#Anisotropic Bonded Magnets

Explore tagged Tumblr posts

Text

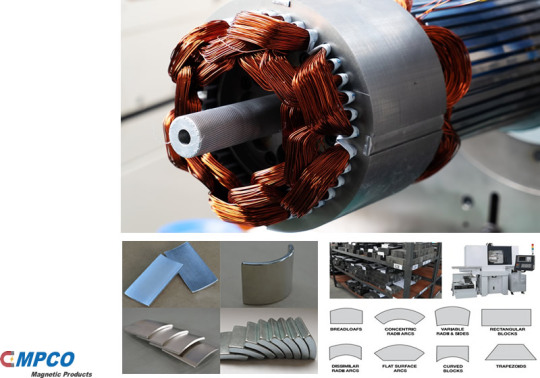

Difference Between Inline and Surface Mount NdFeB Magnets in PM Motors

Difference Between Inline and Surface Mount NdFeB Magnets in PM Motors What is the difference between inline and surface mount design of NdFeB magnets for permanent magnet motors? A permanent magnet (PM) motor is a type of AC motor that uses permanent magnets embedded or attached to the surface of the motor rotor. Electric vehicles use permanent magnet synchronous motors with high torque density…

View On WordPress

#aluminum nickel cobalt#Anisotropic Bonded Magnets#Bonded NdFeB Magnets#bonding magnets#bonding neodymium iron boron#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#hybrid magnets#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#magnetization direction#motor magnets#Nd-Fe-B#Nd-Fe-B magnets#Nd2Fe14B#NdFeB#NdFeB bonded magnet#NdFeB Grinding Process#Neodymium iron boron#Neodymium Magnet#Neodymium Magnets are Made#Neodymium Motor Magnet#permanent magnet motors#Permanent Magnets

0 notes

Text

Neodymium Multipole Radial Ring Magnets

Neodymium Multipole Radial Ring Magnets

Neodymium Multipole Radial Ring Magnets, Multipole Radial Magnetization Magnet, Customized Radial Magnetic Ring Magnet, Radially Oriented Ring Magnet, Multipolar Radial Ring Permanent NdFeB Magnet Ring Multipole Radial Ring Neodymium Magnets – Sintered rare earth magnet: Neodymium Multipole Radial Ring Magnets Radially oriented ring magnet usually refers to sintered magnet. The sintered rare…

View On WordPress

#anisotropic bonded magnets#Anisotropic injection molded magnet#anisotropic radial magnetization ring magnet#anisotropic radially-oriented ring magnet#Bonded magnets#hot-pressed isotropic NdFeB magnet#Isotropic bonded magnet#multipolar magnetization#multipole magnet#Multipole Radial Ring Magnets#Multipole Ring Magnets#Radial Magnetic Ring#radial magnetization ring magnet#radial magnetized magnet#Radial Magnets#Radial Ring Magnets#radially oriented permanent magnets#radially oriented ring magnets#ring magnet#sintered radially oriented magnet

0 notes

Photo

Scientists develop colossal 3D electrical anisotropy of MoAlB single crystal

Three-dimensional (3D) anisotropic functional properties of a single material (such as magnetic, electrical, thermal and optical properties, etc.) are not only conducive to the multi-use of materials, but also help to enrich the regulatory dimension of functional materials.

Researchers from the Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences (CAS) have successfully grown 3D layered MAB-phase MoAlB single crystal and discovered colossal 3D electrical anisotropy. Related results were published in Small.

They used aluminum as a cosolvent and prepared high-quality and large-sized MoAlB single crystals. In this process, they found, unexpectedly, the huge 3D conductivity anisotropy in MoAlB single crystal, which was larger than previously reported.

According to experimental and theoretical studies, the 3D structural anisotropy of MoAlB was confirmed by single crystal X-ray diffraction and transmission electron microscopy. 3D anisotropic electronic structure and chemical bond of MoAlB were confirmed by theoretical calculation.

Read more.

6 notes

·

View notes

Text

What is Ferrite Magnet?

https://www.maglastic.com/what-is-ferrite-magnet.html

Many people may have heard of ferrite magnet in their lives, but they don't know what they are. Today, I will give you a detailed introduction to what is ferrite magnet.

The main raw materials of ferrite magnet include SrO or BaO and Fe2O3. Ferrite magnet is a sintered permanent magnet material composed of barium and strontium ferrite. In addition to strong anti-demagnetization performance, this magnetic material also has the advantage of low cost. The magnet of the opposite sex must be magnetized in the direction taken because it is oriented along the manufacturing direction; while the magnet of the same sex can be magnetized in any direction because it has no orientation, although a slightly stronger magnetic induction is often found on the side where the pressure is the smallest. Due to low cost, moderate performance, and good temperature resistance, ferrite magnet have a wide range of applications, from motors and speakers to toys and crafts. Therefore, it is currently the most widely used permanent magnet material.

1. Classification of Ferrite Magnet

According to different production processes, ferrite magnet is divided into sintering and bonding. Among them, sintering is divided into dry pressing type and wet pressing type, and bonding is divided into extrusion molding, compression molding and injection molding. Injection magnets are a type of magnet that has grown rapidly in recent years due to its advantages such as low energy consumption, short molding cycle, suitable for mass production, free magnetic pole orientation, and easy molding of complex devices.

According to whether an external magnetic field is applied during molding, it can be divided into isotropic permanent magnets and anisotropic permanent magnets. The magnetic properties of isotropic sintered ferrite magnets are weak, but they can be magnetized in different directions of the magnet; while the anisotropic ferrite magnet has strong magnetic properties, but can only be magnetized along the predetermined magnetization direction.

The soft, elastic and twistable magnet made of bonded ferrite powder and synthetic rubber is also called rubber magnet.

2. Performance Characteristics of Ferrite Magnet

Ferrite magnet is characterized by high coercivity and low remanence in performance. Ferrite magnet has high coercivity as well as strong anti-demagnetization ability, and is suitable for working in dynamic magnetic circuit environments with large temperature changes.

The ferrite magnet is hard and brittle and can be cut with emery tools.

The main raw material is oxide, so it is not easy to corrode and generally does not require plating.

Working temperature: -40℃ to +300℃.

We hope that you can better understand what is a ferrite magnet through the above description.

0 notes

Text

Application of Neodymium Ring Magnet in Motor

The magnetic field distribution of the neodymium ring magnets is as follows: the inner space of the ring still belongs to the outer magnetic field distribution, and part of the magnetic induction line connects the magnetic poles of both ends through the inner hole of the ring.

What is the magnet?

A magnet is a substance that repels each other. If small molecules in an object can be arranged in the same direction, it becomes a magnet. Its composition is iron, cobalt, nickel and another special atomic structure, the atom itself has magnetic moments, the general arrangement of these mineral molecules is disorderly. Magnetic regions interact with each other to show no magnetism, but the direction of molecular alignment tends to be consistent under the guidance of external forces (such as magnetic field), showing magnetism, also known as a magnet.

The magnetization of magnets:

Most magnetic materials can be magnetized to saturation in the same direction, which is called “magnetization direction” (orientation direction). Magnets without orientation (also known as isotropic magnets) are much less magnetic than oriented magnets (also known as anisotropic magnets).

Advantages and disadvantages of ring magnet for motors

Ring magnets used in motors are usually bonded neodymium magnets with injection-molded ferrite rings. The disadvantage is that both materials have poor magnetic properties.

The advantage is that the cost is low, easy to assemble, and the general speed such as 5000rpm or so, no protection outside the magnet, but for the general motor is enough.

What are the advantages and disadvantages of neodymium ring magnets?

Advantages: simple structure, easy installation, and cost-saving.

Disadvantages: cost is more expensive than tile design.

Technically, the radiation ring has been very mature, and some large customers are using it in batches.

Thank you for reading our article, hope it can help you better understand the characteristics of NdFeB magnets. We, Ningbo Tengxiao Magnetic Industry Co., Ltd. have many neodymium ring magnets and custom industrial magnets products. Welcome to visit our website to check.

0 notes

Text

SmCo Magnets

https://www.rishengmagnets.com/products/smco-magnets.html

SmCo magnets (also called Samarium Cobalt magnets) are consist of Sm (samarium), Co (cobalt), and other elements like Hf(hafnium) or Zr(zirconium), they are part of the permanent rare earth magnet family, there are two main types, the composition of SmCo5 is samarium 37% and cobalt 63%, while Sm2Co17 is: samarium 25%, copper 5%, iron 18%, hafnium or zirconium 2%.

As a reputable magnet manufacturer in China, RiSheng has various high quality SmCo magnets for sale, all with affordable prices. The advantages of SmCo magnets supplied by our factory are strong magnetic strength, high-temperature resistance, and reliable performance against corrosion, they can keep their magnetic properties in very high-temperature conditions, the maximum working temperature of SmCo5 is 250℃, while Sm2Co17 is 350℃.

Types Of SmCo Magnets

Samarium Cobalt Magnet

Samarium Magnets

Sm2co17 Magnet

Smco Magnet

Smco Magnet Grades

Grades of SmCo Magnets

Manufacturing Method Of SmCo Magnets

SmCo magnets are produced by sintering process, but also can be produced by injection molding and compression bonding, for sintered SmCo magnets, samarium, cobalt, and other transition metals will be made into micro size SmCo powders, these powders are compacted into a rigid steel mold and pressed, after that sintered at a very high temperature, similar shapes as the final product will be produced, then machined to final size with a good surface finish.

SmCo magnets are hard and brittle, they are easily chipping and cracking, so the machining must be done by the water-cooled diamond-coated grinding machine.

Magnetizing & Surface Treatment Of SmCo Magnets

All SmCo magnets are anisotropic, they are treated and cooled in a magnetic field, then oriented with a preferred magnetic direction with maximum magnetic direction, the extremely high magnetic field is required due to high coercive force, they can only be magnetized along the oriented direction, multi-poles magnetized is also possible with the special magnetizing fixture.

The corrosion-resistant of SmCo magnets is considered good, no surface coating is necessary, but the coatings like NiCuNi, Zn, Black epoxy can be plated if required.

Applications Of SmCo Magnets

SmCo magnets are widely used in the wind, power, medical, aerospace, military, automotive, semiconductor, oil, and energy industry of very high or low-temperature environments, the most common applications are wind turbine equipment, electric motors, turbomachinery, medical devices, accelerometer, particle accelerators, magnetic couplings, sensor systems, magnetic separation devices, high-performance motors, actuators, automation equipment, robotic arms, pipeline inspection, magnetic bearings, traveling wave tubes, robotic arms, magnetic drive components, generators, energy recovery systems, pipeline inspection, magnetic bearings and more.

0 notes

Text

Rubber/Flexible Magnets

Brief introduction of rubber magnets(magnetic rubber):

Rubber magnets sometimes called magnetic rubber. Magnetic rubber itself has no magnetism , the magnetism comes from filled magnetic powder. So the magnetic powder is obligate material for produce magnetic rubber. Magnetic additive can be divided into metal magnetic powder, Fe-Co powder, Fe-Ni powder and Fe-Ba powder. Fe-Co powder is the most widely used. Metal magnetic powder is seldom used because of the expensive cost. At the present, the Fe-O powder mostly used, they are ferric oxide and two valence metal compounds, although is the same ferrite magnetic powder, the ultimate magnetic strength are not the same because of the different crystal habit,particle size, and uniformity. In fact, rubber magnet belong to ferrite magnet series, it is the magnet composed of bond ferrite magnet powder and synthetic rubber, made out by extrusion molding and injection molding, and it can be distorted. Rubber magnets can be machined into rubber magnetic strips, rubber magnetic rolls, rubber magnetic sheets and other different shapes.

Rubber magnet belong to ferrite magnetic materials series, it is made from ferrite magnes powder and rubber by extruding or injecting. It has properties of soft, resilience and twisable. Just because of these properties,it also called flexible magnets. It’s maximum energy is 0.60~1.50 MGOe。

Manufacturing process of rubber magnets(magnetic rubber):

The manufacturing process of magnetic rubber is much the same as other products. At first, determine the variety,particle size and dosage of magnetic powder. Then determine the rubber kinds according to application of rubber magnets. For example, natural rubber needed for wear resistant rubber magnets. The magnetization process need to be added when vulcanize it, which give the products permanent magnetism. The advantage for magnetize it before vulcanizing is external magnetic field not changed and pass the rubber network easily;The passing ability of magnetic field is bad for magnetize it after vulcanizing, but it is easy to operate .

The physical quantity used to represent magnetism of rubber magnets are magnetic induction strength, remanence , and maximum energy etc. Magnetic induction strength is most commonly used, the value of which is required to be 100-600GS.

Rubber magnets made of magnetic powder(SrO6、Fe2O3),(CPE)and other additive(EBSO、DOP),and made out by extruding or calendering. Rubber magnets can be devided into isotropic rubber magnets and anisotropic rubber magnets . It can be machined into rubber magnetic strips, rubber magnetic rolls, rubber magnetic sheets and other different shapes. The maximum energy of rubber magnet is 0.60-1.50 MGOe. The surface of rubber magnet can be covered with PVC,coated paper,adhesive.

Production process of rubber magnets:

ingredient��mixture→extruding/calendering /injecting → machining →magnetizing →inspecting(appearance,size,magnetism,hardness,density, ageing resistance etc) → packing

The application of rubber magnets:

The door sealing strip is on behalf of the traditional application of rubber magnets. With the development of high-tech and household electrical appliance, rubber magnets get more widely used.The main application field of rubber magnets are micro-motors,door sealing for kinds of electrical appliances and advertisement.

https://www.meank-magnet.com/products/magnetic-material/rubber-flexible-magnets/

0 notes

Text

How to distinguish bonded NdFeB and sintered NdFeB?

Neodymium magnets can be called neodymium iron boron magnets, which is a general term for powerful magnets. Its chemical formula is Nd2Fe14B. It is an artificial permanent magnet and has the strongest magnetic force so far. The material grades of neodymium iron boron magnets are N35-N52; the shapes can be processed into different shapes according to specific requirements, including round, square, perforated, magnetic tile, magnetic rod, convex or trapezoidal, etc.

How to distinguish bonded NdFeB and sintered NdFeB? In fact, both types of magnets belong to NdFeB. The two types of magnets are distinguished according to their production processes. The bonded NdFeB magnet is actually formed by injection molding, while the sintered NdFeB magnet is formed by evacuating and then heating at high temperature.

Bonded neodymium iron boron magnets are formed by injection molding, so they contain adhesives, the density of which is generally only 80% of the theoretical. The sintered NdFeB magnet is heated at a high temperature through a complicated process. Therefore, the bonded NdFeB magnet is attenuated by about 30% compared with the sintered NdFeB magnet.

Sintered NdFeB magnet is an anisotropic magnet produced by powder sintering method. Generally, only a blank can be produced through sintering, and then through mechanical processing (such as wire cutting, slicing, grinding, etc.) to become magnets of various shapes. Sintered NdFeB is a hard and brittle material that is difficult to process. It has high loss during processing, high cost, poor dimensional accuracy, poor corrosion resistance, and the surface needs to be electroplated. But the advantage is that the performance is higher, and it has achieved more than 50M.

In summary, the magnetic properties of bonded NdFeB magnets are only about 5% of that of sintered. At present, the energy product of sintered NdFeB magnets can reach more than 50M, while the bonded magnets are generally below 10M, and the best is only 12M. The performance of the magnetic powder used in bonded magnets is generally 15M, and it is only 10.5M at most after being made into bonded magnets. Therefore, sintered NdFeB is generally used in a wider range than bonded NdFeB.

0 notes

Text

Effects of Magnetic Parameters on Permanent Magnet PM Motors

Effects of Magnetic Parameters on Permanent Magnet PM Motors How to measure the magnetic properties of magnet? Almost all magnet manufacturers use B-H curve testing equipment to get the demagnetization curve of magnet. This method is a closed circuit measurement, and an uniform cross-section sample is clamped between the faces of electromagnet. The testing sample is usually cut from the…

View On WordPress

#aluminum nickel cobalt#Anisotropic Bonded Magnets#Bonded NdFeB Magnets#bonding magnets#bonding neodymium iron boron#Ferrite magnet#high-performance permanent magnet motors#hybrid magnets#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#magnetization direction#motor magnets#Nd-Fe-B#Nd-Fe-B magnets#Nd2Fe14B#NdFeB#NdFeB bonded magnet#NdFeB Grinding Process#Neodymium iron boron#Neodymium Magnet#Neodymium Magnets are Made#Neodymium Motor Magnet#permanent magnet motors#Permanent Magnets#REE Magnets

1 note

·

View note

Text

Magnetic Anisotropy

Magnetic Anisotropy is the capacity of a magnet to maximize its magnetic orientation in the direction of its poles, and it is similar to general anisotropy of other material characteristics.

Strong permanent magnets – especially sintered Neodymium magnets- have had their magnetic domains oriented in the direction of the easy axis to maximize their strength.

Anisotropy is the property of any…

View On WordPress

#anisotropic#anisotropic bonded magnets#anisotropic magnets#Bonded magnets#Bonded Neodymium Magnets#ferromagnetism#Hard Magnetic Materials#Hard magnets#isotropic#isotropic magnet#Magnetic Anisotropy#magnetic fields#Magnetic Isotropy#Magnetocrystalline Anisotropy#Magnetoelastic Anisotropy#Neodymium magnets#Sintered magnets#Sintered Neodymium Magnets#SOFT MAGNETIC MATERIALS#Strong permanent magnets

0 notes

Text

Bonded Magnet Market is predicted to be worth 7% CAGR by 2025

According to a recent research report by Transparency Market Research (TMR), the global bonded magnets market is led by leading players such as Allstar Magnetics, Arnold Magnetic Technologies, Neo Magnequench, Alliance LLC, and Viona Magnetics, etc. Market players are operating with intense focus on the integration from raw material supply to manufacturing process, so as to bring about a reduction in the cost of production. Leading players within the market are also vying to boost their product portfolio so as to meet the newer demands from distinct end use industries.

According to Transparency Market Research, the global bonded magnets market will expand at a 7% CAGR between 2017 and 2025 and reach an evaluation of US$2.5 bn by 2025. On the basis of application, the electric and electronics segment is leading both in terms of Revenue and volume. The high demand for hand tool motors, cameras, refrigerator door seals, frictionless bearings, fan motors, gaskets, clocks, and watches is boosting the growth of the electrical and electronic segment. The flourishing automotive sector is also a key application area for bonded magnets period in the automotive sector, bonded magnets are used in the motors for vipers, wheel speed sensors, power windows, crash sensors, wheel speed sensors, crash sensors, sound-deadening panels, chassis height sensor, tachometer, ignition magnets, fuel gauges, and speedometers.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=29480

On the basis of geography, Asia Pacific is witnessing the highest demand for bonded magnet, with China being in the forefront. As South Korea and Japan at a production base for Semiconductor chips and storage devices on hard disk and similar. The product, the demand for bonded magnet is high from these two countries as well. Asia Pacific not only produces but also exports huge amounts of bonded magnets to other regions in the world on account of the height of a lability of raw materials such as rare earth metal, availability of cheap labour, and advanced technologies.

One of the key factors revolutionising the bonded magnets market is additive manufacturing or 3D printing which has changed the production method of the bonded magnets and it is now possible to form complex shapes of both thermoset and thermoplastic bonded magnets with minimal wastage of material and at a reasonable cost. The market is significantly benefitting from the trend of miniaturization. The growing demand for miniaturization of various automotive parts such as sensors and electronic systems will create a heightened demand for bonded magnets. The growing need for boosting performance efficiency in the automotive sector is also behind the high demand for bonded magnets.

Request to view Brochure Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=29480

The information presented in this review is based on a Transparency Market Research report, titled, “Bonded Magnet Market (Product – Rare-earth Bonded Magnets (Isotropic and Anisotropic), Ferrite (Plastic and Rubber), and Hybrid; Process – Calendaring, Extrusion, Injection Molding, and Compression; Application – Automotive, Electrical & Electronics, Industrial, Medical, and Power Generation) – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2017 – 2025”

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,90 State Street,

Suite 700,Albany NY – 12207,United States

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes

Text

Critical Materials Institute Takes Major Step Toward Printed Anisotropic Magnets

Critical Materials Institute Takes Major Step Toward Printed Anisotropic Magnets

The U.S. Department of Energy’s Critical Materials Institute has taken a major step toward printed, aligned anisotropic magnets via additive manufacturing processes.

The Energy Innovation Hub manufactured hybrid nylon bonded neodymium-iron-boron and samarium-iron-nitrogen magnets using the Big Area Additive Manufacturing (BAAM) located at Oak Ridge National Laboratory.

“The application of additiv…

View On WordPress

0 notes

Text

Hybrid Bonded Magnetic Compounds

https://www.maglastic.com/products/hybrid-bonded-magnetic-compounds.html

Hybrid Bonded Magnetic Compounds Introductions:

By mixing different kinds of magnetic powder in different proportions, we can obtain a series of hybrid magnets whose magnetic properties are higher than ferrite bonding magnet and lower than bonded neodymium (anisotropic) magnet, which can meet the customized application demands and reduce the cost.

Properties of Hybrid Bonded Magnetic Compounds:

High corrosion resistance than that of bonded neodymium magnet.

Thermal demagnetization properties change little with temperature

High-cost performance.

Applications of Hybrid Bonded Magnetic Compounds:

Motor rotor; magnetic ring; sensor; etc.

0 notes

Text

Neodymium Magnets

https://www.rishengmagnets.com/products/neodymium-magnets.html

Neodymium magnets (also called NdFeB magnets, Neo magnets) are consisted of Nd (neodymium), Fe (Ferrum), B (boron), and other elements like Dy (dysprosium) and Ti (Titanium). As part of the permanent magnet family, they are the latest generation of rare earth magnets. Neodymium magnets are extremely super strong magnets commercially available in the world, their pull force are quite strong compared to their own size, they have high magnetic remanence, high energy product and relative good coercive, due to these advantages, they are the most widely used magnets today.

As a reputable neodymium permanent magnet manufacturer in China, RiSheng has various types of powerful magnets for sale, in our online shops and physical stores, with competitive price per kg, very cost effective. In terms of the size, our factory supplies not only the small series— paper thin, micro, tiny, mini, but also the big ones—large, huge, giant monster. Considering practical applications, we provide customized neodymium magnets. They are of different shapes: arc, rod, bar, ball, ring, disc, flat, block, sphere, eclipse, curved, bonded, rectangular, cylindrical, with countersunk holes; and are for different purposes and industrial uses: for cutting, drilling, grinding, machining, for therapy, water meter, etc. Some of them can be sintered, silicone coated, some can be made super strong, adhesive, waterproof. For the convinience of our customers, Risheng has already prepared relevant pdf files and videos about neodymium magnets. Contact us immediately, get cheaper price with best service.

Types Of Neodymium Magnets

Permanent Magnets

The Permanent Magnet

Permanent Magnet Materials

Permanent Magnetism

Most Powerful Permanent Magnet

Making A Permanent Magnet

Rare Earth Magnet Strips

Rare Earth Permanent Magnet

Iron Permanent Magnet

Powerful Rare Earth Magnets

Grades Of Neodymium Magnets

We can manufacture and supply all the grades from energy product 35MGOe to 52MGoe and from N series to AH series.

Grades of Neodymium Magnets

Demagnetization Curves Of Neodymium Magnets

We list the performance of the highest grades with different series when demagnetization.

Demagnetization Curves Of Neodymium Magnets

Demagnetization Curves Of Neodymium Magnets

Demagnetization Curves Of Neodymium Magnets.jpg

Demagnetization Curves Of Neodymium Magnets.jpg

Demagnetization Curves Of Neodymium Magnets.jpg

Demagnetization Curves Of Neodymium Magnets.jpg

Physical Properties Of Neodymium Magnets

A few main physical properties are listed, like density, curie temperature, etc.

Physical properties of Neodymium Magnets

Sizes & Tolerance Of Neodymium Magnets

We can produce different shapes, like a disc, cylinder, ring, arc segment, and custom complicated shapes, a wide range of sizes are possible with a few limits.

The standard tolerances are generally +/-0.1mm, while slightly varies depending on how big the size is.

Sizes & Tolerance of Neodymium Magnets

Magnetization Of Neodymium Magnets

All Neodymium magnets are anisotropic and oriented with a preferred direction during production, they can only be magnetized thru the oriented direction. Disc/cylinder/ring magnets are axially or diametrically magnetized, block magnets are magnetized along one side of three sides, arc segment magnets are generally diametrically magnetized.

Magnetization Of Neodymium Magnets

Surface Coatings Of Neodymium Magnets

The corrosion resistance of Neodymium magnets is considered very poor, a surface coating will be necessary, the most common coatings are NiCuNi, Zn, Black Epoxy, Teflon/PTFE, Rubber/Plastic.

Surface coatings of Neodymium Magnets

Manufacturing Method Of Neodymium Magnets

Neodymium magnets are made by a sophisticated process using very advanced metallurgical methods, the main process is Rare earth raw materials - Quick curing - Strip casting - Hydrogen decrepitation - Milling - Pressing - Sintering - BH curve testing - Machining - Plating - Magnetizing - Packaging.

Manufacturing Method

Applications Of Neodymium Magnets

Neodymium magnets are widely used for industrial, technical, commercial, and consumer applications, the most common applications are motors/generators, sensors, audio equipment, holding/lifting systems, magnetic bearings, hard disc drives, levitation devices, magnetically coupled pumps, medical devices, magnetic separators, packaging closures, commercial signage/display.

0 notes

Text

Permanent Magnet Motor Operation Tips

Permanent Magnet Motor Operation Tips Key technical points for maintaining normal operation of permanent magnet motors Once the permanent magnet motor is demagnetized, basically the only option is to replace the motor; the cost of repair and a large amount of how to determine the permanent magnet motor demagnetized it, we go on to see. The machine at the beginning of the operation of the current…

View On WordPress

#aluminum nickel cobalt#Anisotropic Bonded Magnets#Bonded NdFeB Magnets#bonding magnets#bonding neodymium iron boron#Ferrite magnet#high-performance permanent magnet motors#hybrid magnets#Magnetic alloy#magnetic field#magnetic fields#magnetic forces#magnetic properties#magnetization direction#motor magnets#Nd-Fe-B#Nd-Fe-B magnets#Nd2Fe14B#NdFeB#NdFeB bonded magnet#NdFeB Grinding Process#Neodymium iron boron#Neodymium Magnet#Neodymium Magnets are Made#Neodymium Motor Magnet#permanent magnet motors#Permanent Magnets#REE Magnets#samarium cobalt#Sintered Neodymium Magnet

1 note

·

View note

Text

The “Center” of Permanent Magnet Motors

The “Center” of Permanent Magnet Motors – Permanent Magnets The development of permanent magnet motors is closely related to the development of permanent magnet materials. China is the first country in the world to discover the magnetic properties of permanent magnetic materials and apply them to practice. More than 2000 years ago, China made a compass using the magnetic properties of permanent…

View On WordPress

#aluminum nickel cobalt#Anisotropic Bonded Magnets#Bonded NdFeB Magnets#bonding magnets#bonding neodymium iron boron#Ferrite magnet#high-performance permanent magnet motors#hybrid magnets#Magnetic alloy#Magnetic Circuit Structure#magnetic field#magnetic fields#magnetic forces#magnetic properties#Magnetic powder#magnetization direction#Manufacturing Process#motor magnets#Nd-Fe-B#Nd-Fe-B magnets#Nd2Fe14B#NdFeB#NdFeB bonded magnet#NdFeB Grinding Process#NdFeB PPS magnet#NdFeB Semi-finish material#Neodymium iron boron#Neodymium Magnet#Neodymium Magnets are Made#Neodymium Motor Magnet

1 note

·

View note