#Automotive Camshaft Market

Explore tagged Tumblr posts

Text

Automotive Camshaft Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Camshaft Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Camshaft Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Camshaft Market is experiencing robust growth driven by the expanding globally. The Automotive Camshaft Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Camshaft Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Camshaft Market Size, Share & Industry Analysis, By Manufacturing Technology (Cast Camshaft, Forged Camshaft, Assembled Camshaft), By Application Type (Passenger Cars, Light Commercial Vehicles, Heavy Commercial Vehicles) Others and Regional Forecast, 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/102230

Key Strategies

Key strategies in the Automotive Camshaft Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Camshaft Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Camshaft Market.

Major Automotive Camshaft Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive camshaft market include MAHLE GmbH, Thyssenkrupp AG, Newman Cams, Piper RS Ltd., Camshaft Machine Company, Schrick, PCL India, among others.

Rising growth of the automotive sector and also increasing investment in the automotive camshaft companies worldwide is expected to propel the growth of the market. Additionally, the rising trend of the engine downsizing owing to stringent government emission regulations is expected to be a factor for the generation of numerous opportunities for the market players.

Trends Analysis

The Automotive Camshaft Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Camshaft Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Camshaft Market Solutions.

Regions Included in this Automotive Camshaft Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Camshaft Market.

- Changing the Automotive Camshaft Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Camshaft Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Camshaft Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Camshaft Market?

► Who are the prominent players in the Global Automotive Camshaft Market?

► What is the consumer perspective in the Global Automotive Camshaft Market?

► What are the key demand-side and supply-side trends in the Global Automotive Camshaft Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Camshaft Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Camshaft Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Camshaft Market#Automotive Camshaft Market Share#Automotive Camshaft Market Trends#Automotive Camshaft Market Growth#Automotive Camshaft Market Insights

0 notes

Text

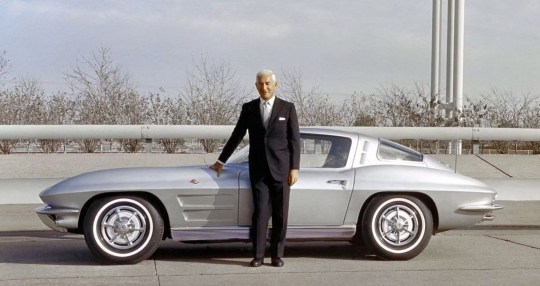

This Day In History, April 23, 1996 Zora Arkus-Duntov, Belgian-American automotive engineer, known as "the Father of the Corvette", dies at 86

Zora Arkus-Duntov (December 25, 1909 – April 21, 1996) was a Belgian-born American engineer whose work on the Chevrolet Corvette earned him the nickname "Father of the Corvette." He is sometimes erroneously referred to as the inventor of the Corvette; that title belongs to Harley Earl. He was also a professional racing driver, appearing at the 24 Hours of Le Mans four times and taking class wins in 1954 and 1955.

Arkus-Duntov joined General Motors in 1953 after seeing the Motorama Corvette on display in New York City. He found the car visually superb, but was disappointed with what was underneath. He wrote Chevrolet chief engineer Ed Cole that it would be a pleasure to work on such a beautiful car; he also included a technical paper which proposed an analytical method of determining a car's top speed. Chevrolet was so impressed, engineer Maurice Olley invited him to come to Detroit. On May 1, 1953, Arkus-Duntov started at Chevrolet as an assistant staff engineer.

Shortly after going to work for Chevrolet, Arkus-Duntov set the tone for what he was about to accomplish in a memo to his bosses. The document, "Thoughts Pertaining to Youth, Hot Rodders and Chevrolet", laid out Duntov's views on overcoming Ford's lead in use by customizers and racers, and how to increase both the acceptance and the likelihood of success of the Chevrolet V8 in this market. In 1957 Arkus-Duntov became Director of High Performance Vehicles at Chevrolet. After helping to introduce the small-block V8 engine to the Corvette in 1955, providing the car with much-needed power, he set about showcasing the engine by ascending Pike's Peak in 1956 in a pre-production car (a 1956 Bel Air 4-door hardtop), setting a stock car record. He took a Corvette to Daytona Beach the same year and hit a record-setting 150 mph (240 km/h) over the flying mile.[citation needed] He also developed the famous Duntov high-lift camshaft and helped bring fuel injection to the Corvette in 1957. He is credited with introducing the first mass-produced American car with four-wheel disc brakes.

A conflict arose between Duntov and Chevrolet chief designer Bill Mitchell over the design of the new C2 Corvette "Sting Ray" model. Mitchell designed the car with a long hood and a raised windsplit that ran the length of the roof and continued down the back on a pillar that bisected the rear window into right and left halves. Duntov felt that the elongated hood interfered with the driver's view of the road ahead, and the rear pillar obscured the driver's view rearwards. The split rear window was widely criticized, and a one-piece backlite was put in its place the next year.

#Zora Arkus-Duntov#Arkus-Duntov#car#cars#muscle car#american muscle#chevrolet#chevy#chevrolet corvette#corvette

114 notes

·

View notes

Note

OMG I'm such a dumbass I knew you did one on the GR Yaris before too, and I love her ALSO, but I actually meant the GR Supra 😳🫣 (slip of the tongue)

Gotcha.

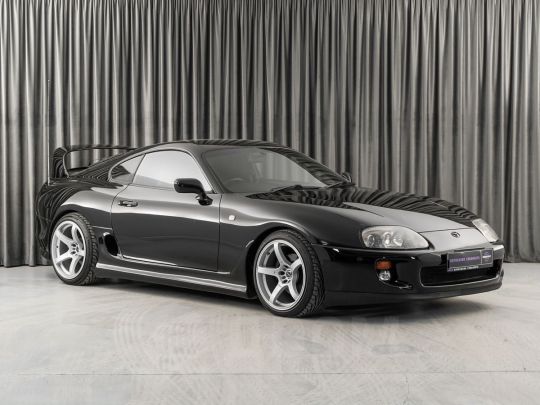

Since I managed to take some two weeks to answer this (got distracted both by real life obligations and other posts that were meant to be very quick to make. Meant to.) y'all may have forgotten, but our dear friend of the blog had asked for opinions on the GR Yaris, hinting to its controversial status. Turns out the GR Supra is what that request, and thus that hint, was actually about - so let's talk about the car and the controversy that engulfs it.

In 1993, Toyota launched the fourth generation of its rear wheel drive sportscar (well, arguably a bit of a Grand Tourer, i.e. something more oriented to cruising than a sportscar) the Supra - which was born a quarter century earlier as a more upmarket, six cylinder version of the Celica, graduating from Celica Supra to its own dignified name with the third generation I talked about that one time I forgot to check what blog I was reblogging with.

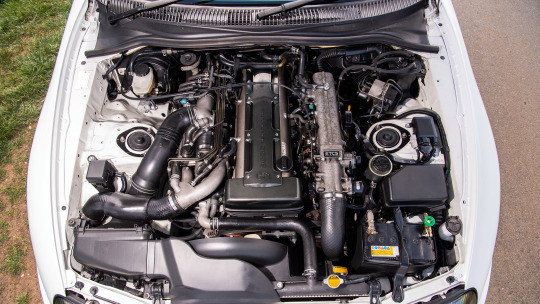

But this time, things would be different. Most notably because the inline six the Mk4 Supra came out with was an absolute MONSTER.

Remember how I talked about the GT-R's RB26 engine being one of the greatest, most coveted production engines to ever come out of Japan? Well, the 2JZ-GTE is the other.

It was larger at 3 liters, no less powerful, and to reduce turbocharger lag it used two of them sequentially: first air goes in the smaller, more responsive turbo, then gradually some of it gets sent to the bigger turbo to make it start spinning, then when it gets going the two are finally used in conjunction. (Imagine the big turbo as a hung husband that takes a while to get it up and the small turbo as an eager stepson ready to take over until the hung one can join in for a spitroast. Or something. I don't watch porn with real people, but from what I gather the plots seem to resemble how sequential turbos work.) It even at one point got Variable Valve Timing, i.e. the ability to vary the time in which the valves open depending on engine speed, which allows to optimize tuning for performance and efficiency! (Cool thing to go over in detail if y'all want me to.) And also, the kind of things that engine is able to take make me wish I hadn't used up my porn analogy quota.

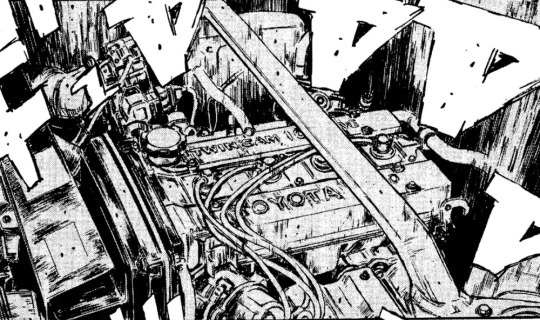

See, to chop off eons of nuance, an engine is just a big block of metal with a lot of bits attached, and the two main measures of an engine's potential are the slope of the line in the Bits Fiddled With / Power Output graph and how far up (It's up, right? The second axis you specify is the vertical one, right?) you can take it before the block becomes the weakest link - with another important point being when you need to start messing with internals, i.e. the components inside the engine, e.g. pistons (the things the boom pushes down), camshaft (the thing the pistons spin) and connecting rods (you can guess).

So for instance, just to make the point that an engine can be beloved without having much overall tuning potential, in one of Toyota's most beloved engines, the 4A-GE four cylinder illustrated above (yes, the one from that white and black car in all the eurobeat videos), some pin the block's limit as low as 250hp. The 2JZ, tho? It can take 800hp without even messing with the internals, and once you get your grubby hands on those you can keep pushing the line to some 2000hp. That is two Bugattis. That is 40 times my car. That is well above the power level where "tires that will at any point grip" and "tires that are in any way road legal" stop intersecting.

I am not in the slightest exaggerating when I say that this and the Skyline GT-R are widely regarded as the top of Japan's 20th century automotive production. The Messi & Ronaldo of the Japanese Domestic Market. It is absolutely no coincidence this was the hero car in The Fast And The Furious.

And then in 2002, as all things, its production ended, and given the abysmal sales and catastrophic recession, Toyota decided that would be that.

And then, years later, The Teasening began.

I want to stress, almost half of my conscious life (I choose to believe the stretch from birth to kindergarten is just run-up) the world was in some state of getting teased with talk of a new Supra. The trademark on the name was renewed in 2010. In 2014 they dropped the FT-1 concept, and of course that became speculation about what the production version would look like.

Because come the fuck on, it's not gonna look like that.

Or was it?

Only five entire years and much more teasing later would we officially get an answer, when after seventeen years, the Toyota GR Supra (and for those wondering what GR means, y'all should've clicked the Yaris link >:C) hit the streets.

You know what, good enough.

Good enough to earn itself a sea of words of praise, Jason Cammisa's "The most punch-above-its-weight sportscar ever made" just some among them.

It did have its share of problems at the start, like its power being 335hp and not 382, a lack of manual transmission, and the inability to spec it with a less powerful 4 cylinder engine - well, I don't know who considered that last one a problem, but Toyota's updates solved that one too.

The Supra has a much bigger problem than those though, one no little update can solve. That red car in the background.

See, the new Supra is actually a joint venture with BMW, who made a new model of its Z4 roadster out of the platform. And unlike with the other joint-venture sportscar Toyota sells, people are big mad about that. Why?

See, the interior is engulfed in BMW switchgear and the drivetrain is all BMW (the manual gearbox took until this year to come out because BMW did not have one for that engine so Toyota had to modify another BMW transmission to fit), giving people the impression that this was less of a joint venture and more of a BMW project that Toyota tacked its design on top of, which is a problem whether true or not.

See, a range-topping sportscar is supposed to represent what the brand is capable of - having it done by someone else (or so the criticism goes) is a bit like performing Hallelujah in playback.

Actually, a better musical analogy: You know "I'm back bitch" singles? When a humongous artist drops a new record with a humongous lead single about absolutely nothing but reaffirming they're the biggest fucking deal in the universe? Without Me, Bad, Gimme More, so on. Well, think of SexyBack - one of the most monumental phenomenons of its decade, most incontrovertibly proving Justin Timberlake sat atop the goddamn world. Now, imagine if, after all the years that went by between that record and the next, when he finally came out with Suit And Tie all the verses were Jay-Z. Going from a humongous statement about having the power to reach the top of the game and stay there to having to get absolutely carried by what in this logic is essentially a competitor. Basically, that's the critics' complaint: the supra went from 2JZ to too much Jay-Z.

And therein lies the other problem of the Supra: the Supra.

See, any time you evaluate something, you do so relative to its context - and when you give it a nameplate, you make that context include where else that nameplate has been. An undeserved name may not just be stupid, but even outright kill the car in some's eyes, see the case of the Dodge Dart, or get me to talk about the Ford Capri prototype recently spotted if you want to find out what I'm like when I lose my cool. (I'd liken this phenomenon to undeserved Grammies but I already used my music analogy quota too.) So the Toyota Supra does not just need to be good, it needs to deserve the name. And some argue it doesn't. But why? This thing is no less powerful, no slower, hell it's not even any bigger or heavier and we've gone over how rare that is these days! So is it the lack of backseats and a targa version? No, no one gives a crap about those. It's something deeper.

Sometimes, the problem with a revival is people base their expectation not on what the original was like in the context of its time but what it's like in the context of today (for example, I've heard people call the latest GT-R "too computerized, too assisted, far from the pure driving experience of its predecessors", when its predecessors had some of the most technologically advanced driving assists of their time and could only be called "pure" and "analog" by comparison with cars decades newer). But of course, that'll only be some people - so if what the original car looks like to modern eyes and what the original car represented at its time are two different enough concepts, any revival will receive some criticism for not being one of the two.

But for the Supra, this compounds with another problem: the original Supra (as in the previous generation, since no one gives a crap about the first three), to modern eyes, looks like a thousand-horsepower flame-spitting beast, because that's what all Supras have been turned into, and that's why you know of Supras in the first place (it sure isn't because people bought it!), and that, consciously or not, exacerbates the problem of misplaced expectations to a level akin to hearing an NBA player is about to have a brother and expecting the baby to be a 6'4" three-shooter.

But I wasn't asked about the controversies, I was asked about my take. And my take is: no realistic expectation of what a Supra would look like today was disappointed - at least not by where the car stands today. Well, unless the expectation involved backseats.

"But it was made by BMW" and so? This is a new Supra, and a good one - what does it matter how it got here? Especially when this is an upgrade over the Z4 in every way - looks way better, drives better, and now has a manual that the Z4 doesn't.

Okay, almost every way: the Supra's roof won't get out of the way. If only though, if only. Could you imagine a Toyota product that looks this good, sounds this good, goes this fast, and has a drop top? ...and maybe backseats?

Well, I can.

Yes, the badge and core concept may have some people consider it from midlife crisis mobile to old man's car. (though we know it's not a car bought by old men because if that was the case someone would be buying these). But just try to imagine sitting in this thing.

Take a couple of seconds to take in that picture and truly immerse yourself. You're in a Lexus LC500 Convertible, with a V8 at your right foot's command, its spectacular sound ready to battle the perfect sound system serenading you with your fanciest CD, because of course Lexuses still come with CD players.

Are you immersed? Okay: Someone just called your Lexus a midlife crisis car. See? You don't give a shit either, do ya.

Automatic only though. The pain. Oh, and it kind of costs as much as two Supras. But, you know, neither of those Supras will be convertibles!

Links in blue are posts of mine about the topic in question - if you liked this post, you might like those!

52 notes

·

View notes

Text

Kawasaki Z1 production began in 1972 as the most powerful Japanese 4-cylinder 4-stroke ever marketed.

The Kawasaki Z1 is a four-cylinder, air-cooled, double-overhead camshaft, carbureted, chain-drive motorcycle introduced in 1972 by Kawasaki. Following the introduction of Honda's CB750 in 1968, the Z1 helped popularize the in-line, across-the-frame four-cylinder, a format that became known as the Universal Japanese Motorcycle or UJM.

ManufacturerKawasaki Heavy Industries, Ltd.Also calledKawasaki 900 Super Four Production1972–1975; 85,000 units. Marketed variously as the Z1-900, 900 Z1 or 900 S4 ("Super Four"), the Z1 was the first of Kawasaki's Z models.

The Z1 was noted for being the first large-capacity Japanese four-cylinder motorcycle to use the double-overhead-camshaft system on a production motorcycle. When it was introduced, only the MV Agusta 750 S used this system; it was a very expensive limited-production machine, as opposed to the Kawasaki which was less than half the price.

The Kawasaki Z1 was developed under the project name "New York Steak".In the late 1960s Kawasaki, already an established manufacturer of two-stroke motorcycles, had begun prototyping a 750 cc four-cylinder four-stroke sports motorcycle working with McFarlane Design in 1969 to develop the bike's overall appearance. When Honda introduced the CB750 to the market first, Kawasaki postponed the Z1's release until its displacement could be increased to 903 cc and the motorcycle could be marketed in the 1000cc-class.

In 1972, the Z1 set the world FIM and AMA record for 24-hour endurance on the banked Daytona racetrack, recording 2,631 miles at an average speed of 109.64 mph. Writing in 1976, LJK Setright commented that this record was only 0.36% faster than the previous figure set in 1961 at Montlhéry, France, by a team using a modified BMW R69S, particularly the engine. Also at this time at Daytona a one-off Z1 ridden by Yvon Duhamel that was tuned by Yoshimura set a one-lap record of 160.288 mph.

The Z1 was awarded the MCN 'Machine of the Year' accolade each year from 1973 to 1976 (an award resulting from a readers' opinion-poll run by UK weekly publication Motorcycle News) The Society of Automotive Engineers of Japan (in Japanese) includes the 1972 Z1 as one of their 240 Landmarks of Japanese Automotive Technology.

The basic design of the Z1 remained relatively unchanged until 1975, when the 903 cc "Z1-B" was introduced, with changes including increased power output, improved suspension, and a stiffer frame. The automatic chain oiler was deleted, the styling was revised – essentially paint scheme and side-panel nomenclature – and the braking was improved.

In 1976 the Z1 was replaced by the Kawasaki KZ900 in the U.S. and Z900 in other markets. This was succeeded by the 1977 Kawasaki Kz1000 ("Z1000") and Kawasaki Z1000 Z1-R, and in 1984 by the Kawasaki Z1100R.

5 notes

·

View notes

Link

0 notes

Text

#Market Research#Business Growth#Data Driven Decisions#Competitive Analysis#Innovation#Strategic Insights#Strategy Building#Introspective Market Research

0 notes

Text

Different Types of Car Engines

Comprehending the different types of engines is essential for the success of your business in multiple aspects. This knowledge will enable you to boost sales, enhance customer satisfaction, and improve marketability. In this article, we will explore the various engine types and their operational mechanisms.

If you are considering starting a car engine business but lack a comprehensive understanding of the industry, it is advisable to review the article below. This resource can provide valuable insights and help you avoid significant financial losses. Gaining new and useful knowledge is often advantageous.

This article aims to equip readers with the necessary knowledge to make well-informed decisions regarding car engines, while also assisting in generating profit from a car engine business.

Engines in Cars: How Do They Work?

Engines are frequently taken for granted due to the ease with which an automobile may be started by simply turning a key. Few drivers notice the scientific magic at work behind the hood as they journey from A to B, but the engine is an engineering marvel in its own right.

Internal combustion engines generate energy via small, precisely controlled explosions. This is the consequence of hundreds of ignitions of the fuel-air mixture in the car’s multiple cylinders hundreds of times per minute, which propels the vehicle forward.

The combustion cycle is the term used to describe the process of feeding the engine. Typically, the cycle is divided into four parts or strokes (hence the name four-stroke engine). There are four: intake, compression, combustion, and exhaust. We’ll examine how each of these strokes contributes to the combustion cycle in an automobile engine in the sections that follow.

Intake

The pistons reach the camshaft-mounted valves as the crankshaft rotates up and down. The timing belt spins the camshaft as the piston lowers, forcing the valves to open and discharge the fuel-air mixture. This is referred to as ingestion.

Compression

Compression occurs when the pistons move upward as the crankshaft rotates down. This compresses the fuel-air mixture in the combustion chamber. The heat from the compressed air and fuel increases the mixture’s temperature to a point where it ignites.

Combustion

The spark plug ignites the fuel-air mixture immediately before the piston drops again, resulting in a tiny explosion. This causes the piston to compress, creating the energy required to run the engine rapidly.

Exhaust

The exhaust valve opens when the piston reaches its lowest point. When the piston rises again, the gases released by the explosion are expelled through the exhaust valve. The procedure is repeated after closing the top exhaust valve.

4 Regular Types of Car Engine Layouts

In its simplest form, an engine layout relates to the number and arrangement of cylinders in a vehicle. There are numerous engine configurations, but the three most typical are for automobiles.

1. Straight/Inline Engine

Straight or inline engines are the most prevalent configuration. As the name implies, the cylinders are arranged vertically in line, one behind the other. This engine can be mounted in the car in either a parallel or perpendicular arrangement, depending on the number of cylinders. Straight refers to an engine parallel to the automobile, whereas Inline refers to an engine that is perpendicular to the car.

Straight/inline engines are frequently used because they are straightforward and inexpensive production and installation processes. Due to its compact shape and ability to incorporate additional automotive components, inline engines are commonly seen in entry-level family automobiles such as hatchbacks.

On the other hand, straight engines can have more cylinders and generate more power. Straight engines are straight under the hoods of luxury vehicles such as BMW and Mercedes.

2. Flat Engine

In comparison to a straight engine, a flat engine’s cylinders are positioned horizontally. The flat engine is named after the piston action, reminiscent of pugilists punching their gloves before a fight. The flat engine is a balanced engine, which means it produces slight vibration due to the force exerted by the piston movement.

Additionally, the Flat Engine’s low center of mass improves the vehicle’s handling. All cylinders are air-cooled equally due to their enormous surface area. Flat engines are more expensive to make than straight engines, and many vehicle manufacturers loathe them due to their large breadth. Only Porsche and Subaru offer flat engines.

3. V-engine

V-engines are a popular engine design seen in practically all high-performance automobiles. The engine’s cylinder banks, or chambers in which the pistons move, form a V shape when viewed from the front.

This architecture is unique among engines because it can fit more cylinders into a smaller space. That is, increased power while keeping the aesthetic of the car. The V Engine is more vibration-prone than a straight engine, and its design is more sophisticated, making repairs more expensive.

On the other hand, this architecture produces more power since each piston reaches its power stroke at a faster rate. Due to its compact size and excellent power output capabilities, the V-engine design is chosen by practically all high-performance automotive manufacturers, including Ferrari, Alfa Romeo, and Mercedes Benz.

6 Common Engine Cylinder Configurations

After discussing engine layouts, let’s discuss cylinder configurations. This section discusses the distinctions between engines based on their cylinder count.

A vehicle’s cylinder count affects its power output and fuel efficiency. This is critical for automobile fans since the cylinder layouts dictate the volume of a car engine. The following are some of the more popular engine cylinder configurations.

1. Twin-Cylinder

Due to their restricted power output and capacity. Several manufacturers are progressively incorporating turbochargers into their engines to build compact, ecologically efficient twin-cylinder engines. The Fiat TwinAir engine, seen in the Fiat 500 TwinAir and Fiat Panda Aria, is an excellent example.

2. Three-Cylinder

While three-cylinder engines are typically found in small cars, with the evolution of turbochargers, they have begun to emerge in bigger family hatchbacks such as the Ford Focus. Three-cylinder engines create a characteristic burbling sound and shaking vibration due to the engine’s balance being influenced by the odd number of cylinders.

3. Four-Cylinder

By far the most popular engine design, four-cylinder engines are featured in most small to mid-sized cars and are virtually usually configured inline. Four-cylinder engines produce a lot of power and can be further enhanced by adding a turbocharger.

4. Five-Cylinder

Five-cylinder engines are highly unusual, with vibrations comparable to three-cylinder engines. Volvo is one manufacturer that regularly uses five-cylinder engines due to the car’s comfort and refinement, which offsets the vibration effect.

5. Six-Cylinder

Six-cylinder engines are prevalent in high-end performance and sports cars and are typically built in a V or straight configuration. Six-cylinder engines were formerly considered underpowered, but the turbocharger has enabled them to be found in some of the world’s most powerful automobiles.

6. Eight+ Cylinders

Due to their large capacity and power output, automobiles with eight or more cylinders are frequently categorized as supercars. They are often grouped in the shape of a V, which gives them the names V8, V10, and V12. Previously, the largest engine available was the V12, but that changed with the debut of the ultra-fast Bugatti Veyron, which had sixteen cylinders.

Which Engine Types Are Good Value for Money?

The straight engine is the most affordable and most popular engine design, which should be no surprise given it’s featured in the most economical family vehicles. One downside is that the engine blocks are relatively large, so engine power is lower than the other two.

The flat engine is the second most affordable. However, this comes at higher production costs, since the engine’s design makes it more complex to produce.

The V-engine is the priciest engine alternative. It is costly to manufacture, but its high power output also costs repairs.

It can be challenging to determine which engine type is the best value for your money. The choice between the three engine types comes down to the individual choice of the vehicle owner. It is also prudent to consider having a truly reliable automotive engine part supplier.

From the perspective of an amateur automobile enthusiast, the V-engine is the best choice. However, its high installation and repair costs are prohibitive to many motorists. The more affordable boxer engine is a good choice for drivers looking for a good balance of price and performance.

Possible Malfunction Reasons

There are different reasons why engine malfunctions happen. Some are due to the car and the engine in a very straightforward manner, and others are due to the engine indirectly.

1. Oil Leakage

This is when your oil level is low, or the oil filter has been blown out. The oil filter is a mechanical filter that strains to remove unwanted particles from the oil. Oil leaks from the base of the cylinder head into the water pump. This is excessive oil consumption. The cylinder head gasket is also a possibility.

2. Poor Compression

An engine’s ability to compress air is an essential component of combustion. The air must be compressed to its maximum capacity before ignition. Otherwise, a misfire will occur. When a cylinder piston kit fails to reach its maximum compression, a rough start, misfiring, and high oil consumption.

3. Engine Trouble Due To Simple Design Issues

The engine’s design is one of the reasons why engine malfunctions happen. Whatever the method, there can be too much friction with parts of a car engine, which may result in malfunction or failure.

4. Lack of Regular Maintenance

A car needs regular and timely maintenance to keep it working at its optimum potential. An engine needs to be checked regularly and kept in good condition if you want it to last for a long time.

5. Improper Usage

Being a device that runs on fuel, customers need to ensure that using the proper fuel and the right amount. Also, they need to obey their fuel tank limits. Otherwise, the engine will be compromised. They can use the car regularly, but they need to ensure that they are driving it moderately.

Conclusion

Hopefully, after reading this article, your customers will understand how any car’s engine works. As a car engine business owner you should understand that a car’s engine is analogous to a person’s heart. It performs all functions in their vehicle.

In addition, Cnfastwin. provides the best products for a car engine’s health; we have a starter motor, a cylinder piston kit, an oil filter, a stator plate, a fuel tank, and many more. We are here to meet any car business needs. Contact us to avail the best deals. For more details about China Car Parts Supplier visit our website https://cnfastwin.com.

0 notes

Link

0 notes

Text

Understanding Round Bar: A Versatile Material for Various Applications

Shashwat Stainless Inc. is the largest Round Bar Manufacturer in India. Round bars are one of the most versatile and widely used forms of metal. Whether in construction, manufacturing, or machining, round bars serve as a crucial component in various industries. These solid bars, which have a circular cross-section, can be made from different metals, such as carbon steel, stainless steel, aluminum, and alloy steel, each suited for specific applications. In this blog, we will explore the characteristics, uses, and advantages of round bars.

What is a Round Bar?

A round bar is a cylindrical metal bar with a uniform circular cross-section. It is produced through various manufacturing processes, including hot rolling, cold rolling, and forging. The size of a round bar can vary, ranging from small diameters to large, heavy-duty bars. These bars are typically available in lengths of several meters and are sold according to their diameter. Round bars are often used as raw materials in machining, fabrication, and manufacturing processes.

Types of Round Bars

Round bars come in various materials, each offering distinct properties suited to specific applications. Some common types of round bars include:

Duplex Steel F53 Round Bars: One of our popular products in the Metal Market is Duplex Steel F53 Round Bars. These ASTM A182 F53 Duplex Round Bars are available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Duplex Steel 2205 Round Bars: Duplex Steel 2205 Round Bars is a popular product in the Metal Market. These Duplex Steel ASTM A182 Gr F53 Bars are available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Duplex Steel F51 Round Bars: One of our popular products in the Metal Market is Duplex Steel F51 Round Bars. These Din 1.4462 Round Bar is available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Duplex Steel 31803 Round Bars: Duplex Steel 31803 Round Bars is a popular product in the Metal Market. These SAF 2205 Round Bars are available in various sizes, forms, and dimensions and can also be customized to meet the needs of our customers.

Common Uses of Round Bars

Round Bar Manufacturers find a broad range of applications across various industries. Some of the most common uses include:

Machining and Fabrication: Round bars are often used as raw materials for machining into components such as shafts, axles, rods, bolts, and bushings. Their ability to be easily cut, drilled, and shaped makes them ideal for custom parts.

Structural Support: Round bars are used in construction and structural engineering for support and reinforcement in beams, columns, and trusses. Their strength and ability to handle heavy loads make them vital in infrastructure projects.

Automotive Parts: Round bars are used in the production of automotive parts such as suspension rods, camshafts, and connecting rods. The strength, precision, and durability of round bars make them an excellent choice for components that must endure high levels of stress and wear.

Advantages of Using Round Bars

Versatility: Round bars suppliers are incredibly versatile and can be used in a wide range of applications. Their variety in size, material, and strength makes them suitable for industries like construction, automotive, aerospace, and manufacturing.

Easy to Machine: One of the key benefits of round bars is their ease of machining. Whether they are being cut, drilled, or shaped into components, round bars are easy to work with and can be tailored to meet specific needs.

Strength and Durability: Round bars are known for their excellent strength, which allows them to perform well under high-stress and high-temperature conditions. Their durability makes them a reliable material for long-lasting components.

Cost-Effective: Round bars supplier in India are generally affordable compared to other materials, making them a cost-effective choice for many applications, especially in industries where large quantities are required.

0 notes

Text

Looking for a Trusted Honda Parts Exporter for Genuine Spare Parts?

Choosing genuine replacement parts is essential if you want to preserve the longevity, performance, and quality of your Honda cars. We at Smart Parts Exports take great satisfaction in being a top Honda parts exporter, providing premium-quality Honda components to international markets. With our knowledge and dedication, we guarantee that consumers everywhere may get dependable components for their Honda automobiles.

Why Choose a Honda Parts Exporter Like Smart Parts Exports?

As a reputed Honda parts exporter from India, Smart Parts Exports stands out for several reasons:

Authenticity Guaranteed: Only original and OEM (Original Equipment Manufacturer) Honda spare parts are available from us, guaranteeing your car will function properly without sacrificing performance or safety.

Wide Range of Products: Our catalog includes all necessary Honda spare parts for a variety of vehicles, both new and vintage, ranging from electrical components and body accessories to engine and brake system components.

Global Reach: We address the needs of consumers globally by shipping to several countries as a reputable supplier of Honda spare parts. Wherever you are, our effective logistics network guarantees on-time delivery.

Competitive Pricing: Honda parts exporters choose us because we source parts directly from manufacturers, offering the greatest costs without sacrificing quality.

Expert Guidance: Our knowledgeable staff assists customers in choosing the appropriate parts for their particular Honda models, guaranteeing compatibility and peak performance.

Advantages of Choosing Honda Genuine Parts

When you opt for genuine Honda spare parts from a reliable Honda parts exporter from India like us, you gain several benefits:

Enhanced Durability: Genuine parts are designed to withstand wear and tear, ensuring a longer lifespan for your vehicle.

Perfect Fit: Honda OEM parts are manufactured to precise specifications, ensuring a seamless fit and function.

Warranty Assurance: Genuine parts often come with warranties, providing peace of mind for your investment.

Optimized Performance: Maintaining the original performance of your vehicle is easier with authentic Honda components.

Honda Spare Parts Exporter: Products We Offer

As a leading Honda spare parts exporter, Smart Parts Exports supplies a comprehensive range of parts, including:

Engine Components: Pistons, crankshafts, camshafts, and cylinder heads.

Brake Systems: Brake pads, rotors, and master cylinders.

Suspension and Steering: Shock absorbers, control arms, and steering racks.

Electrical Parts: Alternators, starters, and wiring harnesses.

Body Components: Bumpers, grilles, headlights, and mirrors.

Regardless of the need, we can meet the demands of people, shops, and companies searching for a trustworthy exporter of Honda components.

Why India is a Hub for Honda Spare Parts Exporters

India is now a significant force in the worldwide market for car spare parts. Smart components Exports, a top exporter of Honda components from India, gains from:

Access to Skilled Manufacturers: India is home to some of the best automotive manufacturers, producing high-quality parts that meet global standards.

Cost-Effective Production: Lower production costs enable us to provide genuine Honda spare parts at competitive prices.

Strategic Location: With well-connected ports and logistics networks, India serves as an ideal base for global exports.

Partner with Smart Parts Exports: Your Honda Parts Exporter

You need look no further than Smart components Exports if you're looking for a trustworthy wholesaler of Honda components. Delivering authentic, premium Honda spare parts to clients across the globe is our top priority. For all of your spare component needs, you can rely on us because of our dedication to quality.

Contact Us Today

Visit our website to learn more about our wide selection of Honda spare parts, or contact our knowledgeable staff. For anything pertaining to authentic Honda components, let Smart components Exports be your first choice.

Conclusion

Keeping your car in good condition requires selecting the correct Honda parts exporter. Reputable Honda spare parts exporter Smart Parts Exports provides outstanding service by fusing genuineness, affordability, and worldwide reach. We can satisfy your needs with unparalleled quality and dependability, whether you're a corporation or an individual car owner.

0 notes

Text

Induction Heating Machine Manufacturers for Automotive Applications

Induction heating plays a vital role in the automotive industry, providing efficient, precise, and energy-saving solutions for critical processes such as hardening, brazing, annealing, and shrink-fitting. Leading manufacturers of induction heating machines design specialized equipment tailored to meet the high-performance demands of automotive production lines.

These machines are essential for manufacturing and treating components like crankshafts, camshafts, gears, valves, and drive shafts, ensuring enhanced durability, minimal distortion, and improved wear resistance. The rapid, localized heating process ensures consistent quality, reducing production time and operational costs.

Key benefits offered by top manufacturers include:

Customization – Machines designed to accommodate various part sizes and shapes, supporting high-volume production.

Energy Efficiency – Advanced systems that minimize energy consumption and heat only targeted areas.

Automation and Integration – Seamless integration with automated production lines for increased productivity and reduced human intervention.

Reliability and Precision – Cutting-edge technology delivering uniform heat distribution and process repeatability.

By partnering with these industry leaders, automotive manufacturers ensure consistent quality, extended component lifespan, and streamlined production processes, giving them a competitive edge in today’s fast-evolving market.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Timing Belts and Banded V Belts: Key Components for Smooth Operations

Timing belts and banded V belts are essential components in machinery, ensuring efficient and synchronized performance. Their unique designs and features make them indispensable in various industries, from automotive to manufacturing. This article delves into their functions, advantages, and the role of trusted dealers in Mumbai.

What Are Timing Belts?

Timing belts are tooth belts made from materials like rubber, polyurethane, and reinforced cords. They are used to synchronize the rotation of camshafts and crankshafts in engines, ensuring precise valve timing.

Features of Timing Belts

Precision: Provides accurate synchronization of mechanical parts.

Durability: Resistant to wear and tear.

Low Maintenance: Requires minimal upkeep, reducing downtime.

Versatility: Suitable for various applications beyond automotive engines.

Applications of Timing Belts

Timing belts are widely used in:

Automobiles: Driving camshafts in internal combustion engines.

Industrial Equipment: Ensuring synchronized movement in machines.

Home Appliances: Powering washing machines and treadmills.

Timing Belt Dealers in Mumbai

Mumbai, being a hub of industrial activity, is home to numerous dealers specializing in timing belts. These dealers offer:

High-Quality Products: Ensuring durability and performance.

Wide Range: From standard to customized timing belts.

Technical Support: Assisting clients in selecting the right products.

What Are Banded V Belts?

Banded V belts consist of multiple V belts joined together by a common backing. This design offers enhanced stability and power transmission compared to single V belts.

Features of Banded V Belts

High Load Capacity: Suitable for heavy-duty applications.

Reduced Vibration: The banded design minimizes vibration and improves stability.

Long Lifespan: Resistant to cracking and stretching.

Efficient Power Transmission: Ensures smooth operation in demanding environments.

Applications of Banded V Belts

Agricultural Machinery: Driving components in tractors and combines.

Construction Equipment: Powering heavy machinery like bulldozers and cranes.

Industrial Applications: Used in conveyors, pumps, and compressors.

Choosing the Right Dealer

When selecting timing belts or banded V belts, it is essential to choose a dealer that offers:

Quality Assurance: Products that meet industry standards.

Competitive Pricing: Value for money.

After-Sales Support: Guidance and maintenance services.

Conclusion

Timing belts and banded V belts are critical for ensuring the seamless operation of machinery across industries. Their unique features and benefits make them a preferred choice for engineers and manufacturers. For premium timing belts and banded V belts, rely on Jigna Sales, a trusted name in the market.

0 notes

Text

Tappet Market

Tappet Market Size, Share, Trends: Schaeffler Group Lead

Integration of Advanced Materials and Coatings in Tappet Manufacturing

Market Overview:

The global Tappet Market is projected to grow at a CAGR of 3.8% from 2024 to 2031. The automotive sector currently dominates the market, holding a significant share driven by increasing vehicle production, rising demand for high-performance engines, and a growing focus on fuel efficiency. The tappet market is growing steadily due to technological advancements in engine design and the global expansion of the automobile industry. The increased emphasis on engine performance optimization and pollution reduction is driving market growth. Advancements in material science and manufacturing processes are improving tappet durability and efficiency, accelerating market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

A major trend in the Tappet Market is the integration of advanced materials and coatings in tappet manufacturing. Manufacturers are increasingly using high-performance materials like titanium alloys and ceramics, along with specialized coatings such as diamond-like carbon (DLC). This trend is driven by the industry's demand for enhanced wear resistance, reduced friction, and longer component lifespan. For instance, a major automotive component manufacturer recently developed a new line of tappets with a nano-composite coating that reduces friction and boosts fuel efficiency. These advanced materials and coatings are extensively used in high-performance and racing engines, where durability and efficiency are critical.

Market Segmentation:

Roller tappets dominate the Tappet Market due to their superior performance qualities, such as lower friction, better fuel efficiency, and greater longevity compared to flat tappets. These benefits make roller tappets ideal for modern high-performance engines that operate at higher RPMs and under greater stress. The design of roller tappets allows for a more efficient transfer of motion from the camshaft to the valve, resulting in less wear and increased engine efficiency.

Recent advancements in roller tappet technology have reinforced their market position. Manufacturers have introduced innovations such as lightweight materials to reduce reciprocating mass, enhanced roller bearing designs for longer lifespan, and friction-reducing coatings. For example, a leading automotive component supplier recently launched a new generation of roller tappets with ceramic rollers, providing superior wear resistance and lower friction, making them ideal for high-performance engines.

Market Key Players:

The Tappet Market is led by several key players who are driving innovation and market expansion. These include Schaeffler Group, Eaton Corporation, Federal-Mogul Corporation (Tenneco Inc.), NSK Ltd., SKF Group, Rane Holdings Limited, Otics Corporation, Riken Corporation, SM Motorenteile GmbH, and Lunati LLC. These companies focus on continuous advancements in product design and technology, ensuring their leadership positions in the market.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Kawasaki Z1 production began in 1972 as the most powerful Japanese 4-cylinder 4-stroke ever marketed.

The Kawasaki Z1 is a four-cylinder, air-cooled, double-overhead camshaft, carbureted, chain-drive motorcycle introduced in 1972 by Kawasaki. Following the introduction of Honda's CB750 in 1968, the Z1 helped popularize the in-line, across-the-frame four-cylinder, a format that became known as the Universal Japanese Motorcycle or UJM.

ManufacturerKawasaki Heavy Industries, Ltd.Also calledKawasaki 900 Super Four Production1972–1975; 85,000 units. Marketed variously as the Z1-900, 900 Z1 or 900 S4 ("Super Four"), the Z1 was the first of Kawasaki's Z models.

The Z1 was noted for being the first large-capacity Japanese four-cylinder motorcycle to use the double-overhead-camshaft system on a production motorcycle. When it was introduced, only the MV Agusta 750 S used this system; it was a very expensive limited-production machine, as opposed to the Kawasaki which was less than half the price.

The Kawasaki Z1 was developed under the project name "New York Steak".In the late 1960s Kawasaki, already an established manufacturer of two-stroke motorcycles, had begun prototyping a 750 cc four-cylinder four-stroke sports motorcycle working with McFarlane Design in 1969 to develop the bike's overall appearance. When Honda introduced the CB750 to the market first, Kawasaki postponed the Z1's release until its displacement could be increased to 903 cc and the motorcycle could be marketed in the 1000cc-class.

In 1972, the Z1 set the world FIM and AMA record for 24-hour endurance on the banked Daytona racetrack, recording 2,631 miles at an average speed of 109.64 mph. Writing in 1976, LJK Setright commented that this record was only 0.36% faster than the previous figure set in 1961 at Montlhéry, France, by a team using a modified BMW R69S, particularly the engine. Also at this time at Daytona a one-off Z1 ridden by Yvon Duhamel that was tuned by Yoshimura set a one-lap record of 160.288 mph.

The Z1 was awarded the MCN 'Machine of the Year' accolade each year from 1973 to 1976 (an award resulting from a readers' opinion-poll run by UK weekly publication Motorcycle News) The Society of Automotive Engineers of Japan (in Japanese) includes the 1972 Z1 as one of their 240 Landmarks of Japanese Automotive Technology.

The basic design of the Z1 remained relatively unchanged until 1975, when the 903 cc "Z1-B" was introduced, with changes including increased power output, improved suspension, and a stiffer frame. The automatic chain oiler was deleted, the styling was revised – essentially paint scheme and side-panel nomenclature – and the braking was improved.

In 1976 the Z1 was replaced by the Kawasaki KZ900 in the U.S. and Z900 in other markets. This was succeeded by the 1977 Kawasaki Kz1000 ("Z1000") and Kawasaki Z1000 Z1-R, and in 1984 by the Kawasaki Z1100R.

2 notes

·

View notes

Link

0 notes

Text

Aceforge: A Leading Name Among Automobile Parts Manufacturing Companies

The automotive industry is a cornerstone of global manufacturing, responsible for the production of millions of vehicles that power economies, connect communities, and enhance lives. Behind every vehicle, there are a myriad of parts and components that ensure smooth performance, safety, and reliability. This is where Aceforge, a leading name in automobile parts manufacturing companies, stands out. With a strong commitment to quality, precision, and innovation, Aceforge plays a pivotal role in supplying high-quality automotive components to manufacturers around the world.

Aceforge’s Expertise in Automobile Parts Manufacturing

Aceforge has established itself as a trusted partner for automotive OEMs (Original Equipment Manufacturers) and Tier-1 suppliers. With years of experience in the industry, Aceforge has developed a reputation for producing a wide range of high-performance, durable automobile parts that meet the stringent demands of the automotive market.

From engine components to structural elements, Aceforge specializes in the forging, casting, and machining of parts that meet the highest standards of quality and performance. By using advanced manufacturing technologies and superior materials, Aceforge ensures that every part it produces delivers reliability, efficiency, and safety.

Comprehensive Range of Automobile Parts

Aceforge manufactures a broad spectrum of automobile parts, serving a diverse array of applications. Here are some key categories of automotive components produced by Aceforge:

Engine Components: The heart of any vehicle is its engine, and Aceforge manufactures critical engine parts such as crankshafts, camshafts, cylinder heads, and pistons. These components are forged with precision to ensure optimal performance and longevity under high stress and temperature conditions.

Transmission Parts: Aceforge produces key transmission components such as gears, shafts, and bearings. These parts are designed to provide smooth shifting and enhance the overall drivability of vehicles, with an emphasis on durability and efficiency.

Suspension and Steering Components: The suspension and steering systems are crucial for vehicle handling and safety. Aceforge manufactures parts such as control arms, steering knuckles, and suspension linkages to ensure stability, comfort, and safety on the road.

Brake and Safety Components: Brake systems are critical for vehicle safety, and Aceforge manufactures brake calipers, rotors, and other related components. These parts are designed to withstand high levels of stress and heat while providing optimal stopping power.

Chassis and Structural Parts: The structural integrity of a vehicle is essential for its overall safety and performance. Aceforge produces chassis frames, cross members, and reinforcement parts to ensure that vehicles maintain their strength and stability during operation.

Why Choose Aceforge as Your Automobile Parts Manufacturer?

1. Advanced Manufacturing TechnologyAt Aceforge, we leverage cutting-edge technologies to ensure that every part meets the highest quality standards. Our state-of-the-art facilities are equipped with advanced machinery, including CNC machines, robotic systems, and die-casting equipment, to produce complex parts with precision. Whether it’s a small batch or high-volume production, Aceforge has the capacity to meet your needs.

2. Quality Assurance and ComplianceAceforge follows stringent quality control measures to ensure that every part we produce is flawless. Our parts undergo rigorous testing, including non-destructive testing (NDT), dimensional inspections, and material analysis, to ensure they comply with industry standards such as ISO 9001 and IATF 16949. This commitment to quality ensures that our clients receive reliable, long-lasting parts for their vehicles.

3. Cost Efficiency and Timely DeliveryWe understand that cost and time are critical factors in the automotive industry. Aceforge is committed to providing cost-effective solutions without compromising on quality. Our efficient production processes allow us to meet tight deadlines and deliver large volumes of parts in a timely manner.

4. Customization and InnovationAs a forward-thinking company, Aceforge embraces innovation and continuously seeks new ways to improve our products. We offer custom design and engineering services to meet the specific needs of our clients. Whether it’s designing a new part or improving an existing one, Aceforge’s expert team works closely with customers to bring their vision to life.

5. Sustainable Manufacturing PracticesIn today’s world, sustainability is key. Aceforge is committed to minimizing its environmental footprint by implementing eco-friendly manufacturing processes, reducing waste, and recycling materials whenever possible. Our sustainable approach helps us meet the growing demand for green automotive solutions.

Conclusion

As one of the leading automobile parts manufacturing companies, Aceforge continues to be a driving force in the automotive industry. With our focus on quality, technology, and customer satisfaction, we provide automobile manufacturers with the reliable and durable parts they need to build the vehicles of tomorrow. Whether you require high-performance engine components or critical safety parts, Aceforge is your trusted partner for automotive parts manufacturing.

If you’re looking for a dependable and innovative manufacturer to supply your automotive components, look no further than Aceforge. We are ready to meet your unique needs with precision-engineered parts that drive success on the road.

0 notes