#Vertical Turret Milling Machine

Explore tagged Tumblr posts

Text

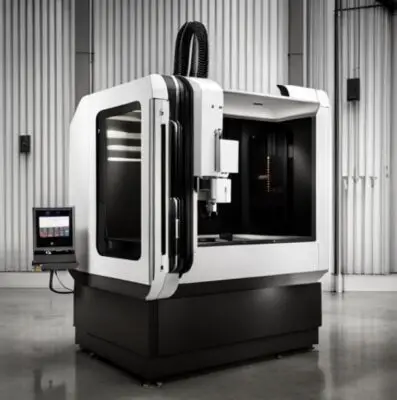

Vertical Turret Milling Machine| Vertical Turret Milling Machine supplier| Vertical Turret Milling Machine manufacturer in pune

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Text

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Link

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in ...

0 notes

Text

Discover the Future of Machining with Cutting Edge Equipment

Machining has come a long way from its humble beginnings. Today, industries demand high precision, efficiency, and versatility. Enter the world of advanced machining solutions like Vertical Turning Lathes (VTLs), 5 axis turnmills, and special purpose machines. These state of the art tools are redefining the boundaries of what’s possible in manufacturing.

The Power of Vertical Turning Lathes

Vertical Turning Lathes (VTLs) are game-changers for industries requiring the machining of large, heavy, and complex parts. Unlike traditional lathes, VTLs hold the workpiece vertically, offering significant advantages in stability and accuracy.

Stability and Precision

The vertical orientation means the workpiece’s weight is supported by the machine base, reducing deflection and vibration. This stability ensures that even the heaviest and most cumbersome parts are machined with unparalleled precision. Whether you’re dealing with large castings or forgings, a VTL can handle the task with ease.

Efficiency in Machining

VTLs are not just about stability; they also bring efficiency to the table. With the ability to perform multiple operations without repositioning the workpiece, these machines reduce setup times and increase throughput. This means more parts machined in less time, directly impacting your bottom line.

The Versatility of 5 Axis Turnmill machines

While VTLs are great for specific tasks, sometimes you need a machine that can do it all. Enter the 5 axis turnmill, a versatile powerhouse capable of milling and turning in a single setup.

Complex Geometries Made Simple

5 axis turnmill machines shine when it comes to machining complex geometries. The additional axes allow for simultaneous multi axis machining, which means intricate parts can be produced without the need for multiple setups. Imagine crafting intricate aerospace components or elaborate automotive parts in a fraction of the time traditionally required.

Reduced Lead Times

One of the standout benefits of a 5 axis turnmil machine is the reduction in lead times. By combining turning and milling processes, manufacturers can streamline their production lines, reduce handling, and improve overall efficiency. This machine’s ability to work on multiple faces of a part simultaneously can significantly cut down production cycles.

Special Purpose Machines for Unique Needs

Not all machining tasks can be handled by standard equipment. That’s where special purpose machines come into play. Designed for specific applications, these machines offer bespoke solutions that cater to unique manufacturing requirements.

Tailored Solutions

Special Purpose machines are engineered to address specific production challenges. Whether it’s a custom built machine for a unique part or an automated solution for high volume production, these machines are tailored to meet the exact needs of your operation. This bespoke approach ensures optimal performance and efficiency.

Increased Productivity

By focusing on a particular task, special purpose machines can operate at peak efficiency, leading to increased productivity. These machines often incorporate automation and advanced control systems, further enhancing their capability to deliver consistent, high quality results.

Conclusion

As manufacturing continues to evolve, the demand for high precision, efficient, and versatile machining solutions grows. Vertical Turning Lathes, 5 axis turnmills, and special purpose machines are at the forefront of this evolution, offering innovative solutions to meet the diverse needs of modern industries.

At WIDMA, we understand the importance of staying ahead of the curve. That’s why we are committed to providing advanced machining solutions that help our clients achieve their production goals with precision and efficiency. Embrace the future of machining with WIDMA and take your manufacturing capabilities to the next level.

#special purpose milling machine#vertical turret lathe#5 axi turn mill#5 axis vertical turning machine#widma

0 notes

Text

Vertical Turret Lathe and Horizontal Boring Mill Machinist - Pay $16-$38

Manual Vertical Turret Lathe and Horizontal Boring Mill Machinist Must have one or more years of manual X, Y, Z, W and B axis’ machining experience with horizontal boring mills and vertical turret lathe experience as well as one or more years of experience reading and interpreting engineering drawings to be considered Work hours are from 6:00 am to 4:30 pm Monday through Thursday Pay is $16 per…

0 notes

Text

What Are The Types Of Milling?

Primarily based on the search outcomes, the sorts of milling operations embody:

Plain Milling: Includes the creation of a flat horizontal floor parallel to the cutter’s axis utilizing a plain milling cutter.

Face Milling: Produces a flat floor perpendicular to the cutter’s axis.

Finish Milling: Produces slots and pockets.

Turret Milling: Makes use of a turret mill for varied milling operations.

Horizontal Milling: Holds and rotates the spindle within the horizontal orientation to take away materials from the floor of a stationary workpiece.

Vertical Milling: Removes materials from flat and vertical surfaces of a workpiece.

Common Milling: Gives versatility in machining operations and may carry out each vertical and horizontal milling.

Dro Milling: Makes use of a digital readout (DRO) system for exact milling operations.

CNC Milling: Managed by a pc numerical management system and a G-code program, permitting for broad functionality machining.

Tracer Managed Milling: Includes the usage of a tracer to regulate the milling operation.

Omniversal Milling: Supplies a variety of machining capabilities for varied milling wants.

Profile Milling: Used for creating advanced shapes and profiles on the workpiece.

Planetary Milling: Includes the usage of planetary movement for milling operations.

Drum Milling: Makes use of a drum milling machine for particular milling necessities.

NC/CNC Milling: Incorporates numerical management for exact and automatic milling operations.

0 notes

Text

Are the CNC and Lath machine same Explain ??

Lathes and CNC machines are both popular tools used in the manufacturing industry for cutting and shaping materials. Although they may seem similar in some aspects, they differ in several ways. In this article, we will explore the differences between the two machines.

A lathe machine is a tool that rotates a workpiece about an axis of rotation to perform various cutting, drilling, and threading operations. The workpiece is held in place by a chuck or collet, and the cutting tool moves along the workpiece to shape it. Lathes come in different types, such as engine lathes, turret lathes, and CNC lathes.

On the other hand, a CNC (Computer Numerical Control) machine is a type of machine tool that uses pre-programmed computer software to control the movements of the machine. The machine can perform a variety of operations, including drilling, milling, and cutting. CNC machines can be used to manufacture complex parts and components with high precision and accuracy.

One of the main differences between a lathe machine and a CNC machine is their level of automation. A lathe machine is operated manually, with the operator controlling the movement of the cutting tool and the workpiece. In contrast, a CNC machine is fully automated and operates based on pre-programmed instructions. Once the program is loaded, the machine can run continuously without any human intervention, except for maintenance and occasional monitoring.

Another difference is the level of precision and accuracy. Lathes are generally used for basic operations such as turning, facing, drilling, and threading. While they can achieve a reasonable level of accuracy, they are not suitable for high-precision tasks. CNC machines, on the other hand, can produce parts with extremely high accuracy and precision due to the use of computer software to control the machine's movements.

CNC machines are also capable of producing complex geometries and shapes that are difficult or impossible to achieve using a lathe machine. This is because the CNC machine can move the cutting tool in multiple directions simultaneously, allowing for more intricate designs and shapes.

In terms of speed, 5 Achsen CNC machines are generally faster than vertical lathe machines. This is because the CNC machine can operate continuously without stopping, while a lathe machine requires the operator to manually stop and start the machine for each operation.

Lastly, cost is a significant difference between the two machines. CNC machines are typically more expensive than lathe machines due to their complexity and automation. However, the increased efficiency, precision, and versatility of CNC machines can justify the higher initial cost in the long run.

In conclusion, lathe machines and CNC machines are both valuable tools used in the manufacturing industry. While they may seem similar, they differ significantly in terms of automation, precision, versatility, speed, and cost. Choosing the right machine for a particular task depends on the nature and complexity of the work, as well as the available budget and resources.

0 notes

Text

What You Should Know Before Buying a CNC Mill

Are you considering the purchase of a CNC (Computer Numerical Control) mill? With increasing options in precision machining and manufacturing, these specialized tools can provide powerful capabilities for detail-oriented work. Before taking the plunge into investing in a CNC mill, there are important points to consider such as cost and performance; understanding what is available on the market will help you make an informed decision. In this blog post, we'll explore some of the key features to look out for when buying a CNC mill so that you can find one that meets your needs while staying within budget.

What is a CNC Mill and how does it work? A CNC mill is a machine used in manufacturing that employs computer-controlled engineering to produce highly precise parts and products. CNC mills utilize instructions in the form of numerical software to control the cutting process of a workpiece. The machine typically consists of a bed, spindle, motor, cutting tools, and worktable. The cutting tools, which range in shape and size, rotate at high speeds, shaving away material from the workpiece to create the desired shape. The CNC mill allows for incredibly accurate and reliable production, making it ideal for creating complex and intricate parts for various industrial applications. The machine can be programmed to cut and shape a variety of materials, including metals, plastics, and composites, to create three-dimensional objects of nearly any shape. The CNC mill works by utilizing a combination of computer software and hardware to control the process. A CAD (computer-aided design) program creates a digital model of the part or product, which is then translated into a series of instructions in G-code. The G-code provides the instructions for the CNC mill to precisely move the cutting tools and worktable, ultimately creating the desired shape. Once the G-code is loaded into the CNC mill's computer, the machine begins cutting, precisely following the programmed instructions. The operator monitors the process, making adjustments as necessary to ensure the workpiece is produced to specifications. The CNC mill provides a highly automated and precise way of manufacturing complex parts and products. By using a combination of computer software and hardware, the machine produces accurate and reliable results, meeting the demands of modern manufacturing processes. What are the Different Types of CNC Mills and Their Uses? Computer Numerical Control (CNC) mills are essential tools in modern-day manufacturing. CNC mills operate with the use of software and computer programs, which allow them to execute precise cutting and shaping of materials. Different types of CNC mills are available, and they come with varying capabilities to perform diverse functions. Here are the different types of CNC mills and their uses: 1. Vertical Milling Machine: Vertical milling machines are designed to work with flat or rectangular metal surfaces. The spindle is positioned vertically, enabling a wide range of cutting possibilities such as drilling, tapping, and milling. This type of mill is perfect for manufacturing large quantities of flat or rectangular parts. 2. Horizontal Milling Machine: This mill is suitable for cutting and shaping materials from different angles. The spindle is positioned parallel to the worktable, allowing for precision cutting, drilling, and boring. Horizontal milling machines are excellent for producing parts in bulk quantities. 3. Bed Milling Machine: Bed milling machines have a vertically adjustable spindle that moves along the Z-axis. The bed can move along the X and Y-axis, allowing the machine to cut along different paths. Bed milling machines are ideal for creating parts with various shapes and sizes. 4. Turret Mill: A turret mill has a rotating spindle with a cutting tool at the end. This machine has a table that can be moved vertically and horizontally, giving it the capacity to cut and shape intricate forms. Turret mills are perfect for delicate jobs that need fewer cuts and a more precise finish. 5. CNC Router: CNC routers are designed to remove material from a workpiece, allowing it to be formed into a particular shape or pattern. It uses a rotating cylindrical tool that moves along multiple axes, providing precision cutting for objects like wooden decorative pieces, furniture parts, signboards, and architectural moldings. Different CNC mills are available for specific purposes, and the choice of the type depends on the materials, shapes, and productivity needs. While operating CNC mills may require skillful expertise, success hinges on selecting the right type of CNC machine for the particular task at hand. Benefits of Using a CNC Mill for Manufacturing Standard benefits: - Increased accuracy and precision of parts compared to manual methods. - Reduced production time with automated processes. - Ability to produce complex shapes with ease. Emotional benefits: - Feel confident in the quality of your products due to increased accuracy and precision. - Enjoy the satisfaction of creating high-quality parts quickly and efficiently using CNC Mill for Manufacturing technology. Advantages and Disadvantages of CNC Milling Computer Numerical Control (CNC) milling is a type of precision engineering process that utilizes computer-controlled cutting tools to remove material from the workpiece. CNC milling has become a popular manufacturing method due to its accuracy, efficiency, and versatility. However, just like any other manufacturing process, CNC milling has its own advantages and disadvantages that must be considered. Advantages: 1. Precision and Accuracy: CNC milling machines are capable of producing complex and intricate shapes with high precision and accuracy. This is because the cutting tools are guided by the computer, which ensures that the dimensions are consistent throughout the production process. 2. Flexibility: CNC milling machines are extremely versatile and can produce a wide range of products. It is possible to create different shapes, sizes, and forms without the need for different setups. 3. Consistency: CNC milling machines can produce identical parts with high consistency. This means that once the program for a particular part has been created, it can be easily replicated with the same level of accuracy every time. 4. Efficiency: CNC milling machines are highly efficient and can produce a high volume of parts within a short time. This helps to reduce production time and costs. 5. Automation: The use of CNC milling machines reduces the need for manual labor, which can lead to a reduction in costs and an increase in productivity. Disadvantages: 1. High Cost: CNC milling machines are expensive to purchase, install, and maintain. This makes it difficult for small businesses and startups to invest in this technology. 2. Complex Programming: CNC milling machines require complex programming to operate. This means that operators need to have specialized skills and knowledge to use them effectively. 3. Dependence on Electricity: CNC milling machines rely on electricity to operate. This means that power outages or fluctuations can result in downtime and production delays. 4. Limited Material Handling: CNC milling machines are limited in their ability to handle certain types of materials. This means that operators will need to use different machines for different materials, leading to increased costs and longer production times. 5. Lack of Flexibility: While CNC milling machines are highly flexible, they can be limited in their ability to produce certain types of shapes and materials. This means that some parts may need to be produced through other methods, leading to longer production times and increased costs. CNC milling has revolutionized the manufacturing industry by providing accurate and efficient production of various parts and products. However, it is important to consider the advantages and disadvantages of this technology before investing in it. By weighing these factors carefully, businesses can make informed decisions about whether CNC milling is the right choice for their production needs.

Factors to Consider When Purchasing a CNC Mill If you're looking to purchase a CNC mill, there are several factors that you should consider before making your final decision. A CNC mill is a computer-controlled machine that uses rotating tools to remove material from a workpiece. It offers many benefits, such as increased accuracy, repeatability, and automation, which improves efficiency and saves time. Here are the factors that you should take into account when purchasing a CNC mill. 1. Machine Size: The size of the CNC mill that you choose will depend on the size of the workpieces that you're planning to mill. If you're working with large pieces of material, you'll need a larger machine that can handle the size and weight of the workpiece. Conversely, if you're working with small pieces, you'll need a smaller machine to ensure accurate and precise cuts. 2. Machine Capability: Different CNC mills have varying capabilities. You should choose a machine that has the capabilities that you need for your specific application. Factors to consider include the number of axes, spindle speed, and cutting capacity. If you're working with complex parts that require multiple cutting operations, you'll need a machine that has a high number of axes to achieve the required cuts accurately. 3. Machine Accuracy: Precision and accuracy are critical in CNC milling. When purchasing a CNC mill, ensure that it has the required tolerances and accuracy level for your application. The accuracy of a CNC mill is usually measured in microns, so choose a machine with an accuracy level that meets your needs. 4. Machine Price: The price of a CNC mill can vary significantly depending on its capabilities, size, and accuracy. Ensure that you have a budget in mind before purchasing a machine, and choose a machine that offers the best value for your needs. Avoid choosing a machine based on price alone, as lower-priced machines may not have the required capabilities or accuracy levels. 5. Machine Support: When purchasing a CNC mill, ensure that the manufacturer offers excellent after-sales support, including installation, training, and maintenance. Ensure that the manufacturer has a good reputation in the market and is known for providing high-quality and reliable machines. Purchasing a CNC mill is a significant investment, and it's essential to consider several factors before making your final decision. Ensure that you choose a machine that has the required capabilities, accuracy, and support to meet your specific needs. How to Operate a CNC Mill Safely CNC mills are powerful machines that operate on computer-aided designs (CAD) to produce precise cuts and shapes in a variety of materials, including wood, metal, and plastics. However, the safety of the operator and those around the machine should always be a top priority. Here are some guidelines for operating a CNC mill safely: 1. Familiarize yourself with the machine: Before operating the mill, it is important to read and understand the owner's manual. Make sure you know the location of all the emergency buttons, switches, and other safety features. Additionally, make sure you are knowledgeable about the materials and tools that will be used during the milling process. 2. Wear appropriate safety gear: Before operating the CNC mill, it is essential to wear appropriate safety gear. This includes safety glasses, earplugs, gloves, and a dust mask to protect yourself from flying debris, loud noise, and harmful dust particles. 3. Secure the workpiece: Ensure that the workpiece is securely fastened to the mill bed before starting the milling process. Use clamps or other securing devices to prevent the workpiece from moving during the operation. 4. Program the CNC mill: A program must be written and loaded into the CNC machine before it can operate. Always double-check the program for errors before running the machine. Pay careful attention that the program does not exceed the limits of the machine’s settings. 5. Stand clear of the machine: Once the milling process begins, stand clear of the machine and never hold the material by hand. Never lean or get too close to the machine while it is operating, and always remove any loose clothing or jewelry. 6. Monitor the milling process closely: Always be vigilant while the machine is operating to ensure everything is running smoothly. Watch for unusual noises or vibrations, which may indicate something is wrong with the machine or tooling. 7. Clean the work area: Once the milling process is complete, ensure that the work area is clean, and the machine is properly turned off. Remove any remaining debris and relabel the program for future use. Taking the necessary safety precautions before and during milling is vital to reduce the risk of accidents and injury. By following these guidelines, you can ensure the safe and efficient operation of your CNC mill. Conclusion: When shopping for a CNC mill, aspiring machinists and hobbyists should put careful consideration into the budget, performance, brand, and model quality that best suits their specific needs. While this process may seem daunting at first, it ultimately ensures that buyers receive a machine that meets their desires in terms of speed, accuracy, available features and more. Furthermore, some manufacturers offer free trials on certain models to give interested customers an opportunity to test before they buy. Before making any actual purchase decisions or commitments with the seller, prospective buyers should always read reviews or contact other satisfied users for guidance. Ultimately, all those seeking a CNC mill should be dedicated to researching their options thoroughly in order to find the perfect model for their project needs! Read the full article

0 notes

Text

• Consolidated B-32 Dominator

The Consolidated B-32 Dominator was an American heavy strategic bomber built for United States Army Air Forces during World War II, which had the distinction of being the last Allied aircraft to be engaged in combat during World War II.

The engineering development of the B-29 had been underway since mid-1938 when, in June 1940, the United States Army Air Corps requested a similar design from the Consolidated Aircraft Company in case of development difficulties with the B-29. The Model 33 on which Consolidated based its proposal was similar to the B-24 Liberator. Like the B-24 it was originally designed with a twin tail and a large Davis wing, but with a longer, rounder fuselage and a rounded nose. The powerplants were to be the same quartet of eighteen-cylinder, 2,200 horsepower (1,600 kW) Wright Duplex-Cyclones, as specified for B-29s. The aircraft was designed to be pressurized, and have remote-controlled retractable gun turrets with fourteen .50 in (12.7 mm) machine guns. It was to have an estimated gross weight of 101,000 lb (46,000 kg). The first XB-32-CO, AAF s/n 41-141, was constructed next to the Army Air Forces (AAF) Base Tarrant Field Airdrome at the AAF Aircraft Plant No. 4 just west of Fort Worth, Texas along the south side of Lake Worth. The Consolidated Vultee Bomber Plant assembly line was six months behind schedule, the aircraft making its first flight on 7 September 1942. Due to problems with the pressurization system, the gun turrets and landing gear doors, these items were omitted on the first prototype. The aircraft had R-3350-13 engines inboard and R-3350-21s outboard, with all four powerplants driving three-bladed propellers. The XB-32 had persistent problems with engine oil leaks and poor cooling, but the B-29 also had similar engine problems. The first XB-32 was armed with eight .50 in (12.7 mm) machine guns in dorsal and ventral turrets, and an odd combination of two .50 caliber and one 20 mm (0.787 in) cannon in each outboard engine nacelle firing rearwards, plus two .50 caliber machine guns in the wings outboard of the propellers. The turrets were remotely controlled from periscopic sights in aiming stations inside the aircraft. The sights were coordinated by a sophisticated analog computer system developed by Sperry Gyroscope Company.

On March 17th, 1943, the initial contract was signed for 300 B-32-CFs but development problems continued. On May 10th, 1943, the first XB-32 crashed on takeoff after making a total of 30 flights before the second XB-32, s/n 41-142, finally flew on July 2nd, 1943. This aircraft had a traditional stepped cockpit canopy. Upon examination and testing, the USAAF recommended a large number of changes that included more conventional gun stations. The pressurization system had problems which were never solved and so the role of the aircraft was changed to operating at low to medium altitude. This decision meant that the pressurization system was easily eliminated from production aircraft. Problems with the remote-controlled gun turrets were never solved and the armament on production aircraft was changed to 10 .50 caliber machine guns in manually operated turrets: Sperry A-17 turrets in the nose and tail, two Martin A-3F-A dorsal turrets, and one Sperry A-13-A ball turret. The bomb load was increased by 4,000 pounds (1,800 kg) to 20,000 pounds (9,100 kg). The second XB-32 continued to have stability problems. In an attempt to resolve this a B-29 style tail was fitted to the aircraft after its 25th flight but this did not resolve the problem and a Consolidated-designed 19.5 ft (5.9 m) vertical tail was added and first flown on the third XB-32, s/n 41-18336 on November 3rd, 1943. The first production aircraft was fitted with a B-29 vertical tail until a new tail was substituted. By 1944 testing of the three prototypes permitted the AAF to place orders for over 1,500 B-32s. The first production aircraft was delivered on September 19th, 1944, by which time the B-29 was in combat in China. The first B-32 crashed on the same day it was delivered when the nose wheel collapsed on landing. Beginning on January 17th, 1945, 40 B-32A-5, -10 and -15 aircraft were delivered as unarmed TB-32-CF crew trainers.

Originally, the Army Air Forces intended the B-32 as a "fallback" design to be used only if the B-29 program fell significantly behind in its development schedule. As development of the B-32 became seriously delayed this plan became unnecessary due to the success of the B-29. Initial plans to use the B-32 to supplement the B-29 in re-equipping B-17 and B-24 groups before redeployment of the Eighth and Fifteenth Air Forces to the Pacific were stymied when only five production models had been delivered by the end of 1944, by which time B-29 operations were underway in the Twentieth Air Force. The first assignment of the B-32 began when General George Kenney, the commander of Allied air forces in the South West Pacific Area and commander of the U.S. Fifth Air Force, traveled to Washington D.C. to request B-29s. Since priority had been given to strategic bombing by the B-29, Kenney's request was denied, after which he then requested the B-32. Following a demonstration, the Army General Staff agreed that Kenney could conduct a combat evaluation, and a test schedule of 11 missions was set up, followed by a plan to re-equip two of the 312th Bomb Group's four Douglas A-20 Havoc squadrons with the B-32. Project crews took three B-32s to Clark Field, Luzon, Philippine Islands, in mid-May 1945 for a series of test flights completed on June 17th. The three test B-32s were assigned to the 312th BG's 386th Bombardment Squadron. On May 29th, 1945, the first of four combat missions by the B-32 was flown against a supply depot at Antatet in the Philippines, followed by two B-32s dropping 16 2,000 lb (910 kg) bombs on a sugar mill at Taito, Formosa, on June 15th. On June 22nd, a B-32 bombed an alcohol plant at Heito, Formosa, with 500 lb (230 kg) bombs, but a second B-32 missed flak positions with its 260 lb (120 kg) fragmentation bombs. The last mission was flown on June 25th, against bridges near Kiirun on Formosa.

The test crews were impressed with its unique reversible-pitch inboard propellers and the Davis wing which gave it excellent landing performance. However, they found a number of faults: the cockpit was noisy and had a poor instrument layout, the bombardier's vision was limited, the aircraft was overweight, and the nacelle design resulted in frequent engine fires (a deficiency shared with the B-29 Superfortress). However, the testing missions were mostly successful. In July 1945, the 386th Bomb Squadron completed its transition to the B-32, flying six more combat missions before the war ended. On August 13th, the 386th BS moved from Luzon to Yontan Airfield on Okinawa and flew mostly photographic reconnaissance missions. The missions were intended to monitor Japan's compliance with the ceasefire and to gather information such as possible routes occupation forces could take into Tokyo. On August 17th, the B-32s were intercepted by Japanese fighters. During the two-hour engagement, the Dominators suffered only minor damage and none of their crew were injured. "Though the B-32 gunners later claimed to have damaged one fighter and 'probably destroyed' two others, surviving Japanese records list no losses for that day or next." On August 18th, 1945, four Dominators were given the task of photographing many of the targets covered on the previous day; however, mechanical problems caused two to be pulled from the flight. Over Japan, a formation of 14 A6M Zeros and three N1K2-J Shiden-Kai (George) fighters attacked the remaining two U.S. aircraft. Saburō Sakai, a Japanese ace, said later that there was concern that the Dominators were attacking. The last B-32 combat photo reconnaissance mission was completed on August 28th, during which two B-32s were destroyed in separate accidents, with 15 of the 26 crewmen killed. On August 30th, the 386th Bomb Squadron stood down from operations.

Production contracts of the B-32 were cancelled on September 8th, 1945, with production ceased by October 12th. Many B-32s ended up being salvaged at Walnut Ridge, Arkansas with a total of 38 flown to Kingman Army Airfield for disposal. No examples of a B-32 remain today. The XB-32 (AAF Ser. No. 41-18336) was used as a ground instructional airframe for fire fighting training. Others were written off after suffering major damage in operational accidents. Excess inventories were flown either to Walnut Ridge Army Airfield, Arkansas, to be scrapped by the Texas Railway Equipment Company, or to Kingman Army Airfield, Arizona to be scrapped by the Wunderlich Construction Company. One of the few portions of a B-32 surviving is a wing panel removed from a static test model and erected at the Montgomery Memorial near San Diego, California as a monument to aviation pioneer John J. Montgomery.

#second world war#world war 2#world war ii#military history#wwii#history#american history#aviation#us army air force#us aircraft#aircraft#bombers

49 notes

·

View notes

Text

ADVANTAGES OF VERTICAL TURNING LATHE

CNC Vertical lathes have long been recognized for their advantages in the machining of heavy or short workpieces. The latest vertical turning lathes also offer additional benefits in terms of diminished cycle times, due to the rapid workpiece transfer and short traverses that can be achieved by working in this plane. Our top-of-the-range vertical lathes have counter-spindles, allowing for even higher productivity. As with all lathes from our leading manufacturer, Index, the vertical lathes we offer are available with a wide range of configuration options that allow them to adapt absolutely to your demands, establishing that your cost-per-part is minimized.

Vertical lathes adapt the spindle in a fixed position in the vertical plane. The workpiece moves up or down to place it in line with the appropriate tool necessary for the desired operation.

Vertical lathes are less complex than horizontal machines. They provide the surpass option for projects that focus on a single side, like large metal plates and sinking dies. They hold an advantage over horizontal lathes in circumstances where workpiece sagging might be a factor.

Vertical turning lathes are large machines, also called vertical boring mills. These lathes are not high-production machines, but they are excellent for heavy-duty and high-power cutting of medium and large parts.

An essential influence of the VTL machine is the ease in which large heavy workpieces can be set and held in place for machining.

Vertical turning lathes that use the main spindle to load and unload themselves are finding consent as multitasking capabilities make them competent transforming centers for producing chucked parts.

Vertical turning lathes give foundries with machine shops as well as those that outsource machining the competence to cut bigger and abundant castings.

An indexable tool turret head distinguishes traditional VTLs from VBMs

Aside from the turret head or ram head, the VTL machine design uses a revolving table to support the workpiece and uses a bridge-type construction that carries the X-axis.

In terms of productivity, vertical turning centers typically progress cycle times because shops can be more aggressive with their cuts.

Jaewoo machines manufacture VMC that is a high-powered device that is perfect for cutting hard metals and metal alloys. Its faster chip removal rate and superior coolant delivery systems make it ideal for difficult jobs that require immense levels of accuracy. Its Servo increases the productivity of the machine making it optimal for cutting steel, cast iron and Aluminum. These machines are perfect for the automobile industry and the aerospace industry. These CNC milling machines will lend technical superiority to your workshop through their highly accurate milling, boring and drilling actions.

#Cnc turning programming#Cnc turning program#Cnc machine price in india#Vertical turning lathes#Indian machines#Price of cnc machine in india#Cnc machines price#Manufacturers of cnc machines in india#Cnc manufacturer#Cost of cnc machine in india#Machine manufacturing companies in india#Buy a cnc machine#Vmc machine tools#Best cnc machine in india

1 note

·

View note

Text

Round Jaws Supplier In USA

Expert Tips on Different Machine Shop Tools

US Machine shops often have professional performing cold-metal work. This work involves an operator using tools to remove a portion of the metal, subsequently shaping it to some specified form or size. Machine tools are designed to perform functions such as threading, boring, turning, and facing. The use of tools in a machine shop varies substantially for both large and small jobs.

These highly specialized and advanced machines can be operated manually or may be powered electronically, depending on the model. Depending on the machining service conducted, the machine shop tools used may differ. By knowing the possibilities and limitations of the tools, a machinist is able to design the intended object more effectively.

People operating machine tools must first learn the safety regulations and precautions for each instrument. Understanding the basic concepts of the various tools helps in identifying its usage. Below is a basic guide on machine shop tools.

Drilling Machines

Drilling machines, also called drill presses, cut holes in metal and wood with a twist drill. There are many shapes and sizes of drilling machines ranging from small hand-held power drills to floor-mounted models. Other than drilling, their use ranges from countersinking, counterboring, reaming, to tapping large or small holes.

There are two types of drilling machines used by maintenance personnel for machine shop repair and fabrication. The bench drill cuts holes through metal, wood, and plastic, while the pillar drill is used to drill more extensive materials and to make larger holes. Control of drilling depth happens by utilizing a depth-stop mechanism located on the side of the spindle.

While drilling in a machine shop, it is crucial to pay attention and remain alert. The operator of the machine must use a sense of feel while feeding the cutting tool into the work. Drill press operators must know how to set up the work, set speed and feed, and provide a coolant to get a quality finished product.

Milling Machines

Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating cutter. A milling machine cuts metal before feeding the workpiece against a rotating cutting tool. Each device has a cutter that operates at a specific range of speed so that the operator can form the required shape.

The machine can also hold one or several cutters at a time. An adjustable speed feature helps regulate the milling machine for a more precise cut. A machine shop relies heavily on milling machines to perform various functions.

A milling machine handles multiple tasks such as carving, threading, milling, drilling, and cutting. These machines come in various types based on precise standard specifications. The most commonly used machines are the column, turret, C-frame, horizontal, bed type, planer-style, and tracer-controlled.

Grinding Machines

A grinding machine uses an abrasive wheel as the cutting tool. The rough surface of the coarse wheel shreds off small portions of the workpiece. Grinding wheels with different grit sizes achieve better grinding passes as required.

For requirements of precision and surface finish, the grinding process acts as a finishing mechanism after the other metalworking operations. Grinding machines are used for smoothing out rough surfaces on hard materials such as tool steel. It is primarily a finishing operation that removes relatively small quantities of metal to deliver highly accurate products.

Grinding is the most accurate of all of the basic machining processes in a machine shop. There are five categories of grinding machines, namely: surface grinders, cylindrical grinders, centerless grinders, internal grinders, and specials.

Shaper Machine

The shaper machine aids in the production of horizontal, vertical, or flat surfaces. When handling the shaper process, the operator removes metal from the surface in the horizontal, vertical, and angular planes by the use of a single-point cutting tool mounted on the ram.

In a shaper machine, the workpiece remains stationary while the cutting tool moves back and forth during the fabrication of the desired product.

1 note

·

View note

Text

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Text

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer

0 notes

Text

Precision Mastery withVertical Turning Lathes, 5-Axis Turnmills, and Special-Purpose Machines

Vertical Turning Lathe (VTL): Precision in Every Revolution

Towering pillars of precision, Vertical Turning Lathes (VTLs) provide a flexible solution for a wide range of machining applications. The unparalleled characteristics that make VTLs essential in precision engineering are examined in more detail below:

The core functionality of VTLs is their extraordinary accuracy in multi-axis machining. With each revolution, these machines redefine precision whether they are drilling, milling, or turning. Because of the versatility that multi-axis machining offers, VTLs are a great option for businesses that need to produce complicated and sophisticated parts.

1. Multi-Axis Versatility: Execute turning or milling and drilling with unparalleled accuracy through multi-axis machining.

2. Adaptability Across Industries: Intricate parts or large components, the Vertical Turning Lathe accommodate various geometries and materials. This offers versatility for diverse industries.

3. Efficiency Through Automation: Easily integrate with automation systems, ensuring rapid machining and precise positioning for enhanced operational efficiency.

5-Axis Turnmill: Precision Unleashed

The 5-Axis Turnmill represents the pinnacle of machining sophistication, combining the capabilities of turning and milling in a single, seamless operation. Here's why the 5-Axis Turnmill is hailed as a game-changer in precision engineering:

1. Simultaneous Multi-Axis Machining: Use several axes of movement to execute intricate tasks.

2. Shorter Set-Up periods: By finishing several tasks in a single setup, you can drastically cut down on set-up periods. As a result, production moves more quickly.

3. Enhanced Surface Finish: Achieve superior surface finishes with optimized tool paths.This reduces tool marks and overall quality is enhanced by the 5-Axis Turnmil.

Special-Purpose Machines: Tailored Precision

Unique challenges demand tailored solutions, Special-Purpose Machines emerge as the answer to specific machining needs.

Special-purpose machines are wonders of precise engineering created to meet particular and unusual machining needs. In contrast to regular machines, these specialized counterparts are designed with a single goal in mind—to solve specific issues in a variety of industries. Their personalization is their main advantage because they are expertly made to carry out particular jobs with unparalleled accuracy.

Special-Purpose Machines simplify processes by customizing their capabilities to meet certain applications, providing a streamlined and effective manufacturing method. This specialization guarantees that every component—from fixtures to tooling—is optimized for the specific work at hand, leading to improved precision and dependability. These machines are essential to industries with specific production requirements because they offer solutions that are not possible with off-the-shelf substitutes. Here's why these machines are indispensable for industries with distinctive requirements:

1. Customization for Unique Applications: Designed for specific requirements, these machines offer tailor-made solutions for unique applications.

2. Efficiency Through Specialization: Streamline workflows by focusing on

Specialized tasks

Optimizing tooling

Fixtures

Processes

3. Cost-Effective Solutions: Despite upfront costs, Special-Purpose Machines provide long-term savings for industries with recurring, specialized production demands.

Redefining Precision in Modern Machining

Modern machining precision is architected by Vertical Turning Lathes, 5-Axis Turnmills, and Special-Purpose Machines. Their effectiveness, adaptability, and custom solutions expand the realm of possibilities and satisfy the ever-changing demands of sectors that settle for nothing less than excellence.

0 notes

Text

Best Milling Machine For Home Use Reviews

Guidelines HOW TO USE A MILLING MACHINE

This website page is best imprinted in Landscape design.

This data was initially ordered by the US Army.

Introduced to you free by American Machine Tools Company.

Processing is the way toward machining level, bended, or sporadic surfaces by taking care of the workpiece against a turning shaper containing various forefronts. The typical Mill comprises fundamentally of an engine driven axle, which mounts and rotates the processing shaper, and a responding movable worktable, which mounts and feeds the workpiece.

youtube

Processing machines are fundamentally delegated vertical or level. These machines are additionally delegated knee-type, slam type, assembling or bed type, and planer-type. Most processing machines have independent electric drive engines, coolant frameworks, variable shaft speeds, and force worked table feeds

Graph of average variable speed processing machine head

Graph of average "Bridgeport style" processing machine head

Kinds OF MILLING MACHINES

KNEE-TYPE

Knee-type plants are portrayed by a vertically flexible worktable laying on a seat which is upheld by a knee. The knee is a huge projecting that rides vertically on the processing machine segment and can be braced inflexibly to the segment in a position where the processing head and processing machine shaft are appropriately balanced vertically for activity.

The plain vertical machines are described by a shaft found vertically, corresponding to the section face, and mounted in a sliding head that can be exhausted and somewhere around hand or force. Current vertical processing machines are planned so the whole head can likewise turn to allow chipping away at rakish surfaces.

The turret and turn head get together is intended for making accuracy cuts and can be swung 360� on its base. Rakish slices to the even plane might be made with exactness by setting the head at any necessary edge inside a 180� bend.

The plain even processing machine's section contains the drive engine and equipping and a fixed position level processing machine axle. A customizable overhead arm containing at least one arbor underpins extends forward from the head of the section. The arm and arbor underpins are utilized to balance out long arbors. Supports can be moved along the overhead arm to help the arbor where backing is wanted relying upon the situation of the processing shaper or cutters.

The processing machine's knee rides up or down the section on an inflexible track. A substantial, vertical situating screw underneath past the processing shaper. The processing machine is fantastic for framing level surfaces, cutting dovetails and keyways, shaping and fluting processing cutters and reamers, cutting riggings, etc. Numerous exceptional tasks can be performed with the connections accessible for processing machine use. the knee is utilized for raising and bringing down. The seat settles upon the knee and supports the worktable. The seat moves in and out on a dovetail to control cross feed of the worktable. The worktable navigates to one side or left upon the seat for taking care of the workpiece past the processing shaper. The table might be physically controlled or power took care of.

All inclusive HORIZONTAL MILLING MACHINE

The essential distinction between an all inclusive level processing machine and a plain even processing machine is the expansion of a table turn lodging between the table and the seat of the widespread machine. This allows the table to swing up to 45� in either bearing for precise and helical processing activities. The general machine can be fitted with different connections, for example, the ordering installation, revolving table, opening and rack cutting connections, and different uncommon apparatuses.

Slam TYPE MILLING MACHINE

The slam type processing machine is described by a shaft mounted to a mobile lodging on the section to allow situating the processing shaper forward or aft in a level plane. Two famous slam type processing machines are the all inclusive processing machine and the turn shaper head smash type processing machine.

All inclusive RAM-TYPE MILLING MACHINE

The all inclusive slam type processing machine is like the general level processing machine, the distinction being, as its name suggests, the shaft is mounted on a smash or versatile lodging.

Turn CUTTER HEAD RAM-TYPE MILLING MACHINE

The shaper head containing the processing machine axle is joined to the smash. The shaper head can be turned from a vertical axle position to an even axle position or can be fixed at any ideal rakish situation among vertical and level. The seat and knee are hand driven for vertical and cross feed alteration while the worktable can be either hand or force driven at the administrator's decision.

Essential processing machine designs are appeared in Figure 8-1.

Wellbeing RULES FOR MILLING MACHINES

Processing machines require unique wellbeing precautionary measures while being utilized. These are notwithstanding those wellbeing safety measures depicted in Chapter 1.

Try not to reach the rotating shaper.

Spot a wooden cushion or appropriate spread over the table surface to shield it from conceivable harm.

Utilize the mate framework while moving overwhelming connections.

Try not to endeavor to fix arbor nuts utilizing machine power.

When introducing or eliminating processing cutters, consistently hold them with a cloth to forestall cutting your hands.

While setting up work, introduce the shaper last to abstain from being cut.

Never change the workpiece or work mounting gadgets when the machine is working.

Chips ought to be eliminated from the workpiece with a suitable rake and a brush.

NOTE Chip rake ought to be manufactured to the size of the T-openings (Figure 8-2).

Stop the machine before making any alterations or estimations.

When utilizing cutting oil, forestall sprinkling by utilizing proper sprinkle watches. Cutting oil on the floor can cause a tricky condition that could bring about administrator injury

Instruments AND EQUIPMENT

Processing CUTTERS

Arrangement of Milling Cutters

Processing cutters are typically made of fast steel and are accessible in an extraordinary assortment of shapes and sizes for different purposes. You should know the names of the most well-known characterizations of cutters, their utilizations, and, in an overall way, the sizes most appropriate to the current work.

Processing Cutter Nomenclature

Figure 8-3 shows two perspectives on a typical processing shaper with its parts and edges distinguished. These parts and points in some structure are normal to every single shaper type.

The pitch alludes to the precise separation between like or neighboring teeth.

The pitch is controlled by the quantity of teeth. The tooth face is the front oriented surface of the tooth that frames the forefront.

The bleeding edge is the edge on every tooth that plays out the cutting.

The land is the tight surface behind the front line on every tooth.

The rake point is the edge framed between the substance of the tooth and the centerline of the shaper. The rake edge characterizes the bleeding edge and gives a way to chips that are cut from the workpiece.

The essential leeway edge is the edge of the place where there is every tooth estimated from a line digression to the centerline of the shaper at the bleeding edge. This edge keeps every tooth from scouring against the workpiece after it makes its cut.

This edge characterizes the place where there is every tooth and gives extra freedom to section of cutting oil and chips.

The gap measurement decides the size of the arbor important to mount the processing shaper.

Plain processing cutters that are more than 3/4 inch in width are typically made with winding or helical teeth. A plain winding tooth processing shaper creates a superior and smoother finish and requires less capacity to work. A plain helical-tooth processing shaper is particularly alluring when processing a lopsided surface or one with openings in it.

Sorts of Teeth

The teeth of processing cutters might be made for right-hand or left-hand pivot, and with either right-hand or left-hand helix. Decide the hand of the shaper by taking a gander at the essence of the shaper when mounted on the axle. A right-hand shaper must pivot counterclockwise; a left-hand shaper must turn clockwise. The right-hand helix is appeared by the flutes prompting the right; a left-hand helix is appeared by the flutes prompting the left. The heading of the helix doesn't influence the cutting capacity of the shaper, however take care to see that the course of revolution is right for the hand of the shaper (Figure 8-4).

Saw Teeth

Saw teeth like those appeared in Figure 8-3 (above) are either straight or helical in the littler sizes of plain processing cutters, metal cutting saw processing cutters, and end processing cutters. The front line is generally given around 5 degrees essential leeway. Now and then the teeth are furnished with off-set scratches which separate chips and make coarser feeds conceivable.

Helical Milling Cutters

The helical processing shaper is comparative, to the plain processing shaper, however the teeth have a helix point of 45� to 60�. The precarious helix delivers a shearing activity that outcomes in smooth, sans vibration cuts. They are accessible for arbor mounting, or with a vital shank with or without a pilot. This sort of helical shaper is especially valuable for processing lengthened openings and for light cuts on delicate metal. See Figure 8-5.

Metal Slitting Saw Milling Cutter

The metal cutting saw processing shaper is basically an extremely slender plain processing shaper. It is ground marginally more slender toward the inside to give side freedom. These cutters are utilized for cutoff activities and for processing profound, slender spaces, and are made in widths from 1/32 to 3/16 inch.

Side Milling Cutters

Side processing cutters are basically plain processing cutters with the expansion of teeth on one or the two sides. A plain side processing shaper has teeth on the two sides and on the fringe. At the point when teeth are added aside just, the shaper is known as a half-side processing shaper and is recognized as being either a right-hand or left-hand shaper.

source

https://reviewkits.com/

1 note

·

View note

Text

Find the Best CNC Turning Center in USA

CNC turning center in USA and lathes may sound the same, but they apply to slightly different devices in general. Lathes may usually only be more sophisticated when turning centers. Such machines like HAAS SL-20T CNC TURNING CENTER SKU may be capable of turning to mask, string, knurling, grinding, boring, reaming and taper.

Horizontal CNC turning machines are more common but use gravity for vertical machines. CNC turning center in USA benefits predictive repair! MachineMetrics will measure the performance of the CNC machine to determine an optimal cycle time at which to run.

Here is a quick guide to find the best CNC Turning Center in USA & Grab HAAS SL-20T CNC TURNING CENTER SKU

Lathe Components

1. Headstock The headstock serves as the main spindle housing, where the jaw chuck which holds the workpiece is attached. The capability of the spindle bore or bar defines the overall diameter of a workpiece which can be placed via the head supply. The headstock is normally positioned on the lathe's left side.

2. Tailstock The tailstock is mounted opposite the headstock on the base of the lathe and moves over it in line with the Z-axis headstock. The tailstock's primary role is to provide assistance to the workpiece being machined between centres. The tailstock has a tapered quill to hold the tooling. CNC turning centres will have a second spindle instead of a tailstock, with sub-spindles (or dual spindles). Sub-spindle enables the machining of the backside of a workpiece without further loading/unloading of the user in the work cycle.

3. The Bed The table, usually made from cast iron, is the foundation on which various fixed and operating pieces are placed. It is related to the headstock and extends the gap between the headstock and the tailstock. It is placed beneath the workspace. Tool turret and various attachments travel across the length of the bed, along the rails or ways. Flat guideways are ideally suited for traversing and machining abrasive structures than deeper rapids. Strongbox ways are more suitable for heavy or interruptive cuts for greater rigidity of the instruments.

4. The Carriage The carriage supports tool cutting turret, steering it against the workpiece and feeding it against it. The main sections are saddle, cross-slide, and cannon. Turning centres with live tool turrets may have controlled rotary tools for milling operations which significantly improves the machine's capability and can minimize or remove second workpiece operations.

1 note

·

View note