#fiber laser cutter

Explore tagged Tumblr posts

Text

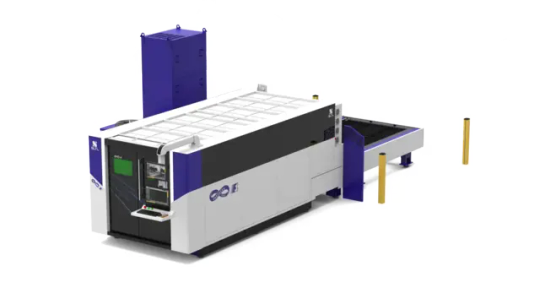

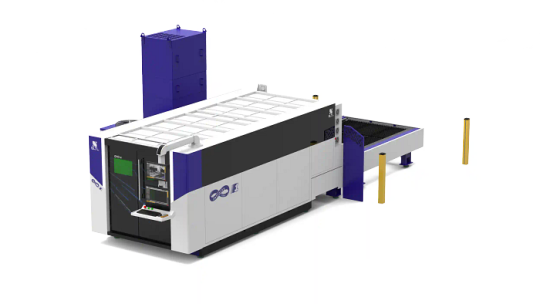

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Text

How Laser Processing of Metals Take Place

Laser marking has wide-ranging applications in the labeling of products where it's used to make available fundamental consumer information such as the cost of the product among many other details. To make the marking achievable you need a marking machine. There are plenty of laser marking machines in the marketplace that you can go for.

The cutting process: The laser cutting of the materials is a widespread application of the laser systems. At the same time as the laser beam is focuses on top of the metal piece the energy is absorbed and changed into heat. Power density is necessary to cut a metal piece or metal sheet. The heat locally incites to a rapid increase of the temperature of the piece, the combination and or the vaporization of the interaction zone settle on the formation of a cut. Laser cutting leaves by way of a boundary having a high-quality surface finish.

The welding process: At what time a low power density laser is employed the laser energy from the fiber laser cutter is deposited on top of the surface of the metal and the heat is transported to the within by means of a method of heat conduction to perform welding process. Higher power densities, on the other hand, engage the direct ionization mechanism to melt the metal piece. The laser beam can be transmitted all the way through air more willingly than requiring a vacuum, the process is easily mechanized with robotic machinery, x-rays are not creates, and LBW effect in superior quality welds.

The drilling process: Similar to other metal processing operations, drilling is accomplished as a result of melting and or vaporization of metal piece in the course of absorption of energy from a focused laser beam. At the same time as the energy required to melt the metal piece is very small compared to in vaporization process, melting is by and large favored. The pulse time and power density determines whether melting or vaporization will go on. Vaporization of a metal takes place at what time pulse duration is too small nevertheless melting takes place at what time pulse duration is larger, what time a flash-lamp pumped laser is utilized.

A Q-switched laser by and large has pulse period in the order of nanoseconds, peak power and a material elimination rate of some micrometers per pulse. At the same time as a flash lamp pumped laser on the whole has a pulse duration varying from microseconds to a millisecond, peak power in the order of secondary, and material removal rate of ten to hundreds of micrometers per pulsation.

The Surface Treatments: The fiber laser cutter tenders unparallel control on the surface to get hold of various structural effects compared to other surface engraving processes. On the other hand, the method is complex and time and again a computer system is employed to make the movements of the laser top. Regardless of this complication, very accurate and clean microstructures and engravings can be achieved at an elevated rate.

Google Site

0 notes

Text

How do Fiber Laser Cutters Work?

A solid-state laser is used by industrial fiber laser cutting machine to melt and pierce metals, producing an accurate and effective cut. Light from a laser diode is transmitted to the fiber optic cable for amplification. The high-intensity light from this strong laser is absorbed by the material's surface and transformed into heat, melting it. Fiber laser cutters use a powerful burst of heat to cut metal when they first come into contact with it. In order to create a clear route for the fiber optic laser to cut the metal, the powerful pulse beam and high-speed airflow employing assist gas work together to remove debris.

0 notes

Text

Dear

We have a new design mini size fiber cutter ,which working size is 200*300mm ,its much suit for sliver and gold cutting ,if there is any interest please feel free to consult me

More details or free tutorials ,please contact on whatsapp :008618053182392/ [email protected], Our website : jxautocnc.com

youtube

0 notes

Text

Video demonstration of a 12,000 watt model 6025 laser plate cutter for live proofing!

0 notes

Text

Why Quality Matters: The Engineering Behind Signvec Technology’s Reliable Machines

In a bustling city where technology and innovation intersect, there was a company named Signvec Technology that stood out for its unwavering commitment to quality. Established in 1997, Signvec was not just any engineering firm; it was a beacon of precision and reliability in the world of laser and rotary engraving, cutting, and marking machines. This is the story of how Signvec Technology became synonymous with excellence, and why quality matters so much in their machines.

The Quest for Precision

In a small workshop filled with the hum of machinery and the glow of laser lights, the engineers at Signvec were on a mission. They weren’t just building machines; they were crafting tools that would push the boundaries of what was possible. At the heart of their quest was the Cornermate, a machine designed for impeccable corner cutting. The engineers spent countless hours fine-tuning every component, ensuring that each cut was not just accurate but perfect. They knew that precision wasn’t just about measurements; it was about the confidence that every cut, every mark, and every engraving would meet the highest standards of accuracy.

Harnessing Cutting-Edge Technology

As the world of technology rapidly evolved, so did Signvec’s approach. They understood that staying at the forefront of innovation was crucial. The engineers eagerly embraced advancements in laser systems and rotary engraving techniques, integrating the latest technologies into their machines. They partnered with leading brands like Universal Laser Systems and Vision Engraving & Router Systems, ensuring that their machines were not only state-of-the-art but also capable of tackling the most demanding tasks. Each machine was a marvel of modern engineering, embodying the latest innovations and setting new standards in the industry.

Building for Durability

In the heart of their manufacturing facility, the team focused on one core principle: durability. They knew that the reliability of their machines hinged on the quality of the materials used. Every component was meticulously selected—each part made from high-grade materials designed to withstand the rigors of continuous use. The engineers knew that robust materials were not just a choice but a necessity to ensure longevity and consistent performance. It wasn’t just about making machines that worked well; it was about making machines that would stand the test of time.

The Art of Quality Control

As the machines rolled off the production line, they didn’t just go straight to the clients. Each one underwent a rigorous quality control process that was almost an art form. The engineers conducted comprehensive performance testing, safety checks, and functionality assessments. They wanted to ensure that every machine not only met but exceeded their high standards. This meticulous process wasn’t just about checking off boxes; it was about instilling confidence that every machine would perform reliably in real-world conditions.

Crafting Custom Solutions

One day, a client walked into the Signvec workshop with a unique challenge. They needed a machine tailored to their specific needs—something that no off-the-shelf solution could provide. The team at Signvec sprang into action, working closely with the client to understand their requirements. They designed and customized a machine that was perfectly suited to the client’s application, resulting in a solution that was both innovative and effective. This custom approach wasn’t just about fulfilling an order; it was about creating something extraordinary that would make a real difference.

Supporting Every Step of the Way

Even after the machines left the workshop, Signvec’s commitment to quality didn’t end. Their after-sales support was a testament to their dedication to long-term relationships with their clients. The team offered comprehensive training, technical support, and maintenance services, ensuring that every machine continued to operate at peak performance. For Signvec, customer support was not just a department; it was an extension of their commitment to quality.

The Legacy of Quality

As the years went by, Signvec Technology continued to build on its legacy of quality. Their machines became known not just for their precision and performance, but for the dedication and craftsmanship behind every component. In the competitive world of manufacturing, Signvec stood as a symbol of reliability and excellence.

In the end, the story of Signvec Technology is a testament to why quality matters. It’s about the relentless pursuit of precision, the embrace of cutting-edge technology, the use of superior materials, and the commitment to exceptional support. For industries that demand the best, Signvec Technology’s machines are more than just tools—they are the embodiment of quality and innovation.

0 notes

Text

Fiber Laser Pipe Cutting Machines: A Boon for Modern Metalworking

Fiber laser pipe cutting machines are revolutionizing the metalworking industry with their precision, speed, and versatility. These machines use a focused beam of light to cut through metal pipes of various thicknesses and shapes, producing clean, burr-free edges with minimal heat-affected zone.

Benefits of Fiber Laser Pipe Cutting Machines

High precision and accuracy: Fiber laser cutting machines can achieve cutting tolerances of up to +/- 0.005 mm, making them ideal for applications requiring tight tolerances.

Fast cutting speeds: These machines can cut through metal pipes at speeds several times faster than traditional plasma or oxy-fuel cutting methods.

Minimal heat-affected zone: The concentrated laser beam creates a narrow kerf, minimizing the heat-affected zone and reducing the risk of distortion or warping.

Versatility: Fiber laser pipe cutting machines can cut a wide variety of metals, including mild steel, stainless steel, aluminum, copper, and brass. They can also cut a variety of pipe shapes, including round, square, rectangular, and oval.

Low operating costs: Fiber laser cutting machines have low operating costs due to their high energy efficiency and minimal maintenance requirements.

Environmentally friendly: These machines produce minimal waste and emissions, making them a more environmentally friendly option than traditional cutting methods.

Applications of Fiber Laser Pipe Cutting Machines in Specific Industries

Automotive industry: Cutting components for cars, trucks, and motorcycles.

Aerospace industry: Cutting lightweight and high-strength materials for aircraft and spacecraft.

Medical device industry: Cutting precision components for medical devices.

Furniture industry: Cutting intricate designs and shapes for furniture parts.

Construction industry: Cutting beams, columns, and other structural components.

Oil and gas industry: Cutting pipes for pipelines and drilling equipment.

Advantages of Fiber Laser Pipe Cutting Machines for Businesses

Increased productivity: The high cutting speed and precision of fiber laser pipe cutting machines can significantly increase production throughput.

Improved product quality: The clean cuts and minimal heat-affected zone produced by these machines result in higher quality finished products.

Reduced material waste: The narrow kerf width of fiber laser cutting minimizes material waste, saving businesses money.

Lower operating costs: The low energy consumption and minimal maintenance requirements of these machines lead to lower operating costs.

Increased competitiveness: Businesses that invest in fiber laser pipe cutting machines can gain a competitive edge by offering faster turnaround times, higher quality products, and lower costs.

If you are a metalworking business looking to improve your productivity, quality, and competitiveness, then a fiber laser pipe cutting machine is a wise investment.

In addition to the benefits mentioned above, fiber laser pipe cutting machines are also:

Easy to operate: These machines are equipped with user-friendly CNC controls that make them easy to operate, even for those with limited experience.

Safe to use: Fiber laser cutting machines are inherently safe due to their enclosed design and laser safety features.

Reliable: These machines are built to last and require minimal maintenance.

Overall, fiber laser pipe cutting machines are a versatile and powerful tool that can benefit businesses of all sizes in a variety of industries.

I hope this blog post has been helpful. If you have any questions, please feel free to leave a comment below.

Call to action:

If you are interested in learning more about fiber laser pipe cutting machines, please contact Chirag International a reputable manufacturer or distributor. They can help you choose the right machine for your needs and budget.

www.chiraginternationals.com

Phone No - 9811958196

#laser#lasercutter#pipecutter#metal cutter#laser metal cutter#lasercutting#fiber laser cutting machine#lasermarking#laserengraved

0 notes

Link

As one of the most professional 1530 fiber laser cutting machine manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to buy 1530 fiber laser cutting machine at competitive price from our factory. 1000w 2000w 3000w 6000w 1530 fiber laser cutting machine 5x10 ft laser cutter for cs steel stainless

0 notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

0 notes

Text

Maximizing Efficiency With Laser-Cutting Machines: Melbourne’s Best Solutions

Laser-cutting technology has revolutionized manufacturing and fabrication across various industries. From precision cutting in metal fabrication to intricate designs in signage and jewelry, laser cutting machines in Melbourne are transforming production processes. Whether you're a small business, startup, or large enterprise, choosing the right laser cutter is essential for efficiency and profitability.

This guide explores the features, benefits, and costs of laser-cutting machines while highlighting why SLTL Group is the go-to provider for advanced laser solutions in Melbourne.

Key Features of Laser Cutting Machines

1. High-Precision Cutting

Modern fiber laser cutting machines offer unmatched precision, making them ideal for industries requiring accuracy in metal and non-metal applications. These machines utilize advanced beam technology, ensuring sharp edges and minimal burrs on cut materials.

2. Speed and Efficiency

With advanced CNC technology, laser cutters provide high-speed cutting, reducing production time and increasing output. This efficiency is particularly beneficial in mass-production industries such as automotive and aerospace manufacturing.

3. Versatility Across Materials

Laser machines can cut a wide range of materials, including:

Stainless steel

Aluminum

Carbon steel

Copper and brass

Acrylic

Wood

Plastics

Composites

4. Automation and Smart Integration

SLTL Group offers automated laser cutting solutions integrated with AI-driven systems, improving workflow and reducing manual labor costs. Features like real-time monitoring, remote control, and predictive maintenance make these machines highly efficient.

5. Energy-Efficient Technology

Modern fiber laser systems consume less power while delivering high-performance cutting, reducing operational expenses. Compared to traditional CO2 laser machines, fiber lasers are more energy-efficient, contributing to sustainable manufacturing practices.

Benefits of Using Laser Cutting Machines

1. Improved Productivity and Output

With high-speed laser cutters, businesses can meet tight deadlines without compromising on quality. Automated feeding systems and multi-axis cutting capabilities further enhance production efficiency.

2. Cost-Effective Operations

Laser cutting reduces material wastage, minimizes labor requirements, and enhances overall cost-efficiency. Traditional cutting methods, such as mechanical or plasma cutting, often result in higher maintenance and operational costs.

3. Enhanced Design Flexibility

Laser technology allows for intricate and complex cuts that traditional methods cannot achieve. This is particularly useful in custom fabrication, where precision and customization are essential.

4. Minimal Maintenance Requirements

Compared to traditional cutting machines, fiber laser cutters require minimal upkeep, leading to lower maintenance costs. The absence of mechanical contact with the material also reduces wear and tear.

5. Safe and Eco-Friendly Processing

SLTL Group’s laser cutting solutions adhere to global safety standards while ensuring eco-friendly operations with minimal emissions. With features such as fume extraction systems and protective enclosures, workplace safety is enhanced.

Understanding Laser Cutting Machine Costs

The cost of laser-cutting machines in Melbourne depends on several factors, including:

1. Type of Laser Cutter

CO2 Laser Cutters: Ideal for non-metal materials like wood and acrylic, generally lower in cost.

Fiber Laser Cutters: Best for metal applications, offering high efficiency but at a higher initial investment.

Hybrid Laser Cutters: Combining fiber and CO2 technology for multi-material applications, often priced at a premium.

2. Power and Cutting Capabilities

Higher-wattage machines provide faster cutting speeds and deeper penetration but come at a premium price. Entry-level laser machines start at around AUD 20,000, while industrial-grade models can exceed AUD 500,000.

3. Automation and Software Integration

Advanced CNC systems with automation features increase machine costs but improve long-term efficiency. Integrated ERP and CAD software compatibility adds to the overall investment.

4. Brand and Warranty

Trusted brands like SLTL Group offer high-quality, reliable laser machines backed by comprehensive warranties and excellent customer support. Investing in a reputable brand ensures long-term reliability and reduced downtime.

Case Study: How SLTL Group Helped a Melbourne Manufacturer Scale Production

A leading sheet metal fabrication company in Melbourne struggled with inefficiencies in its cutting processes, leading to high material wastage and production delays. After integrating an SLTL Group fiber laser cutting machine, the company achieved:

40% faster production times

30% reduction in material wastage

Enhanced precision, eliminating the need for secondary processing

By choosing SLTL Group, the company not only improved operational efficiency but also increased its competitive edge in the market.

Why Choose SLTL Group for Laser Cutting Machines in Melbourne?

SLTL Group is a global leader in fiber laser cutting technology, providing innovative and customized laser solutions to businesses in Melbourne and beyond.

1. Cutting-Edge Laser Solutions

SLTL Group offers state-of-the-art laser cutting machines designed for high-speed, precision cutting across industries. Their machines incorporate AI-driven automation and cloud-based monitoring for optimal performance.

2. Customization Options

Tailored solutions to meet specific industry needs, from small-scale startups to large industrial enterprises. SLTL Group provides customizable laser power options, automation levels, and additional attachments like tube-cutting modules.

3. Comprehensive After-Sales Support

Customers benefit from training programs, maintenance services, and 24/7 support for uninterrupted operations. SLTL Group ensures that businesses maximize the value of their investment.

4. Industry-Leading Experience

With decades of expertise in laser technology, SLTL Group remains at the forefront of innovation. Their ongoing research and development efforts ensure that customers receive cutting-edge solutions tailored to their needs.

Industries Benefiting from SLTL Group’s Laser Cutting Machines

1. Metal Fabrication

High-precision metal cutting for industrial and commercial applications. SLTL Group’s fiber laser cutters are widely used in steel processing plants, HVAC manufacturing, and heavy machinery production.

2. Automotive and Aerospace

Production of lightweight, high-strength components for advanced manufacturing. Aerospace manufacturers rely on laser cutting for producing intricate airframe components with minimal material distortion.

3. Signage and Advertising

Custom signage and branding materials with intricate laser-cut designs. The ability to create precise lettering, logos, and detailed engravings makes laser cutting a preferred choice for the advertising industry.

4. Jewelry and Creative Arts

Fine detailing and engraving for bespoke jewelry and artistic creations. Laser cutting enables jewelry makers to work with precious metals, creating intricate patterns with extreme precision.

Future Trends in Laser Cutting Technology

AI-Powered Automation: Enhancing efficiency with intelligent laser systems that optimize cutting parameters in real time.

Eco-Friendly Processing: Reducing emissions with sustainable laser technology, including energy-efficient fiber lasers.

Smart Manufacturing Integration: Seamless ERP and CAD software integration for optimized production, reducing material waste, and improving workflow automation.

Conclusion

Investing in a high-quality laser cutting machine in Melbourne can transform your business operations, enhancing productivity, precision, and cost-effectiveness. SLTL Group stands as a trusted provider of innovative fiber laser cutting solutions, offering superior performance and unmatched customer support.

Looking for the best laser-cutting machine in Melbourne? Explore SLTL Group’s Laser Solutions today and elevate your production capabilities!

#artificial intelligence#machine learning#business#lasercutting#precision machining#writers on tumblr#blog

0 notes

Text

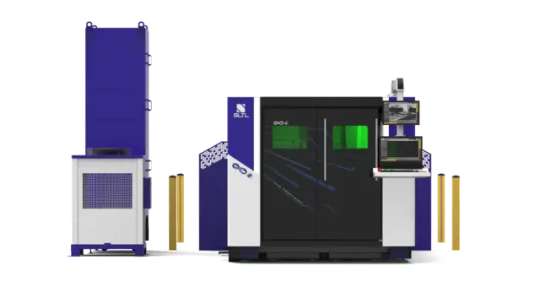

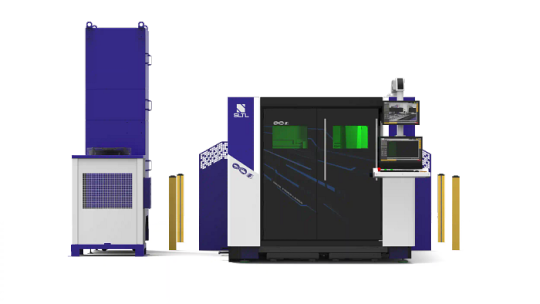

Cutting Through Boundaries: How High Power Fiber Lasers Are Reshaping the Metal Fabrication Industry

Innovation and technology continue to reshape the landscape of metal manufacturing. One such innovation that has been causing a significant stir is the emergence of high-power fiber lasers. These cutting-edge tools are revolutionizing the metal fabrication industry, pushing the boundaries of what was once thought possible. We’ll look at high-power fiber lasers and how they’re changing the metal fabrication business, with an emphasis on the SLTL Laser Cutting Machine — Infinity F1 and other cutting-edge laser technologies.

youtube

Unveiling the Power of High-Power Fiber Lasers

High-power fiber lasers have become the gold standard in precision cutting and welding. Unlike traditional CO2 lasers, fiber lasers utilize optical fibers as their gain medium, allowing for a more concentrated, intense beam of light. This concentrated beam results in superior precision and efficiency in metal laser cutting machine, making it a game-changer for various industries.

The Advantages of Fiber Lasers

Unmatched Precision: Fiber lasers offer an exceptional level of precision, enabling manufacturers to achieve intricate cuts and designs that were once considered too complex. This level of accuracy reduces material waste and rework, ultimately saving time and resources.

Speed and Efficiency: The concentrated beam of fiber lasers translates to faster cutting speeds. This efficiency is crucial in meeting tight production deadlines and handling large-scale projects without compromising quality.

Versatility: High-power fiber lasers can effectively cut a wide range of materials, from metals like Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others. This versatility opens up new possibilities for manufacturers across different industries.

Cost Savings: While the initial investment in fiber laser technology might be higher, the long-term cost savings are substantial. The combination of reduced material waste, energy efficiency, and minimal maintenance leads to a more cost-effective operation.

The SLTL Laser Cutting Machine — Infinity F1: Redefining Metal Fabrication

Unparalleled Precision and Speed

The Infinity F1 boasts a cutting-edge design that maximizes precision and speed. With its high-power fiber laser source, it can effortlessly handle intricate designs and complex cuts, all while maintaining exceptional accuracy. This makes it a sought-after tool for industries requiring intricate components and high-volume production.

Smart and Intuitive Operation

The machine’s user-friendly interface and software make it accessible to both experienced operators and newcomers. Its intuitive controls allow for easy customization and quick setup, reducing downtime between tasks. This ensures a seamless workflow and optimal utilization of resources.

Adaptable to Diverse Materials

One of the standout features of the Infinity F1 is its ability to cut a wide variety of materials with precision. Whether it’s thin sheets of metal or thicker materials, this machine can handle the task effectively, making it a versatile asset for businesses dealing with diverse materials.

Exploring Laser Cutting Possibilities

Fiber Laser Cutter

Fiber laser cutters, in general, are becoming synonymous with efficiency and accuracy. Their solid-state design, absence of moving parts, and minimal maintenance make them an attractive choice for businesses looking to optimize their operations.

CNC Cutting Technology

Computer Numerical Control (CNC) technology has taken laser cutting to new heights. The precision and automation offered by CNC laser cutting machines enhance productivity and reduce human error, leading to consistent, high-quality output.

High Power Laser Cutter: Pushing the Limits

High-power laser cutters, such as the Infinity F1, demonstrate the potential of pushing laser technology to its limits. With power ratings of up to 60 KW, these machines can tackle thick materials and achieve remarkable speeds without compromising precision.

Embracing the Future: The Impact and Beyond

The integration of high-power fiber lasers into the metal fabrication industry is not just a technological leap; it’s a paradigm shift. As these tools continue to evolve, we can expect even greater precision, faster speeds, and expanded material capabilities. However, as with any advancement, questions arise.

What Lies Ahead for Traditional Methods?

The rise of high-power fiber lasers prompts us to question the relevance of traditional cutting methods. While they may not become obsolete, their limitations are more apparent, pushing industries to consider upgrading their equipment to stay competitive.

Balancing Automation and Craftsmanship

As automation becomes more prevalent, there’s a concern about the loss of craftsmanship. Striking a balance between automated precision and the artistic touch of skilled craftsmen will be a challenge the industry must navigate.

Environmental Considerations

With greater power comes increased energy consumption. The industry must address the environmental impact of high-power fiber lasers and work towards sustainable solutions without compromising productivity.

Conclusion: Shaping the Future of Metal Fabrication

In conclusion, the advent of high-power fiber lasers, exemplified by the SLTL Laser Cutting Machine — Infinity F1, marks a turning point in the metal fabrication industry. Their precision, speed, and versatility are rewriting the rules and opening doors to new possibilities. As we journey into this future, it’s imperative for businesses to embrace the potential of these technologies while staying mindful of the challenges and responsibilities that come with them. The fusion of human ingenuity and cutting-edge tools will define the next chapter of metal fabrication’s evolution.

#Laser Cutting Machine#CNC Laser Cutting Machine#Fiber Laser Cutter#CNC Laser Cutter#High Power Laser#Sheet Cutting Machine#sheet metal fabrication#Youtube

0 notes

Text

Welcome to Winarc– Leading the Future of Fiber Laser Cutting

At Winarc, we bring you the next generation of precision cutting with our state-of-the-art fiber laser cutting machines manufacturers. Whether you're in automotive, aerospace, electronics, or metal fabrication, our machines offer unmatched speed, precision, and flexibility to meet your unique cutting needs.

Why Choose Winarc Fiber Laser Cutting Machines?

Unbeatable Precision: Achieve the finest cuts with the most accurate and detailed results, thanks to advanced fiber laser technology.

High-Speed Cutting: Our machines work faster without sacrificing quality, making them ideal for high-volume production lines.

Versatile Material Compatibility: From metals like steel and aluminum to more complex materials, our fiber laser cutters handle a variety of substrates effortlessly.

Eco-Friendly & Energy Efficient: With advanced fiber optics, our machines use less power and generate less heat, reducing environmental impact while saving you on energy costs.

Long-Lasting & Low Maintenance: Our fiber laser cutters are built for durability, offering long operational lifespans and low maintenance requirements, minimizing downtime and costs.

Stay Connected

Want to see our machines in action?

Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#Laser Cutting#Fiber Laser#CNCPrecision#MetalCutting#IndustrialLaser#High Precision Cutting#LaserTechnology#SheetMetalFabrication#AutomatedCutting#ManufacturingSolutions

0 notes

Text

Laser Cut Computer Monitor small cnc laser cutter 2024 Filescnc For Free

In 2024, computer monitor customization is set to transform, with Filescnc leading the way. Their extensive library of laser-cut designs lets you create a monitor that looks stunning and fits perfectly with your tech setup. No more settling for off-the-shelf options. It’s time to craft a monitor that’s truly your own.

Key Takeaways

Explore the exciting world of laser-cut computer monitor customization in 2024.

Discover how small CNC laser cutters are revolutionizing the DIY monitor build industry.

Learn how Filescnc’s innovative designs can help you create a one-of-a-kind computer setup.

Unleash your inner designer and take control of your computer’s aesthetic.

Embrace the future of personalized technology with laser-cut monitor builds.

Understanding Small CNC Laser Cutting Technology

The world of laser cutting has changed a lot. Now, small CNC laser systems lead this change. These tools are key in many fields, from making custom computer monitors to detailed designs. Let’s explore what makes these systems tick.

Basic Principles of Laser Cutting Operations

Laser cutting doesn’t touch the material. It uses a strong laser beam to cut or engrave many materials. This includes acrylic, glass, and metal. The laser melts or vaporizes the material, making complex designs possible with great accuracy and speed.

Components of Modern CNC Laser Systems

Small CNC laser systems have a few main parts. These are the laser source, motion control, and computer interface. The laser source, like a CO2 or fiber laser, creates the high-energy beam. The motion control system moves the laser or workpiece to follow the cutting path. The computer interface lets users design and control the cutting process with CAD/CAM software.

Power Requirements and Specifications

“The versatility and precision of small CNC laser cutting systems have revolutionized the way we approach custom computer monitor builds and design projects.”

Benefits of Custom Monitor Builds in 2024

Exploring custom monitor builds in 2024 opens up new possibilities for personalization. You can create a unique workspace that stands out. This is something off-the-shelf models can’t offer.

One key benefit is the ability to customize size, shape, and look. Whether for a DIY project or a personalized workspace, laser-cut monitors let you design your dream display. It fits perfectly with your setup.

Custom monitors can also save you money. By designing and making them yourself, you can use materials wisely. This way, you get a display that fits your budget and meets your needs.

“The ability to customize every aspect of my monitor has been a game-changer for my productivity and overall workspace satisfaction.”

Custom monitors also offer unique features not found in standard models. You can add special lighting or ergonomic adjustments. The only limit is your creativity and technical skills.

Essential Materials for Laser Cut Computer Monitor Projects

Choosing the right materials is key when making your own laser-cut computer monitor. You’ll need transparent panels for the display and strong metal parts for the structure. Each part is important for the final look and function of your custom monitor.

Acrylic vs. Glass Options

Deciding between acrylic sheets and tempered glass is a big choice. Acrylic is light, shatter-resistant, and affordable. Glass gives a high-end look but costs more. Think about what you need for your project.

Metal Components and Considerations

The metal components like the frame and stand are crucial. Choose metals like stainless steel or aluminum for strength and durability. They help your monitor last longer.

Protective Coatings and Finishes

Adding protective finishes is vital to keep your monitor safe from damage. Look into anti-glare coatings and decorative finishes. They make your monitor look great and last longer.

“The right materials can transform a simple laser-cut project into a professional-grade, visually stunning computer monitor.”

By picking the right acrylic sheets, metal components, and protective finishes, you’ll make a monitor that looks amazing and works perfectly. It will show off your design and skill.

Laser Cut Computer Monitor small cnc laser cutter Setup Guide

Creating a custom computer monitor with a laser cutter needs careful setup. First, make sure your workspace is ready and safe. Here’s how to set up your small CNC laser cutter for a smooth monitor project.

Workspace Preparation

Make a clean, well-ventilated, and organized workspace. Place the laser cutter on a stable, level surface. Keep it away from flammable stuff and blockages. Have all tools like measuring tapes, clamps, and safety gear ready and within reach.

Safety First

When using a laser cutter, safety comes first. Wear the right protective gear like safety glasses, gloves, and a mask. Learn about the laser cutter’s safety features and how to stop it quickly if needed.

Initial Calibration

Do a detailed calibration before starting your project. Adjust the beam, focus the laser, and check the cutting depth and power. Use the maker’s guide or ask experts to get the best cuts.StepDescriptionRecommended Tools1. Workspace PreparationCreate a clean, well-ventilated, and organized work area for the laser cutter.Measuring tape, clamps, cleaning supplies2. Safety EquipmentEquip yourself with the necessary personal protective equipment (PPE).Safety glasses, gloves, respirator mask3. Laser Cutter CalibrationAdjust the beam alignment, focus, and power settings for optimal performance.Manufacturer’s instructions, alignment tools

By following these steps, your small CNC laser cutter will be ready for your custom computer monitor project. Next, we’ll look at design software and file prep.

Design Software and File Preparation

Creating custom monitor designs is easier with the right software. CAD (Computer-Aided Design) offers many tools to help. You can use AutoCAD, SolidWorks, Fusion 360, or SketchUp to bring your ideas to life.

CAD Tools for Monitor Design

AutoCAD and SolidWorks are top choices for detailed designs. They have features for 2D and 3D modeling. Fusion 360 and SketchUp are great for beginners because they are easy to use.

It’s important to learn how to use your CAD software well. This ensures your design works well with laser cutting. You’ll need to know about vector graphics for clean cuts.

File Format Compatibility

After designing, make sure your file works with your laser cutter. DXF and SVG are the best formats for laser cutting. These formats keep your design clear and work well with your CNC laser cutter.

Using the right software, mastering vector graphics, and choosing the right file formats are key. This will help you create amazing laser-cut monitor projects. Preparation is key, so explore tools and resources to make your design a reality.CAD SoftwareKey FeaturesFile FormatsAutoCADComprehensive 2D and 3D modeling, industry-standardDXF, DWGSolidWorksAdvanced 3D modeling, simulation, and engineering toolsSLDPRT, SLDASM, SLDDRWFusion 360Intuitive interface, cloud-based collaboration, CAM integrationDXF, STL, STEPSketchUpUser-friendly 3D modeling, emphasis on rapid prototypingSKP, DXF, STL

“With the right design software and file preparation, the possibilities for custom laser-cut monitor projects are truly endless.” – Filescnc

Safety Measures and Precautions

Working with laser cutting technology needs careful attention to safety. When you start your custom monitor build, remember to wear protective gear and ensure good air flow. This keeps you and your workspace safe.

Wearing the right laser safety gear is key. Get safety goggles that block the laser beam’s intense light. Also, use protective gear like heat-resistant gloves to protect your hands from heat and debris.

Laser safety goggles

Heat-resistant gloves

Well-ventilated workspace

Good ventilation requirements are vital for a safe work area. Make sure your laser cutter is in a place with plenty of air flow. This helps get rid of any fumes or particles made during use. Think about adding an exhaust system or air filter to keep the air clean.Safety MeasureImportanceLaser safety gogglesProtect your eyes from the intense laser beamHeat-resistant glovesShield your hands from heat and debris during cuttingProper ventilationEnsure a healthy, clean working environment by removing fumes and particles

Table of Contents

Key Takeaways

Basic Principles of Laser Cutting Operations

Components of Modern CNC Laser Systems

Power Requirements and Specifications

Acrylic vs. Glass Options

Metal Components and Considerations

Protective Coatings and Finishes

Workspace Preparation

Safety First

Initial Calibration

CAD Tools for Monitor Design

File Format Compatibility

Material Positioning Techniques

Power Settings and Speed Adjustments

What is the latest trend in custom computer monitor builds?

How do small CNC laser cutters work for monitor projects?

What are the key benefits of building a custom laser-cut monitor?

What materials are typically used for laser-cut monitor projects?

How do I set up a small CNC laser cutter for monitor projects?

What design software is best for creating laser-cut monitor plans?

How can I stay safe when using a small CNC laser cutter?

What are the key steps in the actual laser cutting process?

What are the best practices for assembling a laser-cut monitor?

“Safety should always be the top priority when working with powerful tools like laser cutters. Prioritize protective gear and a well-ventilated workspace to ensure a successful and secure project.”

Following these safety steps lets you use your small CNC laser cutter safely. It keeps you and your area safe. Enjoy the process of making your custom monitor with laser cutting technology.

Step-by-Step Cutting Process Overview

To get the most out of your laser-cut computer monitor project, you need to know how to position materials, set laser power, and adjust cutting speed. This guide will show you the key steps for precision, efficiency, and a perfect finish.

Material Positioning Techniques

Getting your material in the right spot is key for laser cutting success. First, clamp your workpiece firmly to keep it steady. Try different clamping ways and spots to find the best for your materials and design.

Make sure your workpiece is perfectly aligned. Any small mistake can cause bad cuts or misalignments.

Power Settings and Speed Adjustments

Finding the right mix of laser power settings and cutting speed optimization is vital for clean cuts. Start by testing on scrap to find the best settings for your material. Then, tweak these settings to get the cleanest cuts.

Getting the right mix of material positioning, laser power settings, and cutting speed optimization is crucial. It can make your laser-cut monitor look professional or not. Take your time to experiment and improve your skills.

Assembly Techniques and Best Practices

Building a custom computer monitor is an exciting adventure. Now, it’s time to put everything together. We’ll focus on the art of assembly, where precision and detail are key. From managing cables to adding the final touches, we’ll make your monitor stand out.

Organizing wires might seem hard, but don’t worry. Our cable management tips will make your monitor look sleek. By routing cables smartly and using cable clips, you’ll avoid messy tangles. This will give your monitor a clean, professional look.

The final touches are what make your monitor truly special. You can choose a matte or high-gloss finish to add sophistication. With careful attention, you’ll turn your laser-cut monitor into a masterpiece. It will be a stunning addition to your desk.

FAQ

What is the latest trend in custom computer monitor builds?

In 2024, the trend is using small CNC laser cutters to make your own monitor. DIY fans love making unique workspaces with their own designs.

How do small CNC laser cutters work for monitor projects?

These cutters use a laser beam to cut through materials like acrylic and glass. They make custom shapes and designs that standard monitors can’t match.

What are the key benefits of building a custom laser-cut monitor?

Building your own monitor lets you personalize it. It’s also cost-effective and can have unique features. You can make it fit your style perfectly.

What materials are typically used for laser-cut monitor projects?

Acrylic and tempered glass are common for the front panel. Metal like aluminum or steel is used for the frame and stand. Finishes and coatings add durability and look.

How do I set up a small CNC laser cutter for monitor projects?

First, set up a safe workspace and install safety gear. Then, calibrate the laser cutter. A step-by-step guide can help you do it right and safely.

What design software is best for creating laser-cut monitor plans?

CAD tools like AutoCAD and SketchUp are great for designing monitors. Make sure the software works with your laser cutter. Sites like Filescnc have designs ready to use.

How can I stay safe when using a small CNC laser cutter?

Safety is key. Wear proper gear, ensure good air flow, and follow safety rules. This prevents accidents and keeps you safe while cutting and assembling.

What are the key steps in the actual laser cutting process?

Position materials carefully, adjust power and speed, and make clean cuts. Learning these steps helps you make high-quality monitor parts.

What are the best practices for assembling a laser-cut monitor?

Use the right assembly techniques and add finishing touches. This turns your parts into a sleek display. Guides and best practices help you achieve a stunning monitor.

0 notes

Text

Choose the Right Fiber Laser Cutting Machine

Selecting the right fiber laser cutting machine is crucial for maximizing efficiency, precision, and profitability in your production processes. Here’s a guide on how to choose the best fiber laser cutting machine based on your needs:

1. Understand Your Cutting Requirements

Determine which materials you'll be cutting (steel, stainless steel, aluminum, copper, etc.). Fiber lasers are versatile and can cut a wide range of metals but perform differently on different materials. Fiber lasers can cut materials of varying thicknesses, so choose a machine with appropriate power. For example:

Thin Materials (up to 1mm): A machine with lower power (500W - 1kW) is suitable.

Medium Thickness (1mm to 6mm): Machines with power between 1kW and 3kW work best.

Thick Materials (6mm and above): Higher-power lasers (4kW to 12kW) are needed to cut thicker materials effectively.

If your production requires high-speed cutting or precise cuts, choose a machine that offers high accuracy and fast processing capabilities.

2. Consider Power Requirements

The power of the fiber laser (measured in watts, W) directly impacts cutting speed and material thickness. Higher power allows for faster cutting and the ability to handle thicker materials. Fiber lasers are generally more energy-efficient than CO2 lasers. Still, ensure the laser power matches your typical cutting needs to optimize energy consumption.

3. Choose the Right Size and Working Area

The cutting bed size should accommodate the largest material size you intend to process. Common sizes include 1.5m x 3m and 2m x 4m. If you're working with large sheets or cutting larger components, opt for a machine with a larger bed size. Some fiber laser cutting machine come with automatic loading and unloading systems, which can improve productivity and reduce labor costs.

4. Look at the Cutting Head and Focus Mechanism

The cutting head is an essential component that influences the precision and quality of your cuts. Look for a machine with:

Autofocus Cutting Head: This allows for automatic adjustments of the focus to adapt to different material thicknesses and types.

Focusing Lenses: Choose machines that use high-quality lenses and offer easy access for maintenance.

5. Consider Maintenance and Serviceability

Fiber lasers require less maintenance than CO2 lasers, but regular upkeep is still necessary to ensure performance. Make sure the machine is easy to maintain and repair. Consider the availability of support from the manufacturer or dealer. Choose a company that offers good customer service, technical support, and training.

6. Assess the Control System and Software Compatibility

The laser cutter should have a reliable CNC control system that’s compatible with your existing CAD/CAM software. A user-friendly interface allows for more intuitive operation and quick setup. Check for software that can easily handle different file types, optimize cutting paths, and improve overall workflow efficiency. Integration with your production management system can also streamline processes.

7. Evaluate Build Quality and Reliability

A robust machine frame ensures better accuracy and reduces vibration, leading to more precise cuts. Research the manufacturer’s reputation and reviews to ensure that the machine is durable and built to high-quality standards.

8. Budget and Total Cost of Ownership (TCO)

Compare the prices of different machines, but keep in mind that the cheapest option may not always be the best in terms of long-term value. Factor in the cost of consumables (nozzles, lenses), maintenance, and power consumption when calculating the total cost of ownership. Consider the machine’s potential to increase productivity and reduce downtime. A higher upfront cost might be justifiable if it provides long-term cost savings and efficiency.

9. Laser Type (Single or Multi-mode Fiber)

Single-mode Fiber Laser, Offers better beam quality and precision, ideal for fine cutting and high-precision tasks.Generally cheaper and suitable for cutting thicker materials at faster speeds but may not offer the same precision as a single-mode laser.

10. Safety Features

Ensure the machine includes safety features like proper shielding, emergency stop buttons, and smoke extraction systems to maintain a safe working environment.

Conclusion

When selecting the right fiber laser cutting machine from Supreme Technologies, focus on matching the machine's capabilities with your specific cutting requirements, including material type, thickness, cutting speed, and precision. Consider the total cost of ownership, including energy efficiency and maintenance, and ensure that you have access to strong after-sales support and service. By carefully assessing these factors, you can find the machine that best suits your needs, ensuring maximum productivity and value.

0 notes

Text

Laser Cutting An Innovation For Highly Accurate And Precision Cutting

Laser cutting is a methodology that uses a laser beam on the surface of the material which has to be cut. This methodology is mostly used in the industrial sector where large blocks of materials like iron and steel have to be cut to the required sizes. The process technically is similar to laser, marking and laser engraving. Even in this case, high power laser beam is directed onto the metal surface through optical devices like convergent lenses.

Computer numerical controls are used to direct the laser beams onto the material surface, which either melts or vaporises the material surface at the point of requirement, thereby living a very high quality finish at that point of cutting. Before the laser cutter or the laser cutting machine, became to be used extensively. These kinds of laser machines are mostly used to drill holes on the material surface. Advanced technology later on was used to cut material surfaces for aerospace applications, which needed a very fine finish. The disadvantages of mechanical cutting on certain material surfaces gave room to the invention of laser cutting machines. The process of laser cutting has its own advantages over the mechanical cutting like easier, cutting, more precision, accuracy, no wear and tear and so on.

Basically, there are three types of laser cutting machines in which the carbon dioxide laser is the best suited for cutting, drilling, and engraving. The ND lasers are used where very high power is needed in case of cutting very thick sheet metal materials. However, both carbon dioxide lasers and ND lasers can be used for the purpose of welding. While carbon dioxide lasers are used for the industrial cutting of many materials, including titanium and stainless steel, the ND lasers are primarily used for cutting ceramics. The laser cutting machine are dependent on the type of a gas flow that is used in it.

The usual types of gases that are used in these machines are carbon dioxide, helium, nitrogen, or a mixture of any of these. A laser cutting machine generates a good amount of heat within itself and hence requires a proper cooling process also. In most of the cases, water is commonly used as a coolant and is circulated during the process. A micro jet of water is integrated at a low pressure, which is used to perform laser cutting functions, which is also helpful in removing the debris and cooling the material.

Another advanced type of laser cutting machine is the fiber laser which is a solid state laser. Here the fiber technology is used to produce a laser beam which is then amplified and is known as fiber with a suitable wavelength. These lasers are very much suitable for cutting metals and metal sheets which reflect the light which is the main advantage of fiber laser cutting machine. Signvec is an organization that deals with laser cutting and engraving machine, known to have a number of advantages like less energy consumption, higher reliability, and performance, less maintenance, very low, operational cost and so on.

In Order To Find Out More Details On Laser Cutter Please Be Touch With Us Today Onwards..!

#Fiber Laser Cutting Machine#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine#Laser Cutter Singapore

0 notes