#CNC technology

Explore tagged Tumblr posts

Photo

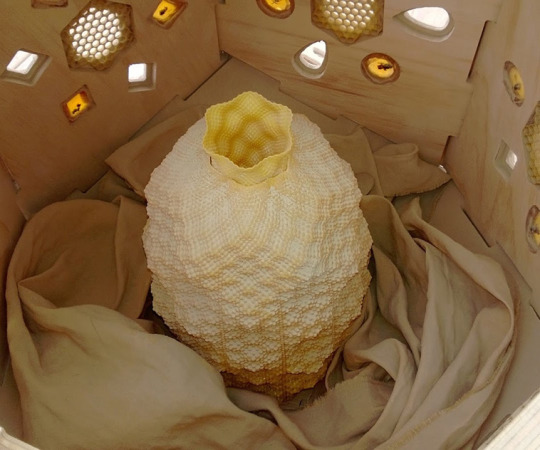

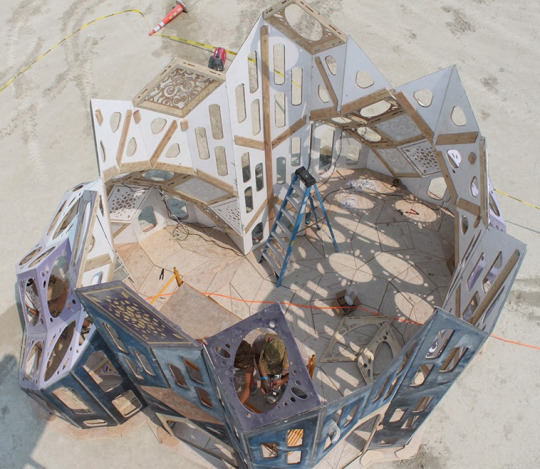

The Zonohedral Cathedral Built by a Software Engineer

Rob Bell is a San Francisco-based artist, designer, and professional software engineer who started a company called Zomadic. It is a design/build company focussing on CNC technology’s creative use. In other words, it is a long time goal for Bell to combine his skills as a programmer with his desire to create concrete objects. So in 2001, he started to take lessons and create his first geometric works, followed by other non-rectilinear geometric designs. Built in 2013 in Nevada, the Zonohedral Cathedral is one of Bell’s Zomadic structures.

#rob bell#artist#san francisco-based artist#designer#professional software engineer#zonohedral cathedral#architecture#zomadic#cnc technology#nevada

3 notes

·

View notes

Text

✨The beauty of shining machinery! Look at this shiny CNC workpiece, each cut is carved with extreme precision, making people love it! 🛠️✨ #CNC technology, #mechanical charm

0 notes

Text

The Role of CNC Technology: Revolutionizing the Automotive Industry

The automotive industry is constantly evolving, with innovations that push the boundaries of design, performance, and safety. One of the driving forces behind this transformation is CNC (Computer Numerical Control) technology, which has revolutionized how auto parts are manufactured. From enhancing production efficiency to ensuring precision in complex components, CNC technology is at the heart of modern automotive manufacturing. Here’s a closer look at how CNC technology is reshaping the automotive landscape, particularly through the expertise of CNC auto parts manufacturers.

The Impact of CNC Technology on Automotive Manufacturing

CNC technology automates the control of machining tools using computer programs, enabling the production of complex and precise auto parts with minimal human intervention. This level of automation has numerous advantages, including:

Enhanced Precision and Consistency CNC machines can produce intricate parts with tolerances as tight as a few microns, ensuring that each component fits perfectly within the assembly. This precision is vital in the automotive industry, where even minor deviations can lead to performance issues or safety concerns.

Increased Production Efficiency CNC technology significantly reduces manufacturing time by automating processes that would otherwise require manual intervention. This efficiency translates into faster production cycles, enabling manufacturers to meet tight deadlines and keep up with market demand.

Material Versatility CNC machines can work with a wide range of materials, including aluminum, steel, titanium, and various plastics, allowing manufacturers to produce everything from engine components to custom interior parts. This versatility helps automotive companies develop innovative designs and lightweight structures that improve fuel efficiency.

Cost Reduction and Waste Minimization CNC machining optimizes material usage, reducing waste and lowering overall production costs. By minimizing errors and enhancing repeatability, CNC technology ensures that resources are used efficiently, a crucial factor for cost-conscious automotive manufacturers.

Rapid Prototyping and Innovation The ability to quickly produce prototypes is a game-changer for automotive companies. CNC technology allows designers and engineers to test new concepts and refine designs with speed and accuracy, accelerating the innovation process. This rapid iteration capability helps automotive brands stay ahead of the competition.

The Role of CNC Auto Parts Manufacturers

CNC auto parts manufacturers play a pivotal role in supplying the industry with high-quality, precision-engineered components. Their expertise in CNC machining allows them to produce parts that meet the exacting standards required for modern vehicles. Here’s how these manufacturers are making a difference:

Custom Solutions for Complex Parts Automotive manufacturers often require custom parts tailored to specific vehicle models or performance requirements. CNC auto parts manufacturers can create bespoke solutions, from engine blocks and transmission components to suspension parts and brake systems. Their ability to deliver custom parts with unmatched precision ensures optimal performance and safety.

High-Volume Production with Consistent Quality The automotive industry relies on mass production to keep costs down and meet global demand. CNC technology enables auto parts manufacturers to produce large volumes of parts without compromising on quality. This consistency is crucial for maintaining the integrity of automotive systems across all vehicles.

Supporting Electric and Autonomous Vehicles As the industry shifts towards electric and autonomous vehicles, the demand for specialized components continues to grow. CNC auto parts manufacturers are at the forefront of this transition, providing the precision parts needed for electric drivetrains, battery systems, and advanced driver-assistance systems (ADAS). Their contribution is essential for the development of next-generation vehicles.

Adherence to Industry Standards and Certifications Quality is paramount in the automotive sector, and CNC auto parts manufacturers adhere to strict industry standards and certifications, such as ISO/TS 16949. These certifications ensure that parts meet the rigorous safety and performance criteria required by automotive manufacturers.

Sustainability and Innovation Modern CNC auto parts manufacturers are also focusing on sustainability, integrating eco-friendly practices into their production processes. From using recyclable materials to reducing energy consumption, they are contributing to the automotive industry’s broader goal of minimizing its environmental impact.

The Future of CNC in the Automotive Industry

The integration of CNC technology is expected to deepen as the automotive industry embraces new manufacturing techniques, such as additive manufacturing (3D printing) and digital twins. CNC’s ability to seamlessly blend with these technologies will enable even more complex and innovative automotive designs. Moreover, the rise of Industry 4.0 and smart factories will further enhance CNC’s role, allowing for real-time monitoring and optimization of machining processes.

CNC technology is revolutionizing the automotive industry by delivering unmatched precision, efficiency, and innovation. CNC auto parts manufacturers are at the forefront of this transformation, supplying the critical components that drive modern vehicles. As the automotive landscape continues to evolve, CNC technology will remain an indispensable tool, ensuring that manufacturers can meet the challenges of tomorrow’s automotive demands. Embracing CNC technology is not just about keeping pace — it’s about leading the way in automotive excellence.

0 notes

Text

#CNC Laser Cutting#Laser Cutting#cnc machining#metal fabrication#metal fabricaters#Custom Cuts#CNC Laser Cutting in Delhi NCR#CNC Laser Cutting in Delhi#CNC Laser Cutting Delhi#Industrial Cutting#CNC technology#Laser Cutter#Creative Designs#Manufacturing Industry

1 note

·

View note

Text

901 notes

·

View notes

Text

Unleash Your Inner Beast: The Ultimate Wolf Transformation T-Shirt – Shop Now on Redbubble!

#Art#Literature#Music#Movies#Travel#Nature#Technology#Sports#Cooking#Animals#usa#america#cnc free use#usa news#appareldesign#creativity#fashiondesign#graphictees#redbubble#tshirtdesign

6 notes

·

View notes

Text

Enhancing Precision Cutting with Oxy-Fuel Cutting Machines

Oxy-fuel cutting machine Manufacturers, also known as oxy-acetylene cutting, is a process that uses a combination of oxygen and fuel gases (typically acetylene) to cut through metal. The process works by heating the metal to its ignition temperature and then directing a high-pressure stream of oxygen onto the heated area. The reaction of the oxygen with the metal causes it to oxidize and burn away, leaving behind a clean cut.

While oxy-fuel cutting was once overshadowed by plasma and laser cutting technologies, it remains one of the most reliable and cost-effective methods for precision cutting, particularly when dealing with thick or heavily oxidized materials.

The Benefits of Oxy-Fuel Cutting Machines

Cost-Effectiveness One of the standout advantages of oxy-fuel cutting is its affordability. Oxy-fuel machines are generally less expensive than their plasma or laser counterparts. The process also requires relatively low maintenance, making it a cost-effective choice for businesses that need precision without breaking the bank.

Versatility Oxy-fuel cutting machines are highly versatile and can be used to cut a wide variety of metals, including carbon steel, stainless steel, and aluminium. Additionally, they are perfect for cutting thick materials, something that other cutting methods like plasma may struggle with.

Precision and Control Modern oxy-fuel cutting machines are equipped with advanced controls that allow for highly precise cuts. With adjustable torch settings and the ability to fine-tune the oxygen flow, operators can achieve cleaner cuts with minimal distortion. This level of control is particularly important for industries that require intricate cuts, such as aerospace and automotive manufacturing.

Ability to Cut Thick Materials Oxy-fuel cutting machines excel when it comes to cutting thick sections of metal, especially those thicker than 1 inch. The ability to cut through heavy materials, such as steel plates used in shipbuilding or construction, makes oxy-fuel machines invaluable in industries that deal with large, heavy components.

Portability Oxy-fuel cutting equipment is relatively portable, especially compared to other cutting technologies like laser cutters. This portability is a huge advantage in industries like construction or shipbuilding, where cutting needs may arise in remote locations or on-site.

Applications of Oxy-Fuel Cutting

Oxy-fuel cutting machines are used across a broad range of industries, thanks to their precision and versatility. Here are some of the sectors that benefit from this technology:

Construction: Oxy-fuel cutting machines are commonly used to cut through steel beams, plates, and other construction materials.

Shipbuilding: The ability to cut thick metal sheets makes oxy-fuel machines a key tool in shipbuilding.

Automotive: For the manufacturing of automotive parts, precision cutting is crucial, and oxy-fuel machines are well-suited to cut through both thick and thin metal components.

Heavy Machinery: Oxy-fuel cutting is ideal for creating precise cuts in large parts used in industrial equipment and machinery.

Aerospace: Aerospace industries require precise cuts for various components, and oxy-fuel cutting ensures a high degree of accuracy.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

#long roller drilling tufting machine#tufting machine manufacturer#roller drilling tufting machine#industrial tufting machine#automated tufting machine#brush tufting machine#cnc tufting machine#high-speed tufting machine#custom tufting machine#tufting equipment supplier#brush making machine#drilling and tufting machine#precision tufting machine#industrial brush machine#tufting technology manufacturer.

0 notes

Text

Online CNC Machining Services

1 note

·

View note

Text

Empowering MSMEs with CNC Manufacturing: Cosmos Impex Leading Industry 4.0 in India

With government support fueling MSME growth, CNC manufacturing is reaching new heights. Cosmos Impex, the best CNC machine manufacturer in India, is driving innovation with precision solutions and advanced technology. Join us as we lead the Industry 4.0 revolution and shape the future of manufacturing.

#Cosmos Impex best CNC machine manufacturer India#CNC Manufacturing Growth#Industry 4.0 in Manufacturing#Empowering MSMEs with Technology#Precision CNC Solutions#Advanced Technology for MSMEs#Future of CNC Manufacturing in India

0 notes

Text

Is Apple Quietly Disrupting Social Apps as We Know Them?

Apple’s latest iOS 18 update is sparking more than just excitement over its AI features. Hidden behind the headlines is a quiet tweak to how contact sharing works. This change might not sound dramatic, but it could shift the landscape for social and messaging apps that have thrived by helping users connect with their existing contacts. Will this subtle shift end the dominance of friend-based social apps, or is it just a necessary step toward better privacy?

#tech#technews#samsung#google#science#iphone#tv shows#positivity#web series#oppo phones#world news#celebrity news#buisness news#news#public news#mobile news#canada#breaking news#technology#apple#ios 18#smartphone#apple intelligence#apps#chandrayaan3#mobile apps#us politics#cnc free use#jordan peele#usa

0 notes

Text

Top Custom Welding Automation Machine Manufacturers in India

Weldarc India is a leading name among welding automation machine manufacturers in India, specializing in custom-made welding solutions to meet the unique needs of various industries. With a commitment to innovation and quality, Weldarc India designs and manufactures state-of-the-art welding machines that enhance precision, efficiency, and productivity. From robotic welding systems to advanced CNC solutions, each machine is engineered to deliver exceptional performance in demanding environments. Trust Weldarc India for state-of-the-art automation that drives your business forward with reliable, custom-crafted welding machines designed to excel in any application.

#welding automation machine manufacturers#custom welding machines#welding machine manufacturers in India#robotic welding systems#CNC welding machines#custom-made welding solutions#welding technology India#Weldarc India#industrial welding machines#advanced welding automation

0 notes

Text

Revolutionizing Welding with Advanced Laser Machines

Laser Welding machine Manufacturers are transforming welding technology by enhancing efficiency, precision, and quality. These cutting-edge machines offer unmatched speed, accuracy, and minimal material distortion, making them indispensable in industries like automotive, aerospace, and medical device manufacturing.

The Rise of Advanced Laser Welding Technology

The demand for laser welding machines has surged due to the increasing need for high-quality and cost-effective welding solutions. Traditional welding methods, such as plasma, and oxy-fuel often face limitations in speed and heat-affected zones. However, advanced laser machines provide:

High Precision: Ensuring clean and strong welds with minimal post-processing.

Non-Contact Process: Eliminating electrode wear and reducing contamination.

Versatility: Suitable for different materials, including stainless steel, aluminum, and titanium.

Energy Efficiency: Reducing power consumption compared to conventional methods.

Key Innovations in Advanced Laser Machines

With advancements in technology, modern laser welding machines now integrate:

AI-Based Monitoring: Enhancing quality control and reducing defects.

Automation Integration: Seamlessly working with robotic and CNC systems.

Enhanced Beam Control: Providing customizable welding depths and patterns.

Smart Sensors: Ensuring real-time adjustments for improved precision.

Applications of Advanced Laser Welding Machines

Laser welding is widely adopted in multiple industries due to its precision and adaptability. Key applications include:

Automotive Industry: Welding complex components, including EV battery enclosures.

Aerospace Industry: High-strength welds for lightweight aircraft components.

Medical Devices: Precision welding for surgical instruments and implants.

Electronics: Seamless micro-welding for circuit boards and connectors.

Choosing the Right Laser Welding Machine

Selecting the right laser welding machine manufacturers depends on factors such as:

Power and Beam Quality: Ensuring optimal penetration and smooth weld finish.

Automation Integration: Compatibility with robotic and CNC systems for improved productivity.

Material Compatibility: Ensuring the machine can handle various metals and alloys.

After-Sales Support: Reliable customer service, training, and spare parts availability.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Video

youtube

Mazak Smooth Technology: Mazak Integrex i 250H ST AG

#youtube#Mazak Integrex i 250H ST AG#Balancing Cutting#Gear Skiving#Hobbing#Endmilling#Engraving#CNC Machining#Machine Tools#Metal Cutting#Manufacturing Technology#Mazak Smooth Technology#CNC Turning#CNC Milling#Gear Manufacturing#Precision Engineering#Machine Tool Demonstration#Metalworking#Industrial Machinery#High-speed cutting#High-precision machining#Hobbing technology#Gear skiving technology#Engraving capabilities#Endmilling capabilities

0 notes

Video

youtube

Precision in Action: Inside the CNC Machining Process #machine #factory ...

#youtube#CNC Machining Manufacturing Engineering Precision Technology IndustrialEngineering CNCProcess TechInAction ManufacturingExcellence#Explanation of Key Elements for CNC Procedure: Accuracy and Precision: CNC machines are designed for high precision. Proper calibration and

1 note

·

View note

Text

Transform Your WhatsApp Video Calls: Unlock the Magic of Filters and Custom Backgrounds

WhatsApp is transforming the way we connect by rolling out brand-new features to make your video calls more engaging. With the addition of filters and customizable backgrounds, the messaging giant is enhancing the video calling experience on both Android and iOS. Let’s dive into how these exciting tools can bring more personality and fun to your everyday chats..

Read more

#tech#technews#google#samsung#iphone#science#tv shows#positivity#web series#oppo phones#us politics#cnc free use#mobile news#breaking news#world news#buisness news#news#newsies#celebrity news#technology#chris evans#state#canada#public news#sonic the hedgehog#biology#david tennant

0 notes