#Ammonia valves

Explore tagged Tumblr posts

Text

Mycom Screw Compressors: A Reliable and Efficient Choice.

Mycom Screw Compressors are renowned for their exceptional performance, reliability, and energy efficiency. These high-quality compressors are designed to meet the demanding requirements of various industries, from manufacturing and construction to refrigeration and air conditioning.

Understanding Mycom Screw Compressors

Mycom Screw Compressors utilize advanced screw technology to deliver consistent and reliable air compression. The twin-screw design ensures smooth operation and minimal vibration, resulting in a quiet and efficient machine. These compressors are known for their durability, long service life, and low maintenance requirements.

Key Features of Mycom Screw Compressors

High Efficiency: Mycom Screw Compressors are designed to optimize energy consumption, reducing operating costs and minimizing environmental impact.

Reliability: Built to withstand demanding applications and provide years of reliable service.

Quiet Operation: The twin-screw design ensures smooth and quiet operation, minimizing noise pollution.

Low Maintenance: Mycom Screw Compressors require minimal maintenance, reducing downtime and maintenance costs.

Versatility: Suitable for a wide range of applications, from general-purpose air supply to specialized industrial processes.

Applications of Mycom Screw Compressors

Mycom Screw Compressors are used in various industries, including:

Manufacturing: Powering pneumatic tools, machinery, and processes.

Construction: Operating pneumatic equipment for drilling, hammering, and other tasks.

Refrigeration and Air Conditioning: Providing compressed air for refrigeration systems and air conditioning units.

Automotive: Used in automotive manufacturing and repair facilities.

Food and Beverage: Powering pneumatic equipment in food processing and packaging.

Choosing the Right Mycom Screw Compressor

When selecting a Mycom Screw Compressor, consider the following factors:

Capacity: Determine the required air flow rate and pressure for your application.

Efficiency: Evaluate the compressor's energy efficiency rating to minimize operating costs.

Noise Level: Consider the noise level if the compressor will be located in a noise-sensitive area.

Maintenance Requirements: Assess the compressor's maintenance needs and the availability of spare parts.

Installation and Support: Ensure the supplier provides professional installation and after-sales support.

Mycom Screw Compressor Maintenance

Proper maintenance is essential to ensure the long-term performance and reliability of your Mycom Screw Compressor. Regular maintenance tasks include:

Oil Changes: Follow the manufacturer's recommended oil change intervals.

Filter Replacements: Replace air filters and oil filters as needed.

Inspections: Conduct regular inspections for any signs of wear, leaks, or damage.

Lubrication: Lubricate moving parts according to the manufacturer's instructions.

Professional Service: Schedule regular maintenance and servicing by qualified technicians.

Mycom Screw Compressors offer a reliable and efficient solution for various industries. By considering the factors mentioned above and investing in proper maintenance, you can ensure the long-term performance and value of your Mycom Screw Compressor.

Visit US - https://www.coldforce.com.au/product-category/compressors/screw/

Contact US - Phone - 0393180903

Mail ID - [email protected]

Timings - 8:00AM - 5:00PM

0 notes

Text

Ammonia valves | Ammonia valves supplier, Manufacturer in Pune, Mumbai, India

Asha Enterprises, is best Ammonia valves supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia valves#Ammonia valves supplier#Ammonia valves manufacturer#Ammonia valves in Pune#Ammonia valves in Mumbai#Ammonia valves in Thane#Ammonia valves in Navi Mumbai#Ammonia valves in Kolhapur#Ammonia valves in Ratnagiri#Ammonia valves in Raigad#Ammonia valves in Nashik#Ammonia valves in Solapur#Ammonia valves in Latur#Ammonia valves in Aurangabad#Ammonia valves in Sindhudurg#Ammonia valves in Sangli#Ammonia valves in Ahmednagar#Ammonia valves in Satara#Ammonia valves in Maharashtra#Ammonia valves supplier in Pune#Ammonia valves supplier in Mumbai#Ammonia valves supplier in Thane

0 notes

Text

The Best Corken Compressors for Your Needs

In industrial settings, compressors are vital components that drive various processes forward. They are essential for tasks like air compression, gas handling, and refrigeration, playing a role in improving efficiency and productivity. This article will discuss the kinds of compressors, their uses, and important factors to consider when choosing the right compressor for your specific requirements. We'll cover topics such as unloading compressors, ammonia compressors, LPG compressors, and CORKEN compressors to give you an understanding of how they work and where they can be applied.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

Ok so in my fic Slip I vaguely based Hydra off of a DOT-114 tanker because i could find the specification really easily they're sometimes used for pressurised gasses, but GOOD NEWS! I was wrong and also stupid :)

I've been recreationally overthinking this all day, for funsies. The interesting thing is, in Europe we don't really have H2 on the rails in that way yet- DB cargo is doing a lot of work there, but not in any formats that match up with the green bean. We know he doesn't carry ammonia or methanol because his fuel is usable without pre-processing, and we know he's not any sort of MEGC. The only other option in europe is cryocontainers of LH2, but they're intermodal- you can put one on a ship, unload it onto a lorry or a flatbed or whatever, and go about your merry way. so not that neither.

(sidebar: I know he is a creation of andrew lloyd webber's twisted mind and also a twink on rollerskates, but shh. im playing touys.)

The likelier option, imo, is that he's carrying cryogenic liquid hydrogen. This would track with some sliiightly older technologies (and i really do mean slightly) like liquid natural gas, which has already been used in duel-fuel locomotives. At time of writing, the only thing I could scrounge up that's actually authorised for cryogenic hydrogen transport on US rails are DOT-113 tanker cars, which are usually designed for other cryogenic liquids but. Uh. Im sure its fine. Nowt in the UK yet, we've got all of it on the roads at the minute. He's some kind of freaky half-to-spec pilot project to me anyways, I just need to ballpark.

According to the Railway Association of Canada's Railway Emergncy guide, DOT-113A60W tankers have a working temperature of -423F, which is the temperature hydrogen becomes liquid at.

So! That means we're working with DOT-113A60W!Hydra, or at least something similar! :D He's got a tank-within-a-tank system, weather-shielded loading/unloading valves, and DO NOT HUMP OR CUT OFF WHILE IN MOTION stenciled somewhere easy to see. Thank you for coming to my ted talk!

#starlight express#stex hydra#hydra the hydrogen tanker#starlight express london 2024#stex london revival#the Articles#my posts

25 notes

·

View notes

Text

H.P. Lovecraft once wrote a story exploring his phobia of air conditioning. This may seem nonsensical now, but back in the 1920's, when all refrigeration and air conditioning systems were basically handcrafted and used ammonia, I'd've been wary of the damn things too.

One of many companies that sold protection from Ammonia was Protecto. I am not sure of the exact date of their founding, but we know that in 1923 they were purchased by a company mostly known at the time for their all-in-one first aid kits, Davis Emergency Equipment Company.

Protecto was a relatively small brand and their name doesn't come up much. We have a couple of photos of their "ammonia helmet" masks. I don't have an exact date on those, but one picture-article I have which shows those photos has 1917 penciled on it. Who knows.

Protecto has two notable contributions to the history of respirators: the aforementioned Davis merger in 1923, and getting sued by Max Yablick in 1927. I guess they were still going by the Protecto name for a time after the buyout.

Yablick is known for patenting the Yablick valve, sometimes incorrectly referred to as a Connell valve, and for developing Kupramite, which absorbs ammonia very effectively and this makes for good mask filters.

As he held the patent for Kupramite, he determined that Protecto's use of it in their masks without his permission was a patent infringment. However, as he had been working for the CWS at the time of his discovery, he lost the lawsuit, on the grounds that you cannot make exclusive private profit off of research that was funded by the American public.

It would be funny as fuck if he also sued all the industrial companies that used Yablick valves on their masks, but I digress.

So, onto the actual mask we're looking at here today, the Absorbits. It's a standard Akron-Tissot Type B facepiece with a standard-size industrial filter. The label is a single strip of paper wrapped around the filter, which is shedding paint.

Easily the coolest part of this is the "decoder" ring on the front of the canister sheath. You basically rotate it after every use to indicate how much time is left on the filter. This is a stupid idea and did not last long, although Davis would keep the basic idea of the metal sheath around for a while, albeit with some refinements. I do like the metal hook for hanging the facepiece though.

Thanks to @goatsludge for editing these pics for me.

5 notes

·

View notes

Note

AITA for misusing chemical weapons? So, I live after a zombie apocalypse, and I noticed a bunch of zombies had grouped together in a poorly ventilated warehouse, near a paper mill and a fertilizer plant. Anyways their stores of bleach and ammonia respectively were both rather elevated, so I had a brilliant idea: gently lower a big tank through the warehouse's skylight, get the chemicals flowing into the tank by sneaking in with some hoses, and opening the valves to release them into the hoses, and just gassing the place.

As it turns out, chloramine gas doesn't actually hurt zombies that badly, actually, that's not true, it turns out the parts of the zombie chloramine gas hurts aren't essential, somehow, and they don't suffocate, actually really bad lung damage makes zombies more dangerous because they stop groaning due to lack of airways. Anyways, a bunch of survivors are giving me shit for filling a warehouse with silent zombies and poison gas, it was already full of zombies, I just thought that, you know, corroding the zombies lungs would deal with them, not make them deadlier.

9 notes

·

View notes

Text

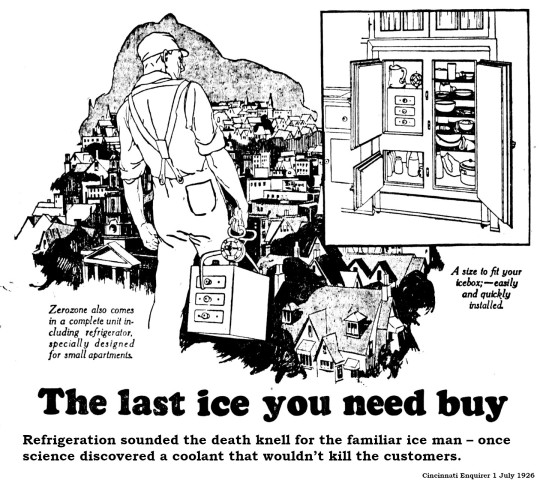

Refrigeration Was A Wonderful Invention When It Wasn’t Trying To Kill You

Over the years, Cincinnatians have discovered myriad methods to kill themselves. Breweries alone offered boiling vats, open shafts, toppling equipment and exploding barrels. At home, poisonous wallpaper, flammable nightgowns and yawning cesspools claimed many lives. As if we needed any additional hazards to jeopardize our safety, the Twentieth Century introduced yet another deadly contraption – the refrigerator.

The Cincinnati Post [22 June 1920] related one incident that nearly ended in tragedy:

“Firemen carried several tenants from upper floors of a four-story building at Eighteenth and Main streets Tuesday when ammonia fumes, escaping from an ice machine in the cellar, entered corridors and apartments. A valve in a machine that supplies refrigeration in the butcher shop of John Stegner, first floor of the building, blew off shortly before 10 a.m., causing the fumes to escape.”

The circumstances involved here were fairly typical for Cincinnati in the early 1920s and 1930s. Refrigeration was just beginning to enter the domestic market and most electric refrigerators were installed by businesses. In the early days, the noisy refrigeration machinery was usually relegated to the basement. The coolant of choice for most commercial systems was ammonia. Some of these installations were ponderous, as reported in the Post [10 March 1930]:

“Attempting to shut off ammonia pipes after a compressor head broke in the 15-ton refrigeration plant at Hamilton County Tuberculosis Sanitarium Monday at 8 a.m., Gus Leistner, 65, of 914 Findlay-st, engineer, partially was overcome by fumes.”

Later that same year, the University Club at Fourth and Broadway had to be evacuated because of ammonia leaking from its refrigeration system. The Strietmann Baking Company at Central Parkway and Plum Street suffered a massive ammonia spill in 1924. Firemen needed gas masks to enter the Hilberg Packing Company at 516 Polar Street in 1928 when ammonia seeping from the refrigerator filled the building.

Despite such catastrophes, ammonia was the most common coolant for the first thirty years of the 1900s. A Cincinnati firm, the F.W. Niebling & Son Co., of 406 Elm Street, boasted in an advertisement [20 February 1927] that the first ammonia-infused refrigeration plant installed by the company was 31 years old and still “in excellent condition.”

Still, ammonia was connected to so many mishaps that advertisers touted any system that did not involve ammonia. In 1926, the Tudor Court Apartments in Clifton installed a building-wide refrigeration system, with each of the 86 apartments equipped with a Frigidaire unit serviced by a massive compressor in the basement. The owners hastened to advertise that “no brine or ammonia” was used in that system.

Ammonia wasn’t the only chemical employed in refrigeration equipment. Responding to a reader’s inquiry, the Post [22 July 1921] inventoried a veritable witch’s cauldron of compounds used in various systems:

“What is the formula for the solution which is used in the cooling coils of an electric refrigerator? Substances are: Ammonia, carbon dioxide, ethyl chloride, methyl chloride and sulphur dioxide.”

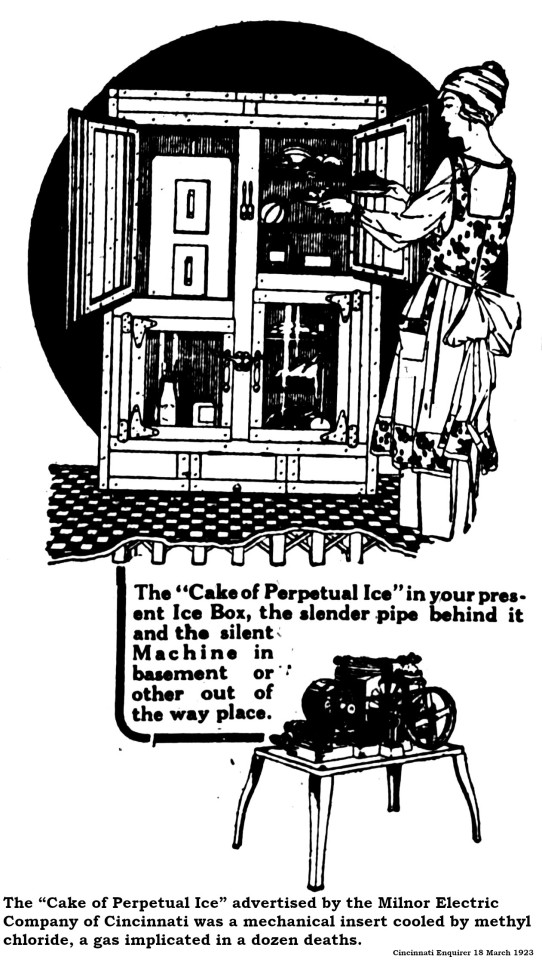

Of that formulary, ammonia’s biggest competitor was methyl chloride, a colorless, odorless, flammable gas. Methyl chloride was more efficient than ammonia and better suited to the small coolant devices required for a single house, as opposed to the big industrial machines cooled by ammonia. Units incorporating methyl chloride were so small they were retrofitted as mechanical ice blocks. Customers kept their old ice boxes, canceled ice delivery and turned on a methyl chloride unit in the same compartment where they would formerly have loaded a block of ice.

Manufacturers also claimed methyl chloride was safer than ammonia. Cincinnati’s Milnor Electric Co. highlighted this benefit in an advertisement [18 March 1923] for their Serv-el Automatic Electric Home Refrigeration products in the Cincinnati Enquirer:

“Important Notice: The gas (methyl-chloride) used in Serv-el is harmless, odorless and non-poisonous. Only Serv-el has this advantage.”

This claim was sorely tested in August 1929 when a rash of deaths blamed on methyl chloride refrigerators was reported from Chicago. The Chicago deaths created a panic among refrigeration companies who appealed to the federal government for assistance. The Cincinnati Enquirer [23 August 1929] reported that three governmental agencies – the Public Health Service, the Bureau of Standards, and the Bureau of Mines – had announced that household refrigeration systems were safe.

“Serious accidents from household refrigeration systems, the statement continued, have been small in comparison to the number in use and added that improvements might be expected that would reduce materially the small hazard that does exist.”

The Chicago deaths gave hope to the consumer ice industry, fighting a losing battle against the march of progress. In an Enquirer advertisement [31 July 1926], the City Ice & Fuel Co. complained that these new-fangled systems required:

“ . . . a complicated, high-cost mechanical-chemical outfit, dependent on a large and continuous supply of electricity to make it ‘run,’ and on some chemical (SULPHUR DIOXIDE OR METHYL CHLORIDE) to create cold – just as ammonia is used in the big ice plants.”

It was, of course, a losing proposition. The old ice boxes were messy, moldy things that really didn’t keep food all that cold and regularly flooded the kitchen with water melted from the huge block of ice delivered by some guy who tracked muddy footprints across your carpet.

All the industry needed was a better coolant, a chemical that cooled your refrigerator but didn’t kill you. The solution came from an inventor named Thomas Midgley Jr., who lived just up the road in Dayton. In 1932, Midgley came up with something called Freon. It checked all the boxes and soon replaced all other coolants for the next 60 years or so.

Problem was, Freon, a chlorofluorocarbon, accumulated in the atmosphere and contributed to the destruction of the ozone layer that protects life on earth from the harmful rays of the sun. So, in essence, to avoid a few disastrous refrigeration accidents, we found a solution that endangered all life on the planet.

Ponder that the next time you pull a brewski from the fridge.

4 notes

·

View notes

Text

Global Hydrogen Valve Market Size, Share, Growth and Forecast 2032

Global Hydrogen Valve Market is projected to witness a CAGR of 7.38% during the forecast period 2025-2032, growing from USD 350.71 million in 2024 to USD 619.91 million in 2032. The market has experienced significant growth in recent years and is projected to witness prosperous growth owing to the expansion of hydrogen infrastructure, rapid investments in hydrogen fueling stations, and increasing focus on decarbonization. The global hydrogen valve market demand is projected to rise due to rising hydrogen requirements, government initiatives to boost hydrogen production and consumption, and increasing emphasis on clean fuels. The rising awareness concerning reducing carbon emissions drives the demand for hydrogen valves, as hydrogen proved to be a clean energy alternative. Emerging countries and companies are efficiently investing in hydrogen production, distribution, and efficient storage, and the requirement for efficient and reliable valves will rise. In addition, the governments of emerging countries are implementing policies and granting monetary and non-monetary incentives to encourage the usage of hydrogen technologies as part of their climate action plans. Not only this, but the government is also increasing the amount of investment in hydrogen infrastructure development, propelling the growing requirement for hydrogen-concerned equipment.

Hydrogen is widely used in industrial processes, including ammonia production, refining, and fuel cells. The advancement and expansion in these industries and the adoption of hydrogen technologies will propel the requirement for specialized valves to handle the hydrogen efficiently and safely. Moreover, companies in the market plan to introduce a new range of valves to meet all the required safety conformance for hydrogen infrastructure.

For instance, in December 2024, Christian Bürkert GmbH & Co. KG announced the launch of ultra-high-pressure valves for hydrogen applications that can control hydrogen up to 1,000 bars, suitable for grid infrastructure and vehicle fueling stations.

Ongoing Technological Advancements Drive the Hydrogen Valve Market Globally

Technological advancements include integrating high-performance materials and processes to confirm stable operations under different conditions, driving the global hydrogen valve market demand in the forecast period. Automation and artificial intelligence are reshaping the global hydrogen valve market by improving the effectiveness and reliability of production procedures. Artificial integration enables predictive maintenance, reduces maintenance costs and downtime, and allows manufacturers to anticipate equipment failures, driving the global market for hydrogen valves in the forecast period. In addition, hydrogen valves embrace digitization and the trend toward intelligence, accomplishing more flexible and efficient functions. The application of high-performance materials and manufacturing technologies enables hydrogen valves to function in a comprehensive range of temperatures and pressures. This advancement in hydrogen valve technology will propel market growth in the forecast period. Furthermore, companies in the market are introducing high-performance and advanced valves for automotive and other industries to expand their market presence and product portfolio.

For instance, in March 2024, Eaton Corporation plc introduced a next-generation fuel tank isolation valve for hybrid electric vehicles to address evaporative emissions that accumulate when the gas engine is not in operation. The new fuel tank isolation valve is easier to mount as these are 27% lighter, 39% smaller, and comprises 24% fewer components than its predecessor.

Rising Concern for Renewable Energy Surges Demand for Hydrogen Valve

The rising awareness concerning renewable energy is driving the global hydrogen valve market demand as hydrogen valves are important for the efficient operation of fuel cells and ensuring proper pressure and volume for high performance. Additionally, the demand for hydrogen valves is rising owing to its diverse range of applications in the energy sector, specifically in power plants and utility systems. These valves control the pressure and flow of hydrogen within the renewable energy system to ensure efficient usage and safe operation of hydrogen. They also allow for the storage of excess energy when they are used in hydrogen storage systems within the power plants during off-peak periods. The surging demand for hydrogen valves can also be attributed to the growing adoption of hydrogen-powered generators to offer backup or off-grid power in applications where renewable energy sources may be unavailable. Companies in the market are announced to expand the product line to satisfy the rising customer requirement for hydrogen valves with larger bore sizes.

For instance, in May 2024, Acme Cryogenics Inc., part of OPW and Dover Corporation, a clean energy solution company, announced that it had developed new 6” and 8” valves for its Model CV Valve product line to meet the evolving requirements of their customers.

Hydrogen Ball Valve Dominates the Global Hydrogen Valve Market Share

Hydrogen ball valve dominates the global market for hydrogen valves owing to technological advancements, rapid investment by the governments of emerging countries in hydrogen infrastructure, and the rising adoption of hydrogen as a clean energy source. Industries are shifting towards sustainable energy solutions, and hydrogen is emerging as a key player throughout this shift. The global hydrogen ball valve market demand is projected to rise due to its significance for controlling and managing hydrogen flow in different applications. The rising awareness concerning carbon emissions, stringent government rules and regulations, and increase in pollution drive the demand for hydrogen ball valves in the hydrogen valve market in the forecast period. In addition, the technological advancements in valve materials and designs have enhanced the performance and safety of hydrogen ball valves, coupled with making them suitable for corrosive environments and high pressure, propelling the global hydrogen valve market growth in the forecast period. Furthermore, companies in the market are placing huge volume orders of ball valves for a diverse range of applications including heat production and others.

For instance, in October 2024, RWE Gas Storage West placed an order for 1400 ball valves from Hartmann Valves GmbH for a new hydrogen storage facility in Lingen. The ball valves are proposed to allow the connection of the cavern in Gronau-Epe to the planned hydrogen network.

Asia-Pacific Registers the Largest Market Share in the Global Market

Asia-Pacific holds the largest market share in the global hydrogen valve market owing to rapid industrialization and the rising requirement for clean energy sources coupled with stringent and favorable government rules and regulations. The governments of emerging countries, including Japan, India, China, and others, are significantly promoting hydrogen production and infrastructure development through incentive and supportive policies. In addition, the government is increasing its investment in hydrogen infrastructure projects, including distribution networks, production facilities, and storage systems, driving the Asia Pacific hydrogen valve market growth. Moreover, the countries in the Asia Pacific are focusing on reducing greenhouse gas emissions and shifting towards sustainable energy solutions, further fostering the requirement for hydrogen valves. The Asia-Pacific market for hydrogen valves is projected to continue its dominance owing to continuous technological advancements, strategic collaborations, and the introduction of factories within the industry.

For instance, in September 2022, Crane Company announced the inauguration of its new engineered check valve factory in Satara, Maharashtra to support the demands of a wide range of industries within the chemical processing, petrochemical, and energy sectors, including renewable energy and other evolving markets, such as hydrogen production.

Download Free Sample Report

Future Market Scenario (2025 – 2032F)

The global shift towards renewable energy sources, including hydrogen, is driving the need for specialized valves to manage hydrogen flow safely and efficiently.

Governments worldwide are setting ambitious targets to reduce greenhouse gas emissions, leading to increased investments in hydrogen infrastructure and technologies.

Innovations in valve materials and designs enhance the performance and safety of hydrogen valves, making them more suitable for high-pressure and corrosive environments.

The expansion of hydrogen production facilities and storage systems requires reliable valves to control and regulate hydrogen flow, ensuring safe and efficient operations.

Report Scope

“Hydrogen Valve Market Assessment, Opportunities and Forecast, 2018-2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the global hydrogen valve market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between 2025 and 2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/hydrogen-valve-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Link

$2,401.56 $ Water Regulating Valve 1-1/4 F.P.T. Johnson - Line Components - V46-AE-9600 https://nzdepot.co.nz/product/water-regulating-valve-1-1-4-f-p-t-johnson-line-components-v46-ae-9600/?feed_id=191346&_unique_id=6784d64cec7b7 Ammonia Type : 246-667R Model Number : V46AE9600 Product Group : Water Regulating Valves Type : V46AE Line Components, COMPONENTS, V46-AE-9600 Why is there a reasonable price displayed? Discover the reason behind our incredibly reasonable prices! At our company, we prioritize your satisfaction and work tirelessly to offer you access to top-notch brands without breaking the bank. Our commitment to minimizing profit margins enables us to deliver affordability without compromising on quality. Shop with confidence and explore a wide range of reputable products at budget-friendly rates. Your satisfaction is our priority! #

0 notes

Text

Refrigerators and Freezer Components: 1- Compressor (Power by motor for cooling by sent gas to condenser on warm portion of circuit), 2- Condenser (Changes gas to liquid by substantial copper coils), 3- Evaporator (Keep content chilled), 3- Capillary Tube of Expansion valve (Tiny set of copper tubes reduces temperature and pressure of liquid refrigerant to facilitate cool conditions inside refrigerator and/or freezer), 4- Refrigerant (Change gas to liquid and back again to gas such as Freon or ammonia gas), 5- Evaporator Fan Motor (Distribute cold air across refrigerator or freezer), 6- Condenser Fan Motor (Drive air through condenser coils with compressor to cool), 7- Thermistor (Monitor internal temperature of refrigerator of freezer), 8- Water Inlet Valve (Responsible for generating enough water pressure and dispense water into ice tray to make ice), 9- Water Filter (Prevent water from reaching ice maker) #geneticteacher

0 notes

Text

Operation Of Concrete Pump

(1) The particle size of sand and gravel, cement grade and mix ratio should meet the requirements of the mechanical performance of the trailer pump according to the factory manual.

(2) The parking brake and locking brake of the pumping equipment should be used at the same time, the tires should be tight, the water supply should be normal and the water tank should be filled with clean water, there should be no debris in the hopper, and all lubrication points should be lubricated normally

(3) The bolts of each part of the pumping equipment should be tightened, the pipe joints should be tightened and sealed, and the protective devices should be complete and reliable.

(4)Trailer pump with diesel engine, the operating openings, adjustment handles, hand wheels, control levers, cocks, etc. of each part should be in the correct position

The hydraulic system should be normal and leak-free

(5) Prepare relevant equipment such as cleaning pipes and cleaning supplies. Before operation, the pipeline must be lubricated with cement mortar prepared according to regulations. Unrelated personnel must leave the pipeline

(6) The legs should be fully extended and supported, and the boom should not be started before it is fixed. The boom can only be rotated after the bracket is raised. The boom should be extended in sequence. It is strictly forbidden to use the boom to lift or drag objects.

(7) When the boom is in the fully extended state, it is strictly forbidden to move the vehicle body. When it is necessary to move during operation, the upper section of the boom should be folded and fixed, and the moving speed should not exceed 10km/h. The boom should not use pipes with diameters exceeding the specified diameter, and the wheel pipes should be equipped with anti-drop safety belts.

(8) Various instruments and indicator lights should be monitored at all times, and if abnormal, they should be adjusted or handled in time. If the conveying pipe is blocked, reverse transport should be carried out to return the concrete to the hopper, and the pipe should be removed to eliminate the blockage if necessary.

(9) When the pumping system is under pressure, no conveying pipeline or hydraulic pipeline should be opened. The safety valve of the hydraulic system should not be adjusted arbitrarily. The accumulator can only be filled with ammonia.

(10) After the operation, all the concrete in the hopper and pipeline must be discharged, and then the pump, hopper and pipeline should be cleaned. When flushing the pipeline with compressed air, no one should stand within 10m in front of the pipeline outlet, and a metal mesh basket should be used to collect the flushed foam rubber and sand and gravel.

(11) It is strictly forbidden to flush the pipes of the placing boom with compressed air. The folding and contraction of the placing boom must be carried out in sequence.

(12) The operating switches, adjustment handles, hand wheels, control knobs, and cocks in each part should be reset. The hydraulic system should be unloaded.

We FOCUS MECHINERY stand for new product ideas and courageous vision of the future, we stand for our never-stopping dedication and devotion to your construction equipment solutions, we focus on your project needs.If you're looking for a particular supplier or specific configurations, I can provide more details or recommendations!

Whatsapp:+86 13676986531

#concrete contractors#concrete plant customization#concrete mixer plant#trailer pump with diesel engine

0 notes

Text

Mastering Industrial Cooling: Frick Screw Compressors.

When it comes to industrial cooling solutions, Frick Screw Compressors stand out as a trusted name in the industry. In this blog post, we'll explore the unparalleled reliability, efficiency, and performance of Frick Screw Compressors and why they're the go-to choice for businesses worldwide.

Reliability Redefined: The Legacy of Frick Screw Compressors

Frick Screw Compressors have earned a reputation for reliability that spans decades. With a legacy of excellence in industrial refrigeration, these compressors have stood the test of time, delivering consistent performance even in the most demanding environments. Businesses rely on Frick Screw Compressors to keep their operations running smoothly day in and day out.

Efficiency in Action: Optimizing Energy Usage

Efficiency is key in industrial cooling applications, and Frick Screw Compressors excel in this aspect. With their advanced design and innovative technology, these compressors optimize energy usage, reducing operating costs while maintaining peak performance. Businesses benefit from lower energy bills and improved sustainability, making Frick Screw Compressors a smart investment for long-term success.

Tailored Solutions: Meeting Diverse Needs

One size doesn't fit all when it comes to industrial cooling, and Frick Screw Compressors recognize this. With a range of models and configurations available, businesses can find the perfect compressor to meet their specific needs. Whether it's for food processing, cold storage, or HVAC systems, Frick Screw Compressors offer tailored solutions that ensure optimal performance and efficiency.

Unmatched Support: Service and Maintenance Excellence

Beyond their superior performance, Frick Screw Compressors are backed by unmatched support and service. From installation to ongoing maintenance and repairs, Frick's team of experts provides comprehensive assistance to keep operations running smoothly. With timely service and proactive maintenance, businesses can minimize downtime and maximize productivity with Frick Screw Compressors.

Conclusion: Elevate Your Cooling Solutions with Frick Screw Compressors

In conclusion, Frick Screw Compressors offer unparalleled reliability, efficiency, and performance for industrial cooling applications. With a legacy of excellence, advanced technology, tailored solutions, and exceptional support, Frick Screw Compressors are the trusted choice for businesses seeking superior cooling solutions. Invest in Frick Screw Compressors to elevate your industrial cooling capabilities and stay ahead in today's competitive landscape.

For More Information Visit - https://www.coldforce.com.au/

Contact US - Phone - 0393180903 Email id- [email protected] Timings - 8am – 5pm.

0 notes

Text

Asha Enterprises | Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves Pune, India

Asha Enterprises is best Ammonia valves, Ammonia refrigeration compressors, Ammonia solenoid valves, Ammonia weldable valves, Ammonia level control with indicator, Ice plant equipment, Ice cans, Refrigeration compressor spare parts, Ammonia compressor spare parts, Ammonia IBT Coil, Ammonia condensers, Ammonia receiver storage tanks supplier, Manufacturer Company in Pune, Mumbai, Thane, Navi Mumbai, Kolhapur, Ratnagiri, Raigad, Nashik, Solapur, Latur, Aurangabad, Sindhudurg, Sangli, Solapur, Ahmednagar, Satara and Maharashtra.

#Asha Enterprises#Asha Enterprises in Pune#Asha Enterprises in India#Ammonia valves#Ammonia refrigeration compressors#Ammonia solenoid valves#Ammonia weldable valves#Ammonia level control with indicator#Ice plant equipment#Ice cans#Refrigeration compressor spare parts#Ammonia compressor spare parts#Ammonia IBT Coil#Ammonia condensers#Ammonia receiver storage tanks#Pune#Mumbai#Thane#Navi Mumbai#Kolhapur#Ratnagiri#Raigad#Nashik#Solapur#Latur#Aurangabad#Sindhudurg#Sangli#Ahmednagar#Satara and Maharashtra.

0 notes

Text

How CORKEN Compressors Are Shaping a Sustainable Energy Landscape in 2024

In today's world, keeping sustainability an integral part of their operational strategy plays an essential role in the success of industries. Keeping the same in mind, industries, known for their contribution to harm, must prioritise practices that lower their carbon footprint and protect natural resources. Embracing sustainable methods not only helps combat climate change but also brings cost savings, market growth, and compliance with regulations. The increasing consumer demand for eco products emphasises the need for industries to focus on sustainability to uphold their reputation and long-term viability. Sustainability is key for industries to safeguard our planet, ensure stability, and secure a future for generations to come.

#Ammonia Compressor#CORKEN Compressor#LPG Compressor#LPG Transfer#unloading compressor#Vane Pump#Pump and Valves#IDEX India

0 notes

Text

How to Select the Best Pond Filter For Your Water Feature?

It is important to consider the size of your water feature as well as its aquatic life. In small and mid-sized water features, a combination between mechanical and bio-filters can be most effective in removing debris. UV clarifiers are also incorporated into large capacity Pond Filter to control algae growth. It doesn't matter what the pond filter is, it should have a balance between water clarity and healthy bacteria.

Pond Filter: Features & Advantages

Most of the best pond filter models come with advanced features, like multi-stage filters. Filters that include UV clarifiers have a better chance of controlling algae growth. They also feature quick release valves for easy use. Filters that are specifically designed for your pond will provide long-lasting reliability.

What is a good filter system to use for my ecosystem and what are the benefits?

Filters can be essential to the health of a pond's ecosystem. In the absence of adequate filters, fish wastes and toxic substances will quickly accumulate, clouding up your crystal clear water. The use of quality filters will not only make your water cleaner, but can also promote bacteria that help break down harmful substances like ammonia or nitrogen oxides. They will also support the health of plants and decrease maintenance costs. Spend money on quality filters now to make your pond more beautiful.Beneficial And Best Pond Filter

Five most recommended pond filter for Koi Ponds

A large volume of fish waste is generated in Koi Ponds. Special filtering systems must be used to handle this waste. Koi-pond filters that are suitable should have a biological filter system with high capacity to handle large waste volumes. They can also be UV clarifiers with multiple stages or pressure filters.

How to maintain an Effective Pond Filter System?

It is important to keep your pond filter in good condition. You should maintain beneficial bacteria on the biological media to break down toxins, and replace UV clarifiers every year to ensure they are effective against algae. By taking care of filters, you can extend their lifespan and increase the clarity of the water.

Why Choose Grand Champion Technologies GC TEK?

Grand Champion Technologies’s (GC TEK), a pond-filtering system with a superior filtration capability and enduring lifespan, is considered to be one of best choices. Filtration system are specifically designed for crystal-clear waters and optimal ecosystem conditions. They filter out harmful substances, organic matter, and debris. Grand Champion Technologies offers customized filtration options to meet the requirements of any aquatic ecosystem.

0 notes

Text

Industrial Refrigeration Engineers: Ensuring Safety and Compliance in Cooling Systems

Maintaining the efficiency, safety, and compliance of a heavy-duty cooling system requires professional industrial refrigeration engineers. From food processing factories and cold storage warehouses to pharmaceutical facilities, reputable��refrigeration companies have a team of engineers ensuring refrigeration systems meet regulatory standards. The engineers can handle the most complex nature of industrial refrigeration, preventing accidents, improving system performance, and minimizing downtime.

Expert Knowledge of Safety Standards

By understanding the responsibilities of industrial refrigeration, engineers ensure that all systems meet high standards of safety and regulations. It includes reviewing industry-required guidelines, such as the Environmental Protection Agency (EPA) regulations, Occupational Safety and Health Administration (OSHA) standards, and the International Institute of Ammonia Refrigeration (IIAR) codes. These contractors are highly trained in manufacturing, installing, and maintaining systems that meet industry standards.

Regular Maintenance and Inspections

Engineers focus on routine maintenance and inspection to ensure the safe functions of industrial refrigeration. A professional industrial refrigeration contractor is responsible for managing equipment repairs and part replacements. With early detection of problems, contractors can prevent refrigeration breakdowns that lead to costly downtime or safety incidents.

Furthermore, engineers conduct routine inspections to detect major issues before they turn into serious problems.Monitoring pressure levels, detecting leaks, and assessing the integrity of valves and pipes are the main inspections that improve the functionality of refrigeration.

Energy Efficiency and Environment Compliance

Industrial refrigeration systems require energy efficiency to perform well. That’s why engineers minimize energy consumption to maintain optimal cooling performance based on energy costs and regulations. The activities are implementing energy-saving technologies, upgrading outdated equipment, and improving insulation in the system.

Modern refrigeration systems are introduced in the industries to ensure sustainable refrigerants that reduce the carbon footprint. Engineers follow environmental laws, including the phase-out of hydrofluorocarbons (HFCs) under international agreements such as the Kigali Amendment. These guidelines help engineers to eliminate greenhouse gas emissions and produce eco-friendly industrial refrigeration.

By using industrial refrigeration designed by engineers, businesses can operate their cooling systems confidently. These systems are not only reliable but also meet the highest standards of safety and compliance.

About ALTA Refrigeration:

ALTA is one of the most trusted industrial & commercial refrigeration solutions. Its industrial refrigeration contractors never compromise with safety, compliance, and efficiency for a large-scale cooling system. An excellent knowledge and deep understanding of safety regulations help them to design a committed cooling system.

Looking for an ideal industrial refrigeration system? Visit https://www.altarefrigeration.com/

Original Source: https://bit.ly/4f3iNEF

0 notes