#sheet metal cutting machine

Explore tagged Tumblr posts

Text

Enhancing Precision Cutting with Oxy-Fuel Cutting Machines

Oxy-fuel cutting machine Manufacturers, also known as oxy-acetylene cutting, is a process that uses a combination of oxygen and fuel gases (typically acetylene) to cut through metal. The process works by heating the metal to its ignition temperature and then directing a high-pressure stream of oxygen onto the heated area. The reaction of the oxygen with the metal causes it to oxidize and burn away, leaving behind a clean cut.

While oxy-fuel cutting was once overshadowed by plasma and laser cutting technologies, it remains one of the most reliable and cost-effective methods for precision cutting, particularly when dealing with thick or heavily oxidized materials.

The Benefits of Oxy-Fuel Cutting Machines

Cost-Effectiveness One of the standout advantages of oxy-fuel cutting is its affordability. Oxy-fuel machines are generally less expensive than their plasma or laser counterparts. The process also requires relatively low maintenance, making it a cost-effective choice for businesses that need precision without breaking the bank.

Versatility Oxy-fuel cutting machines are highly versatile and can be used to cut a wide variety of metals, including carbon steel, stainless steel, and aluminium. Additionally, they are perfect for cutting thick materials, something that other cutting methods like plasma may struggle with.

Precision and Control Modern oxy-fuel cutting machines are equipped with advanced controls that allow for highly precise cuts. With adjustable torch settings and the ability to fine-tune the oxygen flow, operators can achieve cleaner cuts with minimal distortion. This level of control is particularly important for industries that require intricate cuts, such as aerospace and automotive manufacturing.

Ability to Cut Thick Materials Oxy-fuel cutting machines excel when it comes to cutting thick sections of metal, especially those thicker than 1 inch. The ability to cut through heavy materials, such as steel plates used in shipbuilding or construction, makes oxy-fuel machines invaluable in industries that deal with large, heavy components.

Portability Oxy-fuel cutting equipment is relatively portable, especially compared to other cutting technologies like laser cutters. This portability is a huge advantage in industries like construction or shipbuilding, where cutting needs may arise in remote locations or on-site.

Applications of Oxy-Fuel Cutting

Oxy-fuel cutting machines are used across a broad range of industries, thanks to their precision and versatility. Here are some of the sectors that benefit from this technology:

Construction: Oxy-fuel cutting machines are commonly used to cut through steel beams, plates, and other construction materials.

Shipbuilding: The ability to cut thick metal sheets makes oxy-fuel machines a key tool in shipbuilding.

Automotive: For the manufacturing of automotive parts, precision cutting is crucial, and oxy-fuel machines are well-suited to cut through both thick and thin metal components.

Heavy Machinery: Oxy-fuel cutting is ideal for creating precise cuts in large parts used in industrial equipment and machinery.

Aerospace: Aerospace industries require precise cuts for various components, and oxy-fuel cutting ensures a high degree of accuracy.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

Precision Laser Cutting Services in Pune – Expert Laser Cutting Solutions Samarth Sharp Edge is a trusted laser cutting service provider in Pune, offering high-quality laser cutting in metal machines. Our expert team specializes in sheet metal laser cutting Pune, ensuring precision and accuracy for every project. Whether you're looking for laser cutting near me Pune or require precision laser cutting Pune for fabrication purposes, we provide efficient and customized solutions. From small-scale projects to large-scale production, our laser cutting fabrication Pune services meet the highest industry standards.

#Laser cutting fabrication Pune#Precision laser cutting Pune#Laser cutting near me Pune#Sheet metal laser cutting Pune#Laser cutting in Pune#Laser cutting in metal machine#laser cutting service provider

0 notes

Text

Learn the benefits of laser cutting machines for sheet metal fabrication, including precision, speed, cost-efficiency, and versatility, suitable for diverse industrial needs.

#laser cutting machines#sheet metal machinery#laser cutting machine suppliers in india#machine tool suppliers in india

0 notes

Text

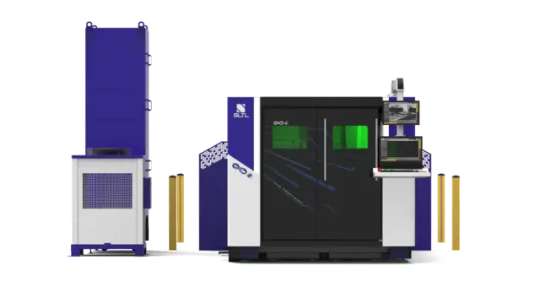

Everything You Need to Know About Laser Cutting Machines

The world of manufacturing and fabrication has been revolutionized by laser cutting machines. From precise metal cutting to creating intricate designs, these machines have become indispensable in industries such as automotive, aerospace, electronics, and more. SLTL Group, a global leader in laser technology, offers a wide range of fiber laser cutting machines, CNC laser cutting machines, and metal laser cutters to cater to diverse industrial needs.

What is a Laser Cutting Machine?

A laser cutting machine uses a focused laser beam to cut or engrave materials with high precision. The laser melts, burns, or vaporizes the material, leaving smooth and accurate edges. These machines are widely used for cutting metals like steel, aluminum, and titanium, as well as non-metals such as plastics and ceramics.

Types of Laser Cutting Machines

SLTL Group specializes in advanced laser cutting machines tailored to meet various industrial requirements:

1. Fiber Laser Cutting Machines

Ideal for cutting metals like stainless steel, aluminum, and brass.

Known for high energy efficiency and minimal maintenance.

Delivers faster and cleaner cuts compared to traditional methods.

2. CNC Laser Cutting Machines

Combines laser technology with CNC (Computer Numerical Control) systems for automated and precise operations.

Perfect for industries that require intricate designs and repetitive cutting tasks.

Reduces human error and increases production efficiency.

3. Metal Laser Cutting Machines

Specifically designed for cutting and shaping metal sheets and plates.

Features high-powered lasers that handle thick and hard metals effortlessly.

Used extensively in automotive, construction, and heavy machinery manufacturing.

Applications of Laser Cutting Machines

Automotive Industry: For cutting and shaping car parts, including body panels and chassis components.

Aerospace: Precision cutting of lightweight materials like aluminum and titanium.

Electronics: Creating intricate circuit boards and enclosures.

Signage and Advertising: Cutting custom designs, letters, and logos.

Jewelry: Crafting delicate designs with unmatched precision.

Benefits of Using SLTL’s Laser Cutting Machines

1. Unmatched Precision

SLTL’s fiber laser cutting machines offer unparalleled accuracy, enabling intricate designs and fine details even in thick materials.

2. Speed and Efficiency

Compared to traditional methods, laser cutting is faster and more efficient, significantly reducing production time.

3. Versatility

Whether it’s metal, wood, plastic, or glass, SLTL’s laser cutting machines can handle a variety of materials and thicknesses.

4. Cost-Effective

With minimal material wastage and reduced maintenance costs, these machines offer long-term savings.

5. Automation and Integration

Our CNC laser cutting machines are equipped with IoT features and advanced automation, ensuring seamless operation and monitoring.

Factors Affecting Laser Cutting Machine Price

If you’re considering investing in a laser cutting sysyem, it’s essential to understand the factors influencing its price:

Laser Power: Machines with higher wattage offer greater cutting capabilities but come at a higher cost.

Machine Size: Larger machines capable of handling bigger materials tend to be more expensive.

Automation Features: IoT integration and smart features increase the price but add significant operational value.

Material Compatibility: Machines designed for specialized materials may cost more.

Brand Value: Trusted brands like SLTL Group ensure quality and support, making their machines a worthwhile investment.

Why Choose SLTL Group?

At SLTL Group, we are committed to delivering world-class laser cutting machines that cater to the ever-evolving needs of industries. Here’s why customers around the globe trust us:

Innovative Technology: We constantly innovate to offer cutting-edge solutions, such as IoT-enabled fiber laser cutting machines and automated systems.

Global Presence: With decades of experience, we have established a strong presence in over 30 countries.

Customizable Solutions: Our machines can be tailored to meet specific industry requirements.

Exceptional Support: We provide comprehensive after-sales support, including training and maintenance services.

How to Choose the Right Laser Cutting Machine?

When selecting a laser cutting machine, consider the following:

Material Type: Ensure the machine is compatible with the materials you work with.

Cutting Thickness: Check the maximum thickness the machine can handle.

Power and Speed: Higher power and speed improve productivity.

Automation Needs: For large-scale operations, opt for CNC laser cutting machines with automation.

Budget: Understand your budget while considering long-term savings.

Future of Laser Cutting Technology

As industries move towards automation and smart manufacturing, laser cutting machines are set to play a pivotal role. Advancements in fiber lasers, AI integration, and green technologies are making these machines more efficient and eco-friendly. SLTL Group is at the forefront of this transformation, offering innovative solutions that not only enhance productivity but also contribute to sustainability.

Conclusion

A laser cutting machine is a valuable investment for any industry looking to improve precision, efficiency, and productivity. Whether you need a high-powered metal laser cutter or an advanced CNC laser cutting machine, SLTL Group offers solutions that cater to diverse needs. With our focus on innovation and customer satisfaction, we help businesses stay ahead in a competitive market.

Explore SLTL’s range of fiber laser cutting machines today and elevate your manufacturing capabilities! For more information or to get a quote on the laser cutting machine price, contact us now.

0 notes

Text

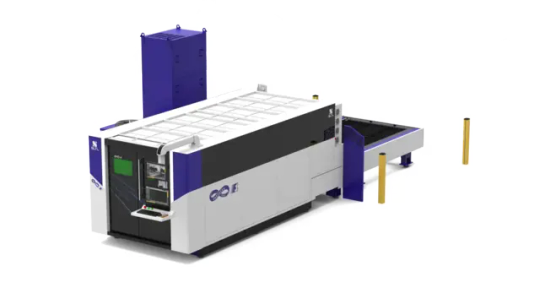

#laser cutting machine#infinity f1#fiber cutting machine#metal laser cutting machine#sheet metal laser cutting#laser cutting#tube cutting machine#metal cutting machine

1 note

·

View note

Text

CNC Shearing Machine: The Cutting-Edge of Precision Metalwork

Designed for durability, accuracy, and efficiency in industrial metalworking applications, our state-of-the-art CNC Shearing Machine can produce faultless cuts.

0 notes

Video

youtube

STARMA cnc 3000w metal sheet tube fiber laser cutting machine 1530

#youtube#STARMA cnc 3000w metal sheet tube fiber laser cutting machine 1530 For this machine use 3000 watt Max laser source and Japan Fuji servo mot

0 notes

Text

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Text

#sheet metal equipment supply#Grooving Machine#Press Brake#Press Brake Tools#Shearing Machine#Laser Cutting Machine#Power Press

0 notes

Text

The coil sheet laser cutting system combines with the de-coiling system, leveling system and laser cutting system. It's suitable to process the multi shape of products, can realize customized manufacturing. Compared with traditional coil processing lines, our sheet metal coil line machine laser cutting system with features of high precision, high productivity, less cost on labors, and stable operation. which is suitable for cutting metal coils, such as stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, galvanized steel, copper, etc. We also provide sheet metal slitting machine for sale. Contact us for further information!

Decoiler,hydraulic lifting, all servo support, and remote control.

Levelling, which is to straighten from coil sheet.

Manufacturing steps: Fiber Laser cutting or Punching Or shearing or folding.

Post-processing, such as robot handling to stack automatically or welding etc.

Coil Fed Laser Cutting Machine Features

Fully-automation can realize to process from the raw metal coils to the final profiles, no need a numeral labors to handle different devices and a few cycles of loading and unloading, There is no need to change the dies, and no waste of time or labors, can realize the higher flexibility manufacturing faster react to the customer's needs and rapid react to the market changes.

Higher productivity, there is no waste of labor landing and blanking compared with traditional line. Only one worker can handle the whole lines. It is stable operation, no need to change the dies, less operation.

High precision and accuracy, the system apply with the servo feeding system and solid fiber laser technology, which make sure the precision.

Coil Laser Cutting Machine Parameter Details

Number

Item

Specification

Laser cutting station

1

Laser source power

1500W

2

Working area

3000mm×1500mm

3

X、Y axis positioning accuracy

±0.05mm/m

4

X、Y axis repositioning accuracy

±0.03mm

5

Max running speed

120m/min

6

Max acceleration

1.2G

7

Workbench maximum load weight

800kg

8

Station weight

6.5T

9

Station size(length*width*height)

6m×2.92m×2.0mm

De-coiling station

10

De-coiling width/capacity

300-1250mm/10T

11

Decoil landing capacity

10T

Levelling station

14

Levelling rollers

Up 5/down 4

15

Output speed

16m/min

0 notes

Text

Revolutionizing Welding with Advanced Laser Machines

Laser Welding machine Manufacturers are transforming welding technology by enhancing efficiency, precision, and quality. These cutting-edge machines offer unmatched speed, accuracy, and minimal material distortion, making them indispensable in industries like automotive, aerospace, and medical device manufacturing.

The Rise of Advanced Laser Welding Technology

The demand for laser welding machines has surged due to the increasing need for high-quality and cost-effective welding solutions. Traditional welding methods, such as plasma, and oxy-fuel often face limitations in speed and heat-affected zones. However, advanced laser machines provide:

High Precision: Ensuring clean and strong welds with minimal post-processing.

Non-Contact Process: Eliminating electrode wear and reducing contamination.

Versatility: Suitable for different materials, including stainless steel, aluminum, and titanium.

Energy Efficiency: Reducing power consumption compared to conventional methods.

Key Innovations in Advanced Laser Machines

With advancements in technology, modern laser welding machines now integrate:

AI-Based Monitoring: Enhancing quality control and reducing defects.

Automation Integration: Seamlessly working with robotic and CNC systems.

Enhanced Beam Control: Providing customizable welding depths and patterns.

Smart Sensors: Ensuring real-time adjustments for improved precision.

Applications of Advanced Laser Welding Machines

Laser welding is widely adopted in multiple industries due to its precision and adaptability. Key applications include:

Automotive Industry: Welding complex components, including EV battery enclosures.

Aerospace Industry: High-strength welds for lightweight aircraft components.

Medical Devices: Precision welding for surgical instruments and implants.

Electronics: Seamless micro-welding for circuit boards and connectors.

Choosing the Right Laser Welding Machine

Selecting the right laser welding machine manufacturers depends on factors such as:

Power and Beam Quality: Ensuring optimal penetration and smooth weld finish.

Automation Integration: Compatibility with robotic and CNC systems for improved productivity.

Material Compatibility: Ensuring the machine can handle various metals and alloys.

After-Sales Support: Reliable customer service, training, and spare parts availability.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

Laser Cutting Services at Samarth Sharp Edge: Precision and Versatility in Every Cut

In today's world of manufacturing, precision and efficiency are key to producing high-quality products. Samarth Sharp Edge, based in Pune, provides top-of-the-line laser cutting services powered by advanced German technology, ensuring clean and precise cuts for a wide range of materials.

Unmatched Precision and Technology

At Samarth Sharp Edge, we employ a 12KW laser cutting machine with a large cutting bed of 6 meters by 2.5 meters, enabling us to handle a wide range of projects. Whether you're working with stainless steel, aluminum, copper, or even wood and acrylic, our technology ensures exceptional accuracy, minimizing waste and improving overall product quality.

Versatility Across Materials

Our laser cutting services cater to a variety of industries by offering compatibility with multiple materials. From metals like stainless steel, aluminum, and copper to non-metallic materials such as wood and acrylic, we provide solutions that fit diverse needs. We specialize in cutting thick materials with impressive capabilities: up to 50 mm for stainless steel and Inconel, and 12.7 mm for copper and brass.

Custom Solutions and Fast Turnaround

Understanding that each project is unique, we work closely with clients to offer tailored solutions that align with their specific requirements. Our large bed size and fast turnaround times ensure efficiency, reducing the need for multiple setups, which is crucial for large-scale projects.

Why Choose Samarth Sharp Edge for Laser Cutting?

High Precision: Our advanced laser technology delivers exceptional accuracy, ensuring intricate designs with smooth finishes.

Wide Material Compatibility: We work with a range of materials, making us a versatile choice for various industries.

Efficiency: Our spacious cutting bed allows us to handle large projects, providing faster production times without sacrificing quality.

Custom Solutions: We collaborate with clients to provide custom laser cutting services that meet their exact specifications.

For your next project requiring laser cutting services, Samarth Sharp Edge is your ideal partner. Contact us today to discuss how we can bring your ideas to life with precision and efficiency.

Visit us at Samarth Sharp Edge Laser Cutting Services.

#Laser cutting fabrication Pune#Precision laser cutting Pune#Laser cutting near me Pune#Sheet metal laser cutting Pune#Laser cutting in Pune#Laser cutting in metal machine

0 notes

Text

Advantages of Using Sheet Metal Laser Cutting

Sheet Metal Laser Cutting is a process used to cut and shape sheet metal using a high-powered laser beam. It is a precise and efficient method commonly used in various industries such as automotive, aerospace, electronics, and manufacturing. Sheet metal laser cutting is widely used due to its ability to produce high-quality cuts with speed and precision.

#Sheet Metal Laser Cutting#sheet metal manufacturing#Sheet metal stamping#CNC machining services#CNC milling services#low volume manufacturing

1 note

·

View note

Text

#lasercutting#fiberlasercutting#laser cutting machine#sheet metal laser cutting machine#laser cutting machine manufacturer#laser cutting machine factory#Laser cutting machine supplier

0 notes

Text

Importance of Safety Protocols in Sheet Metal Laser Cutting

Sheet metal laser cutting machines have revolutionized the manufacturing industry, offering unparalleled precision and efficiency in shaping various metals. However, operating these powerful machines involves inherent risks that must be carefully managed through robust safety protocols. Ensuring the safety of operators and maintaining a secure working environment not only protects personnel but also safeguards equipment and enhances overall productivity.

Understanding the Risks

Sheet metal laser cutting machines utilize high-powered lasers to precisely cut through metal sheets, making them indispensable tools in modern manufacturing. However, these lasers pose significant risks if not handled properly. Direct exposure to the laser beam can cause severe burns and eye injuries, while the cutting process itself generates heat and sparks that can lead to fires or explosions if not controlled.

Implementing Comprehensive Safety Protocols

Operator Training and Certification: Proper training is essential for anyone operating a sheet metal laser cutting machine. Operators must be familiar with machine-specific procedures, emergency protocols, and safety features. Regular certification updates ensure that operators remain informed about the latest safety guidelines.

Personal Protective Equipment (PPE): Adequate PPE is crucial when working with sheet metal laser cutting machines. This includes safety glasses with appropriate filters to protect against laser radiation, gloves to handle sharp metal edges, and fire-resistant clothing to mitigate the risk of burns.

Machine Safety Features: Modern sheet metal laser cutting machines are equipped with safety features such as interlocks, emergency stop buttons, and enclosure systems. These mechanisms prevent unauthorized access to the laser beam and automatically shut down the machine in case of malfunction or operator error.

Ventilation and Fume Extraction: Laser cutting produces fumes and particles that can be hazardous to health if inhaled. Proper ventilation systems and fume extraction equipment are essential to maintain air quality in the workspace and protect operators from respiratory issues.

Regular Maintenance and Inspections: Routine maintenance checks and inspections ensure that sheet metal laser cutting machines operate at optimal efficiency and safety. This includes inspecting laser optics, checking electrical components, and verifying the integrity of safety barriers and enclosures.

Benefits of Adhering to Safety Protocols

Adhering to stringent safety protocols in sheet metal laser cutting operations offers several key benefits:

Reduced Risk of Accidents: By implementing comprehensive safety measures, the likelihood of accidents and injuries associated with sheet metal laser cutting machines is significantly minimized.

Enhanced Equipment Longevity: Regular maintenance and proper use extend the lifespan of sheet metal laser cutting machines, reducing downtime and repair costs.

Improved Productivity: A safe working environment fosters greater confidence and efficiency among operators, leading to increased productivity and higher quality outputs.

Conclusion

In conclusion, while sheet metal laser cutting machines are invaluable tools for modern manufacturing, their operation demands strict adherence to safety protocols. By prioritizing operator training, providing adequate protective equipment, maintaining machine safety features, managing ventilation, and conducting regular maintenance, businesses can mitigate risks and create a safer workplace environment. Ultimately, investing in safety not only protects personnel and equipment but also enhances overall operational efficiency and profitability in sheet metal laser cutting operations.

For businesses considering the adoption or expansion of sheet metal laser cutting capabilities, integrating robust safety protocols ensures that advancements in technology translate into sustainable and safe manufacturing practices.

#laser cutting machine manufacturer#metal laser cutting machine#sheet metal laser cutting machine#laser cutting machines#fiber laser cutting machine

1 note

·

View note

Text

Primapress successfully developed flexible CNC bending machine Full automatic bending machine

Brief description: flexible CNC bending machine_ Full automatic bending machine_ Intelligent bending machine_ The four side bending machine can automatically fold up and down according to the bending process to realize the combined bending of arc, dead edge, and various angles. It can achieve a variety of bending requirements without changing the bending tool, saving a lot of labor and mold costs for enterprises.

After two years of technical research and development, the company’s technology research and development department is committed to developing a servo flexible bending center with the international level of Xinjin. The bending speed is only 0.2 seconds per tool. The equipment can automatically fold up and down according to the bending process to realize the combined bending of arcs, dead edges, and various angles. It can achieve a variety of bending requirements without changing the bending tool, saving enterprises a lot of labor and mold costs.

The maximum size of the processed plate is 2500mmx1500mm, and X, Y, C, V1, V2, Z1, Z2, W1, W2, P are controlled in 10 axes.

The C-type pressure arm structure is adopted, and the end adopts the crank linkage mechanism to drive the presser foot to press and hold the plate, so as to realize the feeding mode of moving and rotating the plate.

Introduction and demonstration of bending body

@The main body of the servo flexible bending center is integrally welded with high-strength steel plates, with stable structure and long service life.

@The heat treatment removes internal stress, has strong rigidity and tonnage, ensures the long-term stability of the machine tool accuracy, and improves the bending accuracy, reliability and durability of the machine tool.

BEND CENTER ADVANTAGES

The flexible bending center can work independently, and can efficiently produce various specifications of components. The universal die can be automatically adjusted according to the size set by the program without any adjustment time, ensuring the safety of the operator and the quality of the product.

The positioning process is only completed once at the beginning of the whole bending. It is operated in this cycle. From the beginning to the completion of the processing, the bending plate and the rotating structure remain unchanged. The 0.01 degree resolution is to ensure high production flexibility.

Prima Flexible Bending Center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi axis concurrent linkage, it can automatically complete the sheet metal operation, solve the dependence on mold and labor from the technical point of view, effectively improve the production efficiency and reduce the production cost.

It is easy to meet the requirements of arc, dead edge, return, closed and other complex sheet metal bending.

Prima flexible bending center can be widely used in the field of steel cabinet shell (file cabinet, tool cabinet, outer cover, electrical cabinet, communication cabinet, gas cabinet, water meter cabinet…), kitchen appliances (refrigerator, air conditioner, cooker…), furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields.

The bending effect is shown in the following figure:

The flexible bending machines produced by our company are divided into PM1400, PMS2000 and PMS2500. Prima Flexible Bending Center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi axis concurrent linkage, it can automatically complete the sheet metal operation, solve the dependence on mold and labor from the technical point of view, effectively improve the production efficiency and reduce the production cost.

It is easy to meet the requirements of arc, dead edge, return, closed and other complex sheet metal bending.

Prima flexible bending center can be widely used in the field of steel cabinet shell (file cabinet, tool cabinet, outer cover, electrical cabinet, communication cabinet, gas cabinet, water meter cabinet…), kitchen appliances (refrigerator, air conditioner, cooker…), furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields. For more details about CNC Press Brake Bending Machineor Press Brake Machinebrowse our website https://www.prima-press.com/press-brake-machine-cnc-bending-machine/

#CNC Press Brake Bending Machine#Hydraulic Press Brake#Sheet Metal Press Brake Bending Machine#CNC Fiber laser cutting machine

1 note

·

View note