.

The dishes were the next thing he handed. The water was cleaner than in Gotham, so he didn't worry about washing the dishes by hand when they all didn't fit in the dishwasher. He dried the ones he'd hand washed before putting them away. Dick had no organisation in his cupboards, so Danny fixed that, too.

The fridge and freezer weren't too bad. Sure, the dairy products had all expired and most of the food was freezer bitten, but none of it was moldy yet and the appliance itself was in perfect working order. He'd have to go shopping later.

Danny had never liked cleaning, but he'd had to when his parents refused to follow any OSHA laws or Lab Safety courses. So, when he found the cleaning supplies, he took a deep breath and began scrubbing the bathroom. It wasn't too bad, thank god, and was already fairly clean. It was quick and he was able to move on very quickly.

The counters, tables, walls, and tile and wooden floors were all easy to clean with a wet rag and a broom. He wasn't going to even try saving the rug because it looked well beyond the point of no return. The couch and chair cushions could be sticked up, but he didn't have a sewing needle and thread with him.

The last thing he did before taking his backpack into the room he'd been given was to write down a shopping list and leave it on the counter. It wasn't a lot, just food and some dishes and toiletries. He'd have to figure out with Dick a way to pay rent, too, but that was a later Danny problem. He'd tired himself out and was still running on pretty much empty. So, he allowed himself to fall asleep. He'd check on Dick when he woke up.

Part 4 Part 6

Tag List:

@flame-343 @ghestie93 @anarinette @aglmry @peachtreewriter @evix-syne666 @loudlypanickinginvenezolano @lumosfeather18581

#part 5#dc x dp crossover#dp x dc#dc x dp#dcxdp#danny phantom#dick grayson#nightwing#death is a legal barrier#work life balance#but it's being explained by a hypocrite 7 years younger than him#danny is going to make sure dick takes care of himself#dick is getting attached#danny needs a hug#dick needs a hug#dick needs help#danny's here to help#is it really adoption if the kid shows up one day and just doesn't leave?#a bit short but that's okay#How To Balance Your Daytime and Nighttime Activities So That You Don't Burn Yourself Out More Than You Already Have

958 notes

·

View notes

Photo

Also! Environmental regulations are being heightened and there is funding for environmental stuff! You just might not know about it! In California, the air pollution laws are very strict! And getting stricter. And it's working! It may be a pain to be told when you can burn or use your outdoor firepit, or getting a ticket for burning garbage. But its helping the air! Almost every facility, major farm, dairy, factory, paint shop, winery, ect is regulated by air districts! Giant generators and engines and boilers and things need permits and are inspected regularly to make sure they aren't polluting! There is a lot of money being funneled into California right now to reduce Agricultural Aor Pollution, not just enforcement, but grants for cleaner farming equipment too! I know about this because I live in the Valley. But there are agencies like air districts and water districts all over the world, quietly enforcing environmental regulations.

358K notes

·

View notes

Text

Revolutionizing Cooling & Cleaning with Dry Ice – Dryice Abudhabi!

When it comes to high-performance cooling, industrial cleaning, and special effects, Dryice Abudhabi is your trusted partner. As a leading Dryice supplier in Abudhabi and Dryice manufacturer in Abudhabi, we provide top-quality dry ice solutions for various industries. But what makes dry ice so exceptional? Let’s explore its benefits and why Dryice Abudhabi is the preferred choice!

Understanding Dry Ice: The Science Behind It

Dry ice is the solid form of carbon dioxide (CO₂), maintaining an ultra-cold temperature of -78.5°C (-109.3°F). Unlike regular ice, it sublimates directly into gas, leaving no water residue. This makes it an unparalleled cooling agent, perfect for industrial and commercial applications.

The Many Advantages of Dry Ice

1. Superior Cooling Efficiency

Dry ice is much colder than traditional ice, making it the preferred option for industries that require ultra-cold storage. It is widely used for transporting perishable food, pharmaceuticals, and medical supplies like vaccines, ensuring they stay at optimal temperatures without melting.

2. Advanced Dry Ice Blasting – A Revolutionary Cleaning Method

Unlike traditional cleaning methods that use water and harsh chemicals, dry ice blasting is a non-abrasive technique that removes contaminants, grease, and coatings without leaving behind any residue. It is ideal for cleaning industrial machinery, food processing equipment, and aerospace applications, ensuring a thorough and eco-friendly clean.

3. Essential for Food Preservation & Transportation

The food industry relies heavily on Dryice for preserving and transporting frozen seafood, meats, dairy, and baked goods. Supermarkets, restaurants, and catering businesses benefit from its cooling power, ensuring fresh delivery to customers.

4. Critical for Medical & Pharmaceutical Applications

Dry ice is indispensable for medical and pharmaceutical industries, ensuring the safe transport of biological samples, vaccines, and life-saving medicines that require precise temperature control. Hospitals, laboratories, and research institutions worldwide rely on dry ice for its reliability.

5. Creating Stunning Special Effects

Want to create mesmerizing fog effects for concerts, events, or films? Dry ice, when mixed with warm water, produces thick, enchanting fog, making it a staple in theatrical performances, movie productions, and even Halloween decorations.

6. Eco-Friendly Pest Control & Agricultural Benefits

Dry ice serves as a non-toxic alternative to chemical pesticides, effectively eliminating pests by releasing carbon dioxide into burrows and suffocating rodents and insects naturally. It also helps protect grain storage facilities from infestations.

7. Safe, Non-Toxic & Sustainable

Unlike chemical coolants, dry ice is completely safe, non-toxic, and environmentally friendly. Since it sublimates directly into CO₂ gas, it leaves no harmful residue. Dry ice is made from recycled carbon dioxide, making it an eco-conscious choice that helps reduce industrial emissions.

8. Emergency Cooling & Backup Refrigeration

Power outage? Dry ice acts as a backup refrigeration solution, ensuring that food, medicines, and other perishable items remain fresh for extended periods. This makes it invaluable for homes, restaurants, and grocery stores.

9. Industrial & Manufacturing Uses

Dry ice is extensively used in industrial applications, including metal shrinking, pipe freezing, and rubber molding. It enables precise assembly of metal components and helps repair underground pipes without the need for complete shutdowns.

10. A Cleaner Alternative to Traditional Ice

Unlike water ice, dry ice does not melt into a liquid, making it ideal for applications where excess moisture is undesirable, such as in pharmaceuticals, electronics, and aerospace industries.

Why Choose Dryice Abudhabi?

✅ Trusted Dry Ice Manufacturer in Abu Dhabi

We are the leading Dryice manufacturer in Abudhabi, supplying high-quality dry ice for various industrial, medical, and commercial needs.

✅ Reliable Dry Ice Supplier in Abu Dhabi

Our Dryice supplier in Abudhabi services ensure businesses receive a steady supply of dry ice with timely delivery across Abu Dhabi and the UAE.

✅ Premium Quality at Competitive Prices

We offer the best quality dry ice at cost-effective rates, making it an affordable solution for all industries.

✅ Customized Dry Ice Solutions

We provide dry ice in various forms, including pellets, blocks, and slices, tailored to meet your specific requirements.

✅ Fast & Reliable Delivery

Timely delivery is crucial, and our streamlined logistics ensure you receive your dry ice on schedule, every time.

📞 Place Your Order Now: +971553635753 🌐 Visit: https://dryiceabudhabi.com/

0 notes

Text

The Magic of Iodophor: The Unsung Hero in Pipeline Cleaning

Pipeliner cleaners have most of us envisioning some futuristic chemical brew bubbling through stubborn grime. But if I told you the real hero here is a relatively unsung, slightly mysterious chemical called iodophor, you might well nod and say, "Yep, that's got a name that sounds like a wizard from a fantasy novel, and honestly, it might just be magical."

What is Iodophor?

Iodophor is basically the cool, less volatile cousin of iodine. It is a mixture of iodine and a surfactant, which is a fancy term for something that makes it spread around better. This concoction is a germ's worst nightmare, used extensively in sanitizing pipelines, brewing equipment, and even dairy machinery. Why? Because it's effective, easy to rinse, and doesn't leave behind weird flavors. Cheers to that!

How Does Iodophor Work?

Iodophor is the party crasher at bacteria's housewarming. It swoops in, disrupts their membranes, and poof! Goodbye, bacteria. Bonus: it doesn't overstay its welcome. Unlike harsher cleaners, iodophor is gentler on your equipment, ensuring no scratches or damage.

Why Pipeline Cleaners Love It

For pipeline cleaners, iodophor is like that all-in-one tool you wish you had in your toolbox. It's versatile, works in both cold and warm water, and requires minimal elbow grease. Plus, it's kind to the environment. You can sleep soundly knowing you're not sending toxic sludge down the drain.

A Pinch of Humor

Picture this: a pipeline so clean it could double as a waterslide. That’s the kind of sparkle iodophor brings to the table. And no, it won’t leave your coffee tasting like iodine—a win for both your taste buds and your peace of mind.

The Bottom Line

Iodophor would never wear a cape, of course, but it is cleaning's unsung hero. Magically, everyone from pipeline cleaners to the purists of all things hygienic and productive requires iodophor. Just remember: next time that pipe is positively glistening for the world, take a step back and honor the iodophor. The magic has won out.

0 notes

Text

Why is Chemtex's Peracetic Acid Preferred for surface disinfection & sanitizer in F&B industries

In the rigorous realm of food and beverage (F&B) production, maintaining the highest standards of hygiene and sanitation isn't just a regulatory requirement—it's pivotal for ensuring food safety and consumer trust. Among the myriad sanitizing agents available today, Peracetic Acid (PAA) emerges as a superior choice, revered for its efficacy, safety, and minimal environmental impact. This article explores the compelling reasons behind the preference for PAA as a leading sanitizer in F&B sectors.

Efficacy in Pathogen Control’

PAA is renowned for its potent antimicrobial properties, effectively neutralizing a broad spectrum of pathogens including bacteria, viruses, fungi, and spores. The mechanism behind its's action is its strong oxidizing capability, which disrupts the cell structure of microorganisms, leading to rapid cell destruction. This makes it uniquely effective, as it requires lower temperatures to achieve disinfection, thereby preserving the integrity of heat-sensitive F&B equipment and surfaces.

Compliance with Industry Standards

PAA's ability to adhere to stringent sanitation standards makes it a staple in F&B environments. It works effectively even at low concentrations and provides rapid sanitization, facilitating continuous and extensive use without compromising safety or efficacy. Notably, PAA is recognized under the Food Safety and Standards Authority of India (FSSAI) in Category 99 for substances added to food, ensuring compliance with national food safety regulations.

The utility of it extends across various real-world applications within the F&B industry. For example, a prominent beverage manufacturer adopted a PAA-based sanitizing protocol across its production facilities, which significantly reduced microbial contamination on surfaces and within the final products. This not only aligned with stringent international safety standards but also enhanced the overall product quality and shelf life.

Another testament to the efficacy of it comes from a meat processing plant where traditional sanitation methods were insufficient. After integrating a PAA-based sanitation system, the facility reported a 99.9% reduction in surface pathogens, dramatically reducing the risk of cross-contamination and elevating product safety.

Advantages Over Other Sanitizers

PAA offers several advantages over traditional sanitizers like chlorine:

No Toxic Residues: it breaks down into water, oxygen, and acetic acid—substances that are harmless and do not require a post-application rinse. This attribute makes PAA an eco-friendlier and more efficient sanitizing solution.

Non-Corrosive Nature: When used at recommended concentrations, it is significantly less corrosive than other chemical sanitizers, extending the lifespan of industrial equipment.

Effectiveness in Organic Presence: Unlike chlorine-based sanitizers, which can become less effective in the presence of organic matter, it maintains its sanitizing power, making it ideal for organic-rich environments like those found in F&B processing.

Introducing Alstasan Activ

Building on the strengths of PAA, Chemtex Speciality Ltd. offers Alstasan Activ, a premium PAA-based sanitizer tailored for the F&B industry. Certified by the National Dairy Research Institute (NDRI), Karnal, as an effective cold sterilant for dairy-related pathogens, Alstasan Activ stands out for its efficacy and compliance with industry standards. As businesses strive to meet ever-tightening safety protocols, integrating Alstasan Activ into your sanitation regimen ensures a cleaner, safer, and more compliant operational environment.

Choose Chemtex Speciality Ltd. and Alstasan Activ for your sanitation needs, and take a proactive step towards enhancing food safety and quality in your production processes.

#peracetic acid#surface disinfection#F&B industries#PAA#sanitation#eco friendly#Alstasan activ#antimicrobial properties#cleaning purposes#food processing industry#chemtex speciality limited

0 notes

Text

Exploring the Applications and Benefits of Tri-Sodium Phosphate Dodecahydrate in Industry

When it comes to versatile chemical compounds, Tri-Sodium Phosphate Dodecahydrate (TSP Dodecahydrate) stands out as a powerhouse across various industries. From its role as a potent cleaning agent to its application as a food additive, this compound has earned its place in both industrial and household settings. But what exactly makes TSP Dodecahydrate so effective, and why is it trusted by professionals around the globe? In this blog, we’ll dive into the unique properties, diverse applications, and safety considerations of Tri-Sodium Phosphate Dodecahydrate, exploring why it’s an essential component in everything from your kitchen pantry to industrial manufacturing processes.

Chemical Formula and Molecular Structure Of Tri-Sodium Phosphate Dodecahydrate

Tri-sodium phosphate dodecahydrate, commonly known as TSP Dodecahydrate, has the chemical formula Na₃PO₄·12H₂O. This formula indicates that each molecule contains three sodium (Na) ions, one phosphate (PO₄) ion, and twelve water molecules (H₂O) of hydration. The presence of these twelve water molecules classifies it as a dodecahydrate, giving it distinct properties compared to its anhydrous or lower hydration counterparts. The molecular structure is composed of sodium cations and phosphate anions, creating a highly soluble and alkaline compound.

Physical Properties Of Tri-Sodium Phosphate Dodecahydrate

In its solid form, TSP Dodecahydrate appears as colorless, crystalline granules or powder. It is highly soluble in water, dissolving easily to create a strongly alkaline solution with a pH typically ranging between 11 and 12. This high solubility makes it an effective agent in applications that require rapid dispersion in water. Stability-wise, TSP Dodecahydrate is stable under normal conditions but may lose its water of hydration when exposed to high temperatures, leading to a conversion to anhydrous sodium phosphate. It is also non-flammable and does not pose a risk of combustion.

Applications Of Tri-Sodium Phosphate Dodecahydrate

Industrial Applications Of Tri-Sodium Phosphate Dodecahydrate

Tri-Sodium Phosphate Dodecahydrate (TSP Dodecahydrate) is a versatile compound with a wide range of industrial applications. Its unique chemical properties make it an essential ingredient in sectors such as cleaning, food processing, and water treatment.

Cleaning and Degreasing Agent: TSP Dodecahydrate is renowned for its powerful cleaning and degreasing capabilities. As an active ingredient in both household and industrial cleaners, it effectively breaks down and removes stubborn grease, oil, and grime from surfaces. Whether it’s for cleaning kitchen appliances, floors, or industrial equipment, TSP Dodecahydrate delivers results by emulsifying fats and oils, making them easier to wash away.

Effectiveness in Removing Grease and Stains: One of the primary reasons TSP Dodecahydrate is favored as a cleaning agent is its high alkalinity, which enhances its ability to tackle tough stains. When mixed with water, it forms a strong alkaline solution that not only cuts through grease but also helps in lifting away dirt, making it a preferred choice for pre-paint surface preparation and other heavy-duty cleaning tasks. This effectiveness extends to a variety of surfaces, including metal, concrete, and even some types of fabric, ensuring a thorough cleaning every time.

Usage Of Tri-Sodium Phosphate Dodecahydrate in Food Processing

In the food industry, Tri-Sodium Phosphate Dodecahydrate plays a crucial role as an emulsifier and pH adjuster. Its ability to stabilize mixtures of oil and water makes it a valuable additive in processed foods like cheese, dairy products, and baked goods. By preventing the separation of ingredients, TSP Dodecahydrate ensures a consistent texture and quality in the final product.

Additionally, TSP Dodecahydrate is used to control the acidity of food products, ensuring that they remain within the desired pH range for flavor, preservation, and safety. This pH adjustment capability is particularly important in the production of meat products, beverages, and other processed foods where specific pH levels are critical to the product’s stability and taste.

The use of TSP Dodecahydrate as a food additive is regulated by authorities like the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). It is Generally Recognized As Safe (GRAS) when used by prescribed limits. However, food manufacturers must adhere to these guidelines to avoid excessive consumption, which could lead to adverse health effects. Proper labeling and adherence to food safety regulations ensure that products containing TSP Dodecahydrate are safe for consumer use.

Usage Of Tri-Sodium Phosphate Dodecahydrate in Water Treatment

Water Softening and Prevention of Corrosion: In the realm of water treatment, TSP Dodecahydrate is utilized for its water-softening properties and its ability to prevent corrosion in pipes and water systems. By binding with calcium and magnesium ions, TSP Dodecahydrate effectively reduces water hardness, which can cause scaling and build-up in plumbing systems. This not only extends the lifespan of water-using appliances but also improves the efficiency of detergents and soaps used with softened water. Additionally, TSP Dodecahydrate helps in inhibiting corrosion by forming a protective layer on metal surfaces, which prevents the oxidative reactions that lead to rust and degradation. This is particularly beneficial in industrial water systems, where the longevity and integrity of the infrastructure are critical.

Impact on Water Quality and Infrastructure Longevity: The application of TSP Dodecahydrate in water treatment has a significant impact on both water quality and infrastructure longevity. By mitigating the effects of hard water and preventing corrosion, it ensures that water systems operate more efficiently and with fewer maintenance issues. This contributes to the overall sustainability and cost-effectiveness of water management practices in both residential and industrial settings.

Health and Safety Considerations Of Tri-Sodium Phosphate Dodecahydrate

Potential Health Risks and Safety Measures: TSP Dodecahydrate is generally safe but can cause skin and respiratory irritation if mishandled. Wearing protective gear like gloves and masks, along with proper ventilation, minimizes exposure risks.

Guidelines for Handling and Storage: Store TSP Dodecahydrate in a cool, dry place, away from strong acids. Keep containers sealed to prevent moisture absorption. Always follow safety data sheets (SDS) and manufacturer guidelines for safe handling.

Environmental Impact and Disposal Methods: While TSP Dodecahydrate has a low environmental impact, improper disposal can lead to water pollution. Follow local disposal regulations and avoid releasing it into waterways to minimize ecological risks.

Innovative Uses and Research Related To TSP Dodecahydrate

TSP Dodecahydrate is finding new applications beyond traditional uses. In industries like biotechnology and electronics, its potential in processes such as protein purification and circuit board cleaning is being explored, showcasing its versatility.

Current Research Trends and Potential Future Developments: Ongoing research is investigating TSP Dodecahydrate’s role in sustainable practices, including eco-friendly cleaning solutions and water treatment methods. Scientists are also exploring its potential to enhance food preservation and improve industrial efficiency, paving the way for future advancements.

Recent case studies highlight innovative uses of TSP Dodecahydrate in areas like 3D printing and advanced manufacturing, where its properties enhance material performance and process efficiency. These examples illustrate the compound’s expanding role in cutting-edge technologies.

Tri-Sodium Phosphate Dodecahydrate is a versatile and indispensable compound with applications spanning from household cleaning to advanced industrial processes. Its unique chemical properties make it a powerful agent in cleaning, food processing, and water treatment, while ongoing research continues to unlock new and innovative uses. However, with its widespread use comes the responsibility of handling it safely and considering its environmental impact. As industries evolve and demand for efficient, multi-functional compounds grows, TSP Dodecahydrate’s role will likely expand further, solidifying its place as a key player in various fields.

Whether you’re a professional in the industry or simply curious about the science behind everyday products, understanding TSP Dodecahydrate offers valuable insights into its critical role in modern life.

Check out the Original Article

0 notes

Text

Enhancing Farm and Stable Environments with Rubber Matting Solutions

Agriculture and equine care require durable, safe, and comfortable environments. One way to achieve this is through the use of high-quality rubber matting. Equine stable matting and agricultural rubber mats offer numerous benefits, making them essential investments for farms and stables. This article will explore the advantages of these mats, their applications, and why they are a worthwhile addition to your agricultural and equine facilities.

The Importance of Comfortable and Safe Flooring

Ensuring that animals have a comfortable and safe environment is paramount. Hard concrete floors or uneven dirt surfaces can lead to discomfort and health issues for animals. Equine stable matting provides a cushioned, non-slip surface that reduces the risk of injuries. These mats are designed to offer comfort and support, which is particularly important for horses that spend long periods standing in their stalls.

Benefits of Equine Stable Matting

Improved Comfort and Health

Equine stable matting significantly enhances the comfort of horses. The mats provide a softer surface than concrete, which helps reduce stress on horses' joints and hooves. This can prevent long-term health issues such as arthritis and lameness, promoting overall well-being.

Easy Maintenance and Hygiene

Rubber mats are easy to clean and maintain, which is crucial for maintaining hygiene in stables. They can be quickly washed down and disinfected, reducing the risk of bacterial growth and infections. This ease of maintenance ensures a cleaner and healthier environment for the animals.

Enhanced Safety

The non-slip surface of equine stable matting helps prevent slips and falls, protecting both the animals and their handlers. This is particularly crucial in damp weather when there is a greater chance of sliding. The mats provide a stable footing, which is essential for the safety of horses during grooming, feeding, and other activities.

Applications of Agricultural Rubber Mats

Agricultural rubber mats are versatile and can be used in various farm settings. Their durability and resilience make them suitable for multiple applications.

Livestock Areas

In livestock areas, agricultural rubber mats provide a comfortable and safe surface for animals such as cows, pigs, and sheep. These mats can help in reducing injuries and stress, leading to healthier and more productive animals. The mats also offer insulation, keeping the animals warm during colder months.

Milking Parlors

Milking parlors can benefit significantly from agricultural rubber mats. The mats provide a non-slip surface, ensuring the safety of both animals and workers. Additionally, they are easy to clean, which helps maintain the hygiene standards necessary for dairy production.

Barns and Sheds

Barns and sheds where equipment and feed are stored can also use rubber mats. The mats help in protecting the floors from wear and tear caused by heavy equipment and provide a safer walking surface for workers. This not only extends the lifespan of the floors but also enhances the overall efficiency of the farm operations.

Environmental Benefits

Apart from the direct benefits to animals and workers, rubber mats also offer environmental advantages. Many rubber mats are made from recycled materials, contributing to waste reduction and promoting sustainability. By choosing rubber matting solutions, farm, and stable owners can support eco-friendly practices while improving their facilities.

Conclusion

Investing in equine stable matting and agricultural rubber mats is a smart decision for anyone involved in farming or equine care. These mats offer improved comfort, safety, and hygiene for animals while also providing durability and ease of maintenance. With their versatile applications and environmental benefits, rubber mats are a valuable addition to any farm or stable.

For more information on high-quality rubber matting solutions, visit cdjrubber.com.au.

0 notes

Text

Successful Implementations of Solar Water Heaters in the Industrial Sector

Industries around the world are increasingly turning to solar water heaters to meet their energy needs in a cost-effective and sustainable manner. The benefits of adopting solar water heating technology extend beyond reducing energy bills; they also contribute to environmental stewardship and compliance with regulations. This blog highlights some successful implementations of solar water heaters in the industrial sector, showcasing how different industries have effectively integrated this technology into their operations.

1. Food and Beverage Industry: Brewing with the Sun

A leading brewery in Germany successfully implemented solar water heaters to meet a significant portion of its hot water needs. The brewery installed a solar thermal system with large flat-plate collectors on its rooftop, which pre-heats water used in the brewing process. By integrating solar heating into their operations, the brewery reduced its reliance on natural gas, cut its energy costs by 30%, and decreased its carbon emissions by 25%. This move not only enhanced the brewery's sustainability credentials but also resonated well with eco-conscious consumers.

2. Textile Industry: Solar Solutions for Dyeing Processes

A textile manufacturer in India faced high energy costs associated with heating water for dyeing fabrics. The company decided to invest in a solar water heating system with evacuated tube collectors, which are highly efficient in converting solar energy into heat. The system was designed to provide hot water at temperatures required for the dyeing process. After implementation, the manufacturer saw a reduction in energy costs by 40% and a return on investment (ROI) within three years. The solar system also contributed to a cleaner production process, aligning with the company's environmental goals.

3. Chemical Industry: Reducing Energy Intensity with Solar Heating

In Spain, a chemical processing plant implemented a solar water heating system to reduce the energy intensity of its operations. The plant required large amounts of hot water for various chemical reactions and cleaning processes. By installing a solar thermal system with advanced tracking collectors that follow the sun’s movement, the plant was able to maximize energy capture. The system provided 60% of the plant’s hot water needs, resulting in significant energy savings and a reduction in greenhouse gas emissions by 35%.

4. Dairy Industry: Sustainable Milk Processing

A dairy processing facility in New Zealand incorporated solar water heaters into its milk pasteurization process. The facility installed solar thermal panels on its rooftops, which are used to pre-heat water before it enters the pasteurization units. This approach reduced the facility’s dependency on conventional energy sources, cutting energy costs by 20% and lowering the overall carbon footprint. The use of solar energy in the dairy process also helped the facility gain recognition for its sustainable practices, boosting its market competitiveness.

5. Hospitality Industry: Solar Water Heating for Laundry Services

A large hotel chain in the United States adopted solar water heating systems to support its laundry operations, which required vast amounts of hot water. By installing solar collectors on the rooftops of its hotels, the chain was able to generate sufficient hot water for laundry services, reducing energy consumption by 50%. This implementation not only resulted in substantial cost savings but also positioned the hotel chain as a leader in sustainable hospitality, attracting eco-conscious guests.

6. Pharmaceutical Industry: Green Energy for Sterilization Processes

A pharmaceutical manufacturing plant in Italy needed a reliable and energy-efficient method to generate hot water for sterilization and cleaning. The plant invested in a solar water heating system equipped with high-efficiency evacuated tube collectors. The system was designed to provide hot water at consistent temperatures, critical for maintaining sterilization standards. Post-implementation, the plant reported a 35% reduction in energy costs and enhanced its compliance with environmental regulations, all while maintaining the quality and safety of its products.

These case studies demonstrate the versatility and effectiveness of solar water heaters across various industries. By leveraging solar energy, companies can significantly reduce their energy costs, enhance sustainability, and improve their bottom line. Whether in food and beverage, textiles, chemicals, dairy, hospitality, or pharmaceuticals, solar water heating systems offer a proven solution for industrial applications.

Are you ready to explore the benefits of solar water heaters for your industrial operations? Contact us today to learn how we can help you implement a solar thermal system tailored to your industry’s needs, ensuring cost savings and sustainability for the future. For more info contact Solar Water Heater Supplier in UAE or call us at +971 4 2522966.

0 notes

Text

The Importance of Commercial Cleaning Supplies for Every Industry

In today's fast-paced world, maintaining clean and hygienic environments is essential for the health, safety, and productivity of individuals across various industries. Commercial cleaning supplies play a crucial role in ensuring cleanliness and sanitation. From office spaces to healthcare facilities, each industry requires specialized cleaning solutions to meet specific needs. Let’s explore some of the key sectors where commercial cleaning supplies are indispensable.

1. Commercial Cleaning

Commercial cleaning involves maintaining the cleanliness of office spaces, corporate buildings, and public areas. For businesses to run efficiently, employees and clients must work in a clean environment. Key commercial cleaning supplies include surface disinfectants, floor cleaners, window cleaning solutions, and carpet care products. These cleaning supplies help in reducing the spread of germs and enhancing the overall productivity of employees.

2. Dairy Industry Cleaning

The dairy industry requires stringent cleaning standards to maintain hygiene and ensure that milk and dairy products are free from contaminants. Specialized cleaning supplies like dairy sanitizers, milk line cleaners, and equipment degreasers are essential in this industry. The cleaning solutions used must meet the health regulations and be effective in eliminating bacteria, mold, and residue that could affect the quality of dairy products. Ensuring the cleanliness of milk tanks, pipelines, and storage areas helps in preventing spoilage and contamination.

3. General & Household Cleaning

For everyday cleaning at home or in small businesses, a variety of general cleaning supplies are needed. All-purpose cleaners, dishwashing liquids, floor detergents, and bathroom disinfectants help maintain a tidy and hygienic space. Commercial-grade products like heavy-duty floor scrubbers, carpet cleaners, and multi-surface wipes can save time and effort, providing a superior clean in less time. Households and businesses alike benefit from easy-to-use, effective products that help maintain cleanliness daily.

4. Hospitality Cleaning

In the hospitality industry, maintaining cleanliness is critical to providing guests with a comfortable and pleasant experience. Hotels, restaurants, and event venues rely on commercial cleaning supplies such as disinfectants, glass cleaners, air fresheners, and specialized laundry detergents. These cleaning products help ensure that rooms, dining areas, and public spaces are spotless, reducing the risk of infection and enhancing customer satisfaction.

5. Industrial Cleaning

Industrial cleaning is essential for ensuring that factories, warehouses, and production facilities remain safe and clean. Heavy-duty industrial cleaners, degreasers, and floor scrubbers are commonly used to remove tough dirt, oil, grease, and other contaminants from machinery and floors. Regular industrial cleaning helps to maintain equipment performance, prevent accidents, and comply with safety regulations, all of which are necessary for smooth operations.

6. Workshop & Transport Cleaning

Workshops and transport vehicles often face high traffic and exposure to dirt, oil, and other stains. Commercial cleaning supplies designed for these environments include industrial-strength degreasers, upholstery cleaners, and vehicle disinfectants. Keeping transport fleets, tools, and machinery clean ensures their longevity, performance, and safety while also preventing the spread of harmful contaminants.

7. Aged Care & Healthcare Cleaning

In aged care facilities and healthcare environments, cleanliness is a matter of life and death. Hospitals, nursing homes, and clinics require specialized cleaning products to maintain a sterile and safe environment. Hospital-grade disinfectants, antibacterial cleaners, and surface sanitizers are crucial in preventing the spread of infections. These products are designed to kill harmful pathogens, ensuring the safety and health of patients, staff, and visitors.

8. Hospital Grade Disinfectants

Hospital-grade disinfectants are essential in all healthcare settings, including hospitals, clinics, and aged care homes. These disinfectants are formulated to kill a wide range of harmful pathogens, including viruses and bacteria, ensuring that surfaces are safe for patients and medical staff. They are also used in high-traffic areas to control the spread of infections, making them a crucial part of any healthcare cleaning routine.

Conclusion

Whether in a corporate office, healthcare facility, or industrial setting, using the right commercial cleaning supplies is critical to maintaining a safe, clean, and productive environment. Industry-specific cleaning products, from hospital-grade disinfectants to dairy sanitizers, are designed to meet the unique needs of each sector, ensuring the highest levels of cleanliness and hygiene. By investing in quality cleaning supplies, businesses can protect their employees, customers, and equipment while enhancing their overall operations.

#Commercial cleaning supplies#Office cleaning supplies#Industrial cleaning products#Dairy industry cleaning supplies#Hospital cleaning products#Healthcare cleaning supplies#Cleaning products for restaurants#Heavy-duty cleaners#Floor scrubbers and cleaners#Hospital-grade disinfectants#Eco-friendly cleaning products#Cleaning supplies for warehouses#Disinfectants for healthcare settings#Cleaning products for transportation#Workplace cleaning solutions#Cleaning products for hotels#Sanitizing products for healthcare#General cleaning supplies for businesses#Aged care facility cleaning#Milk line sanitizers#Commercial disinfectants#All-purpose cleaners#Cleaning solutions for factories#Antibacterial cleaners for healthcare#Workshop cleaning products

0 notes

Text

Boosting Livestock Health: Key Roles of Acidifiers, Disinfectants, and Iodophors

In modern farming, maintaining healthy livestock is considered essential both for productivity and profitability. A healthy farm begins from the animal. Several products can be used to manage and enhance this factor. Most important among them are acidifiers, disinfectants, and iodophors. Each has a unique yet vital role to play in preventing diseases, improving digestion, and keeping farm hygiene. Let us dive into how these three interact in making the farming environment more health-friendly and productive.

Acidifiers: Improve Digestive Health Acidifiers are commonly added in animal feed and drinking water, thereby reducing the pH in the gut. Harmful bacteria such as Salmonella and E. coli thrive when the gut environment becomes too alkaline. Acidifiers, therefore, help restore this balance by making the digestive tract more acidic, which fosters the growth of beneficial bacteria but inhibits the harmful bacteria.

Organic acids such as lactic acid, citric acid, and formic acid are widely used as acidifiers in poultry, swine, and cattle. These acids improve nutrient absorption, enhance gut health, and increase overall performance. For instance, poultry farmers often add acidifiers to drinking water to optimize digestion and prevent harmful bacterial growth in the intestines. In addition to these benefits, acidifiers provide a beneficial microbiome through the development of a good gut, and this helps better conversion rates and growth and efficacy in the animal.

Disinfectants - Keeping the Area Clean for Disease Prevention Disinfectant play a vital role in controlling diseases in the farm. The types of microbes that need to be attacked include bacteria, viruses, fungi, and parasites. Generally, on a farm especially with big populations of animals living close together, it is risky in terms of transferring diseases. This means there is a high demand for the disinfection of equipment and surfaces of areas housing the animals.

Chlorine-based products, quaternary ammonium compounds, and hydrogen peroxide are the most common disinfectants used in agricultural farms. These chemicals are applied to clean floors, walls, water systems, feeding equipment, and even animal housing. Regular disinfection reduces the chances of infections like avian influenza, foot-and-mouth disease, and other zoonotic diseases that can not only harm animals but also pose a threat to farm workers. A routine disinfection pattern would help the farmers avoid infection spreading and would keep a cleaner environment both for the animals and human beings.

Iodophors: Safe Antiseptic Solutions Iodophor are iodine-based antiseptics with a broad spectrum of antimicrobial activity. They are useful for preventing infections in livestock. Iodophors gradually release iodine, which kills bacteria, viruses, fungi, and other microorganisms that could cause infections. They are most commonly used in veterinary care, especially when disinfecting wounds or preparing animals for procedures like vaccinations or surgeries.

In dairy farming, iodophors are especially important. They are used to disinfect cow teats before milking, helping prevent mastitis, a painful and costly infection that affects milk production. Mastitis not only reduces milk yield but can also affect milk quality. By using iodophors to keep teats clean and sanitized, farmers can significantly reduce the risk of infection, promoting both animal health and better milk production.

Conclusion: Key to a Healthier Farm Acidifiers, disinfectant, and iodophors are integral components of a comprehensive health management strategy on any farm. Acidifiers help maintain gut health, improving digestion and nutrient absorption, while disinfectants prevent the spread of harmful pathogens in the farm environment. Iodophors, with their antimicrobial properties, protect animals from infections and promote healing.

By incorporating these tools in their daily management of a farm, productivity is improved, the risk of diseases lowered, and the general health and well-being of their livestock is maintained. A clean and healthy farm is a successful one—and with the help of acidifiers, disinfectants, and iodophors, farmers are set up to create an environment that makes animals thrive.

0 notes

Text

Food Waste Prevention Week

As part of Food Waste Prevention Week, MI Environment is highlighting two Michigan municipalities that are offering residents ways to reduce their food waste by keeping it out of landfills.

Spurt Industries' screening plant, where compost is screened, creating a better finished product and removing clumps in the soil. The equipment also separates and removes large pieces of wood that did not fully decompose and filters out contaminants like plastic and metal. Courtesy of My Green Michigan.

Landfilled food is one of the biggest sources of methane, a key driver of climate change. So it's not a surprise that the state’s MI Healthy Climate Plan has a goal of cutting the amount of landfilled food in half by 2030.

But with more than two billion pounds of food going to Michigan landfills each year, cutting that in half in only six years is a big lift. That is where Southfield and Wixom come in to help foster innovation in the food space. Because Southeast Michigan is the most populated area of the state, addressing food waste is expected to have a major impact on the overall state goal.

Make Food Not Waste, along with 17 local and national partners, is taking food waste head on by defining what it takes to divert all of a city's food waste from landfills, starting with the city of Southfield. The Make Food Not Waste team is creating a detailed plan that incorporates all of the best practices in food waste reduction from around the country. The plan will include recommendations for source reduction, food rescue, upcycling, and organics recycling.

The approach underscores two important points: first, there is no "one" solution to food waste; and second, stopping food from going into landfills only happens by working together.

By early fall, the group will have a detailed map outlining the communication, infrastructure, and logistical needs to divert all of Southfield's food waste to alternate uses detailed in EGLE’s Sustainable Food Hierarchy. With that in place, the plan can be replicated in other highly populated cities. If it sounds ambitious, it is.

Make Food Not Waste, an environmental non-profit based in Detroit, is a recipient of an EGLE Zero Food Waste Pilot grant to tackle this goal. Read about The 2030 Project to learn more.

Another city starting a food scrap program is Wixom. Beginning this week, Wixom is making it easy for residents to have food scraps and yard waste collected weekly curbside. The scraps and yard waste will be composted and used in gardens and city projects.

Acceptable food scraps include fruits and vegetables, dairy products, meats, bones, eggshells, coffee grounds and filters, tea leaves and tea bags, paper napkins and paper towels (free of chemical cleaners), breads, grains, and spoiled food from the refrigerator.

The city is partnering with Spurt Industries, Green for Life, and Resource Recovery and Recycling Authority of Southwest Oakland County (RRASOC) for this program. Check out RRASOC Wixom Food Scrap Program webpage to learn more.

“Efforts by Michigan cities are key to achieving Michigan’s food waste reduction strategy,” said Jeff Spencer, a manager in the EGLE’s Materials Management Division. “Southfield and Wixom are pioneers in this effort. EGLE expects other cities to follow in the footsteps of the work initiated by these progressive communities.”

EGLE continues to prioritize programming for food waste reduction to work toward meeting the MI Healthy Climate Plan goal of a 50% food waste reduction, through the Catalyst Communities Initiative, NextCycle Michigan, and in partnership with Michigan Green Communities (MGC). NextCycle Michigan has eight teams currently working through the Foods, Liquids, & Organic Waste Systems (FLOWS) Accelerator track. MGC will be hosting a webinar "Developing a Baseline Estimate for Food Waste in Your Community" on April 11, and on May15 the Catalyst Communities Initiative will host a Food Waste Workshop for local governments as a MI Healthy Climate Conference pre-Conference event.

Check out EGLE’s Food Waste webpage to learn more.

Source: EGLE Newsroom

0 notes

Text

Milk Can Scrubbing Brush in India

The Milk Can Scrubbing Brush, which is sold on Indian Trade Bird, is the best way to effectively clean dairy equipment. In order to maintain the highest levels of hygiene in dairy farms, milk processing facilities, and creameries, our platform provides a wide selection of premium scrubbing brushes made especially for cleaning milk cans. You can effectively and thoroughly clean milk cans with our Milk Can Scrubbing Brush, getting rid of tenacious residues and guaranteeing the cleanliness of your dairy products. Our brushes are made with sturdy bristles that efficiently remove dirt and bacteria, and their ergonomic form makes them easy to use. With our superior scrubbing brush, you may feel cleaner and more at ease knowing that your milk cans are well cleaned. With our unique cleaning equipment, you can wave goodbye to labor - intensive hand scrubbing techniques and hello to seamless efficiency.

0 notes

Text

"Udderly Important: Enhancing Dairy Cow Health with Wood Shavings - Insights from PhatNguyen Supply"

Hey Dairy Enthusiasts!

Welcome back to the PhatNguyen Supply blog! Today, we're diving into a crucial aspect of dairy farming – maintaining the health of our beloved dairy cows' udders. And guess what? Wood shavings play a starring role in this story!

Calving Comfort:

When it's calving season, we know the significance of a stress-free environment. At PhatNguyen Supply, we recommend creating a cozy haven for our expectant cows with a generous layer of wood shavings. This not only cushions the birthing process but also sets the stage for postpartum udder health.

Postpartum Perfection:

After the little ones arrive, it's time to focus on the postpartum period. Our mantra? Clean and dry bedding. Regularly swapping out soiled shavings keeps udders happy and reduces the risk of infections. Think of it as a spa day for your cows!

Milking Magic:

Milking time is special, and we want to make it as comfortable as possible. Wood shaving in the holding area contribute to a cleaner, healthier milking experience. Plus, don't forget the importance of a meticulous milking routine and equipment hygiene – it's the secret sauce to udder bliss!

Dry Period Delight:

The dry period is like a mini-vacation for our dairy queens. We ensure they relax in a clean and comfortable space using top-notch wood shavings. Monitoring udder health during this phase sets the stage for a successful next lactation cycle.

PhatNguyen Pro Tips:

1. Quality Matters: Source the best wood shavings for cleanliness and comfort.

2. Hygiene Heroes: Embrace good hygiene practices to minimize bacterial threats.

3. Veterinary Valor: Collaborate with a vet to craft a holistic udder health plan.

We're passionate about dairy farming, and we know you are too! Let's prioritize our cows' udder health together. Stay tuned for more insights from PhatNguyen Supply – where your dairy dreams come true!

Until next time,

The PhatNguyen Supply Team

1 note

·

View note

Text

Dairy Cleaning Chemicals List

Eko Power® 101 is a general - purpose cleaner & disinfectant especially designed for use at BMC / MCC for milk cans, silos, dump tanks, tankers, crate washing, floor cleaner, and other equipments.

Visit Us: https://www.ecocaretech.com/dairy-cleaning-chemicals

0 notes

Text

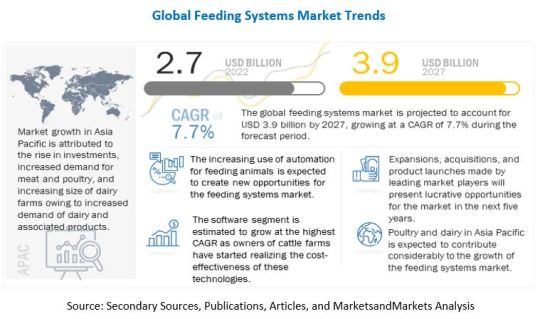

Sustainable Growth Opportunities in the Feeding Systems Market

The global feeding systems market is projected to reach USD 3.9 billion, by 2027, at a CAGR of 7.7% from 2022 to 2027. The growing size of dairy farms, increasing focus of major companies on technological advancements as well as product launches and developments, and substantial cost savings associated with automated feeding systems are the major driving factors for the market. The market also faces some challenges like high capital requirements at the initial stage of installation, which may discourage small and medium-sized farms from automating the feeding process.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=102235948

DeLaval is a market leader providing integrated milking solutions designed to improve dairy farmers’ production, animal welfare, and overall quality of life. The company develops and manufactures equipment for milk production and animal husbandry, including feeding systems worldwide. DeLaval offers highly efficient system solutions for milking, farm and herd management, animal traffic control, feeding, cooling, manure handling, ventilation, and energy recovery. The company supplies highly efficient solutions for cattle feeding, which help in reducing costs and increasing productivity. It has a strong global presence, spanning Europe, the Middle East, Africa, the Americas, and the Asia Pacific. In November 2018, DeLaval (Sweden) announced a partnership with CEJA (European Council of Young Farmers Home) to help farmers in the European Union for better sustainability in the long-term process of farming.

Trioliet B.V provides various solutions mainly to cattle farming. The solutions offered by the company include feeders, weighing systems, and loading equipment. The various feeders devised by the company for feeding bovine animals include mixer feeder wagons and self-loading mixer feeders. The company also provides feeding solutions to dairy farms worldwide. It has a presence in over 50 countries. In 2020, the company launched Triotrac M. It is self-propelled machine and has one vertical auger and a cutting-loading system with a loading rotor to load the feed into the mixing tub. The unique loading system ensures that the feed is processed cleanly and without any wastage during the loading process.

Get 10% Free Customization on this Report: https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=102235948

Lely provides automated feeding, forage harvesting, and milking robot solutions for the agricultural sector. It also offers milking solutions such as robotic milking systems, used milking robots, and detection systems. The company’s product portfolio comprises feeding solutions such as feed pushers, individual feeders, calf feeders, selection boxes, animal feeding solutions, and housing solutions (including lighting systems, mobile barn cleaners, hygienic housing products, and cubicle solutions). Lely sells its products through dealers in Canada, Ireland, Australia, New Zealand, the UK, the US, Spain, Italy, Norway, Portugal, Sweden, Japan, Israel, Estonia, Czech Republic, South Korea, Slovakia, Iceland, and Cyprus. The company is widening its product portfolio and launched Lely Exos in October 2020, first concept for the fully autonomous harvesting and feeding of fresh grass.

The importance of feeding systems is increasing in the region due to the increasing demand for performance-boosting feed for cattle and animal welfare. There has been an increasing shift from conventional to automated systems in the region over the last 30 years due to technological advancements and the high affordability of animal rearers in the region. North American farm owners are focusing on catering to the growing demand from consumers for dairy and meat products. This has led various companies in the global market to develop innovative feeding systems such as individual feeders and group feeders.

In North America, the demand for feeding systems has picked up rapid pace, particularly in the US. Seeing this demand, Lely (Netherlands) introduced Lely Park, its new commercial hub and complex, launched in June 2022. With this development, Lely will be able to greatly boost its production capacity to fulfill the rising needs of North American farmers.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=102235948

#Feeding Systems Market#Feeding Systems Market Size#Feeding Systems Market Share#Feeding Systems Market Growth#Feeding Systems Market Trends#Feeding Systems Market Forecast#Feeding Systems Market Analysis#Feeding Systems Market Research Report#Feeding Systems Market Scope#Feeding Systems Market Overview#Feeding Systems Market Outlook#Feeding Systems Market Drivers#Feeding Systems Market Report

0 notes