#Bulk material transfer

Explore tagged Tumblr posts

Text

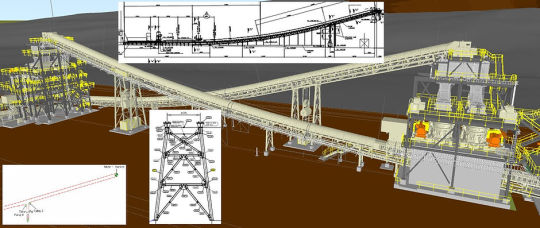

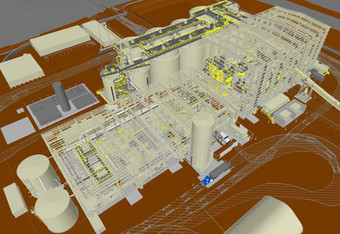

Little P.Eng. Engineering: Pioneering Bulk Material Transfer Design across Canada and the USA

When it comes to the intricate world of bulk material transfer, North America's industrial backbone relies heavily on robust, efficient, and innovative machinery. Operating at the forefront of this industry is Little P.Eng. Engineering, a name synonymous with exemplary structural and mechanical design across Canada and the USA.

Bulk Material Transfer Design: The Pulse of Modern Industry

Transcending borders, bulk material transfer is central to the heartbeat of contemporary industries. From the sprawling mines of Canada to the bustling ports of the USA, the movement, deposition, and retrieval of large-scale materials demand a seamless blend of precision, durability, and adaptability.

Journeying Through Little P.Eng. Engineering’s Pan-North American Impact

Single-boom Spreaders:

Functionality: Essential in the processing of minerals, ores, and coal, these machines promise uniformity in layering vast material amounts.

Little P.Eng. Across Continents: Adapting to the varied terrains and industrial needs of Canada and the USA, Little P.Eng.'s designs optimize weight distribution, longevity, and operational flexibility.

Mobile Stacking Bridges:

Functionality: Mobile and versatile, these units aid in the strategic stockpiling of materials in expansive stockyards.

Little P.Eng.’s Transnational Signature: Ensuring a balance between agility and stability, the design innovations address diverse geographic and operational needs across North America.

Transport Crawlers:

Functionality: These titans manage the internal transportation of massive equipment, streamlining logistical challenges.

Little P.Eng.’s North American Adaptability: By designing crawlers that focus on energy efficiency and terrain adaptability, they address the unique challenges of both Canadian mines and American industrial facilities.

Stackers and Reclaimers (Single & Combined):

Functionality: While stackers deposit materials systematically, reclaimers specialize in their retrieval. Combined machinery handles both roles.

Little P.Eng.'s Pan-American Approach: Catering to the varying scales and nuances of industries across the two nations, designs prioritize transition fluidity and spatial optimization.

Bucket Wheel Reclaimer (Boom & Bridge):

Functionality: With an array of buckets, these reclaimers ensure efficient retrieval from vast stockpiles.

Little P.Eng.’s Cross-Border Excellence: Be it the Canadian cold or the American heat, precision-focused designs ensure efficient operations under diverse conditions.

Scraper, Drum, and Portal Reclaimers:

Functionality: Each variant is uniquely designed to retrieve stockpiled materials, adhering to specific operational demands.

Little P.Eng.’s Continental Precision: By crafting machinery tailored for the specific needs of locations from Alberta to Alabama, the emphasis is on tailored efficiency.

Portal and Bridge-type Scraper Reclaimers:

Functionality: These reclaimers excel in longitudinal stockyards, merging efficiency with compactness.

Little P.Eng.’s Broad Vision: The designs seamlessly integrate with North American industrial landscapes, maximizing space and operational potential.

Ship Loaders & Unloaders:

Functionality: Vital cogs in maritime logistics, these entities manage the intricate process of loading and unloading materials.

Little P.Eng.’s Coastal Touch: With an understanding of the varied port dynamics across the two nations, designs ensure faster operations, minimizing ship turnaround times.

Grab Type Ship Unloader:

Functionality: Specializing in rapid unloading, they promise efficiency at its best.

Little P.Eng.’s Harbor Mastery: Emphasizing precision and speed, designs cater to the bustling ports of both Canada and the USA, ensuring peak operational performance.

Circular Storage with Stacker/Bridge Reclaimer:

Functionality: These units epitomize the optimal utilization of circular stockyards, promising swift stacking and retrieval.

Little P.Eng.’s Circular Innovation: By integrating space-saving techniques with high-speed operations, designs redefine the contours of material storage and retrieval.

Beyond Borders: Little P.Eng. Engineering’s Vision

For Little P.Eng. Engineering, the journey isn’t just about creating machinery. It’s about crafting solutions, ones that resonate with the industrial ethos of both Canada and the USA. Recognizing the unique challenges and potentials of each nation, the company's designs embody adaptability, sustainability, and the future.

Conclusion

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Single-boom spreaders

Mining equipment

Bulk material transfer

North American industries

Mobile stacking bridges

Transport crawlers

Stacker and reclaimers

Bucket wheel reclaimer

Boom & bridge reclaimer

Scraper reclaimers

Drum reclaimers

Portal reclaimers

Bridge-type scraper reclaimers

Ship loaders

Ship unloaders

Grab type ship unloader

Circular storage

Stacker/bridge reclaimer

Material handling machinery

Industrial logistics

Maritime logistics

Stockpile management

Heavy machinery design

Port equipment

Tailored efficiency

Material storage solutions

Sustainable machinery design

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Single-boom spreaders#Mining equipment#Bulk material transfer#North American industries#Mobile stacking bridges#Transport crawlers#Stacker and reclaimers#Bucket wheel reclaimer#Boom & bridge reclaimer#Scraper reclaimers#Drum reclaimers#Portal reclaimers#Bridge-type scraper reclaimers#Ship loaders#Ship unloaders#Grab type ship unloader#Circular storage#Stacker/bridge reclaimer#Material handling machinery#Industrial logistics#Maritime logistics#Stockpile management#Heavy machinery design#Port equipment#Tailored efficiency#Material storage solutions#Sustainable machinery design

0 notes

Link

Looking to store your materials in rail cars? Or Store large quantities of dry bulk materials in Silos or a Warehouse. TTS has got you covered, TTS has 15 rail spurs that can handle 250 rail cars and storage silos that exceed 8,000 MT and expanding Warehouse spaces. Our in-house team can build Silos over 1,000 MT capacity or Warehouses for storage, so you do not have to worry about supply interruption! TTS prides itself to be an end-to-end logistic solution provider.

#Rail Car to PD Tanker Trailer#Rail to Truck Transfer Services#Bulk Material Handling in Edmonton#Dry Bulk Transloading

0 notes

Text

Pneumatic conveyor | Pneumatic conveyor manufacturer | Pneumatic conveying system | pneumatic material handling | bulk material handling

youtube

Enquiry : [email protected]

Contact : 95851 31112

Website: https://altomech.com/pneumatic-conveying-system.php

#pneumatic conveyor#pneumatic conveyor manufacturer#bulk material handling#pneumatic conveying system#pneumatic conveyor system#pneumatic conveying system manufacturers#pneumatic conveying companies#pneumatic powder transfer system#vacuum pneumatic conveying system#pneumatic conveyor systems#pneumatic conveyors#pneumatic grain conveying systems#manufacturer#altomech#Youtube

0 notes

Text

Powder Transfer Systems: Aishin's Solutions for Efficient Material Handling

Powder transfer systems are essential for modern industrial processes, revolutionizing material handling and transfer. In various industries like pharmaceuticals, food processing, and chemical manufacturing, efficient and precise powder handling is crucial for overall productivity, product quality, and workplace safety.

Overview of Powder Transfer Systems

Powder transfer systems are specialized systems crafted for the controlled handling and transfer of powders or granular materials. Precision and automation in powder transfer systems significantly reduce human error and variability, enhancing efficiency and ensuring the consistency of the final product. The ability to control parameters like flow rates and dosages optimizes production workflows, minimizing waste and contamination risks.

Industries are embracing powder transfer systems. In pharmaceuticals, these systems manage active pharmaceutical ingredients with precision. The food and beverage sector relies on them for accurate mixing, while in chemical manufacturing, they handle and transfer various powdered chemicals. The versatility of powder transfer systems makes them indispensable for controlled powder handling in critical production processes across industries.

Types of Powder Transfer Systems:

Powder transfer systems include two types, pneumatic conveying systems and mechanical transfer systems. Each type possesses distinctive features and applications. Pneumatic conveying systems use compressed air to transfer bulk materials like powder and granules through a closed pipe whereas mechanical transfer systems involve the transfer of materials using machinery like belts, rollers, brackets, and motors.

Understanding the unique features of each system aids in selecting the most suitable one for specific tasks. Factors such as the type of powder, required transfer distance, and overall operational efficiency play a important role in the decision-making process. Aligning system attributes with application requirements is essential for optimal performance.

Common Challenges in Powder Transfer

Common challenges in powder transfer processes include clogging and particle segregation, which can lead to downtime and contamination risks. Powder characteristics, such as size, shape, and moisture content, influence transfer efficiency. Fine particles may cause dusting, and cohesive powders can lead to poor flow and clogging. Overcoming these challenges requires specialized equipment design, vibrational assistance, and segregation-prevention techniques.

Aishin's Solutions to Powder Transfer Challenges:

Aishin, a global leader in material handling and powder transfer systems, has manufacturing facilities in Japan, Thailand, China, and India. Their comprehensive range of equipment includes bag dumping stations, rotary valves, knife gate valves, butterfly valves, silo/hoppers, mechanical transfer systems, pneumatic transfer systems, bin scrapers, dosing systems, lump breakers, and more. Aishin excels in addressing challenges associated with powder transfer such as clogging and particle segregation, and also in handling adhesive materials. Their scraper rotary valve is proven effective in overcoming difficulties posed by sticky materials during transfer processes. Aishin is renowned for Japanese engineering and is a leading rotary valve manufacturer in the industry.

Conclusion

Powder transfer systems are vital for industries, ensuring precise handling of powdered materials across sectors. Aishin, as a global leader in material handling equipment, is adept at addressing powder handling challenges. Trust Aishin to resolve powder transfer-related issues, ensuring operational efficiency, product quality, and workplace safety in your industrial processes.

#powder handling#material handling#equipment#powder#powder transfer#pneumatic conveying system#powder transfer system#valves#rotary valves#bulk material handling

0 notes

Text

Resources for Creating: My Go-To things.

Update: I’ll be updating the list on this page from now on, since Tumblr can’t handle so many hyper-links in one post, on Dreamwidth - right here, so I won't have to update it multiple times. Please note: I keep updating this list, and updates aren't showing up on reblogs. Please check the original post for the most up to date list.

Sooo this is going to be a long comprehensive list. I got back to this game after a long time and with a different computer, with a dedicated graphics card, hurray! It made me want to return to making things, so while gathering back all the necessary stuff, I've complied this list. It might be is updated as I go along, but these are the main things I use. Maby one day i'll even finish something. So here are my go-to resources & tutorials; I'm posting it here for safekeeping, and hopefully others will find it helpful. Everything that's listed is here free. So many wonderful things for free under the cut.

Programs – General:

Creating: Blender. Blender Addons: 3D Print Toolbox – comes with blender, enable it from within the program. Originally for 3d printing. Good for fixing flipped normals, and some quick general repairs. Source Tools And source tools wiki – for exporting as SMD!!!! (SimPe: to enable bump maps for the mesh on import). GMDC Addon for Blender 4.0+ by Nopke.

GIMP. GIMP Addons: G'MIC-Qt. Resynthesizer. Nvidia dds?. Doesn’t it come with Gimp?

Other: Nvidia Texture Tools Exporter (iirc it works with all graphic cards that are compatible, doesn’t require Nvidia). For making Normal / Bump / Cube Maps. For high quality compression.

NormalMaps - Online, For making all types of maps, has good setting menus. A very cool tool.

Converting: Umodel, for Unreal Engine (Static meshes: export as gtlf.2. Animated meshes: export as psk. Requires Add-on). AssetStudio, for Unity. AC Viewer, self implied (+ USD Addon for blender). QuickBMS* and support forum, for basically everything else. (don't forget the required scrips, down the same page). *I haven’t tested it fully yet, but it was recommended here. A tutorial for it is listed further down. Works like a charm.

UV Mapping: UV Mapper, Classic (free) and the most recent Demo (for visualization).

Programs – Sims:

Never Mind the Bollox, Here's Osab and MAGIkarp to the rescue!

Latest version of SimPe, works with a non-default installation path. Chris Hatch's updates.

Home Crafter installation, Post by Huge Lunatic at Sims2Artists.

Repository Wizard, by Pick'N'Mix Mods. A game changer.

DBPF Compare, by Pick'N'Mix Mods.

Object Relocator, also by Pick'N'Mix Mods.

SMD Tools, by Lazy Duchess.

The Compressorizer, by JFade – Lazy Duchess's edit.

Bulk Rename Utility, to change file names in well, bulk. As explained by io here.

Lot Adjustor, by Mootilda at MTS.

Tutorials:

Override the game's graphic settings via Nvidia, as explained by iCad. The settings to Nvidia Profile Inspector she linked to at MTS have been deleted for some reason, here they are via WebArchive.

Meshing in Blender:

Mesh Optimization Info (and links), by Crisps&Kerosene.

Additional - Reducing Polycount:

Tutorial, by Flaming-Chickens (another username on other sites perhaps?)

Edge – Un-subdivide, a quick one by CG Link.

Transfer high poly details to low poly object in Blender, by 3Dnot2D.

Shrinkwrap Modifier - Blender Tutorial for Beginners - Basics, by in2vert.

Placeholder for this Addon that I want to try but haven't found, something for AR that was on facebook's defunct AR.

Scaling tips, by Blender Secrets.

How to fix inverted/ flipped normals, by ipaintsmallthings.

Converting: How to Extract 3D Models, Textures, Music from Unreal Engine Games, by iwanMods.

Extract 2D/3D/SFX Unity Assets fast & easy from your Unity Game, by iwanMods as well.

How to use QuickBMS, by darkhorse.

Guide to Converting 3t2 and 4t2 Part 01 and Part 02, by Chiaroscuro/tenlittlepandas.

Converting TS4 Windows and Doors, by Crisps&Kerosene.

Using Different Material Maps as Shading/Details for Base Texture, in Gimp or Blender, by Pineapple Forest & Crisps&Kerosene: https://www.tumblr.com/crispsandkerosene/764893644571525120/great-info-thats-the-reason-some-conversions?source=share

Texture Editing in GIMP:

Using Gimp Add-ons: G'MicQT. Resynthesizer. Both by Davies Media Design. This guy's channel for Gimp in general – here's a good one to begin with. And another one about layer masks.

Making a texture Tile Seamless: 1. My favorite - How to Make Seamless Textures for Cinema 4D - 3 Levels of Photoshop Wizardry using iPhone Photos, by School of Motion.

2. Simple Trick for More Realistic Texture Patterns in GIMP, by Davies Media Design – Quick and simple, using the Resynthesizer plugin. Good for patterns.

Making walls in SimPe out of a square texture, with minimal quality loss. To be written.

SimPe: Cloneable Objects: A List of Good Objects for Cloning, by IgnorantBliss at MTS.

Huge Lunatic's Tutorials, Her website.

Object Creation for Absolute Beginners, by Moune.

Sims 2 start to finish Object Creation Tutorial, by JWoods, Numenor, Lethe_s & IgnorantBliss.

The Material Definition (TXMT) Guide, by PixelHate – very comprehensive. Part 5 is about Bump/ Normal maps.

Null (Texture-less) Groups, by Skell. For bodyshop, for Objects see an elaboration by Midge the Tree below.

Crisps&Kerosene discovered how to add specular maps to objects! It's incredible there are still new things to discover in this ancient game.

More on Specular Maps, by Pineapple Forest.

Making new flooring & walls with SimPE, by Charisa. Includes adding Bump/Normal maps. She added a file to clone from in the comments below. It works for normal maps as well. Here's cool discovery in the game files.

Expanding footprint: a mini tutorial, by Deedee.

How to add correct drop shadows to objects, by Yuxi, via Wayback Machine.

Making Objects Viewable in Neighborhood View, by iCad.

Making Objects Visible In Build/Buy Mode, Invisible In Live Mode, by Midge the Tree.

Making Seasons-Friendly Trees, by Echo.

Io/ Serabiet's resources list, mainly for Bodyshop but not just.

Pineapple Forest's Tutorials, useful tips for efficiency and optimization.

MTS modding forum in General.

The Sims 2 Tutorials, on Tumblr. A database, is more updated.

Sims2Artists tutorials section.

LeeFish modding forum.

Garden of Shadows, Tree of Knowledge section.

Troubleshooting: What to do if you get a System.OutOfMemoryException Error, SimPe Forum, via WayBack Machine. Thank you @fanseelamb for the find.

How to read object error logs: I just want to know what causes it!!, by Episims.

Common TS2 errors, by Midge the Tree.

General game fuckery: How to Stop Sims 2 Crashing (Memory Allocation Fix and 4GB Patch Repair), by Jessa.

Graphics card problems, LeeFish forum.

Graphics help - DIY, by Kiri. How to fix faulty Texture Memory allocation, and the problems that stem from it. Tumblr can't handle anymore hyper links so here it is: https://celebkiriedhel.tumblr.com/post/189431721483/graphics-help-diy

General: Switching between save folders without renaming them, by Nopke.

Resources:

3D Models Online*: Various furniture designers' websites: Porada, Zanotta, Muuto, Hay, Poltrona Frau, many luxury furniture designer basically.

3D Warehouse, belongs to Sketchfab (get the Collada files).

Scan the World.

Wikimedia Commons. And more.

*(NOT OPTIMIZED).

Textures: Architextures.

Fabrics & Wallpapers: Natural Stones: Wall Plasters:

iCad's Woods. Shastakiss's Cluedo Metals, Yeti Metals, Pirate Woods. Goat's Woods.

Textures from other games: Dishonored, Thieve and much more, by Saricoya at GoS. Dreamfell by io.

Resource sharing threads at Garden of Shadows.

SimPe - General: CEP Extras list, HugeLunatic at Sims2Artists.

TXMT settings for different materials, by Hafiseazale.

Extended SimStandardMaterial Shader for the Sims 2 + Optionally Brighter Sims, by Crisps&Kerosene.

Custom CubeMaps, by Crisps&Kerosene.

Shiny TXMT Settings & Cube Maps Packs, by Pineapple Forest.

Build/ Buy: Templates for Recoloring Maxis items; MTS Templates sction, Hafiseazale (+cc), ZeroDark.

Template for Seasonal Trees, Gwenke at Sims2Artists.

Making Roof Recolors, Tutorial & template by Numenor, great template by iCad.

Pack for making food clutter usable, by DeeDee.

CAS: Default Makeup Packages - BYO Packages, by Huge Lunatic.

Body shape, Io/Serabiet on Tumblr.

Skin template, Io/Serabiet on Tumblr.

Hair texture, iCad.

Color Actions, Pooklet on Tumblr.

That's it for now.

Edit: forgot about CEP extras. Added more links. Edit 02: Added Troubleshooting section under tutorials.

#ts2#ts2 resources#ts2 creation resources#ts2 resources for creators#the sims 2#sims 2#resources#ts2 cc#sims 2 cc#the sims 2 cc#well its cc related#sims 2 resources#the sims 2 resources

67 notes

·

View notes

Note

okay so I went to the zoo today and it was so hot and sunny and I wore a sundress that was long but everytime I sat down or propped my legs up it kept riding up my legs. Can I get a small Drabble on how heelead would react had he been there with me? Just a small one? Pleeeeeeease???

Sure. I have time to draft a small something for you. Apologize for it being rushed by I’m at least semi-proofreading as I go. If it’s all good with you, this one will be a heethan Drabble. Seems appropriate.

Warnings: Heethan is a bit unhinged (triggered by you wearing a dress), dominant yandere, yandere love, some non/dubcon acts, sexual acts in public, some cursing…think that’s it. Just the usual.

“Hey. Hey!” Your yelps catches his eye as the wind rushes in between your legs, scooping and flaring the hem of your skirt to ride up your thighs. You ball up the loose material in hand, pushing it down to fall at its rightful length. Heeseung stands there with an aloof, but stern expression. His eyes darken, becoming glossy as he refuses the urge to blink. His jaw is clenched, and his teeth grind while his tongue pokes at the inner cheek.

Initially he didn’t care for the dress—it was too long and far more conservative than what he would have liked. It would have been nice had you opted for something that didn’t necessarily reveal your derrière, but perhaps a little leg wouldn’t have been so bad. When you stood firm about your choice in attire, he figured for the sake of time—and yourself, that he’d make you pay for it all later, once he had time to calm down from the minor frustration of seeing nearly the entire length of your beautiful legs covered. On such a warm, glowing day nonetheless.

But when the wind caught the edge of your skirt and its lining just right, and raising it, there was something so fine and delectable in the manner of how the bulk of material coiled around your upper thighs. Just below your panty line.

The way your hand desperately attempted to smooth it down, but the wind remained as the victor, and continued to lavish you with strong gusts. It was sexy.

The way the skirt kept slinking upwards as you shifted in your seat. Your expression grows frustrated from fighting against it, while his transfers to the look of a feral beast, watching as raw meat dangled in front of his curled snout. A deep instinctive urge rises from deep inside his chest as he watches the skirt go higher, briefly showing off the fabric of said panties—lace. Fuck yeah.

Whether you wore it because you knew it was his favorite, or if it was simply a matter of selected choice at random, it didn’t matter. In you, lace looked just as fitting as frosting on cake. He loved it. What he loved more was that you having it on, proved that you were not only just a doll—his one and only babygirl, but you were also a good doll.

His good girl.

The proof was in what was underneath that skirt. Without even realizing, he took back the harsh gesture in his earlier non-verbals, all expressing distaste for the skirts length. He never knew that the act of coverage slowly unveiling the prize was so appealing. That urge was beginning to coil up in his gut, causing a tingling rage that began to pulsate his member. It started to throb, as if it was breathing on its own. He wasn’t going to be able to wait any longer. Especially not with you blushing, gripping and pulling your skirt, holding it in place, on the verge of tearing up. Oh yeah.

“Come here.” He quietly tells you while raising his hand. You slightly pout as you took hold of it, and let him lead you to an obscured area. You assumed that he noticed the humiliation painted on your face, and was merely taking you to a private spot to fix yourself. Little did you know, he was about to do all the fixing for you.

“Stand here.” His tone continued to be calm and quiet, a bit elusive as he glares down at you through heavy lids. “Strip.”

You looked up, slightly gasping and rather appalled by his sudden demand. His tone went from gentle to firm; a bit demeaning actually. “W-what?”

“I said strip.”

He was serious. His expression and tone remained unaltered. Was he actually going to make you strip in public? Despite being in a secluded zone, away from open view, he couldn’t possibly think this was a suitable spot to do what those dangerous, bedroom eyes entailed. Tucking in our chin, eyeballs shifting to the side, you jerked the skirt up, when he stops you. “Slowly…”

You looked up and watched as he crossed his arms, stirring a look of slight annoyance as if you were purposely defying him. “Drop it.” His voice was still so stark calm. You did as he bids, and let the material fall back down to rest against your ankles. “Now, grab it and slowly drag it up.”

Perhaps he knew you all too well, because the way his dangerous eyes peered down at you, he could already tell that you were beginning to soak through those lace panties. He could smell it. And believe him, it was the sweetest scent that made his mouth water.

Your breath hitches as you watched him glare at you. The firmness in eye contact never breaks as he starts to lean his head back, and those black beady eyes glow from the shadow underneath the bill of his cap. You gush at the sight of that forceful, yet intimidating feature. What a man.

You drag the lace lining slowly, letting it subtly graze against your skin as it rises higher, and higher. You let out a breath, shaken and unsteady, as it slowly seeps beyond those small, pursed lips. Of course, you had on that favorite red color he liked—cherry red. All the better.

Your fingers and thighs begin to tremble, while your chest heaves. Watching as you attempt to force each breath to come out steady, but failing, he feels himself breaching a snapping point, when suddenly he hears you shakily spill out in such a chiming, bell-like tone…

“daddy?”

Snapped.

Without so much as a predatory command or heads up, he dives down and immediately grabs hold of your hips. Swooping a hand underneath, he loops your thigh up and over his shoulder, making you inherit the position for what was coming. Ripping those delicate lace panties, he’s shreds them as he forces his fingers to tear through the soft mesh pattern. Reaching up, he harshly grips the button front resting against your cleaver, and tears it apart. Buttons snap and fly off to the side as his cool hands warm themselves on your breasts. Huh…no bra. Good girl.

Squeezing and digging his fingers into the softness of those fleshy mounds, he reaches down and slips a finger in between your folds, avoiding direct penetration. Not yet.

His tongue swirls, licks, and drags up towards your clit. He coils his oral muscle around it, flickering the tip as his nose digs in. Tasting you, he inhales and releases a deep moan as he suspends your weight higher, causing you to lose footing with the one that remained touching ground. Your ankle dangles against his back shoulder as he forces his hold on you. He digs his fingers into your thigh whenever you jerked from the heightened sense of stimulation, causing you to have a moment of relapse and removing your leg off his shoulder. But he won’t let you off the hook so easily, especially when you’re spewing out moans that carried a hybrid tone of his name and gasps for air.

With tender kisses against the inner flesh of your leg, just underneath where those juicy, plush lips laid nestled, he takes a moment to show you his softer side in appreciating your skin. But it only lasts for just a few seconds, then he dives back in like a hungry wolf. Starved for your moans, he wants to hear more. Wants to hear you call out his name.

“Open.” He mumbles as he extends a hand upward, able to reach your throat and grab on while demanding you to open your legs back up. The sensation was too great, you kept clenching your thighs together, trying to restrict his access. But you knew better.

With your dragging against the planked wall, your body shifts up and down as you absorb the momentum of his act. The way he dove in, pushing his nose and lips against you, his tongue deeper inside you, your body hand no choice but to take in everything he was willing to give. And he gave a lot.

You choked out your moans, gasped for air, and breathlessly call out his name. Your stomach trembles, and your chest extends towards the sky, leaving your head to lay restlessly aback while you swallow nothing but the warm air. Your body is chaotic—not knowing whether to breathe or scream as you come undone, feeling him slurp and clean you entirely too well.

When all was said and done, he stands and places small, petal kisses on your lips, while his grip on your neck remains—and even tightens. Amidst receiving those petal kisses, you watch as he takes his free hand and dives it down. The sound of his belt unbuckling snd jeans unzipping causes your chest to panic as you grow both dreadful—and delighted, in what he was about to do. “Did you cum for daddy?” He asks laconically while placing another soft kiss to your lips. You nods with your brows slightly furrowed in despair, but also yearning for it.

“Good.” He calmly spits out. He makes you stare into those beady eyes as he swipes the tip up and down in between your folds, pushing it against your clit. “My turn.” For a moment, you watched as those eyes widened rather psychotically as his level of possessiveness grew. He was going to claim you in the way he does best…by making you scream. Whether anyone hears you is all entirely up to how good you could keep yourself quiet. Like a good girl, right?

“Say ‘please, daddy, please.’ And I might let you cum one more time.”

You nod as you bit down on your lower lip. Eyes watery, and cheeks flushed. He smirks and releases a dark chuckle. That damn smirk of his. It does something to you, every time.

“Ready?”

You watched his smirk grow wider as you felt the tip of his throbbing member begin to enter.

“Ready or not, here I come.” >:)

#heeseung x reader#heeseung scenarios#heeseung smut#enha x reader#heeseung hard hours#heeseung hard thoughts#heeseung fanfic#enhypen hard hours#enhypen smut#enha heeseung#yandere heeseung imagines#heeseung yandere#yandere heeseung#heeseung imagines#yandere enhypen#heeseung au#heeseung x you#enhypen heeseung smut#enha smut#anon answered

138 notes

·

View notes

Text

lancer character extreme ramble edition below but the tldr is yeah yeah everyone makes the jokes about tgirl horus pilots but what about a horus mech that actually does very much trans your gender. character so fun and complex i had to draw a diagram:

the long version:

we had to rework some things due to a last minute module switch (he was going to be a little older and number and due to needing to be in mech school we had to roll the timeline back to immediately after the incident, but in summary:

CALLSIGN: Firebird

The Royal Karrakin Foundries were conducting some experiments on a Horus-pattern Pegasus class unit, referred to as "The Asset" which had a dual-pilot chassis (very very weird).

One particular graduating class at a low level flight and mechanic school academy was targeted and graduates were offered a high paying job requiring a degree of security clearance very far away.

This is what we call a bold-faced lie

On record everyone is just working somewhere far off and deployed on secret tasks. Firebird is aware that there was a number of unquantifiable "mistakes" (there is a lack of appropriate records) that resulted in the death of multiple rounds of test pilots alongside some of the mechanical staff.

Eventually, two graduating students (Aphra and Mavet) were selected as the next round of candidates due to situational proximity of seemingly random biometric markers (CBC, LDL, ESR, CRP-, and some unknown)

This seemed to work, and Aphra and Mavet began to build a coworkerly relationship, though they also had fairly good chemistry, and Aphra at least began to develop feelings for the man.

Both chose callsigns for each other based on a shared affinity for old music - Aphra was CALLSIGN: Faun, and Mavet was CALLSIGN: Firebird

The rationale for Aphra's callsign was never explained to her.

During a test instance, there was what is referred to internally as "The Incident." It is unclear to both pilot and observers what occurred, but the surviving pilot suspects there was a certain degree of raw, hardcore interfacing with something in the machine.

OOC, Mavet made unfiltered contact with the unshackled Ushabti Omnigun and the mech reacted.

Three things happened as a result:

Aphra's corporeal form was reduced into a smear of meat.

The person who was once Mavet was effectively killed - theoretically. It is possible he was incorporated into the Ushabti Omnigun, or one of 20 other options, but what is known to the surviving pilot alone is that his mind was effectively wiped from his corpse. His body also sustained significant blast damage and some degree of permanent neurological injury.

The Pegasus, henceforth dubbed RITE OF SPRING, exploded, incorporating the bulk of Aphra's body into surviving parts of its chassis, eliminating a secondary seat, and patching Mavet's corpse with material from the mech, preserving the mind that was formerly Aphra's in his body.

Legally, Aphra is dead. Metaphysically, Aphra is still around, but would never admit it because legally, Mavet is still alive. He prefers to go by (now his) callsign as he feels if nothing else, he earned the transfer of that name. Firebird is now attempting to reconstruct the Pegasus chassis in pursuit of closure and an attempt to make contact with whatever remains of Mavet.

The Royal Foundaries are overjoyed and consider the experiment a complete and utter success. Mavet was diagnosed with a mild case of memory loss as a result of neurological injury or potential integration of schrapnel. They suspect nothing at this point in time. However, we now have extremely fucked up blood test results due to maybe having a bit of Pegasus meat in us but that's not shared outside the experimental team.... as far as Firebird knows.

And now for the gay pining section of this lancer character:

And this is how the Horus Pegasus-TM made me gay and transgender

What if you can't hate the body you are now stuck in because you loved it before it ever was yours? (It isn't yours)

What if you like it better this way but liking it better feels like an unfathomable sin because This all comes at the expense of someone you never got the chance to love.

We were late on day one of mech school due to guessing our own shoe and shirt size wrong.

Multitrack drifting my body as a prison-temple. Haunting reminder, unfulfilled everything, object of mourning, constant horrible just in your face forever... but you can't change any of it. It's not yours to change and it'd be disrespecting his memory. Blah blah blah blah blah I'm going to go insane.

Current vibe is "everything happens so much" and "can you guys please leave me out of antagonizing the nobility they already hate me and i want to retain my ribs unbroken."

He's retained his own personal memory, etc, personality, but inherited Mavet's muscle memory and preferences. Which is such a blessing-curse because it's like. Oh you never had the chance to ask what food he likes? Well Now You Know. But not because he told you.

Anyway since we're here this is why the naming went the way it did:

Rite of Spring as the ballet about a person chosen to lead their own sacrifice and consumption by the earth. Points also for the funky choreo and ungodly music and riots resonating with Horus Weirdness. That one line about the lead ballerina dancing, instead of out of love of leaping, as if she hates the very ground she stands on. The mental breakdown barely avoided during the choreography. The multiple people quitting production.

The unfathomable pitching of the bassoon. The superimposing of a dominant 7th on a major triad half a step higher. Alternating 2, 4, 2, 5, 1, 6, but notating in 8 sometimes. How many times do you want to change signatures and tempos? Yes. What do you think about constantly going in and out of 5/16. Let's do 444 time signature changes and oh a delicious bar of 11/4. Fuck it, submelody referred to as the Sentence of Doom.

Firebird callsign is 1 bit phoenix joke (why it was retained) and 1 bit it also being a production involving the ruination of a man's career and several marriages. The endless searching in some versions for the live bird based solely on one tail feather. Faun is for the prelude to the afternoon of, because both involved Nijinsky and were the fucketh around with ballets.

Everybody say thank you to Frank Bidart

30 notes

·

View notes

Text

Sacrum of the Daspletosaurus wilsoni holotype (Sisyphus)

Sacrum of the holotype of Daspletosaurus wilsoni with a significant portion still covered by concreted sandstone.

Steve Clawson and I started out sharing the duty of bulk matrix removal with heavy duty air scribes such as the ZOIC Bronto (ZPT-BR). I took over and got the matrix down close to the bone and then switched to the ZOIC T-rex (ZPT-TR) with a chisel tip for somewhat more precise prep around the centra. For even finer detail I used the ZOIC Velociraptor (ZPT-VR).

In addition to mechanical preparation, acid prep was also conducted using vinegar to scrub and dissolve matrix in hard to reach places.

Once the centra were cleaned, I rotated the sacrum and worked on the processes. The matrix was mostly sand with far less concreted material.

Sacrum with the processes and zygapophyses facing forward

I constructed a transfer prep cradle using a thin layer of ethafoam, a layer of tyvek cloth as a water barrier, and two layers of fiberglass and hydrocal dipped in plaster of Paris.

Transfer cradle (underside) with the field jacket on top

The side of the specimen that was exposed in the field was in slightly worse condition than the underside that was in the matrix. A majority of the bone on the anterior end was weathered and abraded, giving it a cracked texture and making it susceptible to destabilize when exposed to acetone. It took less time to clean than the first side because there was no concretion, only sand.

side of the specimen that was facing up in the field

It was then flipped again for the display cradle to be made. Some consolidant leaked through to the underside while it was being cleaned, so one final bit of acetone scrubbing was done to make it presentable.

The display cradle was made and the sacrum was flipped onto it. The unweathered side is facing up.

To prepare it for display, the sacrum was treated with a coat of thin paraloid and cracks and crevices were filled with grey Apoxie putty (not to be confused with epoxie) as to not blend in with the bone.

the sacrum resting in its display cradle

This was my (literal) biggest solo project to date and the largest element in Sisyphus' skeleton. It took about 300 hours from start to finish.

#fossil#paleontology#daspletosaurus wilsoni#paleo#palaeo#paleoblr#daspletosaurus#dinosaurs#prehistoric#cretaceous#tyrannosaur#fossil prep#badlands dinosaur museum#sisyphus#portfolio

117 notes

·

View notes

Text

While Quiet Zero (and each Gundam) utilized massive amounts of Permet, Suletta and Ericht’s shared desire to break free from Quiet Zero manifested as linguistic code within the Permet, triggering an unprecedented data storm among surrounding Permet particles. This exponential data explosion, never before witnessed by humanity, overwhelmed even the GUND Format’s network-based tolerance thresholds. Unable to process this surge, the system released excess data as heat. The resulting information entropy generated enough thermal energy to reduce Quiet Zero and the Gundams’ component materials to particles, leading to their dissolution. When Aerial vanished alongside the Calibarn, Ericht appeared to have disappeared with it. However, the surrounding Permet particles, through repeated aggregation and condensation, successfully preserved her individual biological information within crystallized Permet. This essence found its way into “Hot” the keychain Suletta carried. The decomposition of Quiet Zero’s massive bulk into particle form created a region of extraordinarily high Permet concentration in the surrounding space. Normally, Permet is inherently unstable and readily breaks down without systems to maintain it. However, within this newly formed “Permet Sea,” Suletta accomplished something remarkable: she successfully stabilized the volatile Permet into crystal form, enabling Ericht’s consciousness to transfer into Hot. In other words, without Quiet Zero’s dissolution, preserving Ericht’s existence would have been impossible.

Ok so Suletta and Ericht literally performed magic to free Ericht from Quiet Zero.

8 notes

·

View notes

Text

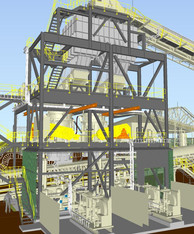

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm's reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client's requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.'s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

3. Bulk Material Treatment

Treatment of bulk materials, whether it's refining, purification, or simply grading, is a complex process. Little P.Eng.'s role in this domain is critical.

Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it's transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

Material Integrity: When transferring materials, there's a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.'s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren't just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that's not just equipped to meet these demands but one that's committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they're not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

Industries served through our Bulk Material Handling Engineering Services

Grains

Mining

Mills

Metals

Manufacturing

Maintenance

Fabrication

Agriculture

Packaging

Safety

Fire & Explosion

Ship/Barge Loading & Unloading

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

Discrete Element Modeling (DEM)

Calculation based modeling

Allows for visualizing results

Particle velocity

Forces (shear and normal) and moments (bending and torsional)

Acceleration and material scatter

More than just flow simulation of bulk materials

wear Patterns

Mixing

Center loading

DEM Benefits

Reduced Dust Levels

Reduced Noise

Reduced Chute Plugging

Better Conveyor Tracking (Center Loading)

Reduced Belt Cover Wear

Reduced Chute Wear

Reduced Equipment Wear

Structural Engineering Services

Foundation Design

Concrete Structure Design

Steel Structure Design

Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

Storage Solutions:

Design and layout of silos, bins, and stockpiles

Assessment of material flow properties to reduce issues like bridging or rat-holing

Conveyor Systems:

Design and optimization of belt, screw, chain, and pneumatic conveyors

Selection of appropriate conveyor belts, idlers, and drives

Loading and Unloading Systems:

Railcar and truck loading/unloading facilities

Ship and barge loading/unloading equipment

Reclaiming Systems:

Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

Size Reduction Equipment:

Crushers, grinders, and milling equipment

Sizers and chutes to manage particle sizes

Screening and Sorting:

Vibrating screens, trommels, and sorters

Density separation using jigs or cyclones

Feeding and Metering Equipment:

Feeders for accurate and controlled material flow

Rotary valves, weigh feeders, and volumetric feeders

Material Transfer:

Chutes, hoppers, and gates

Transfer tower and junction house design

Dust Control and Suppression:

Dust collection and filtration systems

Wet suppression and foam suppression systems

Safety and Environmental Considerations:

Explosion and fire protection in dusty environments

Erosion control and spill prevention

Flow Aids and Devices:

Vibrators and air cannons to aid material flow

Flow liners and internal coatings

Bulk Material Testing:

Evaluating flowability, abrasiveness, and other material properties

Moisture content and material density testing

Rail and Marine Infrastructure:

Rail siding design and layout

Port and harbor infrastructure for bulk material export/import

Automation and Controls:

Automated monitoring of material levels in bins and silos

Control systems for conveyor speed, material flow, and routing

Maintenance and Wear Protection:

Wear liners and abrasion-resistant materials

Maintenance strategies and schedules

Bulk Material Transport:

Pipeline transport for slurry and other bulk fluids

Pneumatic transport systems for powders and granules

Economic Analysis:

Cost estimation for bulk material handling projects

Return on investment (ROI) calculations

Regulatory Compliance and Standards:

Ensuring designs meet relevant industry standards

Adherence to safety and environmental regulations

Continuous Improvement and Upgrades:

Evaluation of existing systems for performance enhancement

Retrofitting and upgrading older infrastructure

Consultation and Advisory Services:

Providing expertise on specific bulk material challenges

Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

Little P.Eng. Engineering

Structural design

Compliance

Mechanical design

Energy efficiency

Single-boom spreaders

Bulk material transfer

Bulk material transport

Client-centric approach

Environmental impact

Material handling

Treatment facilities

Conveyor systems

Infrastructure design

Pneumatic transport

Refining

Material grading

Transfer points

Dust suppression

Material contamination

Bulk material degradation

Silo design

Loading docks

Workflow optimization

Advanced ventilation systems

Risk assessment

Sustainable engineering

Material integrity

Client testimonials

Automation in material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Compliance#Mechanical design#Energy efficiency#Single-boom spreaders#Bulk material transfer#Bulk material transport#Client-centric approach#Environmental impact#Material handling#Treatment facilities#Conveyor systems#Infrastructure design#Pneumatic transport#Refining#Material grading#Transfer points#Dust suppression#Material contamination#Bulk material degradation#Silo design#Loading docks#Workflow optimization#Advanced ventilation systems#Risk assessment#Sustainable engineering#Material integrity#Client testimonials

0 notes

Text

About agri world on Lords of Silence by Chris Wraight

Najan is an agri world. There are templates for such places, drawn up in the fathomless past and never altered by the Administratum. All agri worlds are of similar size, located in similar orbital zones within their void systems and subject to specific exposure to a prescribed spectrum of solar radiation. Their soils have to be within a tight compositional range, and they have to be close to major supply worlds.

The Imperium is not a gentle custodian of such places. After discovery of a candidate planet, the first fifty years are spent in terraforming according to well-worn Martian procedures. All pre-existing life is scrubbed from the rocks, either by the application of controlled virus-chewers or by timed flame-drops. The atmosphere is regulated, first through the actions of gigantic macro-processors and thereafter by a land-based network of control units, more commonly referred to as command nodes. Weather, as least as generally understood, disappears. Rainfall becomes a matter of controlled timing, governed by satellites in low orbit and kept in line by fleets of dirigibles. The empty landscape is divided up into colossal production zones, each patrolled by crawlers and pest-thopters. Millions of base-level servitors are imported, kept at the very lowest level of cognitive function but bulked up by a ruthless level of muscle-binders.

Soon after this process completes, every agri world looks exactly the same – a flat, wind-rummaged plain of high-yield crops swaying towards the empty horizon. A person could walk for days and never see a distinctive feature. Not that anyone sane would choose to walk in such places – the industrial fertiliser dumps are so powerful that they turn the air orange and make it impossible to breathe unfiltered. A single growing season exhausts the soil completely, requiring continual delivery of more sprays of nitrates and phosphates, all delivered from the grimy berths of hovering despatch flyers. The entire world is given over to a remorseless monoculture, with orthogonal drainage channels burning with chem-residue and topsoil continually degrading into flimsier and flimsier dust.

But that doesn’t matter. A planet can be driven like this for thousands of years before it eventually keels over and becomes a death world. The quality of the crops gets steadily worse, but the quantity can be sustained almost indefinitely, assuming that supply lines are maintained and imports remain consistent. At the end of every season, the great harvester leviathans are stoked up and dragged from their pens and let loose on the grey fields, smokestacks belching and tracked under carriages sinking deep. These massive creatures of high-sided metal and intricate pipework, the smallest of which are a hundred metres long, crawl across the blasted prairies, sucking up every last speck of pallid grain and piping it directly to antiseptic internal hoppers. Feed-landers come down from high flight, dock with the still-trundling leviathans and extract the raw material, from where it is taken into the city-sized processor vats, blasted with antibiotics, smashed, burned, crushed, then stamped and packaged. Once ready for transport, containers are dragged up into orbit aboard swell-bellied landers, ready for transfer to the void-bound mass conveyers, which deliver the refined product to every starving hive world and forge world in their long circuits.

There is a quaint tradition in the various propaganda departmentos of the Administratum of marketing agri worlds as quasi-paradises, free of the squalor and overcrowding of a standard urban station, and full of bucolic ease. Vid-cards are dropped into communal hab-warrens, extolling the virtues of a life lived outdoors with the sun on your back and a ruddy-faced boy or girl – subject to preference – by your side. In reality, life on an agri world is as unrelenting, back-breaking and monotonous as the vast majority of other Imperial vocations. There are no trees laden with glossy fruit, only kilometre after kilometre of hissing corn. There are no gentle strolls under the warming sun, only punishing work details in rad-suits, leaning into the dust-laden winds that howl around the equator with nothing to halt their rampage. Once the new arrivals have made planetfall and found this out, it is too late. Crew transports arrive on agri worlds full and leave empty.

There is a saying among the indentured workers – you come for the soil, you end up part of it.

3 notes

·

View notes

Text

How is offset printing different from digital printing for commercial use?

When it comes to commercial printing, choosing the right printing technology is essential for delivering quality, consistency, and cost-efficiency. Two leading technologies dominate the market: Offset Printing and Digital Printing. Each has its strengths and ideal use cases, but understanding the key differences between them can help businesses make the right decision for their printing needs.

At Prakash Machineries Pvt. Ltd , we specialize in high-performance offset printing machinery and cater to clients across India and abroad who need bulk, high-quality print jobs at competitive costs. In this blog, we’ll explore how offset printing compares to digital printing, particularly in a commercial setting—from print quality to scalability, cost, and beyond.

1. Printing Process: How They Work

Offset Printing: Offset printing involves transferring an inked image from a plate to a rubber blanket, and then onto the paper. It requires preparation of printing plates, making it ideal for large, consistent print runs.

Digital Printing: Digital printing doesn’t use plates. Instead, it uses toner or inkjet technology to print directly from a digital file onto paper or other substrates. It’s a more straightforward, plug-and-play solution for shorter print jobs.

✅ Verdict: Offset is ideal for high-volume runs; digital is best for quick, low-volume jobs.

2. Print Volume & Cost Efficiency

Offset Printing: The initial setup (plates, calibration, and ink) takes time and effort, but once set, the cost per unit significantly decreases as the volume increases. This makes it very cost-effective for bulk printing—like newspapers, brochures, packaging, or books.

Digital Printing: There’s no setup cost, which is perfect for small quantities. However, the cost per print remains consistent and doesn’t reduce with larger volumes, making it less economical for high-quantity jobs.

✅ Verdict: Offset is more cost-efficient for large volumes; digital is better for short runs.

3. Print Quality and Color Accuracy

Offset Printing: Known for superior image clarity, sharpness, and color consistency. With CMYK and Pantone matching, offset offers precise color reproduction and smooth gradients—crucial for branding and packaging work.

Digital Printing: While digital quality has improved, it can still lack the depth and richness of offset printing, especially in solid color areas. It also offers fewer options for special inks or custom finishes.

✅ Verdict: Offset offers higher and more consistent print quality, especially for color-critical jobs.

4. Customization and Personalization

Offset Printing: Not ideal for variable data printing. Changing text, images, or names requires re-plate and re-setup, making personalization expensive and time-consuming.

Digital Printing: A perfect fit for personalized content, like invitation cards, customized mailers, ID cards, or certificates. You can change data from sheet to sheet without stopping the press.

✅ Verdict: Digital is better for customization and one-off jobs.

5. Turnaround Time

Offset Printing: Requires setup time for plates, calibration, and initial proofs, which may delay the start of production. However, once running, it prints very fast in large volumes.

Digital Printing: Minimal setup time—just send the file and start printing. It’s excellent for urgent jobs or small quantities needed on short notice.

✅ Verdict: Digital printing is faster for urgent, small orders; offset wins for speed in large runs.

6. Material Versatility

Offset Printing: Can print on a wide range of substrates, including textured papers, thick boards, Kraft sheets, and specialty stocks. Also suitable for large-format sheets.

Digital Printing: Limited to standard sizes and types of media, depending on the printer. Some heavy stocks or coated papers may not be compatible with all digital machines.

✅ Verdict: Offset offers more flexibility with materials and finishes.

7. Environmental Impact

Offset Printing: Traditionally uses more water, chemicals, and setup materials. However, modern offset machines like those from Prakash Machineries Pvt. Ltd are becoming more eco-friendly with features like:

Low-ink wastage

Recyclable plates

Alcohol-free dampening systems

Digital Printing: Produces less waste per job due to on-demand printing, but toner cartridges and ink packaging contribute to waste and can be costly to recycle.

✅ Verdict: Both have environmental pros and cons, but modern offset presses are catching up in eco-friendliness.

When Should You Choose Offset Printing?

Offset printing is your best option if you need:

Large volume production (e.g., 1,000+ copies)

Superior image quality and color matching

Cost-effective bulk printing

Durable, long-lasting prints

Custom paper and finishing options

Ideal use cases: Newspapers, catalogs, packaging, brochures, books, corporate stationery, paper bags

When Should You Choose Digital Printing?

Digital printing is suitable for:

Low-quantity, quick-turnaround jobs

Personalized or one-off prints

Prototyping or samples

Frequent content changes

Ideal use cases: Business cards, photo books, small marketing runs, ID cards, direct mail campaigns

Both printing methods have their place in today’s commercial print world. Offset printing remains unmatched for high-volume, cost-effective, and professional-grade output, making it the backbone of commercial production in 2025. Meanwhile, digital printing is perfect for flexibility and speed in short runs.

At Prakash Machineries Pvt. Ltd , we help businesses across India and abroad unlock the power of offset printing with our advanced machinery—including web offset, mini offset, and packaging solutions. Whether you're scaling up your operations or starting a new print business, our machines give you the quality, reliability, and efficiency you need to succeed.

Need help deciding the right printing solution for your business? Contact Prakash Machineries Pvt. Ltd today for expert advice and customized printing machinery solutions.

#paper bag manufacturer#paper bag#v bottom#square bottom#paper#machine#cake#chris sturniolo#cooking#critical role#dan and phil#chocolate#delicious#breakfast#alien stage#baking

1 note

·

View note

Text

Building a cargo spaceship capable of exploring our solar system based on current technology and the knowledge gleaned from our understanding of engineering, science, and chemistry requires us to work within practical and realistic constraints, given that we're not yet in an era of faster-than-light travel. This project would involve a modular design, reliable propulsion systems, life support, cargo handling, and advanced automation or AI. Here’s a conceptual breakdown:

1. Ship Structure

Hull and Frame: A spaceship designed for deep space exploration needs a durable, lightweight frame. Advanced materials like titanium alloys and carbon-fiber composites would be used to ensure structural integrity under the stress of space travel while keeping the mass low. The outer hull would be made with multi-layered insulation to protect against micrometeorites and space radiation.

Dimensions: A cargo space vessel could be roughly 80-100 meters long and 30 meters wide, giving it sufficient space for cargo holds, living quarters, and propulsion systems.

Cost: $500 million (materials, assembly, and insulation).

2. Propulsion Systems

Primary Propulsion: Nuclear Thermal Propulsion (NTP) or Nuclear Electric Propulsion (NEP):

NTP would involve heating hydrogen with a nuclear reactor to achieve high exhaust velocities, providing faster travel times across the solar system. NEP converts nuclear energy into electricity, driving highly efficient ion thrusters. Both systems offer relatively efficient interplanetary travel.

A hybrid solution between NTP and NEP could optimize fuel efficiency for longer trips and maneuverability near celestial bodies.

Cost: $1 billion (development of nuclear propulsion, reactors, and installation).

Fuel: For NTP, hydrogen would be used as a propellant; for NEP, xenon or argon would be the ionized fuel. It would be replenished through in-space refueling depots or by mining water on asteroids and moons (future prospect).

Cost (fuel): $50 million.

3. Power Systems

Nuclear Fission Reactor: A compact fission reactor would power the ship’s life support, propulsion, and onboard systems. Reactors designed by NASA’s Kilopower project would provide consistent energy for long missions.

Backup Solar Arrays: Solar panels, optimized for efficiency beyond Mars’ orbit, would serve as secondary power sources in case of reactor failure.

Cost: $300 million (including reactors, solar panels, and energy storage systems).

4. Cargo Modules

The cargo holds need to be pressurized and temperature-controlled for sensitive materials or scientific samples, while some holds could be left unpressurized for bulk materials like metals, water, or fuel.

Modular Design: The ship should have detachable cargo pods for easy unloading and resupply at different planetary bodies or space stations.

Cost: $200 million (modular design, pressurization systems, automation).

5. Life Support Systems

Water and Oxygen Recycling: Systems like NASA’s Environmental Control and Life Support System (ECLSS) would recycle water, oxygen, and even waste. These systems are key for long-duration missions where resupply may be limited.

CO2 Scrubbers: To remove carbon dioxide from the air, maintaining breathable conditions for the crew.

Artificial Gravity (optional): A rotating section of the ship could generate artificial gravity through centripetal force, improving the crew’s health on longer missions. However, this would increase complexity and cost.

Cost: $200 million (life support systems, with optional artificial gravity setup).

6. AI and Automation

AI-Controlled Systems: AI would manage navigation, propulsion optimization, cargo handling, and even medical diagnostics. Automated drones could be used for ship maintenance and repairs in space.

Navigation: Advanced AI would assist in calculating complex orbital maneuvers, interplanetary transfers, and landings.

Autonomous Cargo Handling: Robotics and AI would ensure that cargo can be efficiently moved between space stations, planets, and the ship.

Cost: $150 million (AI development, robotics, automation).

7. Communication and Sensors

Communication Arrays: High-gain antennas would allow for deep-space communication back to Earth, supplemented by laser communication systems for high-speed data transfers.

Radars and Sensors: For mapping asteroid belts, detecting anomalies, and navigating planets, advanced LIDAR, radar, and spectrometers would be necessary. These sensors would aid in planetary exploration and mining operations.

Cost: $100 million (communication systems, sensors, and diagnostics).

8. Radiation Protection

Water Shielding: Water, which is also used in life support, would double as a radiation shield around the living quarters.

Electromagnetic Shields: Experimental concepts involve creating a small electromagnetic field around the ship to deflect solar and cosmic radiation (early TRL, requires more development).

Cost: $50 million (radiation shielding).

9. Crew Quarters

Living Quarters: Designed for long-duration missions with the capability to house 4-6 crew members comfortably. The quarters would feature radiation protection, artificial lighting cycles to simulate day and night, and recreational facilities to maintain crew morale on multi-year missions.

Medical Bay: An AI-assisted medical bay equipped with robotic surgery and telemedicine would ensure the crew remains healthy.

Cost: $100 million (crew quarters, recreational facilities, medical systems).

10. Landing and Exploration Modules

Surface Exploration Vehicles: For landing on moons or planets like Mars or Europa, a modular lander or rover system would be required. These vehicles would use methane/oxygen engines or electric propulsion to take off and land on various celestial bodies.

Cost: $300 million (lander, rovers, exploration modules).

---

Total Estimated Cost: $2.95 Billion

Additional Considerations:

1. Launch Vehicles: To get the spacecraft into orbit, you would need a heavy-lift rocket like SpaceX’s Starship or NASA’s Space Launch System (SLS). Multiple launches may be required to assemble the ship in orbit.

Cost (launch): $500 million (several launches).

2. In-Space Assembly: The ship would likely be built and assembled in low-Earth orbit (LEO), with components brought up in stages by heavy-lift rockets.

Cost: $200 million (orbital assembly infrastructure and operations).

---

Grand Total: $3.65 Billion

This estimate provides a general cost breakdown for building a cargo spaceship that could explore and transport materials across the solar system. This concept ship is realistic based on near-future technologies, leveraging both nuclear propulsion and automation to ensure efficient exploration and cargo transportation across the solar system.

#canada#canadian politics#space#science#scifi#scifiart#sci fi and fantasy#nasa#nasa photos#elon musk#share#engineering#ideas#ai#scientificresearch#billionaire

6 notes

·

View notes

Text

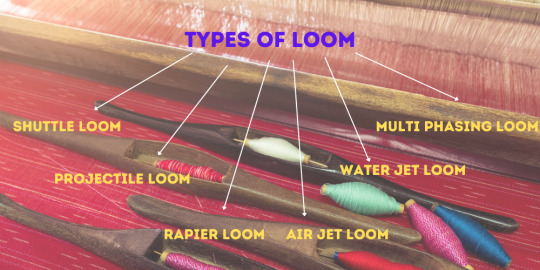

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

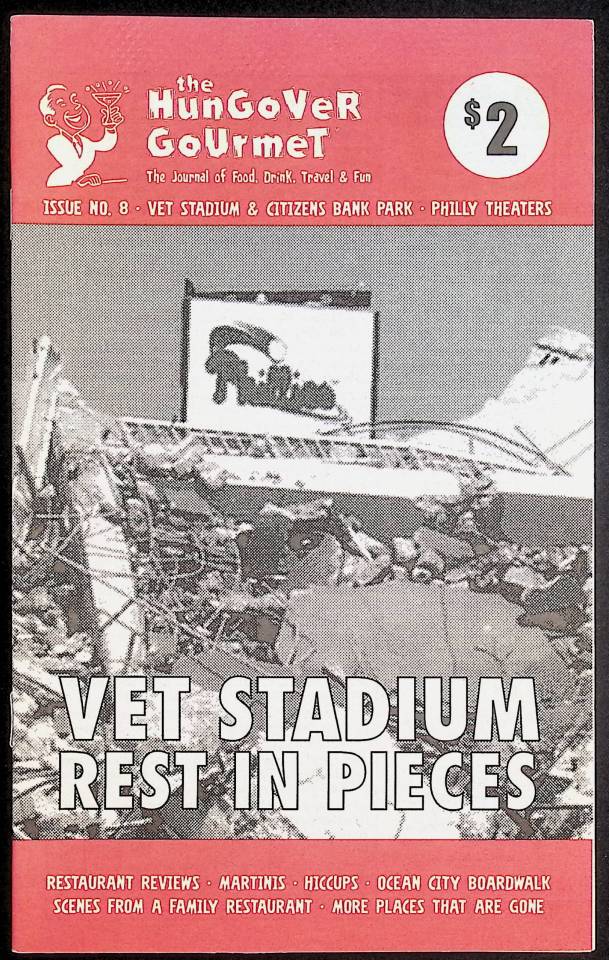

Fanzine Friday #24: Hungover Chili

A slow-cooker brew for the day after

Ingredients

1 lb. bulk sweet Italian sausage

1 lb. lean ground beef