#CNC Fiber laser cutting machine

Explore tagged Tumblr posts

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

CNC Fiber Laser Cutting Machine supplier | CNC Fiber Laser Cutting Machine Manufacturer in pune, India | CNC Fiber Laser Cut | Fiber Laser Cutting Machine

Best company for CNC Fiber Laser Cutting Machine supplier, CNC Fiber Laser Cutting Machine Manufacturer in pune, Mumbai, Delhi, India. Buy CNC Fiber Laser Cutting Machine at best cost only berlin-machineries.com

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer

2 notes

·

View notes

Text

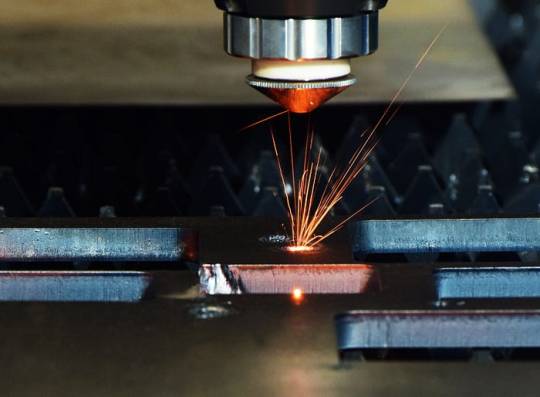

Revolutionizing Precision: Unveiling the Power of Fiber Laser Cutting Machines in 2D, 3D, and Tube Cutting

In the dynamic landscape of manufacturing, the advent of Fiber Laser Cutting Machines has emerged as a transformative force, redefining precision in 2D, 3D, and Tube Cutting processes. This comprehensive article explores the capabilities of these cutting-edge machines, shedding light on their applications, advantages, and the future they herald. Understanding the Basics: Fiber Laser Technology

1. The Essence of Fiber Lasers

Fiber lasers operate on a unique principle, utilizing optical fibers doped with rare-earth elements to amplify light. This results in a highly concentrated and powerful laser beam, ideal for intricate cutting tasks. The technology’s inherent efficiency and precision make it a game-changer in various industries.

2. 2D Cutting Mastery

In the realm of 2D Fiber Laser Cutting Machines stand out for their unparalleled precision and speed. From intricate patterns to straight cuts, these machines excel in transforming raw materials into precise components. The flexibility they offer caters to diverse industries, from automotive to electronics.

youtube

3. Breaking into the Third Dimension

Venturing into the 3D Fiber Laser Cutting Machines bring a new dimension to manufacturing. Their ability to navigate complex geometries with precision opens doors to limitless design possibilities. Whether it’s creating artistic sculptures or crafting intricate components, the versatility of these machines knows no bounds.

youtube

Specialized Expertise: Tube Cutting Capabilities

4. Mastering Tube Cutting Challenges

The unique challenges posed by tube cutting find an effective solution in fiber laser tube cutting machines. With advanced focusing capabilities and rapid cutting speeds, these machines ensure clean and precise cuts on various tube profiles. The adaptability of Fiber Lasers makes them indispensable in industries where tube cutting is a critical component.

youtube

Advantages That Redefine Manufacturing Standards

5. Unrivaled Speed and Efficiency

Laser Cutting Machines are synonymous with speed and efficiency. The rapid cutting speeds, coupled with minimal downtime, translate to enhanced productivity. Manufacturers embracing this technology witness a significant boost in overall operational efficiency.

6. Precision Beyond Comparison

Precision is the hallmark of Fiber Laser Technology. The ability to make micro-cuts with utmost accuracy not only reduces material waste but also elevates the quality of finished products. In industries where precision is non-negotiable, Fiber Lasers are the ultimate choice.

The Future Landscape: Innovations on the Horizon

As technology continues to evolve, so do Fiber Laser Cutting Machines. The integration of artificial intelligence, automation, and enhanced connectivity promises a future where these machines operate seamlessly in smart manufacturing environments. This evolution not only enhances efficiency but also sets the stage for unparalleled advancements in the manufacturing sector.

Conclusion: Transforming Possibilities with Fiber Laser Cutting

In conclusion, Fiber Laser Cutting Machines have emerged as the driving force behind a manufacturing revolution. From mastering 2D and 3D cutting to tackling the intricacies of tube cutting, these machines redefine the possibilities in precision engineering. As industries increasingly adopt Fiber Laser Technology, they not only keep pace with current manufacturing demands but also position themselves at the forefront of innovation, ready to shape the future of manufacturing.

#Laser Cutting machine#Fiber Laser cutting machine#laser cutting solution#Tube cutting machine#2d laser cutting machine#3D laser cutting machine#ultra high power laser machines#cnc laser cutting machine#cnc fiber laser cutting machine#Youtube

0 notes

Text

Primapress successfully developed flexible CNC bending machine Full automatic bending machine

Brief description: flexible CNC bending machine_ Full automatic bending machine_ Intelligent bending machine_ The four side bending machine can automatically fold up and down according to the bending process to realize the combined bending of arc, dead edge, and various angles. It can achieve a variety of bending requirements without changing the bending tool, saving a lot of labor and mold costs for enterprises.

After two years of technical research and development, the company’s technology research and development department is committed to developing a servo flexible bending center with the international level of Xinjin. The bending speed is only 0.2 seconds per tool. The equipment can automatically fold up and down according to the bending process to realize the combined bending of arcs, dead edges, and various angles. It can achieve a variety of bending requirements without changing the bending tool, saving enterprises a lot of labor and mold costs.

The maximum size of the processed plate is 2500mmx1500mm, and X, Y, C, V1, V2, Z1, Z2, W1, W2, P are controlled in 10 axes.

The C-type pressure arm structure is adopted, and the end adopts the crank linkage mechanism to drive the presser foot to press and hold the plate, so as to realize the feeding mode of moving and rotating the plate.

Introduction and demonstration of bending body

@The main body of the servo flexible bending center is integrally welded with high-strength steel plates, with stable structure and long service life.

@The heat treatment removes internal stress, has strong rigidity and tonnage, ensures the long-term stability of the machine tool accuracy, and improves the bending accuracy, reliability and durability of the machine tool.

BEND CENTER ADVANTAGES

The flexible bending center can work independently, and can efficiently produce various specifications of components. The universal die can be automatically adjusted according to the size set by the program without any adjustment time, ensuring the safety of the operator and the quality of the product.

The positioning process is only completed once at the beginning of the whole bending. It is operated in this cycle. From the beginning to the completion of the processing, the bending plate and the rotating structure remain unchanged. The 0.01 degree resolution is to ensure high production flexibility.

Prima Flexible Bending Center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi axis concurrent linkage, it can automatically complete the sheet metal operation, solve the dependence on mold and labor from the technical point of view, effectively improve the production efficiency and reduce the production cost.

It is easy to meet the requirements of arc, dead edge, return, closed and other complex sheet metal bending.

Prima flexible bending center can be widely used in the field of steel cabinet shell (file cabinet, tool cabinet, outer cover, electrical cabinet, communication cabinet, gas cabinet, water meter cabinet…), kitchen appliances (refrigerator, air conditioner, cooker…), furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields.

The bending effect is shown in the following figure:

The flexible bending machines produced by our company are divided into PM1400, PMS2000 and PMS2500. Prima Flexible Bending Center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi axis concurrent linkage, it can automatically complete the sheet metal operation, solve the dependence on mold and labor from the technical point of view, effectively improve the production efficiency and reduce the production cost.

It is easy to meet the requirements of arc, dead edge, return, closed and other complex sheet metal bending.

Prima flexible bending center can be widely used in the field of steel cabinet shell (file cabinet, tool cabinet, outer cover, electrical cabinet, communication cabinet, gas cabinet, water meter cabinet…), kitchen appliances (refrigerator, air conditioner, cooker…), furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields. For more details about CNC Press Brake Bending Machineor Press Brake Machinebrowse our website https://www.prima-press.com/press-brake-machine-cnc-bending-machine/

#CNC Press Brake Bending Machine#Hydraulic Press Brake#Sheet Metal Press Brake Bending Machine#CNC Fiber laser cutting machine

1 note

·

View note

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Text

Enhancing Precision Cutting with Oxy-Fuel Cutting Machines

Oxy-fuel cutting machine Manufacturers, also known as oxy-acetylene cutting, is a process that uses a combination of oxygen and fuel gases (typically acetylene) to cut through metal. The process works by heating the metal to its ignition temperature and then directing a high-pressure stream of oxygen onto the heated area. The reaction of the oxygen with the metal causes it to oxidize and burn away, leaving behind a clean cut.

While oxy-fuel cutting was once overshadowed by plasma and laser cutting technologies, it remains one of the most reliable and cost-effective methods for precision cutting, particularly when dealing with thick or heavily oxidized materials.

The Benefits of Oxy-Fuel Cutting Machines

Cost-Effectiveness One of the standout advantages of oxy-fuel cutting is its affordability. Oxy-fuel machines are generally less expensive than their plasma or laser counterparts. The process also requires relatively low maintenance, making it a cost-effective choice for businesses that need precision without breaking the bank.

Versatility Oxy-fuel cutting machines are highly versatile and can be used to cut a wide variety of metals, including carbon steel, stainless steel, and aluminium. Additionally, they are perfect for cutting thick materials, something that other cutting methods like plasma may struggle with.

Precision and Control Modern oxy-fuel cutting machines are equipped with advanced controls that allow for highly precise cuts. With adjustable torch settings and the ability to fine-tune the oxygen flow, operators can achieve cleaner cuts with minimal distortion. This level of control is particularly important for industries that require intricate cuts, such as aerospace and automotive manufacturing.

Ability to Cut Thick Materials Oxy-fuel cutting machines excel when it comes to cutting thick sections of metal, especially those thicker than 1 inch. The ability to cut through heavy materials, such as steel plates used in shipbuilding or construction, makes oxy-fuel machines invaluable in industries that deal with large, heavy components.

Portability Oxy-fuel cutting equipment is relatively portable, especially compared to other cutting technologies like laser cutters. This portability is a huge advantage in industries like construction or shipbuilding, where cutting needs may arise in remote locations or on-site.

Applications of Oxy-Fuel Cutting

Oxy-fuel cutting machines are used across a broad range of industries, thanks to their precision and versatility. Here are some of the sectors that benefit from this technology:

Construction: Oxy-fuel cutting machines are commonly used to cut through steel beams, plates, and other construction materials.

Shipbuilding: The ability to cut thick metal sheets makes oxy-fuel machines a key tool in shipbuilding.

Automotive: For the manufacturing of automotive parts, precision cutting is crucial, and oxy-fuel machines are well-suited to cut through both thick and thin metal components.

Heavy Machinery: Oxy-fuel cutting is ideal for creating precise cuts in large parts used in industrial equipment and machinery.

Aerospace: Aerospace industries require precise cuts for various components, and oxy-fuel cutting ensures a high degree of accuracy.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

How Laser Sheet Cutting Machines Are Revolutionizing Metal Fabrication

The metal fabrication industry is undergoing rapid changes, thanks to advancements in technology. One of the most significant breakthroughs is the development of laser sheet-cutting machines. These machines have revolutionized how metals are cut, shaped, and designed. It makes the process faster, more efficient, and highly accurate.

What is a laser sheet-cutting machine?

A laser sheet cutting machine is a device that uses high-powered lasers to cut through metal sheets. These machines are programmed to cut metals with extreme precision. It makes them a favorite tool in industries that demand accuracy, such as automotive, aerospace, and construction. The lasers used in these machines are incredibly powerful.

Why Are Laser Sheet Cutting Machines Important in Metal Fabrication?

Metal fabrication involves processes like cutting, bending, and assembling metal parts. Traditional cutting methods like mechanical sawing and plasma cutting have their limitations. They can be slow, less accurate, and may require post-processing work to smooth rough edges. Laser sheet-cutting machines, on the other hand, offer several advantages:

Precision: The high accuracy of laser cutting reduces errors and the need for secondary processes.

Speed: Laser sheet cutting machines can cut through metal quickly, speeding up production times.

Clean Cuts: Since the laser melts or vaporizes the metal, the cut edges are smooth and do not need additional finishing.

Versatility: They can cut through various metals, including stainless steel, aluminum, and copper.

How Do High-Power Fiber Lasers Work?

High-power fiber lasers are the core technology behind many modern laser cutting machines. These lasers produce a concentrated beam of light, which is directed at the metal surface. The laser's intensity is so high that it heats and melts the metal. Also, it creates a clean and precise cut.

Fiber lasers are favored for their ability to cut reflective metals like copper and aluminum. Their efficiency, low maintenance, and high energy output make them ideal for large-scale metal fabrication.

The Role of Laser Cutting Machine Manufacturers

Choosing the right laser cutting machine manufacturer is crucial for any business looking to invest in this technology. Reputable manufacturers offer machines that are reliable, durable, and equipped with the latest innovations. Some manufacturers also provide after-sales support, including maintenance and training.

How Laser Sheet Cutting Machines Are Redefining Efficiency

One of the biggest advantages of laser sheet cutting machines is their ability to automate tasks that once required significant manual effort. In traditional fabrication, human operators had to handle the materials, adjust the cutting tools, and monitor the process constantly. With modern laser sheet-cutting machines, much of this process is automated.

For instance, CNC (Computer Numerical Control) systems allow operators to program the machine for specific cuts. This automation speeds up production and reduces human errors.

Can laser sheet-cutting machines handle complex designs?

Absolutely. One of the standout features of laser sheet cutting machines is their ability to handle intricate and complex designs. Whether it’s creating delicate patterns or cutting precise holes in a metal sheet, these machines can deliver superior results. This capability has opened new opportunities for designers and engineers who require precise and elaborate metal components.

What Industries Benefit the Most from Laser Sheet Cutting?

Laser sheet cutting machines are used in a wide range of industries. Some of the most common include:

Automotive: Laser cutting is used to create car parts, including engine components, body panels, and exhaust systems.

Aerospace: The precision of laser cutting is essential for manufacturing aircraft parts, which require high tolerances.

Construction: Steel beams, metal frames, and other structural components are often cut using laser sheet cutting machines.

Medical Devices: Laser-cut metal parts are used in the production of medical instruments and implants.

Electronics: Thin metal sheets used in electronic components are often cut with lasers for precision and speed.

How Do Laser Cutting Machines Improve Safety?

Laser sheet-cutting machines are also enhancing safety in metal fabrication. Traditional cutting methods often involve sharp tools, which pose a risk of injury to workers. With laser cutting, the machine does the work, and operators have less direct interaction with dangerous materials. Moreover, modern machines are equipped with safety features like automatic shutoff systems and protective enclosures, reducing the risk of accidents.

Common Questions About Laser Sheet Cutting Machines

1. Can laser sheet-cutting machines cut all types of metal?

Yes, laser sheet cutting machines can cut a wide variety of metals, including steel, aluminum, copper, brass, and titanium. The type of laser and its power may need to be adjusted depending on the metal.

2. Are laser sheet-cutting machines expensive?

While the initial investment in a laser cutting machine can be high, the long-term benefits often outweigh the cost. These machines can increase efficiency, reduce waste, and lower labor costs. It makes them a worthwhile investment for many businesses.

3. How long do laser sheet-cutting machines last?

With proper maintenance, a laser sheet cutting machine can last many years. The lifespan depends on the quality of the machine and how well it is maintained. Many manufacturers offer service packages to keep the machine running smoothly.

What to Look for When Choosing a Laser Cutting Machine Manufacturer

When selecting a laser cutting machine manufacturer, consider factors like:

Select manufacturers who have a track record of success in the sector based on their experience and reputation.

Customization Options: Some manufacturers offer customized machines to fit specific industrial needs.

Technical Support and Training: Ensure the manufacturer provides training on how to use the machine and ongoing technical support.

Warranty and Maintenance Services: A good manufacturer will offer comprehensive warranties and maintenance services.

Conclusion

Laser sheet cutting machines have brought a new era of precision, speed, and efficiency to the metal fabrication industry. With high-power fiber lasers at the core, these machines can cut through metals with unmatched accuracy, reduce labor costs, and produce complex designs that were once difficult to achieve. As laser cutting technology continues to evolve, we can expect even more innovations that will further revolutionize metal fabrication.

If you're in the market for a laser sheet cutting machine, be sure to choose a trusted laser cutting machine manufacturer that offers the best in technology, service, and support.

0 notes

Text

How CNC Fiber Laser Cutting Enhances Efficiency in Production

CNC (Computer Numerical Control) fibre laser cutting is revolutionizing the manufacturing industry by offering unparalleled precision, speed, and efficiency. Whether you're in the automotive, aerospace, or metalworking sector, Laser Cutting Machines have become crucial in enhancing productivity and ensuring high-quality outcomes. This article delves into how CNC fibre laser cutting enhances efficiency in production and why it is becoming an essential tool in modern manufacturing processes.

Introduction to CNC Fiber Laser Cutting

CNC fibre laser cutting involves the use of high-powered lasers directed through fibre optics to cut through various materials. The CNC aspect of the process ensures that the cutting is automated, highly accurate, and capable of producing intricate designs that would be challenging to achieve manually. Laser Laser-cutting machines' precision is unmatched, making them indispensable in industries where detail and accuracy are paramount.

The Technology Behind CNC Fiber Laser Cutting

The technology behind CNC fibre laser cutting combines advanced laser systems with sophisticated CNC controls. The laser generates a high-energy beam that is focused on the material, melting, burning, or vaporizing it to create clean cuts. The CNC controls guide the laser with extreme precision, allowing intricate patterns and designs to be cut with minimal material wastage.

2.1 The Role of Fiber Optics

Fibre optics play a crucial role in CNC fibre laser cutting. They deliver the laser beam to the cutting head with minimal loss of energy, ensuring that the maximum amount of power is available for cutting. This technology also allows for more flexible and dynamic movement of the laser, which is essential for cutting complex shapes.

2.2 Advanced CNC Controls

The CNC system in fibre laser cutting machines is responsible for controlling the movement of the cutting head and the laser. These controls are highly sophisticated, enabling the machine to follow complex designs with precision. The CNC system can be programmed to cut a wide range of materials, including metals, plastics, and composites, making it a versatile tool in the manufacturing process.

Critical Benefits of CNC Fiber Laser Cutting

CNC fibre laser cutting offers numerous benefits that contribute to enhanced production efficiency. These benefits include precision, speed, versatility, and cost-effectiveness, all of which are essential for modern manufacturing.

3.1 Precision and Accuracy

One of the most significant advantages of CNC fibre laser cutting is its precision. Laser Cutting Machines are capable of cutting materials with an accuracy of up to ±0.001 inches, ensuring that each part is identical and meets the required specifications. This level of precision reduces the need for post-processing and minimizes material wastage.

3.2 Speed and Efficiency

CNC fibre laser cutting is significantly faster than traditional cutting methods. The laser can cut through materials at high speeds, reducing production time and increasing throughput. The process's automation also means that the machine can operate continuously, further enhancing productivity.

3.3 Versatility

CNC fibre laser cutting machines are highly versatile and can cut a wide range of materials, including steel, aluminium, copper, brass, and even non-metals like plastics and ceramics. This versatility makes them suitable for a variety of industries, from automotive to electronics.

3.4 Cost-Effectiveness

While the initial investment in CNC fibre laser cutting machines may be high, the long-term cost savings are significant. The machines' precision and speed reduce material wastage and labour costs, leading to a more cost-effective production process. Additionally, fibre lasers' durability ensures a longer lifespan for the machine, reducing maintenance and replacement costs.

How CNC Fiber Laser Cutting Enhances Production Efficiency

CNC fibre laser cutting enhances production efficiency in several ways, from reducing setup times to improving product quality. Let's explore how these machines are transforming manufacturing processes.

4.1 Reduced Setup Time

Traditional cutting methods often require extensive setup times, including manual adjustments and calibration. CNC fibre laser cutting machines, on the other hand, are equipped with automated systems that dramatically reduce setup times. Once the design is programmed into the CNC system, the machine can start cutting immediately, leading to faster production cycles.

4.2 Improved Material Utilization

Material utilization is a critical factor in manufacturing efficiency. Laser Cutting Machines are designed to minimize material wastage by optimizing the cutting process. The laser's precision allows for tighter nesting of parts, ensuring that more components can be cut from a single sheet of material. This not only reduces waste but also lowers material costs.

4.3 Enhanced Product Quality

The quality of the finished product is directly related to the cutting process. CNC fibre laser cutting produces clean, burr-free edges that require little to no post-processing. This improves the overall quality of the product and reduces the time and cost associated with additional finishing processes.

4.4 Flexibility in Design

CNC fibre laser cutting machines offer unparalleled flexibility in design. The CNC system can be programmed to cut complex shapes and patterns with ease, allowing manufacturers to create customized products without the need for expensive tooling. This flexibility is particularly beneficial in industries where design changes are frequent.

4.5 Automation and Integration

The automation capabilities of CNC fibre laser cutting machines are a significant factor in enhancing production efficiency. These machines can be integrated into automated production lines, allowing for continuous operation with minimal human intervention. The ability to run the machines 24/7 increases production output and reduces downtime.

Applications of CNC Fiber Laser Cutting

CNC fibre laser cutting is used in a wide range of industries, from automotive manufacturing to aerospace and electronics. Its versatility and precision make it suitable for various applications, including:

5.1 Automotive Industry

In the automotive industry, CNC fibre laser cutting is used to cut metal components with high precision. This includes cutting parts for engines, chassis, and body panels. The speed and accuracy of laser cutting help automotive manufacturers meet the high demands of production while maintaining strict quality standards.

5.2 Aerospace Industry

The aerospace industry requires components that meet stringent quality and safety standards. CNC fibre laser cutting is ideal for producing these components, as it can cut complex shapes with high precision. The ability to cut lightweight materials like aluminium and titanium also makes it a valuable tool in aerospace manufacturing.

5.3 Electronics Industry

In the electronics industry, CNC fibre laser cutting is used to cut delicate components with extreme accuracy. This includes cutting circuit boards, connectors, and other small parts. The precision of laser cutting ensures that these components meet the required specifications and function correctly in electronic devices.

5.4 Metalworking Industry

The metalworking industry benefits significantly from CNC fibre laser cutting, as it allows for the precise cutting of metal sheets and plates. Laser cutting machines' versatility makes them suitable for producing a wide range of metal products, from structural components to decorative items.

The Future of CNC Fiber Laser Cutting

The future of CNC fibre laser cutting looks promising, with ongoing advancements in technology expected to enhance its capabilities further. As lasers become more powerful and CNC systems become more sophisticated, manufacturers can expect even greater precision, speed, and efficiency in their production processes.

6.1 Advancements in Laser Technology

One key area of development in CNC fibre laser cutting is the improvement of laser technology. Higher-powered lasers are being developed, allowing for faster cutting speeds and the ability to cut thicker materials. These advancements will expand the range of applications for CNC fibre laser cutting, making it an even more valuable tool in manufacturing.

6.2 Integration with Industry 4.0

Another area of growth is the integration of CNC fibre laser cutting machines with Industry 4.0 technologies. Smart factories equipped with interconnected machines and data-driven systems will be able to optimize production processes in real-time, further enhancing efficiency. CNC fibre laser cutting machines will play a crucial role in these advanced manufacturing environments.

6.3 Sustainability in Manufacturing

As sustainability becomes a more significant concern in manufacturing, CNC fibre laser cutting offers several advantages. Laser cutting's precision and efficiency reduce material waste, while fibre lasers' energy efficiency contributes to lower overall energy consumption. These factors make CNC fibre laser cutting a more environmentally friendly option compared to traditional cutting methods.

Conclusion

CNC fiber laser cutting is a breakthrough technology in the manufacturing industry that delivers unmatched precision, speed, and efficiency. Yash Lasertek's advanced Laser Cutting Machines empower manufacturers to create high-quality components with minimal waste and shorter production times. As this technology evolves, CNC fibre laser cutting will play an increasingly vital role in modern manufacturing, driving innovation and enhancing efficiency across various industries.

0 notes

Text

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

Find the best laser cutting machine in UAE on TradersFind

Find the best laser cutting machines in UAE on TradersFind. This platform provides access to a vast selection of high-quality 3D laser cutting machines, fiber laser cutting machines, and CNC laser cutting machines from the top manufacturers in UAE. Customers can easily connect with these leading companies and explore the latest laser cutting machines in UAE to enhance their operations. Contact Now!

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#best laser cutting machine#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Text

Top laser cutting machine companies in UAE on TradersFind

Top laser cutting machine companies in UAE on TradersFind. It is offering a comprehensive selection of cutting-edge solutions for various industries. These companies are recognized for their quality products, technological expertise, and customer satisfaction. With a focus on innovation and precision, laser cutting machine companies provide businesses with top-tier laser cutting machines to enhance their operations. For more information visit:

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#best laser cutting machine#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Text

cnc press brake - Anhui Wenying Machinery Technology Co., Ltd.

Streamline your manufacturing processes and achieve accurate bending results with advanced CNC technology. Visit winying.com for more detail

0 notes

Text

Maximizing the Capabilities of SLTL Laser Cutting Machines

SLTL laser cutting machines are cutting-edge tools that utilize laser beams to precisely cut through various materials. These machines offer several features that make them highly efficient and versatile. They are equipped with advanced control systems, high-power lasers, and intelligent software for optimal performance. Additionally, they often come with automated features like material handling systems and real-time monitoring capabilities.

The advantages of using SLTL laser cutting machines are numerous.

high precision and accuracy, allowing for intricate and complex designs

clean cuts with minimal material wastage

fast cutting speeds,.

can work with a wide range of metals, including Aluminum,Copper,Iron, Steel, Brass, Bronze, Silver, Gold, etc

Overall, SLTL laser cutting machines provide efficiency, flexibility, and quality in cutting.

youtube

To unleash the full potential of SLTL laser cutting machines, businesses can take several steps:

Upgrade the software and hardware

Keeping the machines up to date with the latest software and hardware upgrades ensures optimal performance. This includes installing the latest control systems, software updates, and laser sources. Upgrades can enhance cutting precision, speed, and overall efficiency.

Optimize the cutting parameters

Fine-tuning the cutting parameters, such as laser power, cutting speed, and focus, can improve the quality and efficiency of the cutting process. Conducting tests and experiments to find the optimal settings for different materials and thicknesses is crucial.

Train operators to maximize efficiency

Providing comprehensive training to operators is essential for utilizing the full potential of SLTL laser cutting machines. Operators should be well-versed in machine operation, maintenance, and troubleshooting. Continuous training and skill development can ensure efficient operation and minimize downtime.

SLTL laser cutting machines find extensive applications in various industries, including:

Automotive industry

These machines are used for cutting components like body panels, frames, and exhaust systems. The high precision and speed of SLTL laser cutting machines enable the automotive industry to achieve superior quality and efficiency in manufacturing processes.

Aerospace industry

SLTL laser cutting machines play a crucial role in aerospace manufacturing. They are utilized for cutting complex shapes in materials like aluminum, titanium, and composite materials. These machines enable the production of lightweight components with high structural integrity, meeting the stringent requirements of the aerospace industry.

Medical industry

SLTL laser cutting machines are employed in the medical field for cutting surgical instruments, implants, and medical devices. The precise cutting capabilities of these machines ensure accurate and reliable production of medical equipment, contributing to improved patient outcomes.

In conclusion, unleashing the potential of SLTL laser cutting machines can bring significant advantages to businesses across various industries. These machines offer high precision, clean cuts, and fast cutting speeds. By upgrading software and hardware, optimizing cutting parameters, and training operators, businesses can maximize the efficiency and productivity of these machines. Furthermore, SLTL laser cutting machines find applications in the automotive, aerospace, and medical industries, enabling superior quality and advanced manufacturing capabilities.

#cnc laser cutting machines#laser cutting machines#fiber laser cutting machines#laser machine#Youtube

2 notes

·

View notes

Text

Revolutionizing Welding with Advanced Laser Machines

Laser Welding machine Manufacturers are transforming welding technology by enhancing efficiency, precision, and quality. These cutting-edge machines offer unmatched speed, accuracy, and minimal material distortion, making them indispensable in industries like automotive, aerospace, and medical device manufacturing.

The Rise of Advanced Laser Welding Technology

The demand for laser welding machines has surged due to the increasing need for high-quality and cost-effective welding solutions. Traditional welding methods, such as plasma, and oxy-fuel often face limitations in speed and heat-affected zones. However, advanced laser machines provide:

High Precision: Ensuring clean and strong welds with minimal post-processing.

Non-Contact Process: Eliminating electrode wear and reducing contamination.

Versatility: Suitable for different materials, including stainless steel, aluminum, and titanium.

Energy Efficiency: Reducing power consumption compared to conventional methods.

Key Innovations in Advanced Laser Machines

With advancements in technology, modern laser welding machines now integrate:

AI-Based Monitoring: Enhancing quality control and reducing defects.

Automation Integration: Seamlessly working with robotic and CNC systems.

Enhanced Beam Control: Providing customizable welding depths and patterns.

Smart Sensors: Ensuring real-time adjustments for improved precision.

Applications of Advanced Laser Welding Machines

Laser welding is widely adopted in multiple industries due to its precision and adaptability. Key applications include:

Automotive Industry: Welding complex components, including EV battery enclosures.

Aerospace Industry: High-strength welds for lightweight aircraft components.

Medical Devices: Precision welding for surgical instruments and implants.

Electronics: Seamless micro-welding for circuit boards and connectors.

Choosing the Right Laser Welding Machine

Selecting the right laser welding machine manufacturers depends on factors such as:

Power and Beam Quality: Ensuring optimal penetration and smooth weld finish.

Automation Integration: Compatibility with robotic and CNC systems for improved productivity.

Material Compatibility: Ensuring the machine can handle various metals and alloys.

After-Sales Support: Reliable customer service, training, and spare parts availability.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

How to Optimize Materials with 20kW CNC Fiber Laser Cutting Machine

Using a 20kW CNC fiber laser cutting machine to optimize materials for optimal efficiency is important to producing accurate and superior outcomes. Operators will improve cutting efficiency and reduce problems like burrs and dross development by choosing the proper material qualities, like thickness, conductivity, and reflectivity. By ensuring that the laser energy is efficiently absorbed and used, optimizing the materials will result in higher cutting rates and lower manufacturing costs.

Improving the materials used for a 20kW CNC fiber laser cutting machine is important to raising the general effectiveness and caliber of the cutting operation. Through careful selection of materials consistent with their unique qualities and attributes, operators will minimize waste and mistakes while achieving excellent outcomes. To completely utilize the laser cutting machine's potential and lift industrial productivity as an entire, material optimization must be a top priority. By putting the recommendations and techniques covered in this article into practice, readers will surely be ready to increase the accuracy and efficiency of their laser-cutting procedures.

Choosing the Proper Materials

To get the simplest results from laser cutting, the proper materials must be used. Selecting materials for a 20kW CNC fiber laser cutting machine that will tolerate the laser beam's high power and intensity is crucial. Because they cut well and precisely, materials, including steel, aluminum, and chrome steel, are frequently utilized.

Due to differences in their composition and characteristics, many materials answer laser cutting in several ways. For instance, because they're more reflective than steel, metals like copper and brass have to be used at higher power levels. It is important to switch the facility, speed, and focus of the laser cutting device appropriately to ensure precise cuts and stop problems like burrs or material deformation.

Test cuts on sample materials should be performed to seek out the simplest settings for every sort of material to maximize the cutting process. Operators can attain greater cutting quality and efficiency by adjusting settings that are consistent with the fabric being utilized. Additionally, to ensure consistent performance while handling various materials, frequent calibration and adequate maintenance of the laser cutting equipment are necessary.

Optimizing Cutting Parameters

Optimizing cutting parameters, including power, focus, and speed, is important to maximizing cutting process efficiency. You'll improve the cut's overall quality, hamper production time, and increase cutting performance by tweaking these settings. Power governs the cutting action's intensity, speed decides how quickly the fabric is cut, and concentration manages the cut's accuracy. For best outcomes, these parameters with a CNC laser welding machine manufacturer in India must be adjusted by the actual needs of the fabric being processed.

Optimizing cutting parameters requires taking the type of fabric to be rigged into account. The qualities of various materials influence the simplest cutting conditions. For example, hard materials like metals can need higher power settings and slower speeds to make clean cuts. In contrast, softer materials like plastics might enjoy quicker speeds and lower power levels. Efficient cutting could also be achieved by modifying the cutting settings consistent with the hardness, thickness, and composition of the fabric.

It is impossible to overestimate the influence of varied cutting factors on the ultimate product's quality and overall effectiveness. Inaccurate settings can save time and money by causing problems like material deformation, uneven edges, or unfinished cuts. You'll maximize manufacturing productivity, reduce material waste, and acquire exact cuts by carefully adjusting cutting settings. To maximize productivity and uphold high standards for cutting quality, it's essential to periodically check and modify the cutting settings in accordance with the characteristics of the fabric and, therefore, the intended results.

Maximizing Efficiency and Minimizing Waste

To realize maximum production throughout the laser cutting process, efficiency must be optimized. Nesting software, which places pieces closer together to scale back material waste, is an efficient technique. A method to save lots of time and resources is to carefully organize the location of pieces on the fabric so that there's less scrap and more components produced from one sheet. You can easily have the option to buy a 6kw laser cutting machine.

If it's feasible, believe in automating the cutting process to extend efficiency even further. Automation guarantees uniform quality, expedites production, and lowers human error. Purchasing contemporary laser cutting equipment with cutting-edge features like material management systems and automatic nozzle changes will greatly increase productivity and efficiency.

In a 20kw CNC fiber Laser Cutting Machine, it's crucial to optimize material utilization and reduce waste, as well as maximize efficiency. You'll minimize waste and save production expenses by precisely estimating the quantity of fabric needed for every task and strategically scheduling cuts. A corporation will become more economical and sustainable by implementing a waste management system to collect and recycle unwanted resources.

Conclusion

Material optimization is a crucial aspect to think about if you would like your laser cutting operations to be optimized. Readers will maximize the performance of their 20kW CNC fiber laser cutting equipment by being consistent with the instructions provided in this blog article. Adopting material optimization improves final product quality, expedites manufacturing processes, and lowers operating expenses.

#buy laser welding machine in India#laser sheet cutting machine#20kw cnc fiber Laser Cutting Machine

0 notes